Patents

Literature

75results about How to "Reduce color difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for calibrating colour print engines

InactiveUS20070024657A1Reduce color differenceReduce the differenceOther printing apparatusPictoral communicationEngineeringDigital image

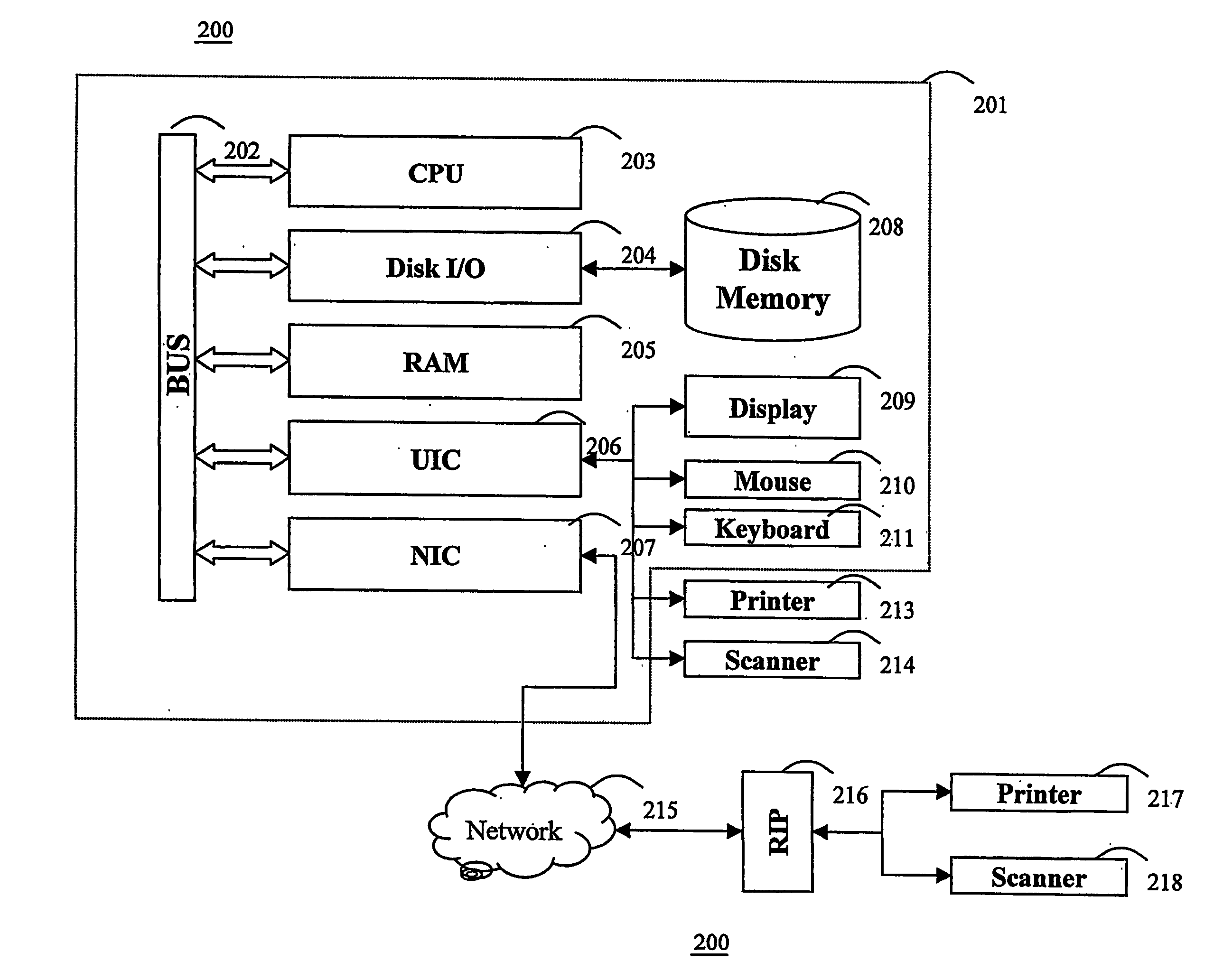

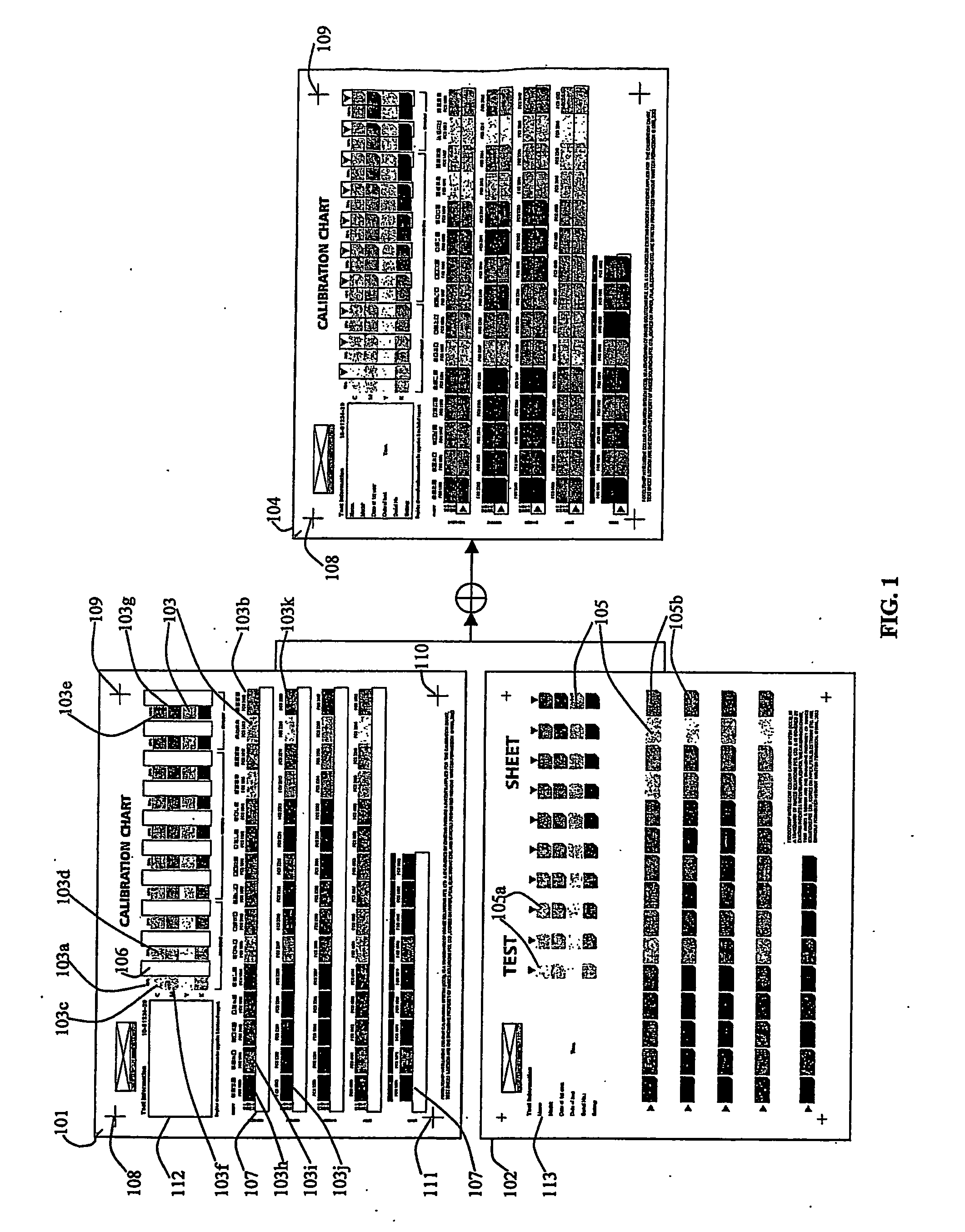

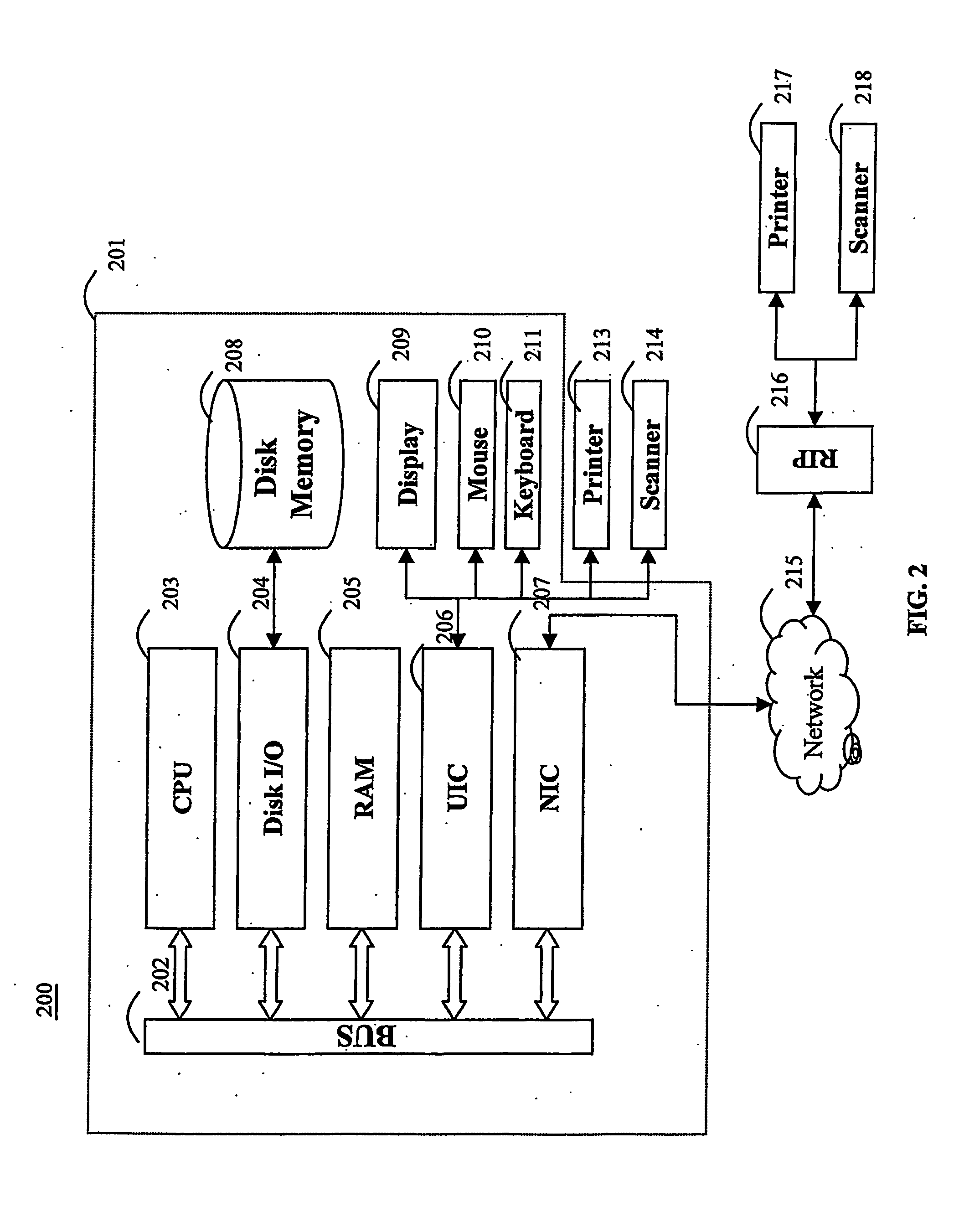

A calibration method for print engines is disclosed herein. In a preferred embodiment, the method comprised the steps of: providing a calibration chart (101) having a first array of reference colours thereon; printing a separate test sheet (102) at step (301) from a said print engine; the test sheet (102) having a second array of test colours thereon, each test colour corresponding to one reference colour of the first array; arranging both sheets (101, 102) together; scanning the sheets (101, 102) at step (302) to capture a digital image of the reference and test colours; analysing the colour characteristics at step (303) to obtain the colour difference between corresponding pairs of reference and test colours; and compensating any colour difference at step (304) by automatically adjusting the printer in accordance with the colour difference.

Owner:ZHANG NENGSHENG ALLAN +1

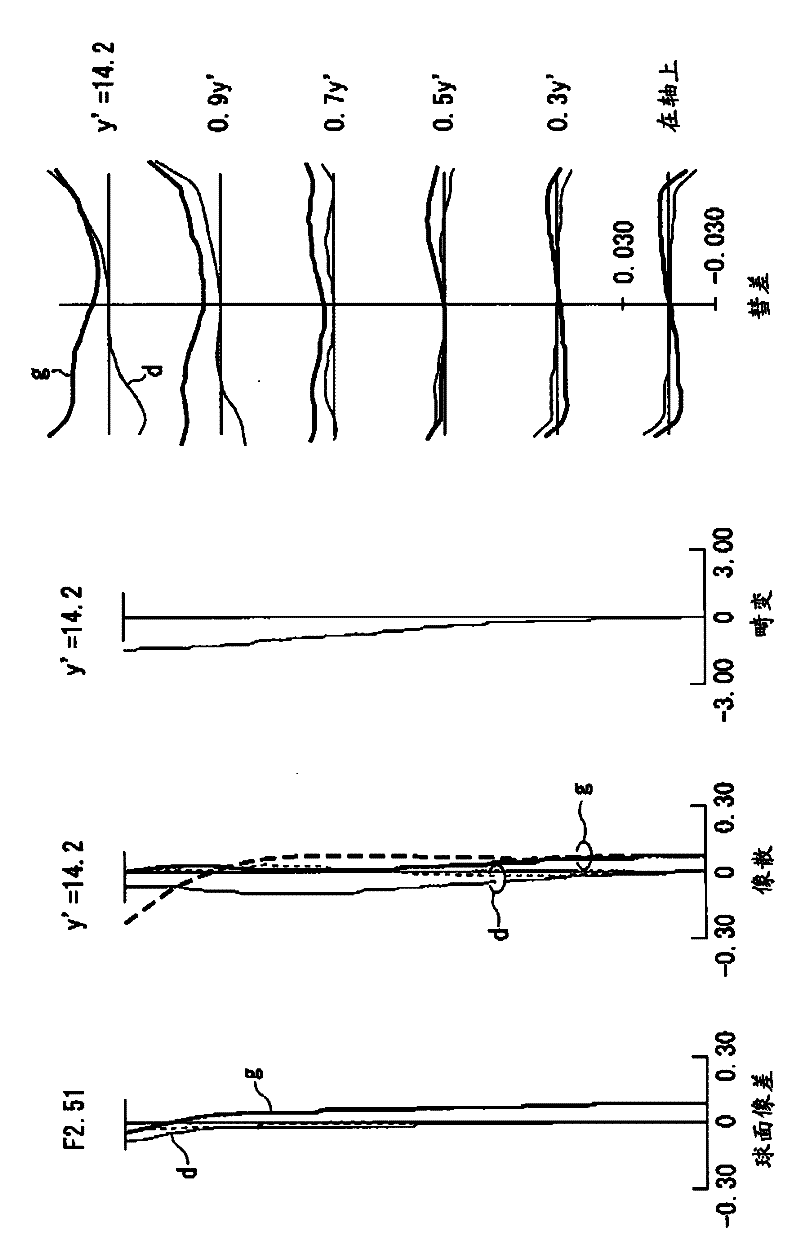

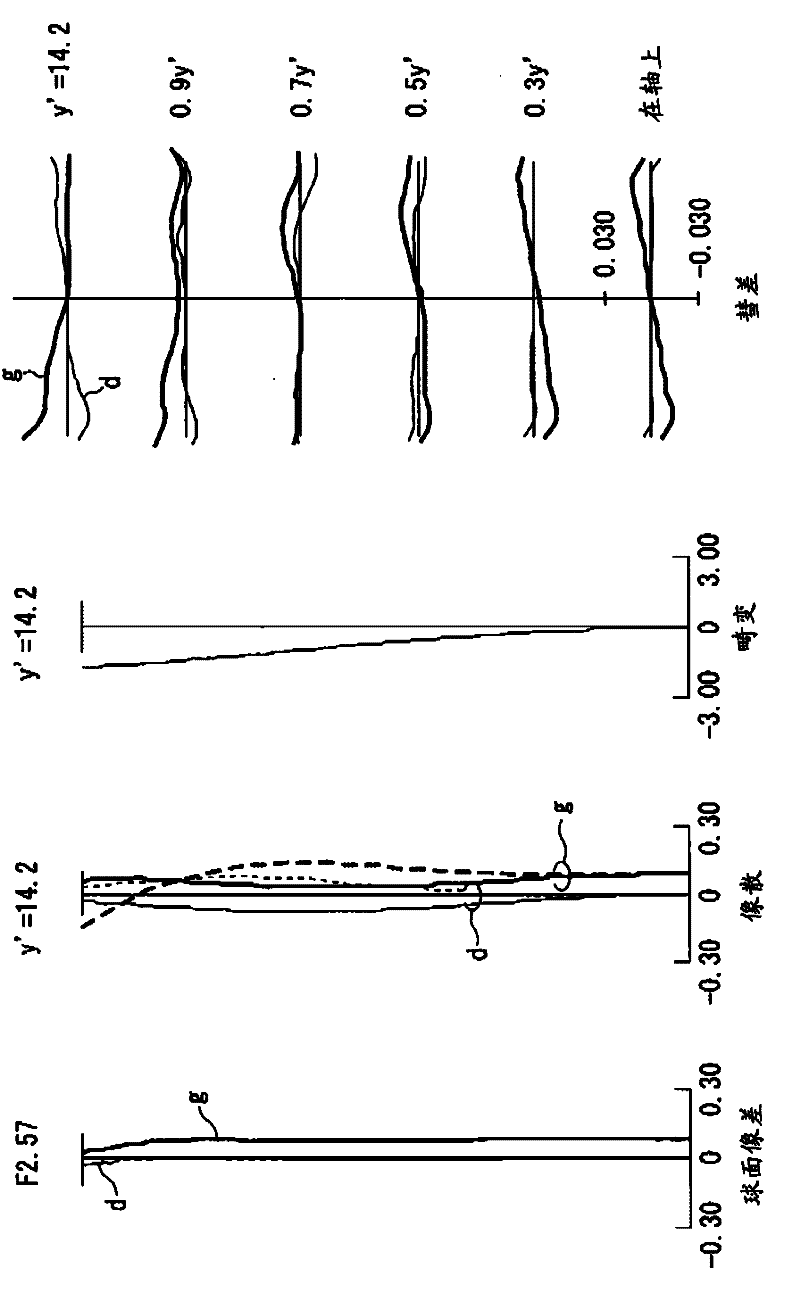

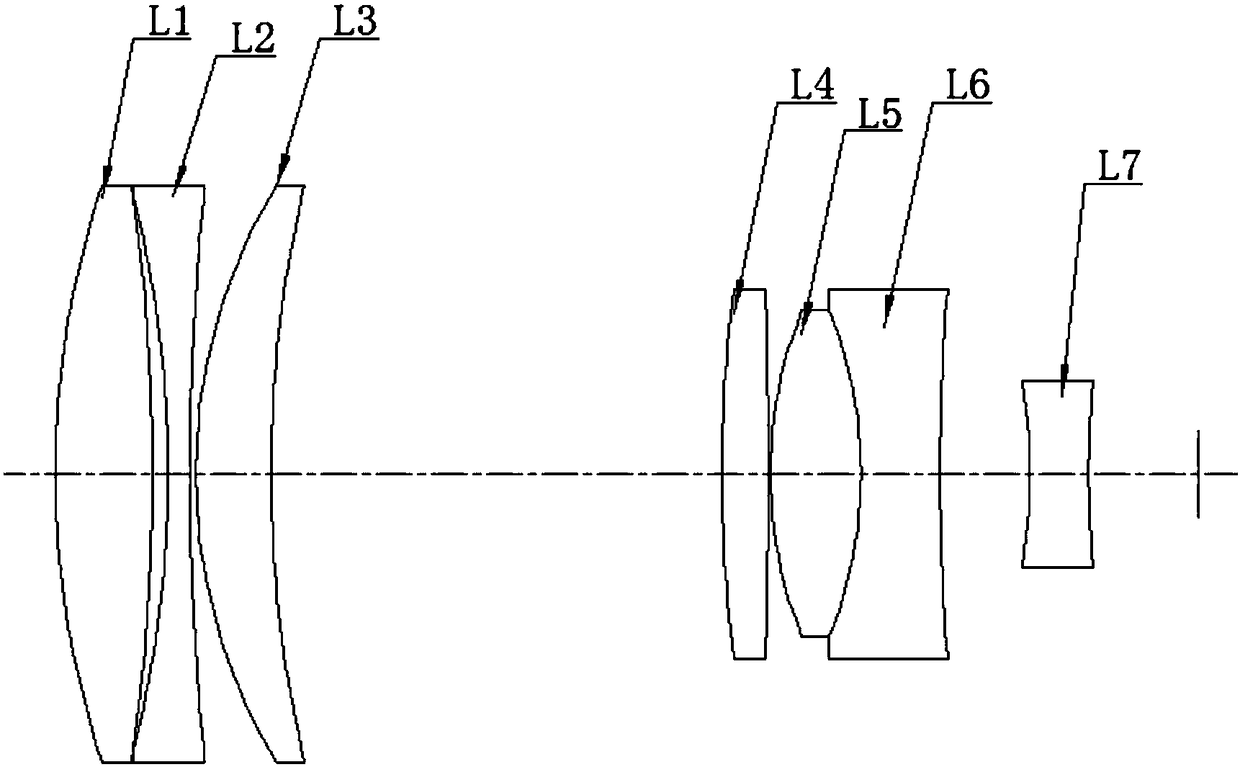

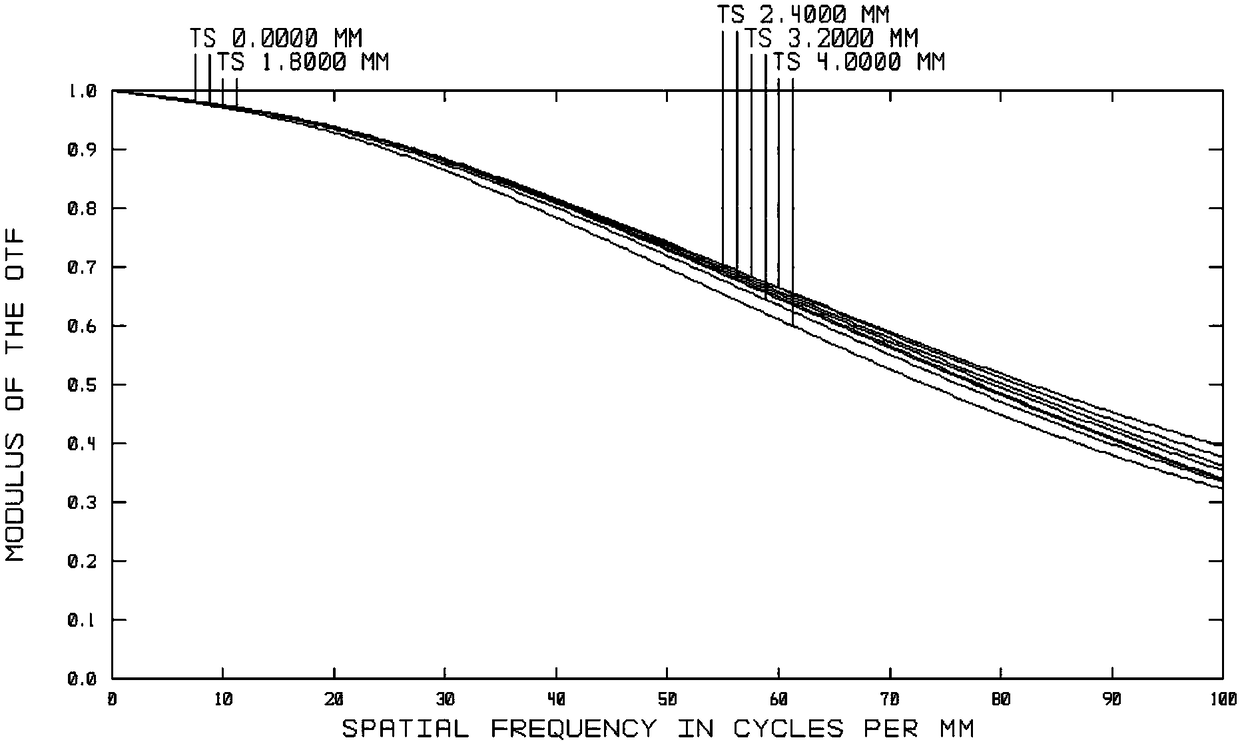

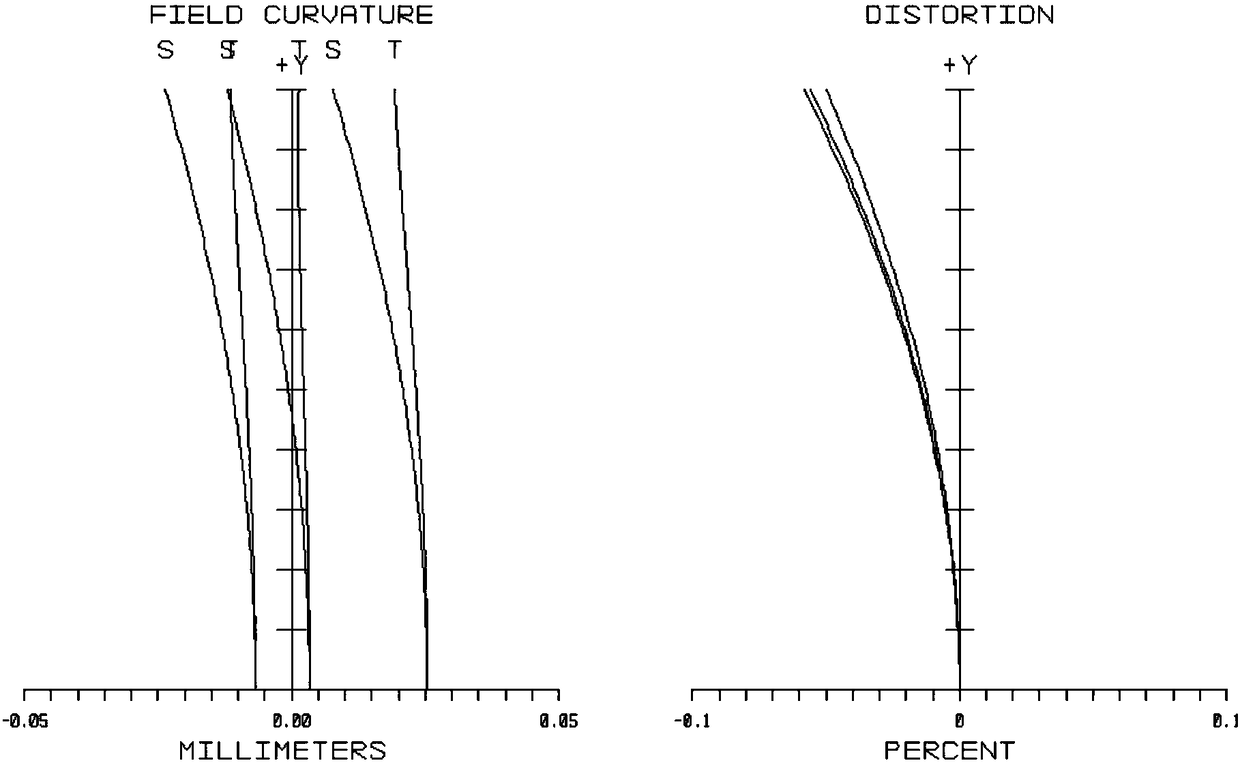

Image-Forming Lens, and Imaging Apparatus and Information Device Using the Image-Forming Lens

ActiveCN102298195AReduce color differenceIncrease contrastTelevision system detailsColor television detailsCamera lensConditional expression

An image-forming lens comprising, from an object side to an image side in order: a first lens group; an aperture; and a second lens group with a positive refractive power, the first lens group including, from the object side in order: a first F lens group with a negative refractive power; and a first R lens group with a positive refractive power, the first F lens group including, from the object side in order: a first negative lens which has a surface on the image side having a large curvature; and a second negative lens which has a surface on the object side having a large curvature, and the first R lens group including: any one of a positive lens and a cemented lens with a positive refractive power as a whole, wherein a distance from a surface on a most object side of the first lens group to an image plane in a state of focusing on an infinity object: L, and a maximum image height:; Y' satisfy Conditional expression 1:2.8<L / Y'<4.3.

Owner:RICOH KK

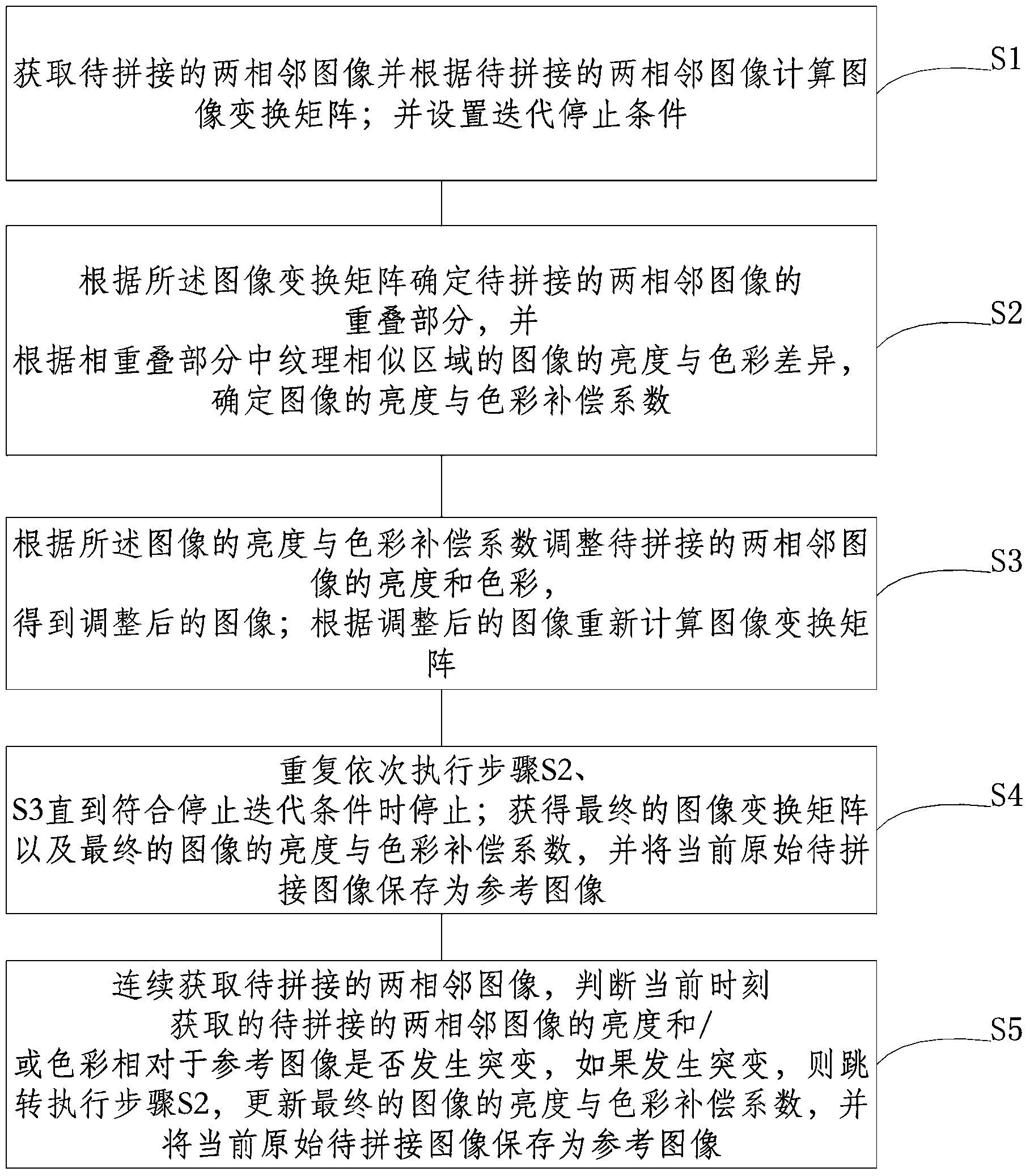

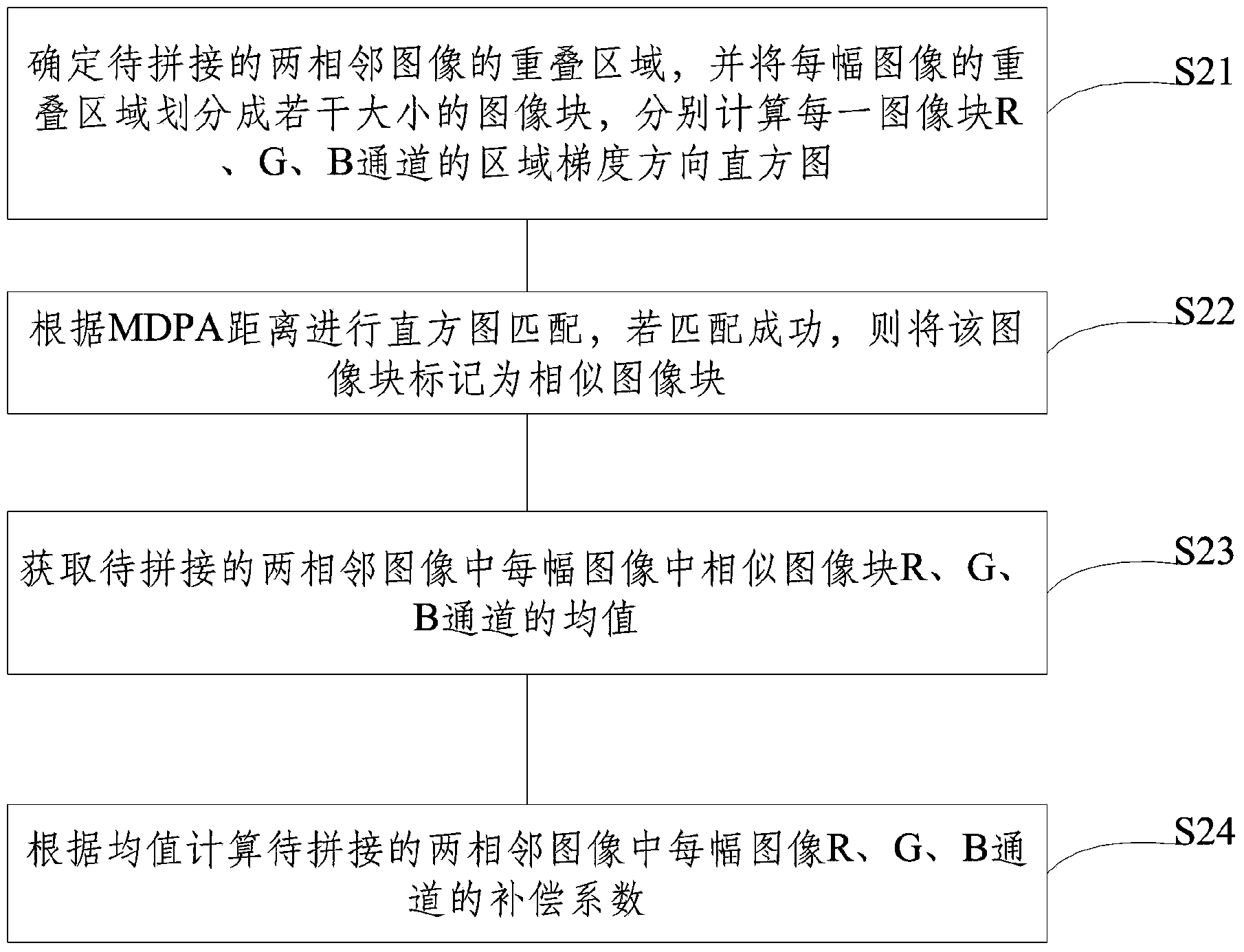

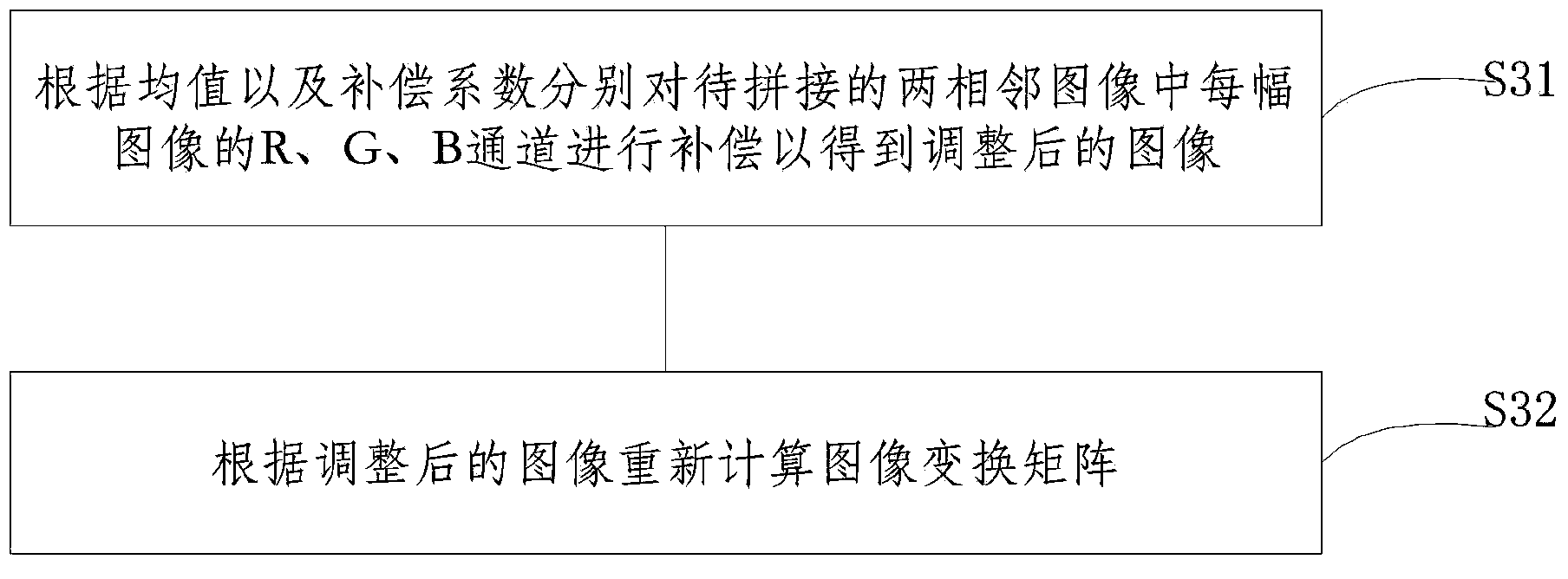

Image brightness and color balancing method and system for video stitching

ActiveCN104240211ASmooth transitionReduce brightnessImage enhancementColor compensationReference image

The invention discloses an image brightness and color balancing method and system for video stitching. The method comprises the steps of S1, acquiring two adjacent images to be stitched, calculating an image transformation matrix according to the two adjacent images to be stitched and setting an iteration suspensive condition; S2, determining the overlapping part of the two adjacent images to be stitched according to the image transformation matrix, and determining the brightness and color compensation coefficients of the images according to the brightness and color difference of the images with similar textures in the overlapping part; S3, adjusting the brightness and color of the two adjacent images to be stitched to obtain an adjusted image according to the brightness and color compensation coefficients of the images, and recalculating the image transformation matrix according to the adjusted image; S4, repeating S2 and S3 in sequence till the iteration suspensive condition is met, obtaining a final image transformation matrix and the brightness and color compensation coefficients of the final image, and saving the current original images to be stitched as reference images. By the adoption of the method and system, brightness and color jump occurring during video stitching can be eliminated.

Owner:武汉凌久微电子有限公司

Solar battery module

InactiveUS6452089B1Improve reflectivityIncrease absorbancePV power plantsSynthetic resin layered productsElectricityColor film

An object of the invention is to provide a solar battery module having a high efficiency power generating ability, a harmony of design without an odd sensation, and a freedom of design. The object is achieved by a solar battery module comprising, on a light-receiving surface thereof, a photoelectric conversion section for converting incident light into electricity, the photoelectric conversion section comprising silicon, and an insulating color film disposed in regions other than the photoelectric conversion section for reducing a color difference from the photoelectric conversion section.

Owner:TDK CORPARATION

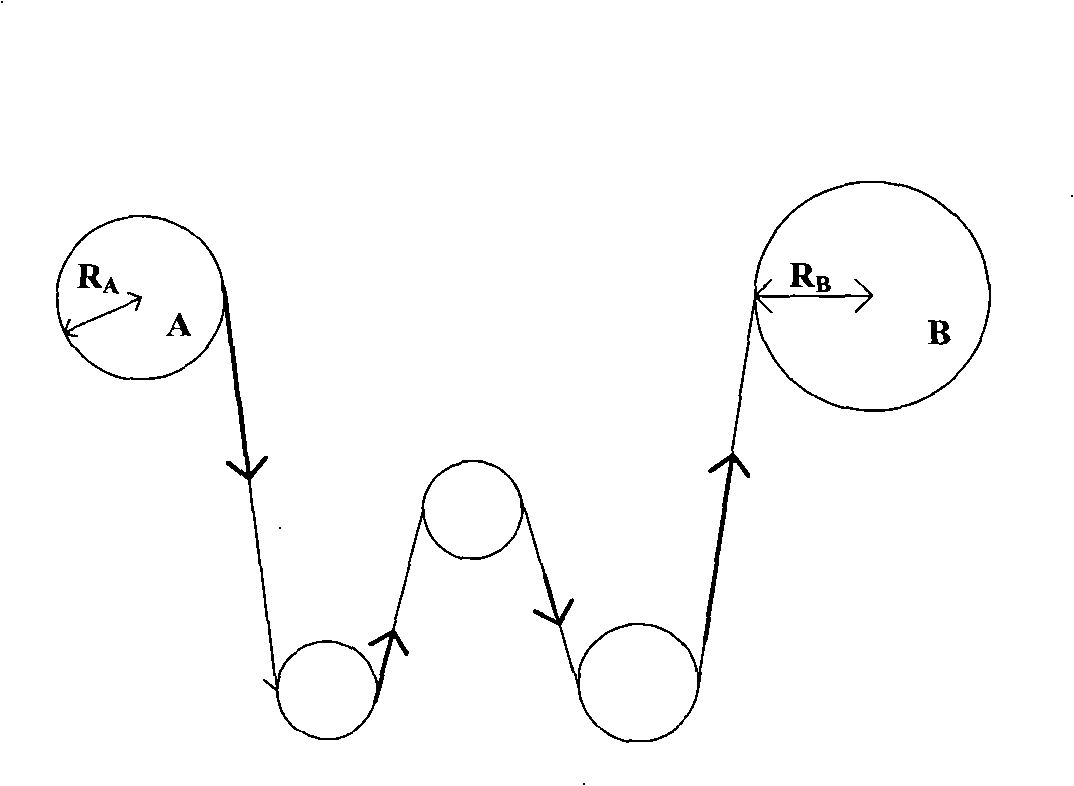

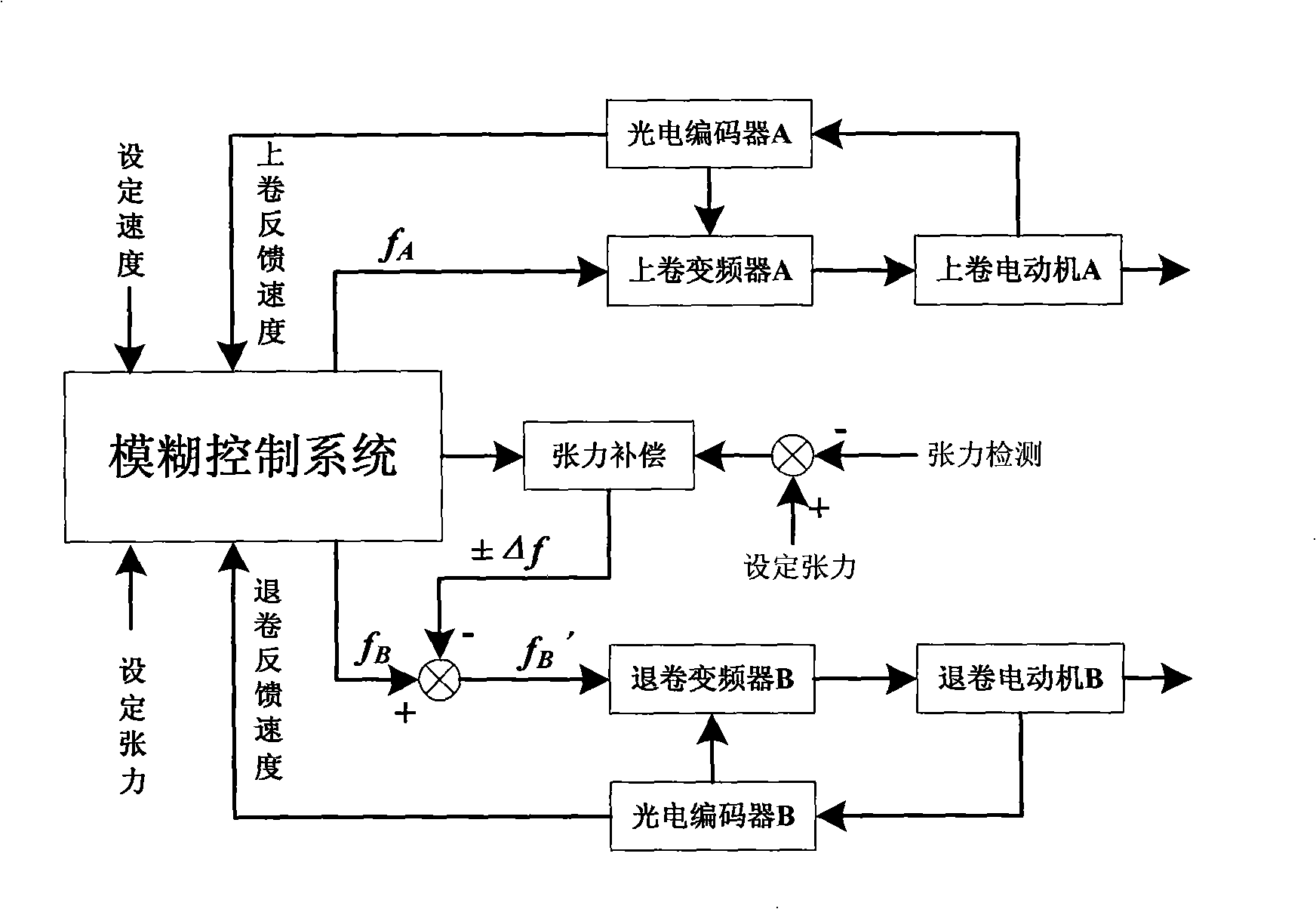

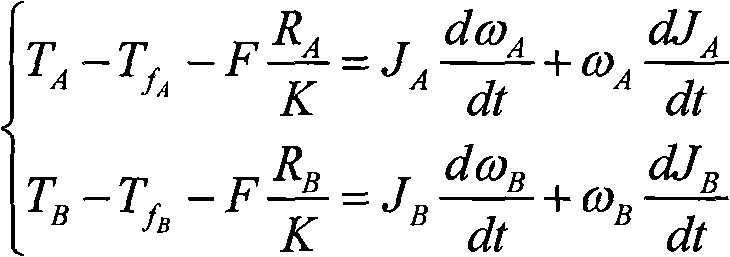

Beam dyeing machine cloth velocity-tension coordinating control method

InactiveCN101308363AImprove dyeing qualitySolve the coupling problemLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsWire speedVelocity constant

The invention discloses a speed-tension coordination control method for jigger fabrics; the method mainly uses a fuzzy control system to compare the sampling speed of a photoelectric coder with the set speed, and compare the tension-detection value of a tension detection device with the set tension, so as to timely adjust the control rules according to the dynamic changes of the errors to subsectionally and alternately control the speed and the tension to respectively obtain a coiling frequency fA and an unwinding frequency fB needed in maintaining the equal linear velocity constant tension of dyeing fabrics; a coiling electromotor and an unwinding electromotor are respectively controlled by a coiling transducer working in speed mode and an unwinding transducer working in torque conversion mode. The method solves the coupling problem between the speed and the tension of the jigger fabrics and makes more accurate speed-tension coordination control of the double-input / double-output, coupled and time-varying non-linear system of jiggers, so as to reduce dyeing color difference caused by instable speed and tension and improve the dyeing quality of fabrics.

Owner:ZHEJIANG UNIV

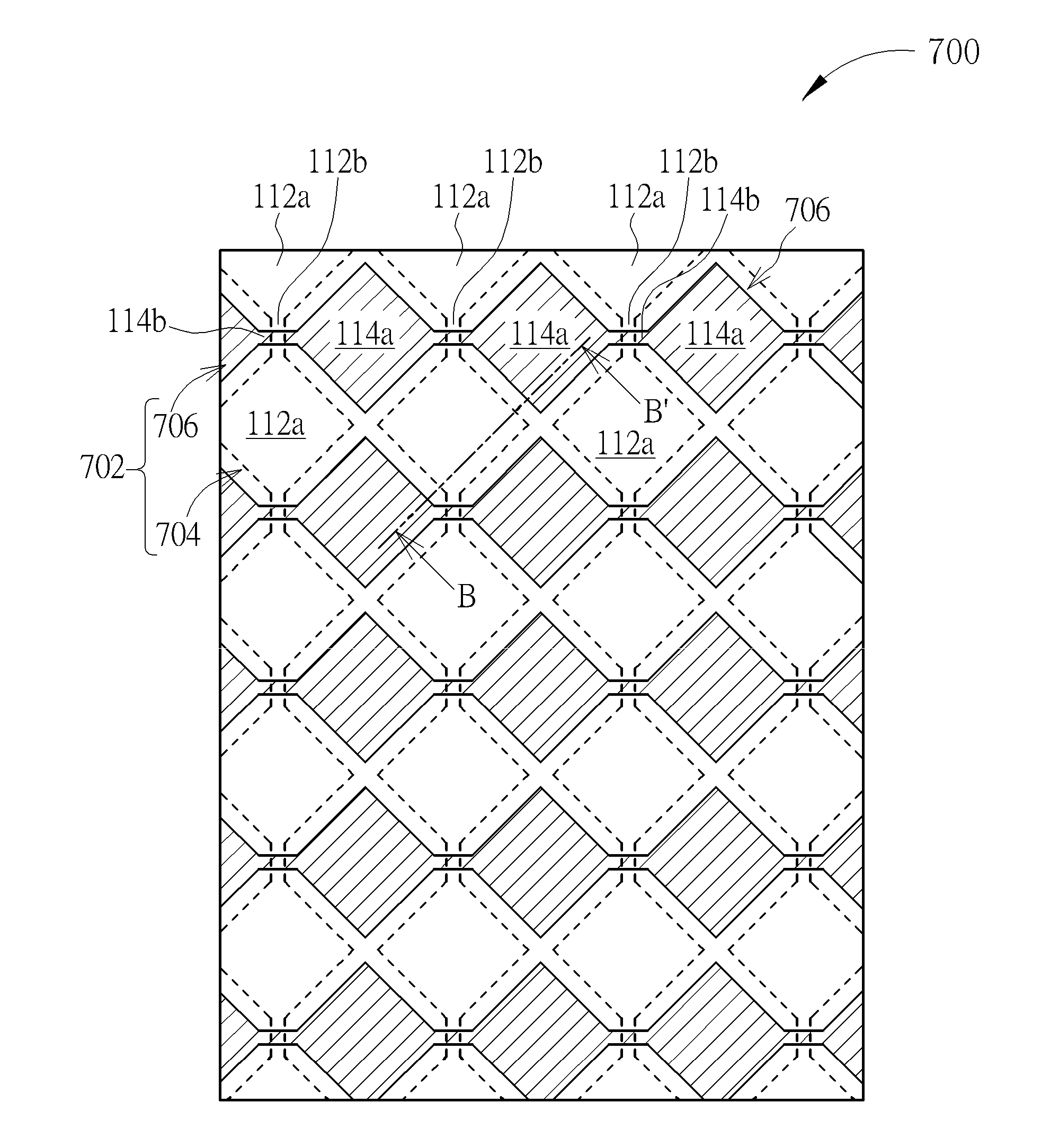

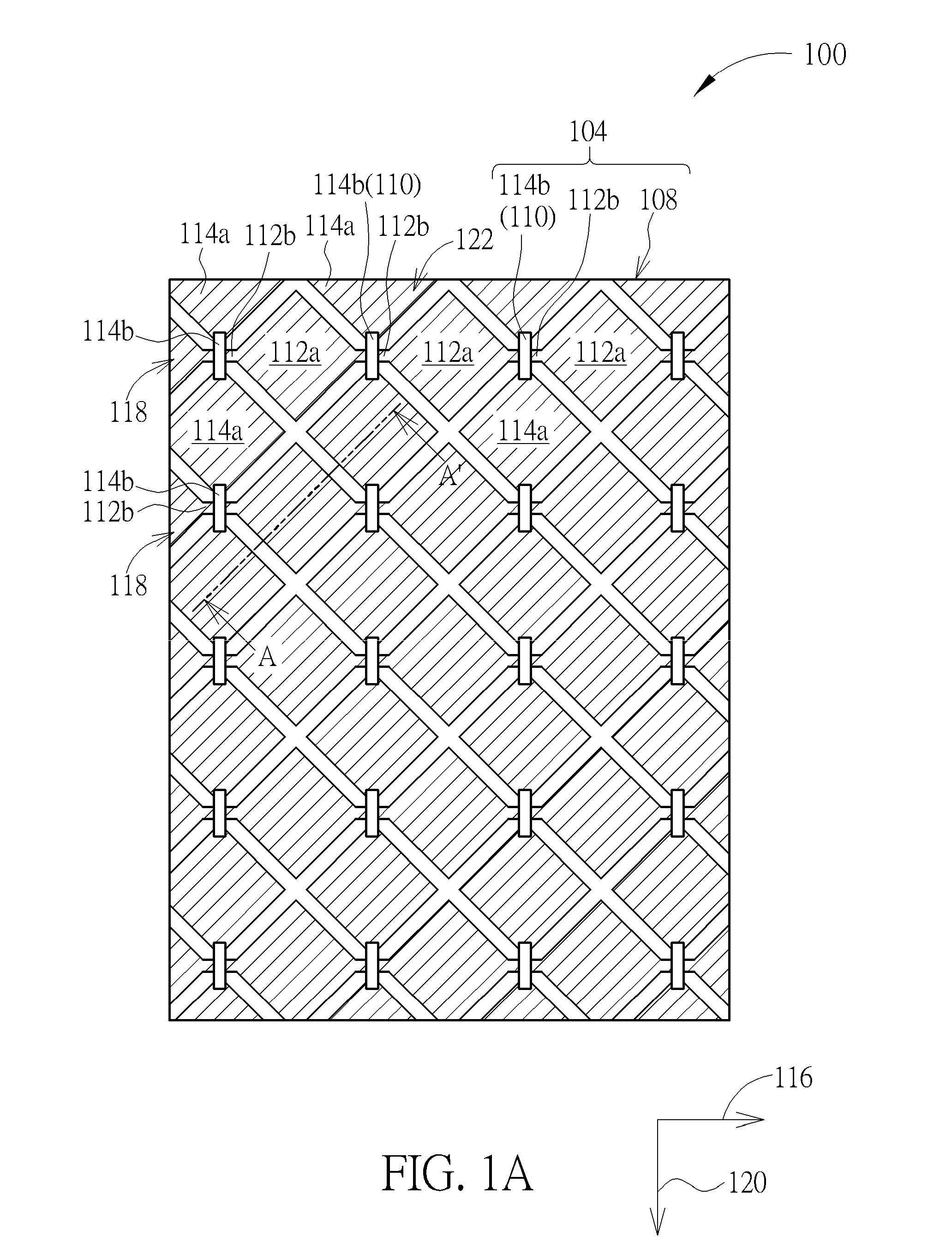

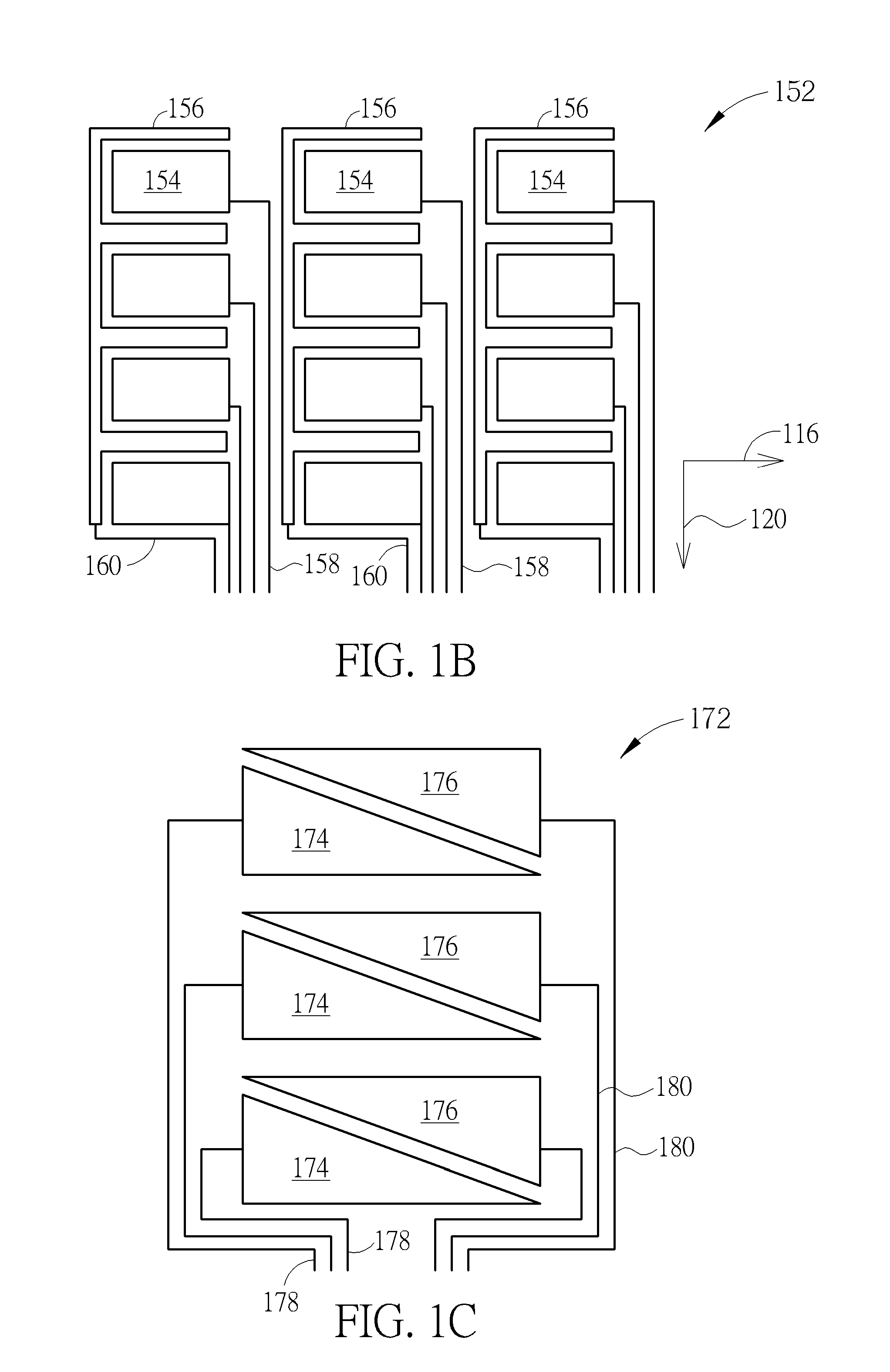

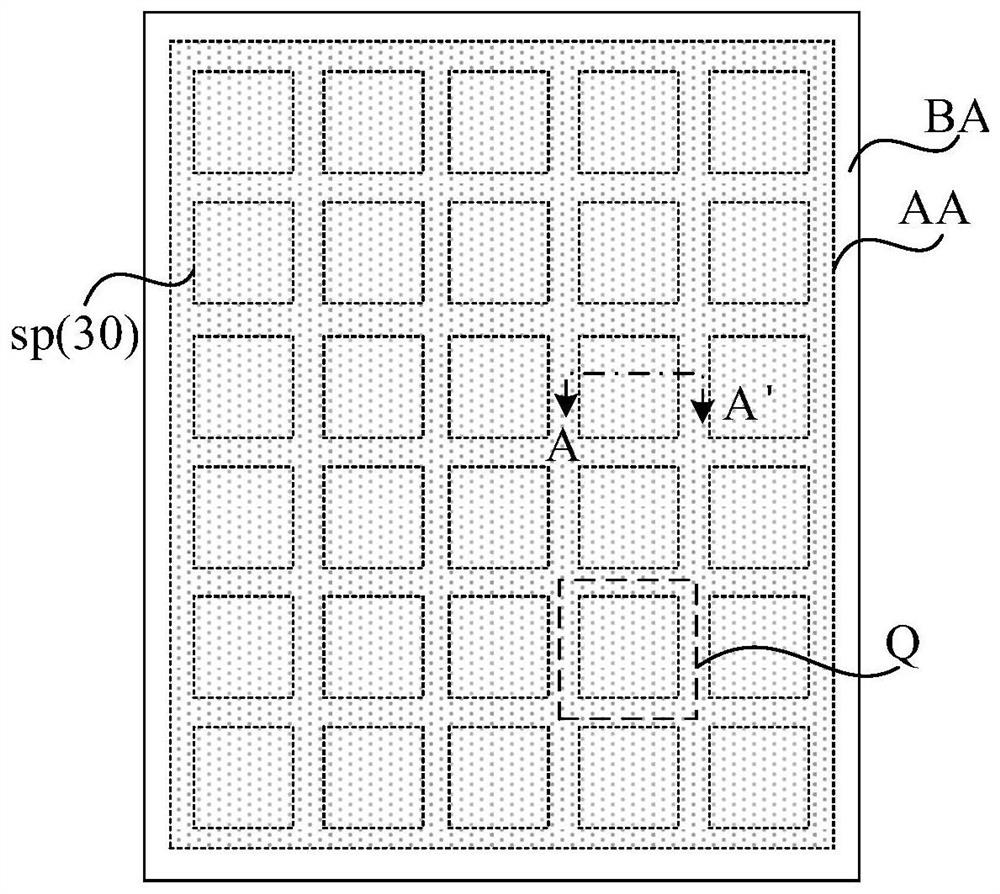

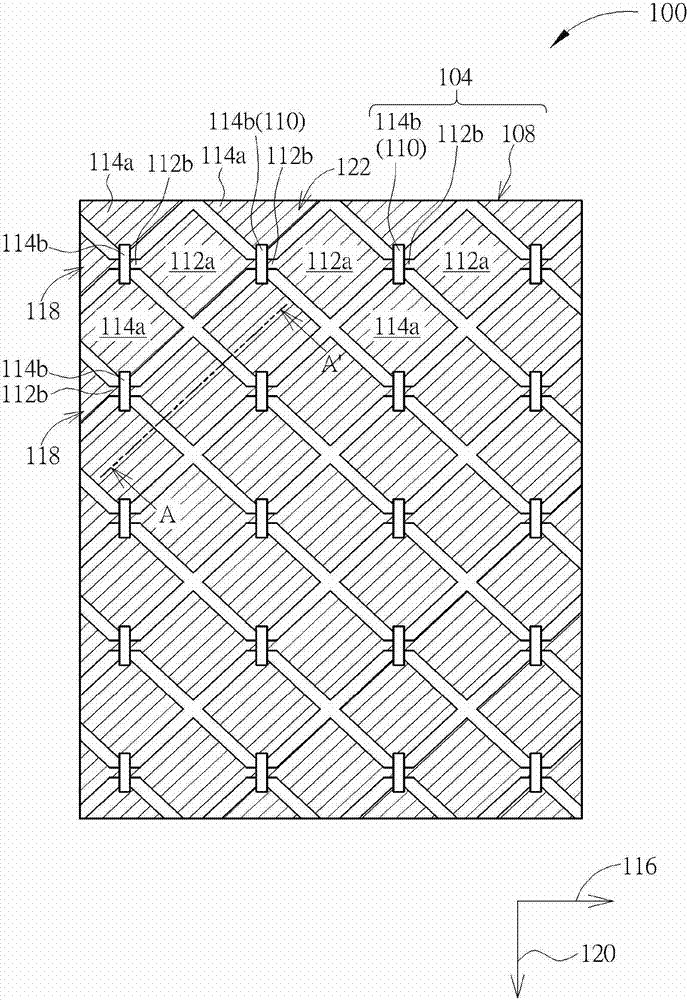

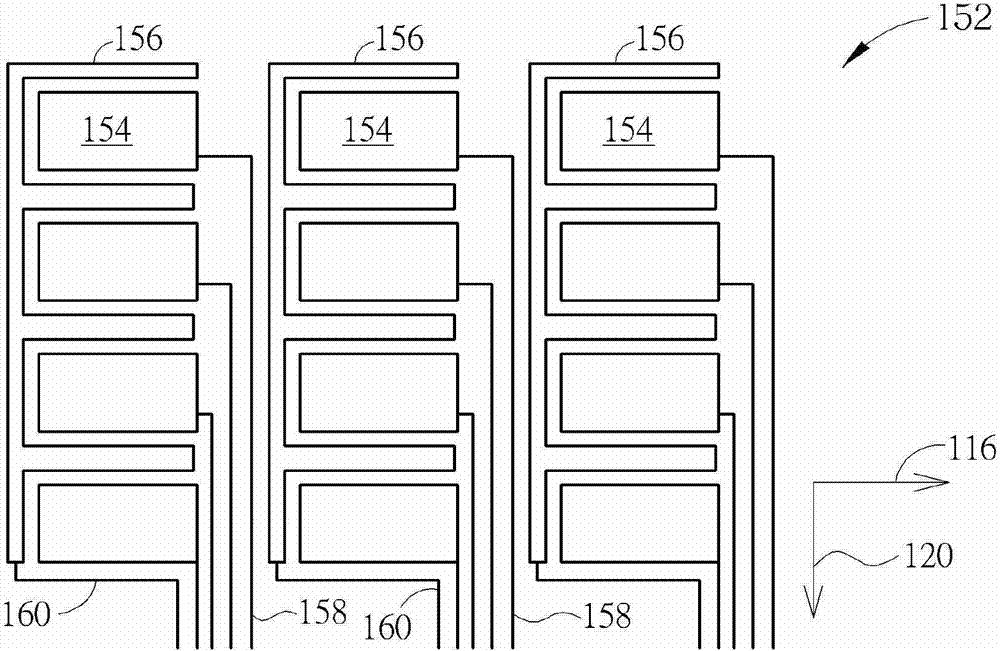

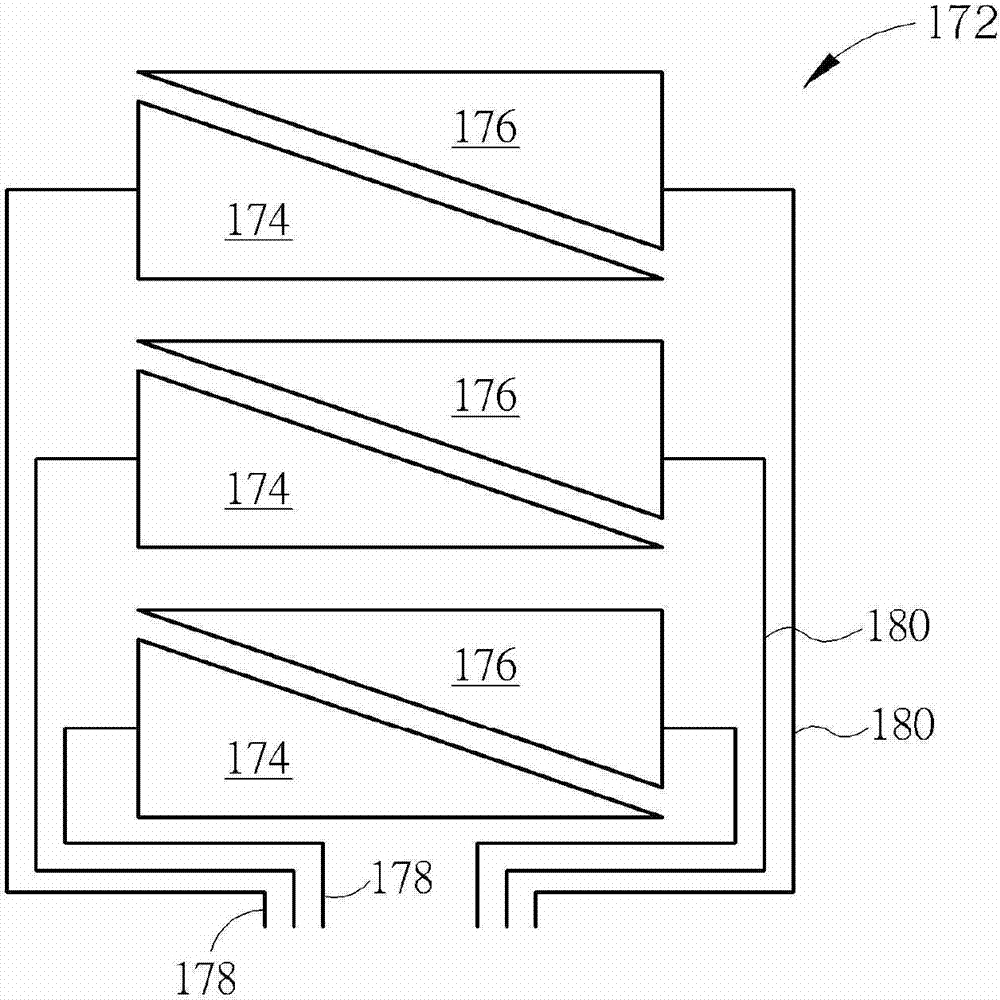

Touch panel and touch display panel

InactiveUS20150022739A1Reduce brightness differenceReduce color differenceDigital data processing detailsNon-linear opticsTouch SensesAlloy

The present invention provides a touch panel. The touch panel includes a substrate, a touch sensing device, and an optical matching layer. The touch sensing device is disposed on one side of the substrate, and includes an electrode pattern. The electrode pattern includes silver or silver alloy. At least one side of the substrate has the optical matching layer disposed thereon.

Owner:WINTEK CORP

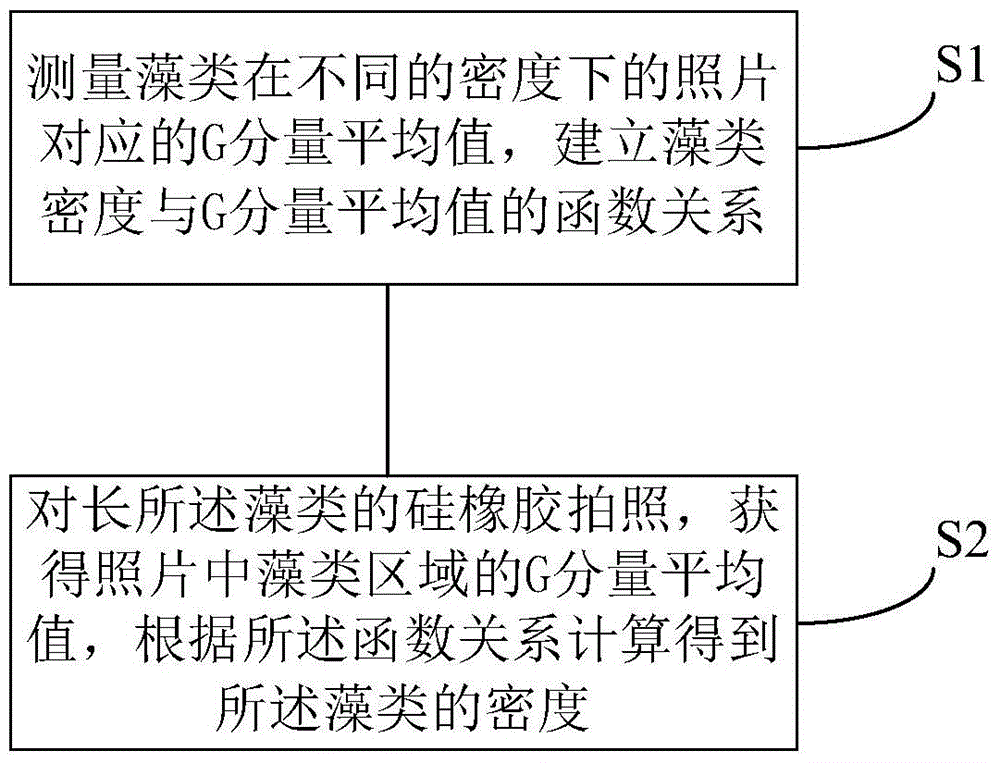

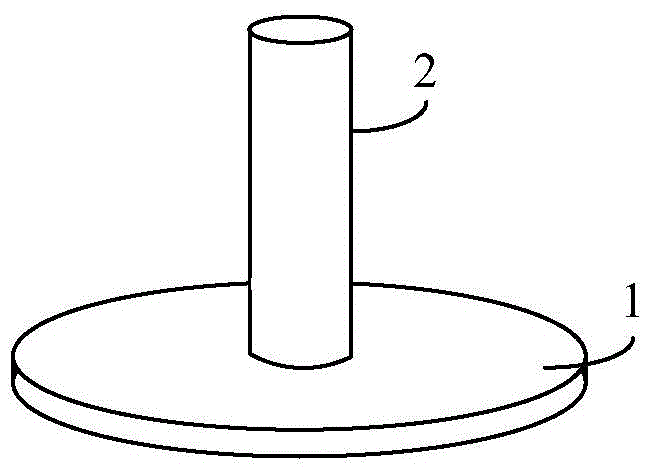

Measuring method and measuring apparatus of growth degree of algae on silicone rubber surface on the basis of image processing

InactiveCN105738364AAvoid huge errorsNo safety hazardImage enhancementImage analysisAlgaeImaging processing

The invention discloses a measuring method and a measuring apparatus of growth degree of algae on a silicone rubber surface on the basis of image processing. The method includes the following steps: S1) measuring the average value of a G component corresponding to photographs in different algae density, and establishing a function relationship between the algae density and the average value of the G component; and S2) photographing silicone rubber on which the algae grow to obtain the average value of the G component of an algae region in the photographs, and calculating the algae density according to the function relationship. The method avoids a step of taking the algae from a surface of an insulator, thereby avoiding a huge error during the algae taking process. The method only needs photographing during on-site operations, is simple and is free of safety hidden risk, adapts different environments, and satisfies demands on safety and power supply reliability in power generation. Through white balance treatment, difference on color of the photographs due to factors, such as weather, illumination and the like, is reduced as more as possible, thereby avoiding error in the growth degree of algae.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +2

PC/ABS material composition for relieving yellow discoloration

ActiveCN101759979AReduce color differenceMeet the requirements of color differenceYELLOW DYEPolycarbonate

The invention discloses a PC / ABS material composition for relieving the yellow discoloration, which is prepared from the following ingredients in percentage by weight: 10 to 60 parts of acrylonitrile-butadiene-styrene graft copolymers, 30 to 85 parts of polycarbonate, 0 to 10 parts of acrylics graft rubber, 0.25 to 0.88 parts of coloring agents, 0 to 1 part of antioxidizers and 0 to 1 part of light stabilizers. Yellow dyes without light illumination resistance performance exist in a dye system, and the dyes can not influence the whole coloring process of plastics in the plastic coloring process, but in the light illumination process, the dyes gradually fade, the PC / ABS materials carry out yellow discoloration in the light illumination process, so the two mutually inconsistent processes have the mutual counteraction effect, and the color aberration of the whole PC / ABS composition is reduced after the light illumination. At the same time, the mechanical property of the composition material is not obviously reduced.

Owner:CHONGQNG PRET NEW MATERIAL +2

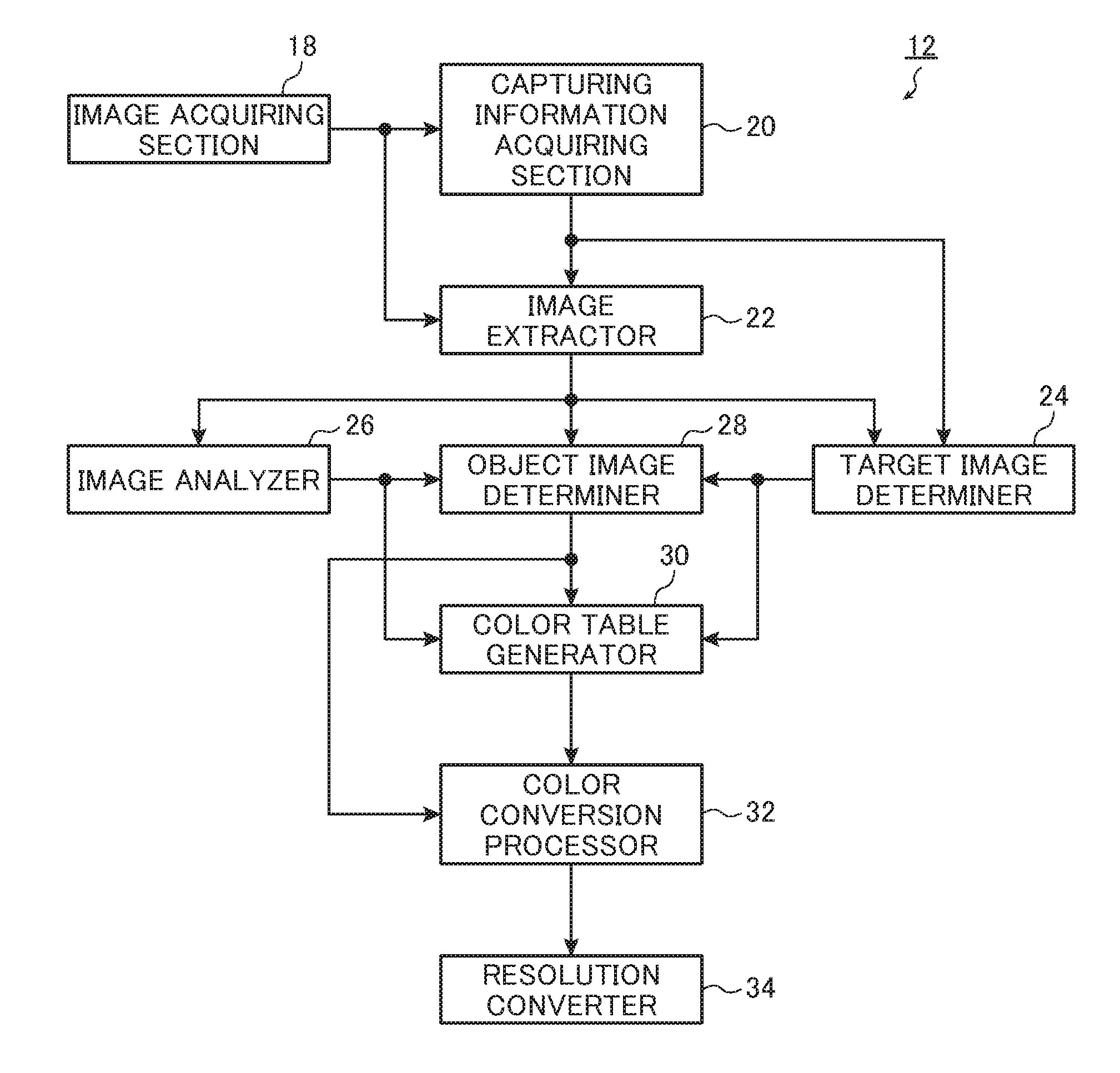

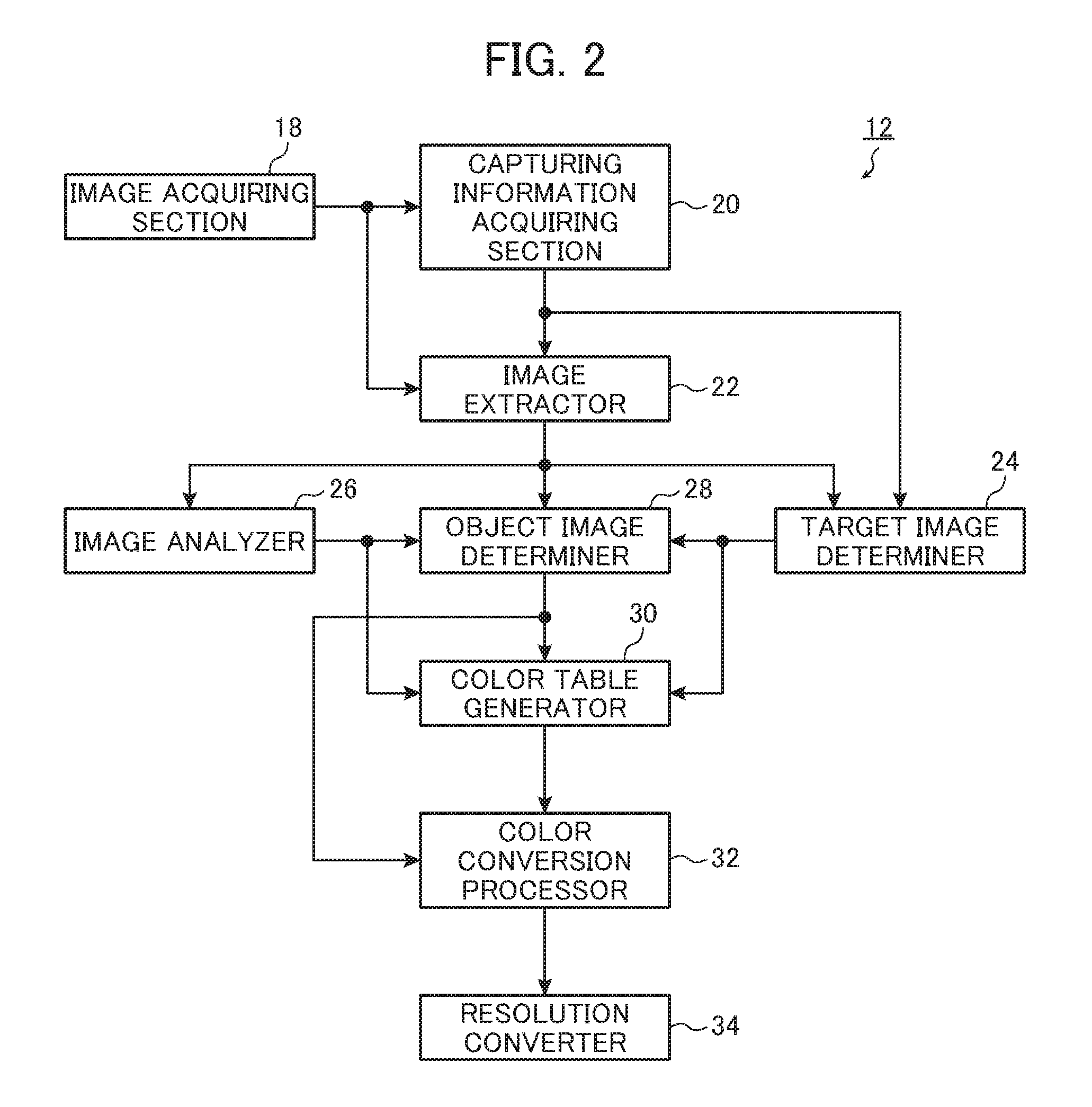

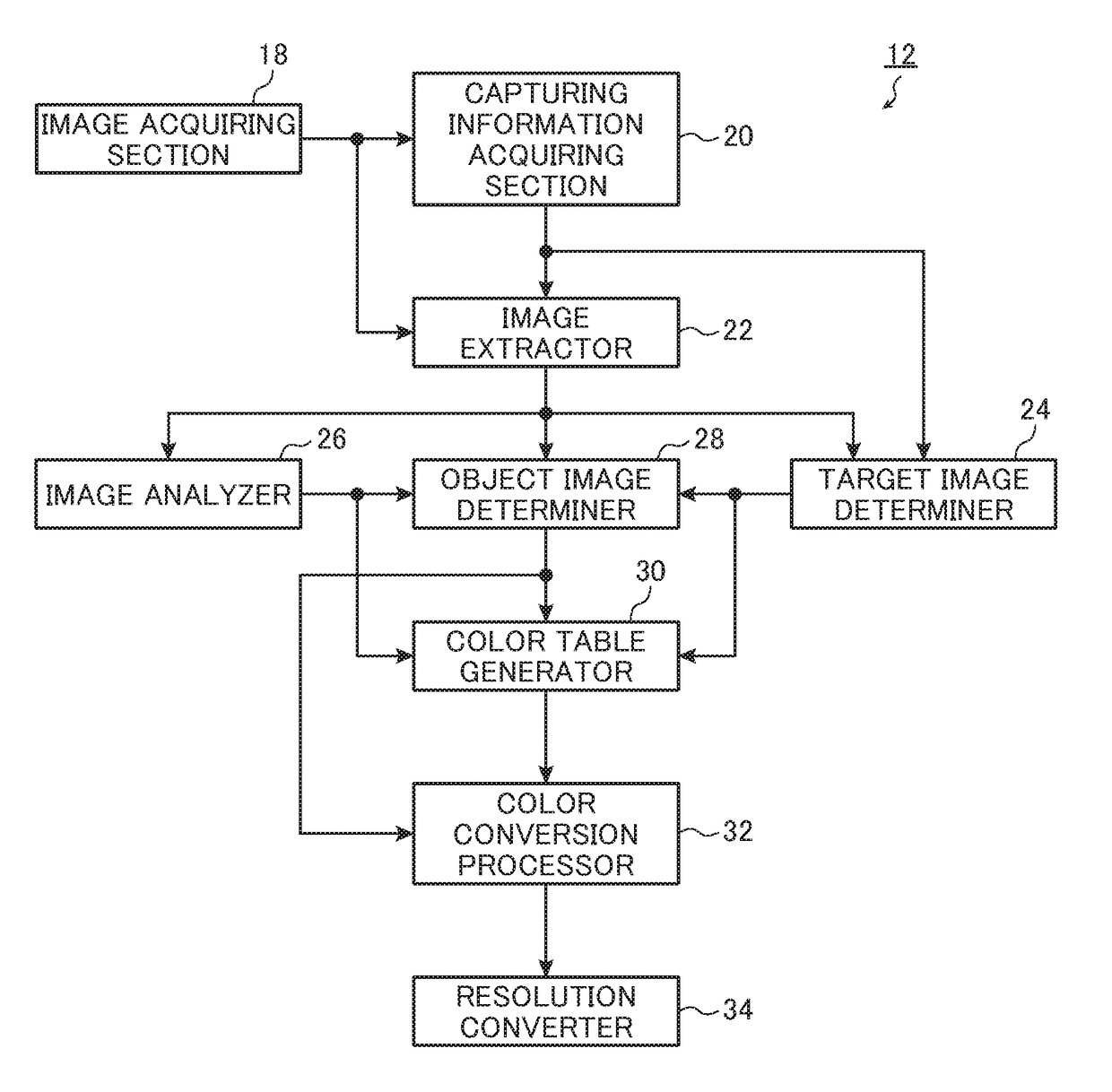

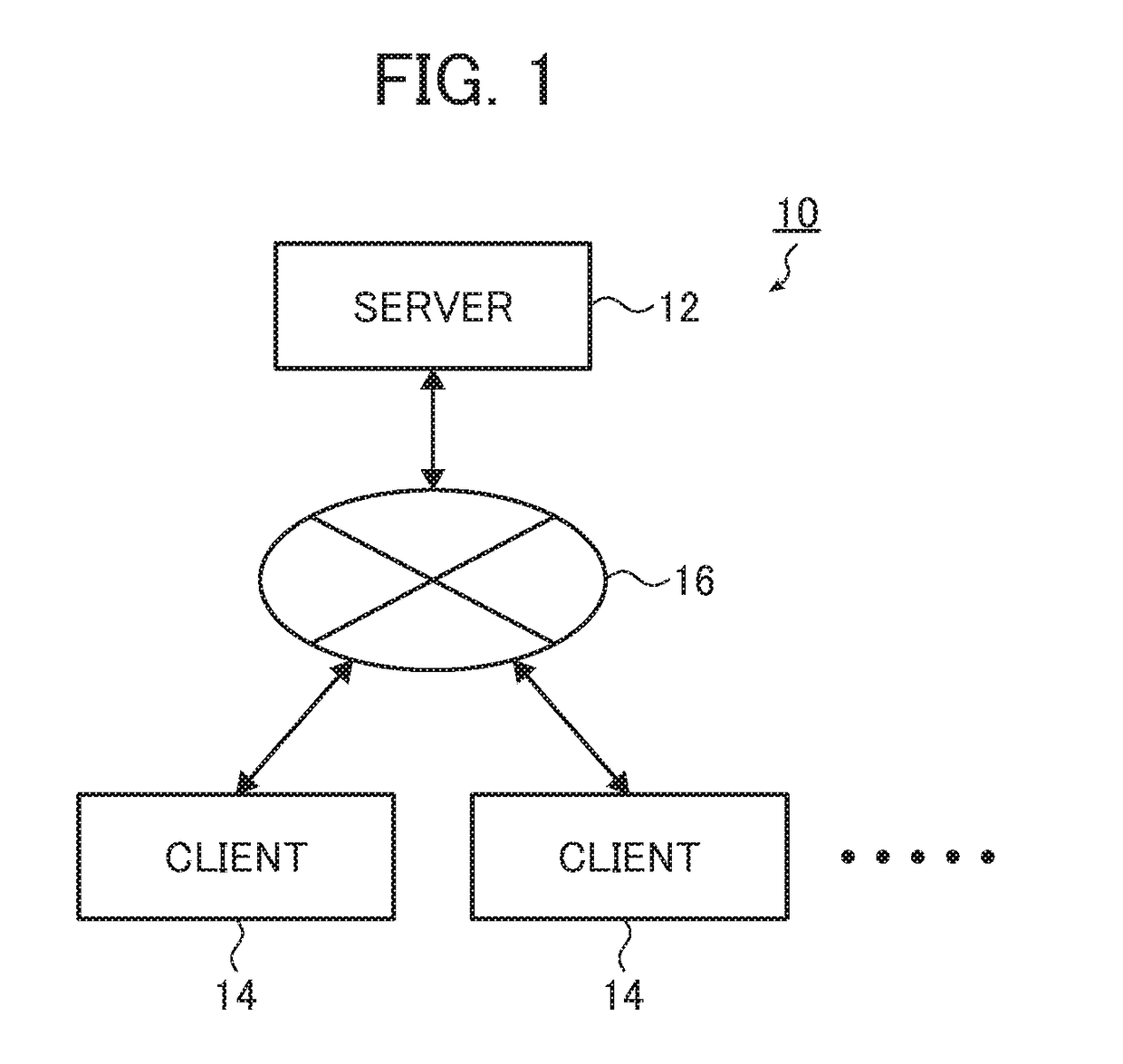

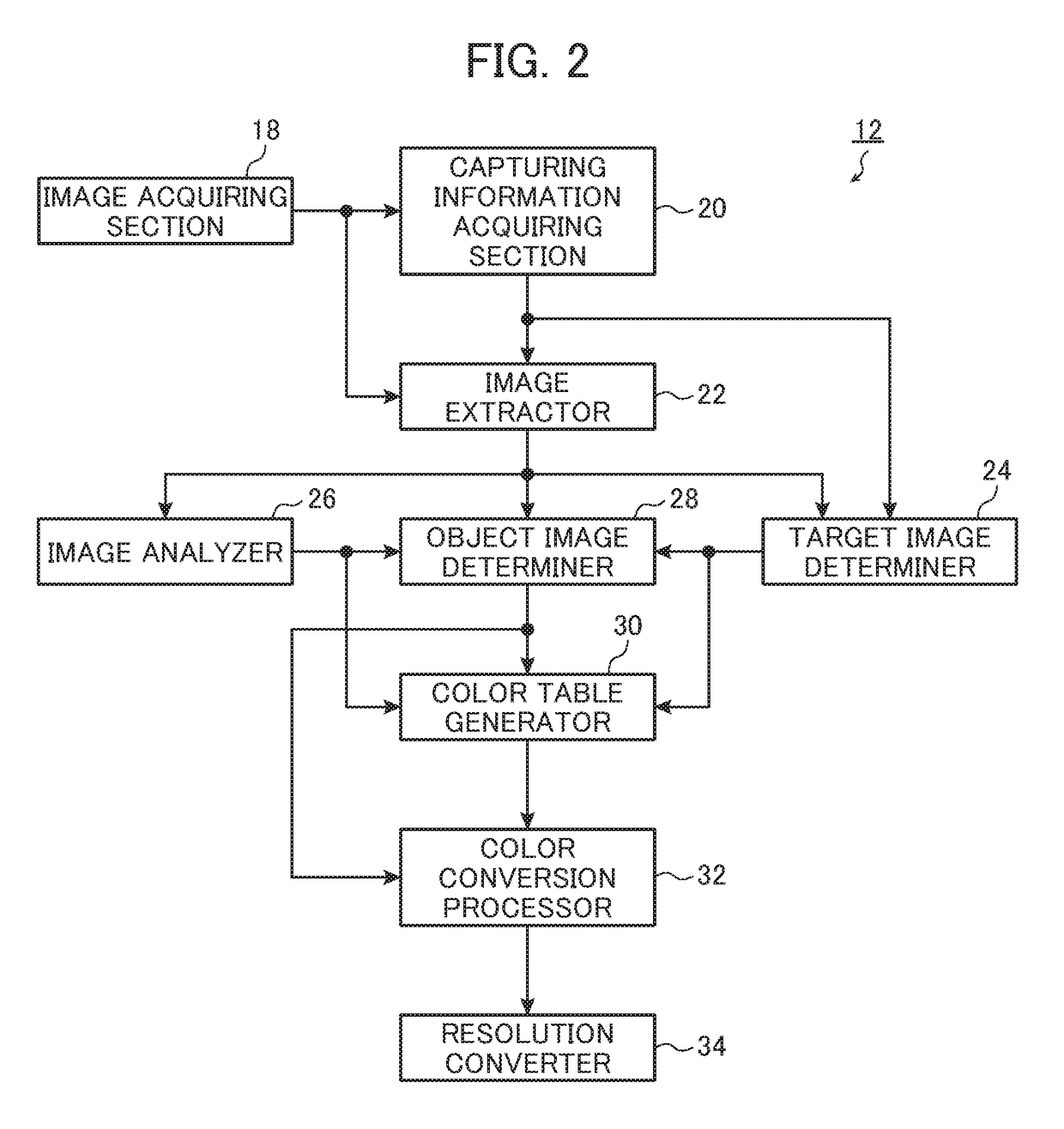

Image processing device, image processing method and recording medium

ActiveUS20170026552A1Limit environmentThe location is limitedImage analysisTexturing/coloringImage extractionTime range

In the image processing device, the image processing method and the recording medium, the image extractor extracts, from the captured images, captured images regarded as being captured in the same time range, as extracted images. The target image determiner selects an extracted image which were captured by a capturing person who captured largest number of extracted images and with a capturing device of a type used to capture largest number of extracted images, as a target image. The object image determiner selects an extracted image showing a subject similar to a subject present in the target image, as an object image. The color table generator generates a color table for matching colors of the object image to colors of the target image. The color conversion processor carries out the color conversion applying the color table to the object image.

Owner:FUJIFILM CORP

Hotpressed or embossed artificial leather and preparation method thereof

The invention relates to hotpressed or embossed artificial leather, which comprises a surface layer, a foaming layer and a base cloth layer in sequential arrangement, wherein the surface layer is a polyurethane surface layer; the polyurethane surface layer is prepared from the following preparation raw materials in parts by weight: 95 to 105 parts of polyurethane resin, 0.1 to 0.3 part of flattingagents, 15 parts of antiaging agents, 1 to 10 parts of coloring agents and 100 parts of compound organic solvents. The invention also relates to a preparation method of the hotpressed or embossed artificial leather. The hotpressed or embossed artificial leather has the advantage that the hand feeling and the exquisite feeling of the leather after the stamping are improved.

Owner:FUJIAN POLYTECH TECH CO LTD

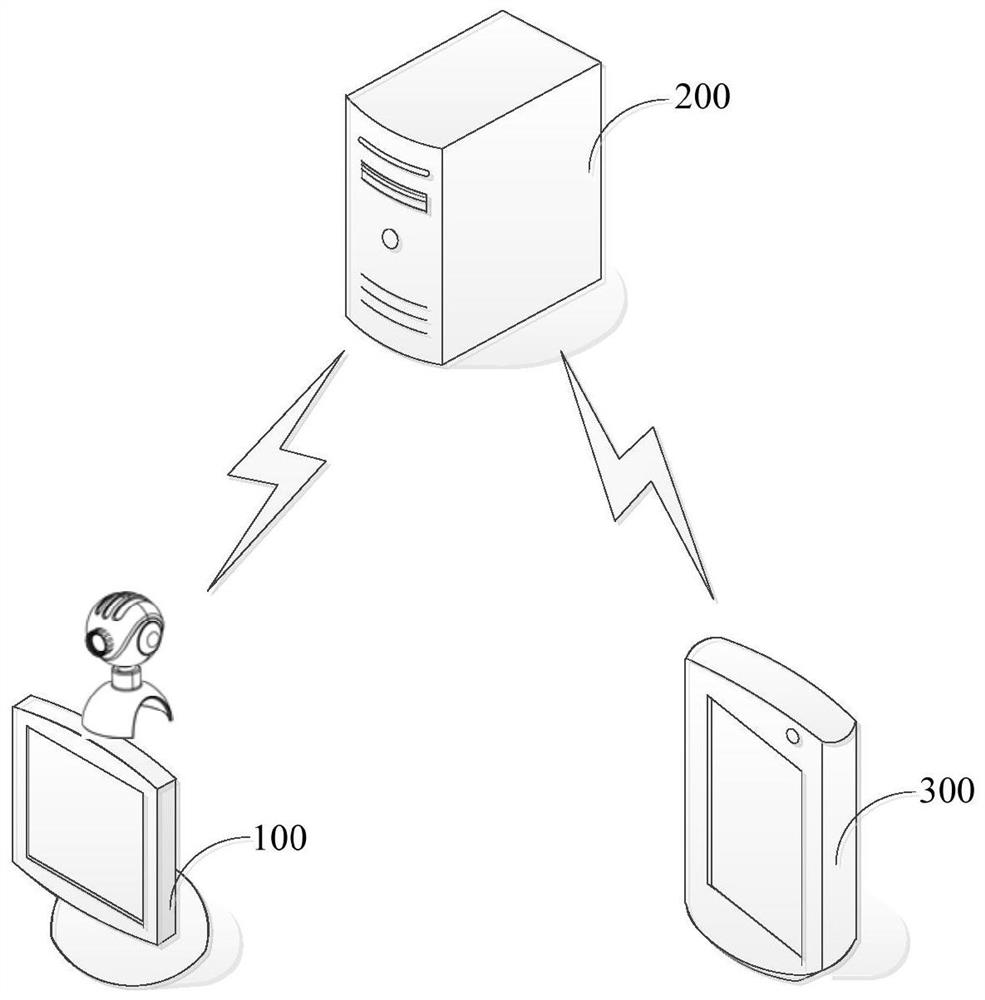

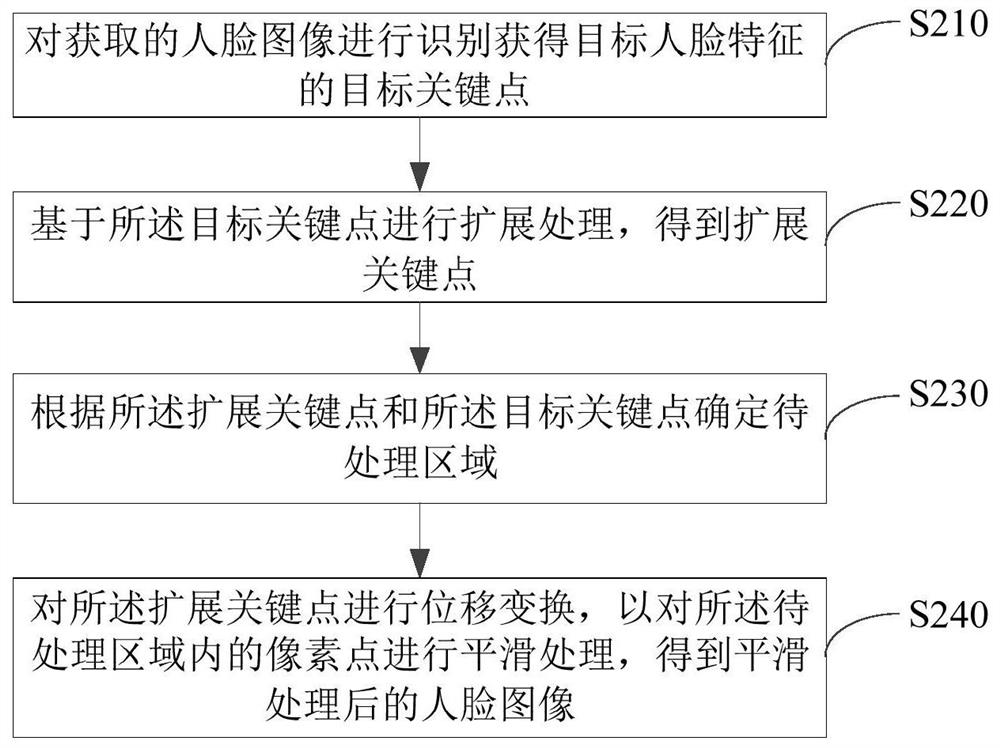

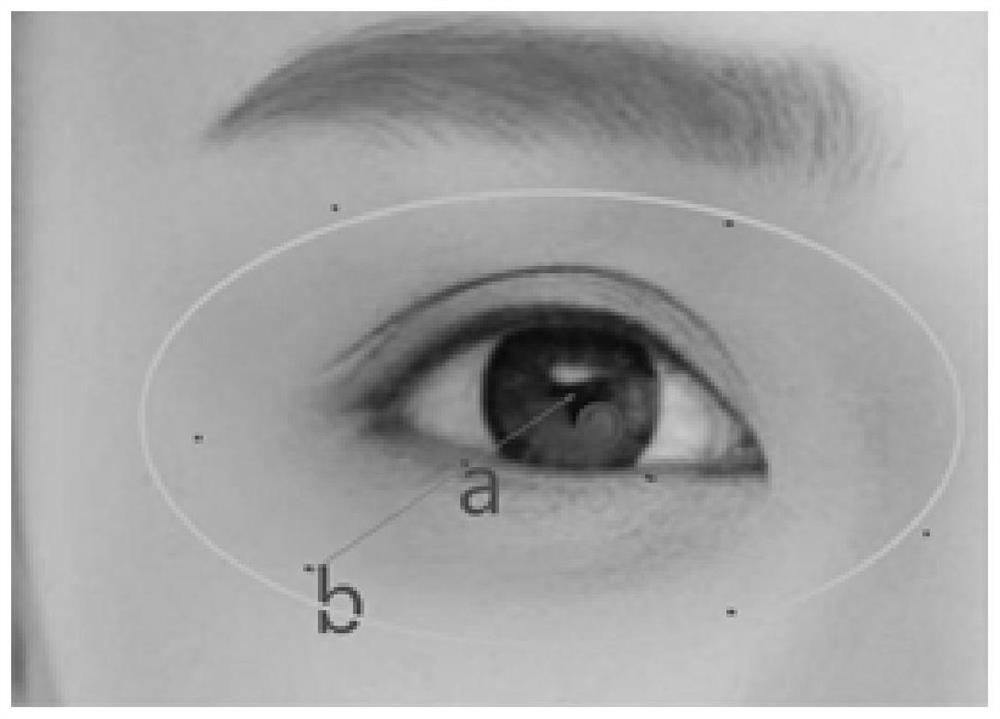

Image processing method and device, electronic equipment and computer readable storage medium

PendingCN112102198AReduce color differenceReduce fitImage enhancementImage analysisImaging processingComputer graphics (images)

The invention provides an image processing method and device, electronic equipment and a computer readable storage medium, and the method comprises the steps: carrying out the recognition of an obtained face image to obtain a target key point of a target face feature, carrying out the extension processing based on the target key point to obtain an extended key point, and determining a to-be-processed region according to the extended key point and the target key point; performing displacement transformation on the extended key points to perform smoothing processing on pixel points in the to-be-processed area so as to obtain a face image after smoothing processing. Therefore, because the points for smoothing processing are the points in the original face image and processing is carried out in the determined to-be-processed region, problems of color difference and edge non-fitting after processing can be reduced.

Owner:GUANGZHOU HUYA TECH CO LTD

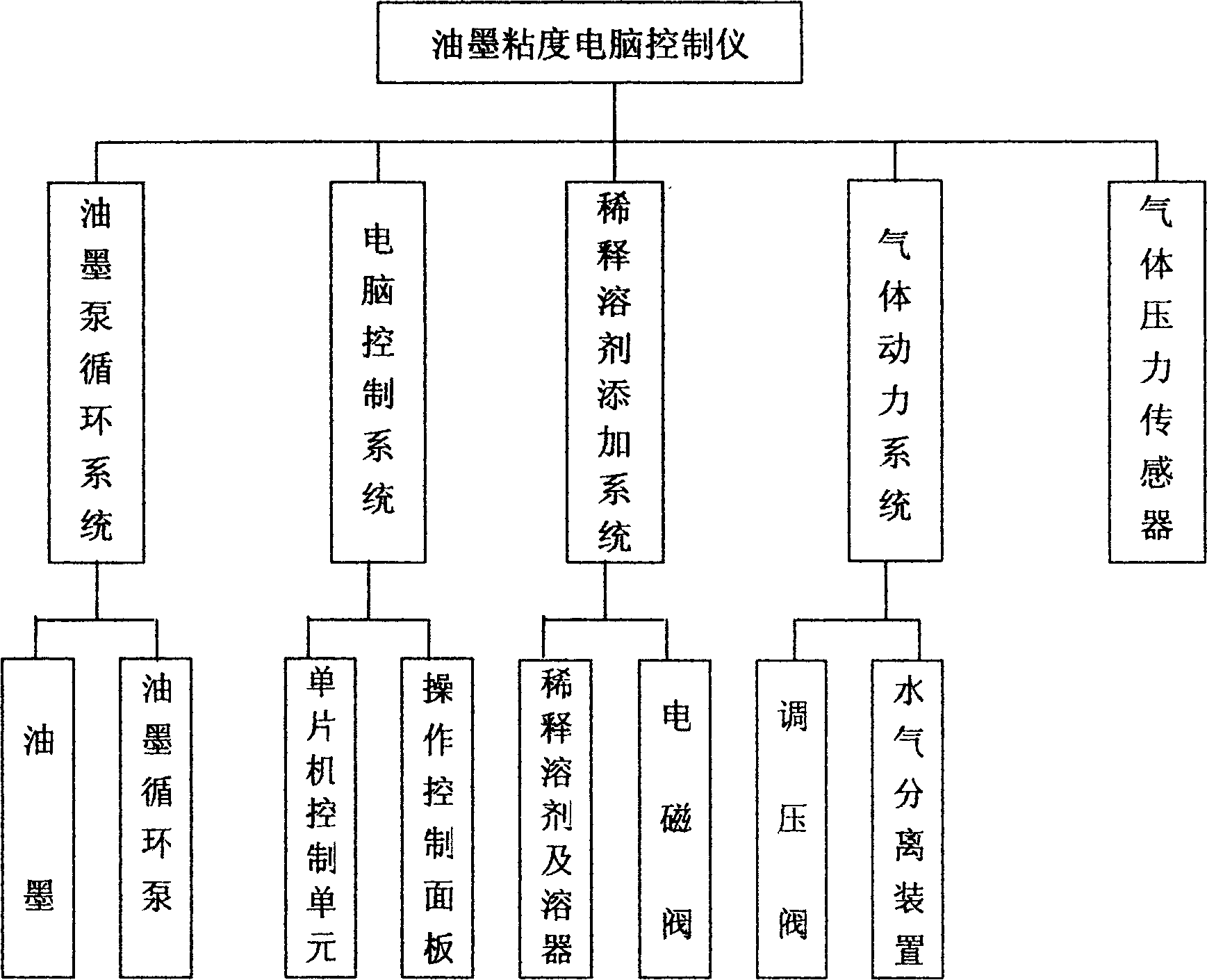

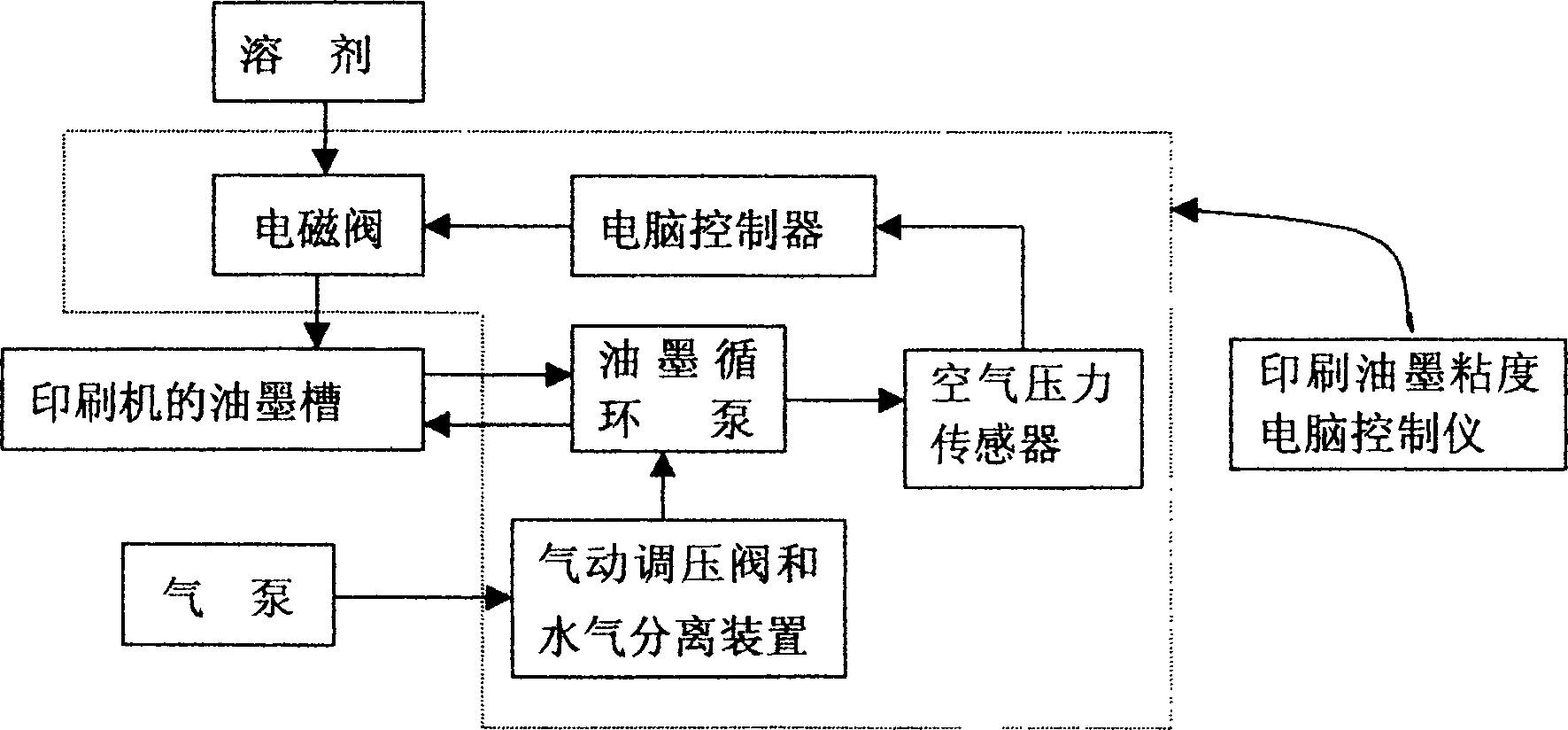

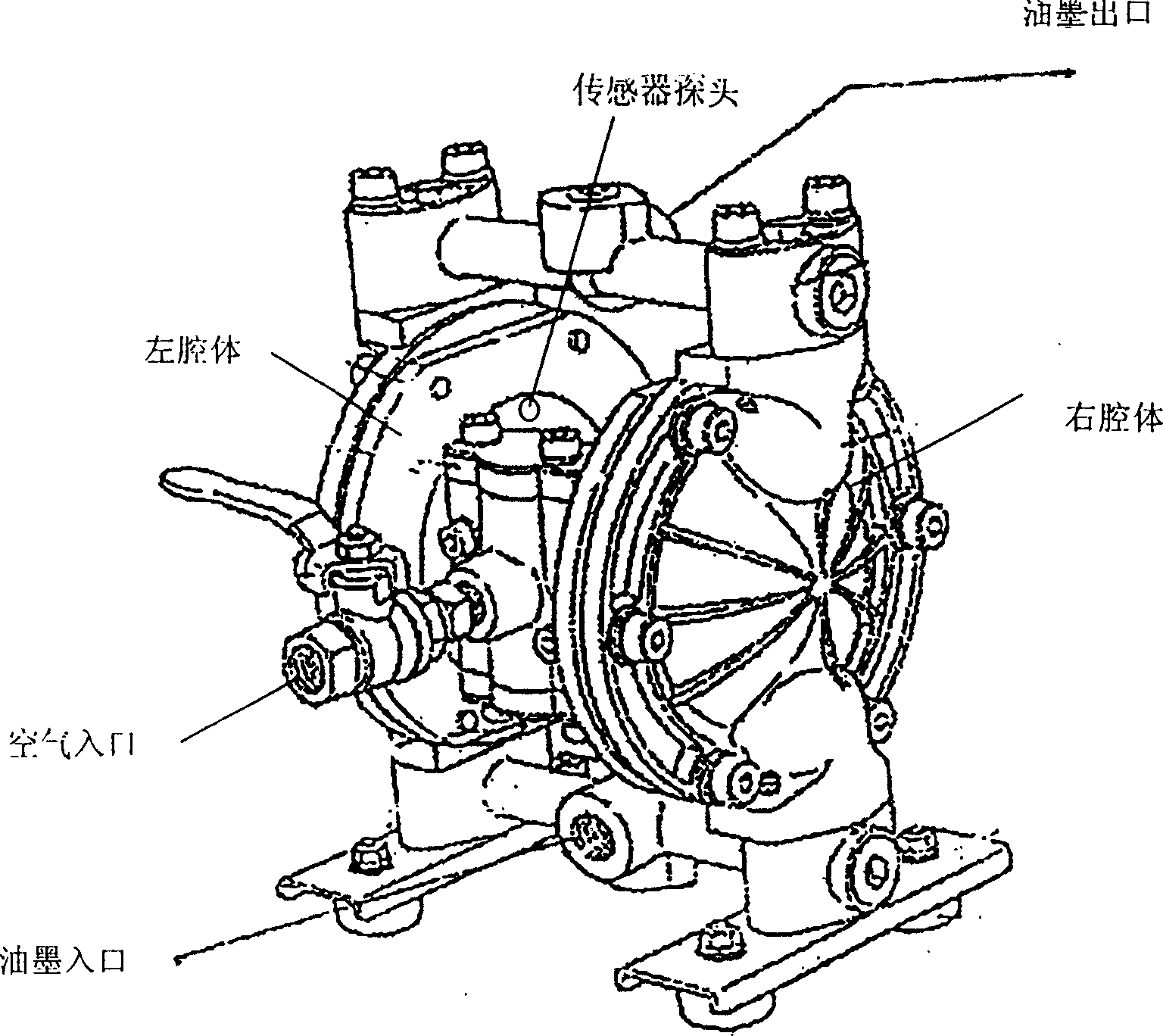

Computer control apparatus for printing ink viscosity

InactiveCN1504329AReal-time and precise controlImprove printing qualityPrinting press partsAutomatic controlSolenoid valve

The invention relates to a computer-controlled device of printing ink glutinous viscosity comprising mainly a printing ink circulation pump, a computer-controlled apparatus, a solenoid valve, an air pressure sensor, an air-actuated pressure regulating valve and vapor separating arrangement. The invention can realize the substitution of the traditional artificial hand-operated regulation and control by the automatic computer control.

Owner:江文发 +1

Manufacturing method of light-golden zippers

InactiveCN103340494AReduce color differenceStable productionSlide fastenersLiquid/solution decomposition chemical coatingTinningCooking & baking

The invention relates to a manufacturing method of light-golden zippers, and belongs to the field of zippers. The manufacturing method of the light-golden zippers includes the steps that after the zippers are processed in an oil-removing mode, the zippers are processed in a chemical polishing mode, after the chemical polishing, silver is displaced chemically to form a silver layer, then the zippers are dried in a water-throwing mode, the zippers are baked for 20-30 minutes at the temperature of 120-130 DEG C, and finally, varnish coating and stoving curing are performed. Traditionally, by relying on manual experience, the light-golden zippers are formed in a chemical tinning mode, but according to the manufacturing method, yellowing processing is performed after the sliver is displaced chemically, through accurate control of the baking temperature and the baking time, color difference of the zippers is reduced, reworking is reduced, and the zippers are steadily produced.

Owner:王萍煌

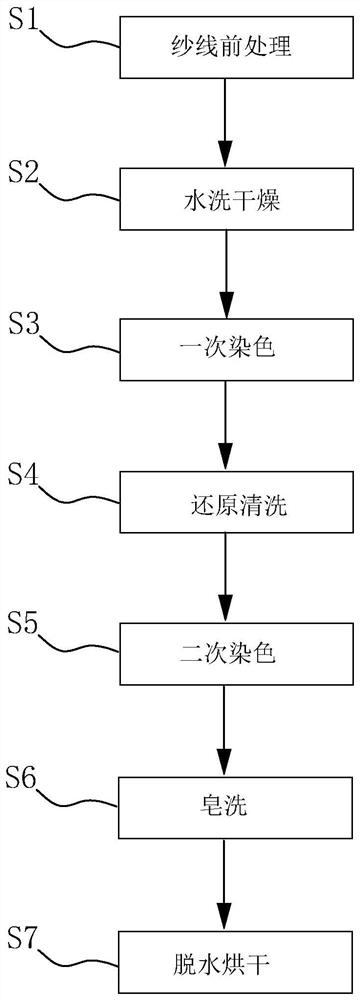

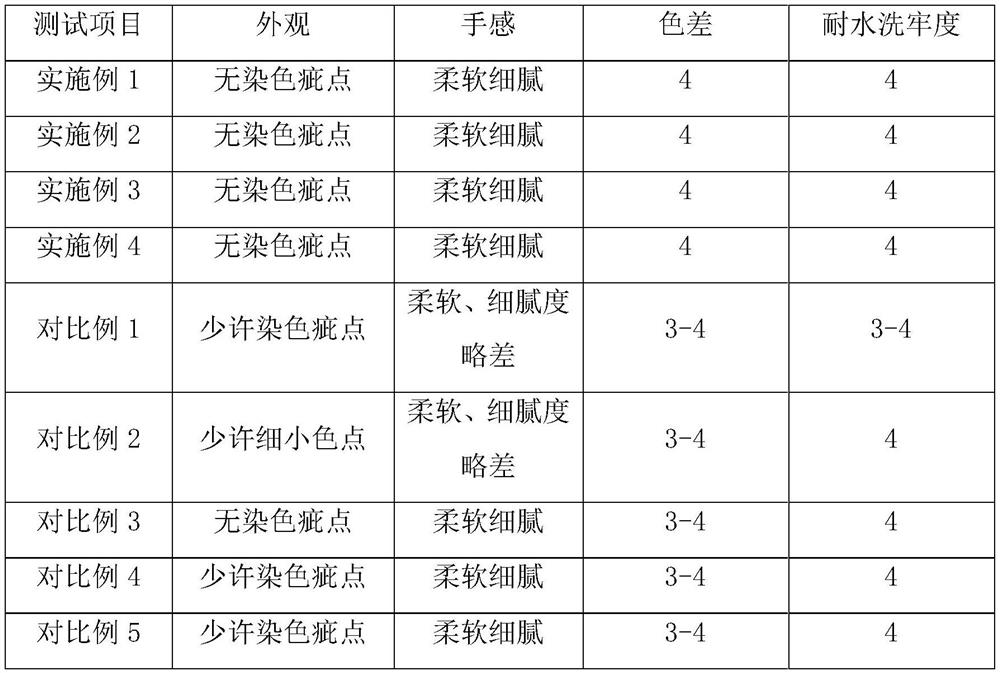

Polyester-cotton blended yarn dyeing process

The invention relates to the technical field of yarn dyeing and finishing, and particularly discloses a polyester-cotton blended yarn dyeing process. The polyester-cotton blended yarn dyeing process comprises the following steps of S1, performing yarn pretreatment; S2, performing washing and drying; S3, performing primary dyeing: adding 1.5-3 g / L of a disperse dye leveling agent into a primary dyeing bathtub, performing heating to 75 DEG C, adding a disperse dye, then performing heating to 85 DEG C, sending the washed and dried yarns into primary dyeing liquid for dip dyeing at a bath ratio of1: (9-11), and performing heat preservation dyeing for 45-55min; S4, performing reduction cleaning; S5, performing secondary dyeing, wherein the bath ratio is 1: (9-11), the temperature is increasedto 75-85 DEG C, heat preservation is performed for 18-22 min, then the temperature is increased to 90 DEG C, heat preservation dyeing is performed for 30-35 min, and secondary dyeing liquid is activedyeing liquid; S6, performing soaping; and S7, performing dehydration and drying, wherein pretreatment liquid comprises the following components in parts by weight: 3-6 parts of pectinase, 4-8 parts of alpha-amylase, 4-7 parts of hydrogen peroxide, 0.5-1 part of sodium silicate, 1-3 parts of a penetrant, 0.5-1 part of cocamidopropyl hydroxy sulfobetaine and 65-85 parts of deionized water. The method has the advantages of effectively improving the dyeing uniformity of the cotton-polyester blended yarns and improving the yarn quality.

Owner:南通云花色织有限公司

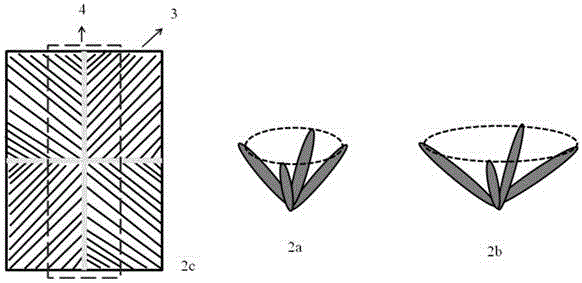

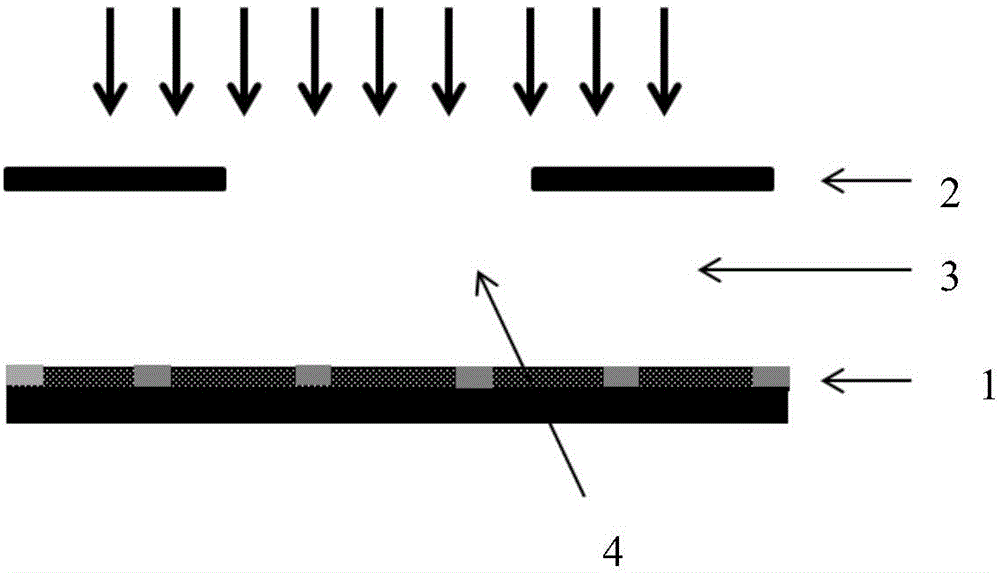

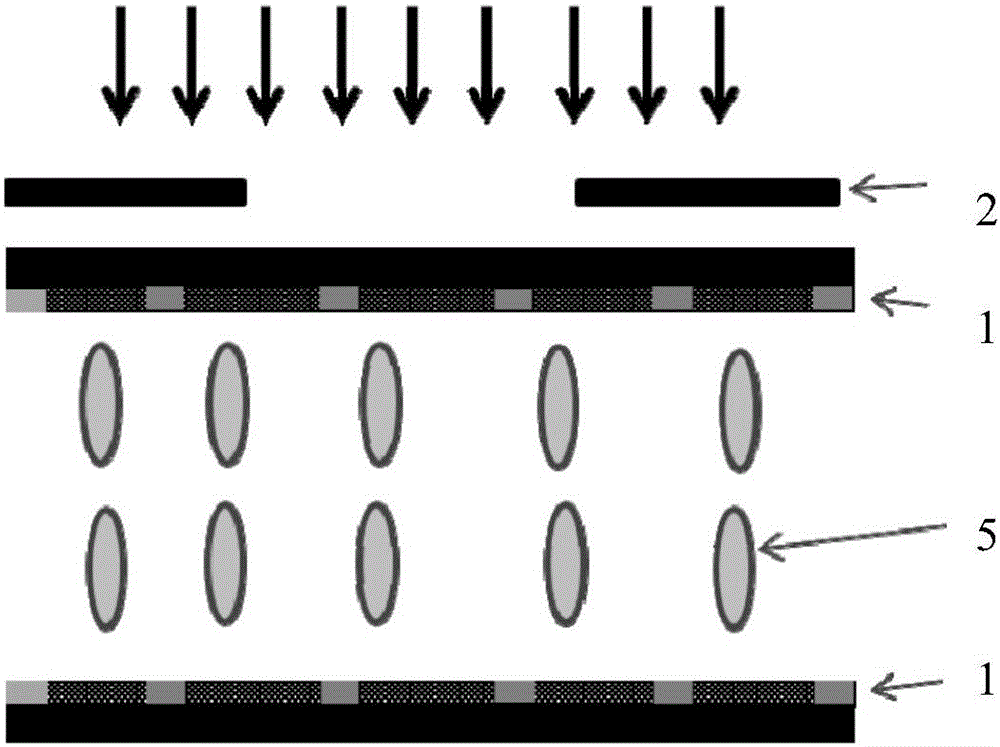

Method for preparing display panel and prepared display panel

ActiveCN106773334AImprove viewing angleSolve the problem of color castNon-linear opticsUltraviolet lightsIrradiation

The invention discloses a method for preparing a display panel. The method includes the following steps that S1, a first substrate and a second substrate are coated with alignment films respectively, and the alignment films are preheated; S2, the first substrate and the second substrate coated with the alignment films are each divided into an irradiation region and a shielding region; the first substrate and the second substrate coated with the alignment films are irradiated by ultraviolet light, and polymers in the alignment films in the irradiation regions are degraded; S3, the alignment films on the irradiated first substrate and second substrate are heated, and the alignment films are cured; S4, the cured alignment films on the first substrate and the second substrate are subjected to directional friction treatment, and grooves are formed; S5, the first substrate and the second substrate obtained after directional friction treatment are paired, liquid crystal molecules are injected, a liquid crystal box is formed, and finally the display panel is prepared. The display panel can achieve multi-domain display.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

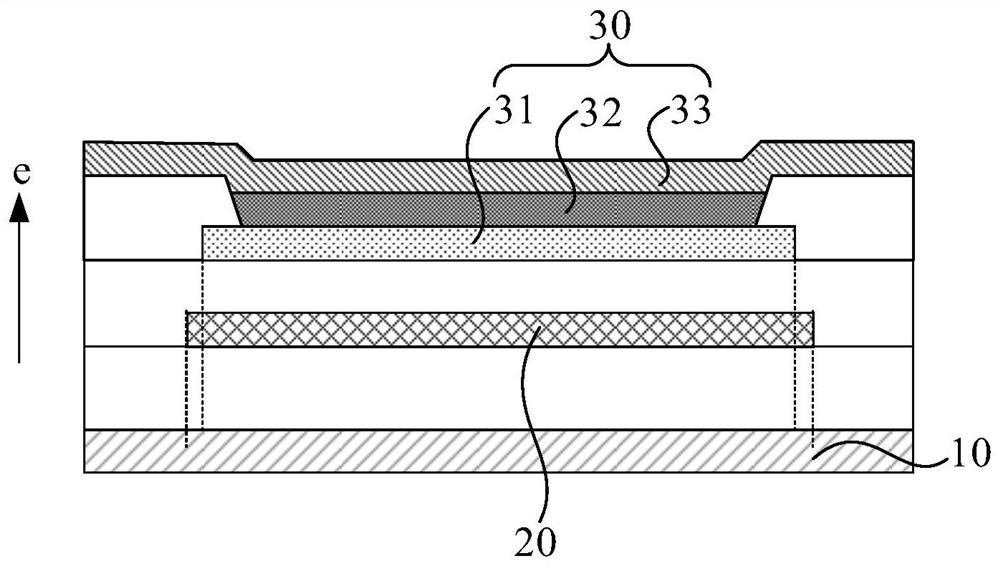

Display panel and display device

ActiveCN112786812AImprove dispersionImprove the big screen role deviation problemSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The embodiment of the invention provides a display panel and a display device. The display panel includes: a substrate; a metal part positioned on the substrate; and a plurality of light-emitting elements located on the side, away from the substrate, of the metal part, wherein each light-emitting element comprises a first electrode, a light-emitting layer and a second electrode which are sequentially stacked in the light emitting direction of the display panel, and the orthographic projection of the metal part on the substrate covers the orthographic projection of the first electrodes and the light-emitting layers on the substrate. According to the embodiment of the invention, the first electrodes have a relatively flat surface, so that the probability of mutual interference between ambient light reflected by the first electrodes is reduced, the dispersion phenomenon of the display panel in a dark state can be improved, and the appearance quality is improved; and meanwhile, the relatively flat first electrodes can also reduce the color difference of pixel light-emitting area colors at different viewing angles, the large-viewing-angle color cast problem of the display panel is improved, and the display effect is improved.

Owner:HUBEI YANGTZE IND INNOVAION CENT OF ADVANCED DISPLAY CO LTD

Dyeing process of dual-type cashmere fiber

ActiveCN103276597AImprove dye uptakeImprove product qualityDyeing processAnimal fibresPre treatmentDyeing

The invention relates to the dyeing field of cashmere textile industry, in particular relates to the field of the dyeing technology for the dual-type fibers and the 'two fuzzes' of cashmere fibers and provides a dyeing process of dual-type cashmere fibers. The method has the biggest characteristic that the disulfide bonds on the surfaces of the dual-type cashmere fibers are opened by utilizing the pre-treatment technology; the dual-type cashmere fibers and the 'two fuzzes' are treated with a protein dialysate which is applied to the surfaces of the fibers; then the protein and the disulfide bonds are combined again through a reaction between active protein groups in the dialysate and the disulfide bonds, so that a layer of protein membranes is formed on the surface of each dual-type cashmere fiber and dried so as to enhance the dyeing property of the dual-type fibers; and finally the dyeing operation is carried out. The method has the superiority of being high in dyeing rate and small in dyeing color difference and realizing reduction in subsequent fuzz picking operations.

Owner:宁夏新澳羊绒有限公司

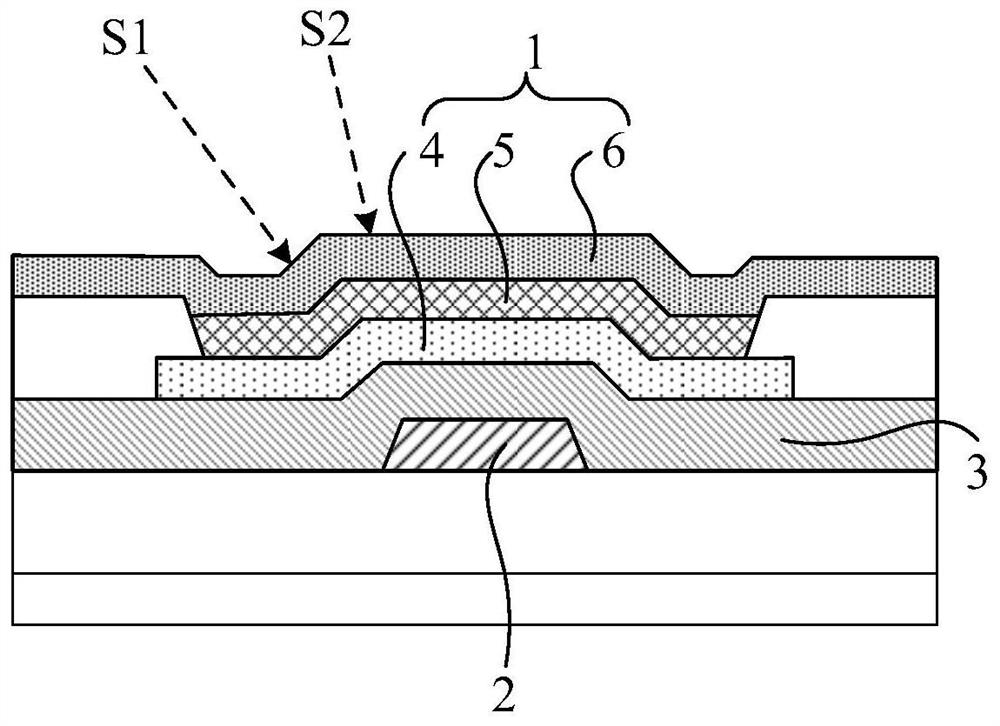

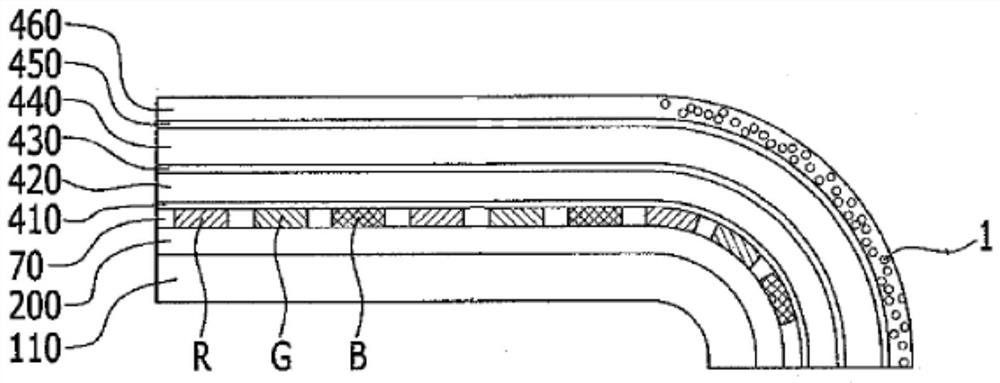

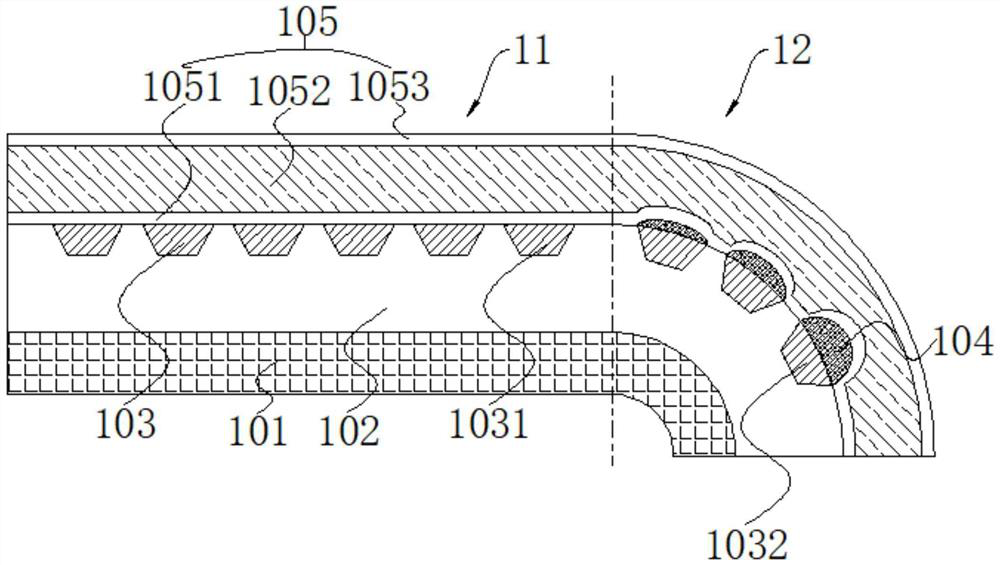

OLED display panel

ActiveCN112002734AReduce color differenceThe display effect is consistent or nearly consistentSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneMaterials science

An OLED display panel is provided with a plane region and a bent region located on at least one side of the plane region, and further comprises a flexible substrate, an array structure layer formed onthe flexible substrate, a plurality of organic light-emitting units formed on the array structure layer, a plurality of convex lens components and a thin film packaging layer, wherein the organic light-emitting units comprise a plurality of first organic light-emitting units located in the plane region and a plurality of second organic light-emitting units located in the bent region; the plurality of convex lens components are located in the bent region and are in one-to-one correspondence with the second organic light-emitting units, and the convex lens components are made of high-transmittance organic matters; and the thin film packaging layer is formed on the array structure layer, the thin film packaging layer completely covers the plurality of first organic light-emitting units in the plane region, and the thin film packaging layer completely covers the convex lens component in the bent region.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

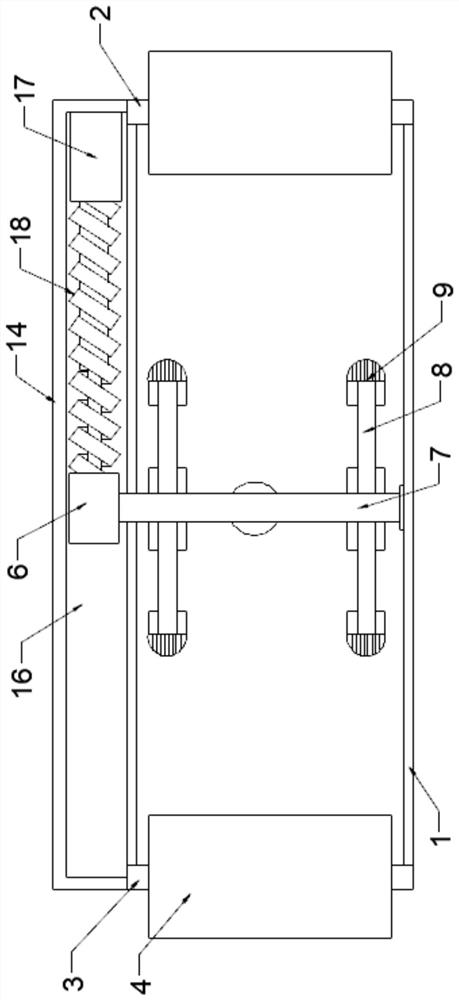

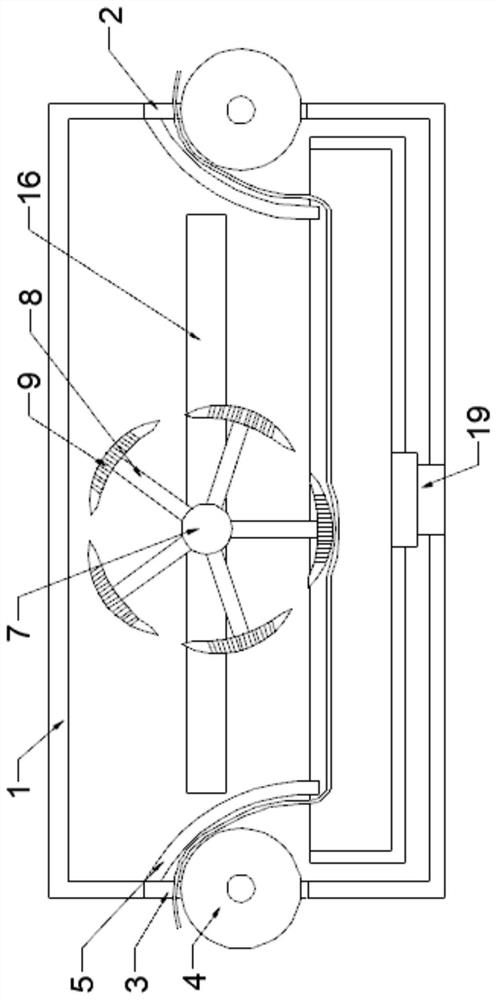

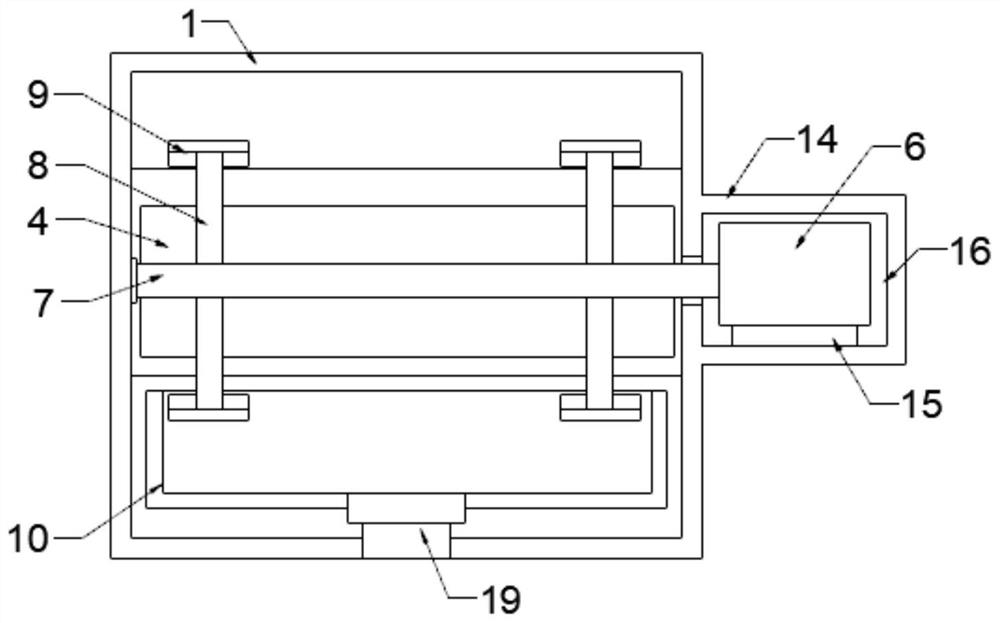

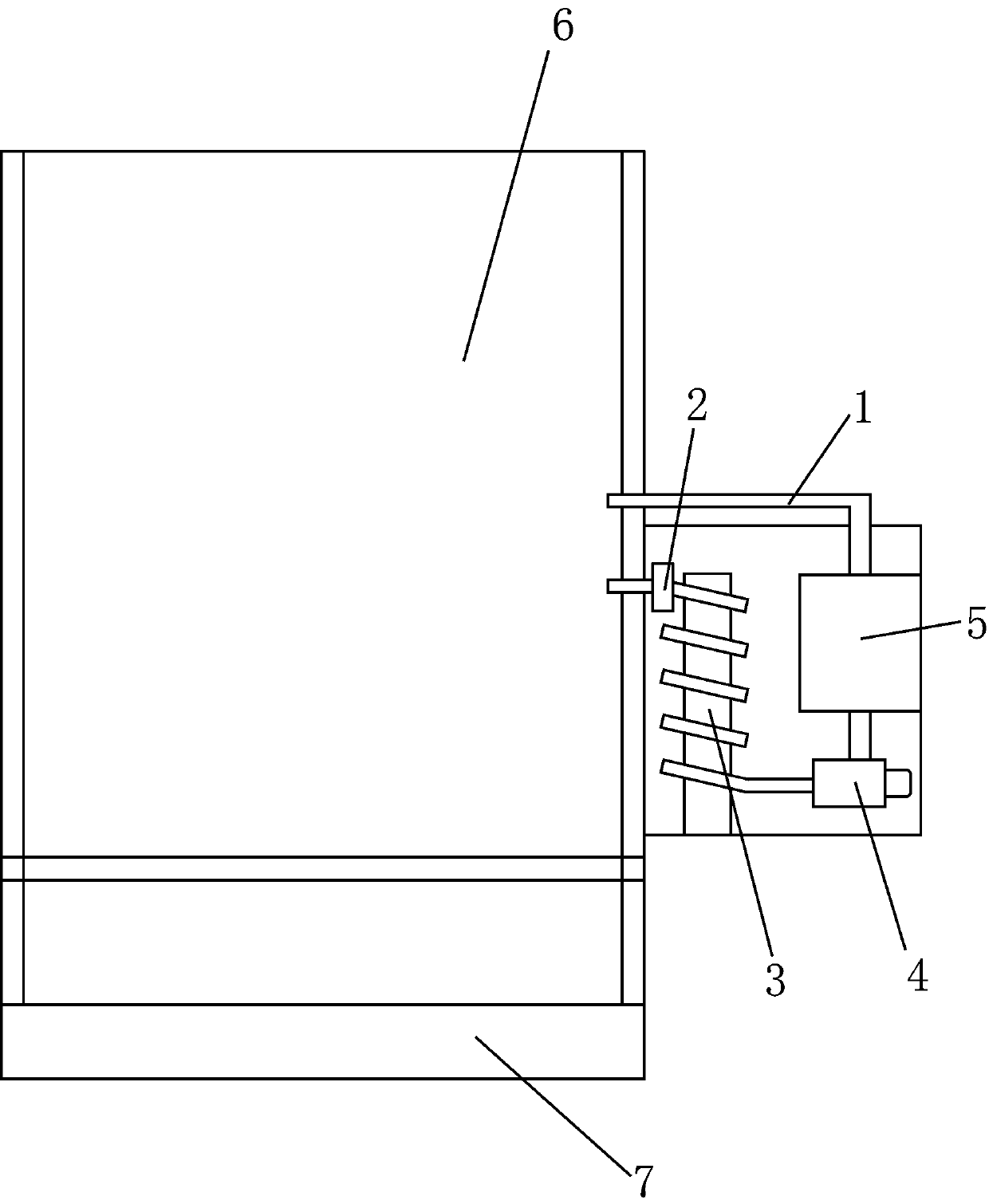

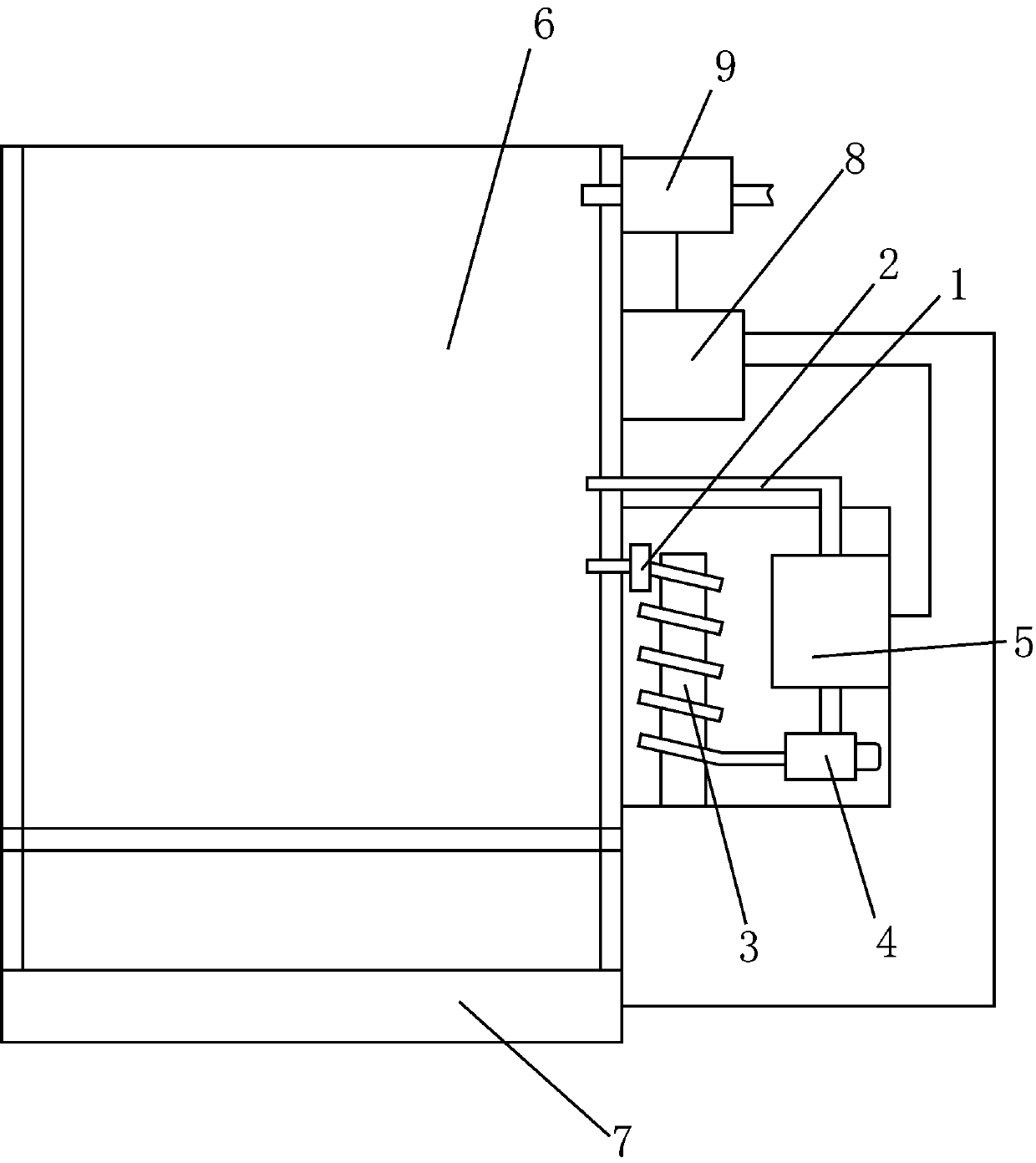

Dyeing device for fabric deep dip dyeing

PendingCN112760862AFully impregnatedDip dyed evenlyTextile treatment containersLiquid/gas/vapor textile treatmentPolymer scienceEngineering

The invention discloses a dyeing device for fabric deep dip dyeing. The dyeing device comprises a shell, a cloth pressing mechanism and a dye mechanism, wherein the shell comprises a shell, a cloth inlet, a cloth outlet, guide wheels and guide plates; the cloth inlet and the cloth outlet are formed in the two sides of the shell respectively; the two guide wheels are rotationally installed in the cloth inlet and the cloth outlet; the two guide plates are fixedly mounted on two opposite inner walls of the shell; the cloth pressing mechanism comprises a motor, a mounting rod, rotating rods and pressing pieces; the motor is slidably mounted on the side wall of the shell through a sliding mechanism; the output end of the motor is fixedly connected with the mounting rod; the multiple rotating rods are fixedly connected to the side wall of the mounting rod, and the rotating rods and the pressing piece form one pressing wheel; and the dye mechanism is used for dyeing the cloth. According to the dyeing device, the dip dyeing effect on the cloth is enhanced, all parts of the cloth are uniformly dip-dyed, the dyeing color difference of different parts of the cloth is reduced, and the attractiveness degree of the dyed cloth is improved.

Owner:李勇平

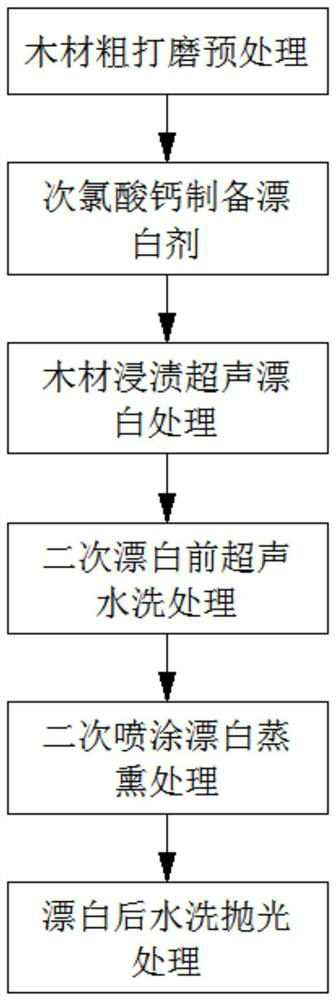

Wood color difference bleaching and desalting treatment process

InactiveCN113021544AIncrease roughnessFast and Deep PenetrationWood treatment detailsPretreatment apparatusBleachPulp and paper industry

The invention discloses a wood color difference bleaching and desalting treatment process which comprises the following steps: step 1, wood rough grinding pretreatment; step 2, preparation of a bleaching agent from calcium hypochlorite; step 3, wood dipping and ultrasonic bleaching treatment; step 4, ultrasonic washing treatment before secondary bleaching; The color difference defect of the wood surface is bleached by using the bleaching agent prepared from calcium hypochlorite, so that the color difference of the produced wood product is greatly reduced, the product quality is ensured, and the roughness of the wood surface is increased by adopting raw abrasive paper for polishing before bleaching treatment; The bleaching agent can more quickly and deeply permeate into the surface of the wood during dipping and bleaching, ultrasonic treatment and two-time bleaching treatment are matched, so that the bleaching effect of the wood is better, and the color difference of the bleached wood is lower.

Owner:来安县扬子地板有限公司

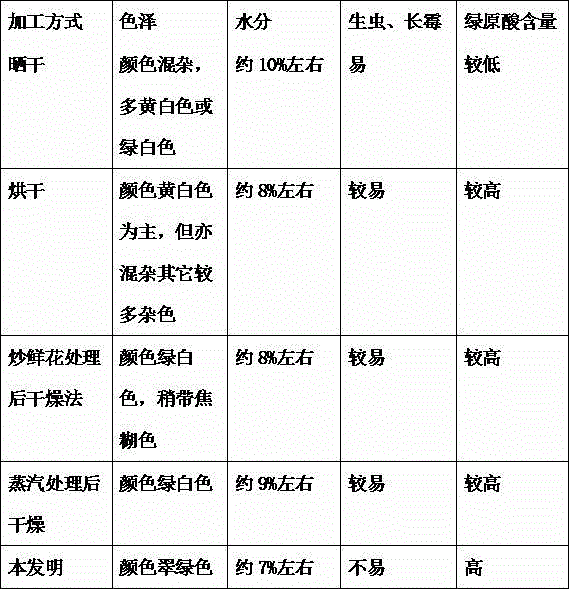

Processing method for honeysuckle

InactiveCN105309651AReduce color differenceReduce color protectionPre-extraction tea treatmentWater contentChemistry

The invention provides a processing method for honeysuckle. The processing method includes the following specific steps that a, flower picking, wherein flower picking time ranges from nine O'clock to twelve O'clock in the morning, and flowers are not suitable for being picked on dew days or rainy days; b, water removal, wherein the picked flowers are subjected to water removal in time, the water removal temperature ranges from 115 DEG C to 125 DEG C, the water removal time ranges from 28 seconds to 34 seconds, the weight of honeysuckle subjected to water removal every time ranges from 190 g to 210 g, and after water removal, honeysuckle needs to be spread to be cooled in time; c, drying, wherein the hot air temperature of an oven is gradually raised from bottom to top, hot air flows from bottom to top, the temperature of the hot air on the lower portion is controlled to range from 115 DEG C to 125 DEG C, the temperature of the hot air in the middle ranges from 70 DEG C to 85 DEG C, the temperature of the hot air on the upper portion ranges from 48 DEG C to 55 DEG C, the drying condition of all the layers is checked once every 15-20 seconds, honeysuckle dried on the lower layer is taken out, and honeysuckle is moved downwards and dried layer by layer. The processed honeysuckle is bright green in color, the water content is about 7%, no worm or mould is likely to be generated, and the content of chlorogenic acid is high.

Owner:HUBEI SHENNONG BENCAO CHINESE HERBAL PIECES CO LTD

Touch panel and touch display panel

InactiveCN104298389AReduce color differenceReduce brightnessDigital data processing detailsInput/output processes for data processingTouch SensesAlloy

The present invention provides a touch panel. The touch panel includes a substrate, a touch sensing device, and an optical matching layer. The touch sensing device is disposed on one side of the substrate, and includes an electrode pattern. The electrode pattern includes silver or silver alloy. At least one side of the substrate has the optical matching layer disposed thereon.

Owner:WINTEK CORP

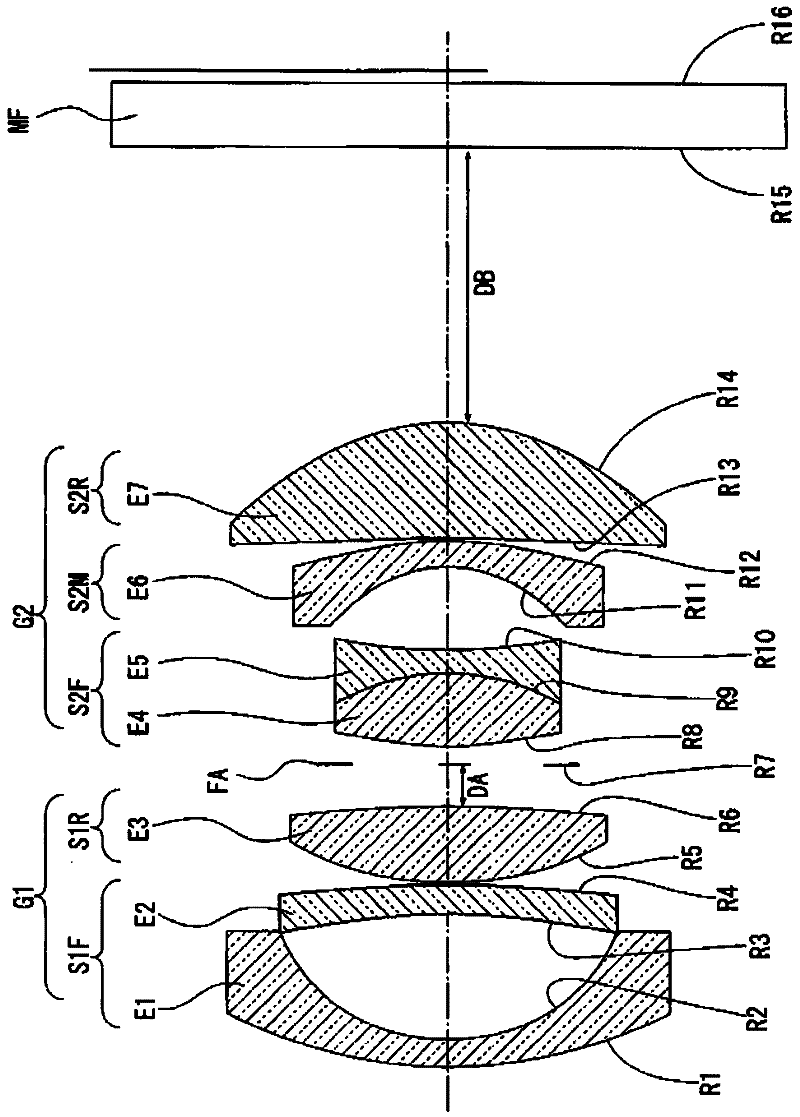

Starlight level sighting object lens

InactiveCN109425956AReduce aberrationReduce spherical aberrationOptical elementsCamera lensIlluminance

The invention discloses a starlight level sighting object lens, and belongs to the field of light-mechanical-electric integration. The focal power of an optical system is distributed reasonable and glass of ultra-low dispersion is used, so that optical aberration mainly including spherical aberration and color aberration can be corrected effectively, the lens has a relatively long focal length, the relative aperture of the lens reaches F1.4, high-definition imaging can realized in day and low-illuminance conditions, the object lens can be applied to a sighting device with a starlight-level ultra-low-illuminance camera, and thus, the sighting device have good using effects in day and night.

Owner:FUZHOU DEV ZONE HONGFA OPTOELECTRONICS TECH

Image processing device, image processing method and recording medium

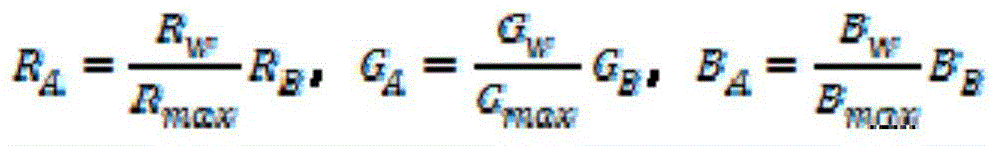

ActiveUS9749503B2Reduce color differenceLimit environmentImage analysisTexturing/coloringTime rangeImaging processing

In the image processing device, the image processing method and the recording medium, the image extractor extracts, from the captured images, captured images regarded as being captured in the same time range, as extracted images. The target image determiner selects an extracted image which were captured by a capturing person who captured largest number of extracted images and with a capturing device of a type used to capture largest number of extracted images, as a target image. The object image determiner selects an extracted image showing a subject similar to a subject present in the target image, as an object image. The color table generator generates a color table for matching colors of the object image to colors of the target image. The color conversion processor carries out the color conversion applying the color table to the object image.

Owner:FUJIFILM CORP

Improved manufacturing method of light gold zipper

InactiveCN104814575AReduce color differenceStable productionSlide fastenersLiquid/solution decomposition chemical coatingTinningCooking & baking

Owner:王萍煌

Device for quickly calculating supplementing amount of dye recycled from dyeing residual liquid and dye supplementing method

ActiveCN111006929AReduce color differenceEasy to calculatePreparing sample for investigationColor/spectral properties measurementsOptical absorbanceDyeing

The invention discloses a device for quickly calculating the supplementing amount of dye recycled from dyeing residual liquid and a dye supplementing method. The device comprises a filter, a cooler, acirculating pump and a spectrophotometer which are sequentially connected through a pipeline. The pipeline is in end-to-end connection with an auxiliary cylinder for storing dyeing residual liquid; and a weighing device for weighing the mass of the dyeing residual liquid is arranged at the bottom of the auxiliary cylinder. The method comprises the following steps: drawing a concentration-absorbance working curve of required basic dye under light rays with different wavelengths; arranging the device directly on a residual liquid auxiliary cylinder of a dyeing machine, detecting residual liquidin an on line manner, and detecting the absorbance of the light rays with multiple wavelengths; acquiring the concentration of the residual liquid corresponding to each wavelength absorbance according to the concentration-absorbance working curve of the basic dye; and then taking a concentration average value , calculating the amount of the dye needing to be added according to the concentration average value of the dyeing residual liquid and the concentration and total amount of the original dyeing liquid, then adding the dye for reuse. Therefore, dyeing color difference of the reuse liquid can be effectively reduced, and detection is more convenient.

Owner:ZHEJIANG QIAOERTINGTING FASHION

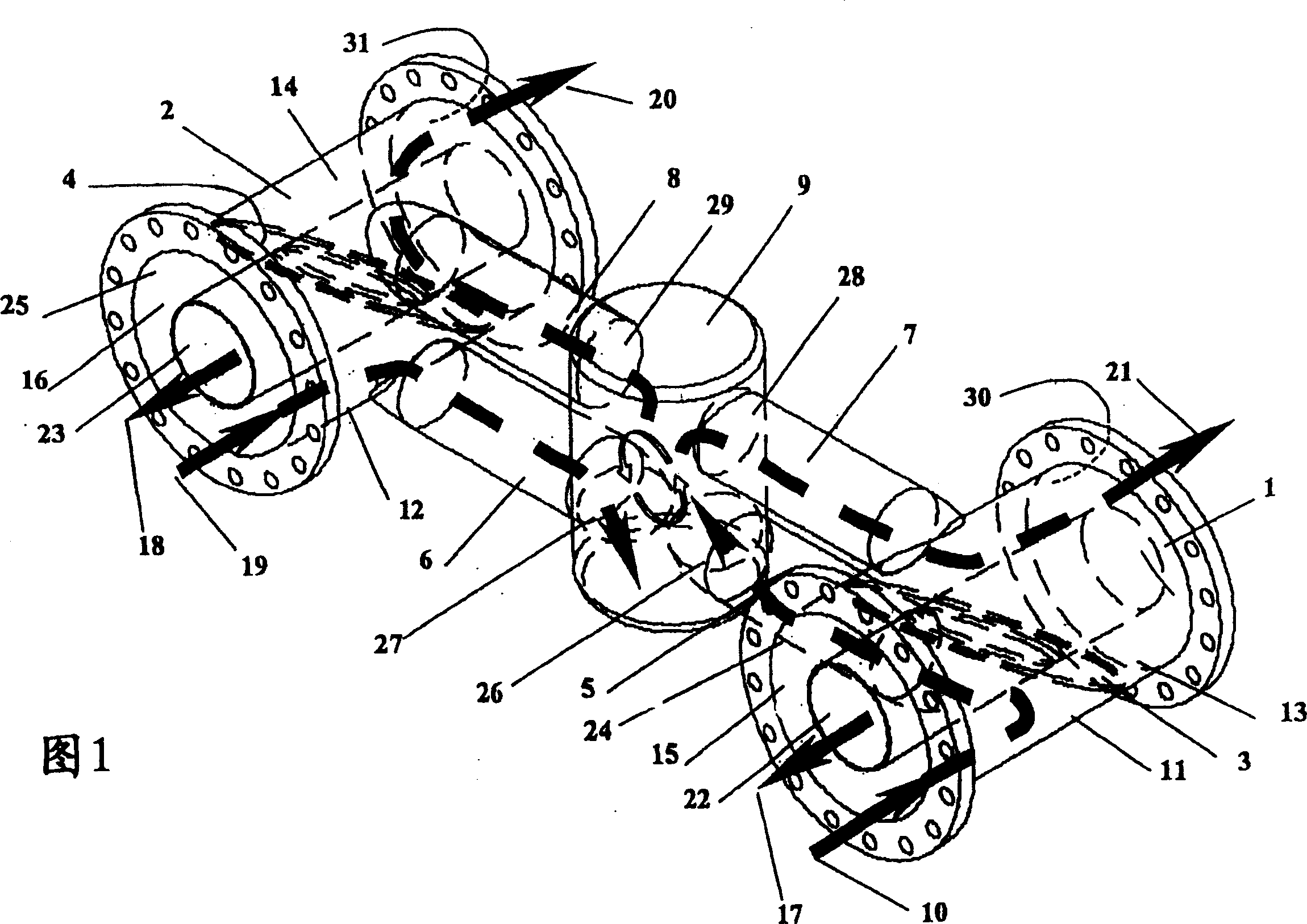

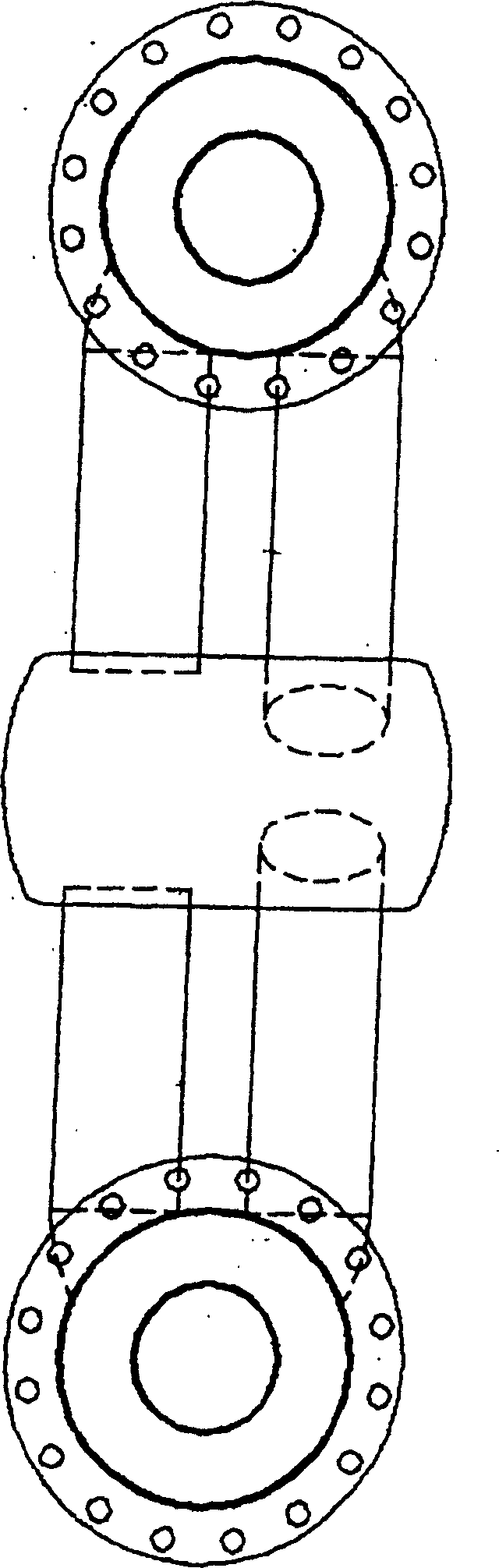

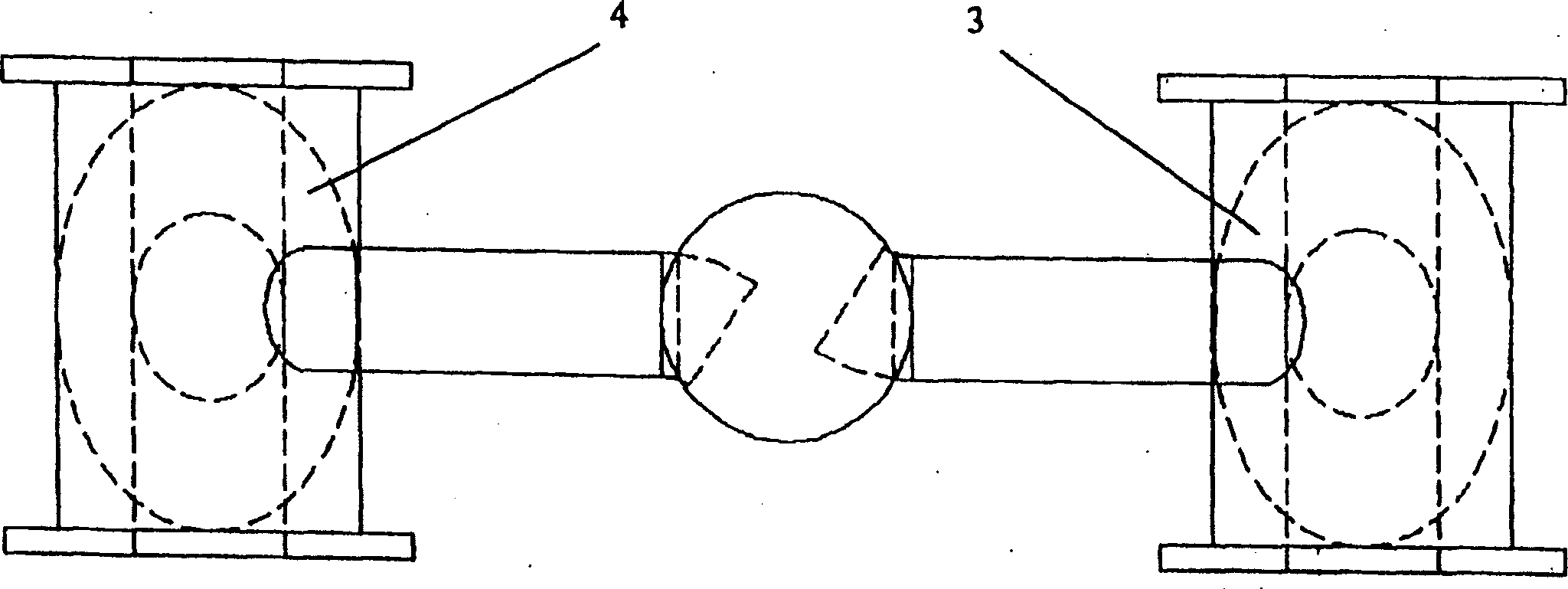

Fluid distribution device

InactiveCN1259517CSimple configurationReduce colorFlow mixersTextile treatment machine partsEngineeringMechanical engineering

A fluid dispensing device comprising a container (9) having a plurality of inlet tubes (5,6) and a plurality of outlet tubes (7,8) to facilitate the distribution of fluid to A corresponding number of textile processing machines (not shown). Each inlet tube (5, 6) is arranged to receive fluid and deliver the fluid to the container (9). The fluids are mixed in the container (9) and then distributed from the container (9) via outlet pipes (7, 8) to each textile processing machine (not shown).

Owner:FALMER INVESTMENTS LTD

Preparation method of bunting fabric

InactiveCN109403012AUniform dyeing colorReduce color differenceFibre typesDyeing processPolyesterDyeing

The invention relates to the technical field of printing and dyeing application and specifically relates to a preparation method of bunting fabric. The preparation method comprises the following steps: (S1) modeling; (S2) steaming and pre-setting; (S3) desizing; (S4) boiling; (S5) bleaching; (S6) coloring; (S7) setting and drying; (S8) printing and manufacturing. According to the preparation method provided by the invention, through the steaming, the fabric slowly and uniformly shrinks before the dyeing process, then a pre-shrinkage setting effect consistent on the inner and outer layers is realized, intense shrinkage of the fabric is avoided after entering the dyeing process, and the defect of different densities on two sides of the fabric caused by the compaction and coverage of the positive and negative yarns of the fabric is prevented; meanwhile, a specific dyeing heating curve is adopted during high-temperature dyeing, a computer automatically and strictly controls the dyeing heating speed and the heat preservation time so as to guarantee uniform dyeing and realize better dyeing fastness; moreover, internal structure of polyester molecules in the fabric is changed, and the features of relatively hard hand feeling and poor comfort of polyester fiber are eliminated.

Owner:迦南(福建)新材料科技有限公司

Dyeing process of dual-type cashmere fiber

ActiveCN103276597BImprove dyeing effectImprove dye uptakeDyeing processAnimal fibresDisulfide bondingFiber

The invention relates to the dyeing field of cashmere textile industry, in particular relates to the field of the dyeing technology for the dual-type fibers and the 'two fuzzes' of cashmere fibers and provides a dyeing process of dual-type cashmere fibers. The method has the biggest characteristic that the disulfide bonds on the surfaces of the dual-type cashmere fibers are opened by utilizing the pre-treatment technology; the dual-type cashmere fibers and the 'two fuzzes' are treated with a protein dialysate which is applied to the surfaces of the fibers; then the protein and the disulfide bonds are combined again through a reaction between active protein groups in the dialysate and the disulfide bonds, so that a layer of protein membranes is formed on the surface of each dual-type cashmere fiber and dried so as to enhance the dyeing property of the dual-type fibers; and finally the dyeing operation is carried out. The method has the superiority of being high in dyeing rate and small in dyeing color difference and realizing reduction in subsequent fuzz picking operations.

Owner:宁夏新澳羊绒有限公司

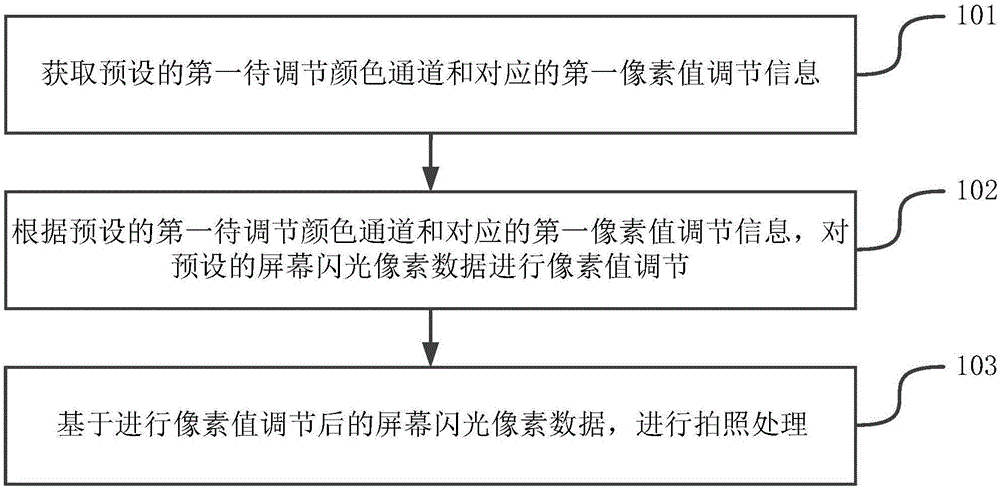

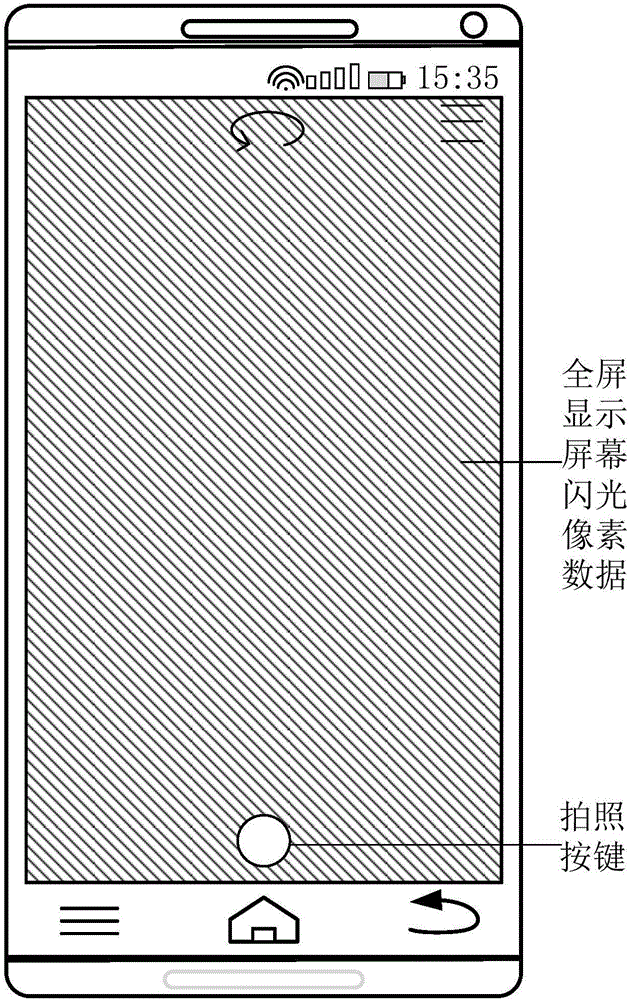

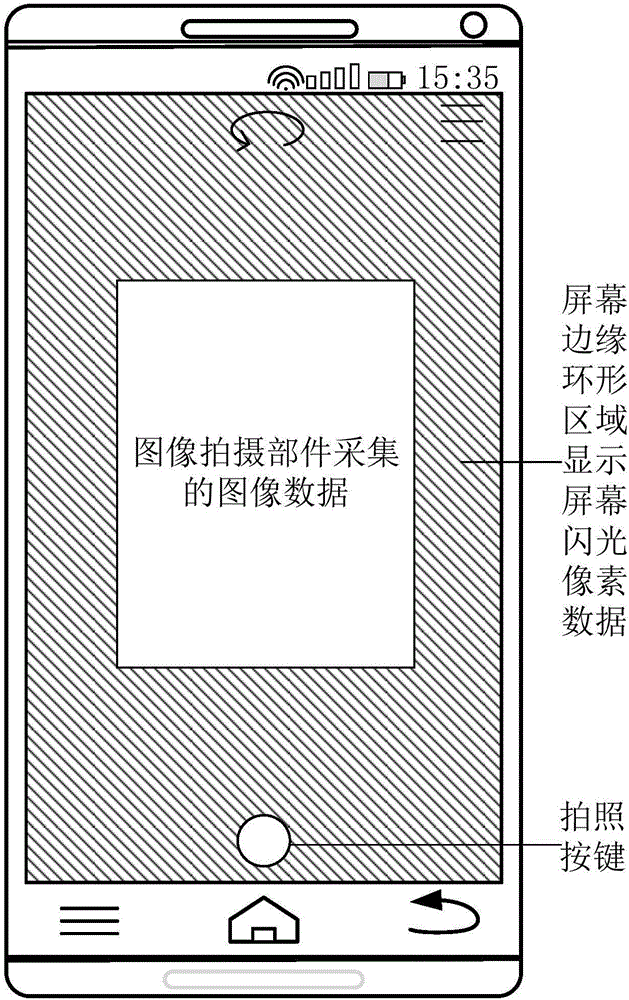

Image shooting method and image shooting device

ActiveCN106713782AReduce colorReduce color differenceTelevision system detailsColor television detailsShooting methodColor difference

The invention discloses an image shooting method and an image shooting device, belonging to the technical field of computers. The method comprises the following steps: acquiring a preset first to-be-adjusted color channel and corresponding first pixel value adjustment information; performing pixel value adjustment on preset screen flash pixel data according to the preset first to-be-adjusted color channel and the corresponding first pixel value adjustment information; and shooting based on the screen flash pixel data subjected to pixel value adjustment. According to the image shooting method and the image shooting device disclosed by the invention, the color difference of the color of a shot image and an actual color can be reduced.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com