Patents

Literature

56results about How to "Uniform light transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

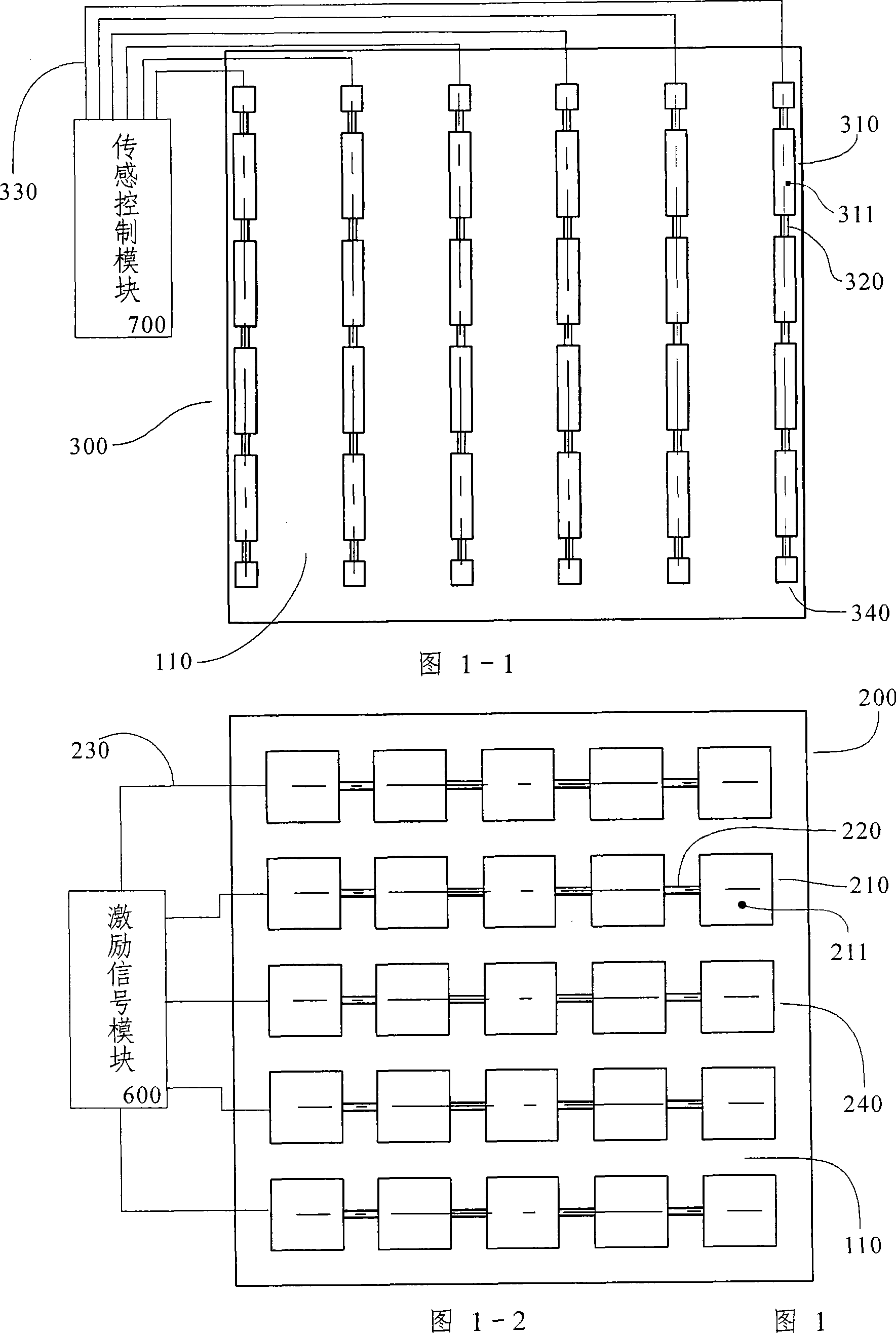

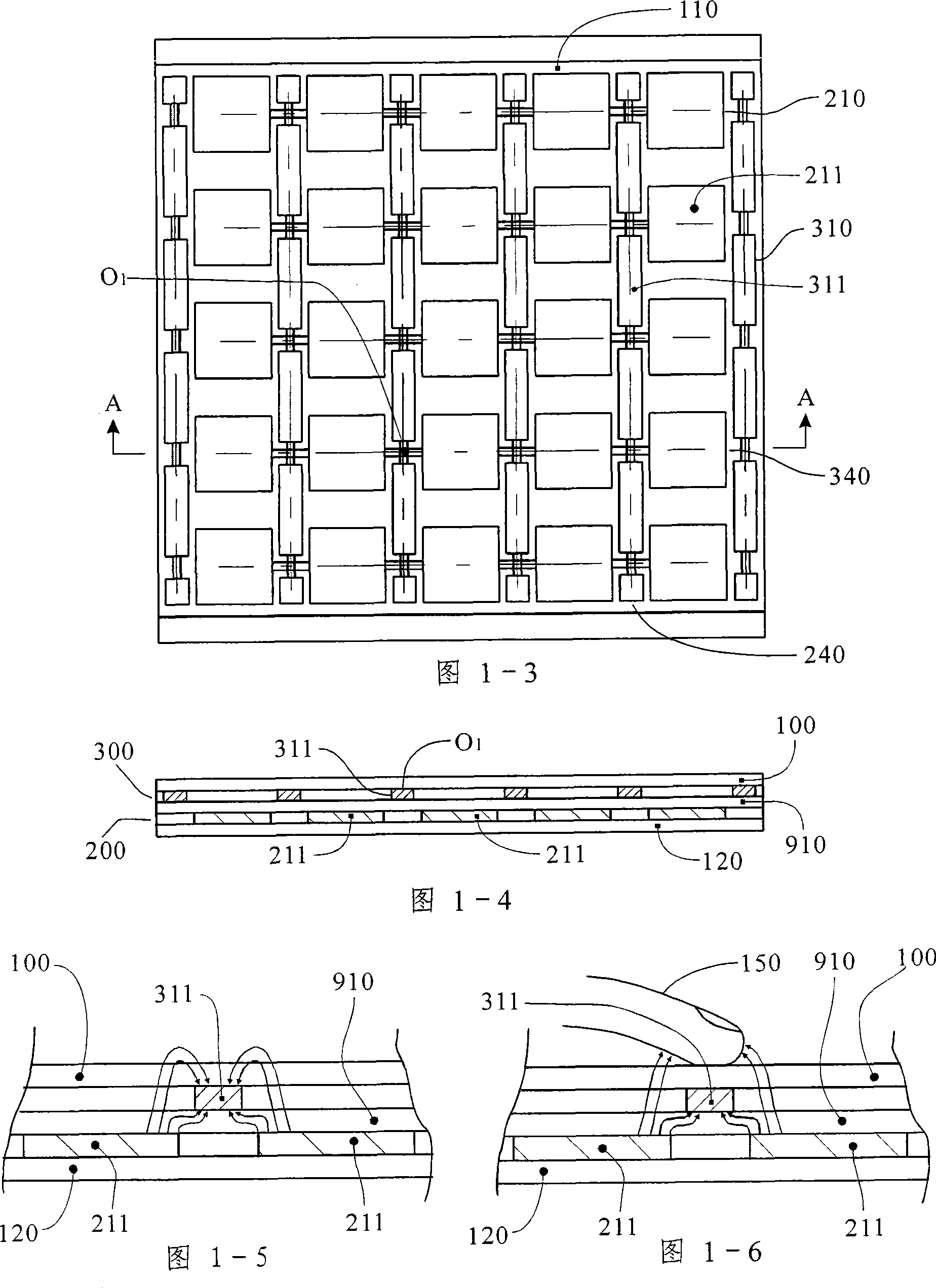

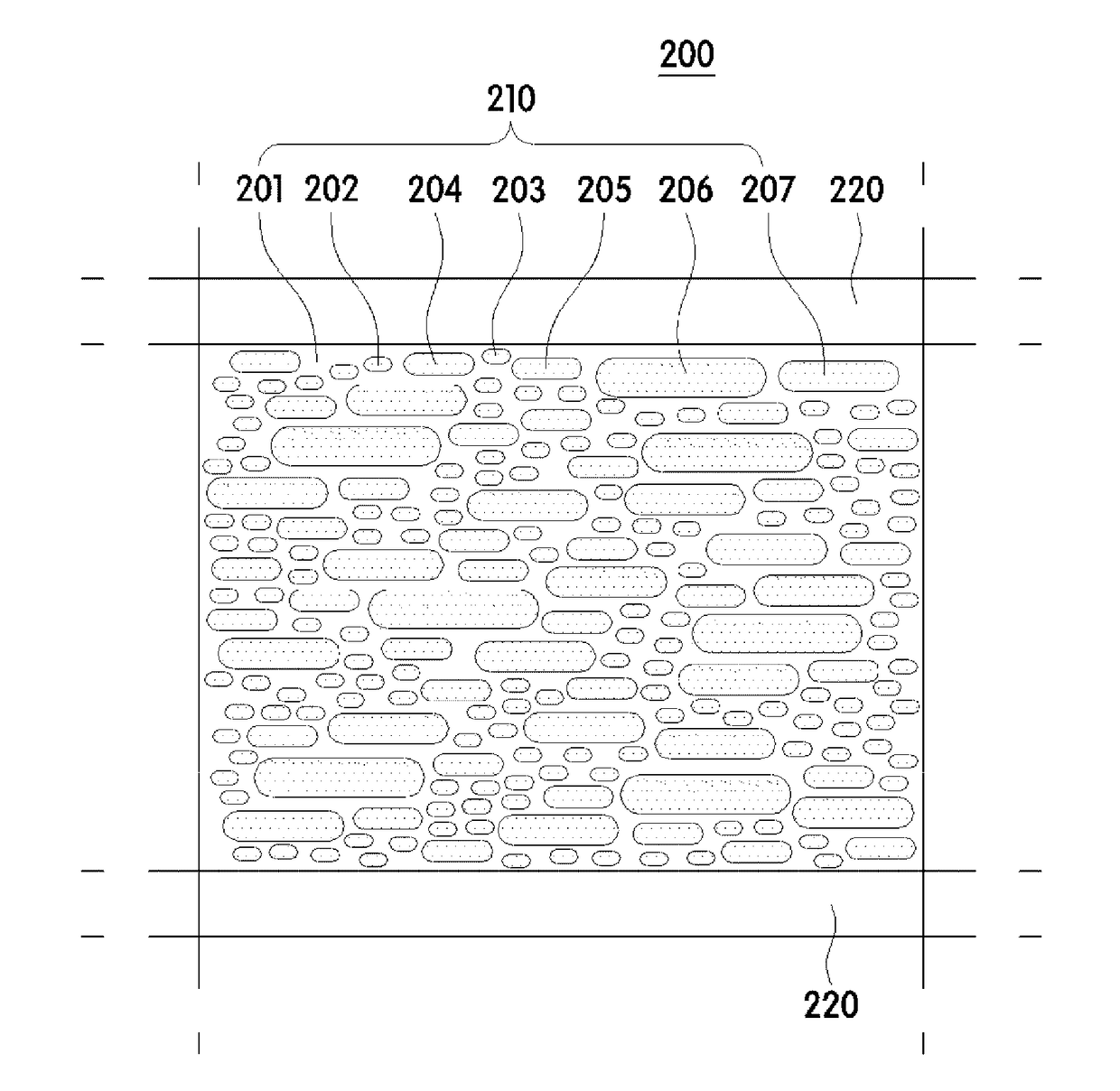

Mutual capacitance touch screen and combination mutual capacitance touch screen

ActiveCN101393502AIncrease effective permittivityRaise the ratioInput/output processes for data processingTouchscreenEffective capacitance

The invention relates to a mutual capacitance-type touch screen and a combined mutual capacitance-type touch screen which is combined by the mutual capacitance-type touch screen. The mutual capacitance-type touch screen comprises a driving layer (200) and a sensing layer (300), wherein the driving layer (200) comprises drive electrodes (210) which are alternately distributed on the same plane; the sensing layer (300) comprises sensing electrodes (310) which are alternately distributed on the same plane; the sensing electrodes (310) are distributed in areas in the sensing layer (300) and the driving layer (200) facing to mutual gap areas of the drive electrodes (210); and the drive electrodes (210) and the sensing electrodes (310) are filled into a touch area (110) of the touch screen together. The space positions of the drive electrodes and the sensing electrodes are not opposite, thereby improving the proportion of capacitances CT formed between tops of the drive electrodes and the sensing electrodes in a mutual capacitance C and effectively increasing the effective inductive capacity of the mutual capacitance-type touch screen.

Owner:FOCALTECH ELECTRONICS SHENZHEN CO LTD

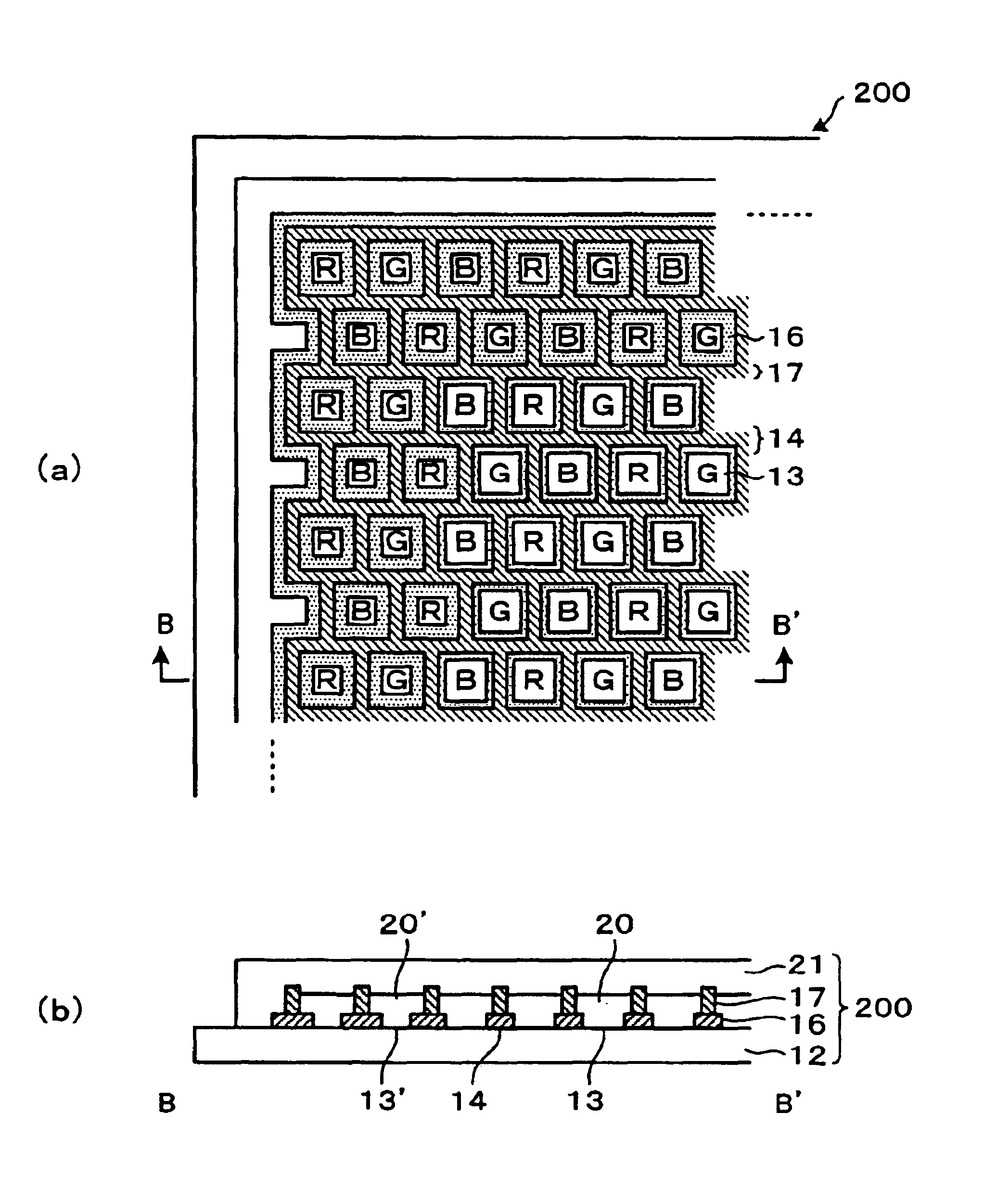

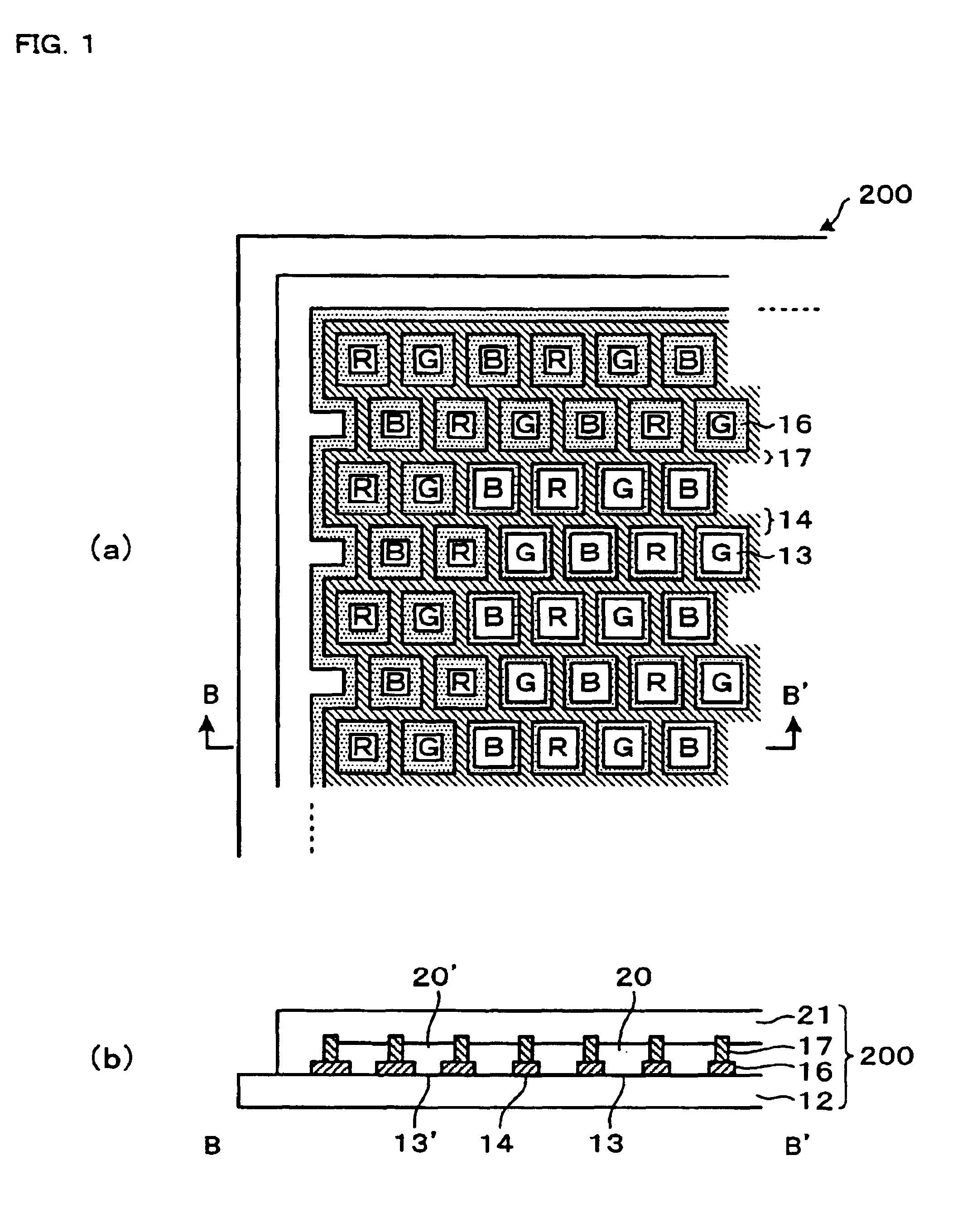

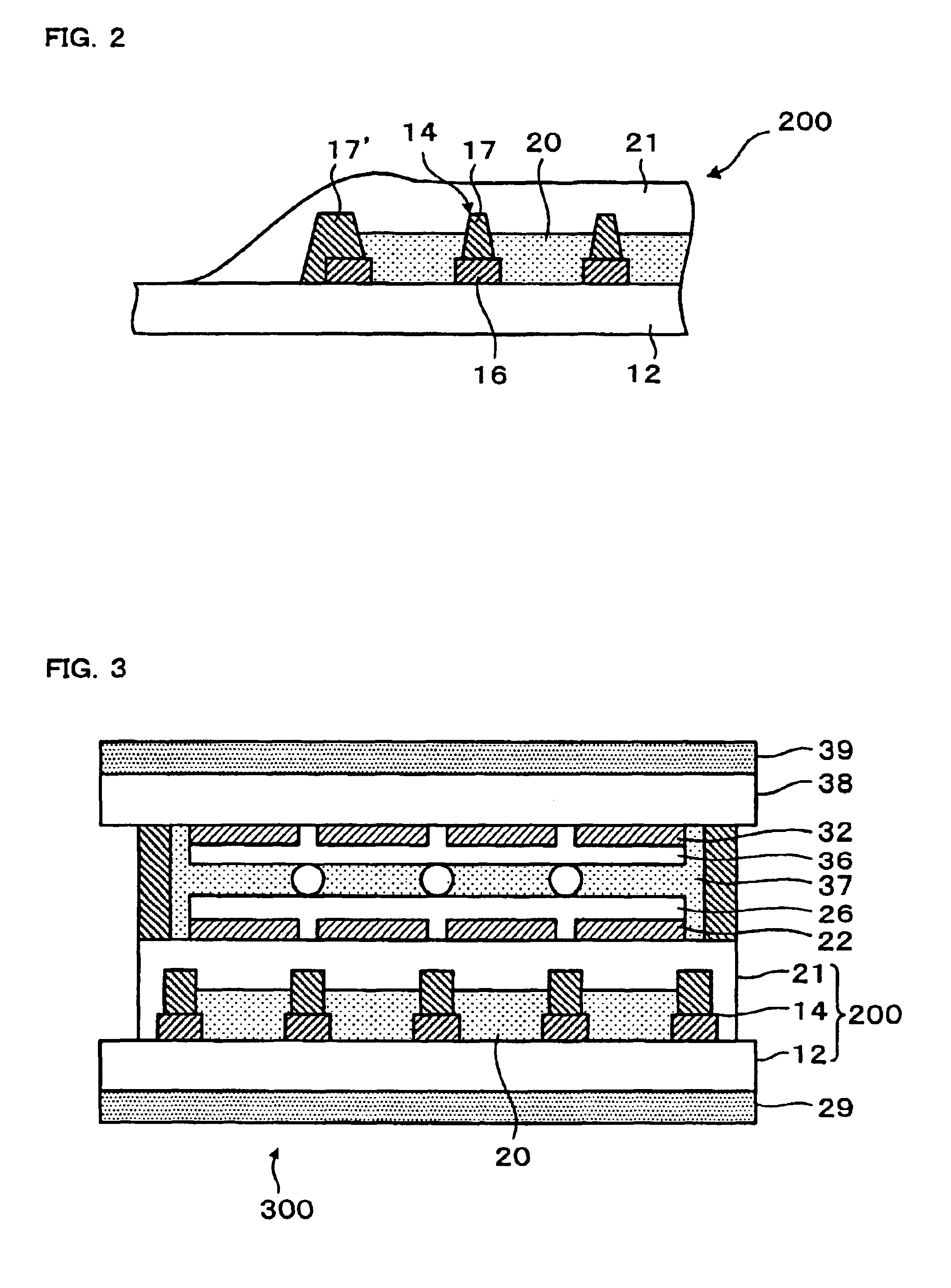

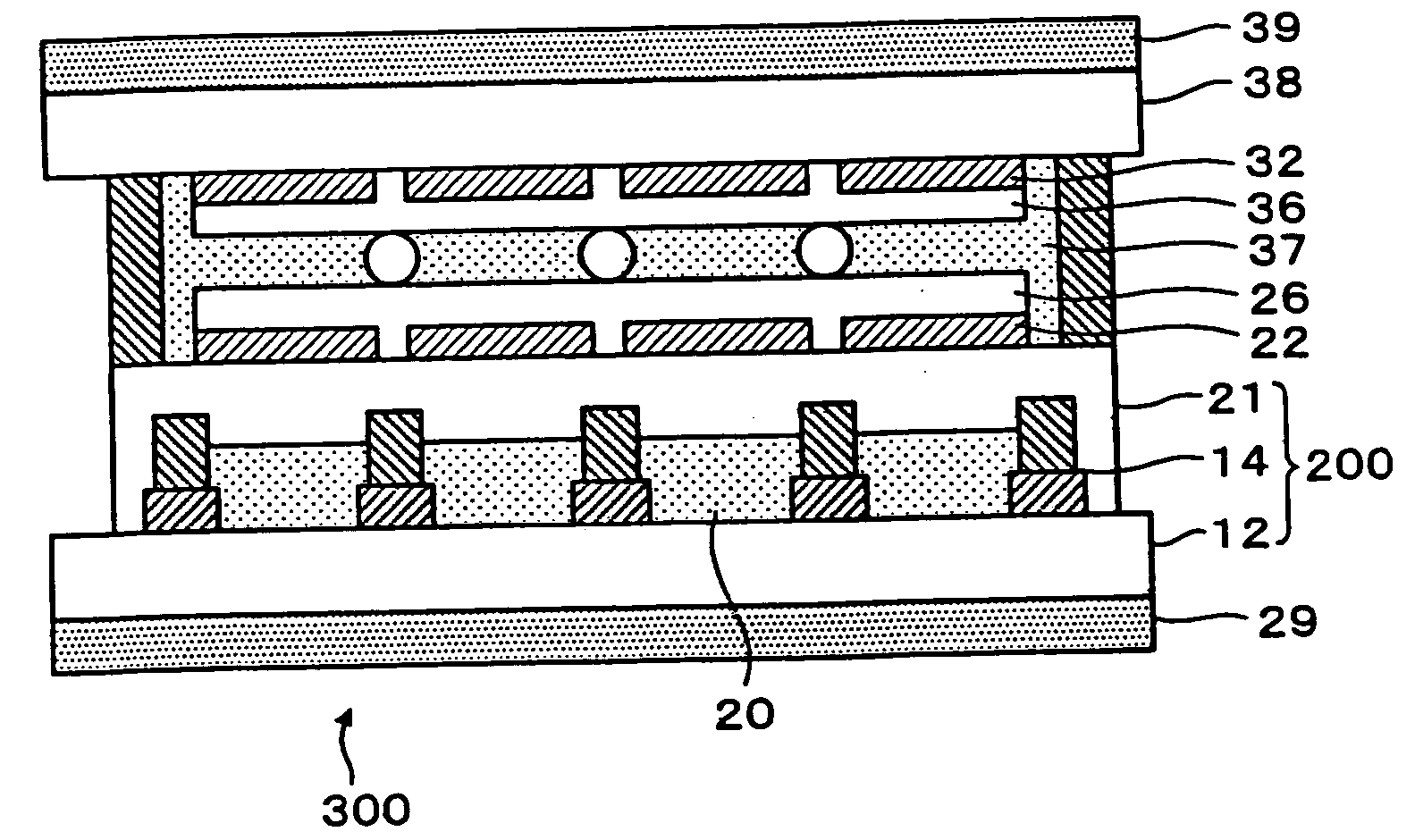

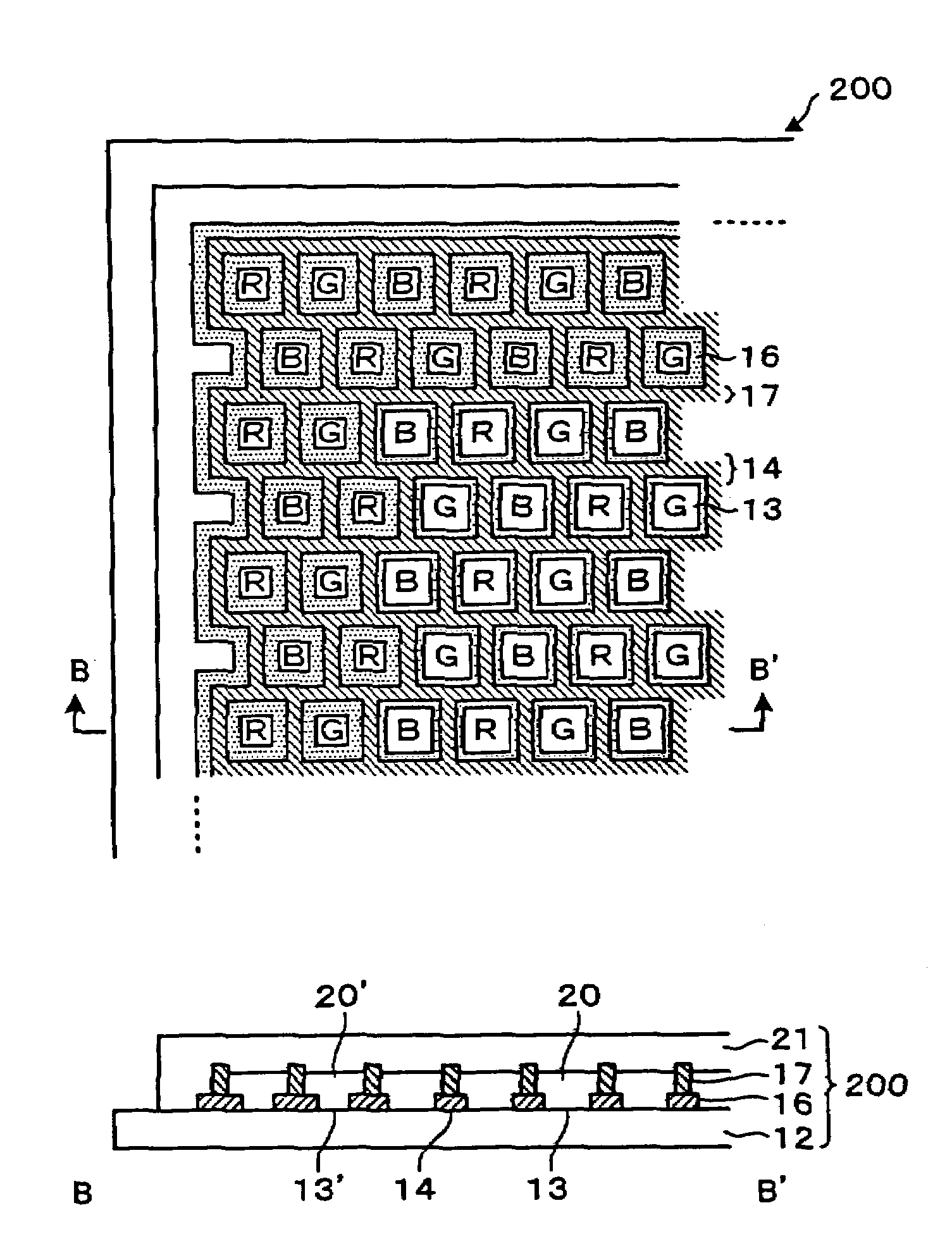

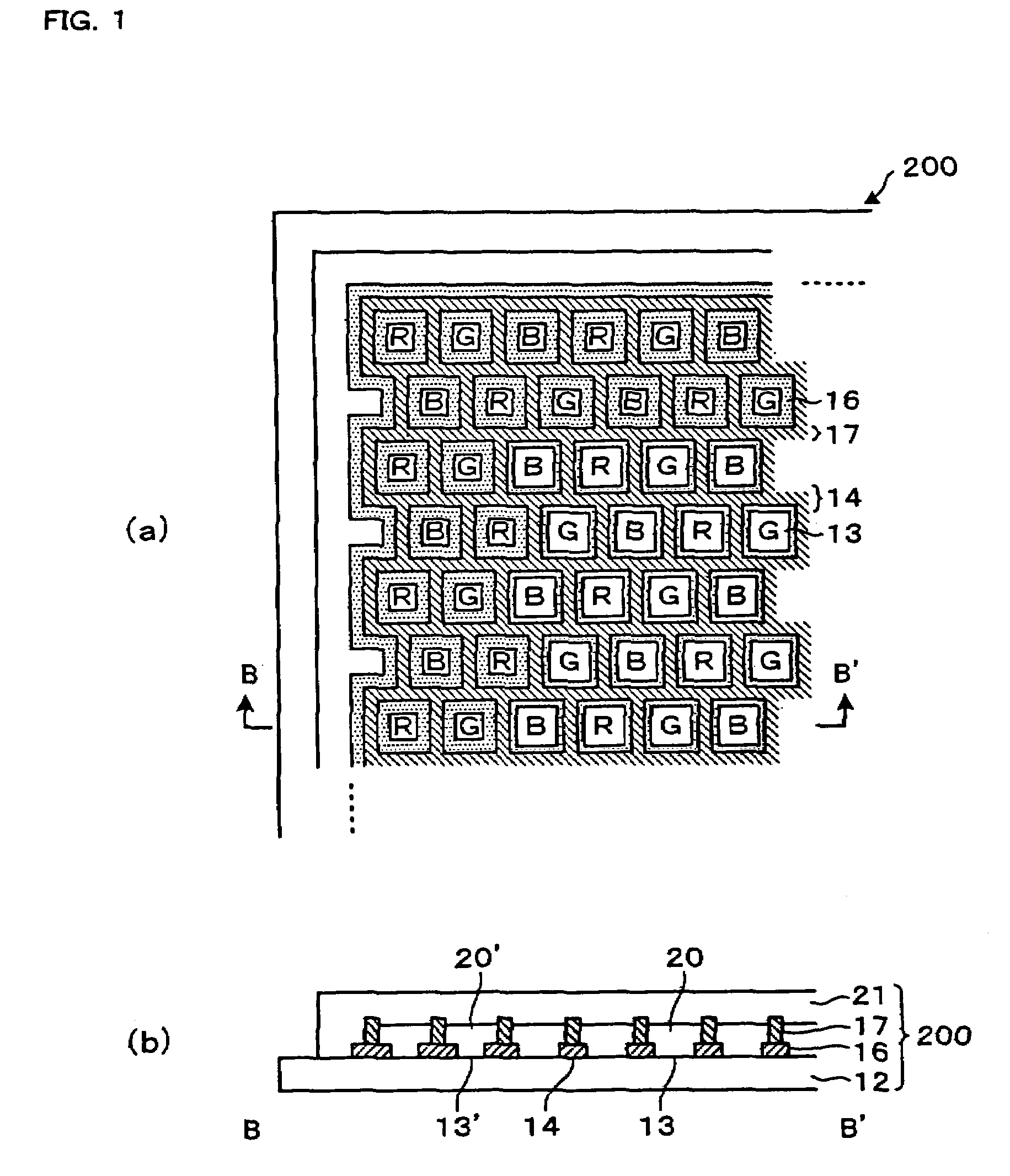

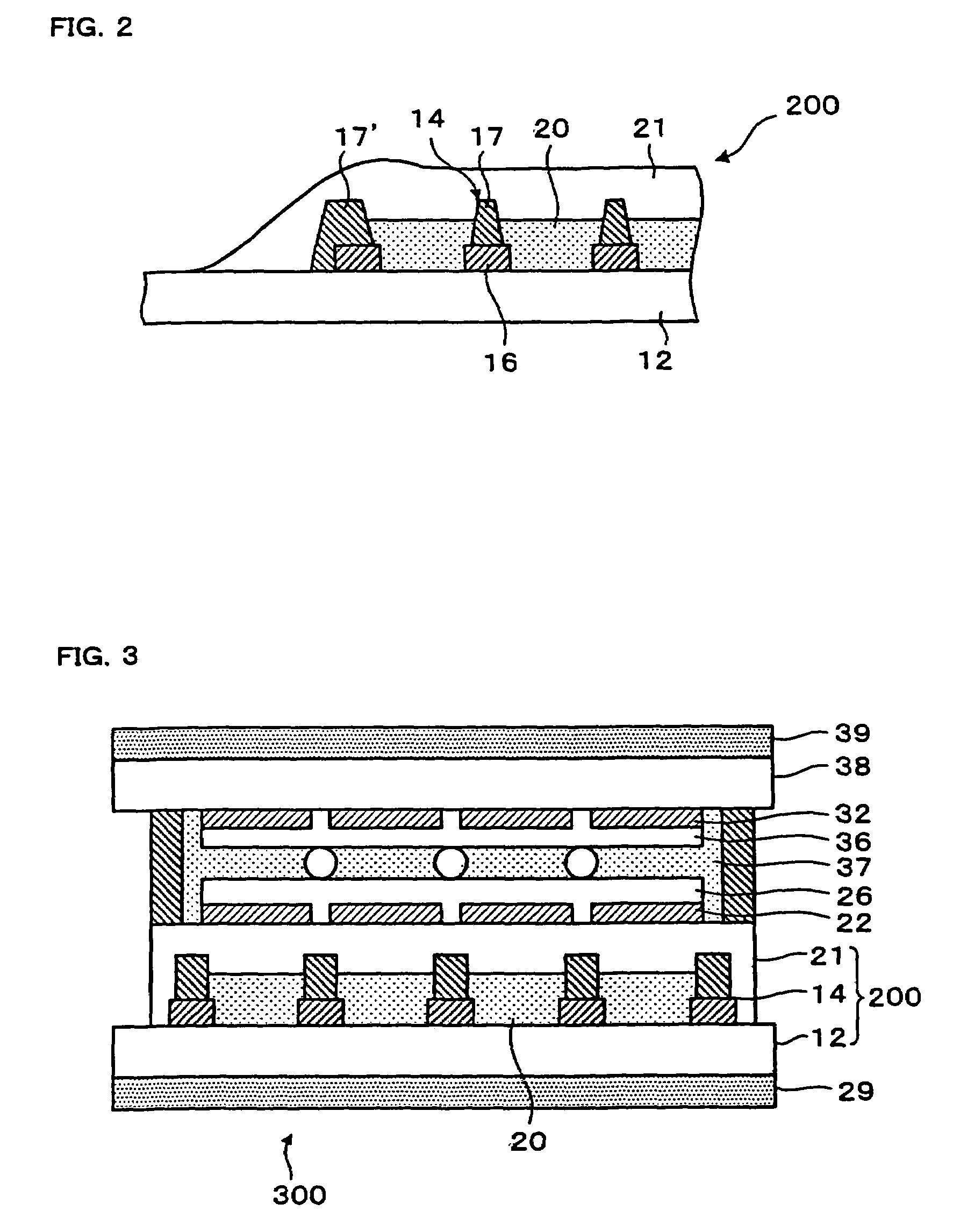

Color filter and electro-optical device

InactiveUS6887631B2Difference in qualityEvenly distributedAddress electrodesSustain/scan electrodesTectorial membraneColor gel

Owner:KATEEVA

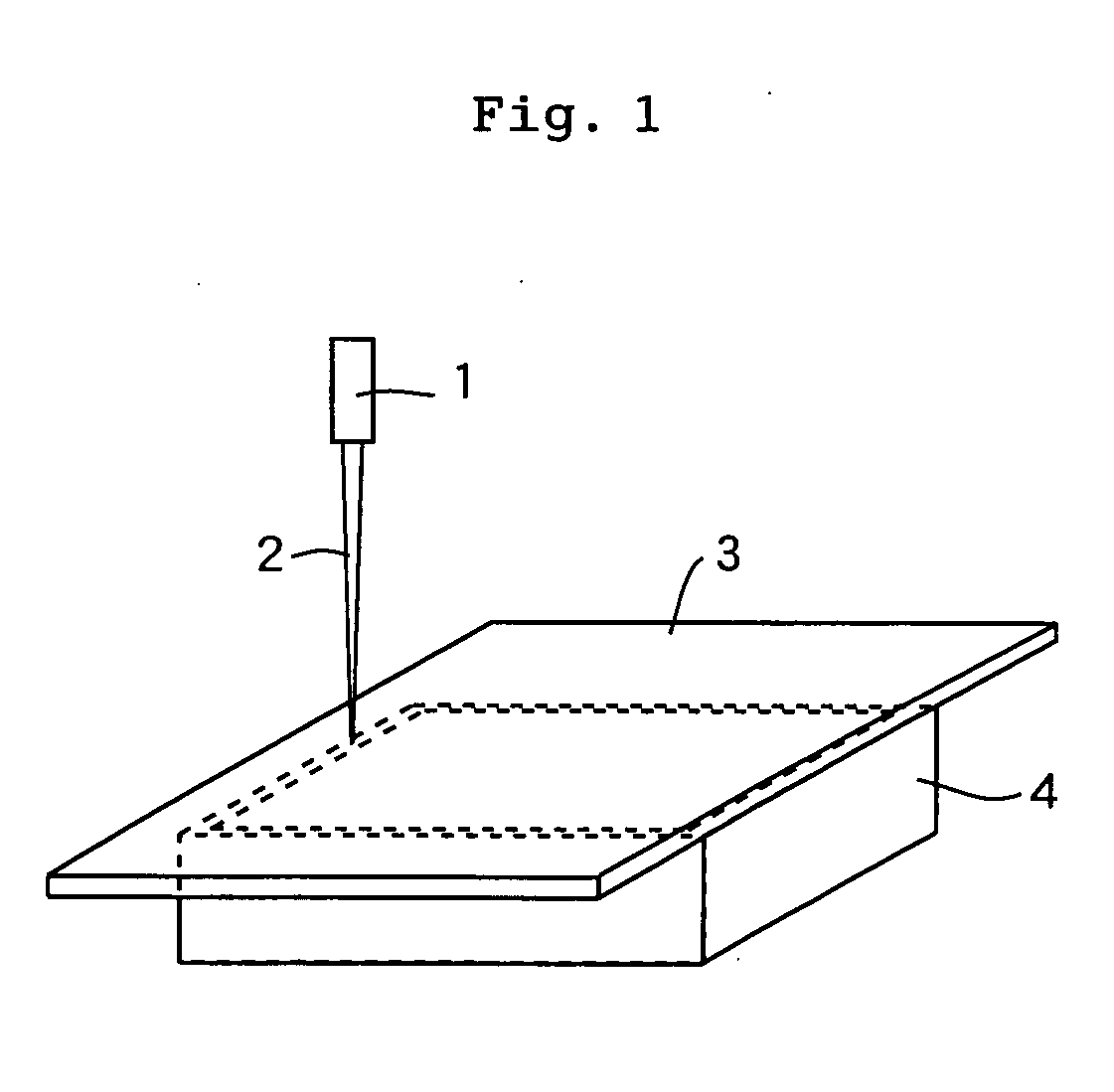

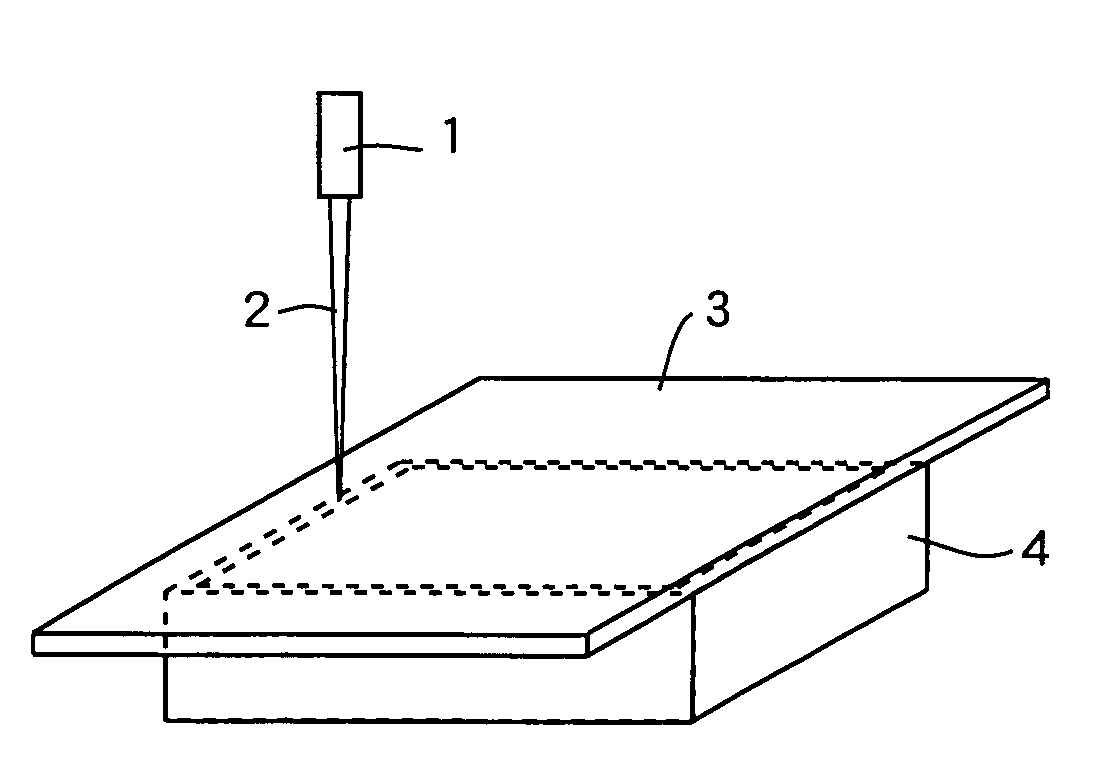

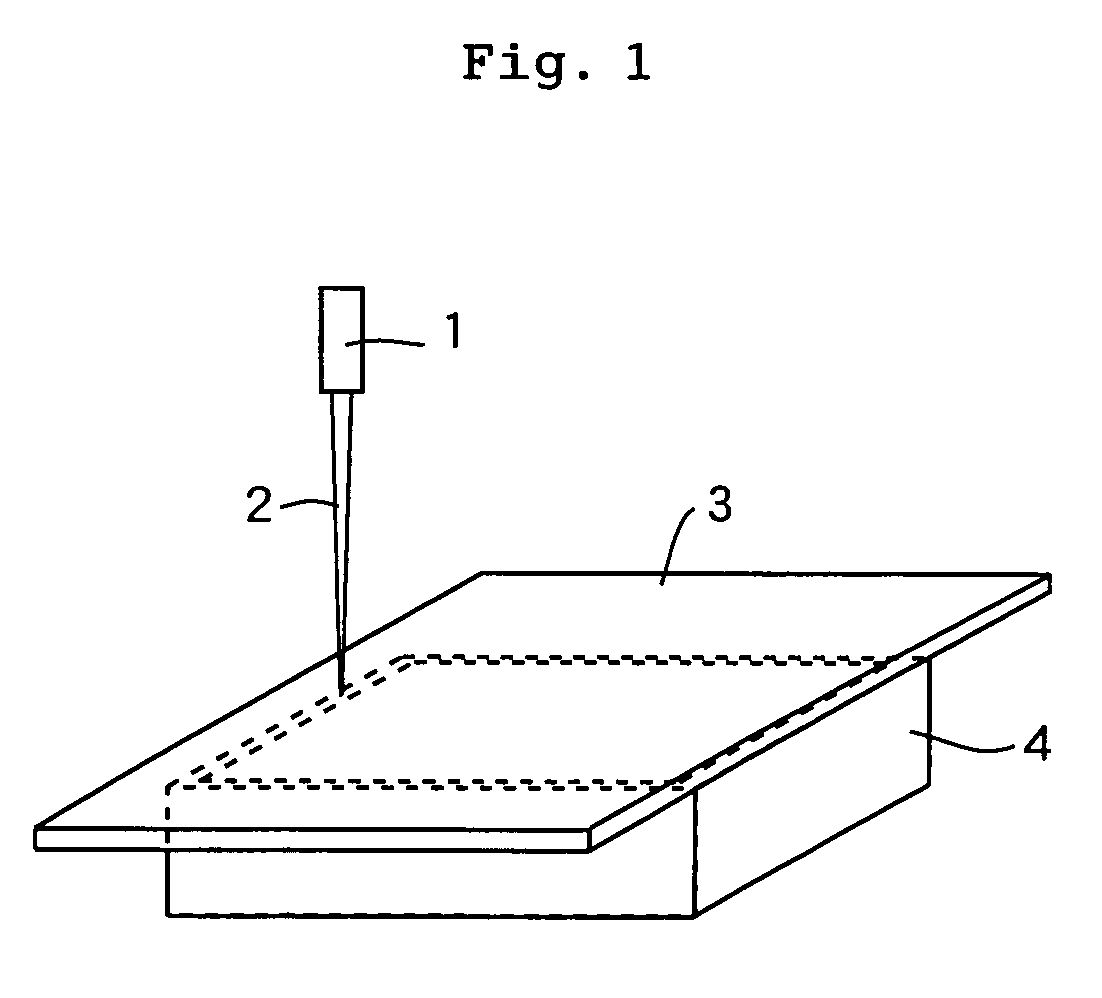

Resin composition for laser welding and molded article

ActiveUS20070129475A1Transmittance be uniformHigh welding strengthLamination ancillary operationsLaminationChemistryPlasticizer

A laser weldable PBT-series resin composition and a molded product thereof are provided, in which the composition is weldable uniformly and has high welding strength even when the composition comprises a polybutylene terephthalate (PBT) as a base. The laser weldable resin composition comprises 1 to 50 parts by weight of (B) an elastomer (such as a polystyrene-series thermoplastic elastomer or a polyester-series thermoplastic elastomer), 5 to 100 parts by weight of (C) a polycarbonate-series resin, 1 to 10 parts by weight of (D) a plasticizer (e.g., an aromatic polycarboxylic acid ester, and an acrylic plasticizer), and 0 to 100 parts by weight of (E) a filler or reinforcing agent (such as a glass fiber), relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin (a homopolyester or a copolyester). The molded product prepared from the resin composition has a small light transmittance fluctuation range depending on sites to be irradiated of the molded product. Thus, the molded product can be bonded to a counter part article uniformly by a laser welding.

Owner:POLYPLASTICS CO LTD

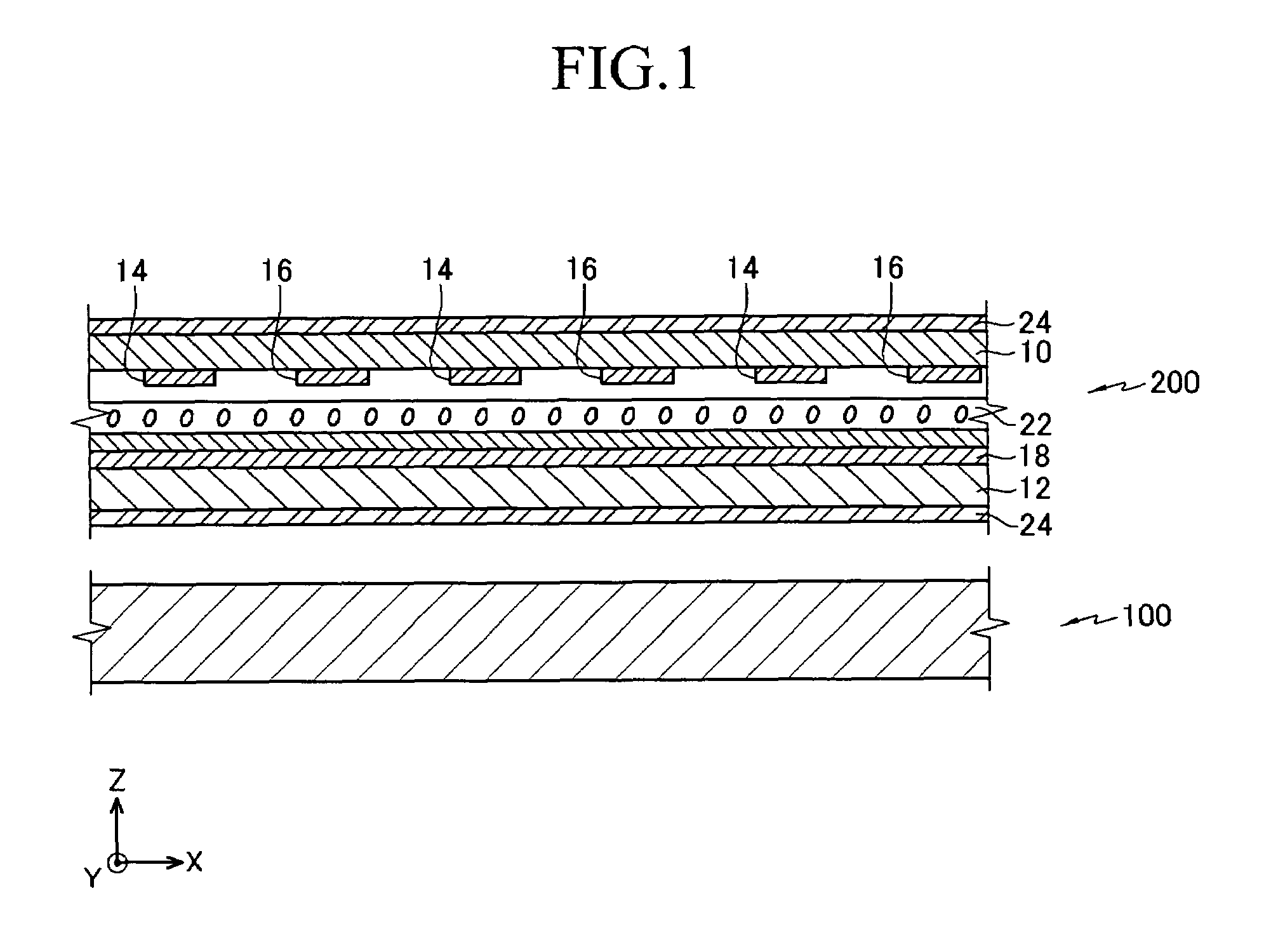

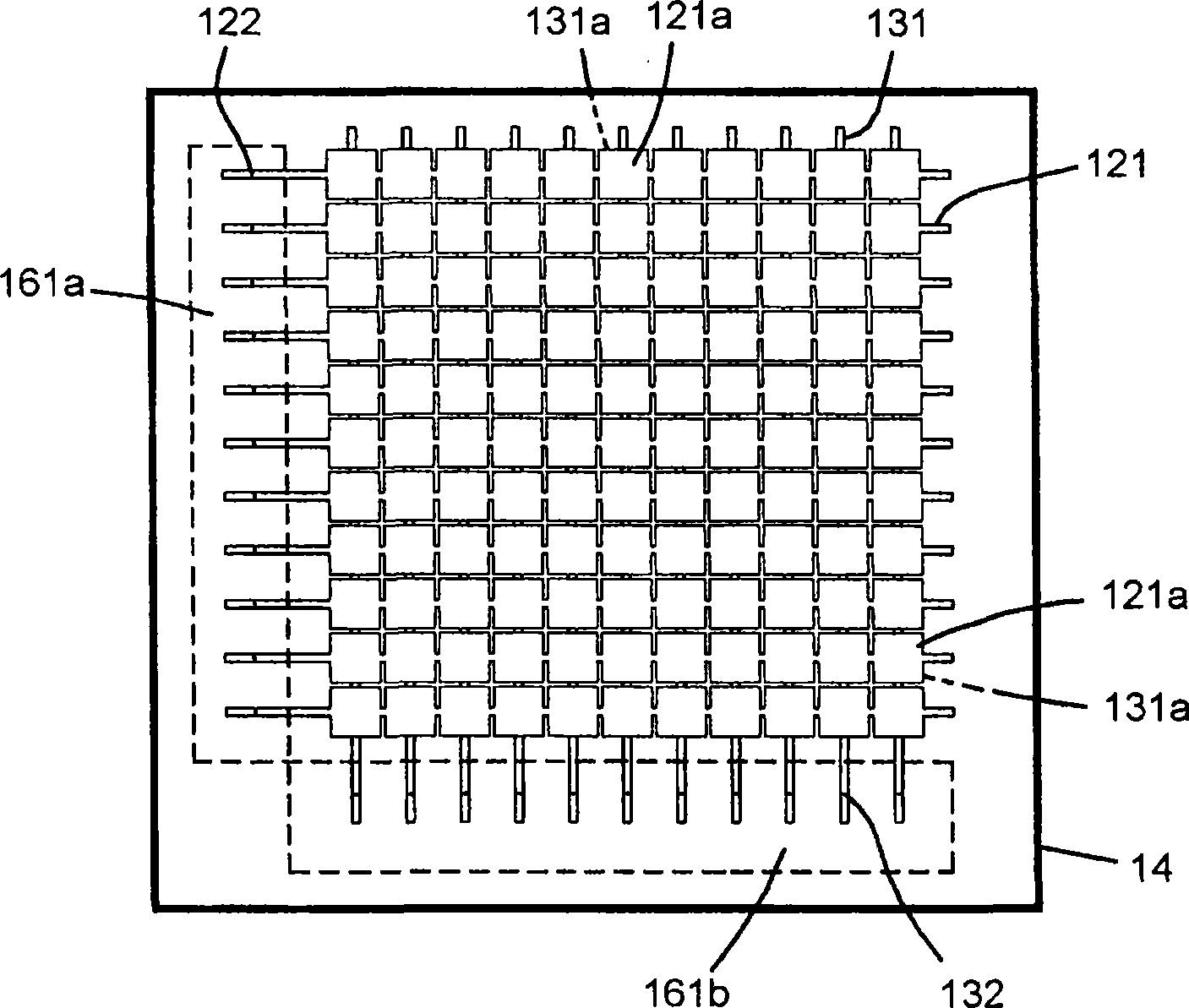

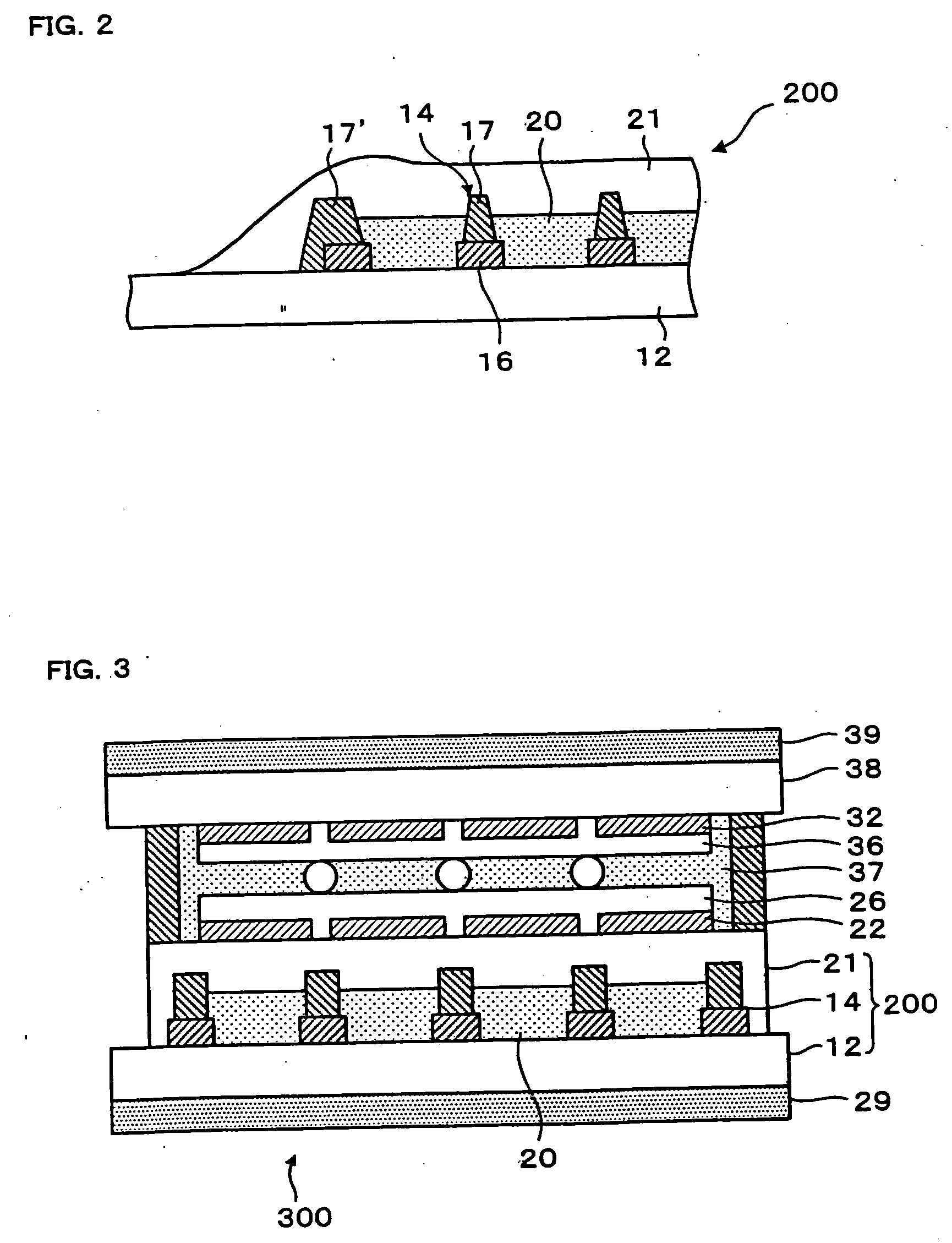

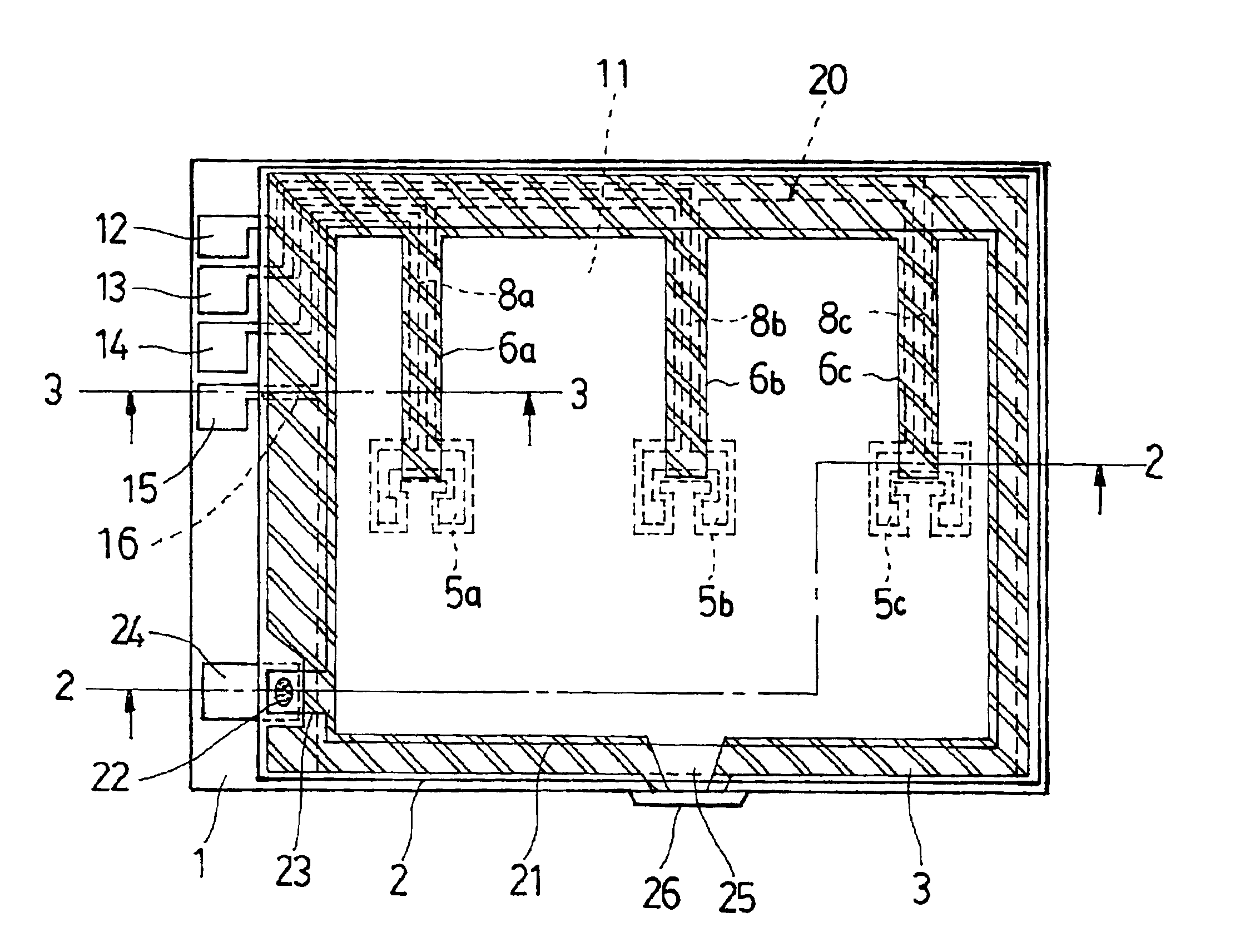

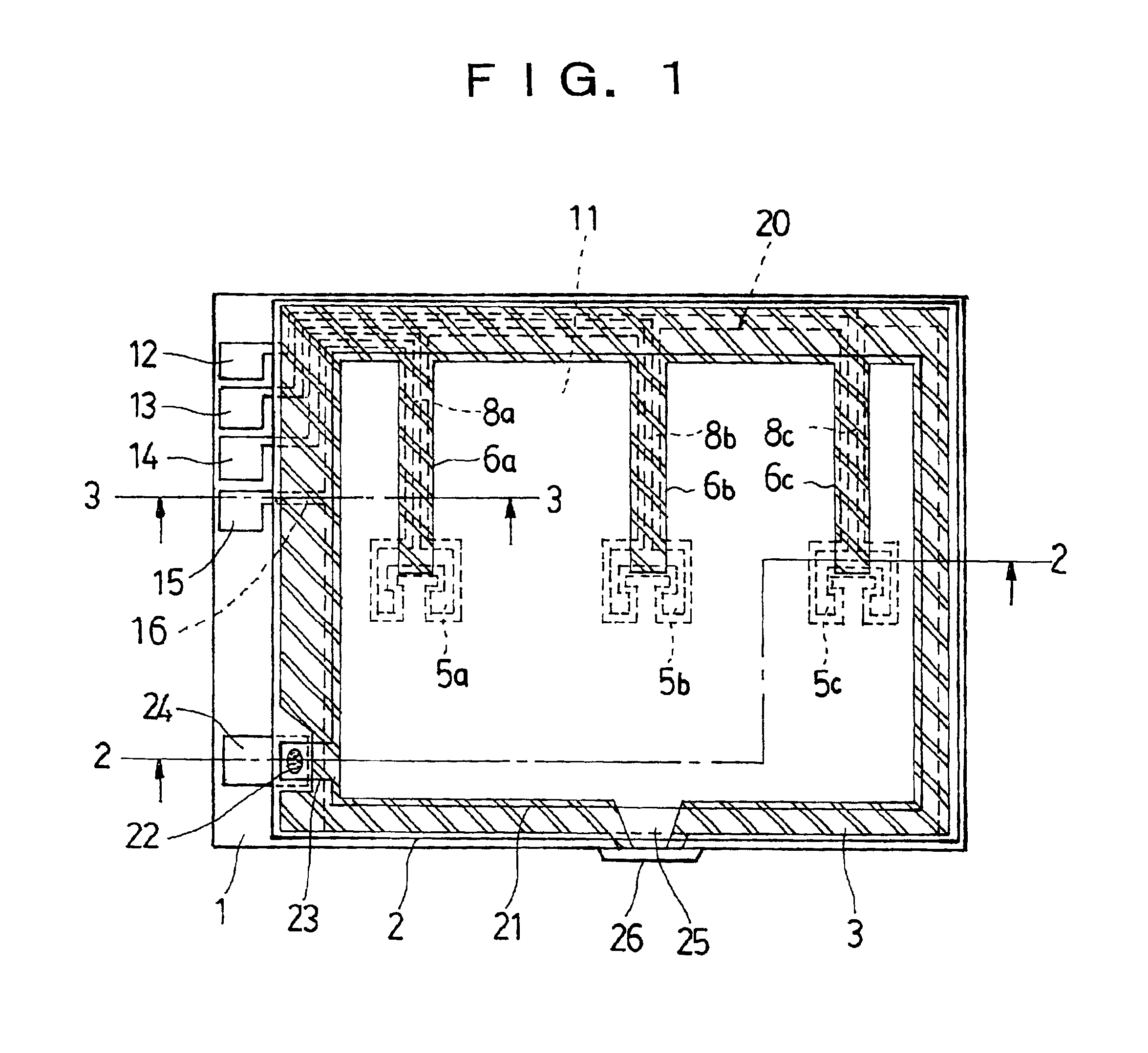

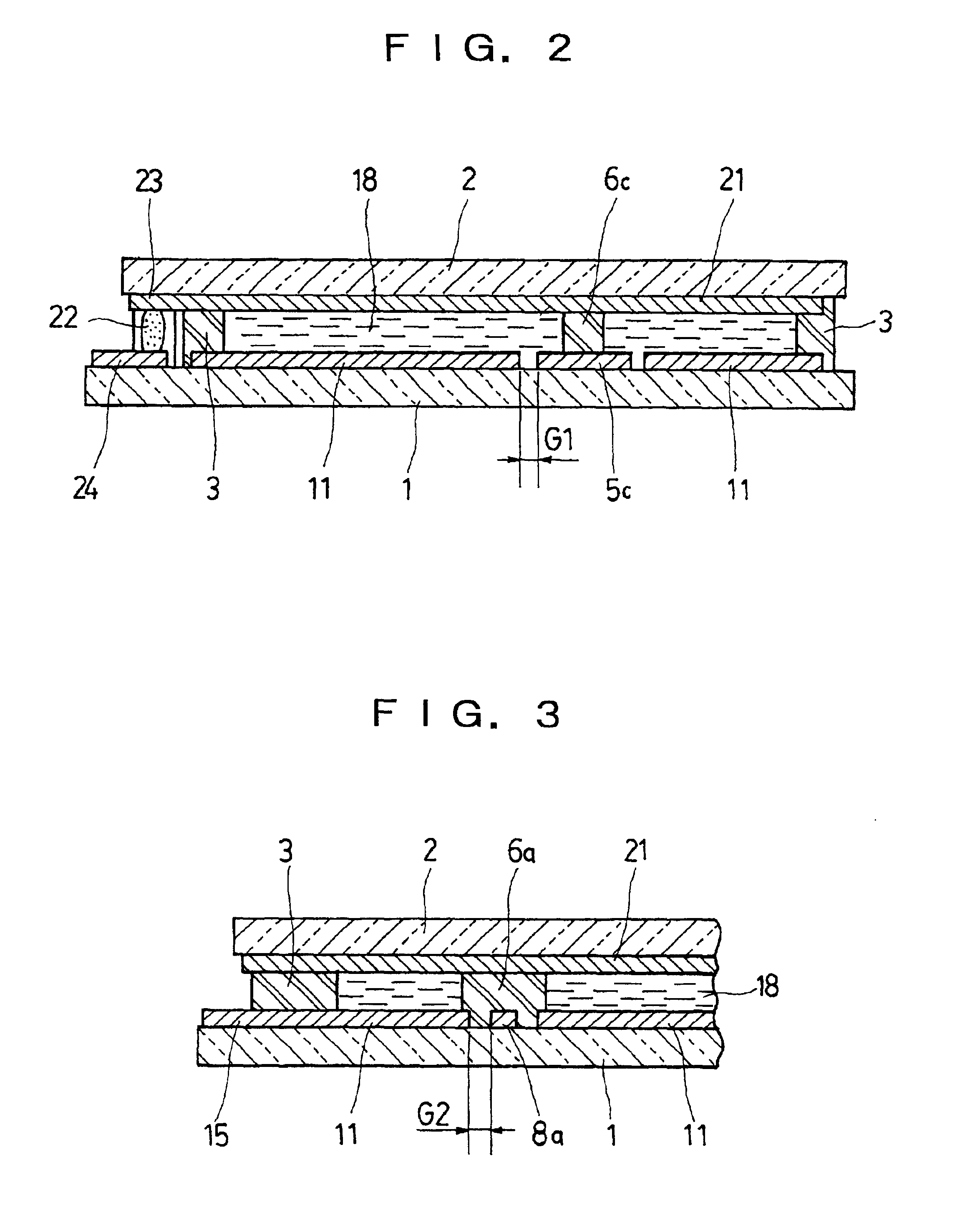

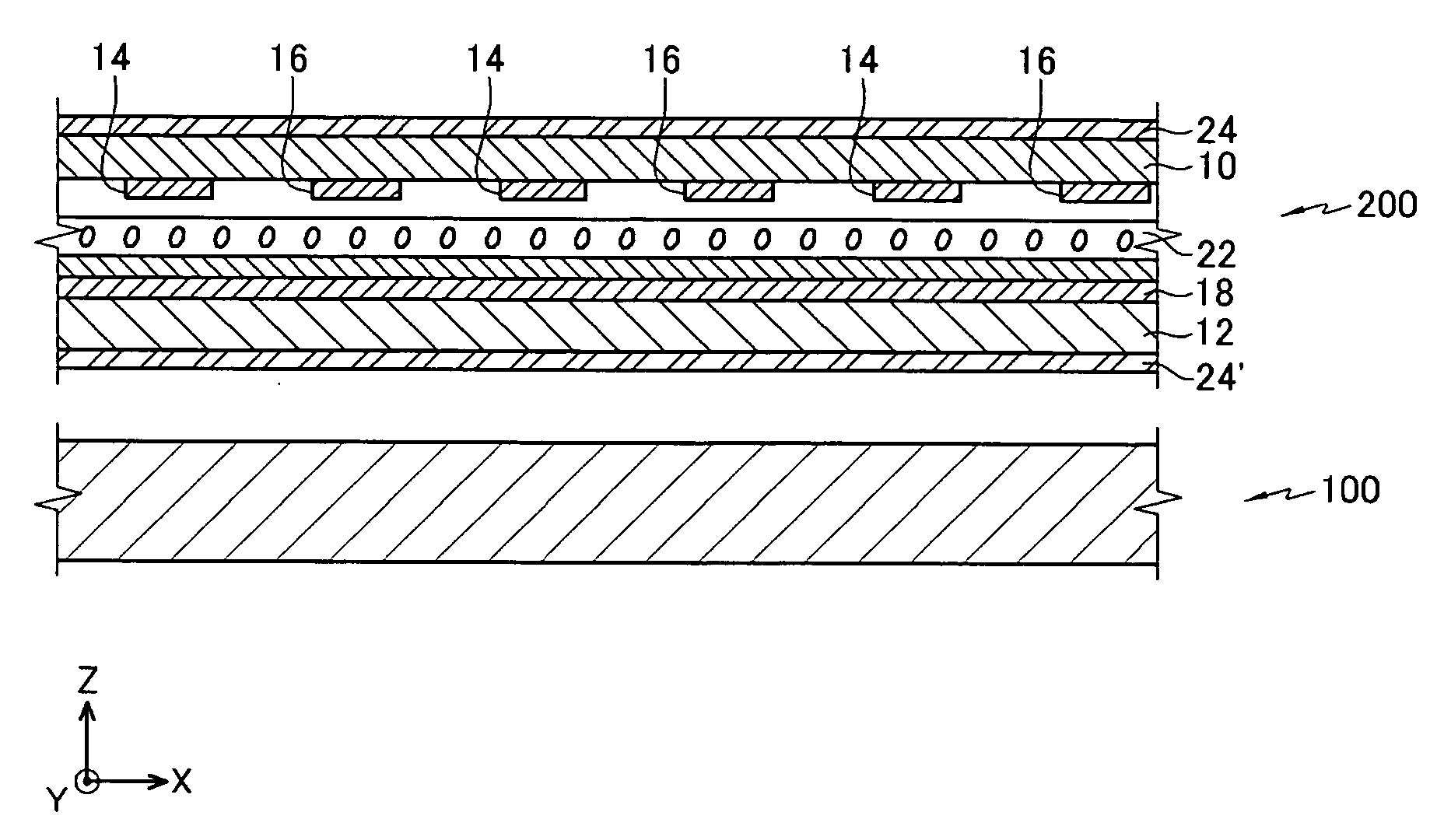

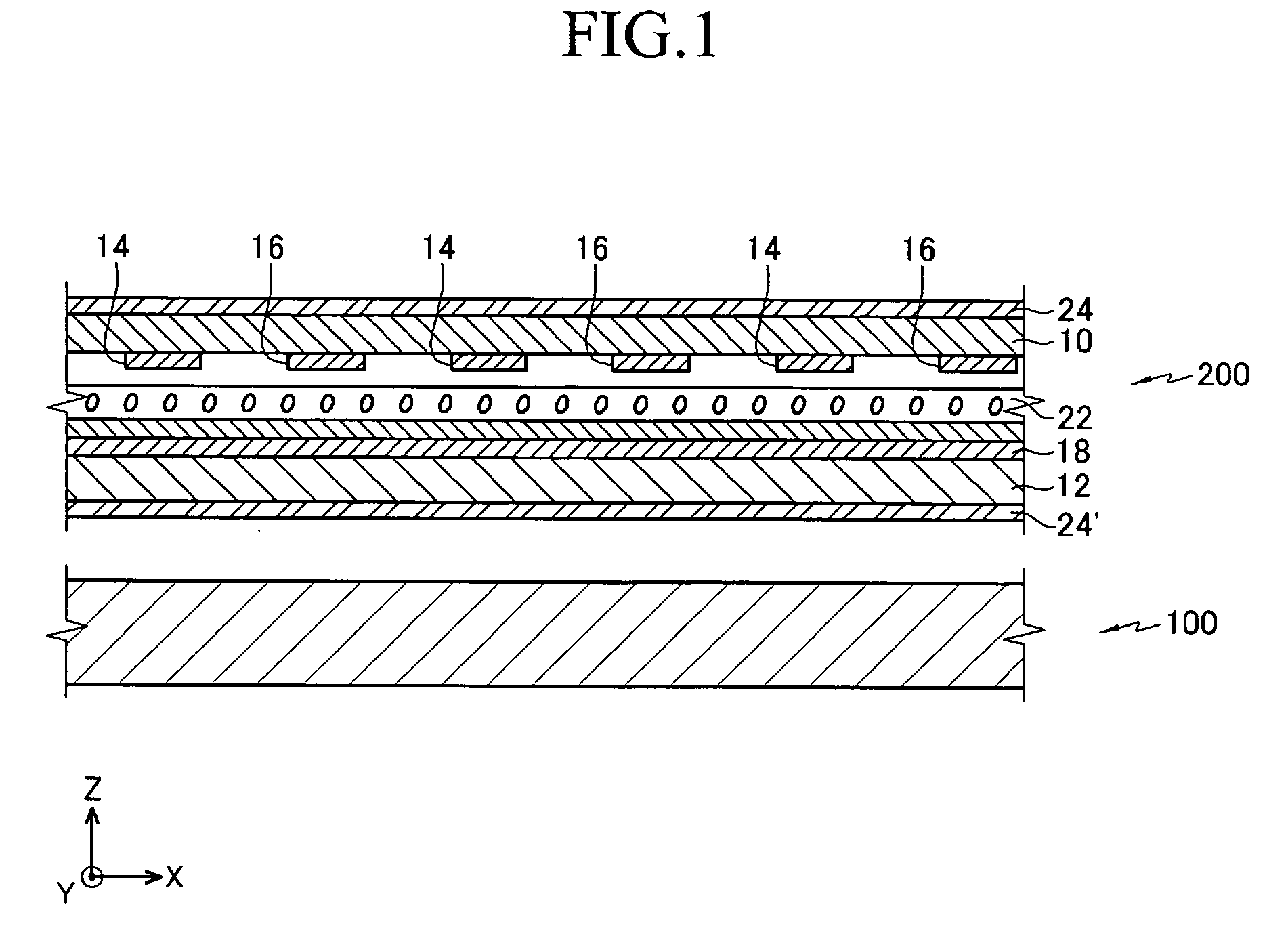

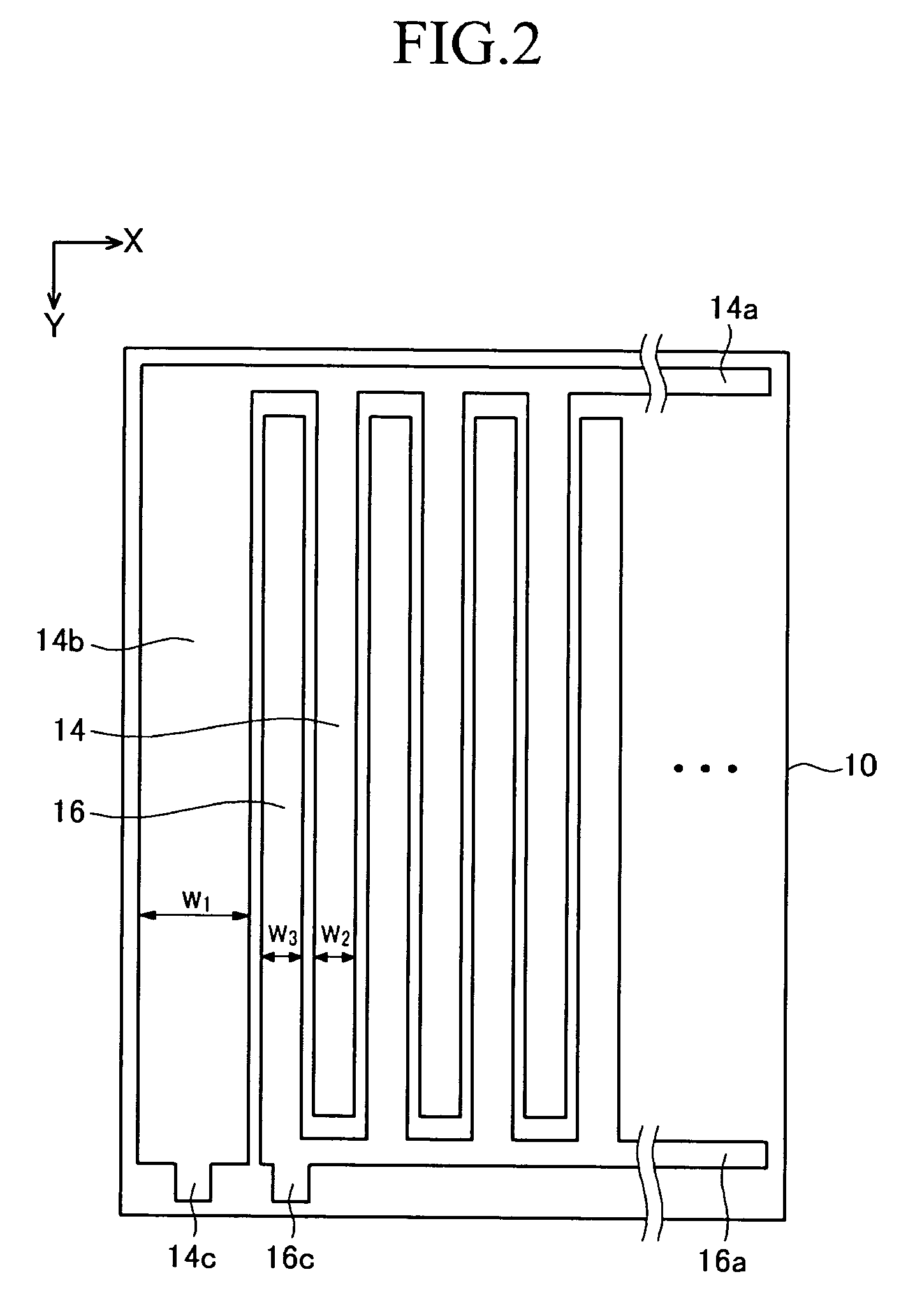

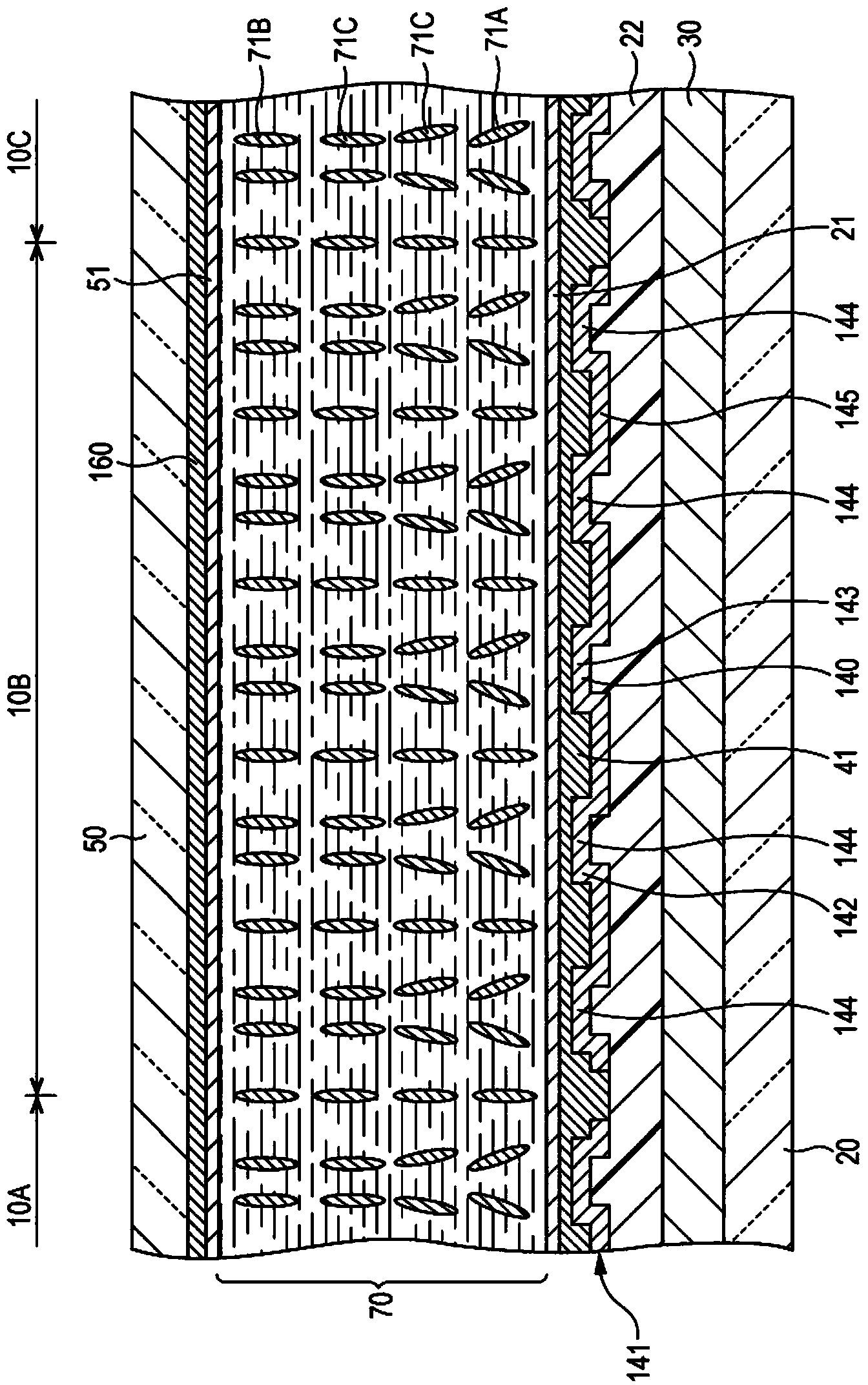

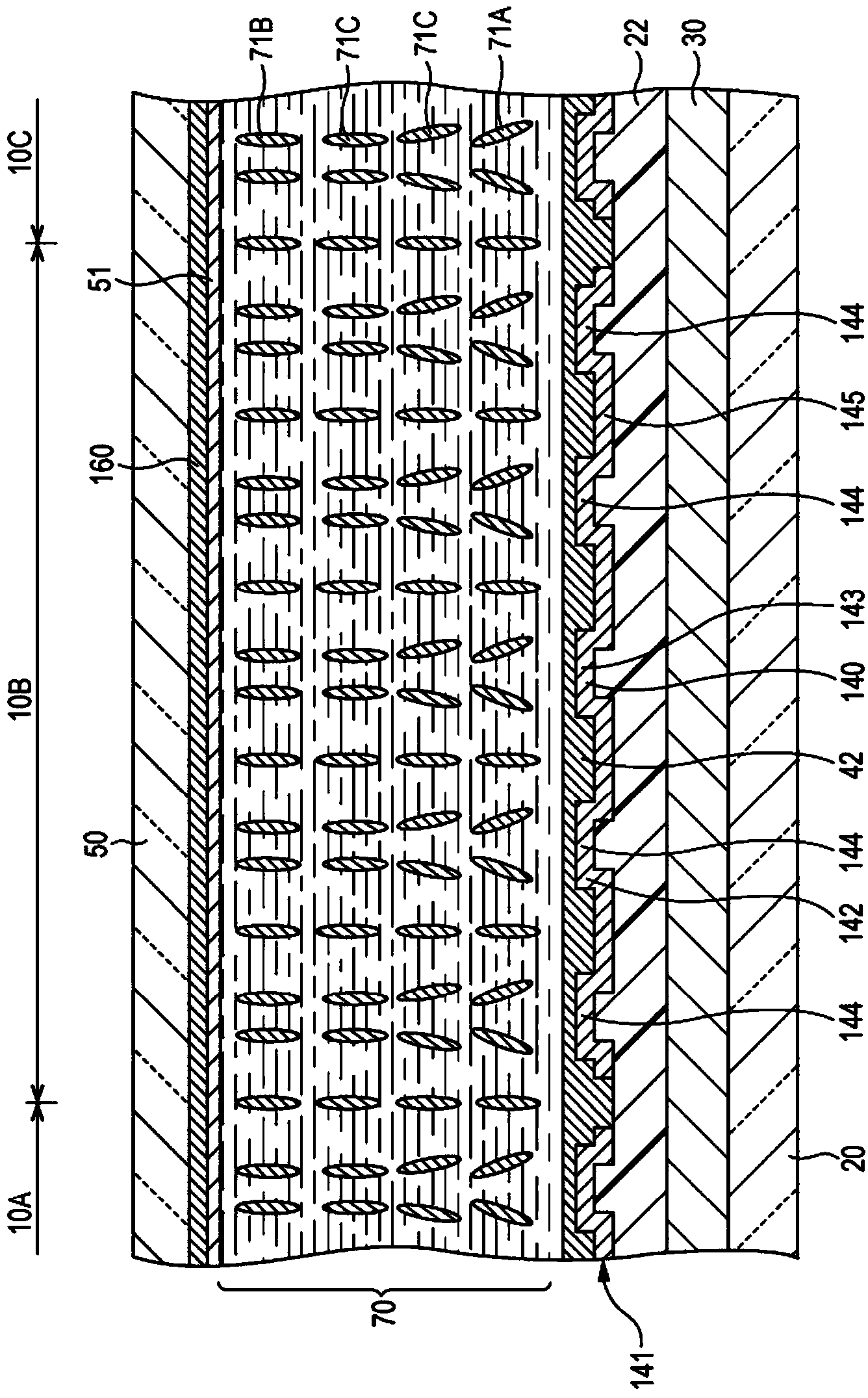

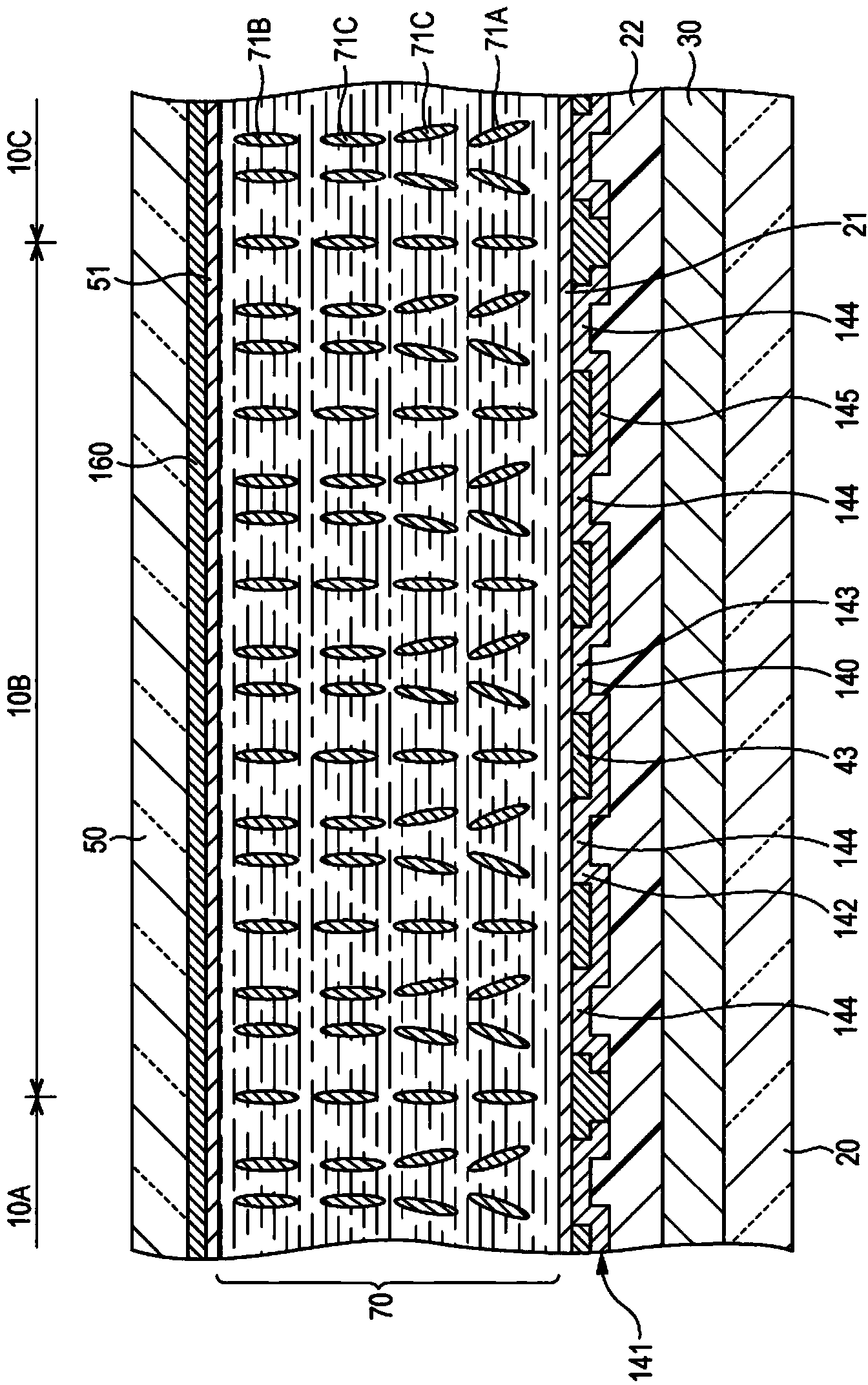

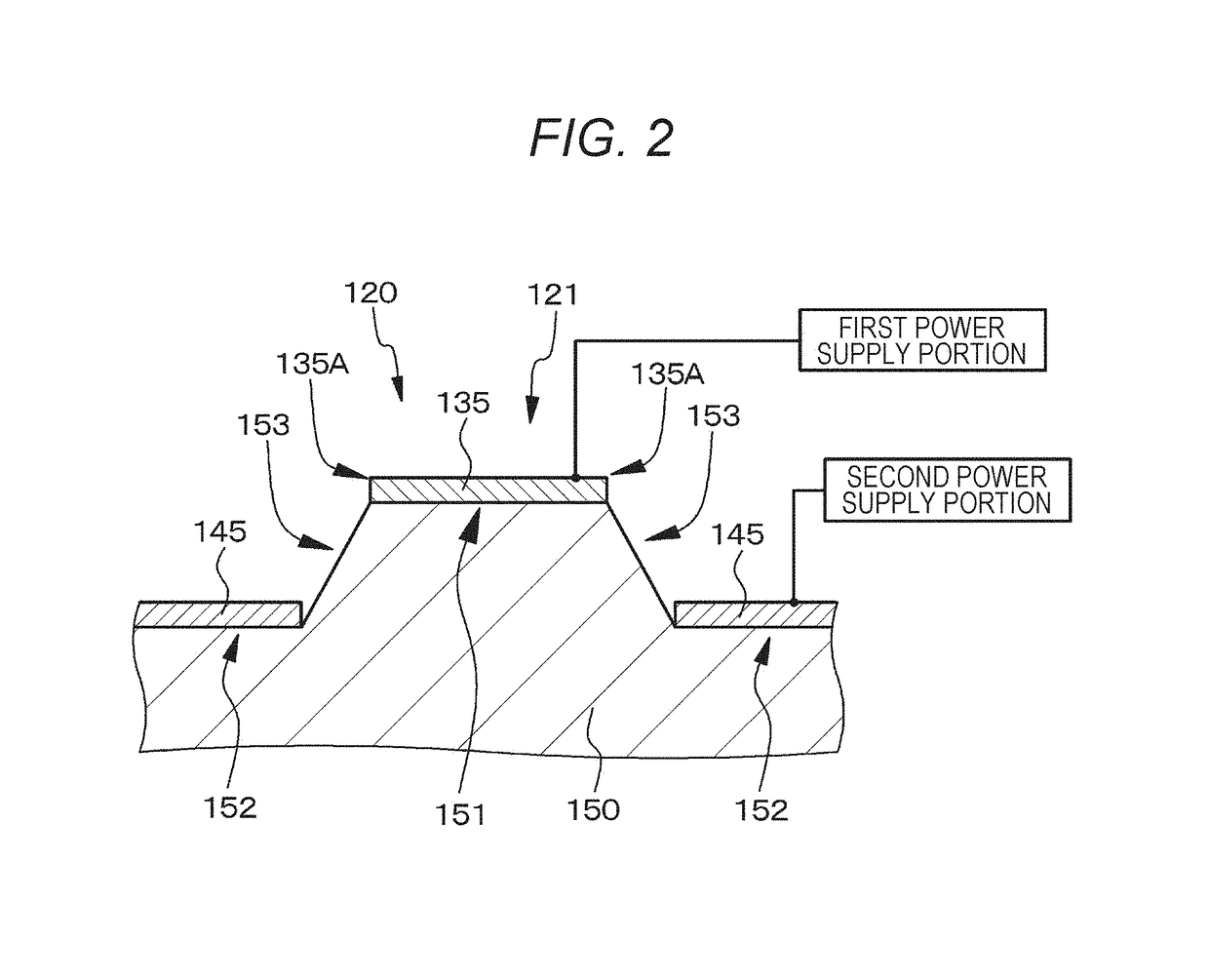

Three-dimensional display device

InactiveUS7511774B2Uniform light transmittanceLower Level RequirementsStatic indicating devicesStereoscopic photographyElectricityParallax barrier

A three-dimensional display device includes an image display portion displaying left and right eye images, and a parallax barrier directing the left and right eye images respectively towards left and right eyes of a user.The parallax barrier includes first electrodes located on a first substrate, a first connection electrode electrically connecting the first electrodes, a first terminal electrode connected to an end of the first connection electrode, a first connection terminal connected to the first terminal electrode, second electrodes located between the first electrodes, a second connection electrode electrically connecting the second electrodes, a second connection terminal connected to an end of the second connection electrode, a common electrode located on a second substrate facing the first substrate, and a liquid crystal layer disposed between the first and second substrates.The first terminal electrode has a lower electric resistance than the first electrodes and the second electrodes.

Owner:SAMSUNG DISPLAY CO LTD

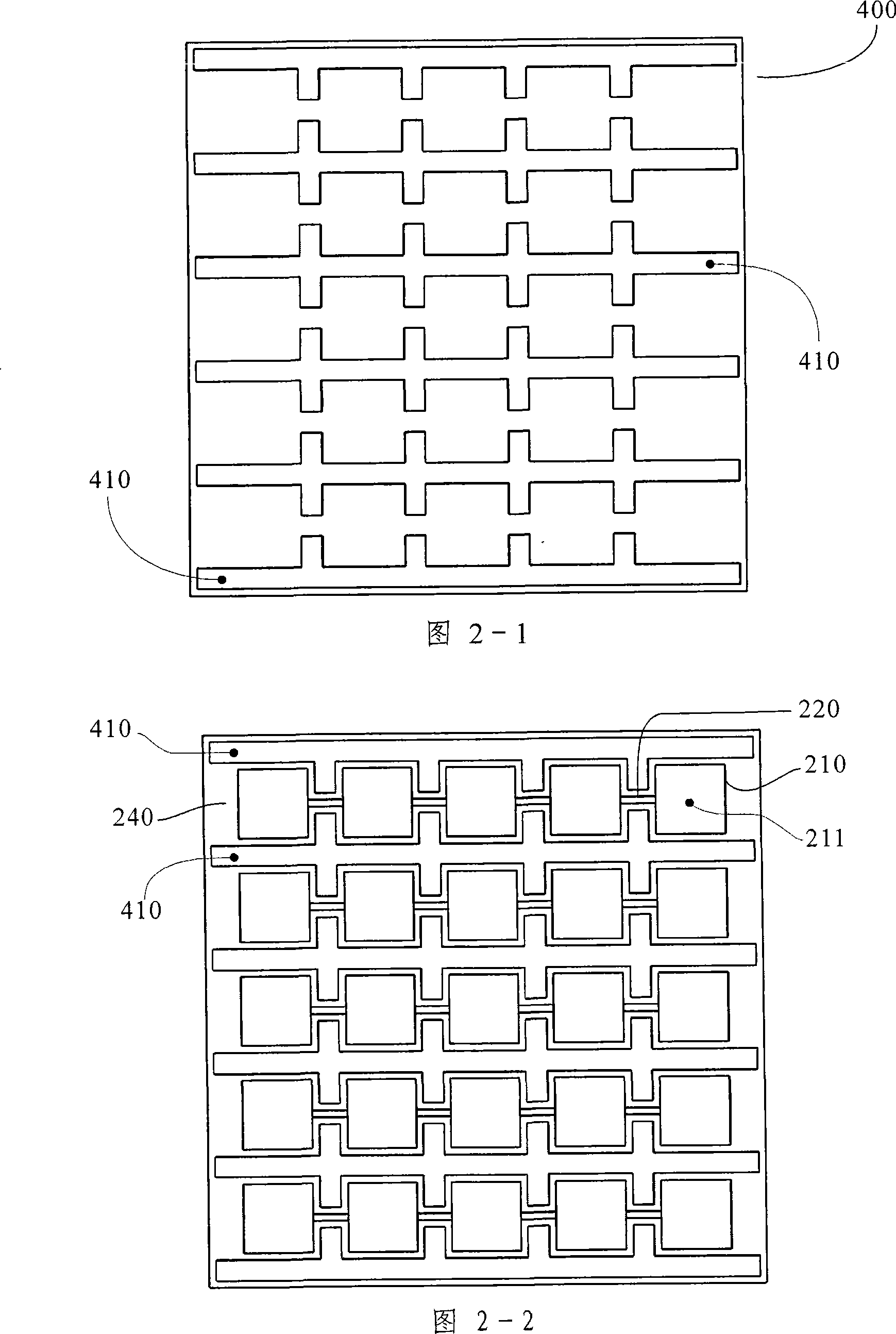

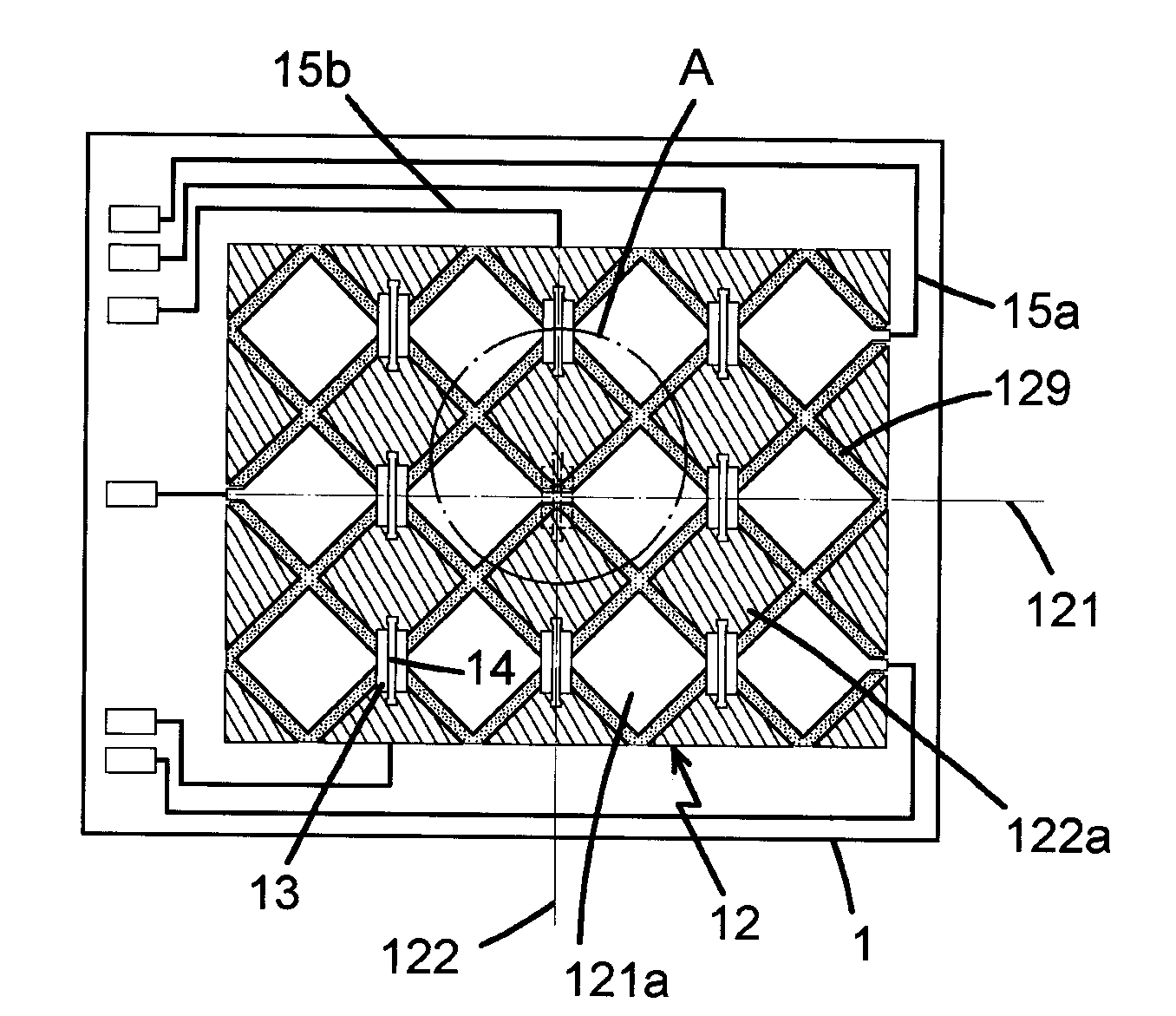

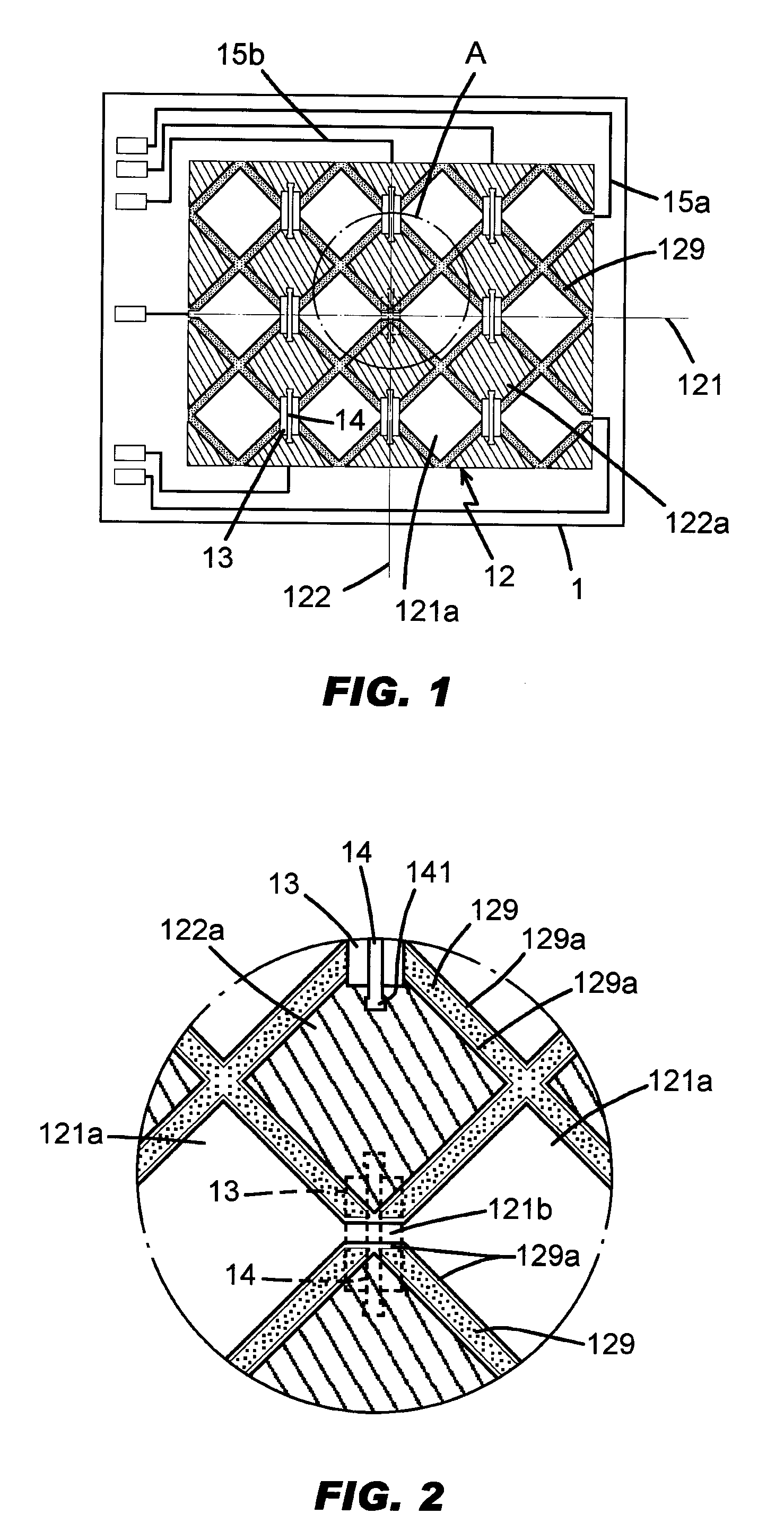

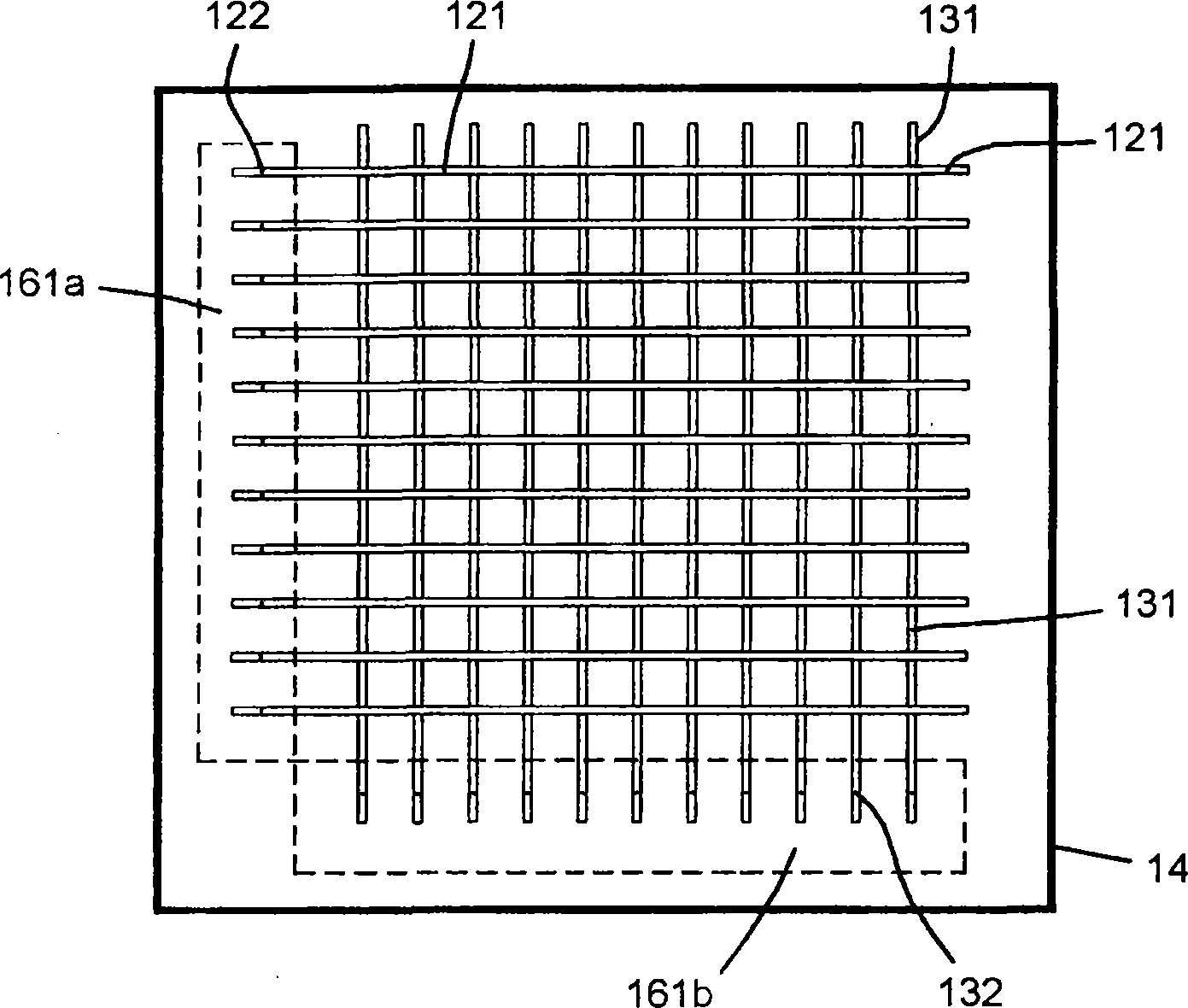

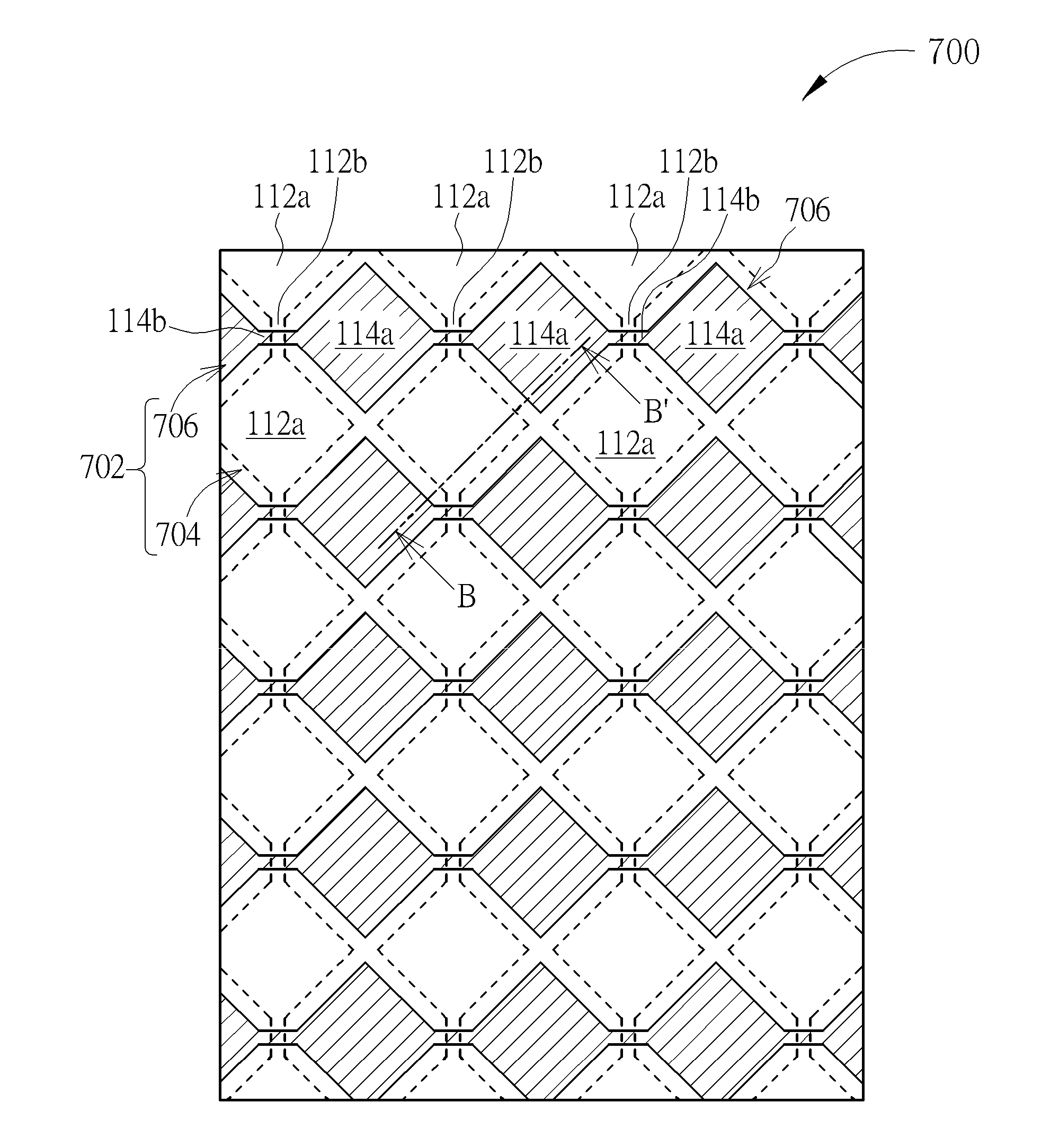

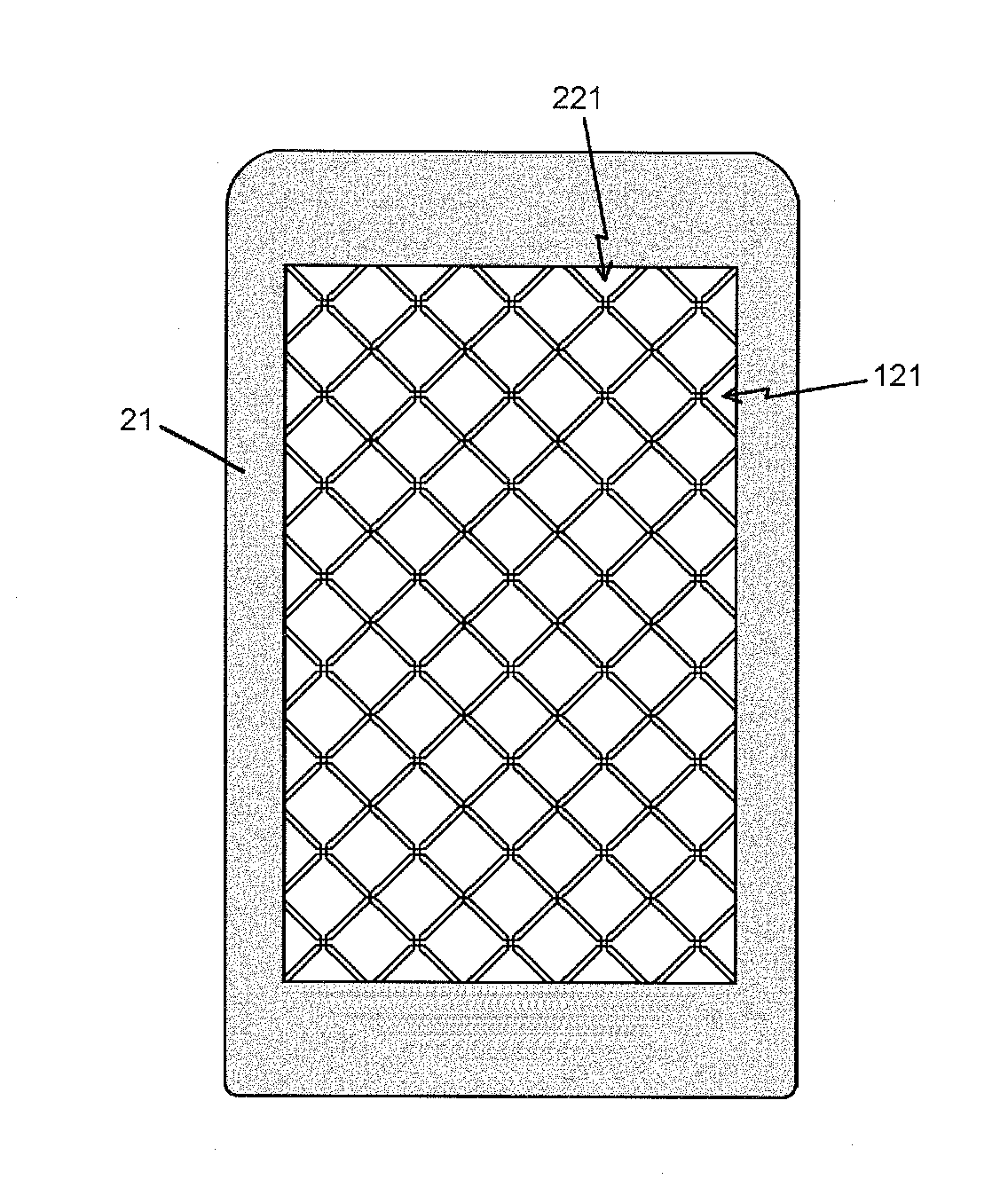

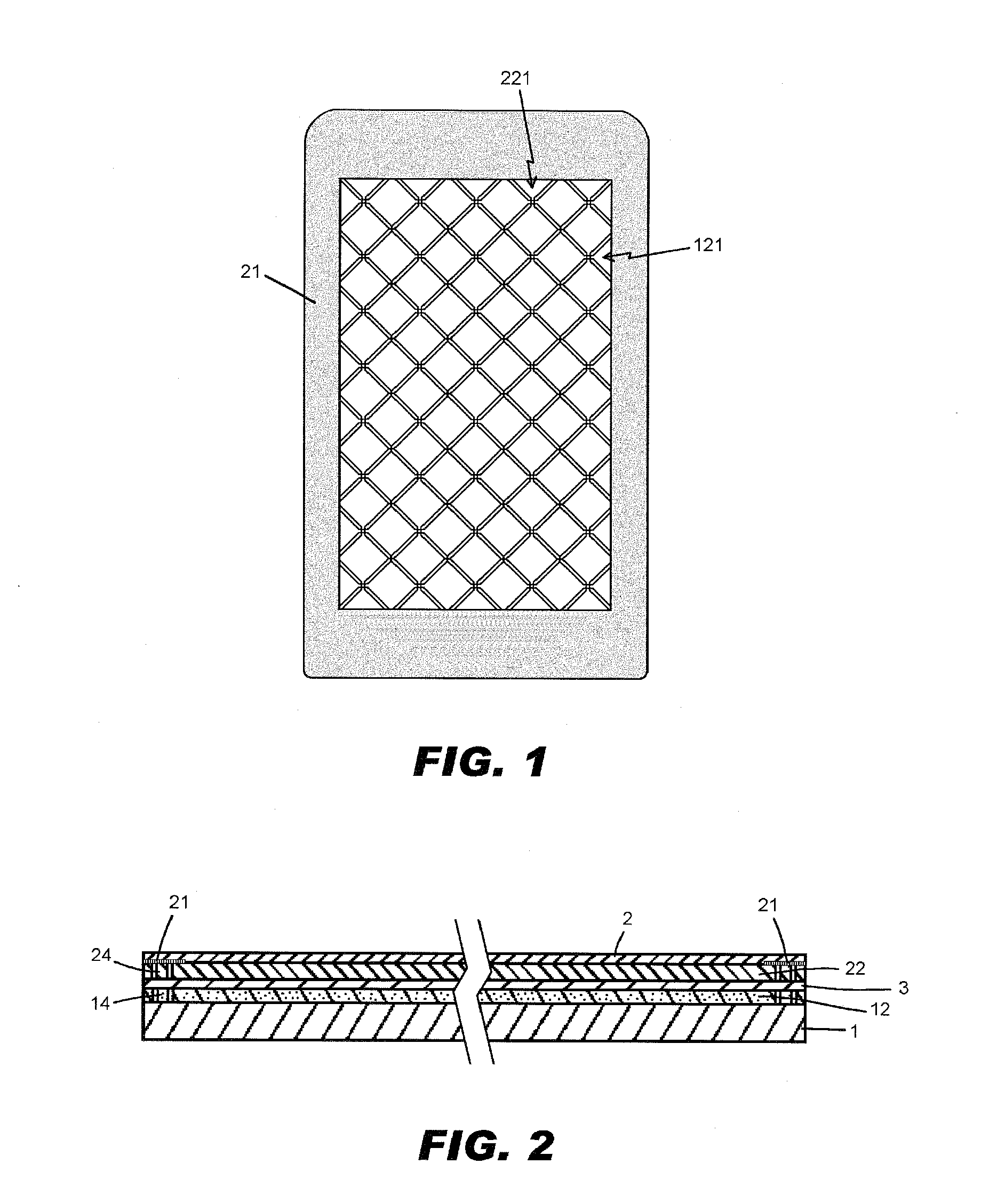

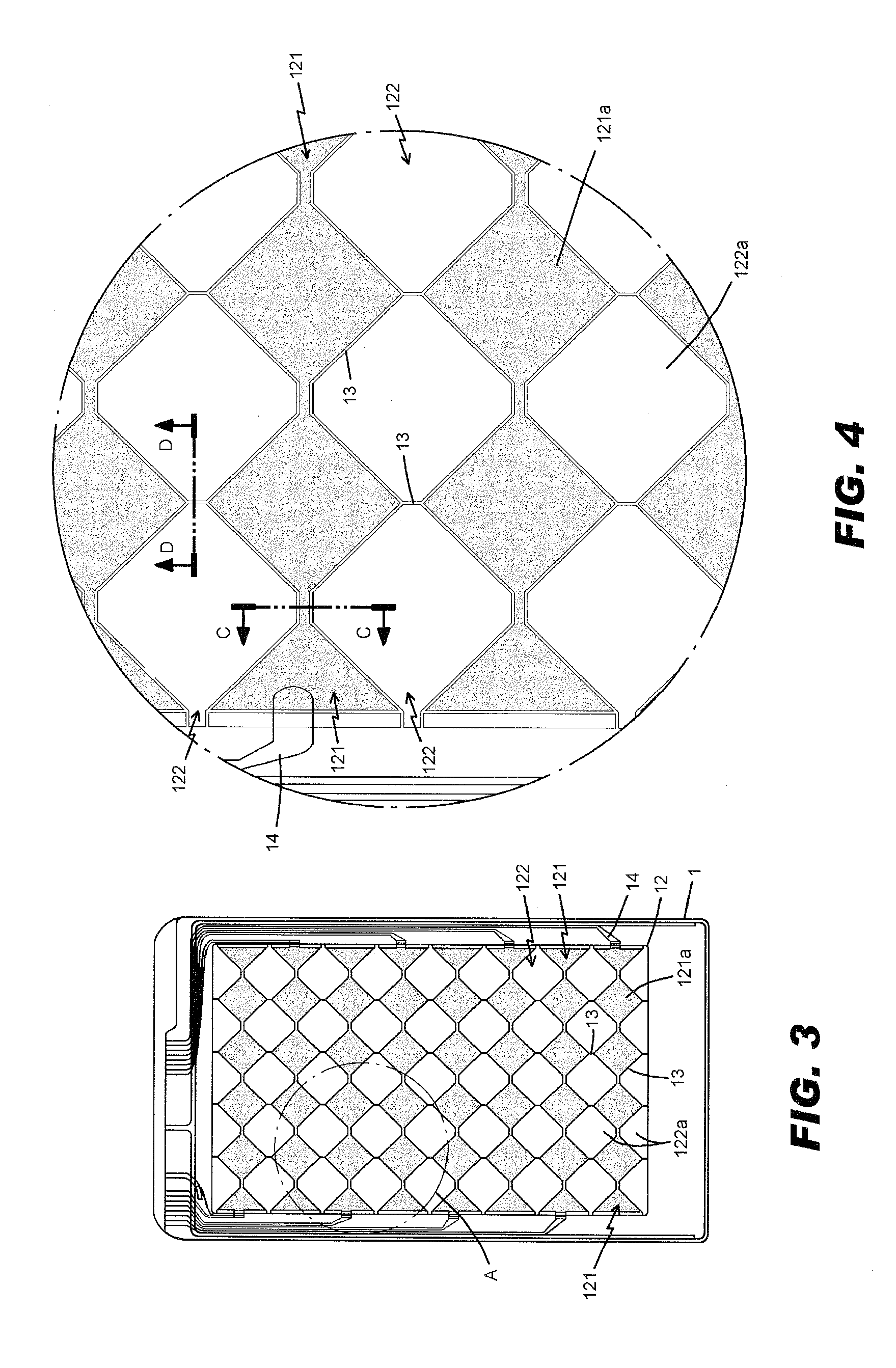

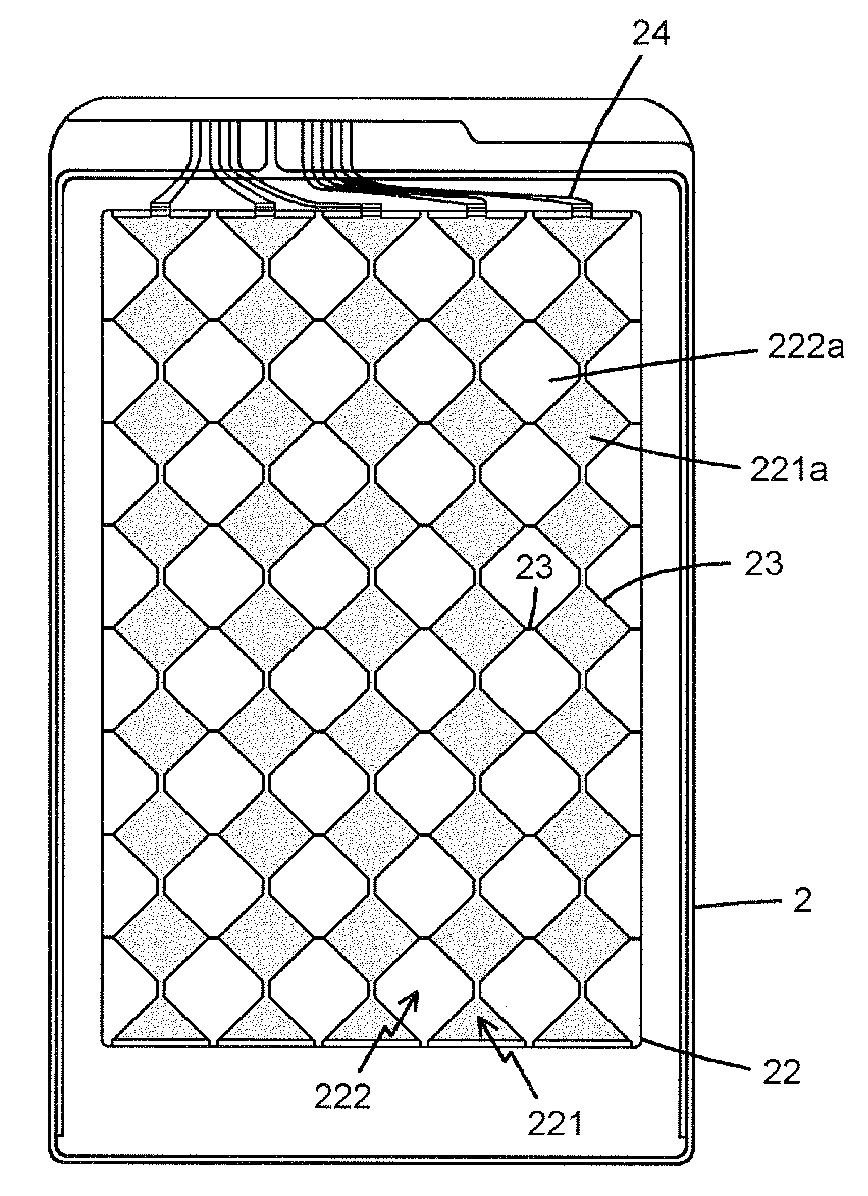

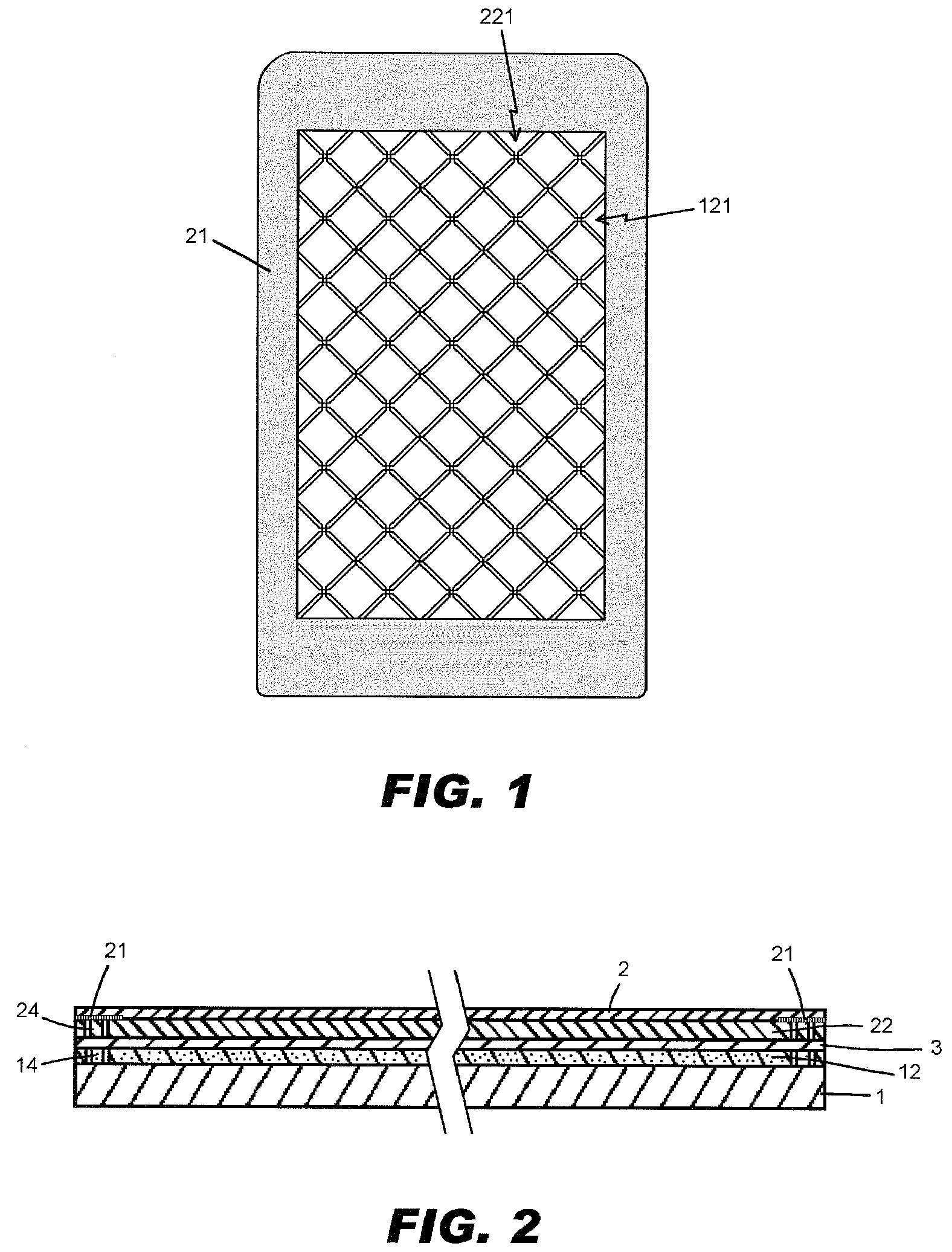

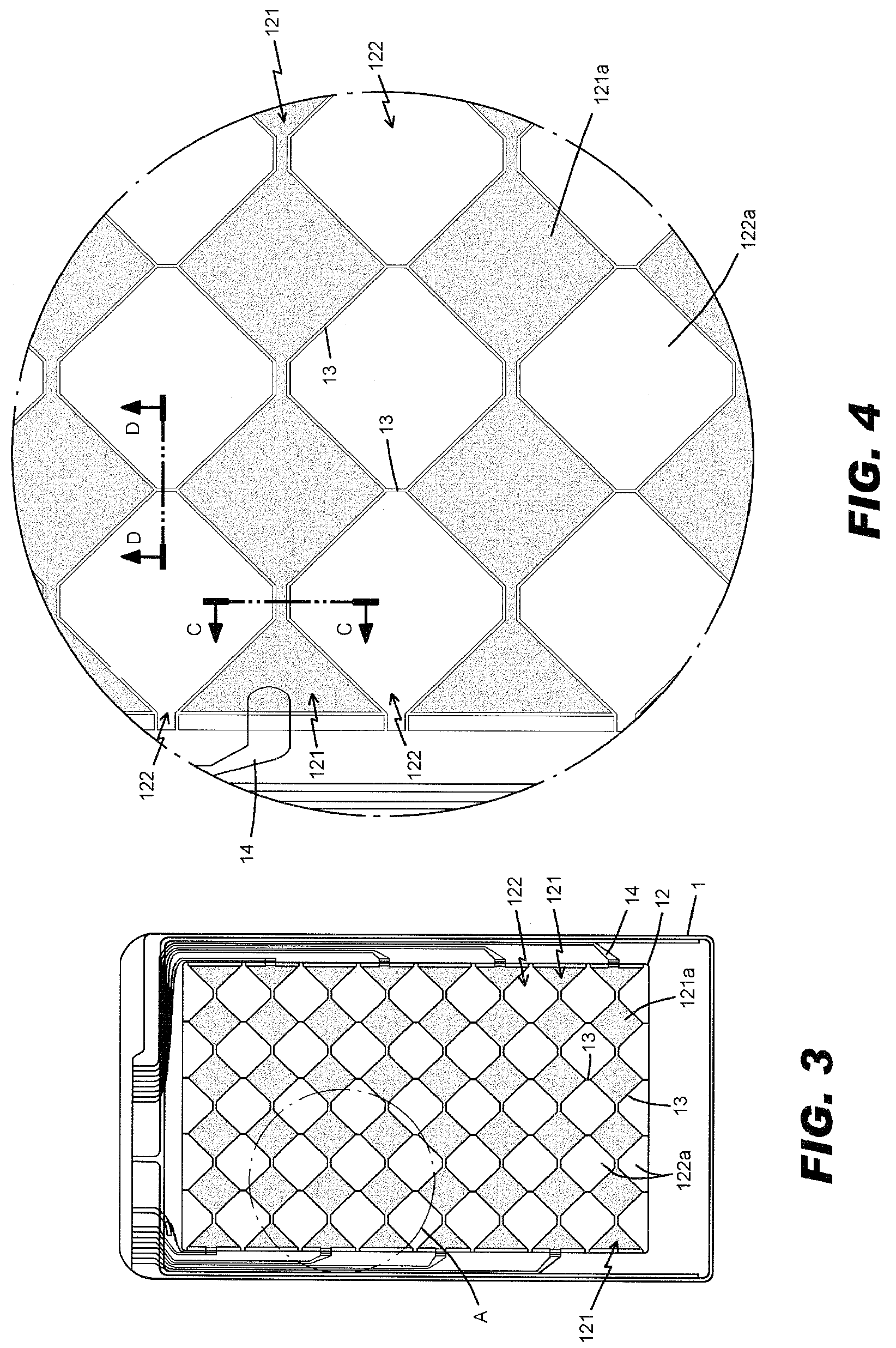

Capacitive sensing assembly of touch panel

InactiveUS20100309160A1Reduce capacitanceFlatness be increaseInput/output processes for data processingPhysicsTouch panel

A capacitive sensing assembly of a touch panel comprises a plurality of transparent X axis traces having a plurality of X axis sensing units; a plurality of transparent Y axis traces having a plurality of connected Y axis sensing units. The Y axis traces are alternatively arranged with the X axis traces so that the X axis sensing units and Y axis sensing units are arranged as a matrix at a working area of a touch panel. Gaps between the X axis traces and Y axis traces are arranged with dummy patterns. Furthermore, a capacitive sensing assembly of a touch panel is provided, which includes a lower substrate; an upper panel; a capacitive sensing layer installed connected the lower substrate and the upper panel. In a working area of a touch panel, the capacitive sensing layer having a plurality of sensing units which are arranged alternatively and gaps between the sensing units are filled with dummy patterns.

Owner:YOUNG FAST OPTOELECTRONICS

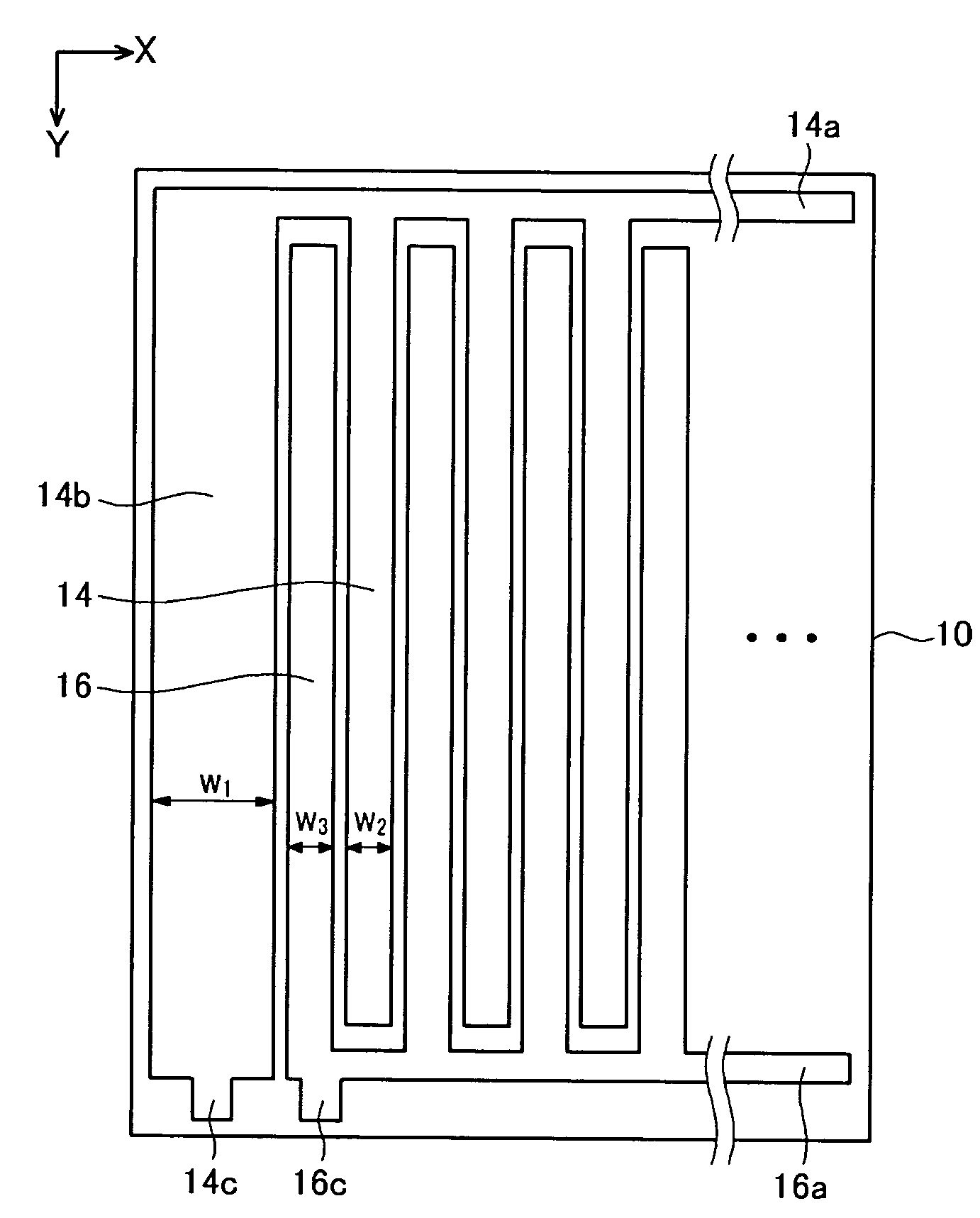

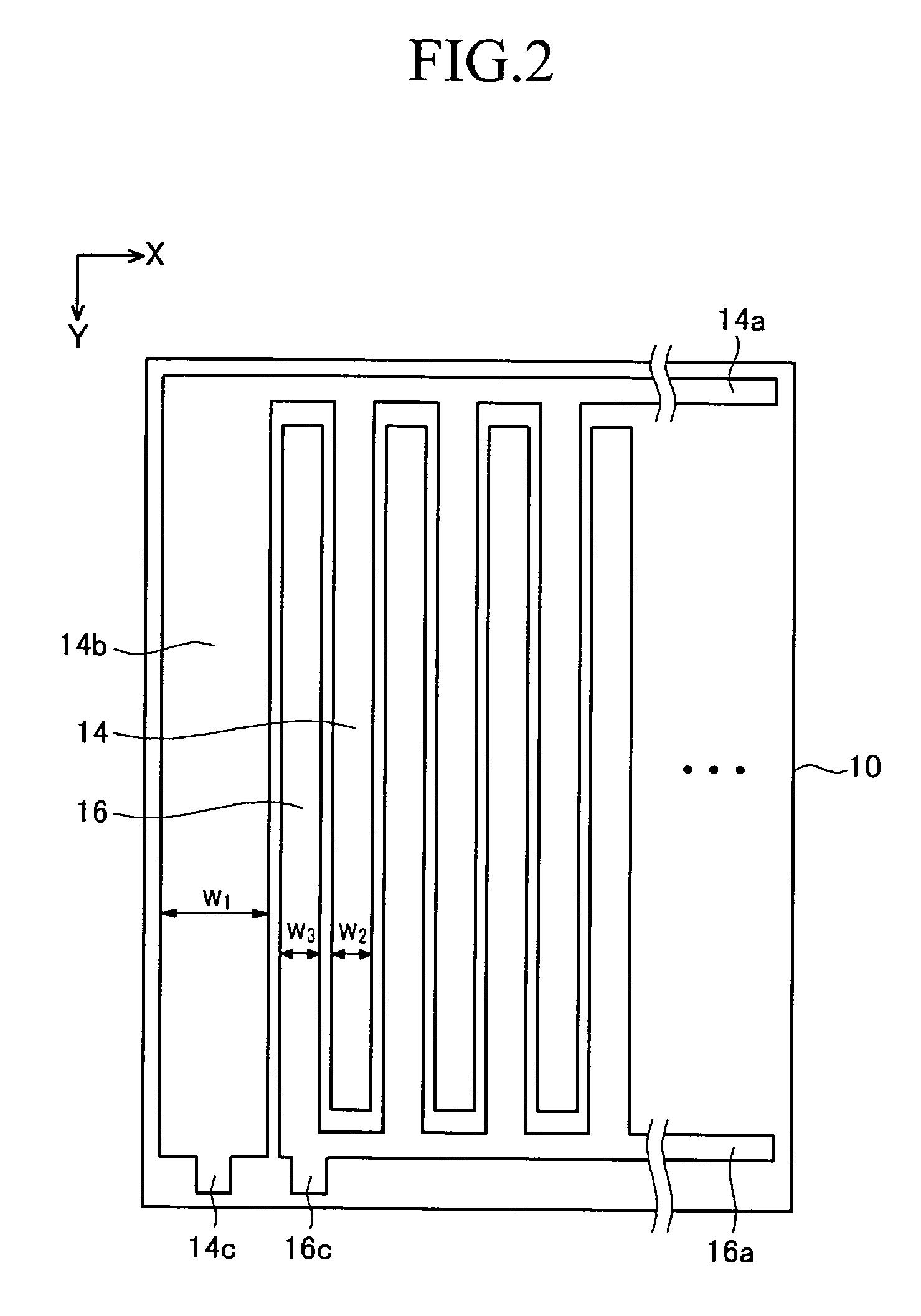

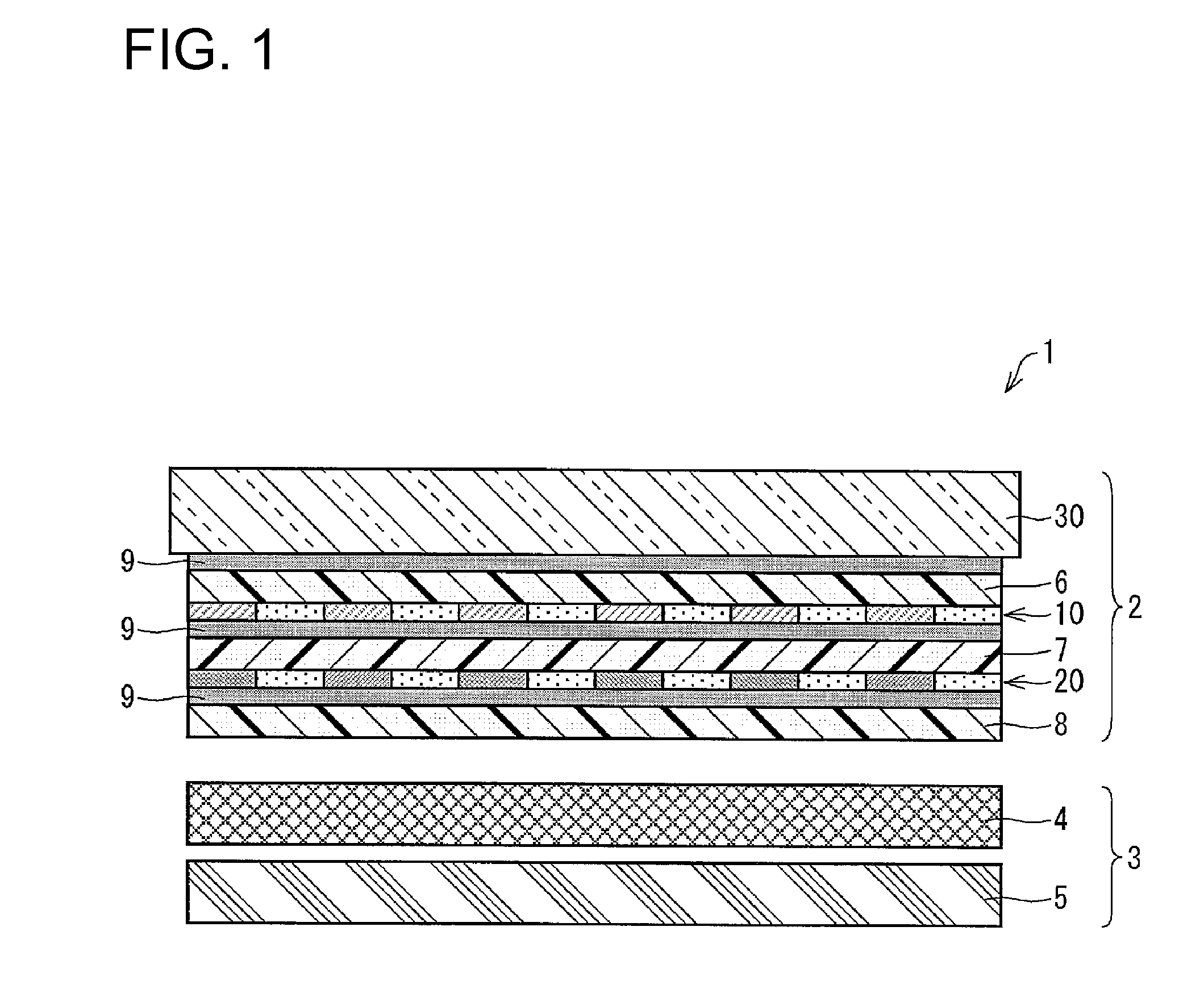

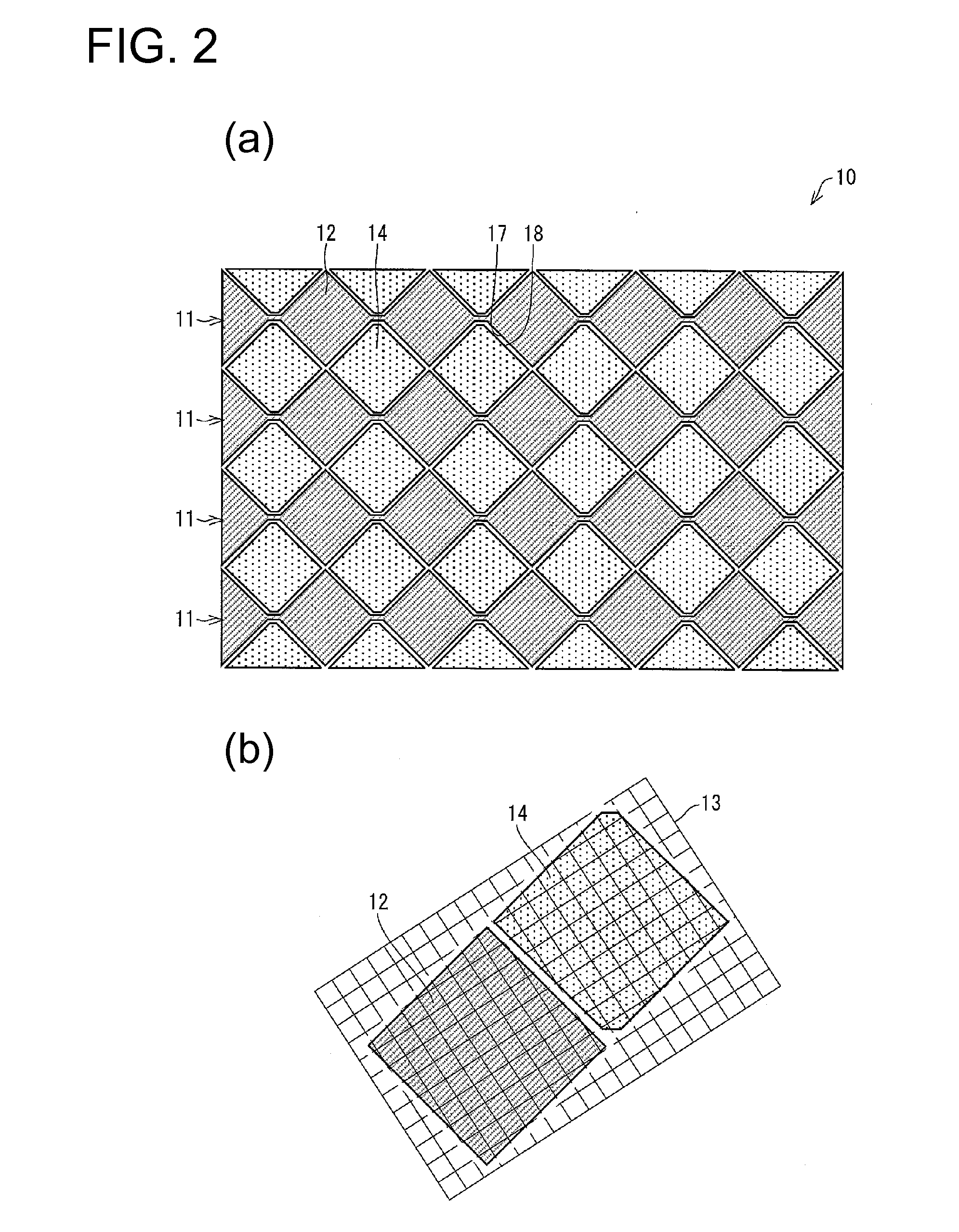

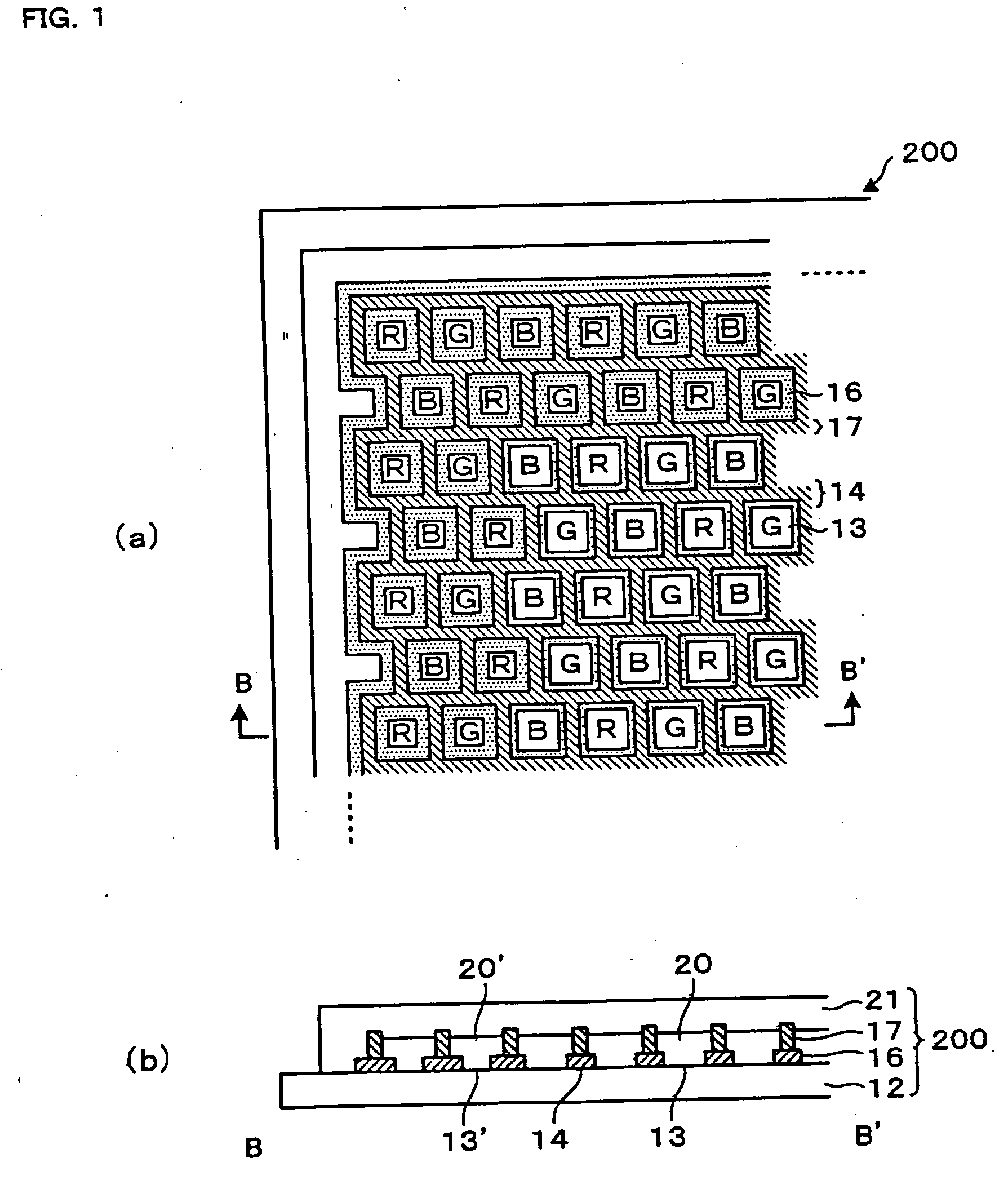

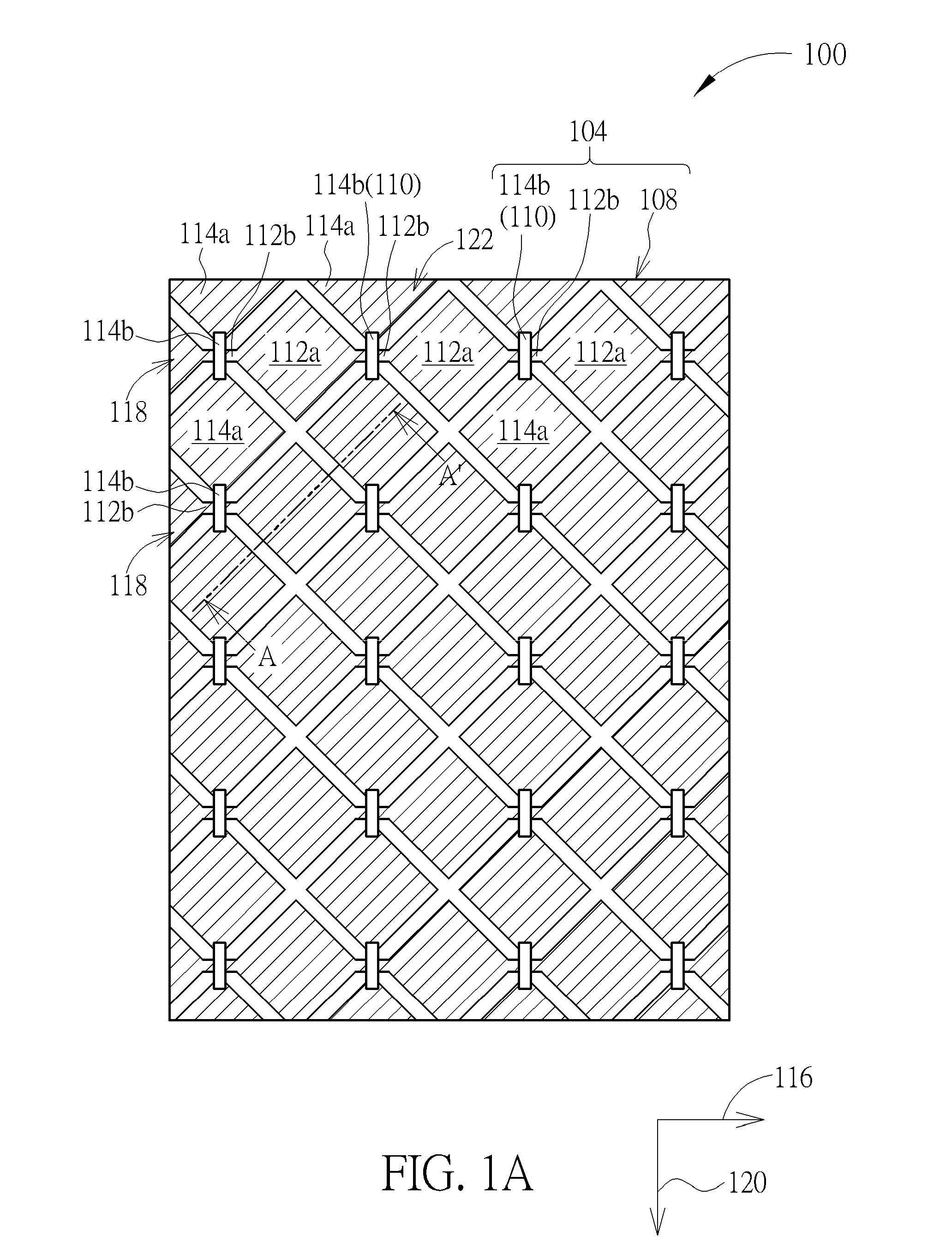

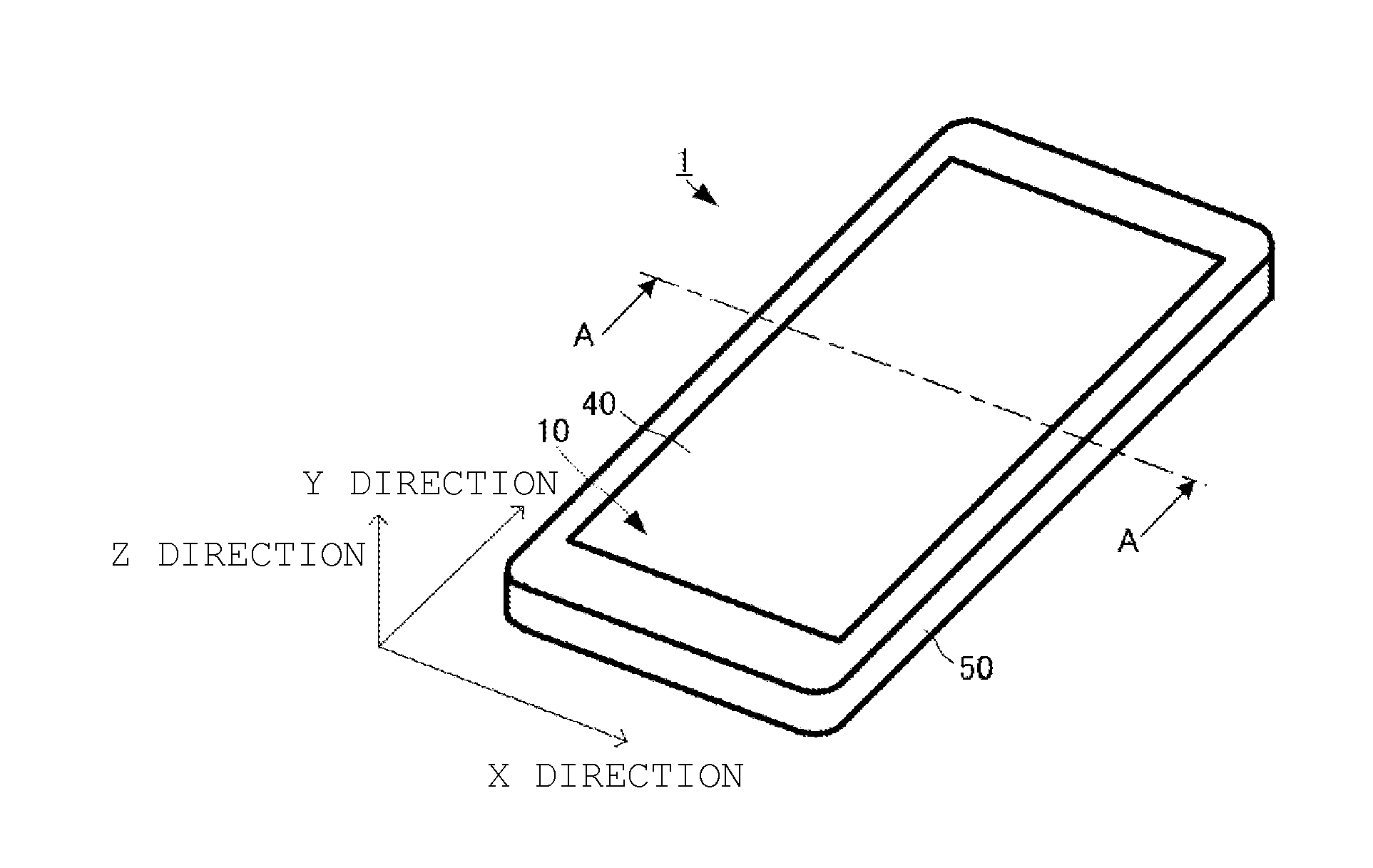

Touch panel substrate and electronic apparatus

InactiveUS20160085339A1Uniform light transmittanceInput/output processes for data processingTransmittanceEngineering

A touch panel substrate that has more uniform light transmittance in the surface thereof is provided. An electrode layer is made of a mesh of first conductive lines. The mesh has first cuts that partition the first conductive lines to form a plurality of first sensor electrodes. The plurality of first sensor electrodes each further include second cuts while maintaining an electrical continuity within each of the plurality of first sensor electrodes.

Owner:SHARP KK

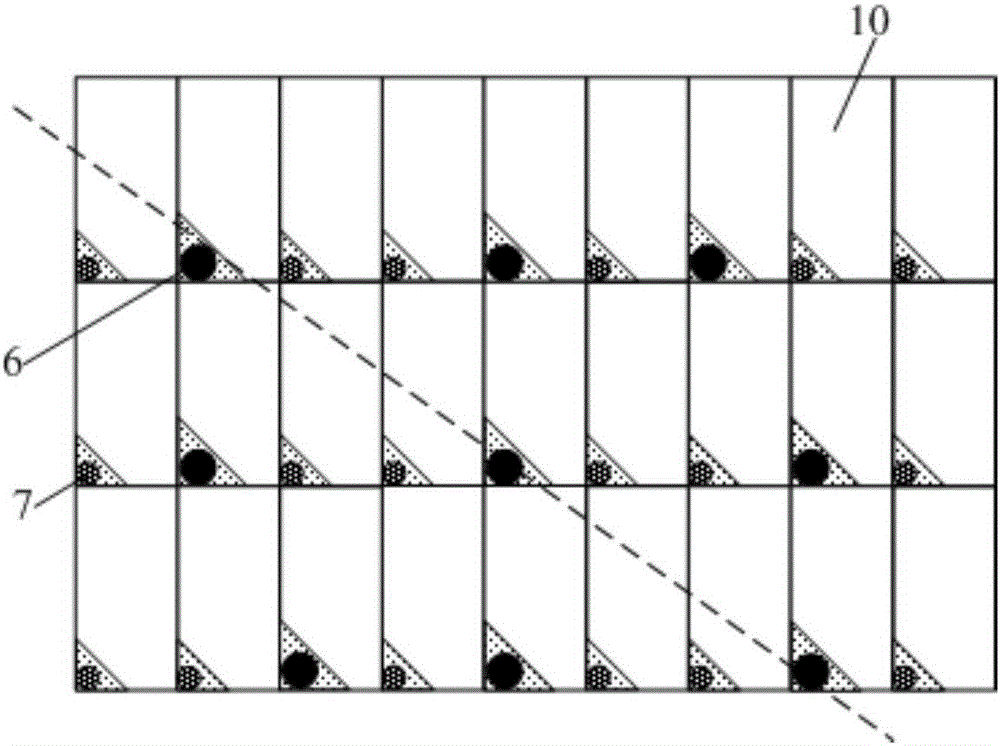

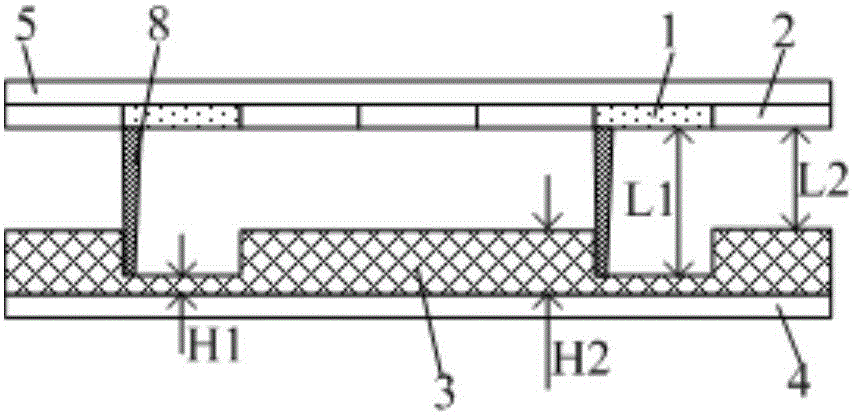

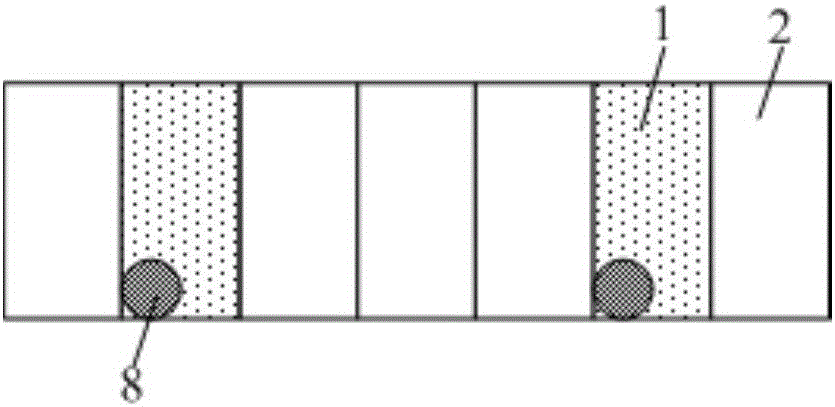

Liquid crystal display panel, manufacturing method thereof, and liquid display device

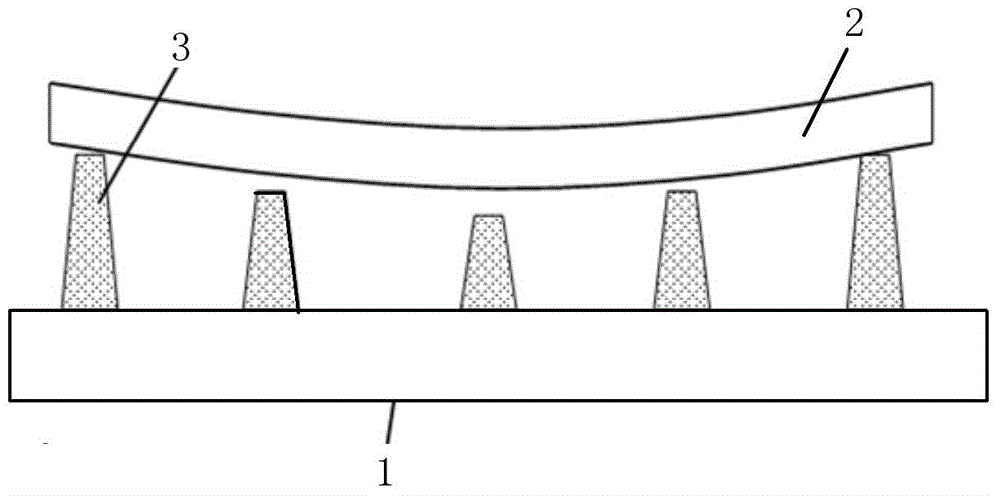

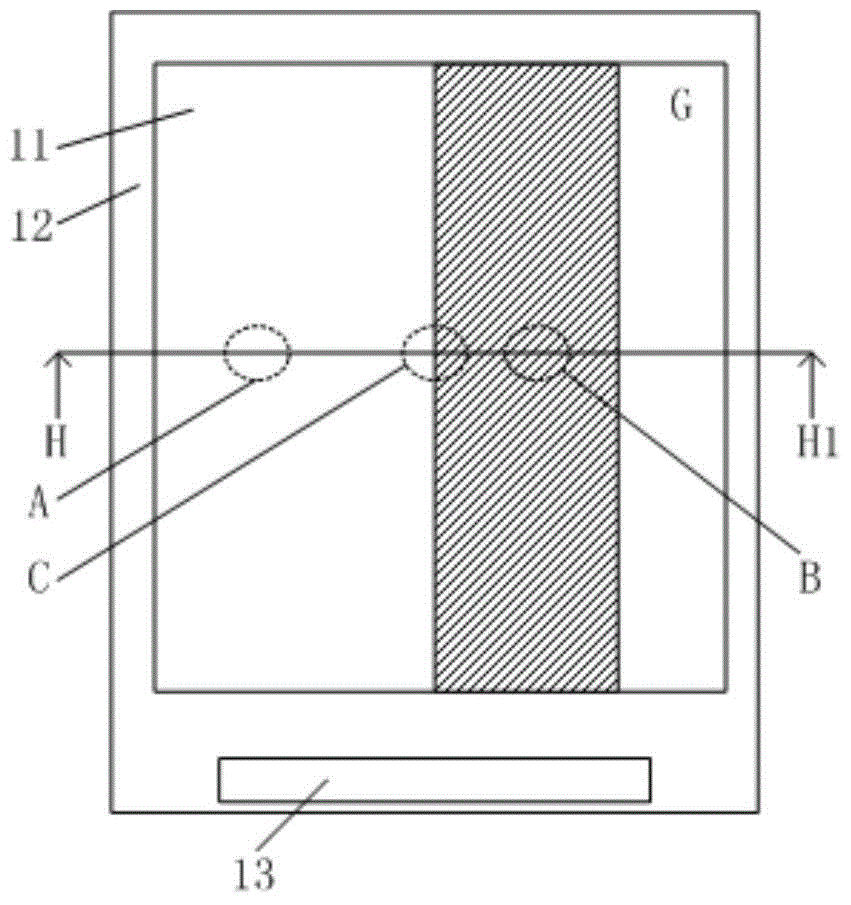

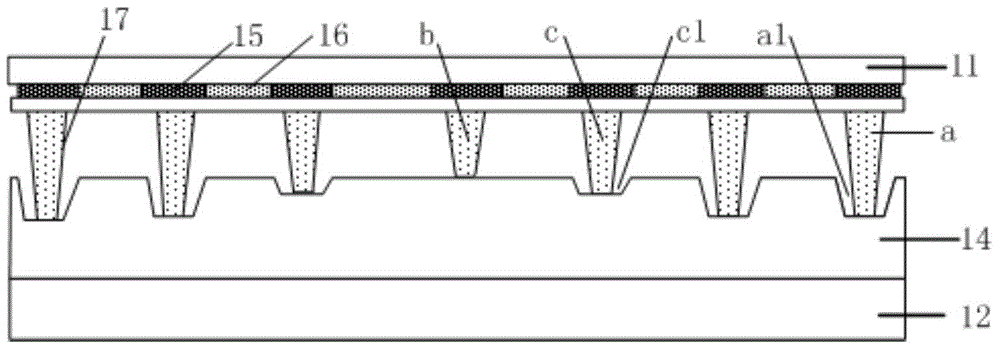

ActiveCN104460121AImprove display unevennessUniform box thicknessNon-linear opticsConvex structureDisplay device

The invention discloses a liquid crystal display panel, a manufacturing method of the liquid crystal display panel and a liquid display device. The liquid crystal display panel comprises a first substrate, a second substrate, a plurality of supporting pillars and a film structure, wherein the first substrate and the second substrate are arranged oppositely, the multiple supporting pillars are arranged between the first substrate and the second substrate, the first end of each supporting pillar is connected with the first substrate, the film structure is arranged on the second substrate, a concave-convex structure is arranged on the surface of the film structure, and the surface of the film structure makes contact with the second ends of the supporting pillars so that the distances between the first ends of the supporting pillars and the side, far away from the supporting pillars, of the second substrate are the same. The second ends of the supporting pillars are near the film structure. The thickness of a liquid crystal box of the liquid crystal display device is uniform, the light transmitting rate is uniform, and the phenomenon of non-uniform display of the liquid crystal display device is further solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS +1

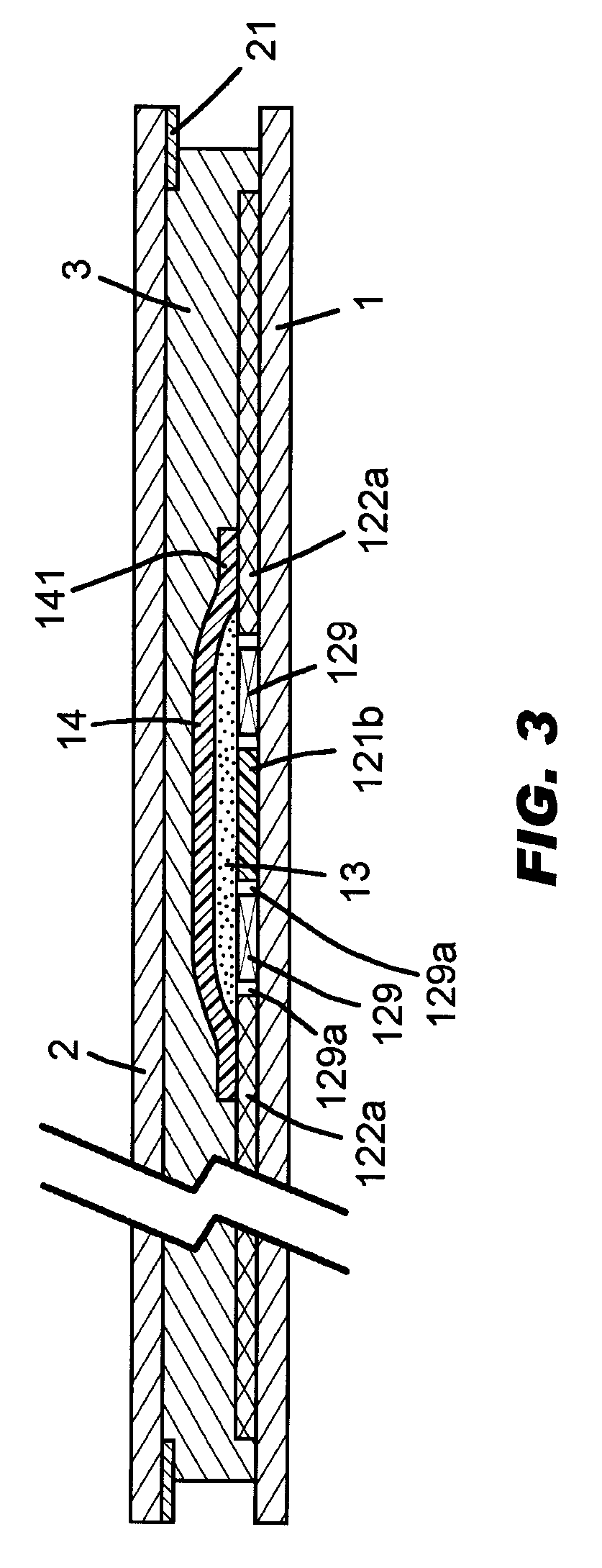

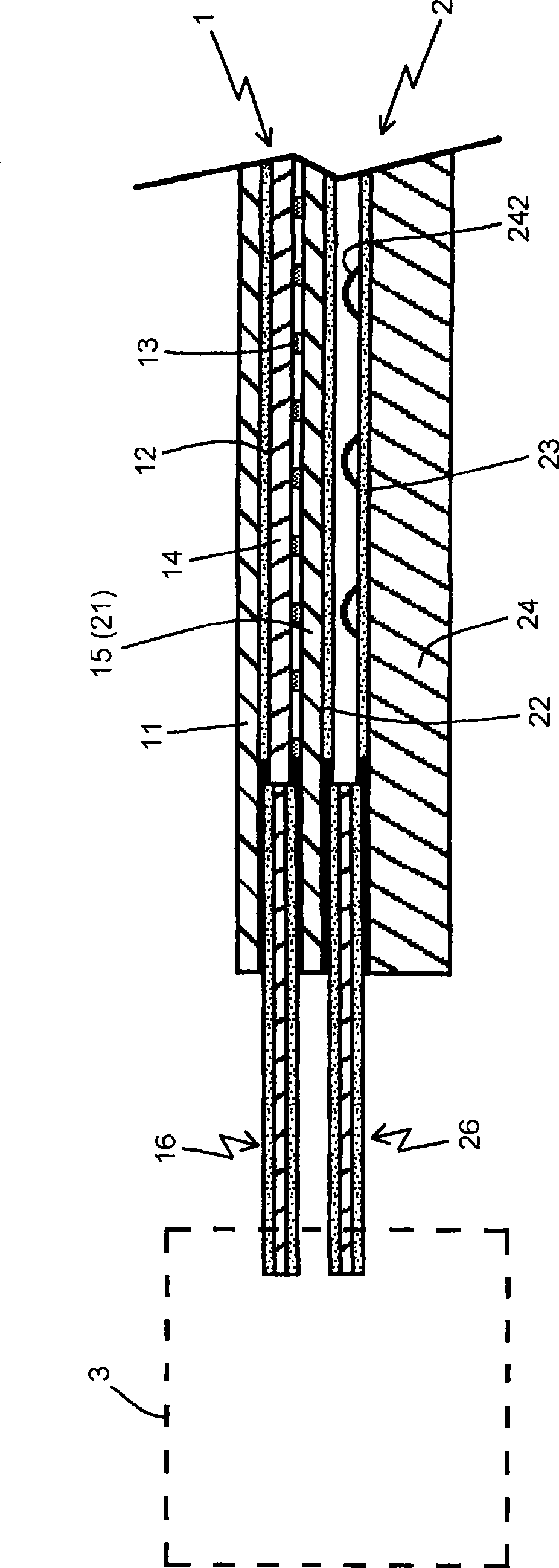

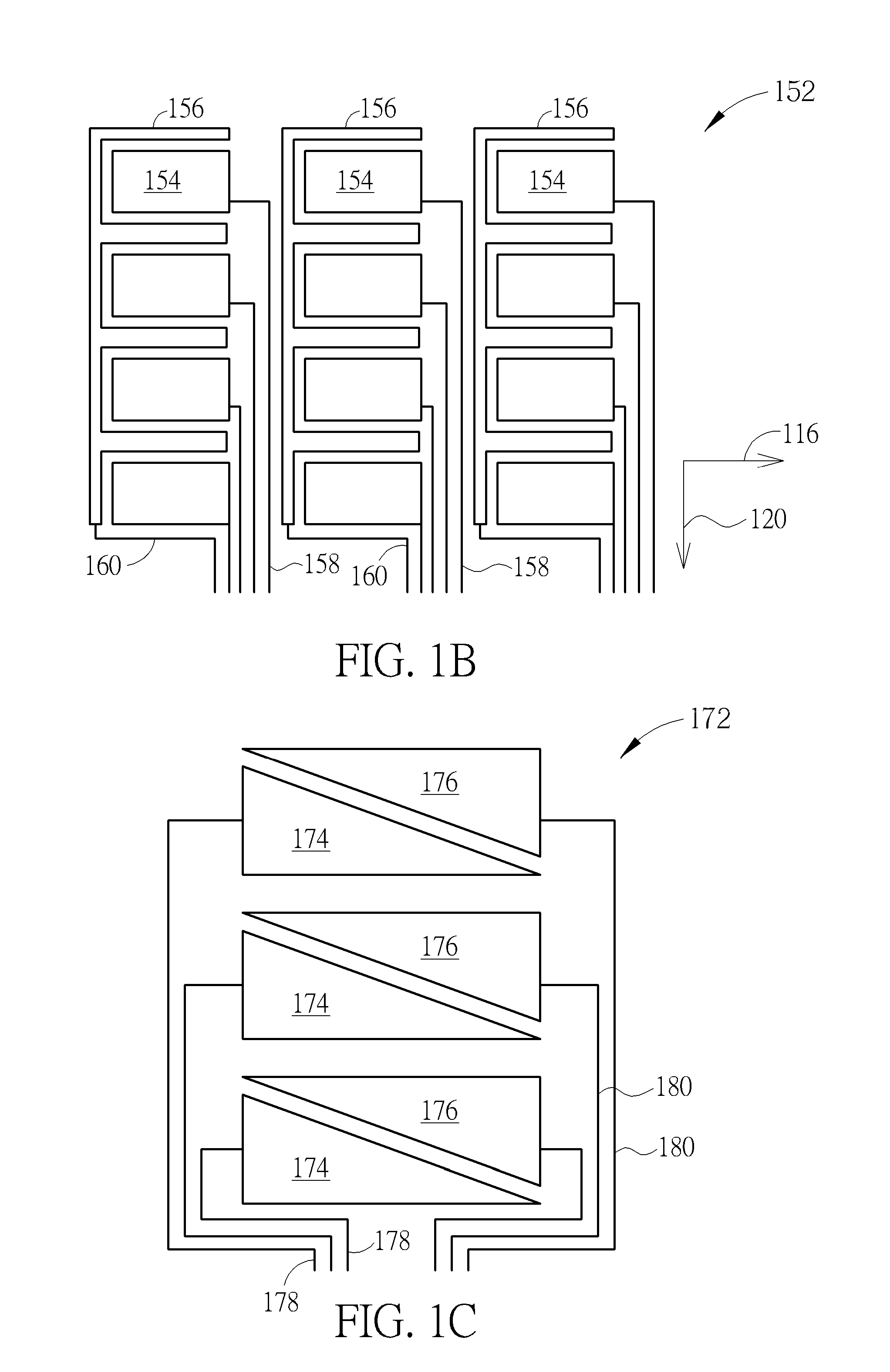

Duplexing touch control board

InactiveCN101470554AGood electrical conductivityEnlarging the sensing surfaceInput/output processes for data processingCapacitanceComputer science

The invention relates to a duplex touch pad, which is spliced by combining a capacitance-type touch pad unit and a resistance-type touch pad unit to form a combined touch pad body, thereby enabling the combined touch pad to have a touch induction interface of the capacitance-type touch pad and the resistance-type touch pad. Touch induction signals of the two touch pad units of the combined touch pad are transmitted to a signal processing unit, the signal processing unit at least provided with one signal discrimination circuit discriminates types of touch induction signals transmitted by the capacitance-type touch pad unit and / or the resistance-type touch pad unit, automatically selects a suitable signal processing mode and non-interlaced signal processing steps. The capacitance-type touch pad unit is respectively provided with a plurality of transparent stitches which are equidistant and are arrayed parallelly at a first axial stitch and a second axial stitch, thereby enabling the first axial stitch and the second axial stitch to be perpendicularly intercrossed, separated from and opposite to each other. Expanded induction surfaces are respectively arranged on intercrossed junctions of the first axial stitch and the second axial stitch, thereby increasing the luminousness uniformity of the working area of the touch pad.

Owner:YOUNG FAST OPTOELECTRONICS

Color filter and electro-optical device

InactiveUS20050174043A1Difference in qualityUniform liquid distributionAddress electrodesSustain/scan electrodesTectorial membraneColor gel

Owner:KATEEVA

Touch panel and touch display panel

InactiveUS20150022739A1Reduce brightness differenceReduce color differenceDigital data processing detailsNon-linear opticsTouch SensesAlloy

The present invention provides a touch panel. The touch panel includes a substrate, a touch sensing device, and an optical matching layer. The touch sensing device is disposed on one side of the substrate, and includes an electrode pattern. The electrode pattern includes silver or silver alloy. At least one side of the substrate has the optical matching layer disposed thereon.

Owner:WINTEK CORP

Resin composition for laser welding and molded article

ActiveUS8052830B2Uniform light transmittanceHighly uniform weldabilityLamination ancillary operationsLaminationElastomerPolytetramethylene terephthalate

A laser weldable PBT-series resin composition and a molded product thereof are provided, in which the composition is weldable uniformly and has high welding strength even when the composition comprises a polybutylene terephthalate (PBT) as a base.The laser weldable resin composition comprises 1 to 50 parts by weight of (B) an elastomer (such as a polystyrene-series thermoplastic elastomer or a polyester-series thermoplastic elastomer), 5 to 100 parts by weight of (C) a polycarbonate-series resin, 1 to 10 parts by weight of (D) a plasticizer (e.g., an aromatic polycarboxylic acid ester, and an acrylic plasticizer), and 0 to 100 parts by weight of (E) a filler or reinforcing agent (such as a glass fiber), relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin (a homopolyester or a copolyester). The molded product prepared from the resin composition has a small light transmittance fluctuation range depending on sites to be irradiated of the molded product. Thus, the molded product can be bonded to a counter part article uniformly by a laser welding.

Owner:POLYPLASTICS CO LTD

Liquid crystal display panel

InactiveUS6768532B1Uniform light transmittanceAvoid reflectionsStatic indicating devicesNon-linear opticsTransmittanceLiquid-crystal display

A liquid crystal display panel fabricated by bonding a first substrate and a second substrate together with a peripheral sealing section, providing a given spacing therebetween. A signal electrode is disposed so as to oppose an opposite electrode, and a liquid crystal layer is sealed in-between the spacing such that a transmittance thereof increases by applying a voltage thereto. The signal electrode is composed of target electrodes, wiring electrodes, and a peripheral electrode, and wiring sealing sections formed of a transparent sealing material are installed in regions where wiring electrodes are opposed to the opposite electrode such that a transmittance of the regions is always substantially equal to that of regions of the liquid crystal layer where a voltage is applied, thereby enabling a transmitting state to occur to the entire area of a display region in a condition wherein no voltage is applied.

Owner:CITIZEN WATCH CO LTD

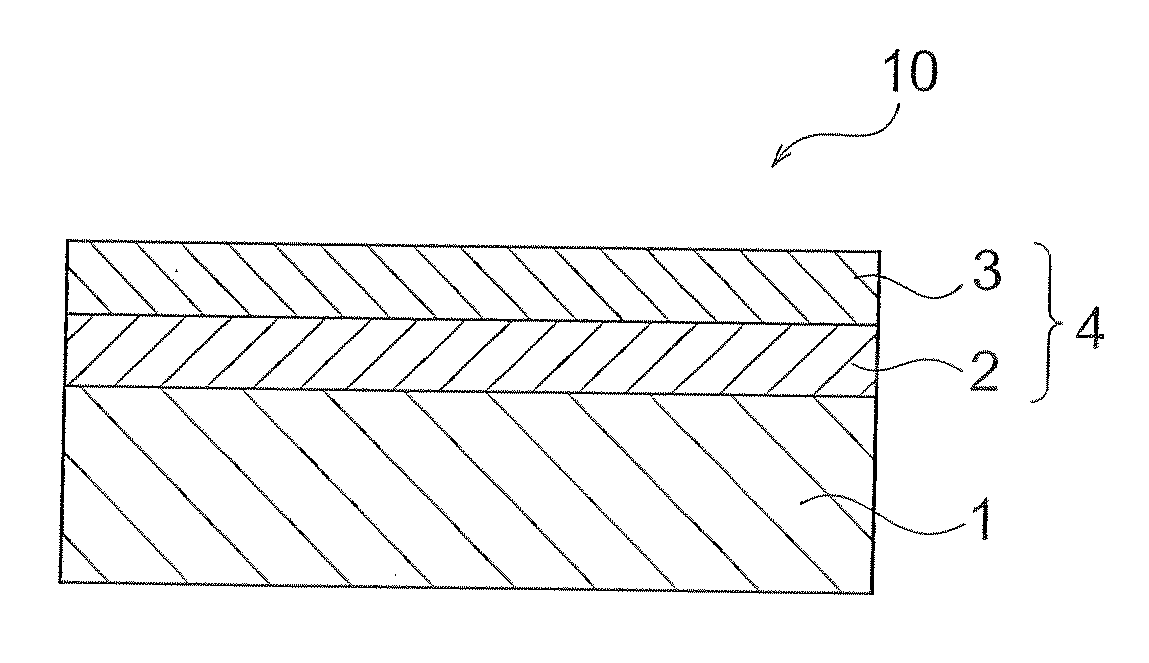

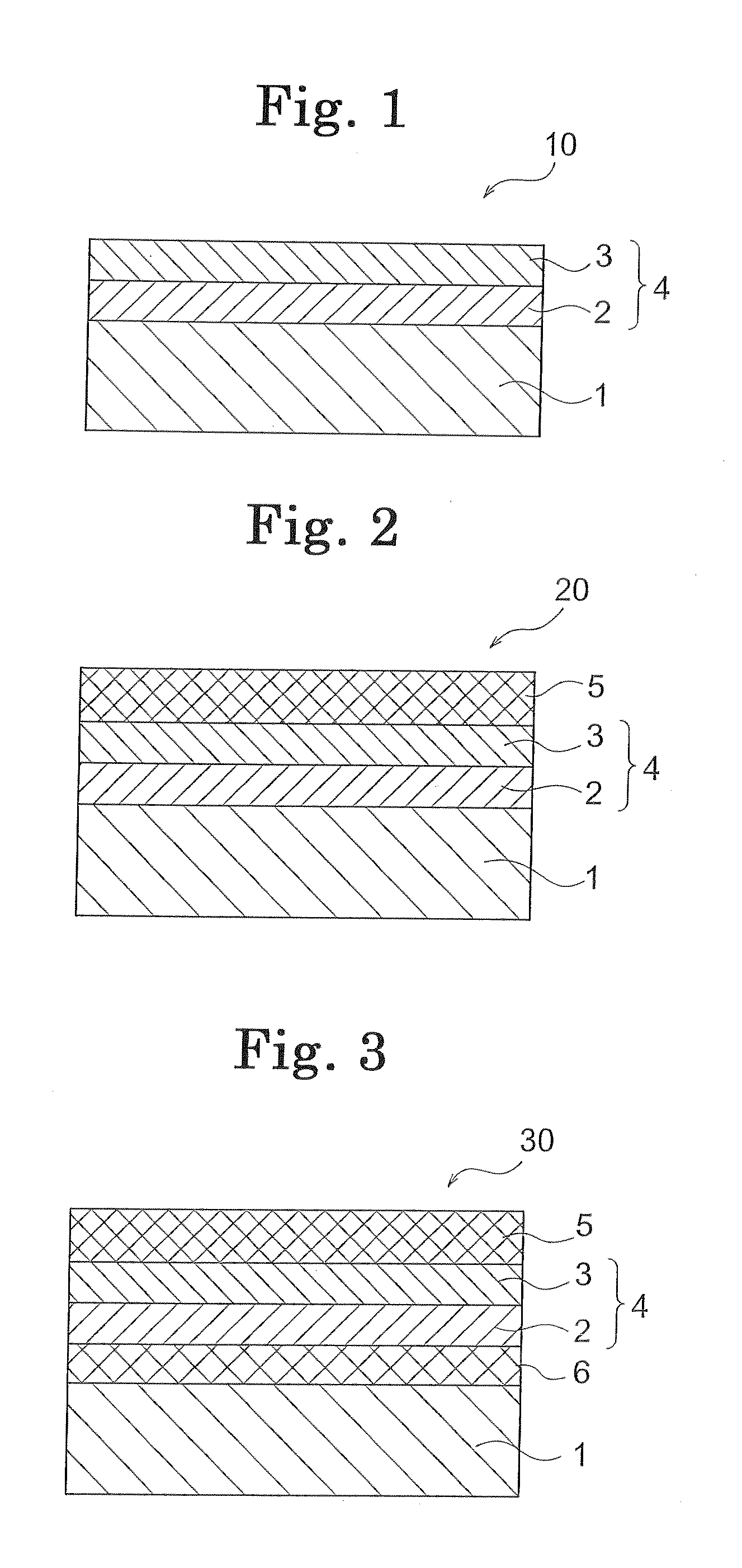

Member for masking film, process for producing masking film using the same, and process for producing photosensitive resin printing plate

ActiveUS20120015288A1Improve production stabilityMaintaining abrasion resistancePhotomechanical exposure apparatusMicrolithography exposure apparatusOptical propertyHigh carbon

A member for masking films which includes a base film transparent to ultraviolet rays and, on one surface thereof, an ultraviolet-shielding resin layer capable of being removed by irradiation with laser light beams and having an average thickness of 0.1 to 30 μm, wherein the ultraviolet-shielding resin layer is a multilayer structure composed of two or more layers including a resin layer (A) having a high carbon black content and a resin layer (B) having a low carbon black content, the layer (A) and the layer (B) being located on the base-film side and on the printing-plate side of ultraviolet-shielding resin layer, respectively, and the ultraviolet-shielding resin layer has specific optical properties. This member for masking films has the following features: the accurate and precise removal of the ultraviolet-shielding resin layer using a low-energy laser beam gives areas with uniform light transmittance; the ultraviolet-shielding resin is resistant to scratches; and positioning is easy, and when making close contact with a plate, air trapping is less likely to occur so that the entire surface easily comes into close contact with a printing material.

Owner:LINTEC CORP

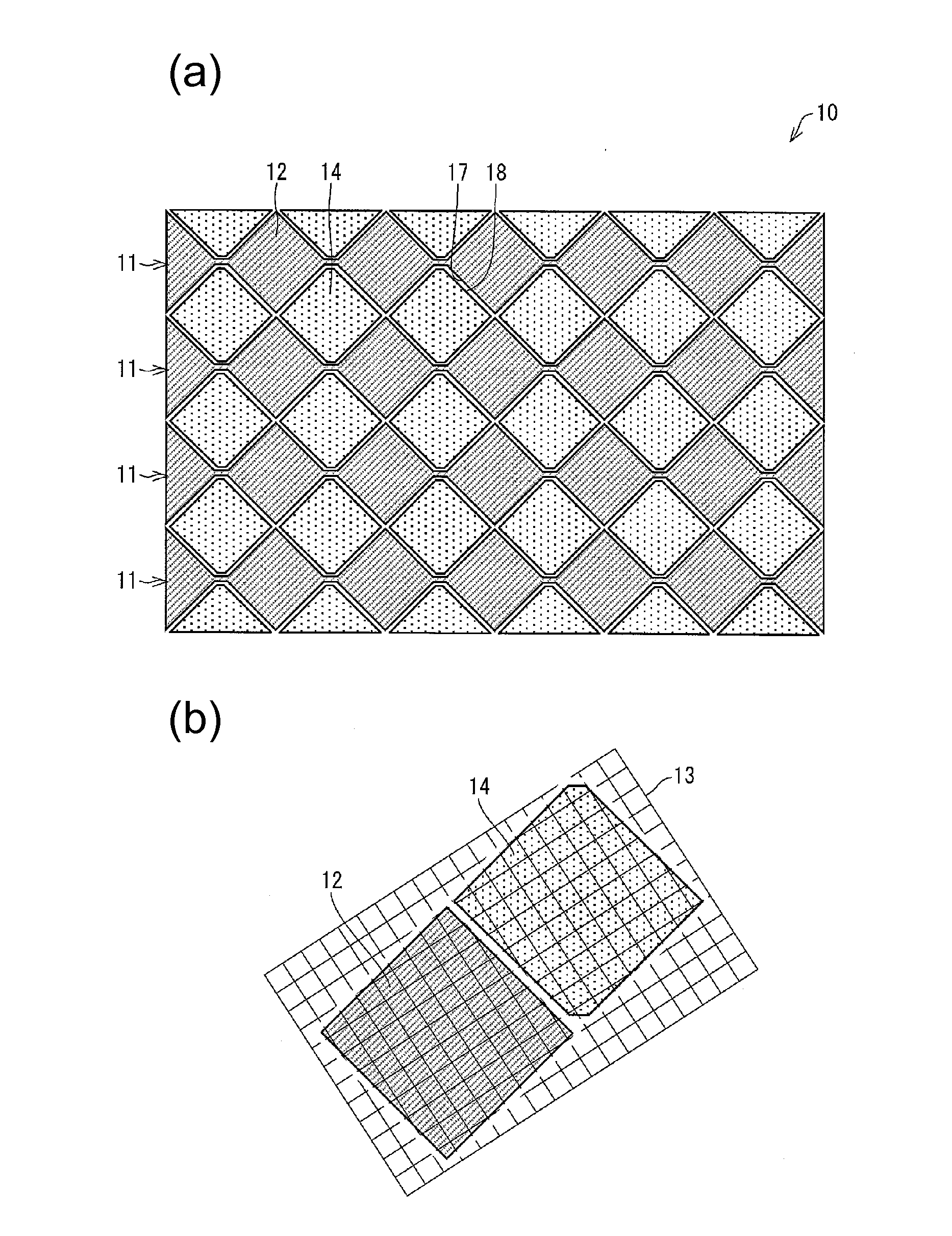

Capacitive touch pad

InactiveUS20120044189A1Increase capacitanceImprove flatnessElectronic switchingInput/output processes for data processingCapacitanceTouchpad

A capacitive touch panel has precise etching lines formed on a transparent conductive film so as to form with a desired pattern. As a result, the hollowed portion on the conductive film will be reduced greatly and thus the flatness of the capacitance sensing structure will be improved and the transmittances in different areas will tend to be uniform. Thus the image distortion in the screen below the touch panel will be improved. Besides, the etching lines will divide the waste etching areas on the conductive lines into a plurality of small units which can reduce the capacitances of the noises.

Owner:YOUNG FAST OPTOELECTRONICS

Three-dimensional display device

InactiveUS20070120768A1Uniform light transmittanceLower Level RequirementsStatic indicating devicesStereoscopic photographyElectricityParallax barrier

A three-dimensional display device includes an image display portion displaying left and right eye images, and a parallax barrier directing the left and right eye images respectively towards left and right eyes of a user. The parallax barrier includes first electrodes located on a first substrate, a first connection electrode electrically connecting the first electrodes, a first terminal electrode connected to an end of the first connection electrode, a first connection terminal connected to the first terminal electrode, second electrodes located between the first electrodes, a second connection electrode electrically connecting the second electrodes, a second connection terminal connected to an end of the second connection electrode, a common electrode located on a second substrate facing the first substrate, and a liquid crystal layer disposed between the first and second substrates. The first terminal electrode has a lower electric resistance than the first electrodes and the second electrodes.

Owner:SAMSUNG DISPLAY CO LTD

Electro-optical display having an arrangement of active and dummy coloring pixels performing as a color filter element

InactiveUS7282843B2Difference in qualityEvenly distributedAddress electrodesSustain/scan electrodesDisplay deviceEngineering

Owner:KATEEVA

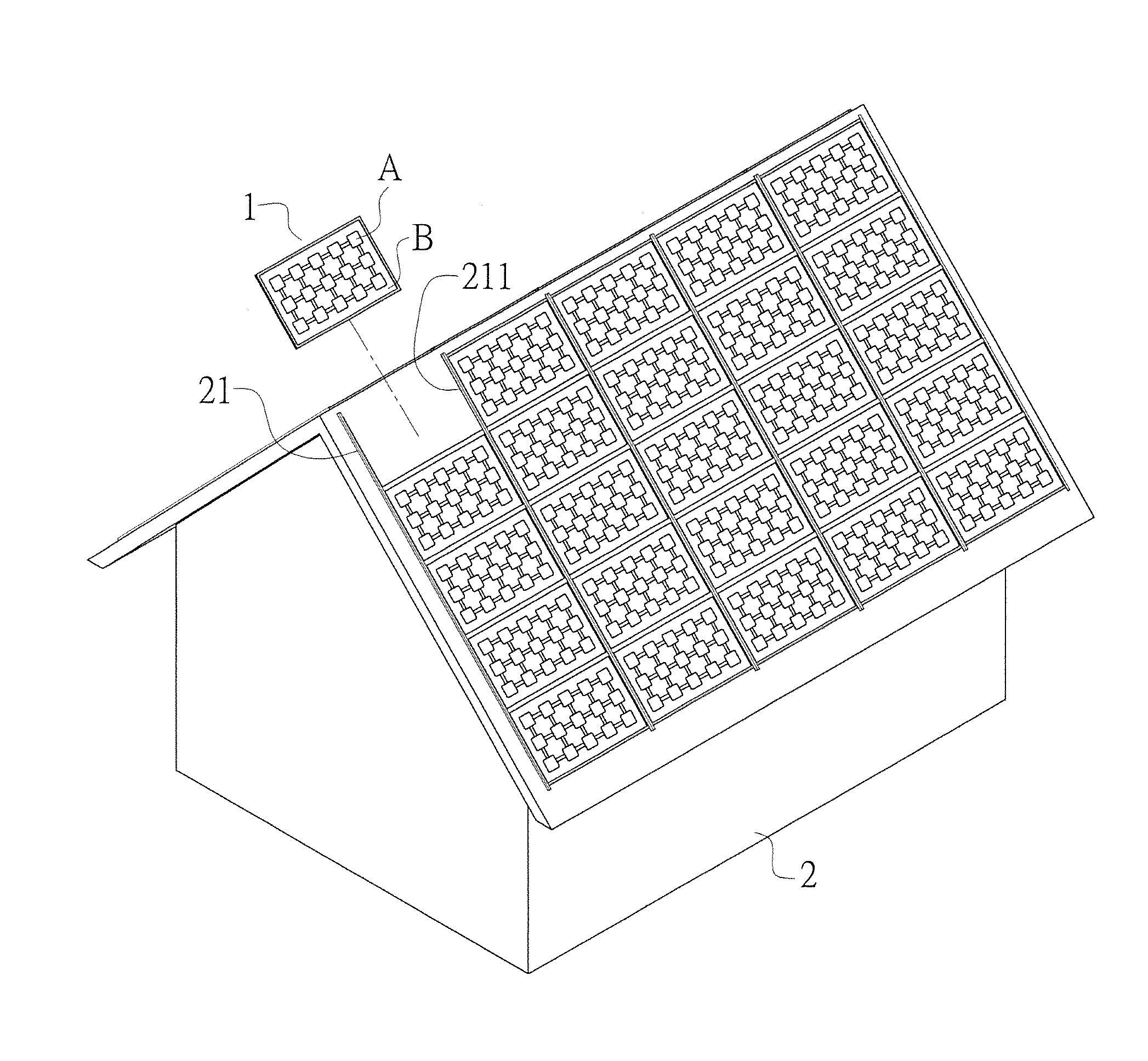

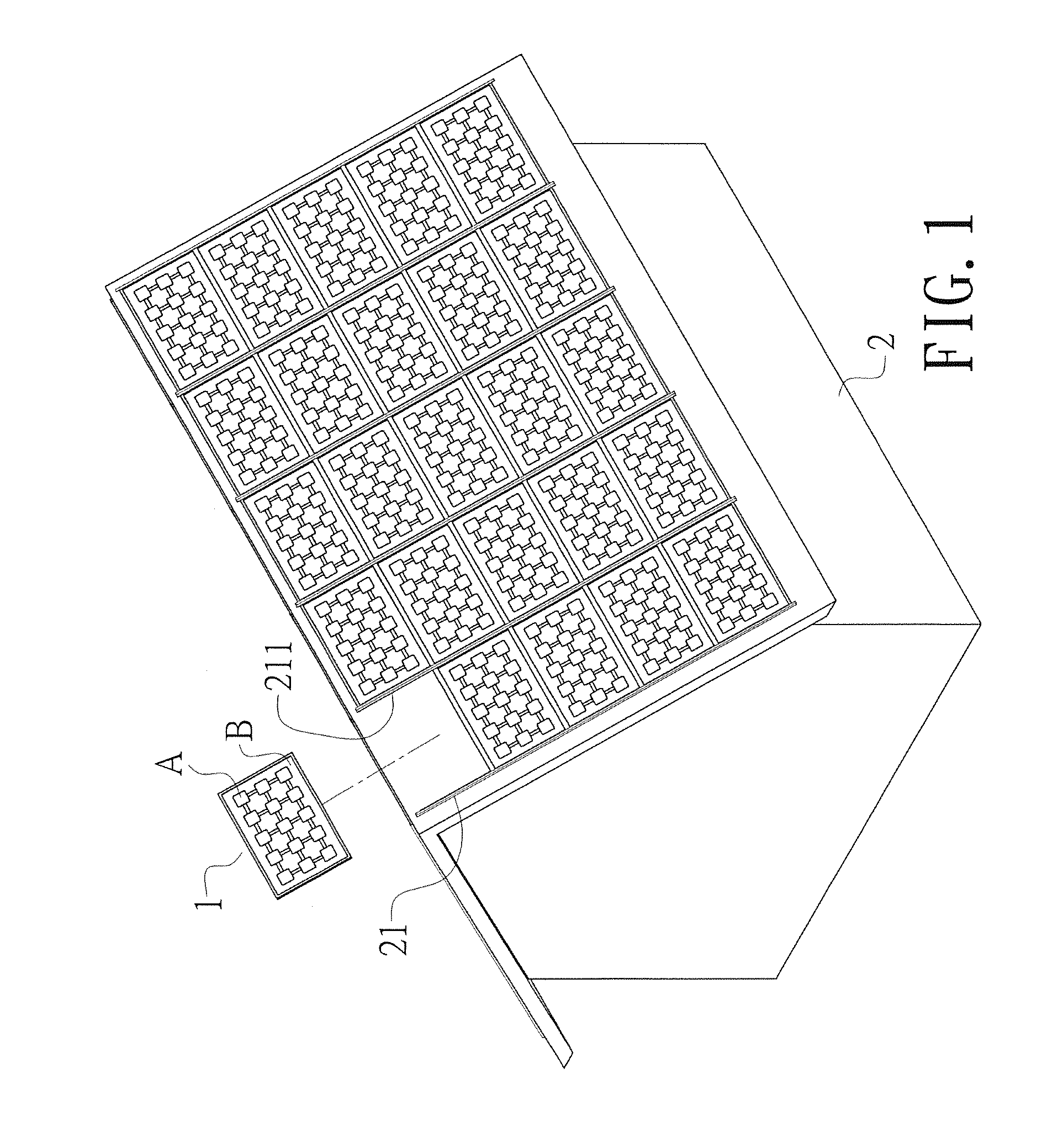

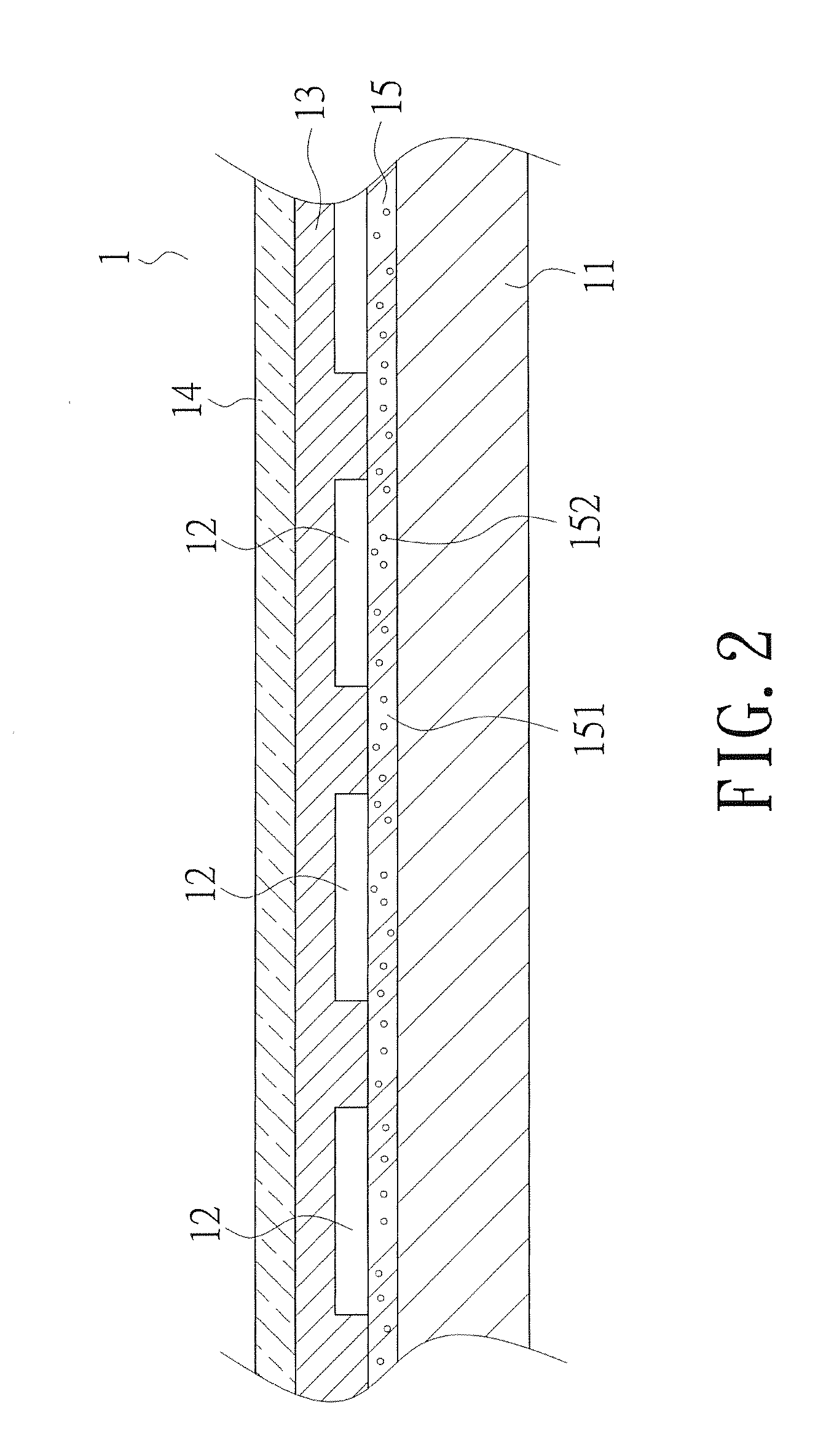

Solar module having uniform light

InactiveUS20140332073A1Uniform light transmittanceUniform illuminationPhotovoltaic supportsPhotovoltaic energy generationEngineeringHot-melt adhesive

A solar module having uniform light for assembling on the top of a building to act as a roof is revealed. It comprises a transparent substrate, at least one solar chip, a hot melt adhesive film, a transparent cover plate, and a diffusion film disposed between the transparent substrate and the solar chip.

Owner:SOUTHERN TAIWAN UNIVERSITY OF TECHNOLOGY

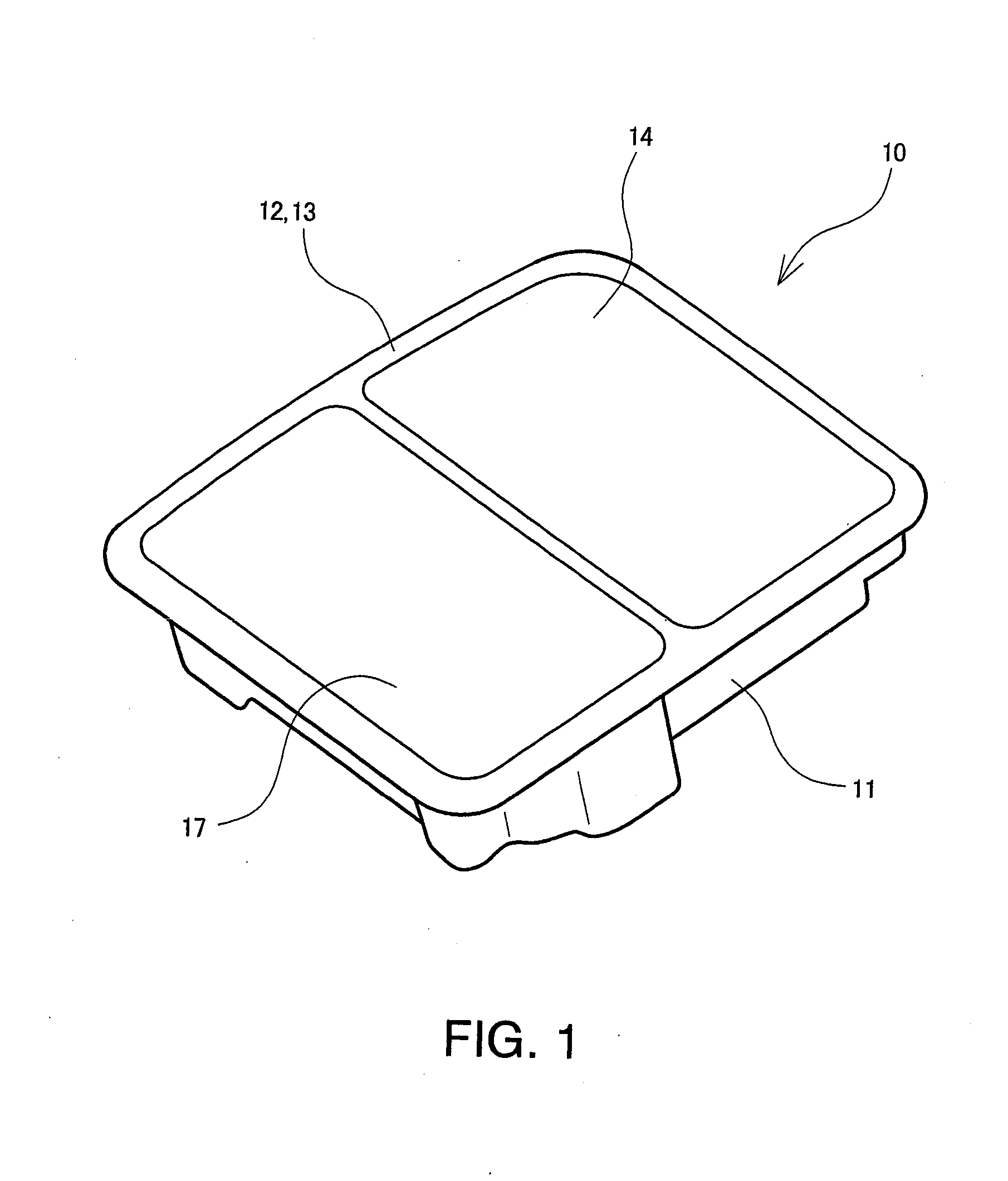

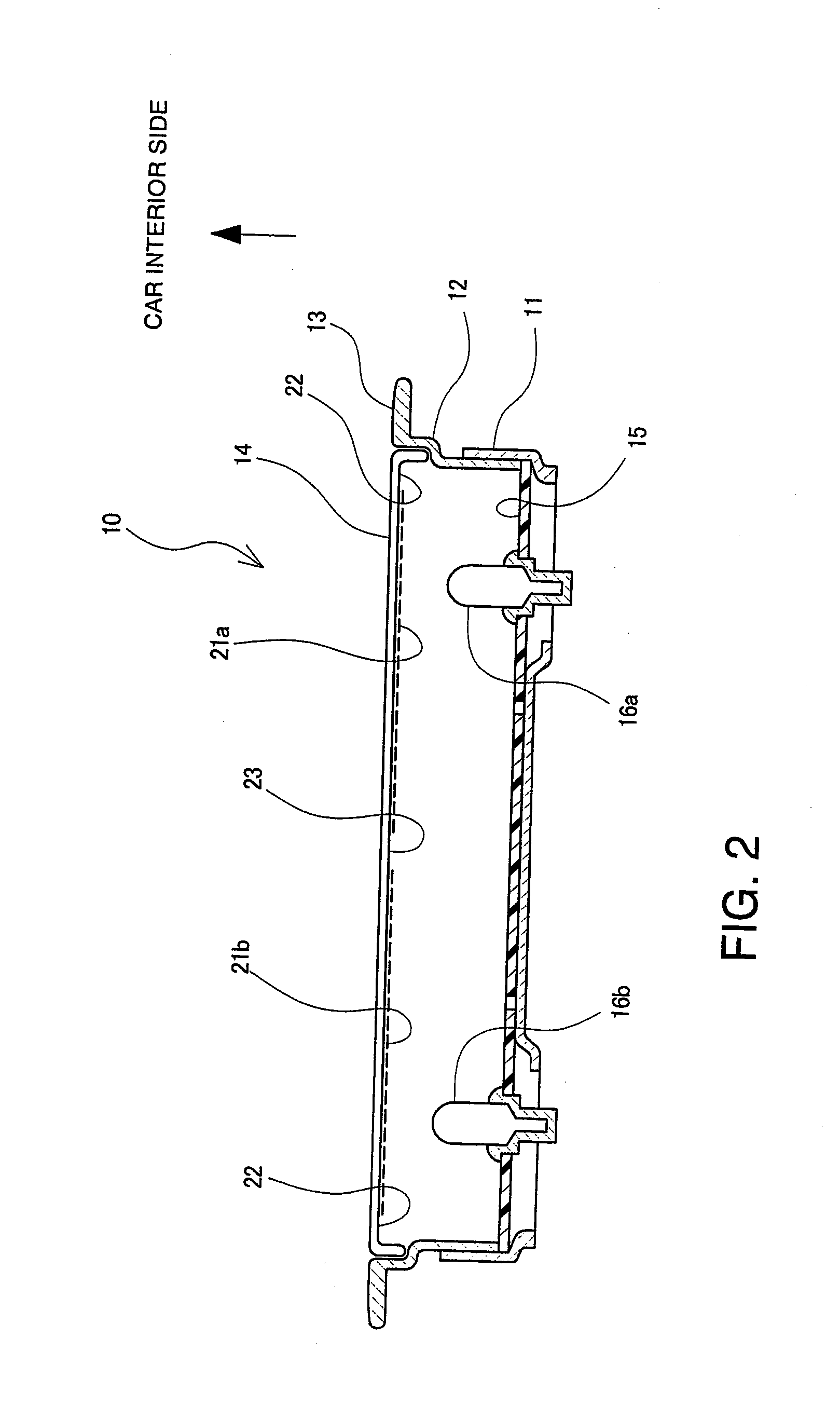

Light lens for car interior lighting device

InactiveUS20100110712A1Uniform light transmittanceLighting circuitsDiffusing elementsCapacitanceConductive coating

A light lens used for a car interior lighting device for transmitting light from a light source therethrough and illuminating the car interior is provided, and the light lens has a transparent light lens body, electrodes that are colored transparent conductive coating films for detecting the capacitance and located on a light source side of the light lens, and an insulative coating film that has almost the same color and transmission rate as the conductive coating films and is located on the periphery of the conductive coating films. With this configuration, the uniform light transmission rate is achieved over the light lens.

Owner:KOJIMA PRESS IND CO LTD +1

Liquid crystal display device

ActiveCN104252072AUniform orientation stateUniform light transmittanceNon-linear opticsLiquid crystal molecule

A liquid crystal display device capable of realizing uniform light transmissivity includes multiple pixels which are arrayed. Each pixel includes a first substrate, a second substrate, a first electrode formed on an opposing face of the first substrate which faces the second substrate, a second electrode formed on an opposing face of the second substrate which faces the first substrate, a liquid crystal layer which includes liquid crystal molecules, situated between the first electrode and the second electrode, and a planarization layer. The liquid crystal molecules are pretilted. Multiple ridge-and-groove portions are formed at the first electrode. At least the grooves of the first electrode are filled in by the planarization layer.

Owner:SONY CORP

Preparation method and application of polyvinyl alcohol film for producing polarizer

InactiveCN103724642AImprove polarization performanceGood effectPolarising elementsPolyvinyl alcoholMaterials science

The invention discloses a preparation method of a polyvinyl alcohol film for producing a polarizer. The method is characterized by comprising the following steps: with polyvinyl alcohol as a solute and water as a solvent, preparing a polyvinyl alcohol solution; adding iodide ions to the polyvinyl alcohol solution; evenly stirring to obtain an iodine polyvinyl alcohol solution; and preparing the polyvinyl alcohol film from the iodine-ion-containing polyvinyl alcohol solution by a tape casting method or a strip coating method. According to the preparation method, iodine is added to the polyvinyl alcohol solution, so that the iodide ions can be uniformly distributed into a polyvinyl alcohol structure in a mechanical mixing manner. The preparation method has a better effect than an existing diffusion method. The produced polarizer has a better polarizing effect.

Owner:安徽皖维膜材料有限责任公司

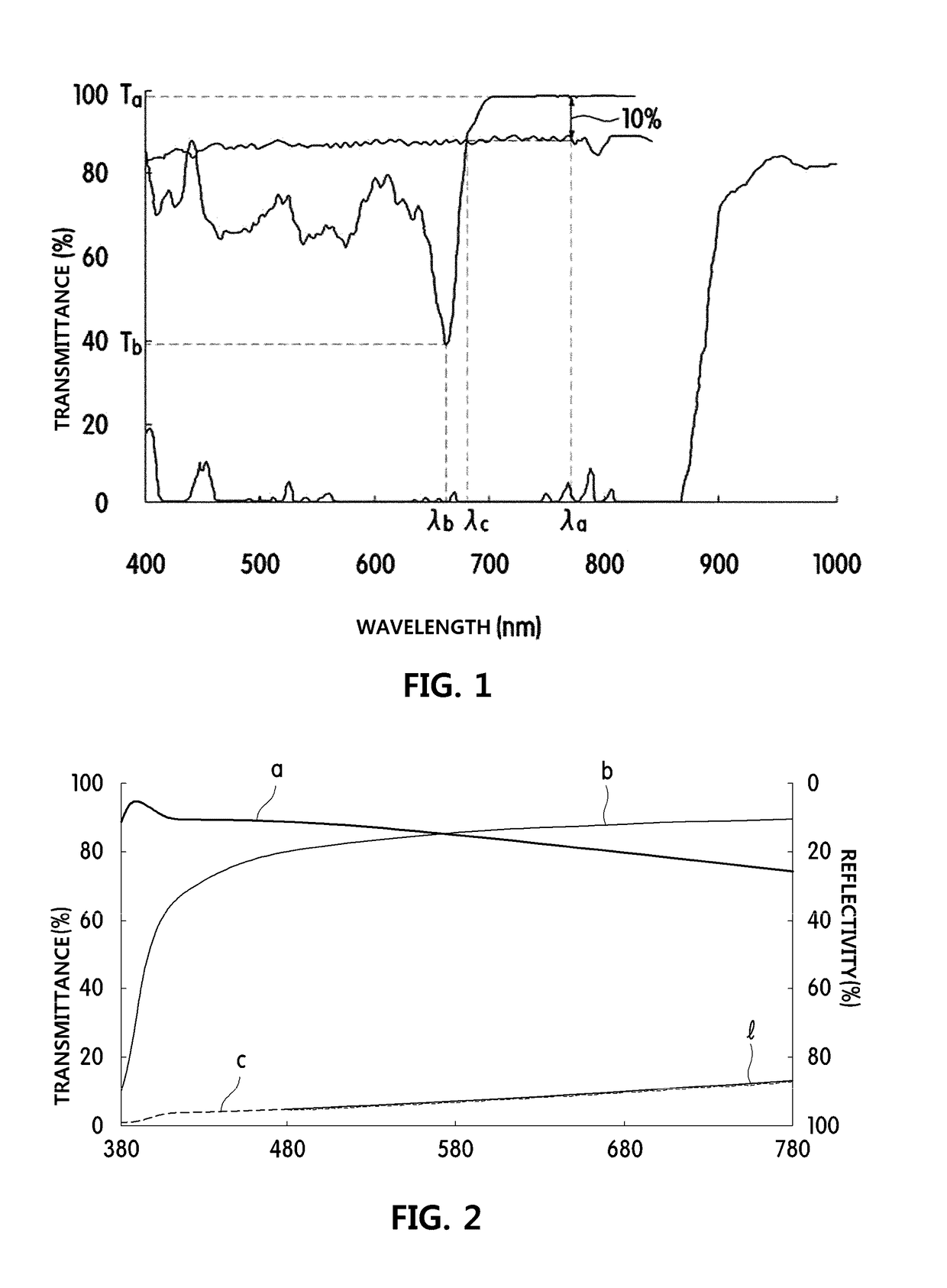

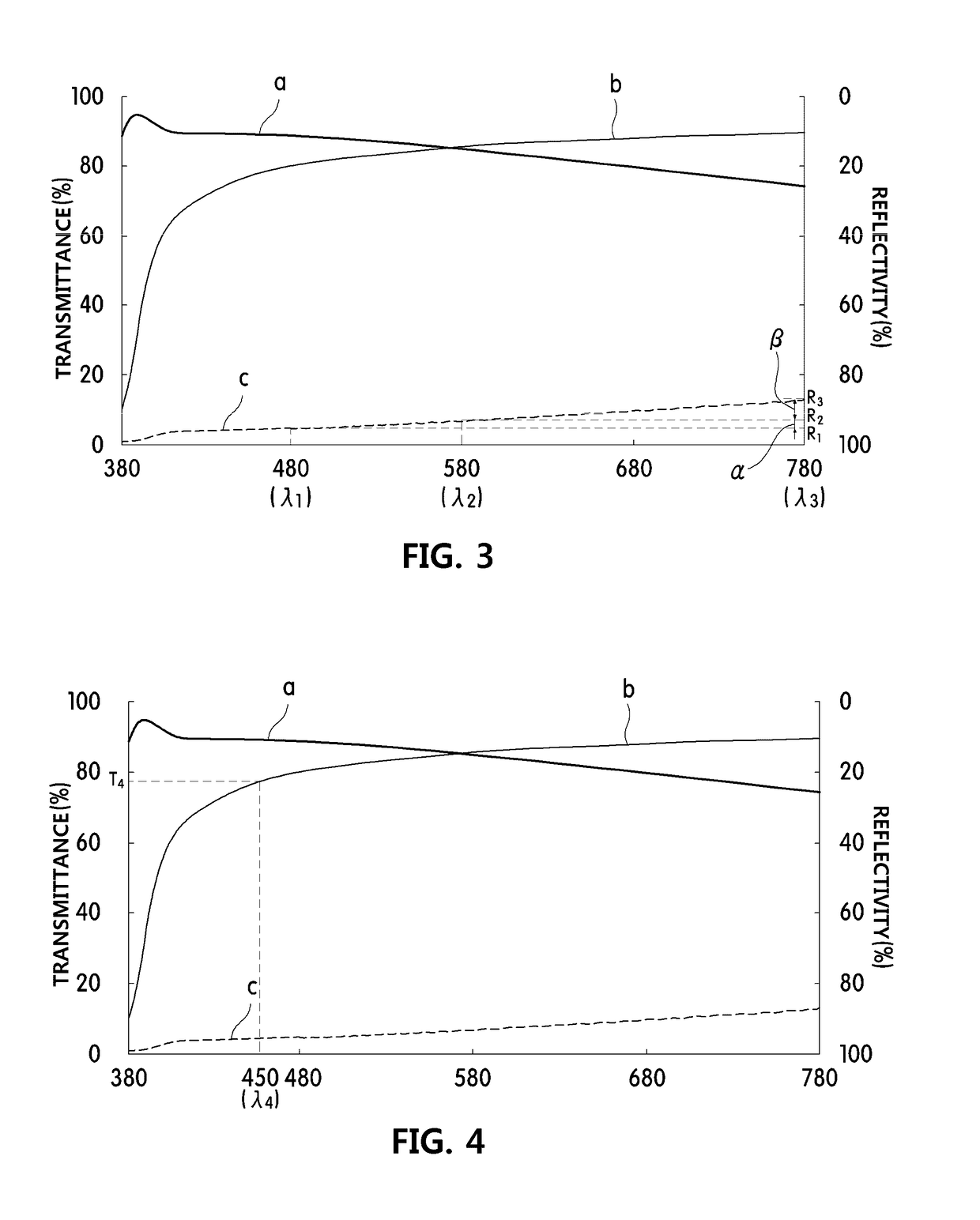

Reflective polarizer and backlight unit including same

ActiveUS20180172887A1Excellent and uniform brightnessLight transmittancePolarising elementsOptical light guidesPolarizerReflectivity

The present invention relates to a reflective polarizer and a backlight unit including same and, more particularly, to a reflective polarizer and a backlight unit including same which can display excellent and uniform brightness throughout the visible light wavelength range in the following manner. Regardless of the incident angle of incident light, a discordance in the refractive index in one particular direction is minimized, and the transmissivity of polarized light targeted within the visible light wavelength range is uniform. Thus, light transmitted through the reflective polarizer is not biased toward a particular wavelength range, and the exterior is not colorful or a particular color due to rainbow-colored light. Because the reflectivity of polarized light not targeted within the visible light wavelength range is significantly large, the light is not biased toward a particular wavelength range.

Owner:TORAY ADVANCED MATERIALS KOREA

Etching solution for preparing filter glass and preparation method of filter glass

ActiveCN111393031AMeet the special requirements of output and inputHigh precisionOptical filtersEtchingO-Phosphoric Acid

The invention belongs to the technical field of glass chemical etching, and particularly relates to an etching solution for preparing filter glass and a preparation method of the filter glass. The etching solution for preparing the filter glass is prepared from the following raw materials in percentage by mass: 5 to 10% of ammonium bifluoride, 4 to 6% of ammonium fluoride, 12 to 18% of sulfuric acid, 15 to 28% of hydrofluoric acid, 3 to 8% of phosphoric acid, 4 to 8% of copper sulfate, 0.5 to 0.8% of borax, 10 to 25% of cane sugar and 5 to 20% of water. The etching solution is used for treating glass, so that the filter glass meeting the use requirements of medical instruments can be prepared.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

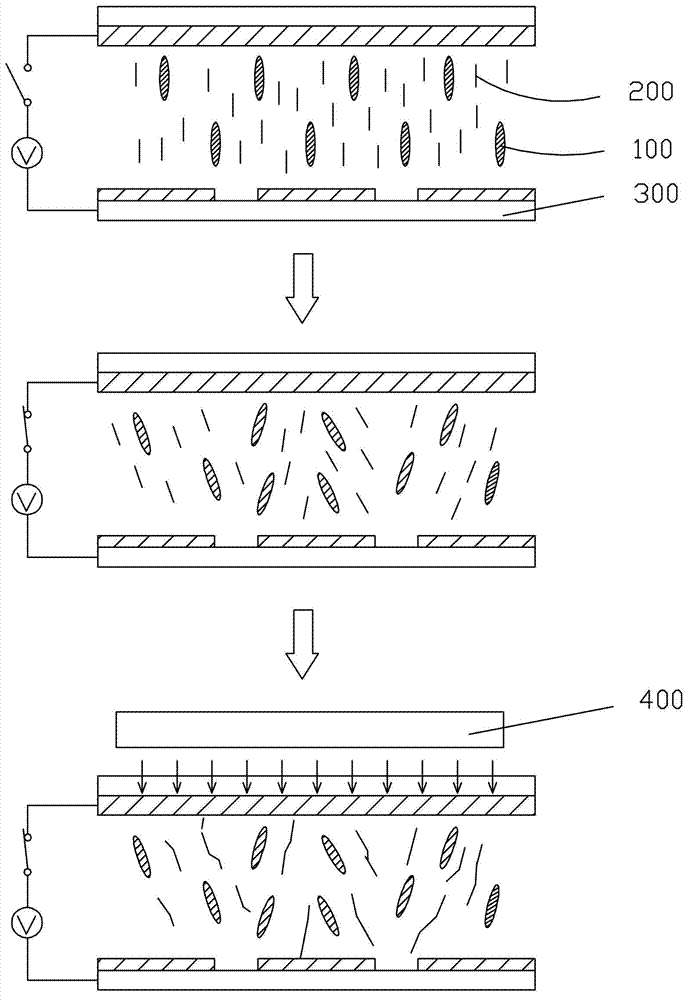

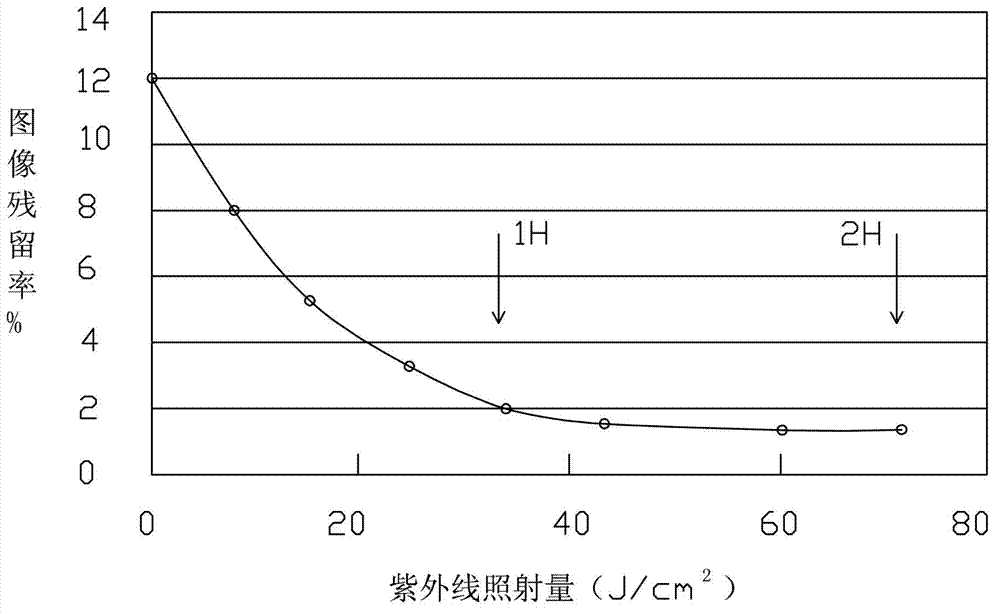

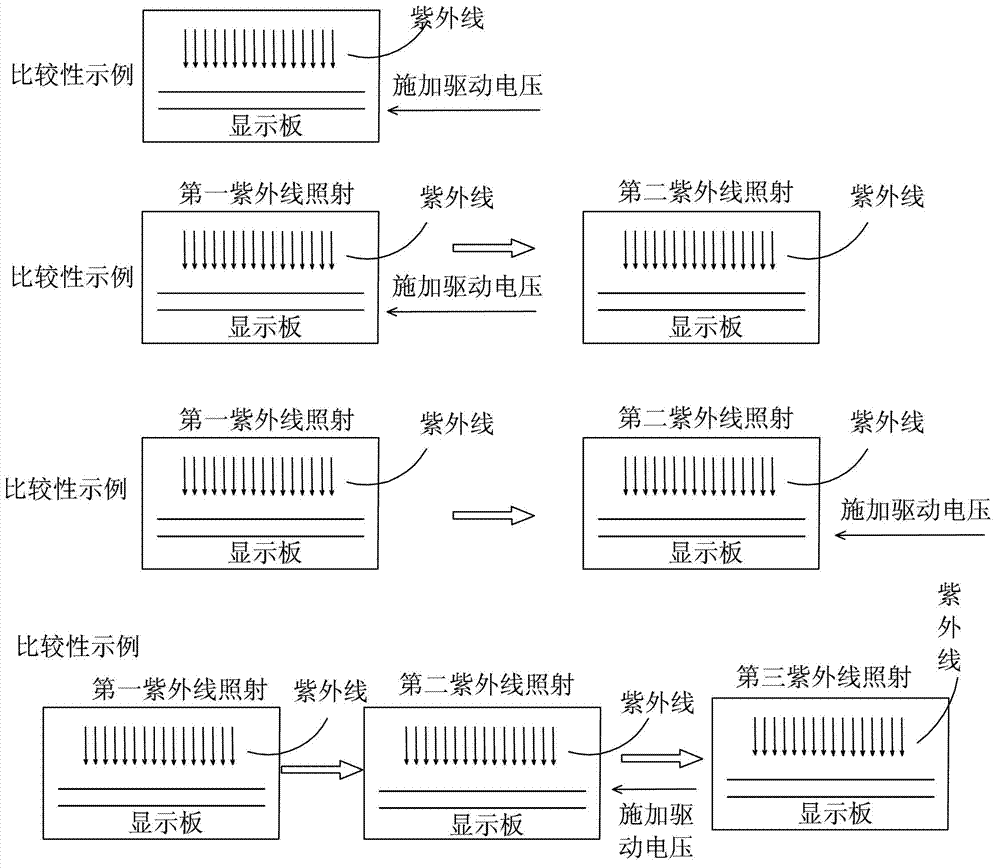

Method for setting pretilt angle of liquid crystal molecules

ActiveCN102902106AUniform light transmittanceGuaranteed ContrastNon-linear opticsSmall amplitudeUltraviolet lights

The invention provides a method for setting a pretilt angle of liquid crystal molecules, comprising the following steps of: step 1, providing a liquid crystal material, a CF (Color Filter) substrate and a TFT (Thin Film Transistor) substrate; step 2, arranging the CF substrate and the TFT substrate in parallel to form a receiving gap, and filling the liquid crystal material in the receiving gap to form a liquid crystal box; step 3, providing a driving control circuit capable of generating a plurality of driving voltages, and electrically connecting the driving control circuit with the TFT substrate; step 4, providing a small-amplitude oscillating device and an ultraviolet light source variable in irradiation intensity, and arranging the liquid crystal box on the small-amplitude oscillating device; step 5, starting the small-amplitude oscillating device so that the liquid crystal box generates small-amplitude oscillation, closing the driving control circuit and employing the plurality of driving voltages to drive the liquid crystal material, and simultaneously, irradiating the liquid crystal through the ultraviolet light source by different intensities; and step 6, performing the operation of the step 5 not less than one time on the liquid crystal box, thereby completing the setting of the pretilt angle.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

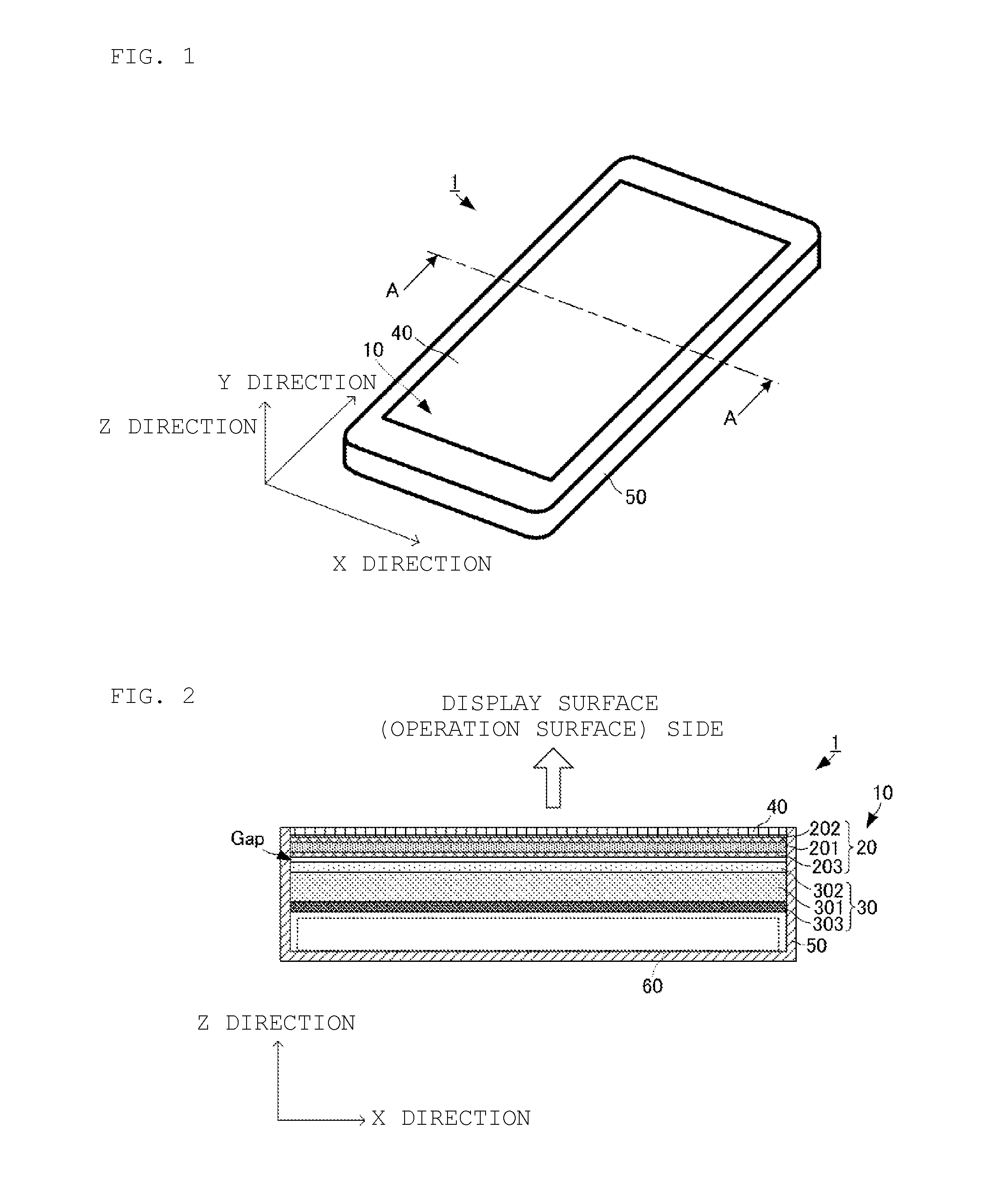

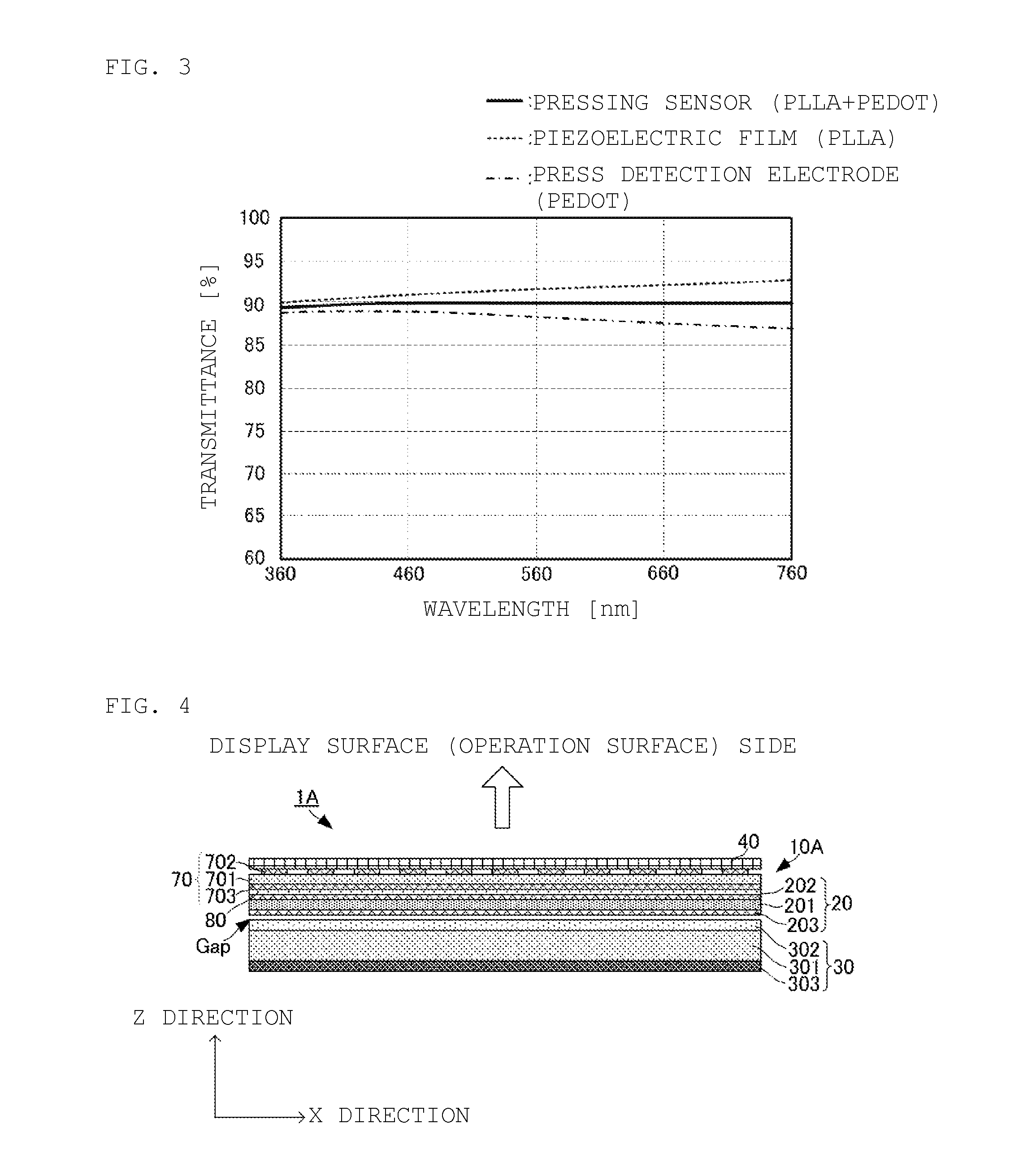

Pressing sensor, touch sensor, pressing sensor-equipped display panel, and touch sensor-equipped display panel

InactiveUS20160147355A1High light transmittanceUniform light transmittanceInput/output processes for data processingImage formationTransmittance

A pressing sensor-equipped display panel that includes a pressing sensor and a display panel. The pressing sensor is arranged between a protecting member which composes an operation surface and the display panel. The pressing sensor includes a piezoelectric film which is made of polylactic acid which is an organic piezoelectric material. Electrodes are formed on both principal surfaces of the piezoelectric film. At least one of the electrodes is made of a polythiophene material. Display image formation light which has been emitted from the display panel and been incident on the pressing sensor transmits through the piezoelectric film and the electrodes. In this regard, a variation of a transmittance of each wavelength of the piezoelectric film, and a variation of a transmittance of each wavelength of an electrode made of the polythiophene material cancel each other.

Owner:MURATA MFG CO LTD

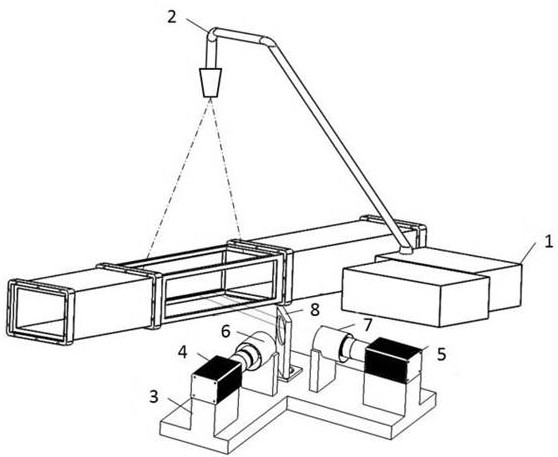

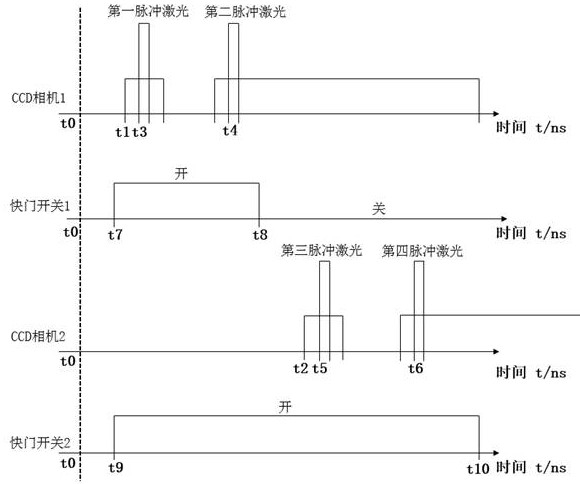

Shutter integrated device, control system and time sequence control method

ActiveCN112730875ASolve debugging difficultiesImprove efficiencyTelevision system detailsColor television detailsComputer hardwareShutter

The invention discloses a shutter integrated device, a control system and a time sequence control method. The shutter integrated device comprises an integrated device bottom plate, a first CCD camera, a second CCD camera, a first shutter switch, a second shutter switch and a light splitting device. The first CCD camera, the second CCD camera and the light splitting device are all installed on the integrated device bottom plate. The first shutter switch is arranged on the first CCD camera, and the second shutter switch is arranged on the second CCD camera; and the first shutter switch and the second shutter switch are respectively connected with the control system. According to the invention, the debugging difficulty caused by the position and state difference of the camera is avoided, the efficiency is improved, the system error is eliminated, the MHz exposure is realized, the exposure images do not interfere with each other and influence each other, and the overall precision and stability of the system are improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Display panel and manufacturing method thereof, and display apparatus

InactiveCN106773356AHigh light transmittanceImprove light transmittance differenceSolid-state devicesNon-linear opticsInsulation layerTransmittance

The invention provides a display panel and a manufacturing method thereof, and a display apparatus. The display panel includes first sub pixel areas and second sub pixel areas, wherein the aperture ratio of the first sub pixel areas is less than that of the second sub pixel areas; the thickness of an insulation layer corresponding to the first sub pixel areas is less than the thickness of the insulation layer corresponding to the second sub pixel areas such that the cell gap of the display panel corresponding to the first sub pixel areas is greater than the cell gap of the display panel corresponding to the second sub pixel areas, and the aperture ratios of the first sub pixel areas and the second sub pixel areas are even. Liquid crystal lighting effect difference between the display panel corresponding to the first sub pixel areas and the display panel corresponding to the second sub pixel areas can remedy aperture ratio difference between the first sub pixel areas and the second sub pixel areas, and then the light transmittance of the display pane in the first sub pixel areas and the second sub pixel areas can be improved, the light transmittance of the display panel is more even, and the display effect of the display panel is improved.

Owner:BOE TECH GRP CO LTD +1

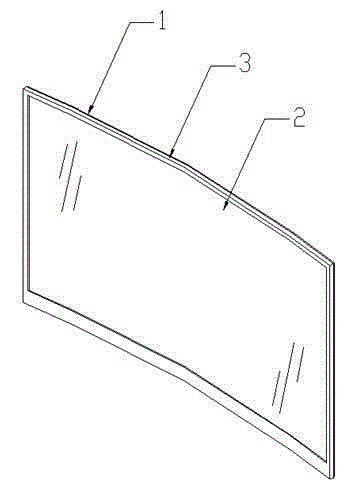

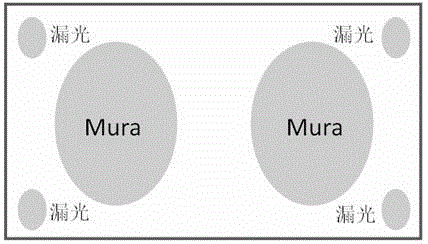

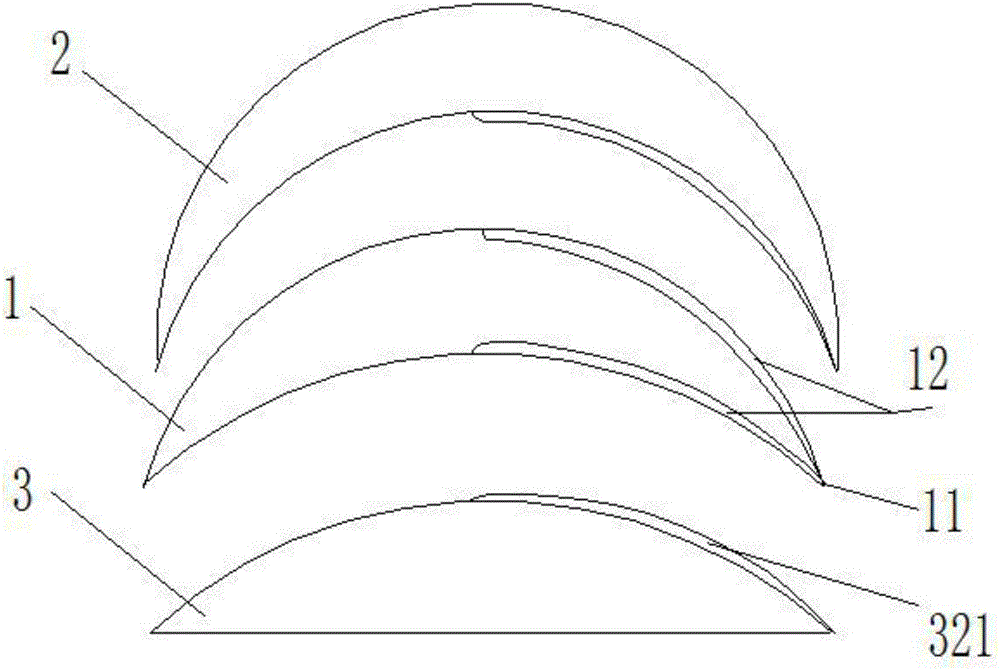

Inwards concave spherical surface liquid crystal display module

InactiveCN104914608AUniform light transmittanceSolve the problem of isometric visual errorNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses an inwards concave spherical surface liquid crystal display module. The inwards concave spherical surface liquid crystal display module comprises a backlight module, a liquid crystal panel arranged on the backlight module and a frame arranged on the periphery of the backlight module and the liquid crystal panel, wherein the backlight module, the liquid crystal panel and the frame are all of curved surface structures in the horizontal and vertical directions, the radius of curvature of the curved surface structure in the horizontal direction is smaller than 3000 mm, and the radius of curvature of the curved surface structure in the vertical direction is smaller than 10000 mm. The inwards concave spherical surface liquid crystal display module can effectively resolve the problems of equal-visual-range visual errors, and Mura and light leakage of picture displaying.

Owner:ALLIN OPTO ELECTRONICS SUZHOU CO LTD

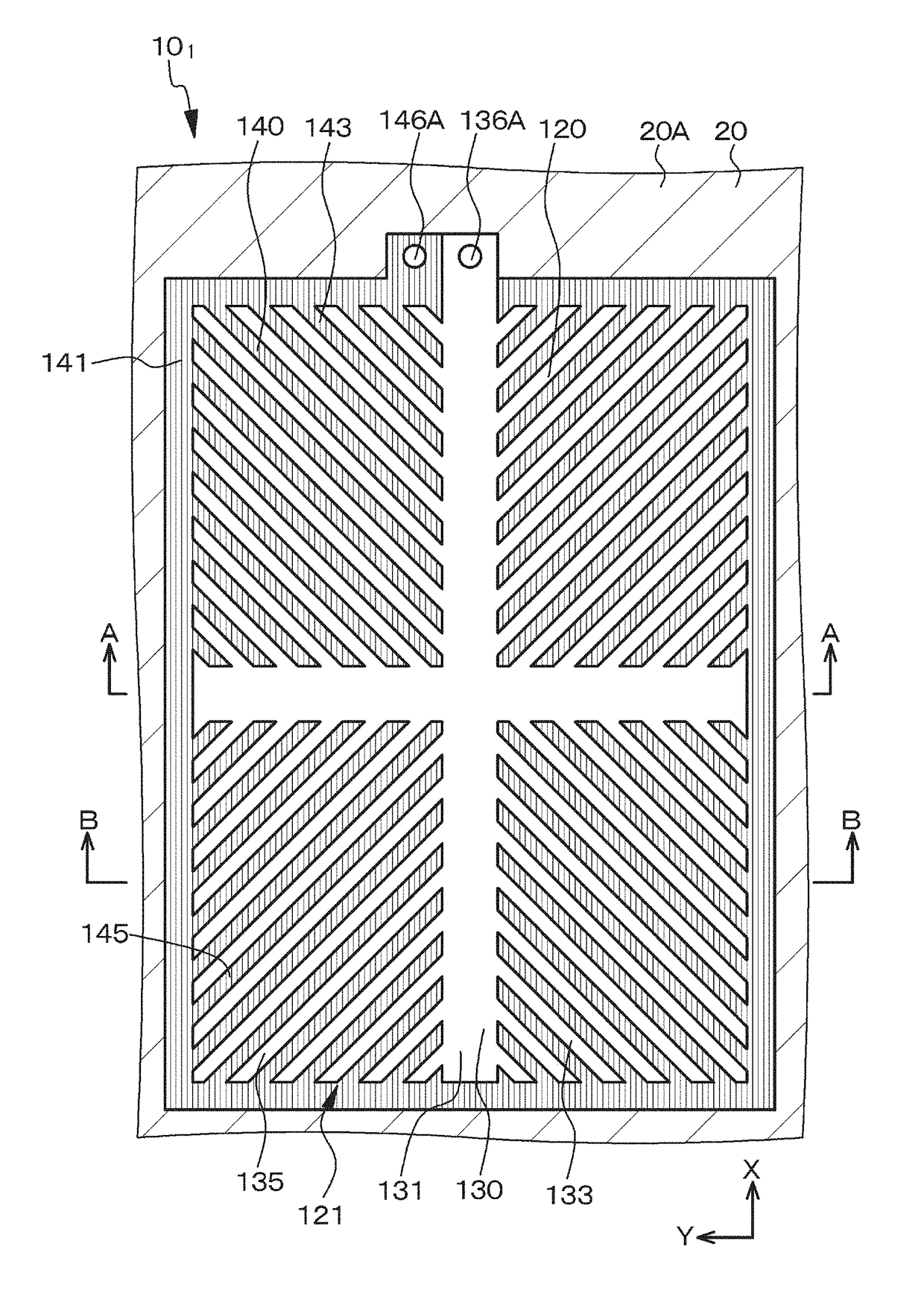

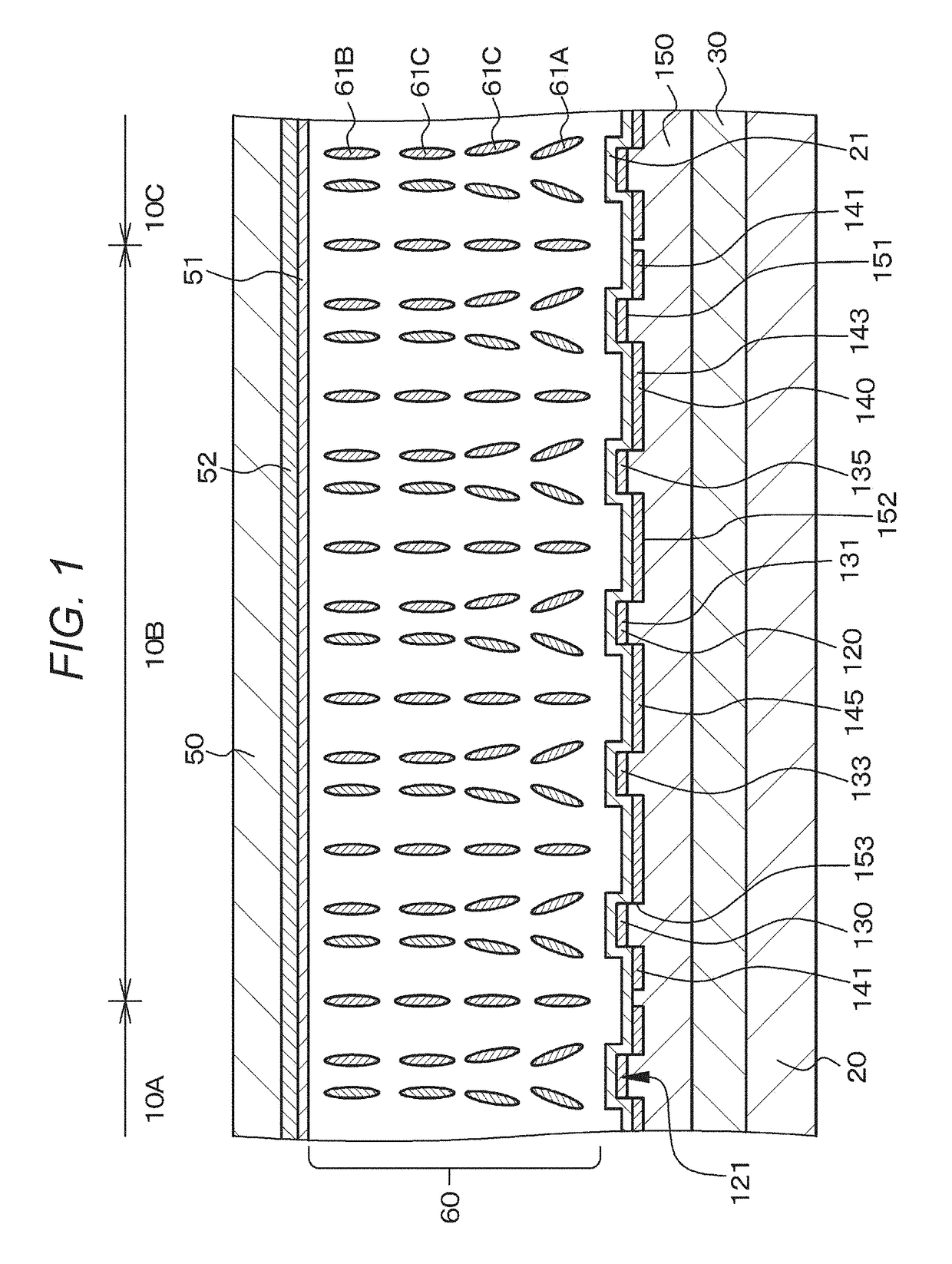

Liquid crystal display device

ActiveUS10120242B2Layer is highHigh strengthStatic indicating devicesNon-linear opticsConductive materialsLiquid crystal molecule

Owner:SATURN LICENSING LLC

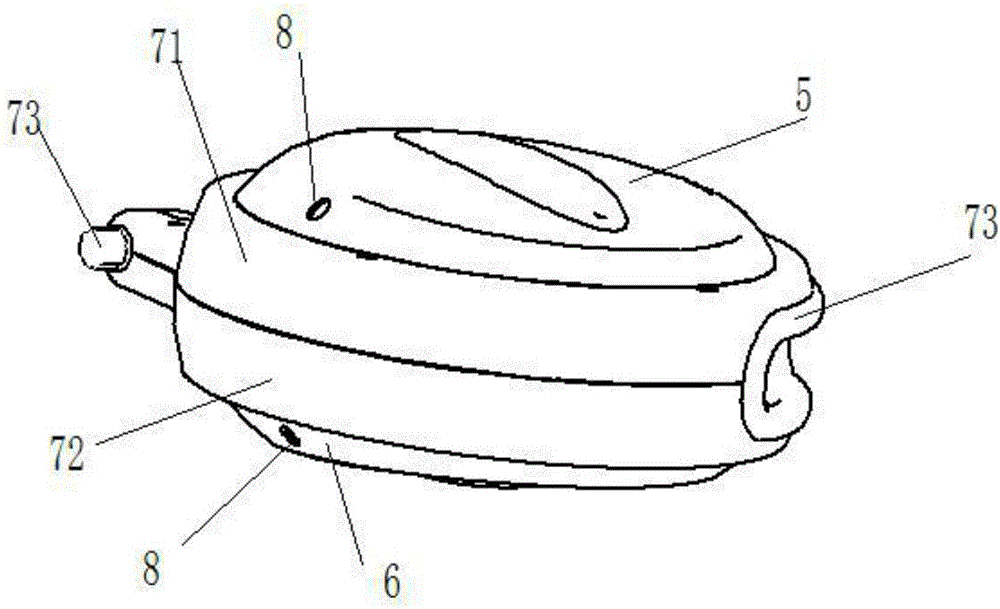

Manufacturing method and injection mold for multi-layer lens

InactiveCN106393573AShorten cooling timeUniform light transmittanceOptical articlesRaw materialPhysics

Owner:TAIZHOU DIANJING MOLD

Capacitive touch pad

InactiveUS8674249B2Increase capacitanceReduce capacitanceElectronic switchingInput/output processes for data processingCapacitanceTransmittance

A capacitive touch panel has precise etching lines formed on a transparent conductive film so as to form with a desired pattern. As a result, the hollowed portion on the conductive film will be reduced greatly and thus the flatness of the capacitance sensing structure will be improved and the transmittances in different areas will tend to be uniform. Thus the image distortion in the screen below the touch panel will be improved. Besides, the etching lines will divide the waste etching areas on the conductive lines into a plurality of small units which can reduce the capacitances of the noises.

Owner:YOUNG FAST OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com