Patents

Literature

388results about How to "Improve dyeing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

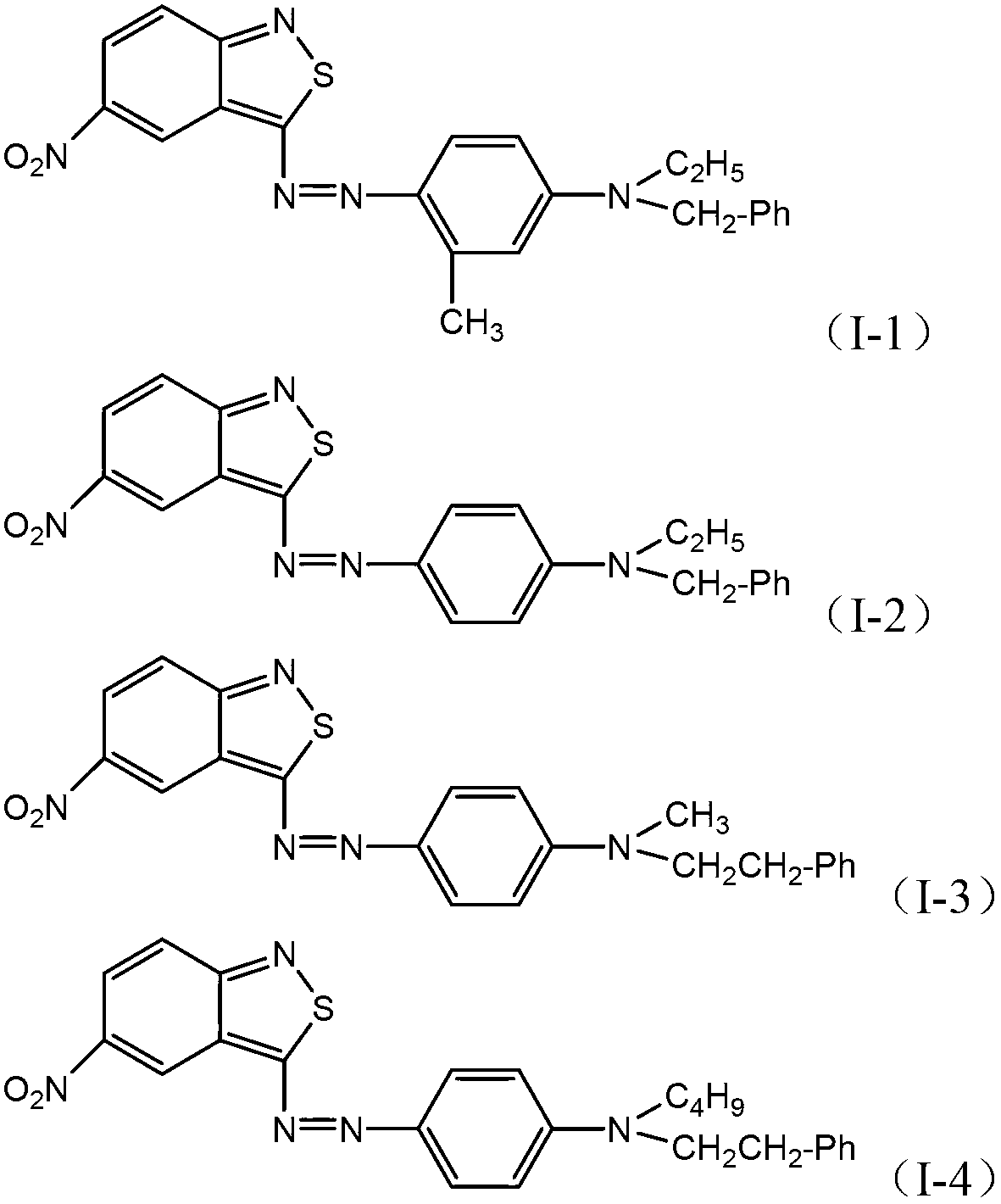

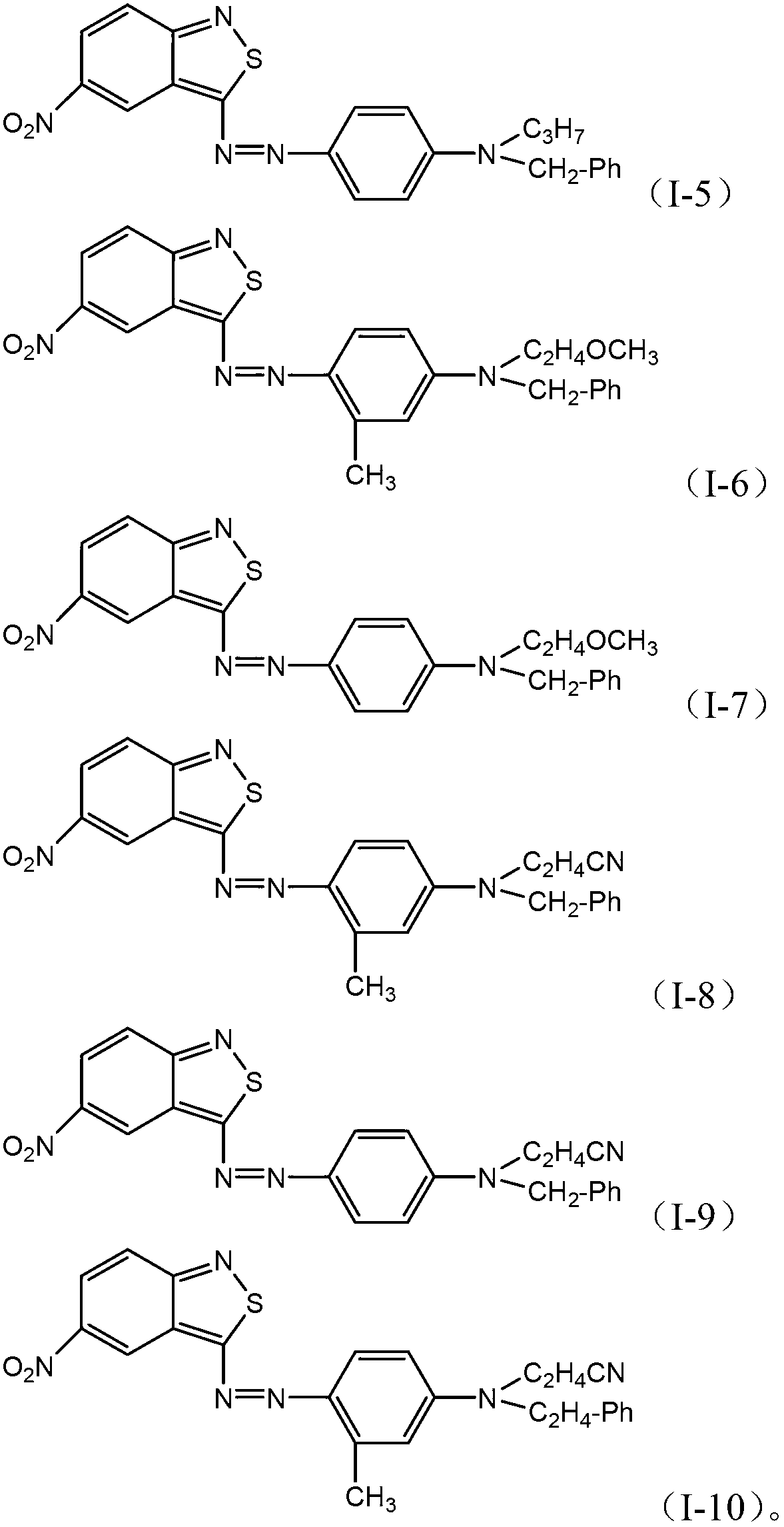

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

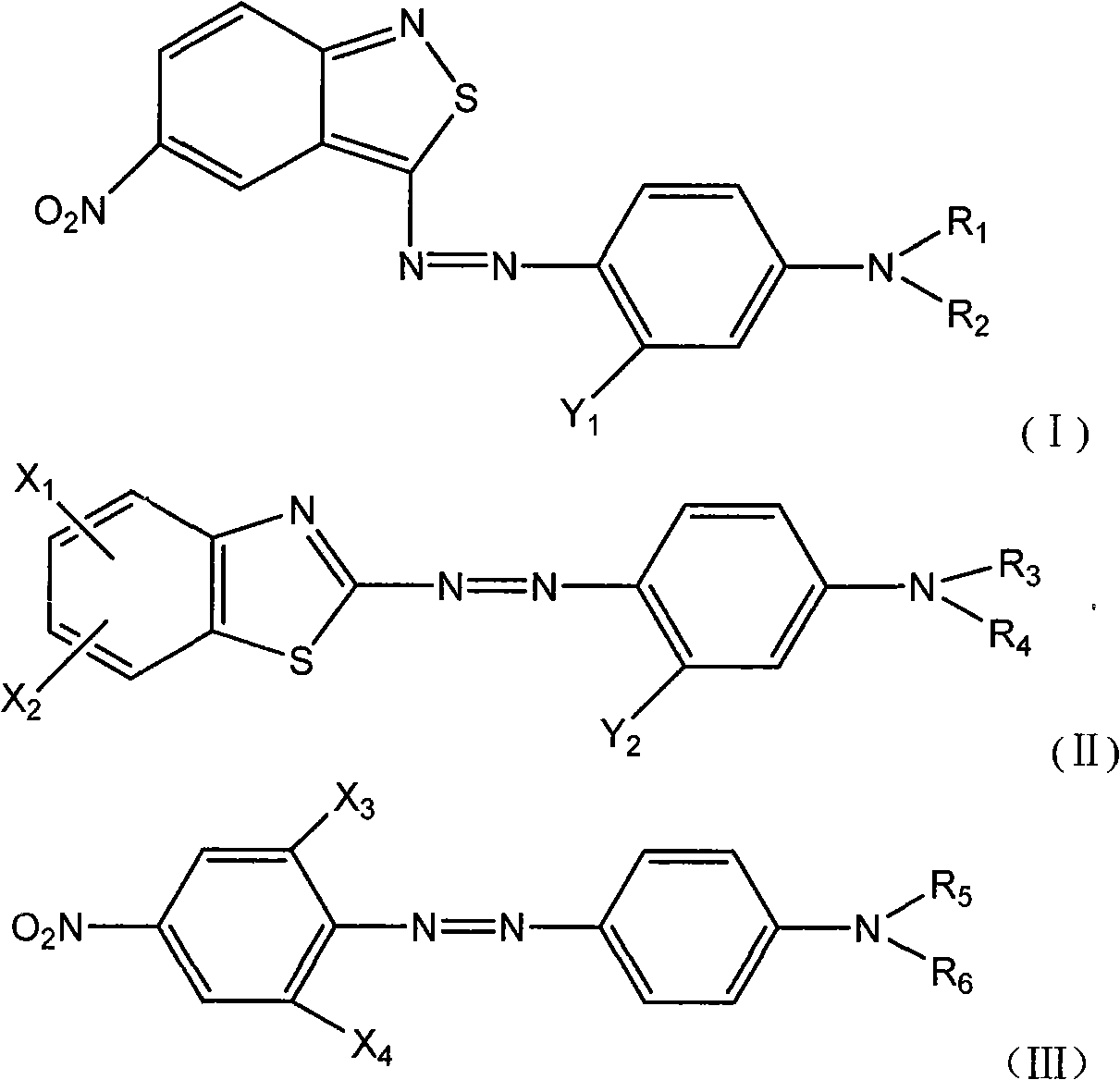

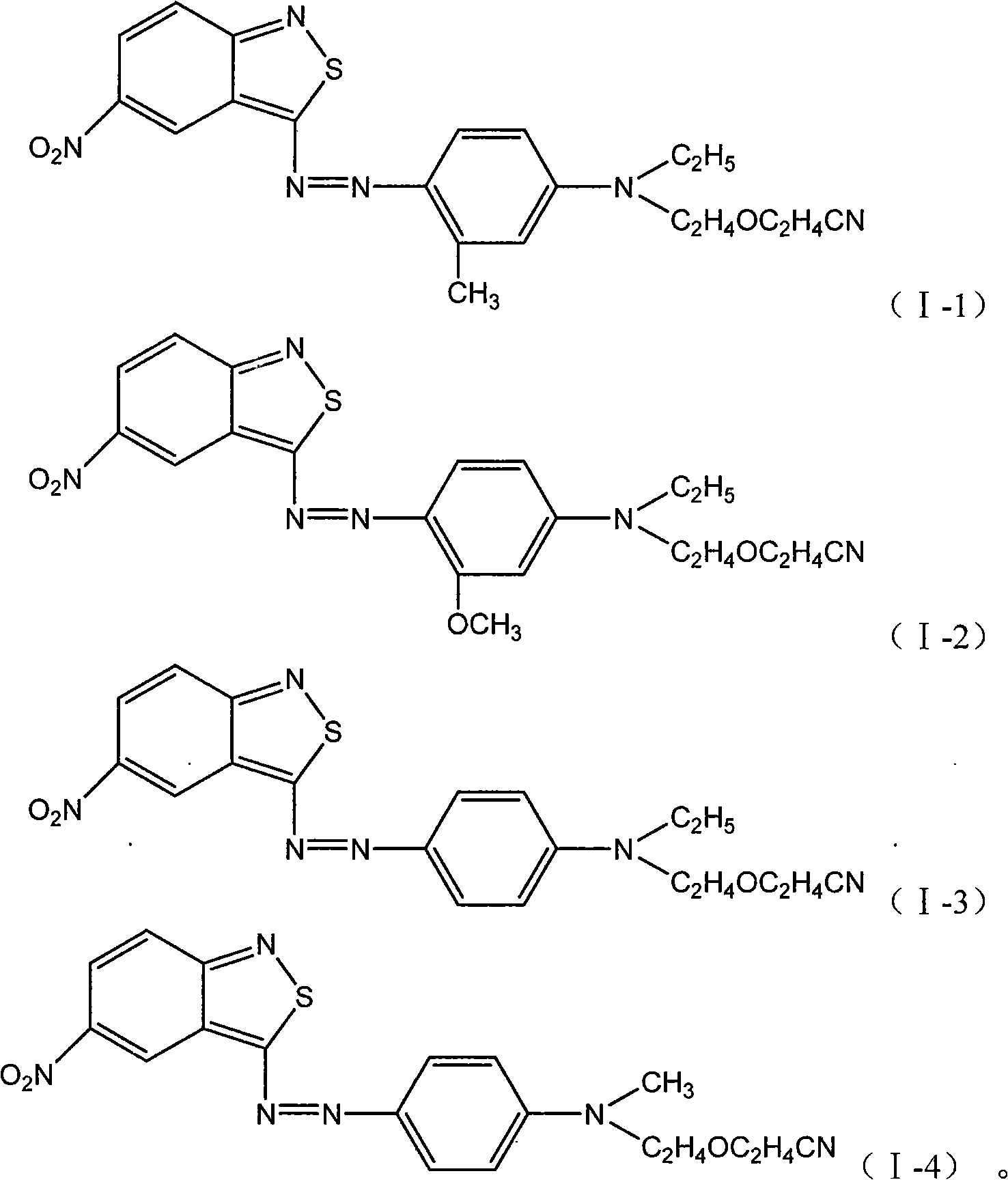

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

Method for dyeing modified cellulose fiber fabric on rhubarb and curcuma longa dyes

InactiveCN101349020AHigh fixation rateStable color fastnessDyeing processVegetal fibresHigh rateCellulose fiber

The invention provides a method for dyeing a modified cellulose fiber textile by a rhubarb and turmeric dye. The method comprises the following: 1. a step of modifying a quaternary ammonium group of the cellulose fiber textile, in which a modifying agent with a concentration of 50 to 60 g / l and sodium hydrate with a concentration of 12 to 18g / l react for 40 to 60 minutes at a temperature of between 64 and 75 DEG C, the bath ratio is 1:30; in the post treatment after the modification, the fiber textile is washed by hot water at a temperature of between 40 and 50 DEG C for 10 minutes, is washed by cold water, is prickled by HAC with a concentration of 2 to 3g / l for 2 minutes, is washed by water to be neutral and is dried; 2. a step of preparing the dye solution by the sodium hydrate extracting agent with a concentration of 15 to 45g / l; and 3. a step in which the modified cellulose fiber textile is dyed, washed by water and dried directly by the dyeing technique and is washed by soap, washed by water and dried. The technique is simple and easy to implement, does not need the mordanting and the fixation processes and the like, has high rate of dye-uptake, good dye quality and the friction resisting color fastness and the colorfastness to washing up to more than three grades, is nontoxic, does not pollute the environment, and has low cost, and remarkable economic benefits and environmental benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Blue-to-black disperse dye composition

ActiveCN102746713AStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

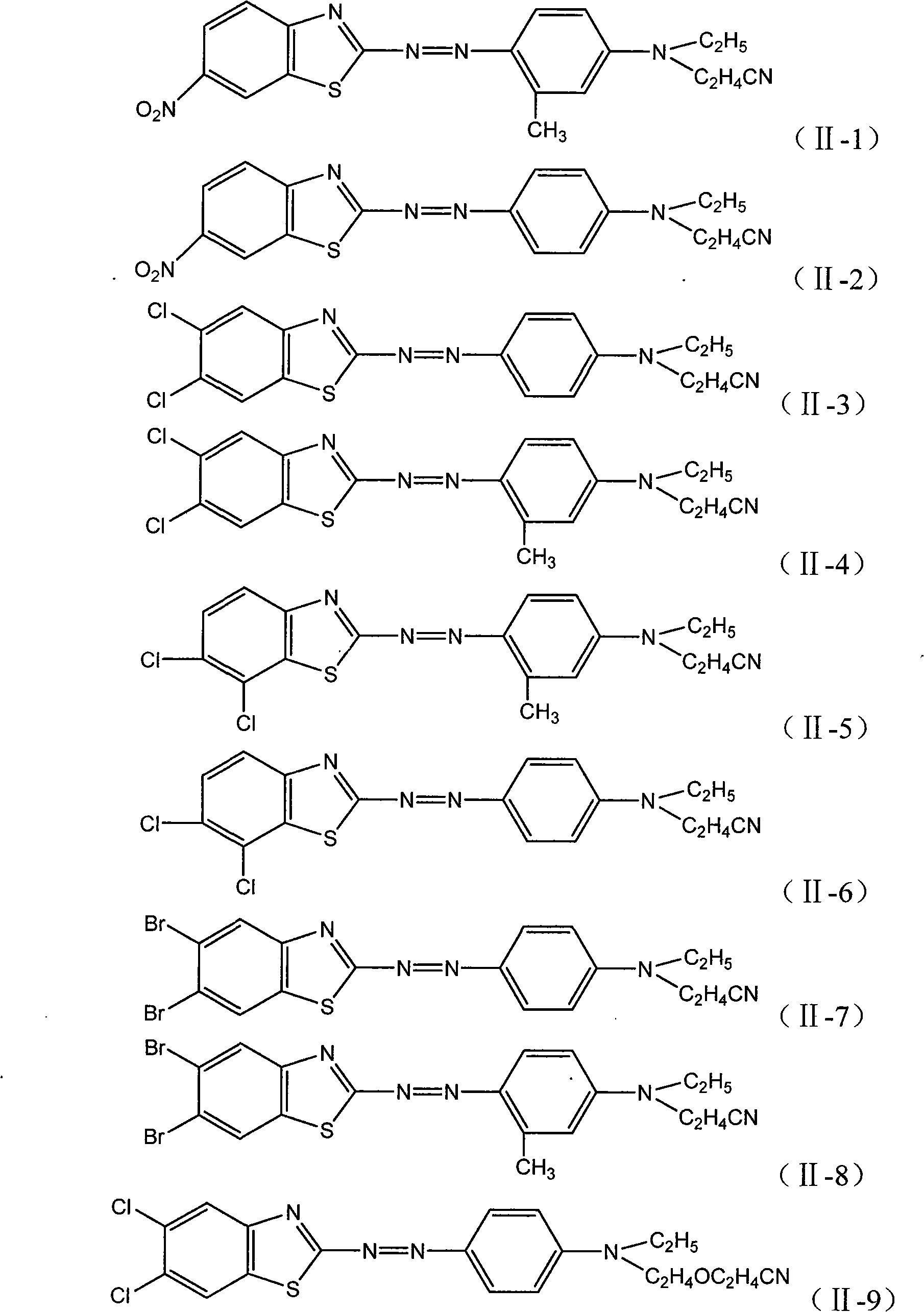

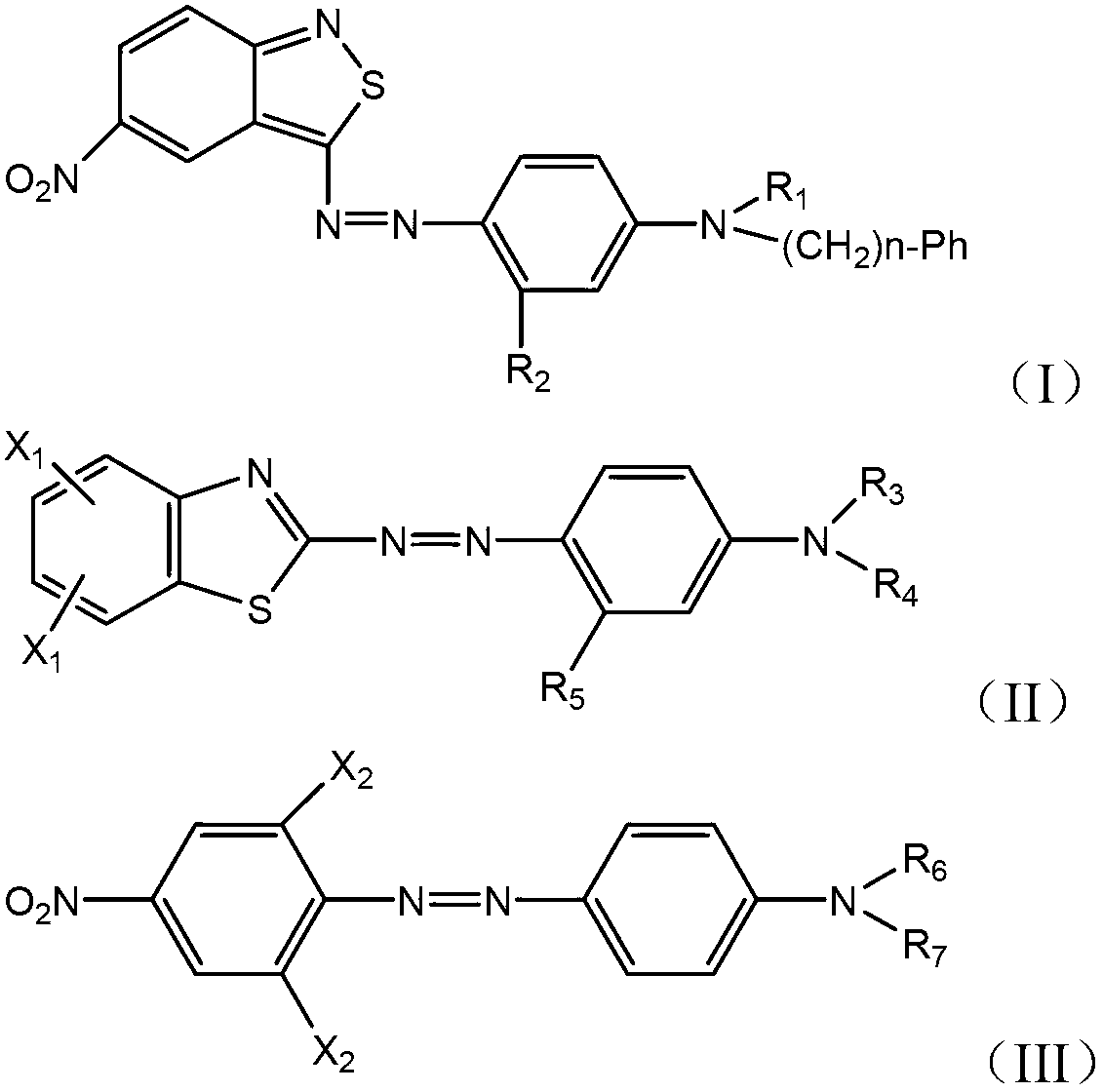

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

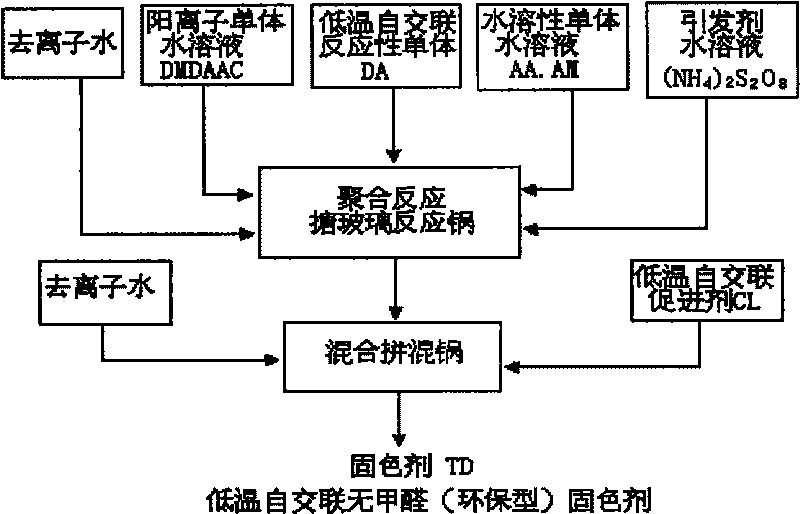

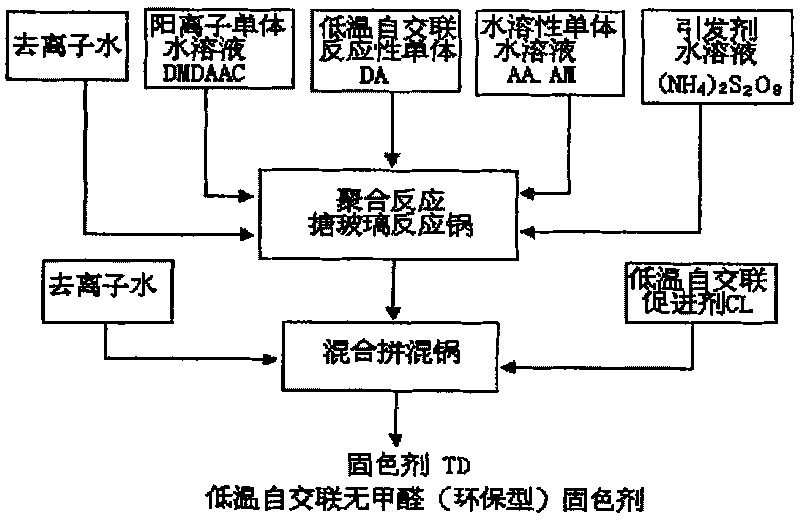

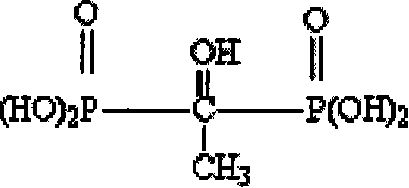

Cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent and preparation method thereof

The invention relates to a cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent and a preparation method. The color fixing agent is prepared from the following raw materials: dimethyl diallyl ammonium chloride containing 350 to 420kg of cationic monomer, water-soluble monomer comprising 0 to 20kg of acrylamide and 0 to 20kg of allyl amine, 10 to 20kg of low-temperature self-crosslinking reactive monomer, 10 to 20kg of low-temperature self-crosslinking accelerant, 1.0 to 2.0kg of evocating agent (ammonium persulfate) and 380 to 450kg of deionized water. The cationic high-molecular low-temperature self-crosslinking formaldehyde-free color fixing agent has the advantages that the color fixing agent can achieve ideal color-fixing effect and increase dye utilization rate, dyeing fastness and product quality. The preparation method has simple production process flow and low cost, and adopts a closed production process and special production equipment, thereby converting all input raw materials into products; and 'three wastes' (waste gas, waste water and waste residue) do not generated during the entire production course and the method is suitable for industrialized production.

Owner:JIANDE BAISHA CHEM

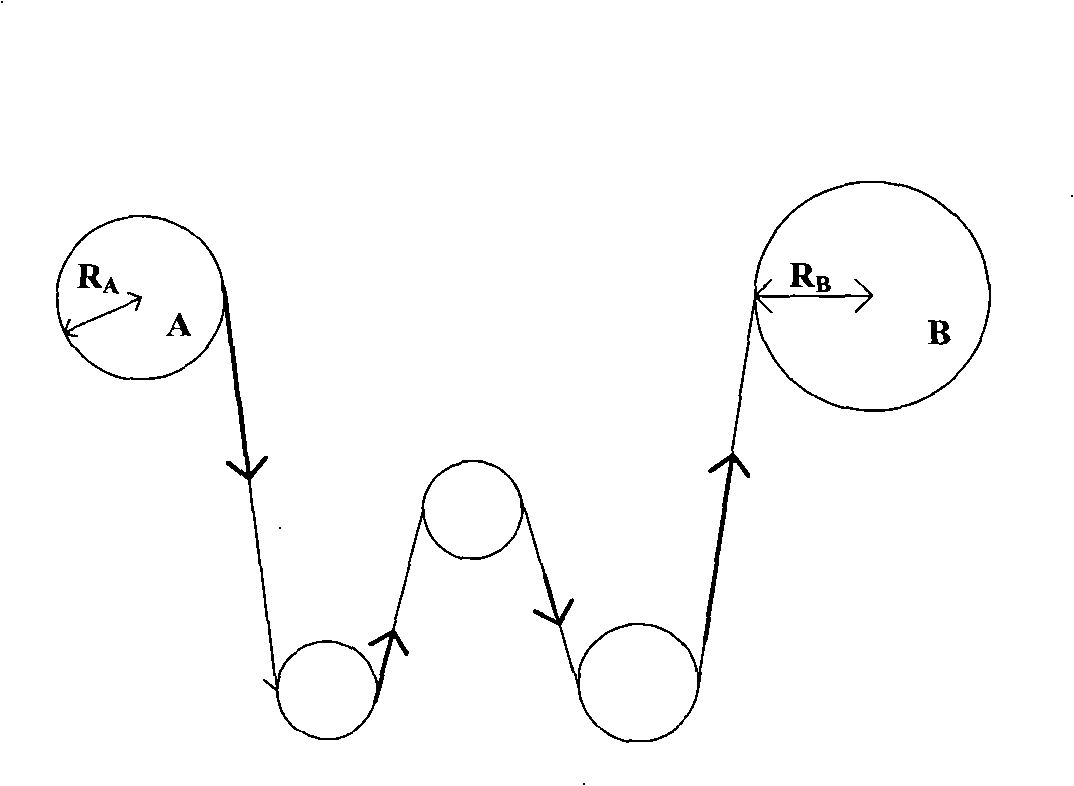

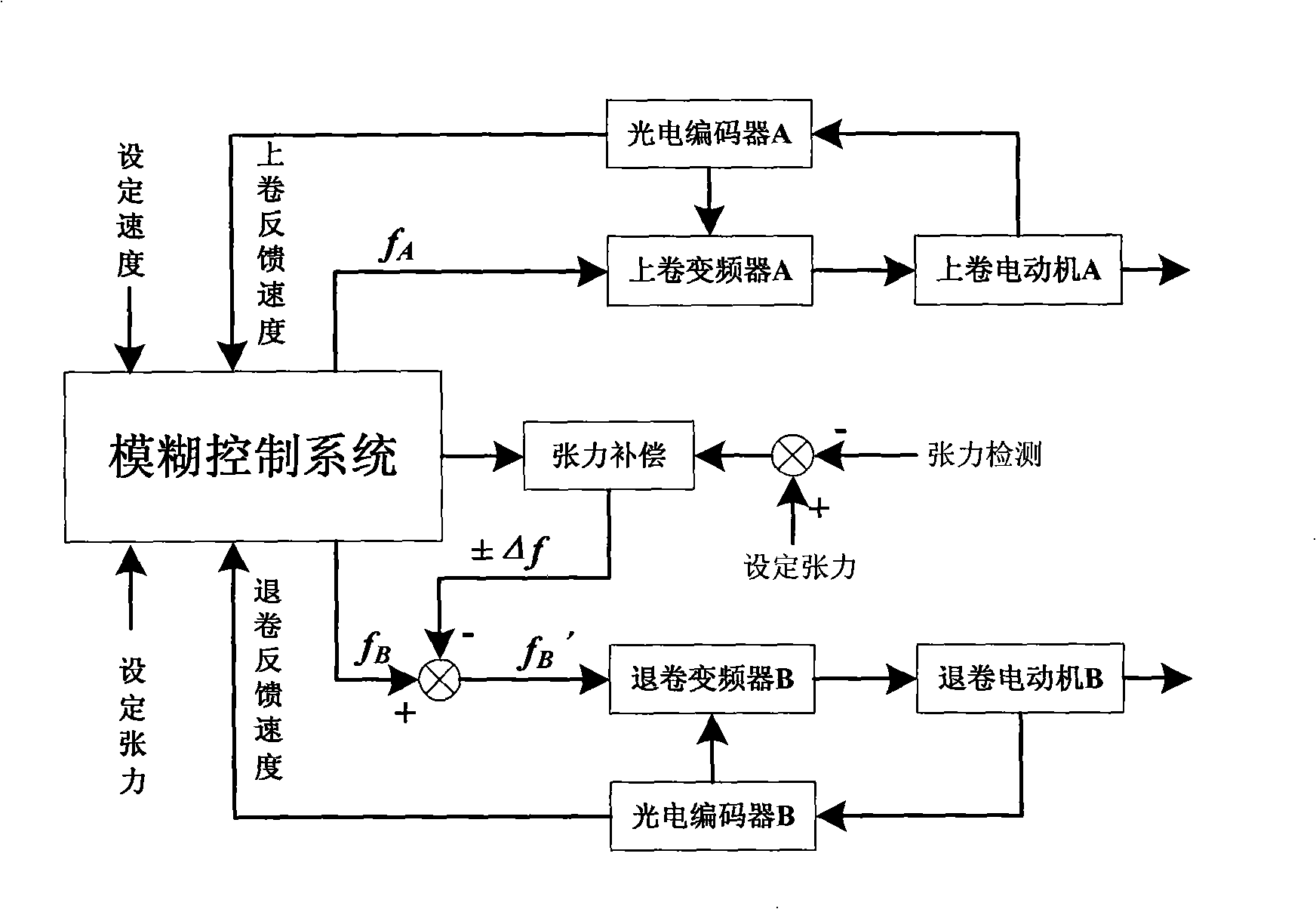

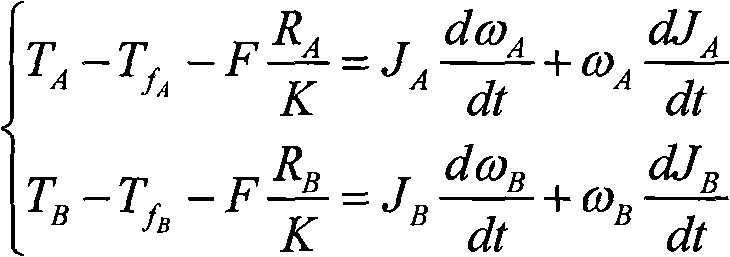

Beam dyeing machine cloth velocity-tension coordinating control method

InactiveCN101308363AImprove dyeing qualitySolve the coupling problemLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsWire speedVelocity constant

The invention discloses a speed-tension coordination control method for jigger fabrics; the method mainly uses a fuzzy control system to compare the sampling speed of a photoelectric coder with the set speed, and compare the tension-detection value of a tension detection device with the set tension, so as to timely adjust the control rules according to the dynamic changes of the errors to subsectionally and alternately control the speed and the tension to respectively obtain a coiling frequency fA and an unwinding frequency fB needed in maintaining the equal linear velocity constant tension of dyeing fabrics; a coiling electromotor and an unwinding electromotor are respectively controlled by a coiling transducer working in speed mode and an unwinding transducer working in torque conversion mode. The method solves the coupling problem between the speed and the tension of the jigger fabrics and makes more accurate speed-tension coordination control of the double-input / double-output, coupled and time-varying non-linear system of jiggers, so as to reduce dyeing color difference caused by instable speed and tension and improve the dyeing quality of fabrics.

Owner:ZHEJIANG UNIV

Auxiliary agent of formulation for dyeing Terylene

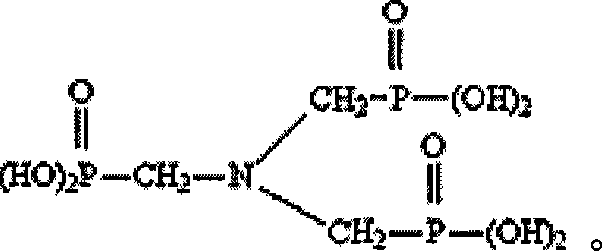

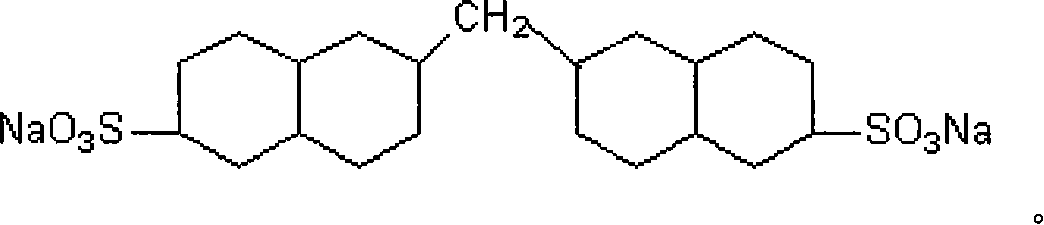

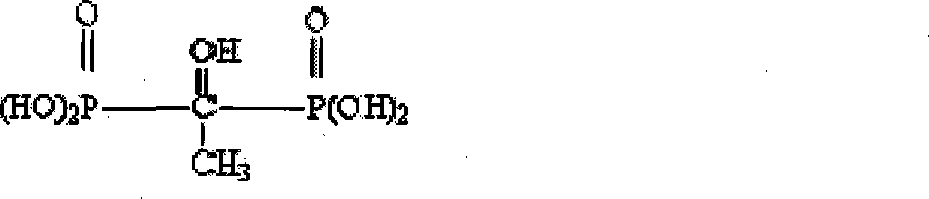

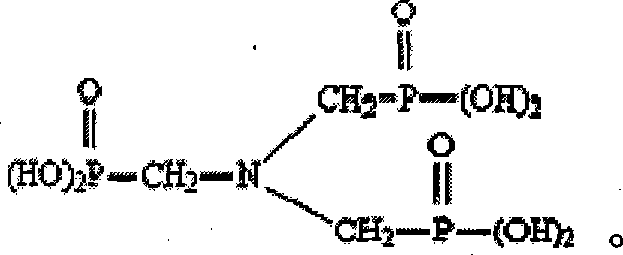

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

High-efficiency environment protection acidic color fixing agent and manufacture method thereof

InactiveCN101245563ARaw material environmental protectionWill not affect healthDyeing processMeth-Hazardous substance

The invention relates to an effective environment protective acid fixing agent that is prepared by a polypropylene acid fixing agent, an addition agent and a solvent which are matched. The polypropylene acid fixing agent is prepared by the following steps: mixing isopropanol, methacrylic acid, 2-acrylamido-2-methylpropane sulfoacid, acrylic acid and sodium persulfate in deionized water to be reacted for 1 to 5 hours at 80 to 90 DEG C and acquiring a reaction product, namely, the polypropylene acid fixing agent by post treatment. The preparation method of the effective environment protective acid fixing agent includes: adding proper water, adding all the materials under the condition of stirring at 40 to 50 DEG C in sequence to be mixed for 2 to 3 hours, uniformly dissolving, filtering, discharging and controlling the pH to be 6 to 7. The materials of the invention are environment-protective, can reduce the treatment cost of waste water and can generate remarkable social and economic benefits.

Owner:杭州下沙恒升化工有限公司

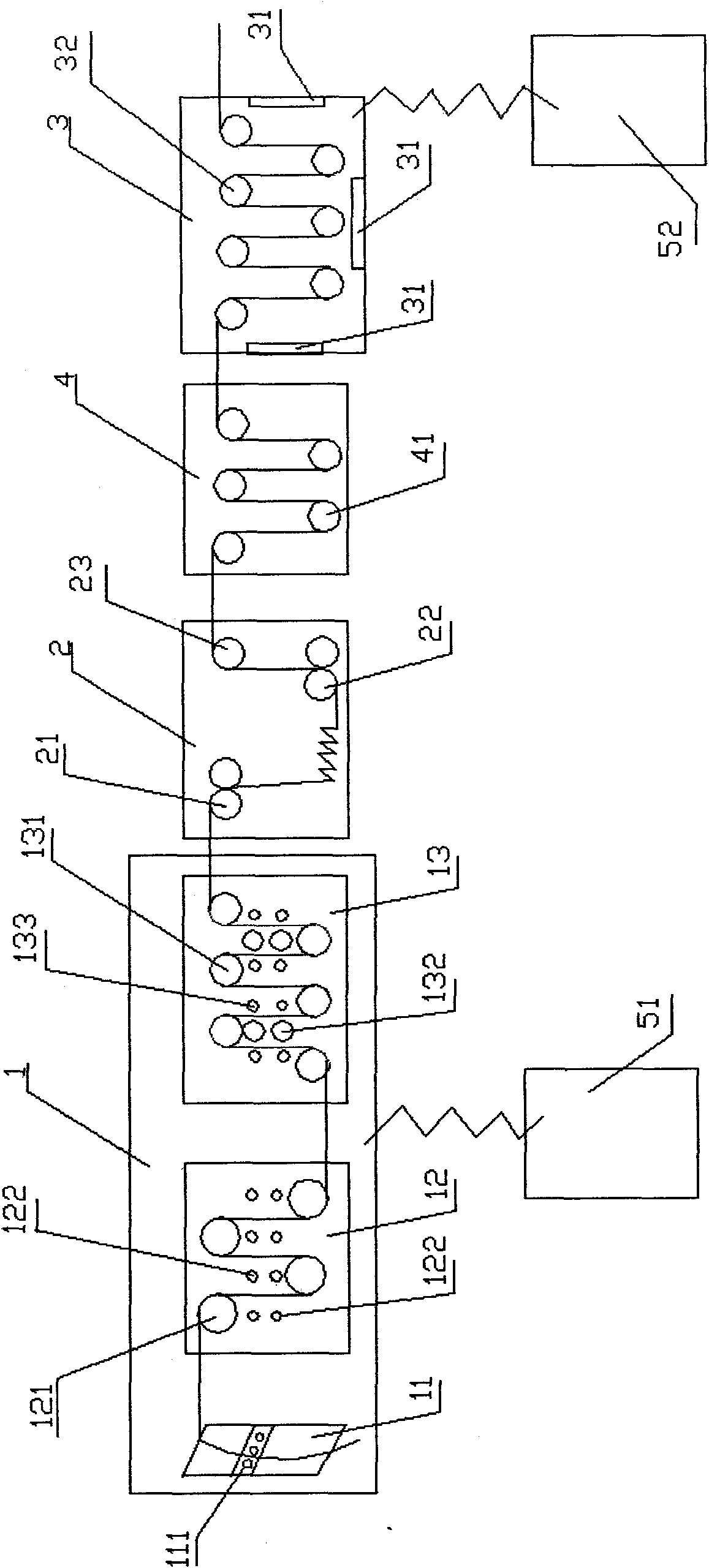

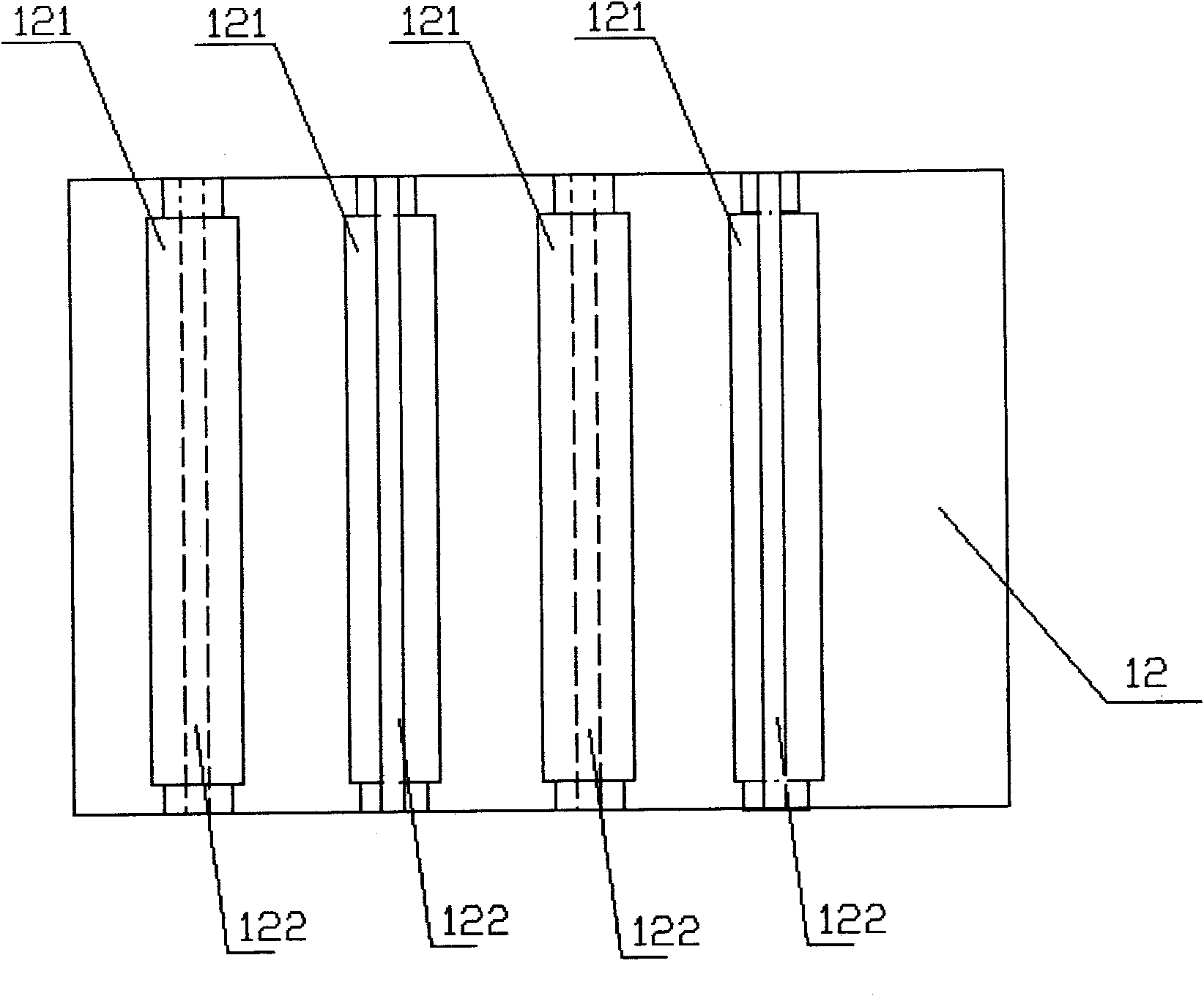

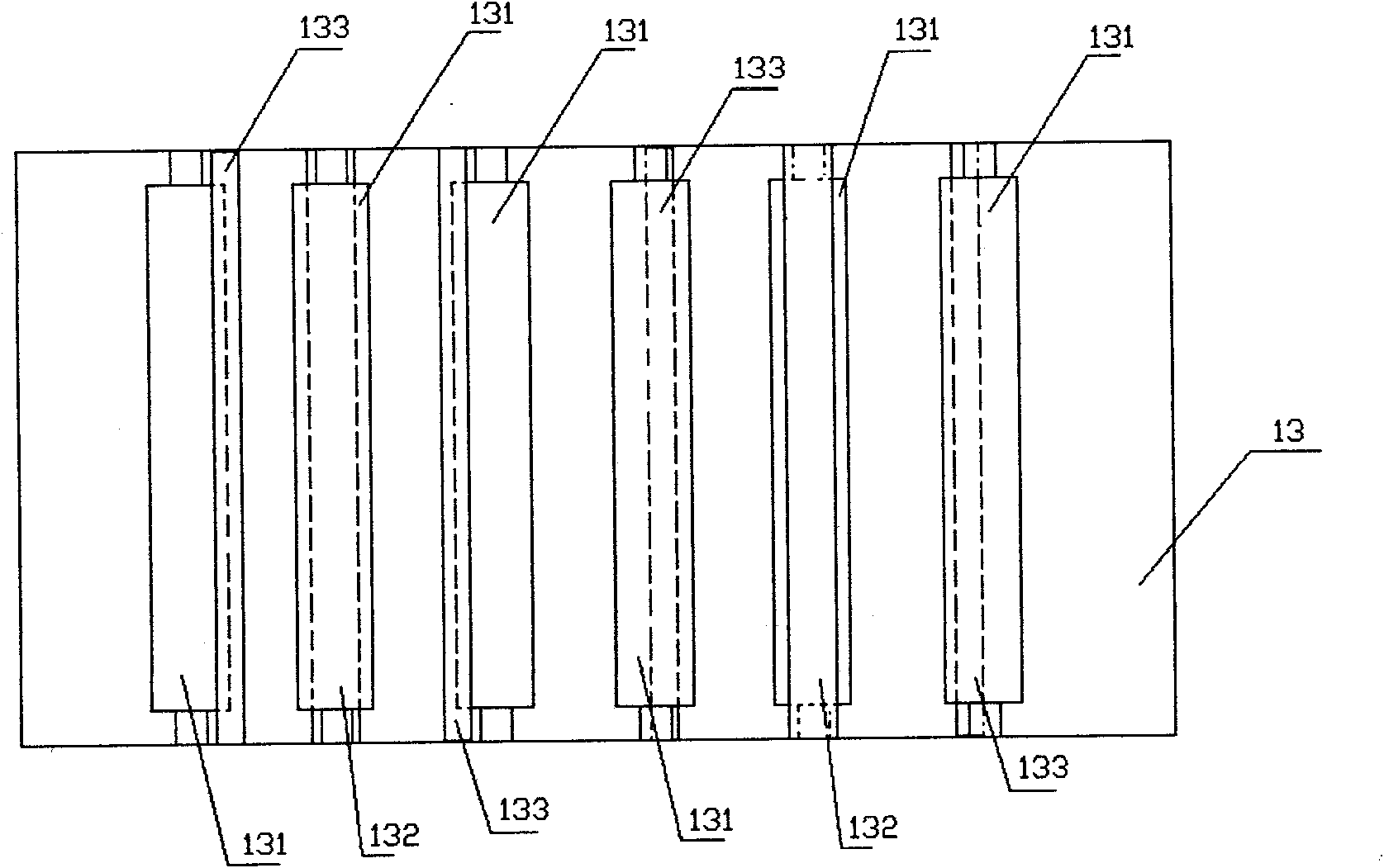

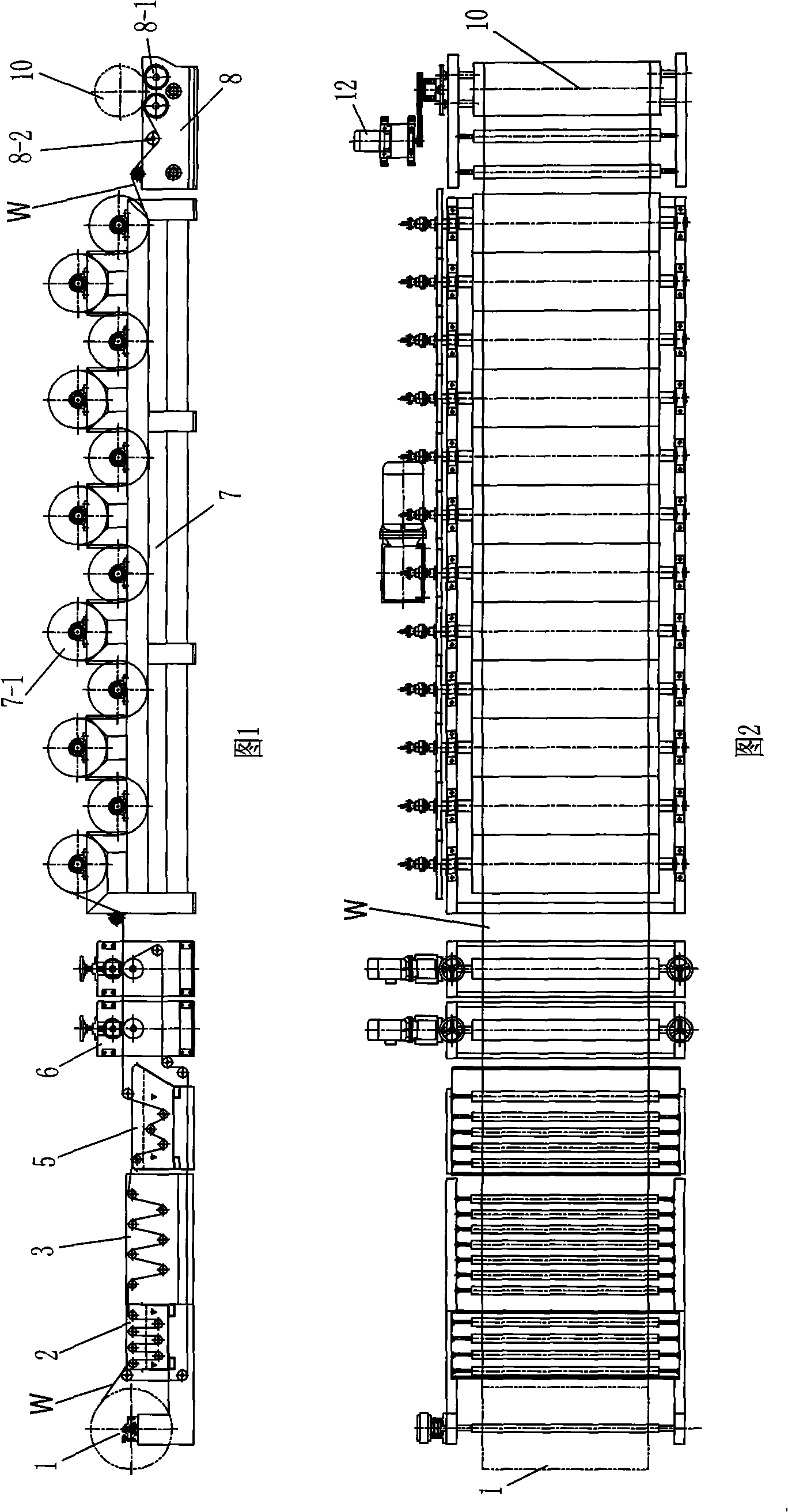

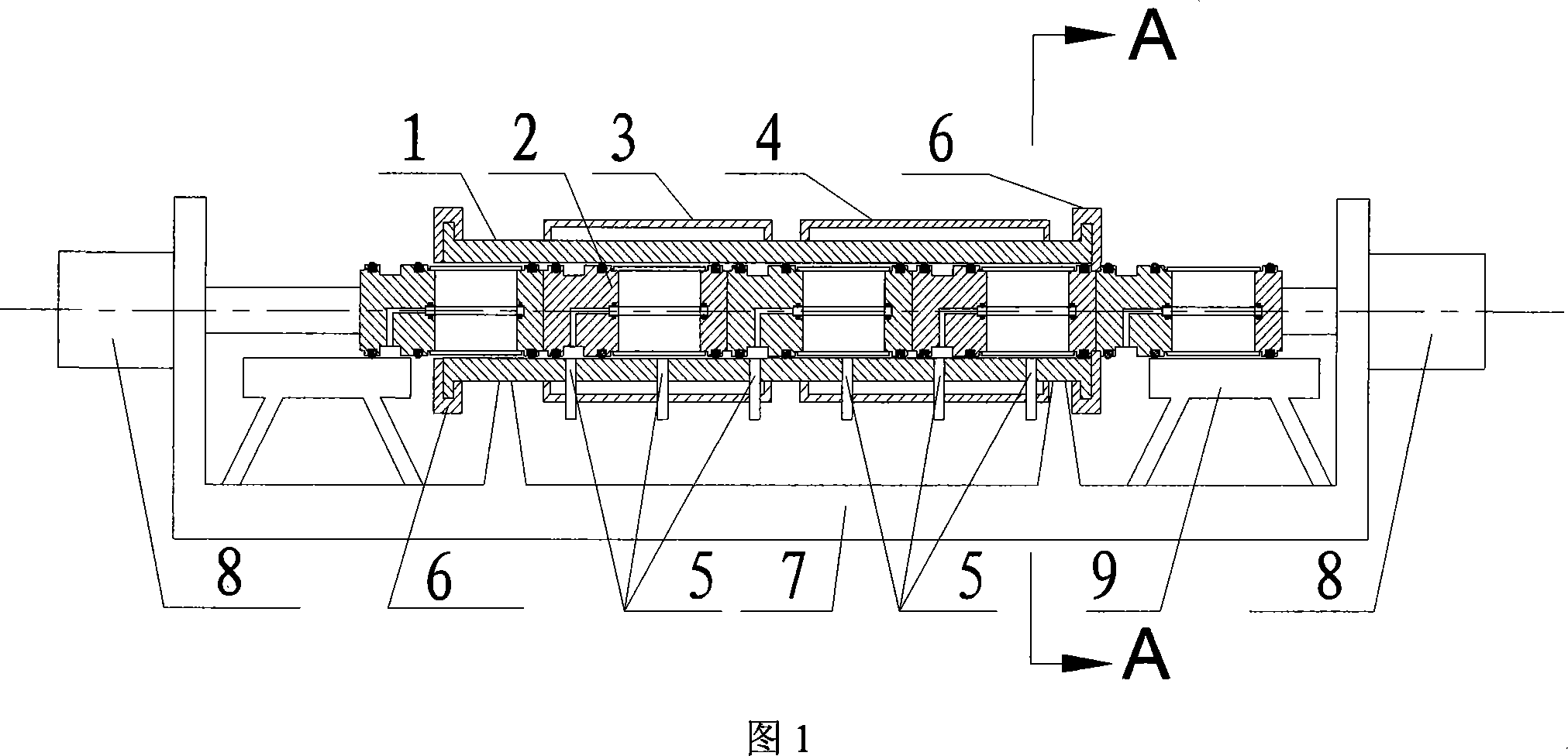

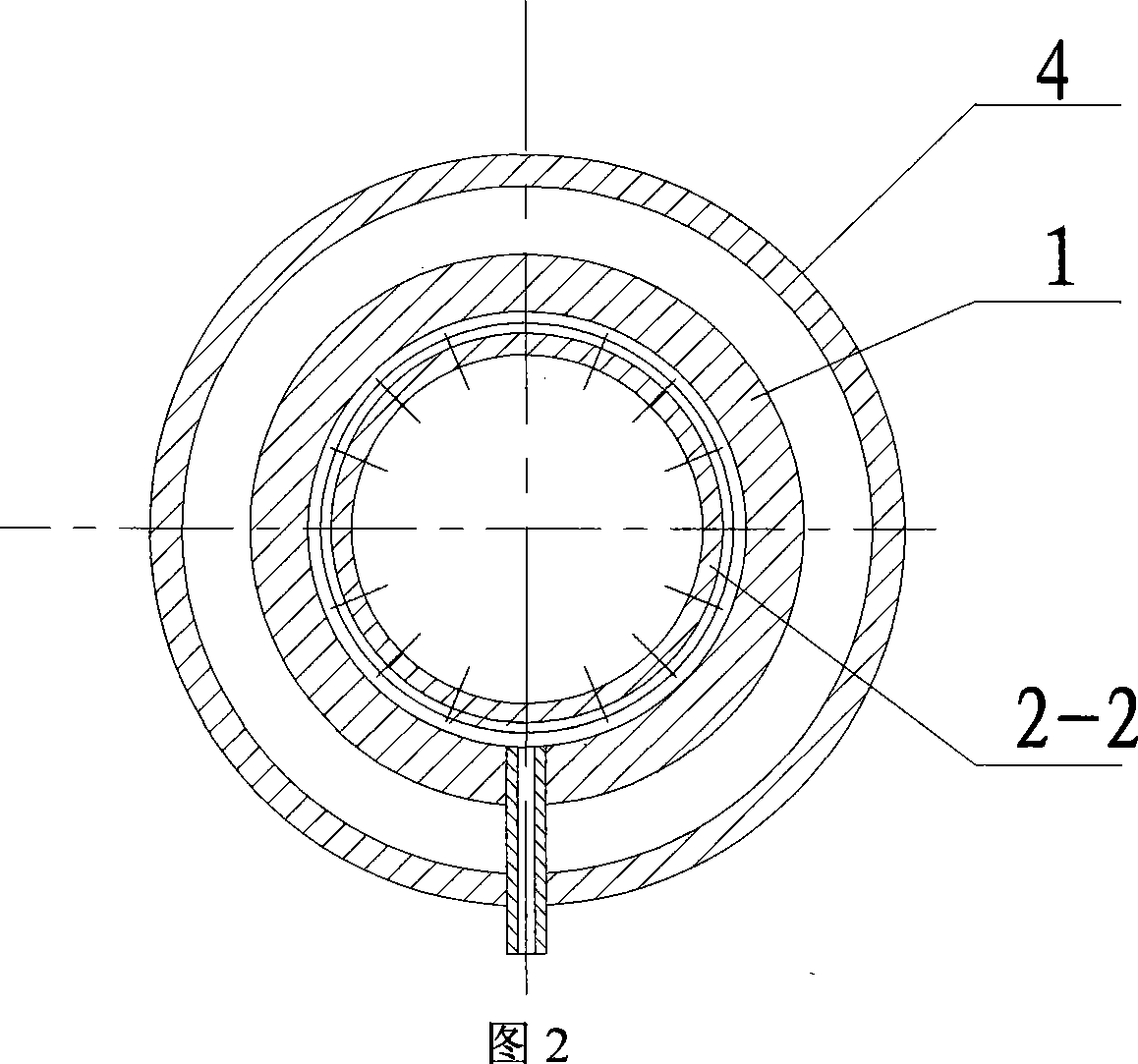

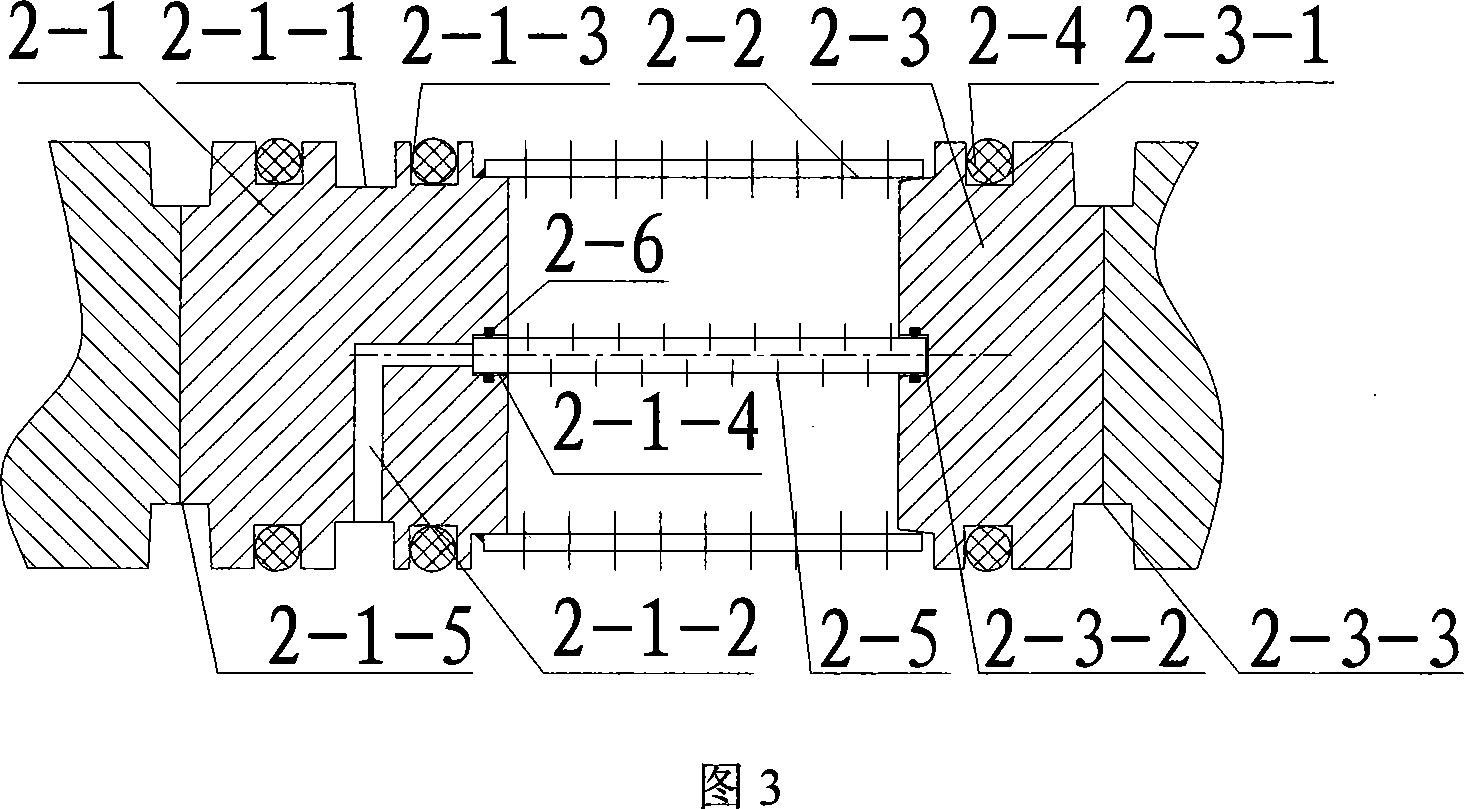

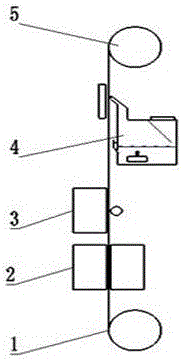

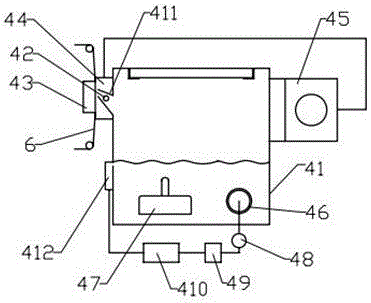

Process for dyeing fabrics by combining with plasma and ultrasonic and special device thereof

InactiveCN101880960AImprove dye uptakeReduce dosageDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentControl systemGraft reaction

The invention relates to the field of fabrics dyeing and finishing processes, in particular to a process for dyeing fabrics by combining with plasma and ultrasonic and a special device thereof. The special device comprises low-temperature normal-pressure plasma equipment, grafting reaction equipment, ultrasonic dyeing equipment, a rinsing bath and two groups of control systems, wherein the low-temperature normal-pressure plasma equipment, the grafting reaction equipment, the rinsing bath and the ultrasonic dyeing equipment are sequentially connected, one group of control systems is connected with the low-temperature normal-pressure plasma equipment, and the other group of control systems is connected with the ultrasonic dyeing equipment. The invention organically combines the low-temperature normal-pressure plasma equipment and the ultrasonic dyeing equipment, solves the problem that the dye uptake and the dyeing quality can not improved in a process of dyeing fabrics in a high crystalline region or solves the problem of high energy consumption and high pollution in the dyeing process, and can effectively realize that the dye uptake and the dyeing quality can be improved while realizing environmental-friendly production with low energy consumption and low pollution.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

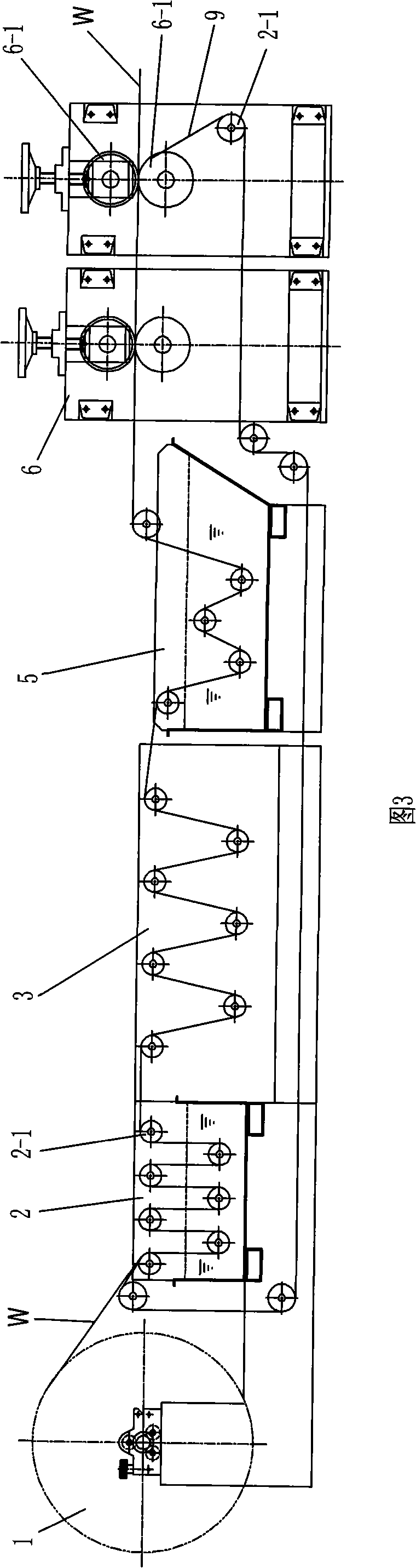

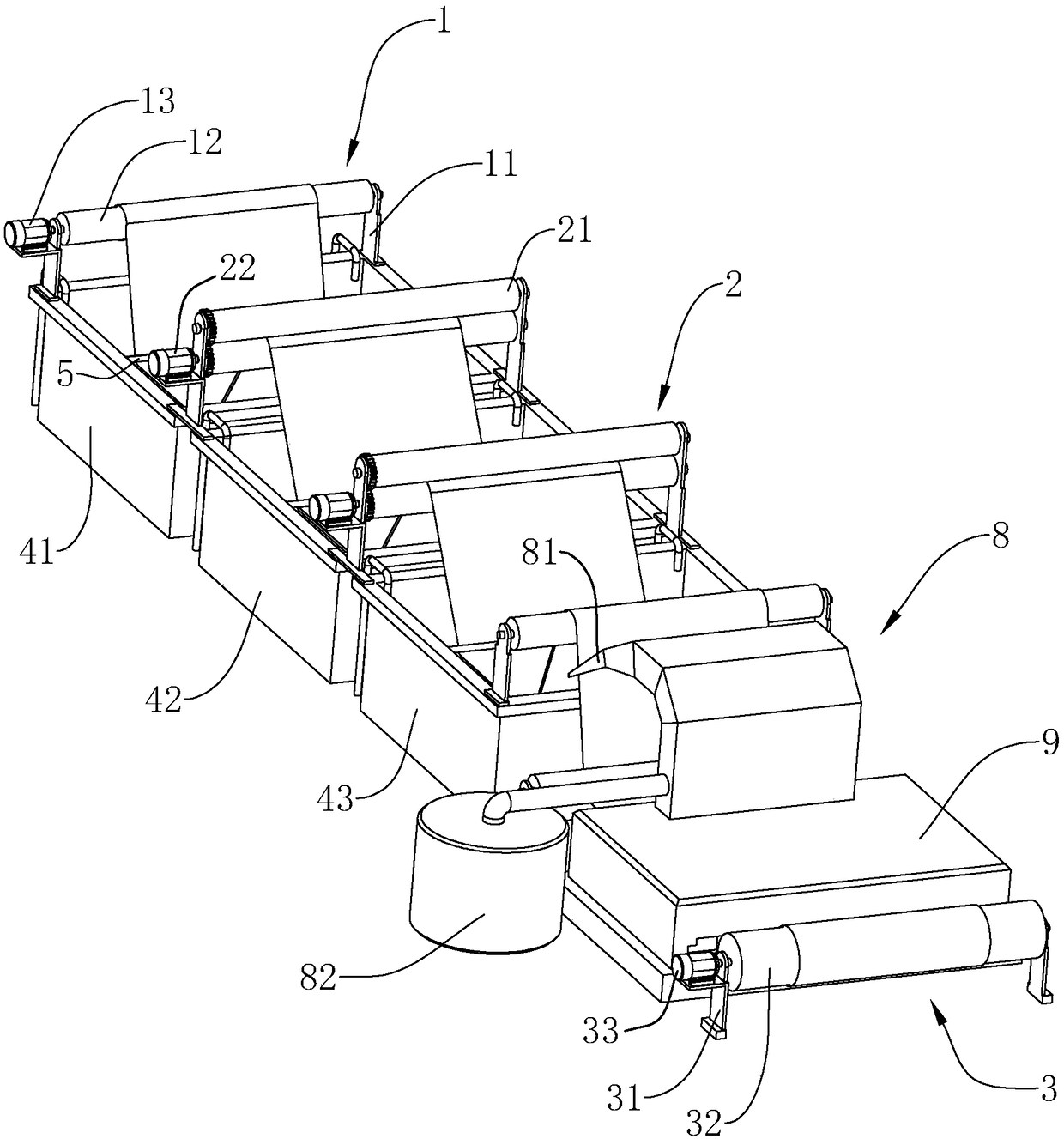

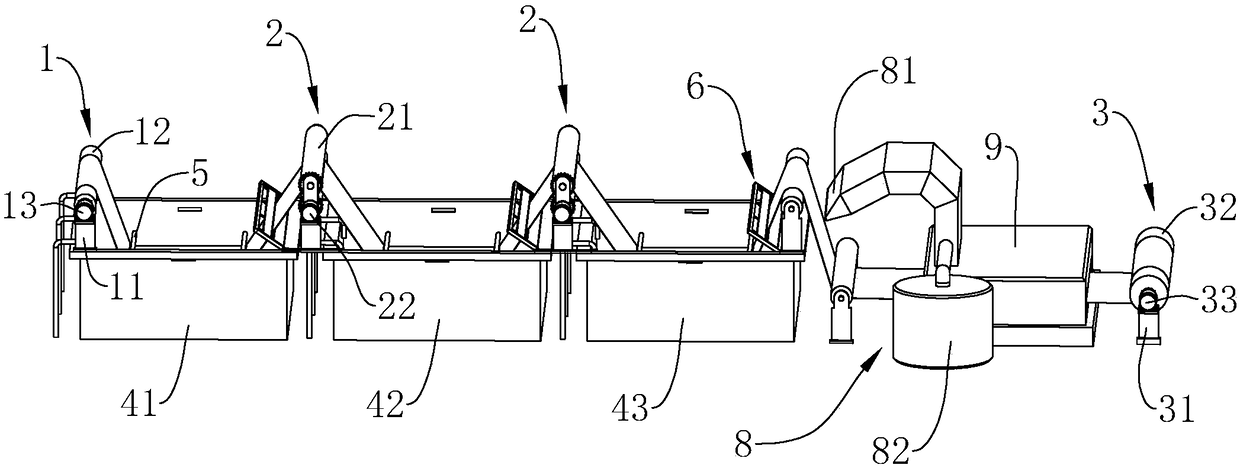

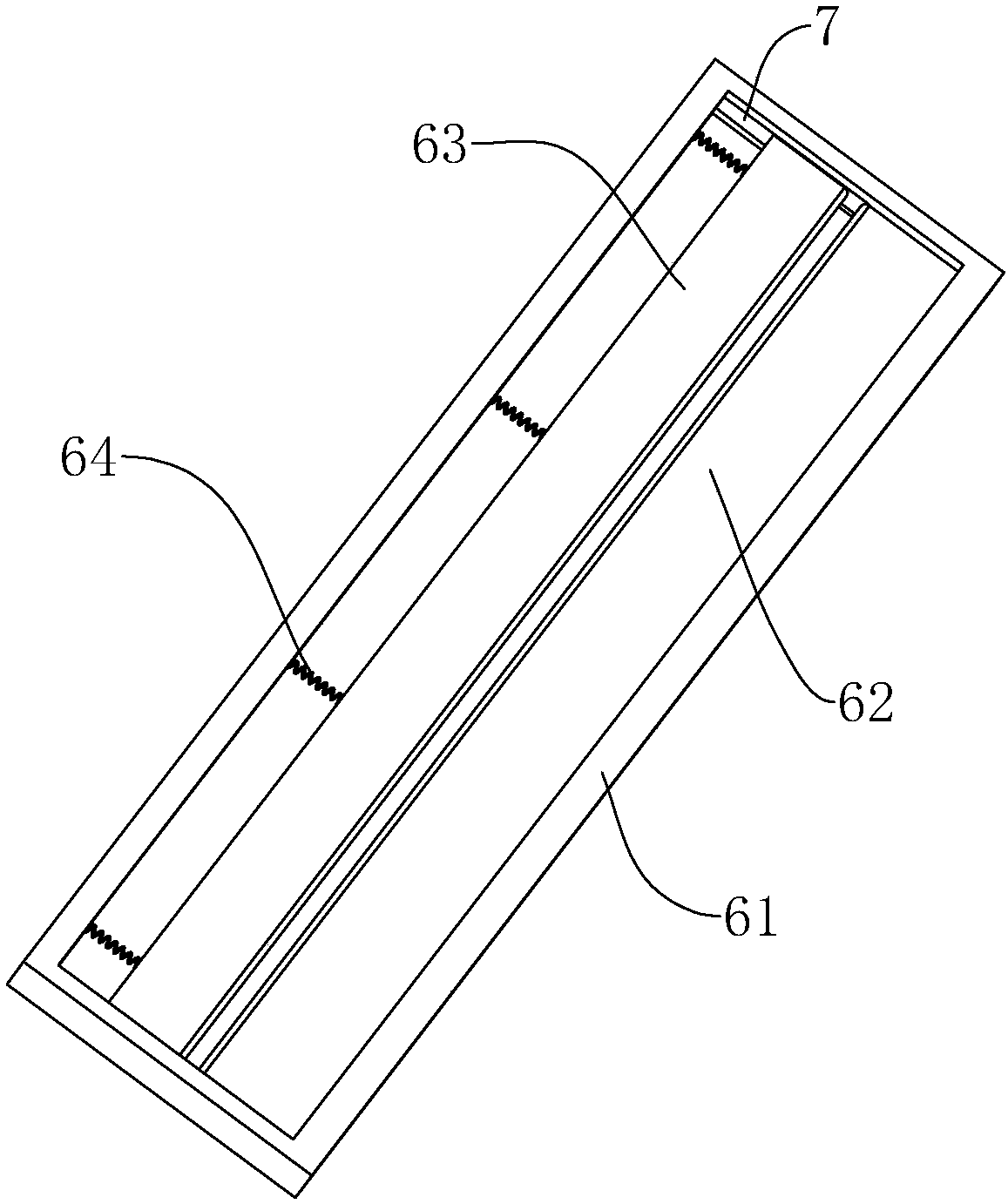

Nonwoven cloth dyeing technique and nonwoven cloth dyeing assembly line

InactiveCN101343824ASolve the strength problemSolve difficult-to-stain problemsTextile treatment machine partsLiquid/gas/vapor textile treatmentPulp and paper industryAssembly line

The invention relates to a non-woven fabric dyeing process and a non-woven fabric dyeing production line, aiming to make the process and the production line have the characteristics of high production efficiency and good dyeing quality. The invention adopts the technical proposal of the non-woven fabric dyeing process, and comprises the steps: a non-woven fabric to be dyed is soaked into a dyeing solution of a dyeing vessel for dyeing; afterwards, the non-woven fabric is cleaned with clear water, then the water is removed; and drying is performed and then the non-woven fabric is rolled into coils. The dyeing, cleaning and water removing of the non-woven fabric are performed under the holding of the mesh belt. The non-woven fabric dyeing production line comprises an uncoiling machine, a dyeing vessel, a cleaning vessel, a squeezing part, a drying cylinder group and a coiling part; the net belt is driven by a plurality of rollers arranged in parallel, and penetrates through the dyeing vessel, the cleaning vessel and the squeezing part and winds back to perform the circulating motion, so as to hold the non-woven fabric to be processed together; at least two pairs of mill rollers are arranged at the squeezing part in parallel, so as to extrude the non-woven fabric to remove the water; a plurality of dying cylinders are arranged at the drying cylinder group in parallel for heating and drying the non-woven fabric; and a cloth roller is arranged at the coiling part to roll the dried non-woven fabric.

Owner:HANGZHOU SHENGHE NONWOVEN FABRIC

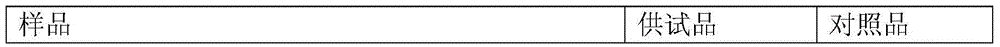

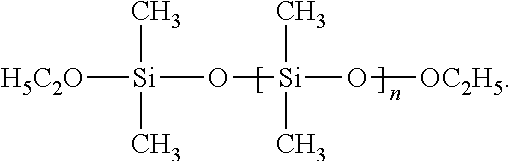

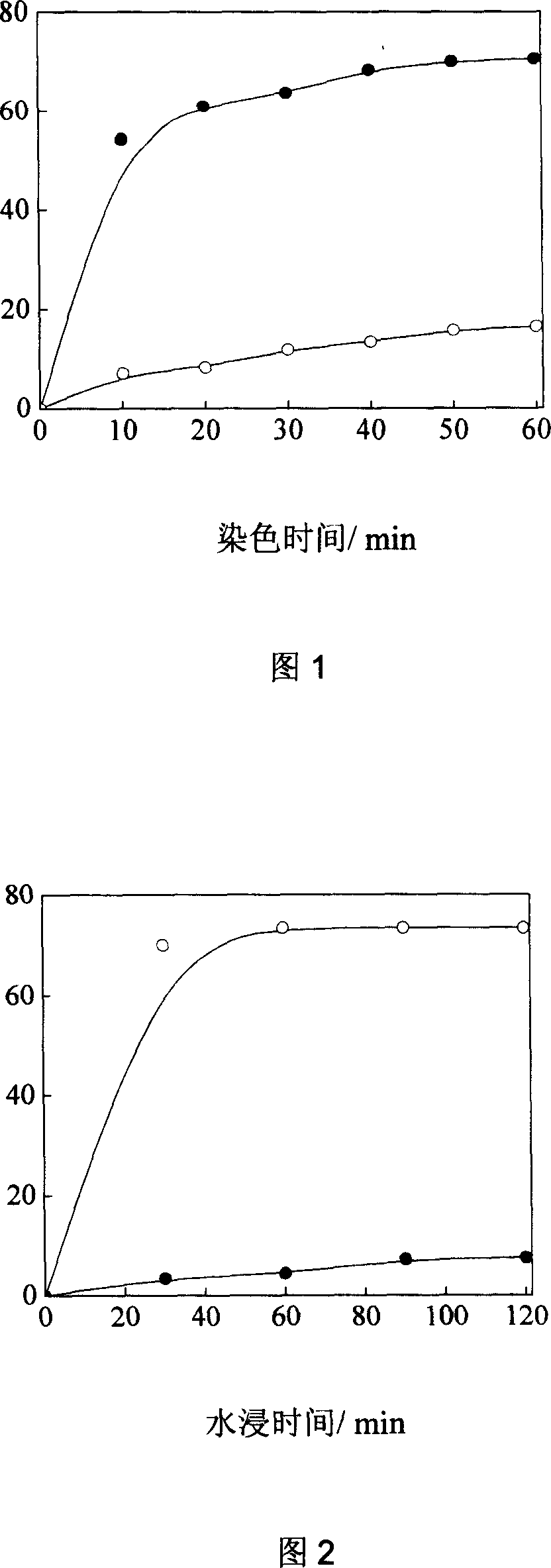

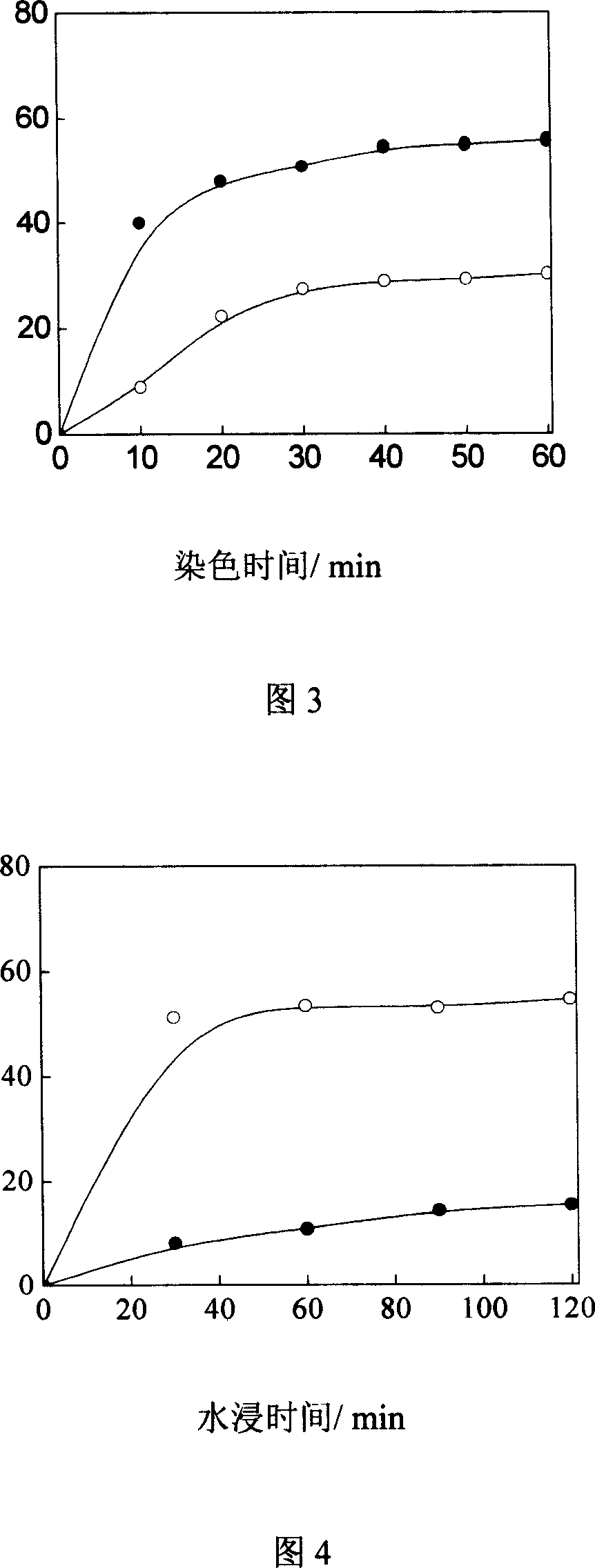

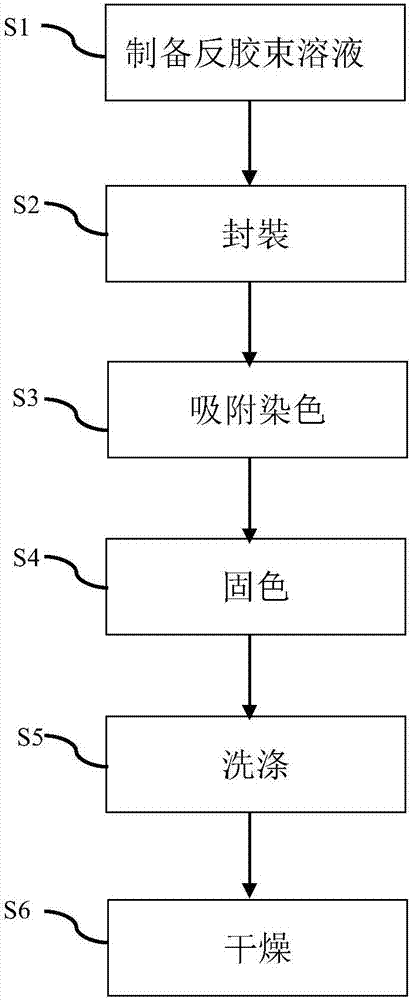

Cotton fabric non-aqueous dyeing process and reverse micelle encapsulated reactive dye liquid

ActiveCN105442359ADyeing is effectiveNot easy to degradeOrganic dyesDyeing processOrganic solventWastewater

The invention relates to a cotton fabric non-aqueous dyeing process and a reverse micelle encapsulated reactive dye liquid, and concretely relates to a method for carrying out non-aqueous dyeing on a cotton fabric by using the nonionic surfactant reverse micelle encapsulated reactive dye liquid. The dyeing method has the advantages of low cost, good dyeing quality, and simple and safe operation; a good dyeing effect can be reached in the dyeing process without strict process conditions, so the energy consumption is saved; the non-aqueous dyeing process of the cotton fabric by the reactive dye is basically completed at normal temperature to a medium temperature, and the reactive dye is difficult to degrade, so the reactive dye can be recovered, and the color of the dyed cotton fabric obtained after the non-aqueous dyeing process is completed difficultly fades; and use an organic solvent as a medium reduces the water in order to reduce treatment of colored wastewater, and the colored wastewater and the organic solvent can be effectively recovered, so environment pollution is reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

Purified cotton cloth reactive dye wet steaming deep color dyeing method

InactiveCN101328688AStrong penetrating powerImprove uniformityDyeing processLiquid/gas/vapor textile treatmentCotton clothSteaming

The invention provides a pure cotton cloth reactive dye wet short steaming dyeing dark color method, belonging to a cloth dyeing method. The dyeing method comprises the following steps that: a vinyl sulfone reactive dye is selected, and a penetrating agent CWA, urea and a chelated dispersing agent DF101 are dissolved in a dye solution so as to obtain a mixed solution; sodium hydroxide and sodium silicate with a concentration equal to 38 baume degrees are dissolved in water to obtain an alkaline agent solution; the mixed solution and the alkaline agent solution are mixed according to the volume ratio of between 8 and 2, and are fed into a dye solution trough so as to obtain a dye solution; and when dipped in the dye solution for one time and rolled by a padder for one time, cloth is subjected to steam fixation and water washing, soap boiling and water washing so as to complete dyeing. The pure cotton cloth reactive dye wet short steaming dyeing dark color method completes dipping, rolling, padding, steaming and water washing at one step after the dye and the alkaline agent solution are mixed, thereby ensuring simple working procedure and short flow; moreover, the method adopts less equipment and has lower energy consumption, no migration, high dyeing quality and better dyeing penetration, evenness, and smoothness of dyed cloth than the prior dyeing method.

Owner:郭利

Dyeing method of mulberry silk cheese

InactiveCN101838941AAvoid deformationDegumming evenly and fullyDyeing processLiquid/gas/vapor textile treatmentFiberEngineering

The invention provides a dyeing method of a mulberry silk cheese, comprising the following procedures: slack-spooling, pre-processing, dehydrating, drying, dyeing, postprocessing, dehydrating and drying. The dyeing method is characterized in that the constant weight of the cheese for slack-spooling is 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese is wrapped by an elastic fiber sleeve and then is subjected to the pre-processing procedure; and secondary slack-spooling is carried out on the cheese after the procedures of pre-processing, dehydrating and drying, the constant weight of the cheese is still 0.55-0.6kg / pcs, the density is 0.35-0.4g / cu.cm., and the cheese performed with secondary slack-spooling is wrapped by the elastic fiber sleeve and then is subjected tp the dyeing procedure. In the invention, slack-spooling and secondary slack-spooling can effectively overcome various adverse factors affecting the density and the shape of the cheese in the procedures; and situations of uneven dyeing and great inner-outer color difference owing to overlarge density do not occur, and cheese collapse owing to too small density does not occur, thus ensuring the dyeing quality of the cheese. The dyeing method has the outstanding advantage of effectively solving unstable dyeing quality of the mulberry silk cheese.

Owner:TIANJIN TIANGE TEXTILE

Preparation method of liquid disperse dye

A liquid-state disperse dye is prepared through reaction, press filter to obtain cake, dissolving it in acetone or alcohol, dissolving disperser in water, mixing them together while stirring, and heating for evaporating organic solvent.

Owner:ZHEJIANG YUDA CHEM IND

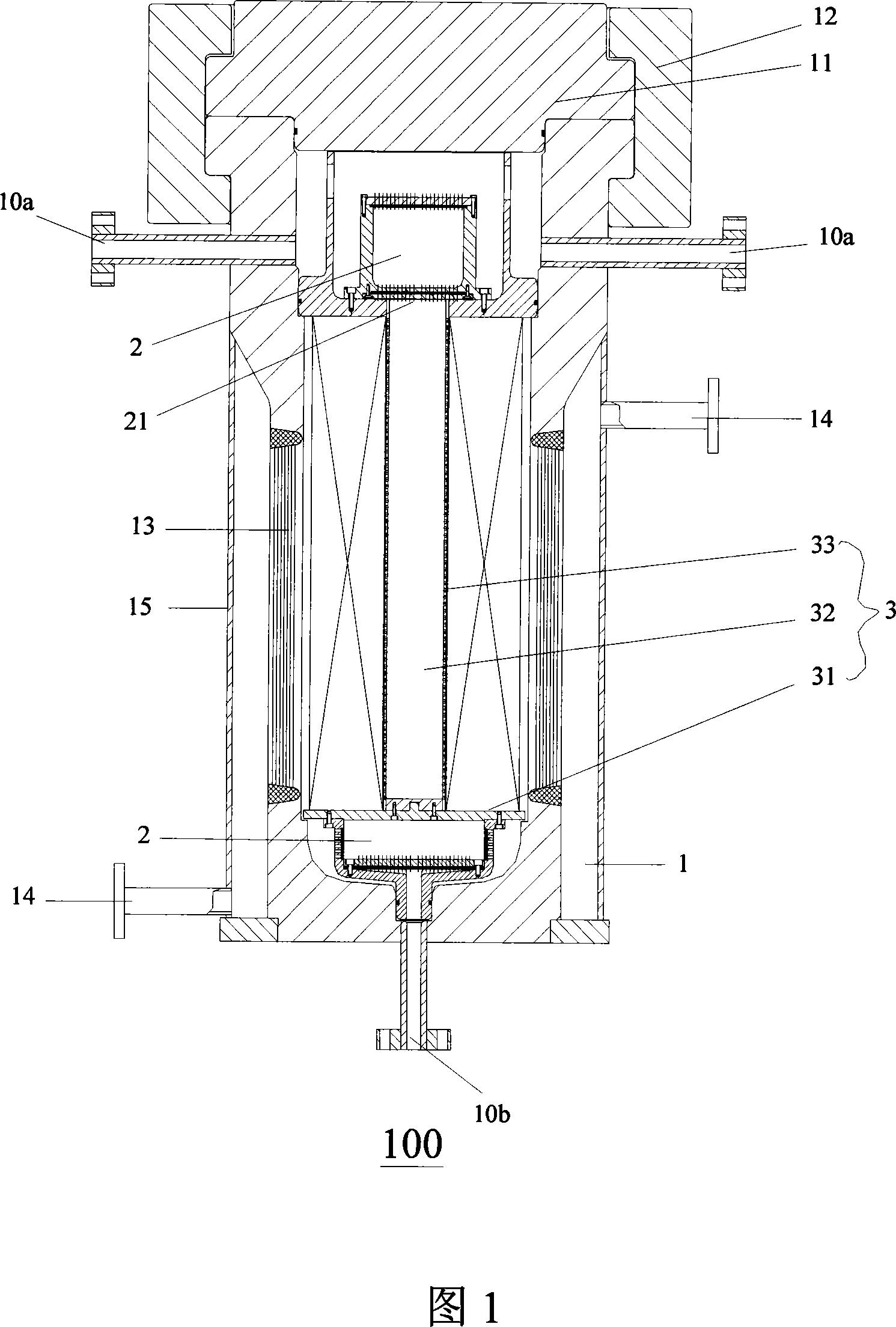

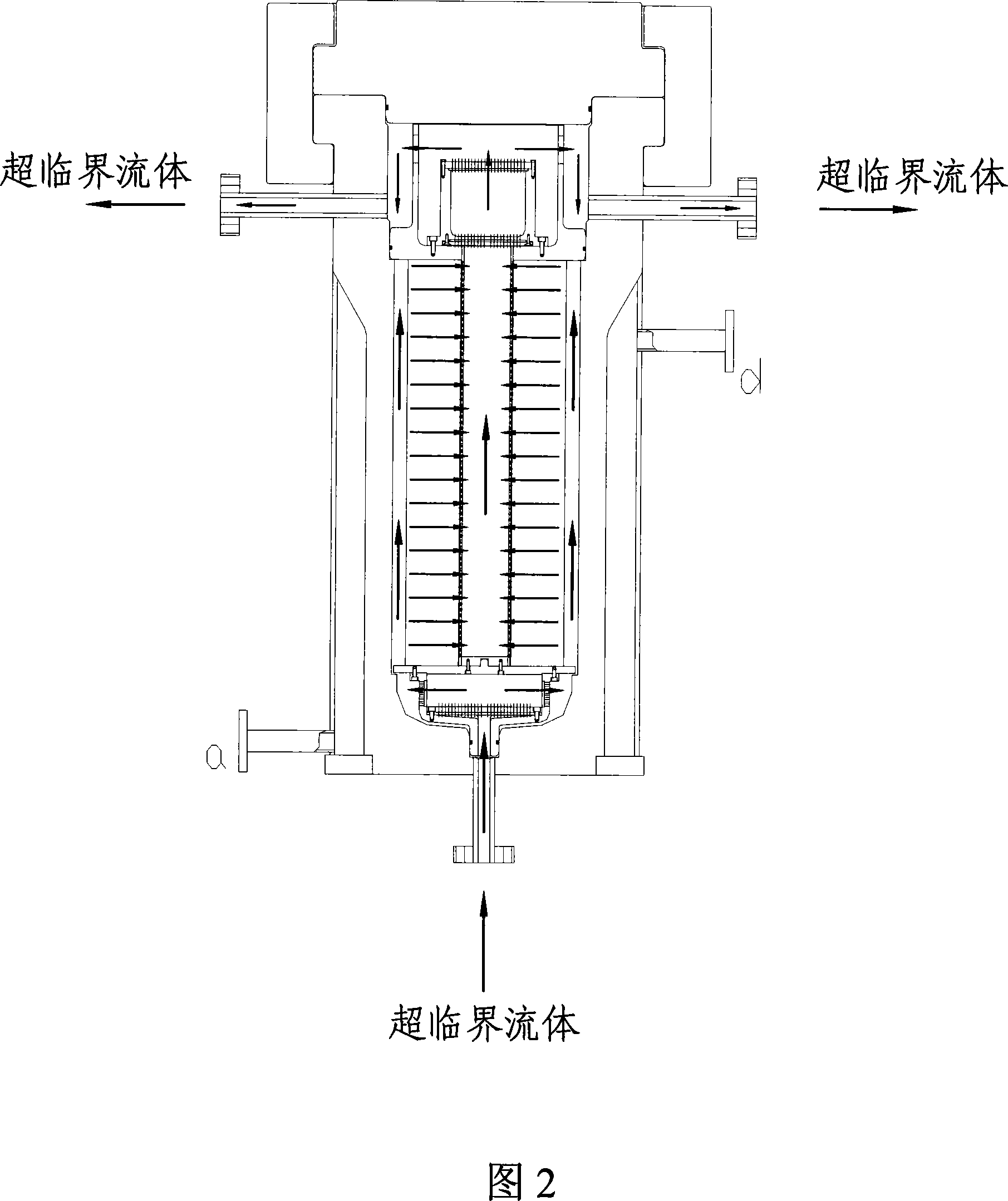

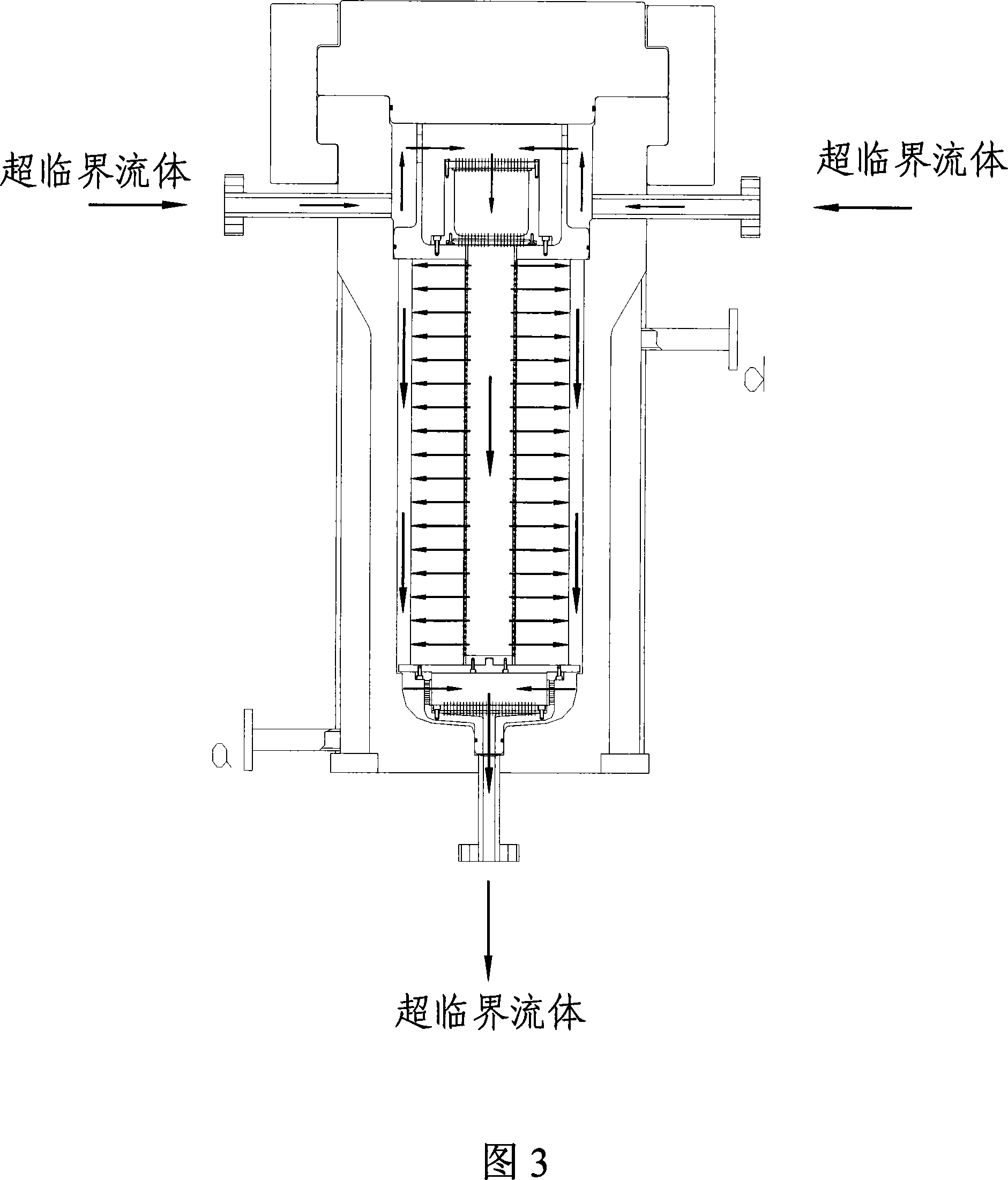

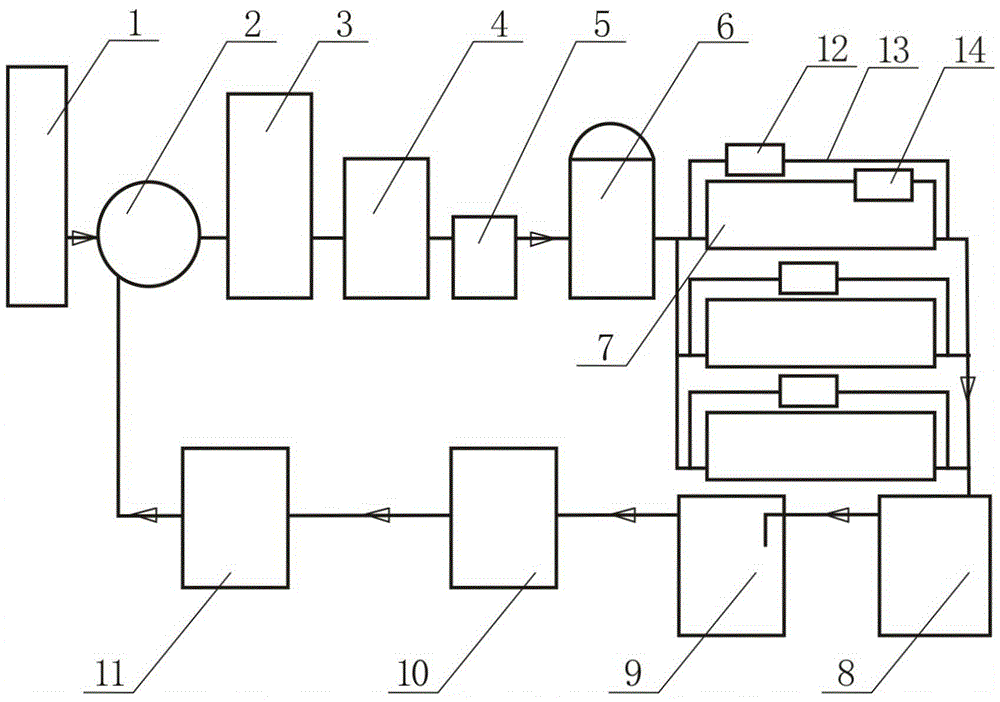

Integrated dyeing kettle

InactiveCN101021038AReduce lossReduce energy consumptionTextile treatment containersDyeing processEngineeringSupercritical fluid

The present invention provides one kind of integrated dyeing kettle for continuous dyeing process. The integrated dyeing kettle has one kettle body with supercritical fluid inlet and outlet, one fabric fixing device and at least one dye holding device inside the kettle body. The present invention combines the dye kettle and the dyeing kettle into one kettle and has the two technological steps of dissolving dye and dyeing fabric completed in the same kettle, so that the present invention has reduced supercritical fluid and dye loss, reduced power consumption and raised production efficiency.

Owner:MASSON GROUP

Snagging-prevention and anti-pilling fiber fabric dyeing technology

ActiveCN105220540AReduce snaggingReduce color flower phenomenonHeating/cooling textile fabricsDyeing processYarnFiber

The invention discloses a snagging-prevention and anti-pilling fiber fabric dyeing technology. The technology comprises the following steps of vat distributing, dye melting, dye adding, warming, heat preservation, cooling, color fixing, acid pickling and finished-product shaping. The shaping temperature is controlled to be 130-170 DEG C, and the shaping padder speed is controlled to be 25-28 m per minute. Meanwhile, a four-in-one softening agent of 1-5 g / L is added, plain cloth passes through a padder, and thus the hand feeling of fabric is made soft. In this way, 20D or 30D dacron high-stretch-yarn fabric obtained through the snagging-prevention and anti-pilling fiber fabric dyeing technology is soft and comfortable, the hand feeling is similar to that of cotton, and the phenomena of snagging and defect dyeing of fabric of 48 F or above are effectively reduced; besides, the anti-pilling grade is high, and the dyeing quality of the fabric is good.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

InactiveCN105297320AImprove permeabilityImprove solubilityTextile treatment containersSolvent treatment with solvent recoveryCirculating pumpCotton material

The invention discloses a supercritical CO2 waterless dyeing system and a cloth dyeing method thereof. The method comprises the following steps of A, preparing and storing of CO2; B, cooling; C, pressurizing; D, heating, wherein a heating device is utilized for enabling CO2 to form supercritical fluid, and the supercritical fluid is heated to 120-150 DEG C; E, dyeing, wherein a circulating pump pushes a mixture of the supercritical fluid and dye to circularly flow inside a circulation channel, cloths inside a pressure kettle are dyed, the pressure inside the pressure kettle is 28-30 MPA, the temperature is 120-150 DEG C, the circulation flowing time is 20-40 min, and the circulation flow is not smaller than 10 M<3> per hour; F, pressure relieving, wherein a nanoscale color masterbatch is dissolved through the supercritical CO2 fluid, the cloths are dyed, and dyeing technological conditions such as pressure, temperature and time are optimized at the same time so as to improve the dyeing efficiency and dyeing quality.

Owner:梁鼎天 +1

Supercritical fluid continuous yarn dyeing instrument

InactiveCN101078154AReasonable structureEasy to controlTextile treatment machine partsLiquid/gas/vapor treatment of definite length materialsYarnFiber

This invention belongs to the dyeing device for the fibre, yarn and textile, it especially relates to the super critical fluid continuously yarn dyeing machine of the device. It consists of the cavity body, yarn storehouse, heater, cut-off device for the yarn storehouse, basement, driving configure and bracket of the yarn storehouse. The cavity body installs on the basement, the outside of the body is heater, and there is pipe interface for the fluid on the cavity body. The yarn storehouse sets up in the cavity, the cut-off device installs on the both sides of the cavity. The driving configure installs two sides of the basement, and the momentum output device is corresponding to the yarn storehouse inside the cavity, and the bracket of the yarn storehouse fixes on the inlet of the cavity. The structure of this invention is rational, the controlling is simple, and it realize the continuously operation of dyeing and cleaning the float color at the sealing high pressure condition.

Owner:SHANDONG UNIV

Modifier for polyester fiber as well as preparation method and application of the same

InactiveUS20110265273A1Comfortability can be improvedGood effectOrganic dyesGrip property fibresPolyesterFiber

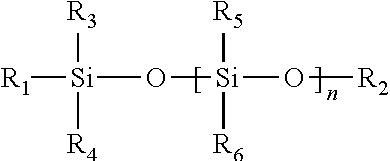

The present invention discloses a modifier for modifying the polyester fiber as well as preparation method and application of the same. The modifier contains ethylene glycol, two-hydroxy-end polyether, dimethyl terephthalate, two-polyether-end modified organosilicon, and metal acetate catalyst. A two-step continuous production process is adopted. The first step is esterification; that is, ethylene glycol, two-hydroxy-end polyether, dimethyl terephthalate, and two-polyether-end organosilicon are added into a reactor, and have an esterification reaction in the presence of the catalyst. In the second step, the materials produced by the esterification is transported to a polymerizer, and have a polymerization reaction under the conditions of high temperature, vacuum and catalyst, producing the high molecular weight polyester / polyether / organosilicon terpolymer with a molecular weight of 1000˜50000 as the desired modifier. This modifier can be used either directly or in combination with some other substances such as surfactants, so as to modify the polyester fiber.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Supercritical carbon dioxide one-step dyeing method using natural pigment

InactiveCN1963014ANo pollution in the processRealize cleaner productionDyeing processCellulose fiberNatural fiber

The invention relates to natural pigment supercritical carbon dioxide one step dyeing method. The technological process is: placing the natural pigment raw materials disintegrated and the fabric materials in supercritical carbon dioxide dyeing device; abstraction and dyeing for 50 ~ 120min in the condition of 70~150degreeC, 18-30MPa in one step; then releasing the pressure and recovering the carbon dioxide and pigment under 4-5MPa; recovering to normal and preparing dyeing fabric. Said fabric fibers are natural cellulose fiber, natural protein fiber and chemical fiber. The prominent characteristic of the invention is: it achieves the abstraction of natural pigments and the dyeing fabric completed in one step. The dyeing quality of fabric fiber is fine, process is short, and it achieves cleaning production of no abandoned products and pollution-free; the integrated cost is low, but the economic efficiency and environmental benefits are notable. Particularly, the natural pigment raw materials are medicinal plants usually, so the fiber fabric dyed could be given special medicinal function prospects.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

Fibroin protein coating fabric dying method

InactiveCN101008157AReduce pollutionImprove dyeing qualityFibre treatmentDyeing processSocial benefitsDying processes

The invention relates to a method for dying the fabric with fibroin coat, which utilizes the cation dye and acid dye to dye the rear cotton, nylone and terylene. The inventive method comprises that 1, treating the coat that furnishing the fabric in fibroin / silicon dioxide nanometer sol, drying at 40-80Deg. C, treating with methanol and drying, baking at 100-150Deg. C for several minutes, washing in water and drying; 2, pretreatment before dying comprises that 1, wetting the fabric and preparing the anion dye which is 0.1-2.0% of object mass, while the bath ratio is 1:50-1:100, and using acetate to adjust the pH value to 4.0-8.0; 2, wetting the fabric and preparing the acid dye at 0.1-2.0% of object mass, while the bath ration is 1:50-1:100, using acetate to adjust the pH value to 2.0-3.5; 3, dying process comprises that 1, dying with anion, 2, dying with acid dye; 4, drying and ironing the object. The invention has simple process, dye-uptake and high color stability, without other agents and pollution, but high economic and social benefits.

Owner:DONGHUA UNIV

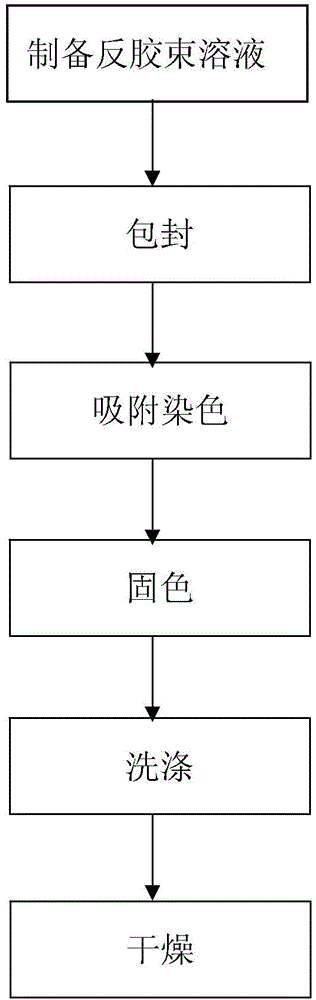

Fabric non-water dyeing method

The invention relates to a fabric non-water dyeing method. The method comprises the following steps: pre-mixing a nonionic surfactant and a co-surfactant, dissolving the mixture into an organic solvent to prepare a reversed micelle solution; slowly adding an active dye solution into the reversed micelle solution, at the same time, stirring the solution until the turbid reversed micelle solution becomes clear to obtain a reversed micelle encapsulated active dye solution; soaking fabrics in the reversed micelle encapsulated active dye solution, vibrating the dye solution continuously to carry out adsorption dyeing at a constant temperature until a balance of adsorption dyeing is reached; adding a color fastening agent solution to obtain reversed micelle encapsulated fastening agent solution; and vibrating the solution continuously so as to fix the color of fabrics at a constant temperature. The fabrics are dyed by a one bath method based on a nonionic surfactant. The cost is reduced, and the dyeing effect is guaranteed. At the same time, an organic solvent is taken as the medium; the using amount of water is reduced, moreover, the organic solvent can be recovered effectively, and the environmental pollution is reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

Polyester yarn dyeing technology

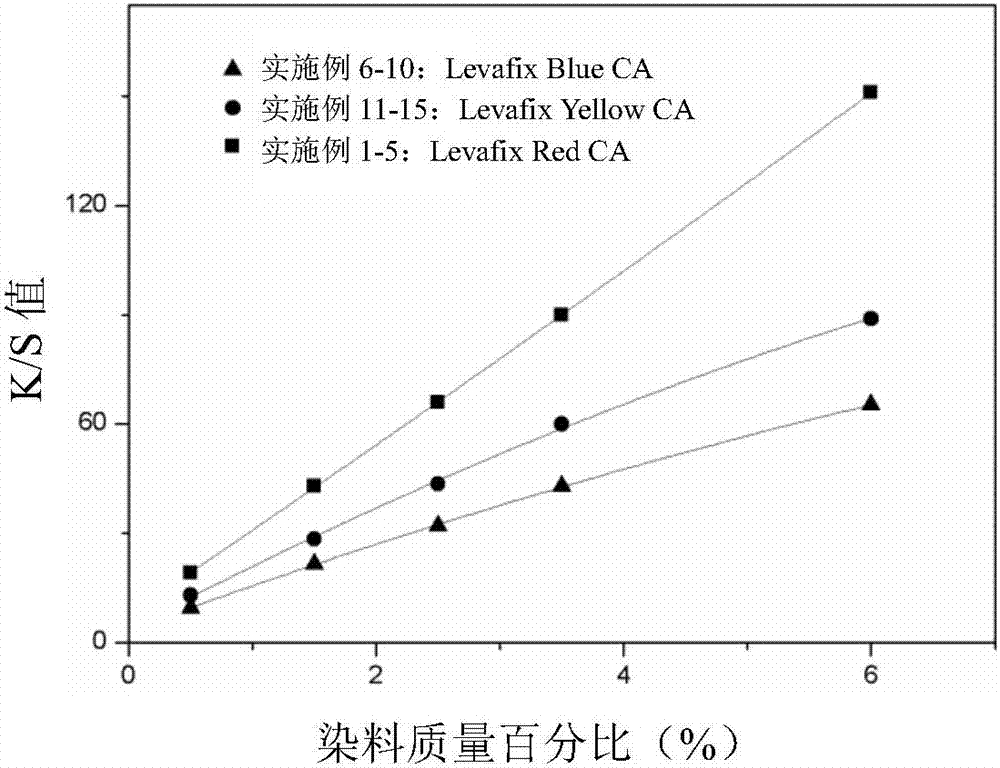

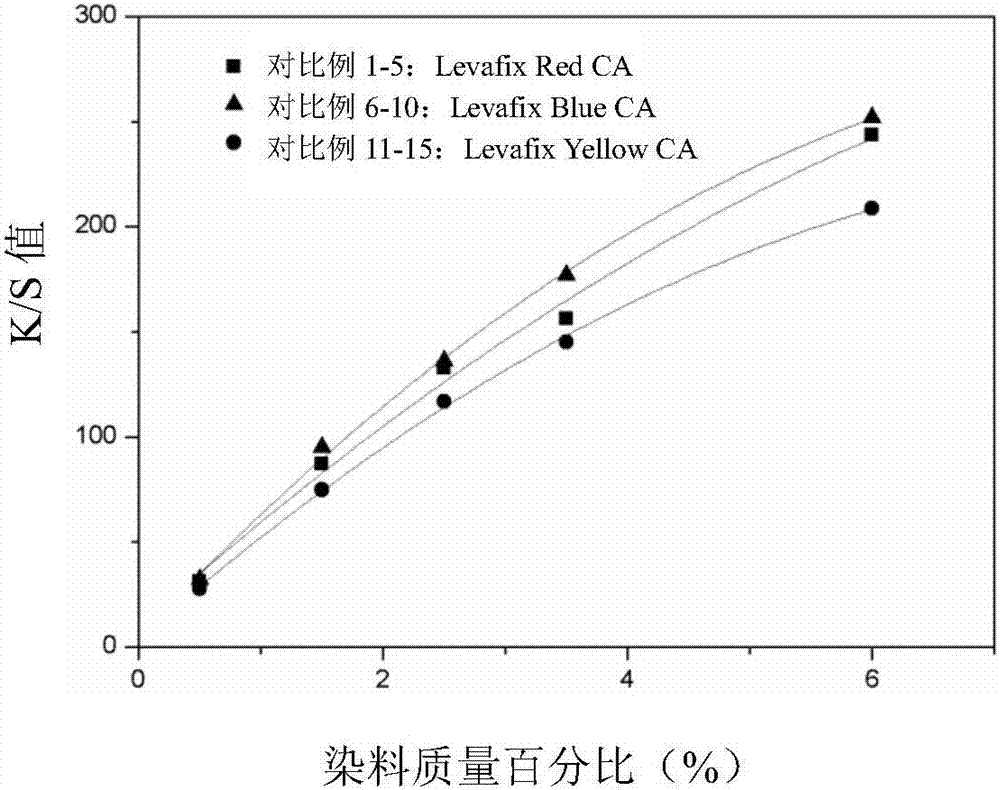

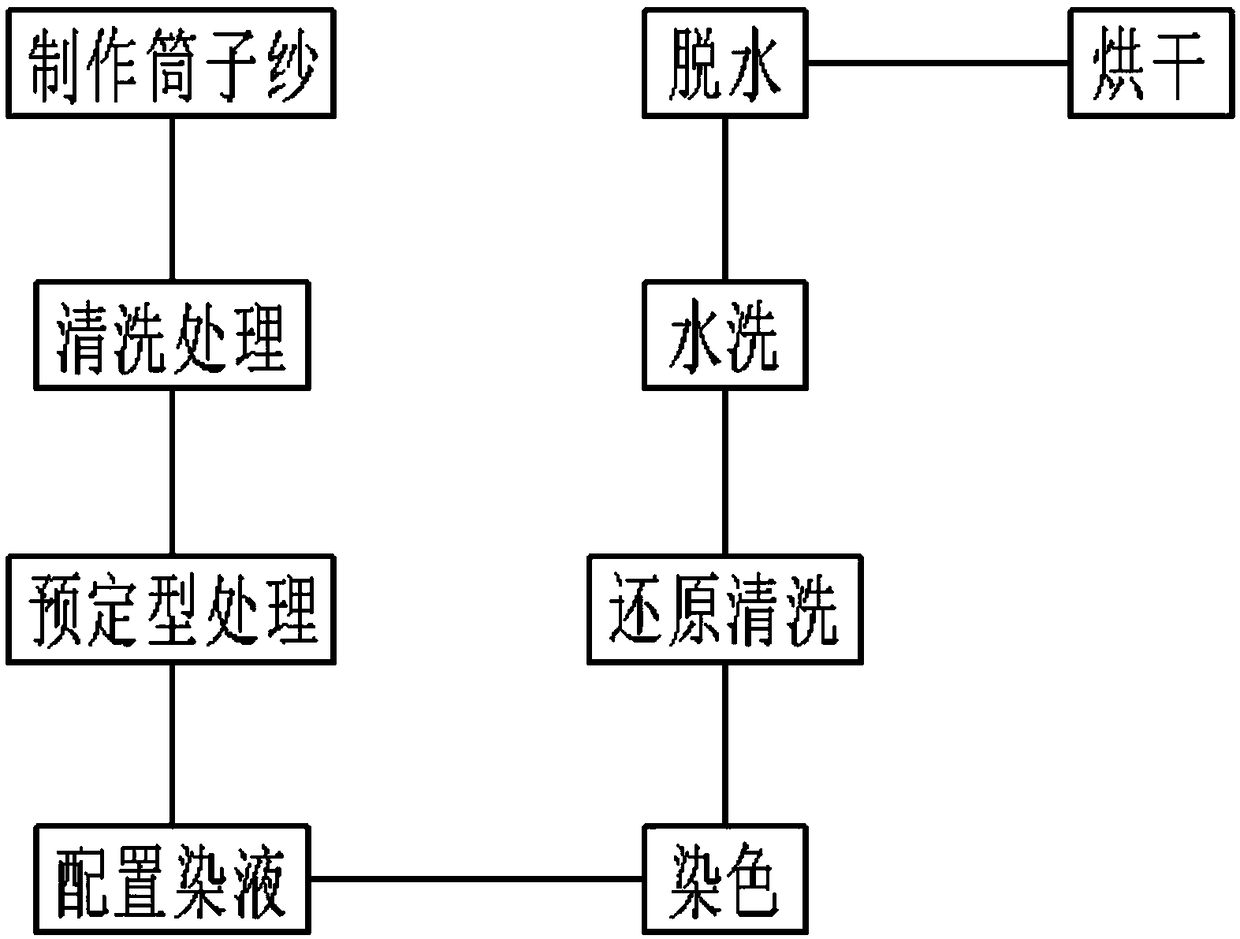

The invention discloses a polyester yarn dyeing technology which comprises the following steps of preparation of cheese, cleaning treatment, presetting treatment, preparation of dye liquor, dyeing, reduction cleaning, washing, dehydration and drying, wherein the step of presetting treatment is to put the cheese after cleaning treatment in boiling water for treatment for 12-15 min; the step of preparation of the cheese comprises yarn loosening and caging, wherein the coiling density of polyester yarns after being loosened is 0.32-0.36 g / cm<3>; and the step of cleaning treatment is to immerse the polyester yarns into a light alkali solution, perform treatment for 10 min under the condition with the temperature being 100 DEG C and add 1 g / L soaping agent to perform deoiling treatment. In thepolyester yarn dyeing technology provided by the invention, presetting treatment is performed on the polyester yarns before dyeing, and after presetting treatment, the polyester yarns cannot shrink again or shrink slightly when being subjected to high-temperature dyeing as the polyester yarns are shrunk in advance before dyeing, so that polyester yarn fibers uniformly absorb a dye, and the dyeingquality of the polyester yarns is improved.

Owner:福建省天和纺织实业有限公司

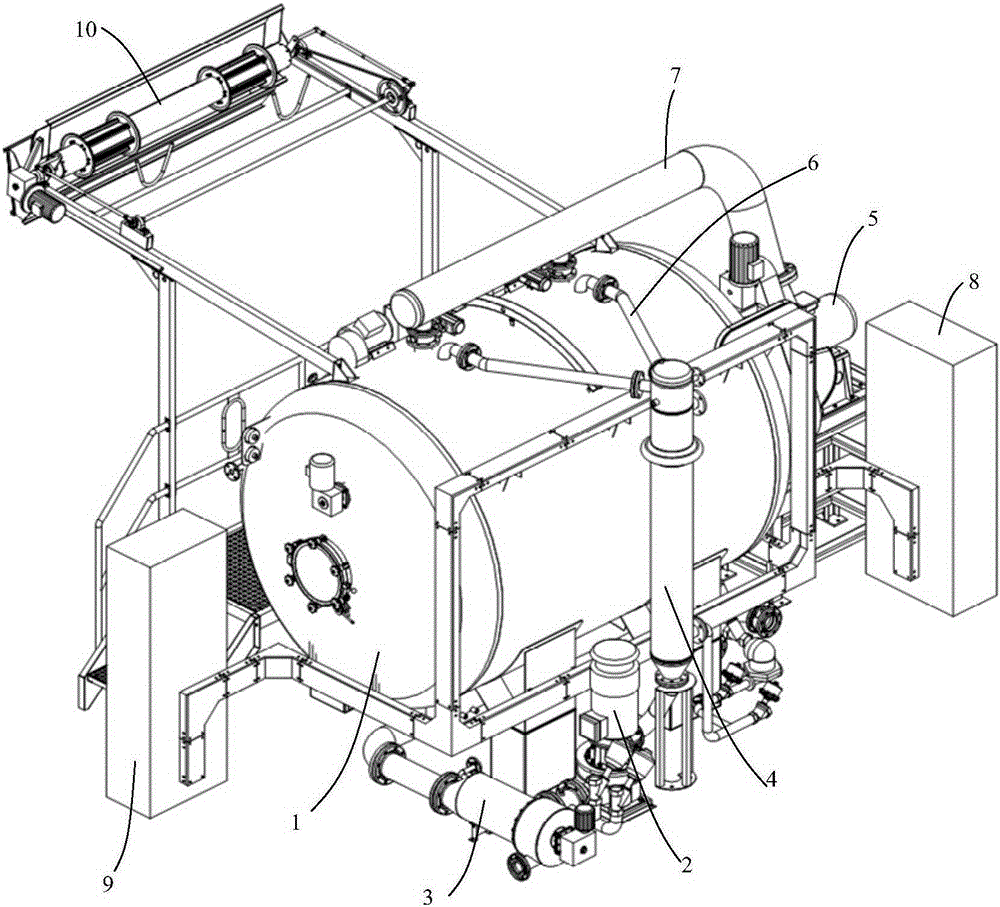

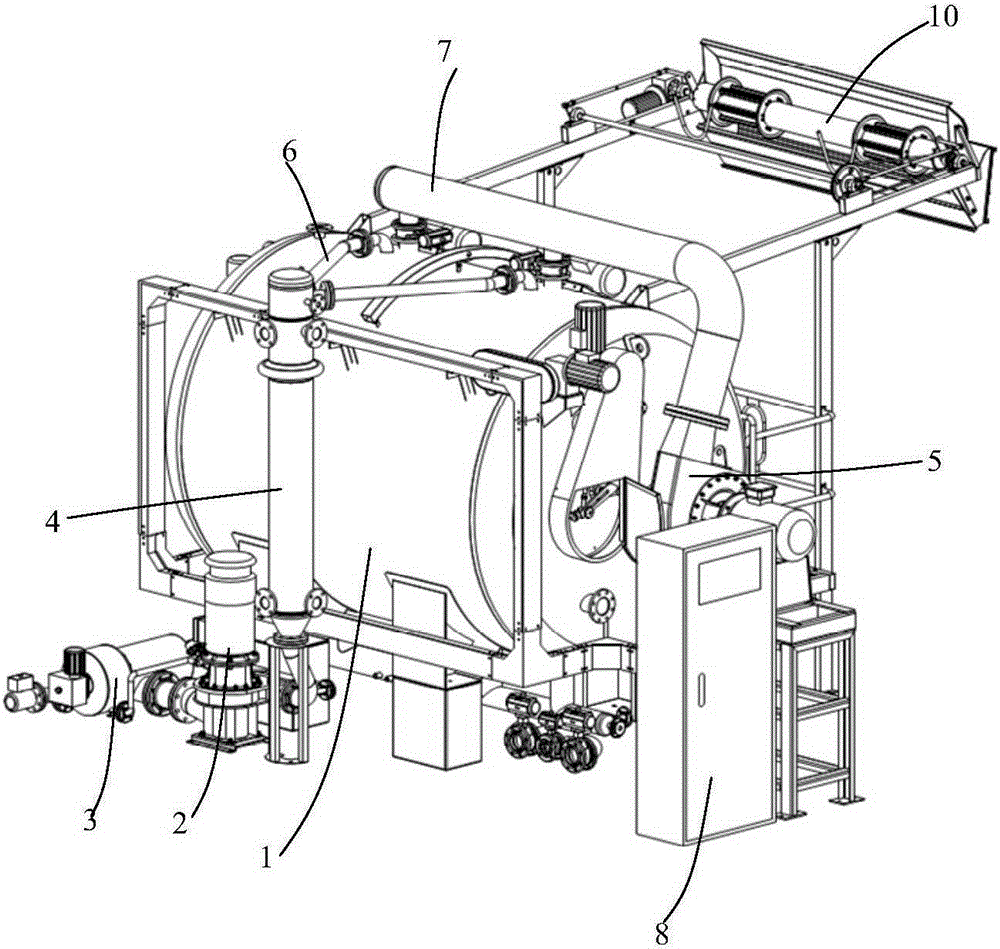

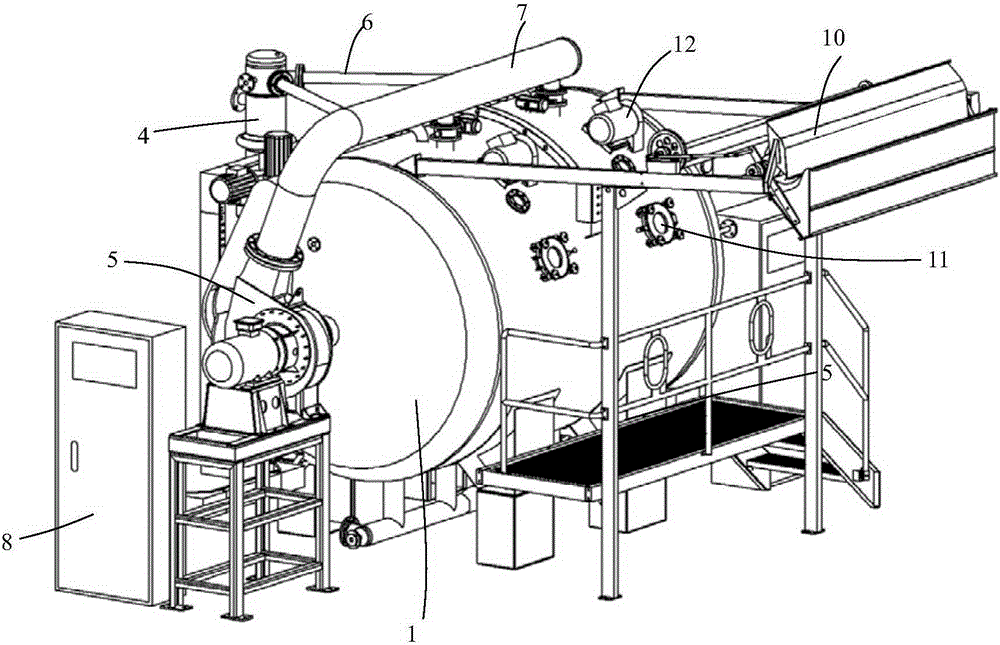

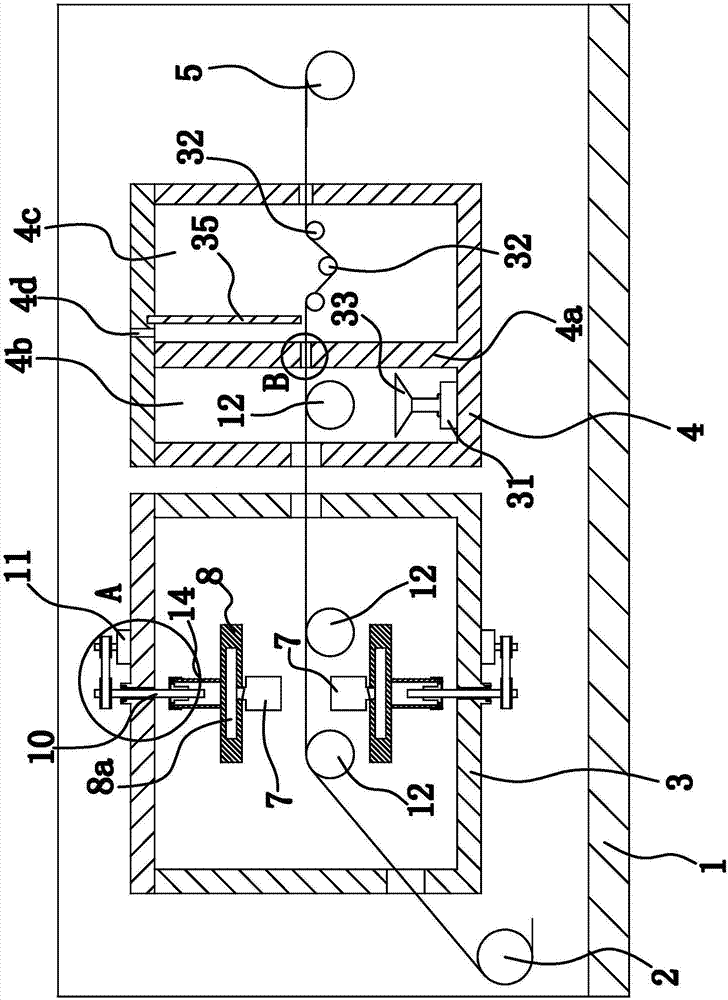

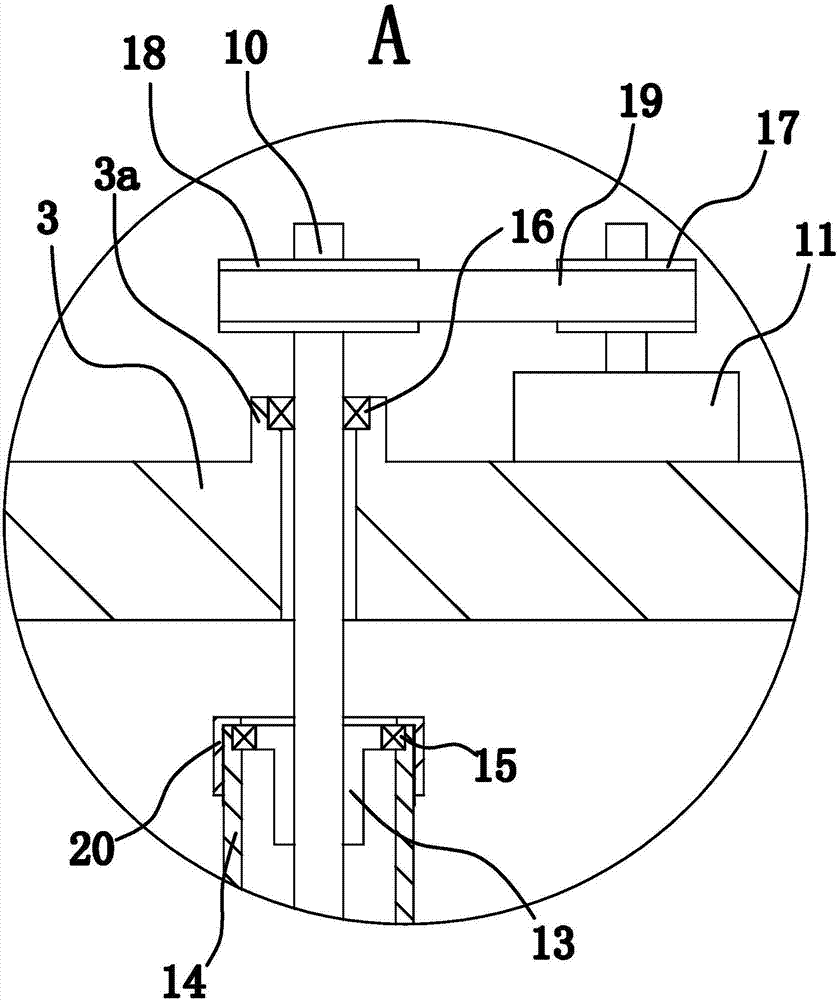

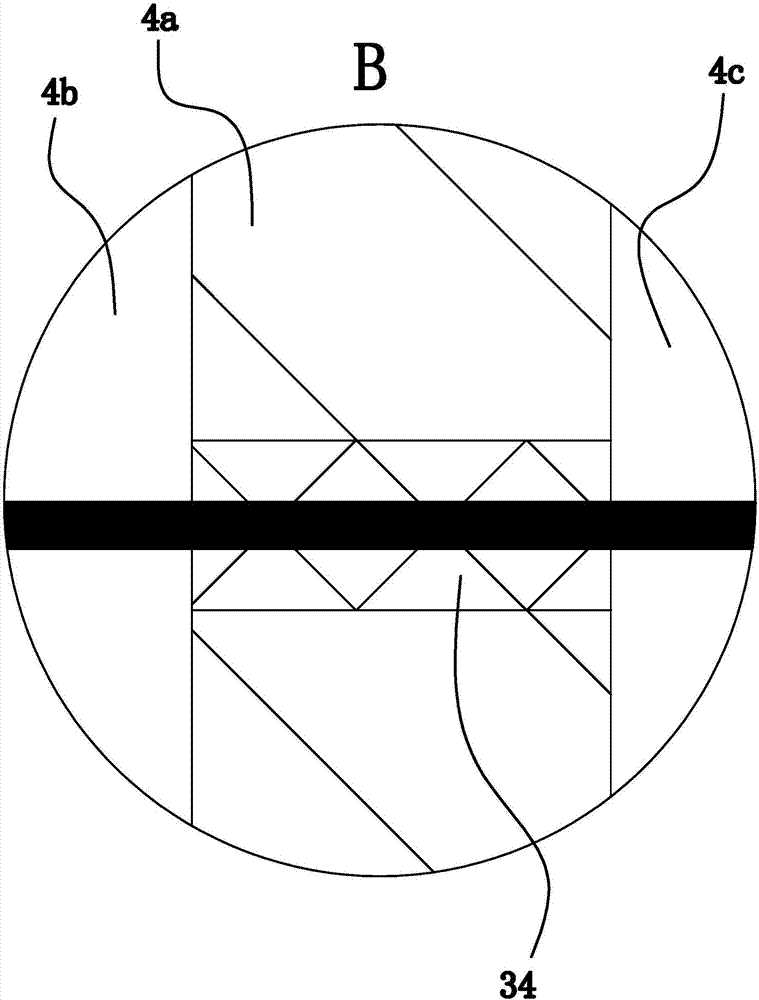

Ultralow liquor ratio gas-liquid splitting dyeing machine with built-in gas-liquid spray-dyeing system and cloth lifting system

ActiveCN105332179AShort tripImprove energy savingTextile storage in superimposed formTextile treatment containersElectric machineryProcess engineering

The invention discloses an ultralow liquor ratio gas-liquid splitting dyeing machine with a built-in gas-liquid spray-dyeing system and a built-in cloth lifting system. The dyeing machine comprises a cylinder body, a main pump, a broken wool filter, a heat exchanger, a blower fan, dye liquor shunt tubes, an air duct, a strong current cabinet, a weak current cabinet, a cloth discharge device, a fabric inlet and outlet, a cloth lifting motor, a cloth lifting wheel, a nozzle, a cloth swing system, a cloth storage groove, a broken wool filtering device, a dye liquor return pipe, and other components. The dyeing machine is compact in structure and simple in operation, and occupation area of the device is greatly reduced, and labor intensity of manufacturing workers is reduced. The machine overturns a blower fan, liquor ratio, cloth swing and folding, fabric operation, dye liquor automatic filtering, and other concepts of an airflow atomizing fabric dyeing machine in the same generation. The device is characterized by low liquor ratio, water saving and electricity saving, reduced emission, high automation degree, high dyeing process efficiency, good quality, high stability, and safe and reliable operation. The dyeing machine is substantial in energy saving and emission reduction effect, and is environmentally friendly and low-carbon. The dyeing machine plays roles of demonstration and leading in a dyeing and finishing equipment industry, and leads development directions of the industry.

Owner:高勋绿色智能装备(佛山)有限公司

Umbrella fabric dyeing and finishing machine

PendingCN106868742AImprove practicalityImprove convenienceTextile treatment machine arrangementsTextile treatment by spraying/projectingDyeingManufacturing engineering

The invention provides an umbrella fabric dyeing and finishing machine, and belongs to the technical field of machinery. The machine solves the problem that existing dyeing and finishing machines are hard to use. The umbrella fabric dyeing and finishing machine comprises a rack and a fabric feeding roller, a dyeing chamber, an ironing chamber and a cloth roller which are all arranged on the rack. A dye tank is arrange at a side of the sack, support plates are arranged in the dyeing chamber, the support plates are two plates wherein a dyeing zone is formed between the two plates, sprayers are arranged at two opposite sides of the two support plates, each support plate is provided with a plurality of the sprayers wherein the sprayer distribution direction is perpendicular to the fabric delivery direction, a strip-like flow channel is arranged on each support plate while the sprayers are communicated with the flow channel, a dye delivery pump is arranged in the dyeing chamber, the inlet of the dye delivery pump is communicated with the dye tank through a pipe, and one end of each flow channel is closed while the other end is open, wherein the open end of each flow channel is communicated with the outlet of the dye delivery pump through a telescopic connecting piece. The dyeing and finishing machine further comprises two elevator mechanisms which can separately drive the up-and-down movement of the two support plates. The machine has the advantage of easy utilization.

Owner:ZHEJIANG XIANYU FIBER WEAVING & DYEING GARMENT CO LTD

Method for dyeing modified cellulose fabrics by green walnut epicarp pigment

InactiveCN102644204ASimple dyeing processImprove dye uptakeDry-cleaning apparatus for textilesNatural dyesColour fastnessModified cellulose

A method for dyeing modified cellulose fabrics by green walnut epicarp pigment includes following steps of dyeing green walnut epicarp pigment dyeing extract liquor on the modified cellulose fabrics; and soaping, washing and drying after dyeing, washing and drying the modified cellulose fabrics by a direct dyeing process. The method is simple and easy in process, does not need mordant dyeing fixation and the like, is high in dyeing efficiency, fine in dyeing quality, free of toxin and pollution, low in cost and remarkable in economic and environment benefits, and has high friction resisting color fastness and washing resisting color fastness which are higher than four levels.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Printing and dyeing pretreatment process for imitated silk fabric

InactiveCN108486810AReduce wrinklesImprove dyeing qualitySucessive textile treatmentsDry-cleaning apparatus for textilesWrinkleStart time

The invention relates to the technical field of cloth dyeing and finishing, in particular to a printing and dyeing pretreatment process for an imitated silk fabric. Influences to follow-up dyeing dueto poor desizing effect are solved. According to the technical scheme, the printing and dyeing pretreatment process for the imitated silk fabric comprises the steps of rolling, desizing, pre-shaping and reeling. In pre-shaping, a steam spraying device cooperates with a shaping machine, wrinkles on greige cloth are reduced favorably, and then, follow-up dyeing operation is facilitated; the startingtime of an unreeling device, the starting time of a transmission device and the starting time of a reeling device are different, and the effects of desizing and cleaning of the greige cloth are improved favorably, and then follow-up greige cloth dyeing quality is enhanced favorably; and by design of a scraping portion, desizing liquid on the greige cloth in a first cleaning tank and first cleaning liquid on the greige cloth in a second cleaning tank are reduced favorably, and thus, the greige cloth cleaning effect is improved.

Owner:嘉兴市金宇达染整有限公司

Production method of cotton acrylic shell fabric

InactiveCN106544887AShort processImprove efficiencySucessive textile treatmentsTwo or more solvent application treatmentYarnRoom temperature

The invention relates to a production method of a cotton acrylic shell fabric. The method comprises yarn loosing, pretreatment, blend dyeing and aftertreatment, wherein the yarn loosing is carrying out tube loosing on blend fiber yarn by adopting a digital winding manner; the pretreatment is adding a refining agent and sodium carbonate, heating to high temperature, performing heat preservation for a period of time and discharging, and directly adding cold water and acid for treatment; the blend dyeing is adding a retarding agent, a dispersing agent, an antireducer, cationic dyes and HAC, heating and performing heat preservation for twice and discharging materials, adding into water, heating to high temperature and discharging, adding into water at normal temperature, adding a dispersing agent and a soaping agent for water washing at high temperature for twice, discharging after each time of heat preservation, after washing with water once at the normal temperature, adding an activated dye for cotton dyeing, softening, dewatering, oven drying, and performing tube splitting and beaming or spooling, thus obtaining the needed yarns. The production method improves the color precision of the cotton acrylic shell fabric greatly.

Owner:ZHEJIANG SAINTYEAR TEXTILE

Superfine dispersion method for dispersed dye

Disclosed is a superfine dispersion method for dispersed dye, wherein dispersion dyes are subject to mechanical dispersion and ultrasonic wave dispersion simultaneously in an aqueous environment, the dispersion dyes are the end product of filter-pressed filter cake or sanded filter cake or dried grout of the original dyes during dispersion dyes manufacturing process, and dispersing agent is charged into the filter cake during the process of mechanical dispersion and supersonic wave dispersion.

Owner:章浩龙

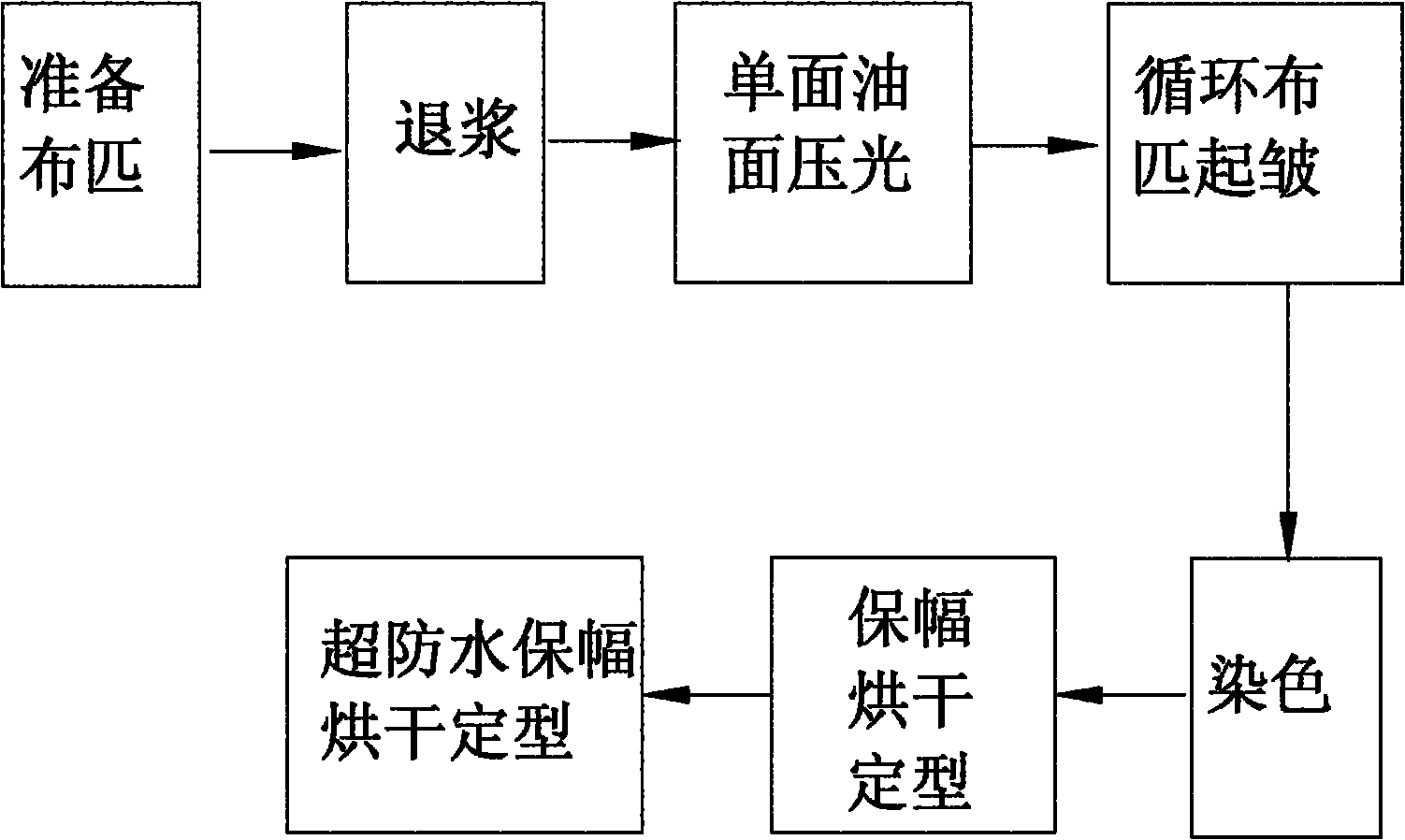

Plain creased fabric and manufacturing method thereof

ActiveCN102094316AIncrease pattern changeBionic effectPattern makingLiquid/gas/vapor textile treatmentEngineeringSizing

The invention discloses a plain creased fabric and a manufacturing method thereof. The manufacturing method comprises the steps of desizing, single oil surface calendering, cloth creasing by means of circular hot and cold water alternatiion, dyeing and width-keeping drying and sizing. The dyeing is carried out by stages in a temperature rise way. In the preparation method disclosed by the invention, because calendering and creasing processing are carried out on a fabric before dyeing after desizing, the dyed cloth creases in a fish-scale shape and has good creasing effect. Two surfaces of the plain creased fabric disclosed by the invention are interwoven from warp yarns and weft yarns; one surface of the fabric is a bright surface, and the other surface is a dark surface; the creases are of a fish scale shape; and the plain creased fabric disclosed by the invention has natural simulated creases because two surfaces of the fabric present different effect, i.e. a bright effect and a dark effect, can be worn in both sides and improves the fashion performance of clothes.

Owner:ZHEJIANG TAIHUA NEW MATERIAL

Plasma dyeing system and method

ActiveCN106087315AUniform particlesUniform dyeingSucessive textile treatmentsTextile treatment machine arrangementsGreen environmentWastewater

The invention discloses a plasma dyeing system. The plasma dyeing system comprises an unwinding mechanism for to-be-dyed fabrics, a fabric heating module, a plasma processing module, a dyeing module and a dyed fabric winding mechanism, wherein the fabric heating module, the plasma processing module, the dyeing module and the dyed fabric winding mechanism are sequentially arranged behind the unwinding mechanism. The invention further discloses a dyeing method utilizing the plasma dyeing system. According to the dyeing method utilizing the system, the combination efficiency of the fabrics and dyes can be improved, the dyeing quality of products is improved, non-adsorbed dyes during the plasma dyeing are cyclically used, no wastewater is discharged, green environment friendliness is achieved, the consumption of the dyes, water and eliminating additives are reduced, and compared with the traditional technique, the method provided by the invention has the advantage of lower dyeing cost.

Owner:JIANGSU S&S INTELLIGENT SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com