Beam dyeing machine cloth velocity-tension coordinating control method

A dyeing jigger and tension technology, applied in adaptive control, general control system, textile material processing, etc., can solve the problems of difficult speed-tension control, ignoring the coupling relationship, etc., to reduce dyeing color difference and improve dyeing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

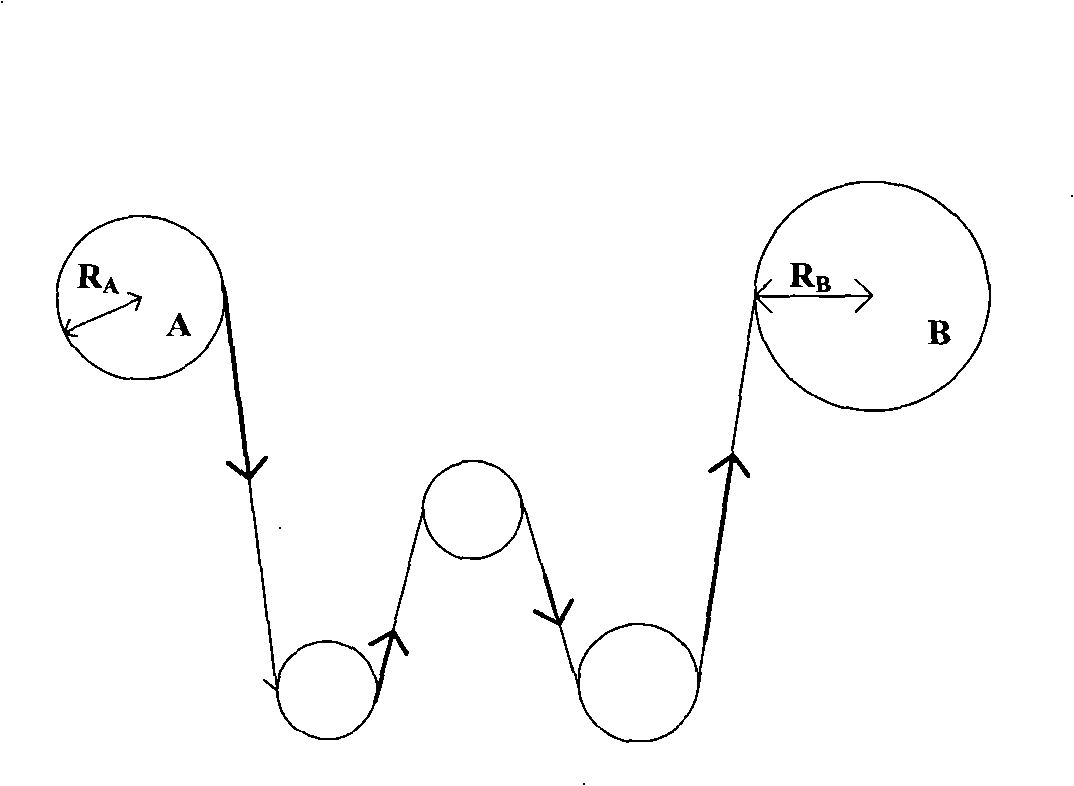

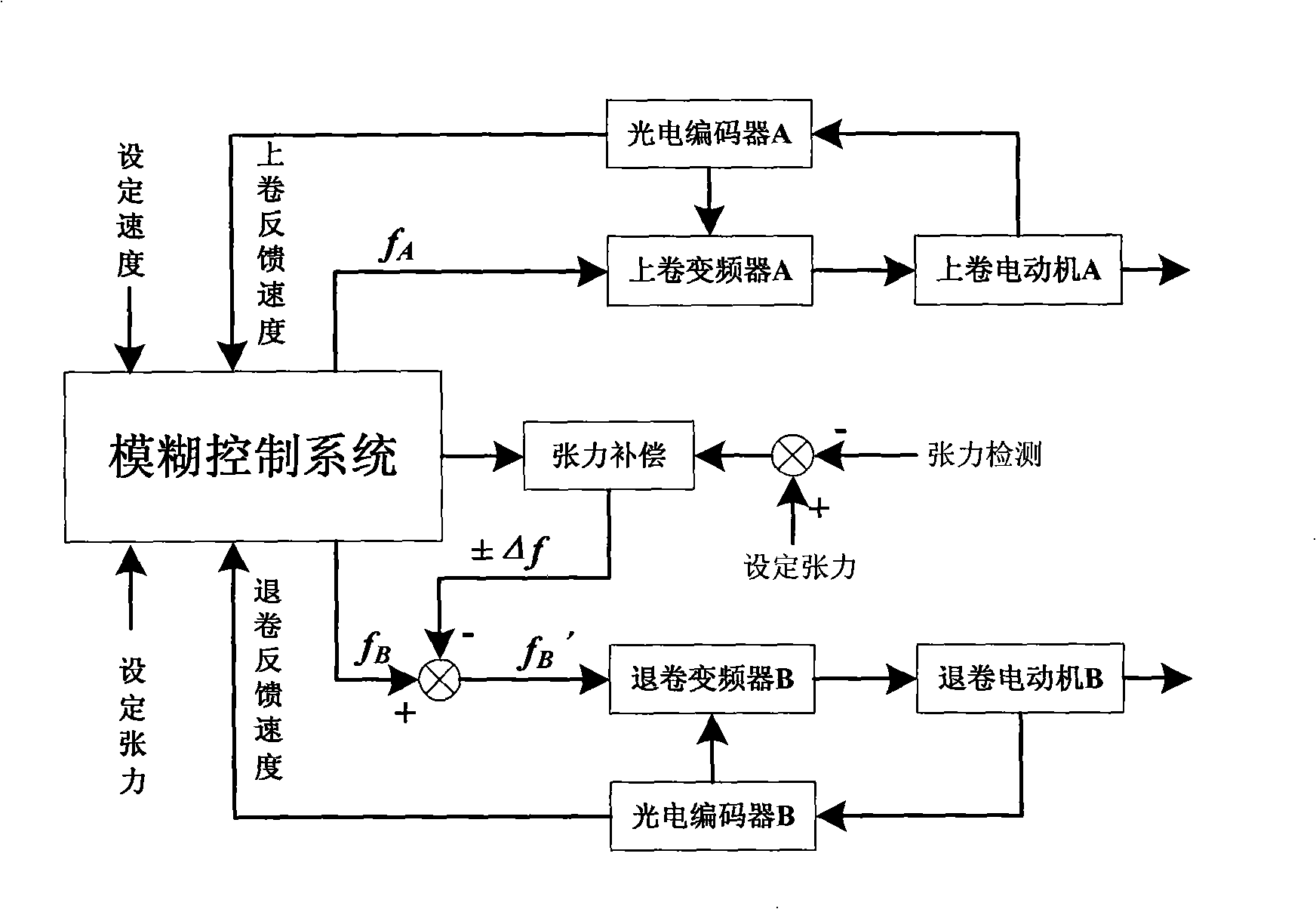

[0019] The speed-tension coordinated control method of jigger cloth will be further described below in conjunction with the accompanying drawings.

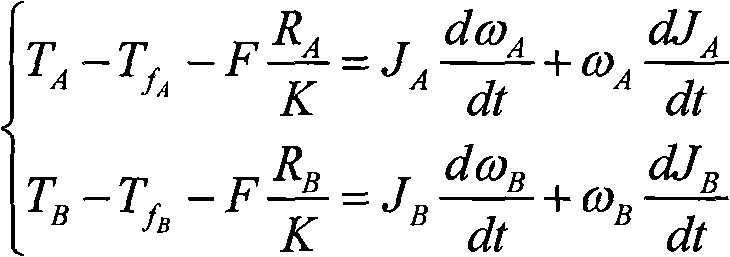

[0020] refer to figure 2 , the speed-tension coordinated control method of jigger cloth, including fuzzy control system, winding control object and unwinding control object, the winding control object includes the servo system composed of winding frequency converter A and winding motor A and installation On the winding photoelectric encoder A of the tail shaft of the winding motor A, the high-speed pulse signal generated by the winding photoelectric encoder A is sent to the winding frequency converter A and the fuzzy control system, and the fuzzy control system obtains the winding feedback speed and sends the winding The volume feedback speed is compared with the set speed, and the frequency f required to keep the cloth line speed constant is obtained by calculation A , the speed of the winding motor A is controlled by the windi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com