Display panel and manufacturing method thereof, and display apparatus

A display panel, consistent technology, applied in optics, instruments, electrical components, etc., can solve the problems affecting the display effect of the screen, and achieve the effect of improving the twill Mura phenomenon, uniform light transmittance, and improving the display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

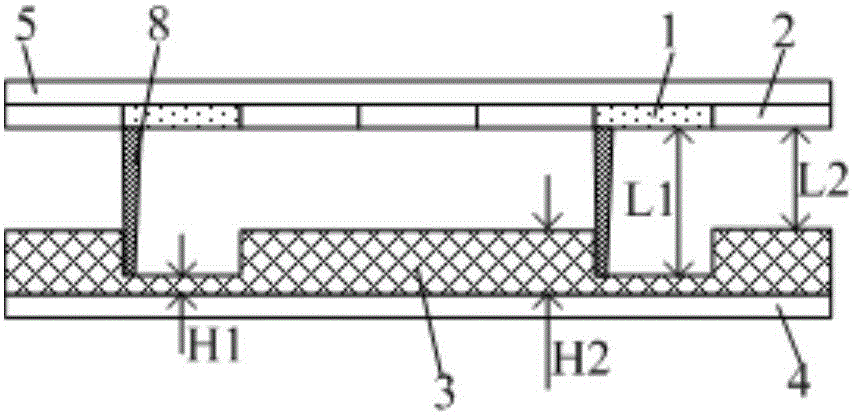

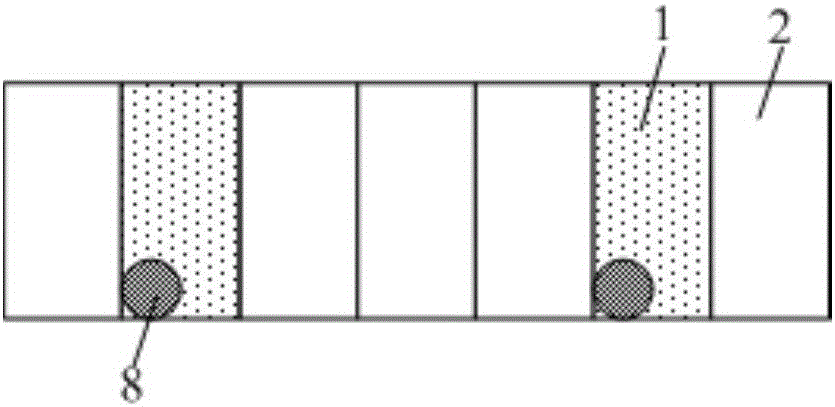

[0042] This embodiment provides a display panel, such as figure 2 and image 3 As shown, the display panel includes a first sub-pixel region 1 and a second sub-pixel region 2, the aperture ratio of the first sub-pixel region 1 is smaller than the aperture ratio of the second sub-pixel region 2; the display panel also includes an insulating layer 3, the insulating layer The thickness H1 corresponding to the first sub-pixel area 1 of 3 is smaller than the thickness H2 corresponding to the second sub-pixel area 2, so that the cell gap L1 corresponding to the first sub-pixel area 1 of the display panel is larger than the corresponding second sub-pixel area 2 The cell gap L2, so that the aperture ratios of the first sub-pixel area 1 and the second sub-pixel area 2 are uniform.

[0043] Wherein, the display panel refers to a liquid crystal display panel. Since the cell thickness of the display panel is positively correlated with its liquid crystal light effect during display, that ...

Embodiment 2

[0056] This embodiment provides a display panel, such as Figure 4 and Figure 5 As shown, the display panel includes a first sub-pixel region 1 and a second sub-pixel region 2, the aperture ratio of the first sub-pixel region 1 is smaller than the aperture ratio of the second sub-pixel region 2; the display panel also includes an insulating layer 3, the insulating layer The thickness H1 corresponding to the first sub-pixel area 1 of 3 is smaller than the thickness H2 corresponding to the second sub-pixel area 2, so that the cell gap L1 corresponding to the first sub-pixel area 1 of the display panel is larger than the corresponding second sub-pixel area 2 The cell gap L2, so that the aperture ratios of the first sub-pixel area 1 and the second sub-pixel area 2 are uniform.

[0057] Wherein, the display panel refers to a liquid crystal display panel. Since the cell thickness of the display panel is positively correlated with its liquid crystal light effect during display, th...

Embodiment 3

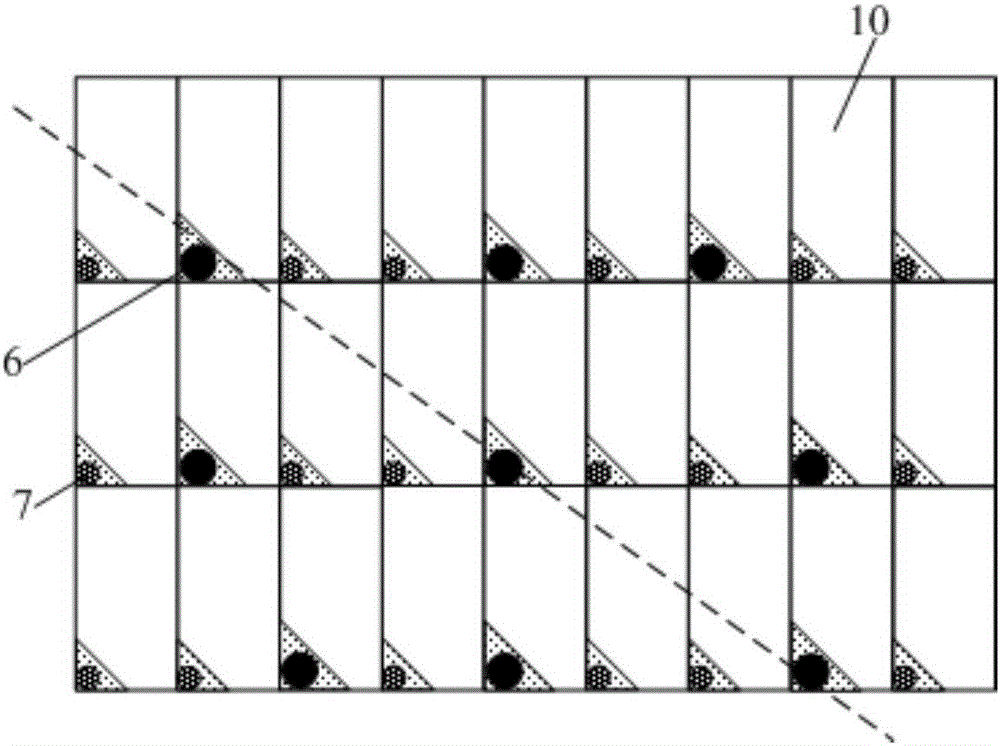

[0070] This embodiment provides a display panel, which is different from Embodiment 1-2, such as Figure 6 and Figure 7 As shown, on the basis of the display panel provided in Embodiment 2, the display panel further includes a third sub-pixel region 9, and the aperture ratio of the second sub-pixel region 2 is smaller than the aperture ratio of the third sub-pixel region 9; The third sub-pixel region 9 is not provided with any spacers; the thickness H2 of the insulating layer 3 corresponding to the second sub-pixel region 2 is smaller than the thickness H3 corresponding to the third sub-pixel region 9, so that the corresponding second sub-pixel of the display panel The cell gap L2 of the region 2 is larger than the cell gap L3 of the corresponding third sub-pixel region 9 , so that the aperture ratios of the second sub-pixel region 2 and the third sub-pixel region 9 are uniform.

[0071] Since the main spacer 6 correspondingly occupies a part of the area in the first sub-pix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com