Nonwoven cloth dyeing technique and nonwoven cloth dyeing assembly line

A technology of non-woven fabrics and production lines, which is applied in textile processing machine accessories, textiles and papermaking, and textile material processing. It can solve the problems of dyeing, unusability, and low wet strength, and achieve high production efficiency, good dyeing quality, and Solve the effect of low wet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

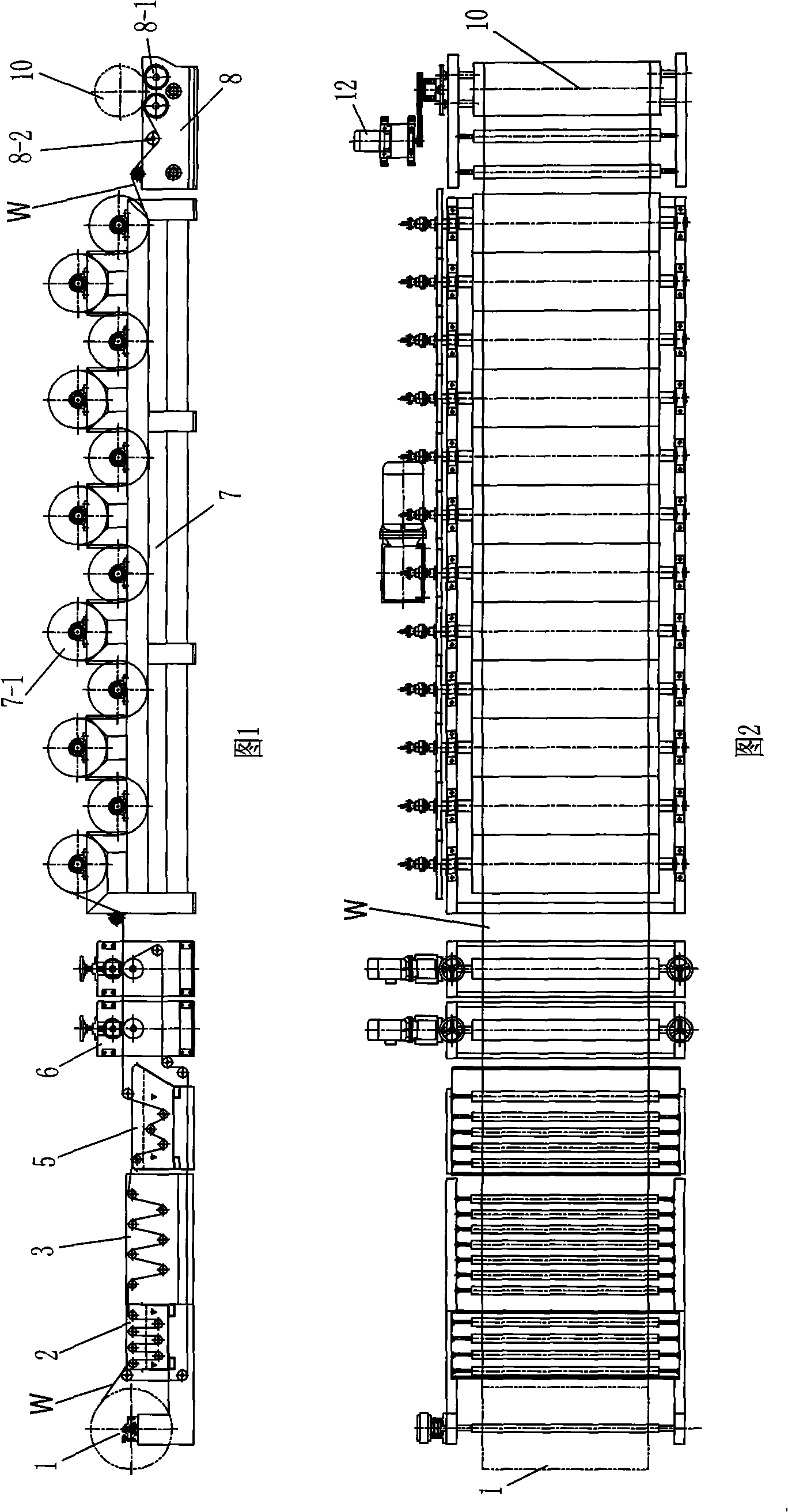

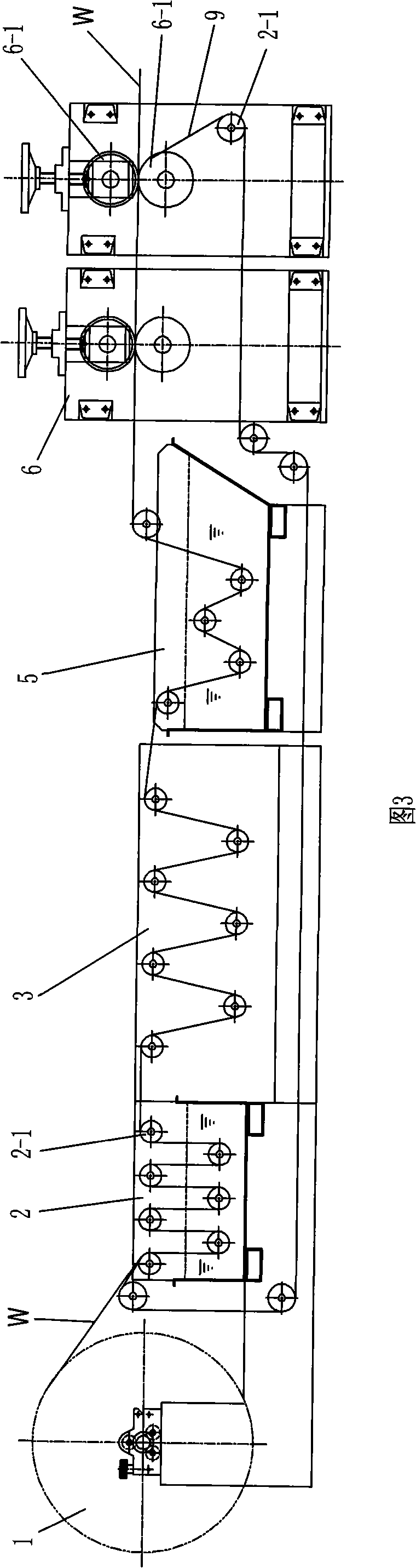

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0022] The dyeing process of non-woven fabrics is carried out according to the following steps:

[0023] 1. The non-woven fabric to be dyed is unwound from the unwinder and immersed in the dyeing solution of the dyeing vat for dyeing; the temperature of the dyeing solution is 95-98°C, and the residence time of the non-woven fabric in the dyeing solution is 3-8 seconds;

[0024] 2. The dyed non-woven fabric is washed in clean water, generally for 3-8 seconds, and then dewatered;

[0025] 3. The colored non-woven fabric that has been dehydrated is dried; the drying temperature is 130-150 ° C, and the drying heating time is 3-8 seconds; then it is rolled.

[0026] The non-woven fabric is unwound from the unwinding machine and is directly spread on the mesh belt in circulation, and enters the dyeing, cleaning and water removal processes under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com