[0003] The structure of the resistive touch panel mainly includes two transparent conductive films separated by a certain gap and arranged oppositely. The conductive film on the top is arranged on a surface of a flexible transparent film, and the conductive film on the bottom The film is set on one surface of a transparent glass substrate with a hard material, and the two conductive films are sealed in a board body; the upper and lower conductive films and the board body of this resistive touch panel are all transparent materials, so It is suitable to be configured in front of the display screen of electronic products, so that users can use the instructions on the screen to lightly touch and press the desired position of the panel to perform input functions, and it can be done by using commonly available pen tips and other objects Precise touch position operation, so it can be applied to smaller use area or higher-precision point input, especially suitable for input operations of

character recognition with many strokes or complex shapes; however, the aforementioned resistive touch panel The input

operation mode through the touch panel will cause the conductive film inside the board to withstand repeated stress and strain to cause damage, so the service life is limited, and when it is used for input with fingers or tools with thicker ends, it often gets relatively poor results. Inaccurate input results, so the adoption of input tools has many limitations

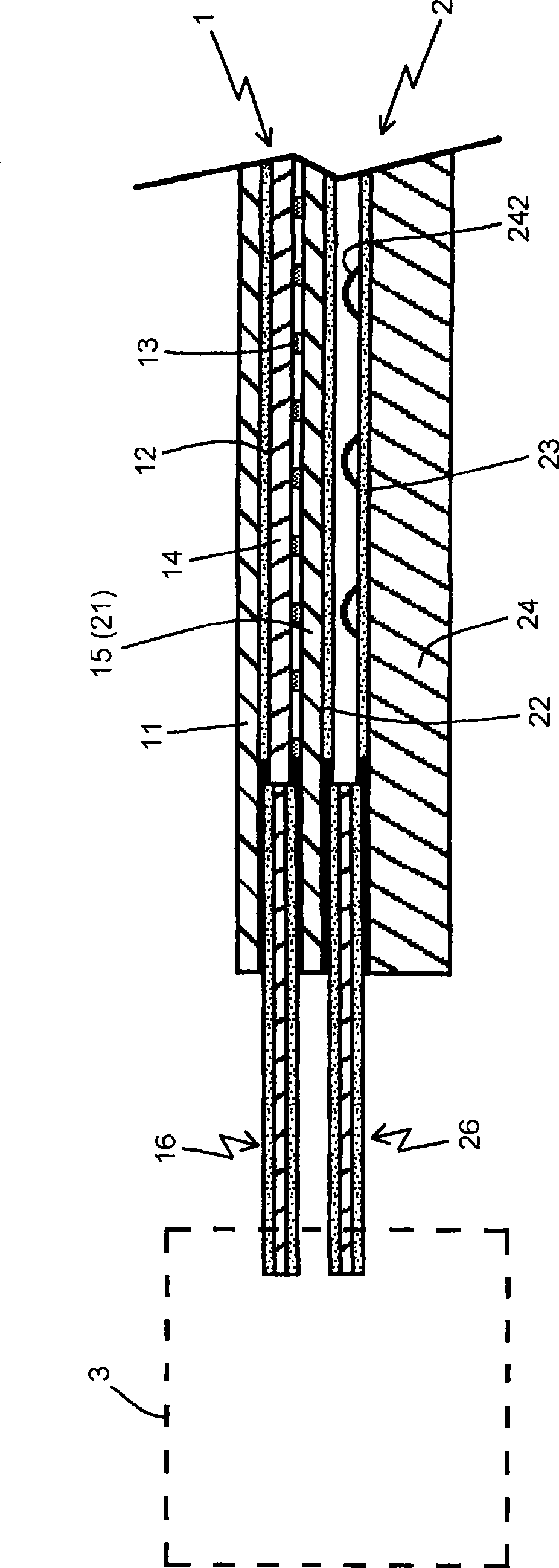

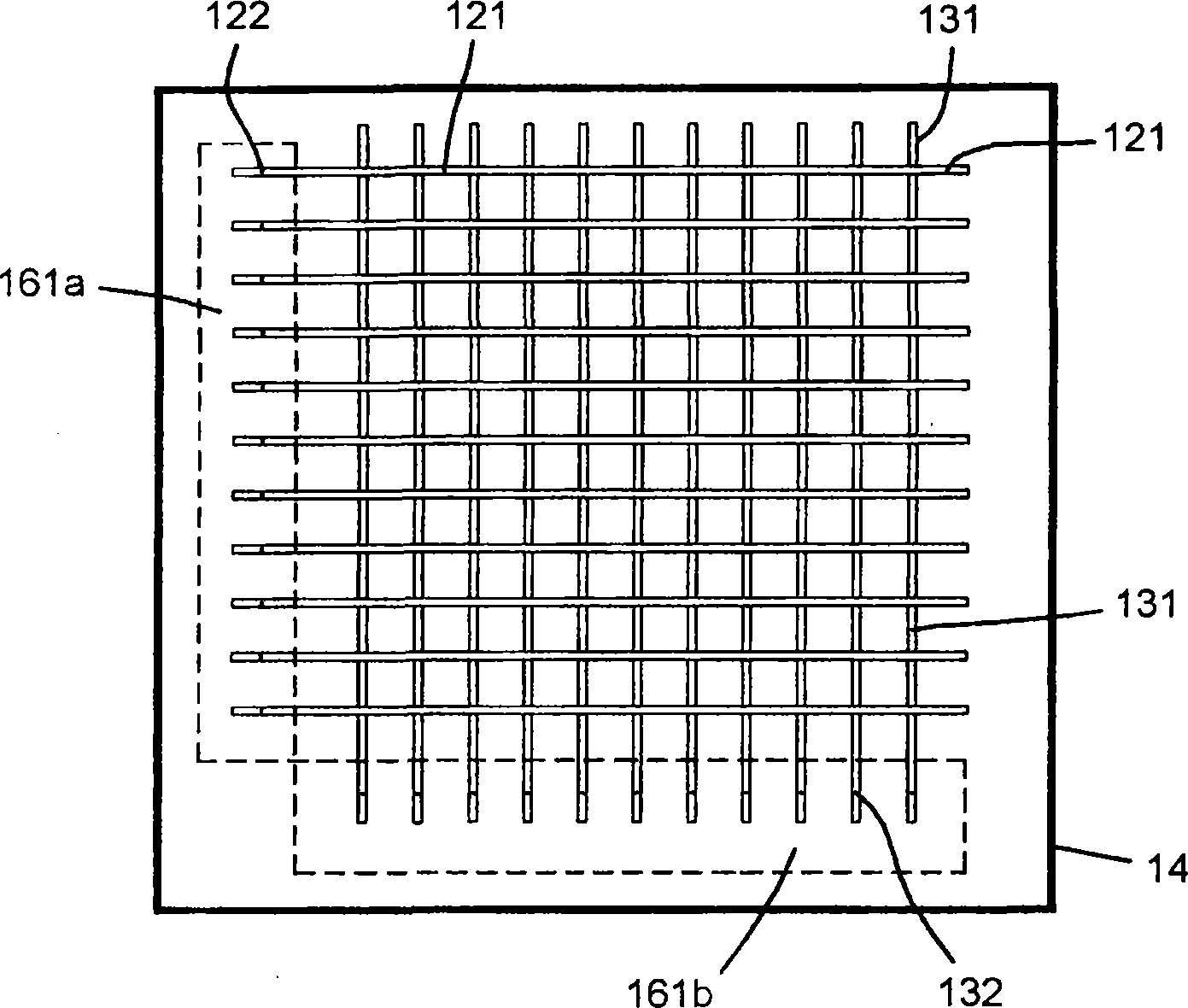

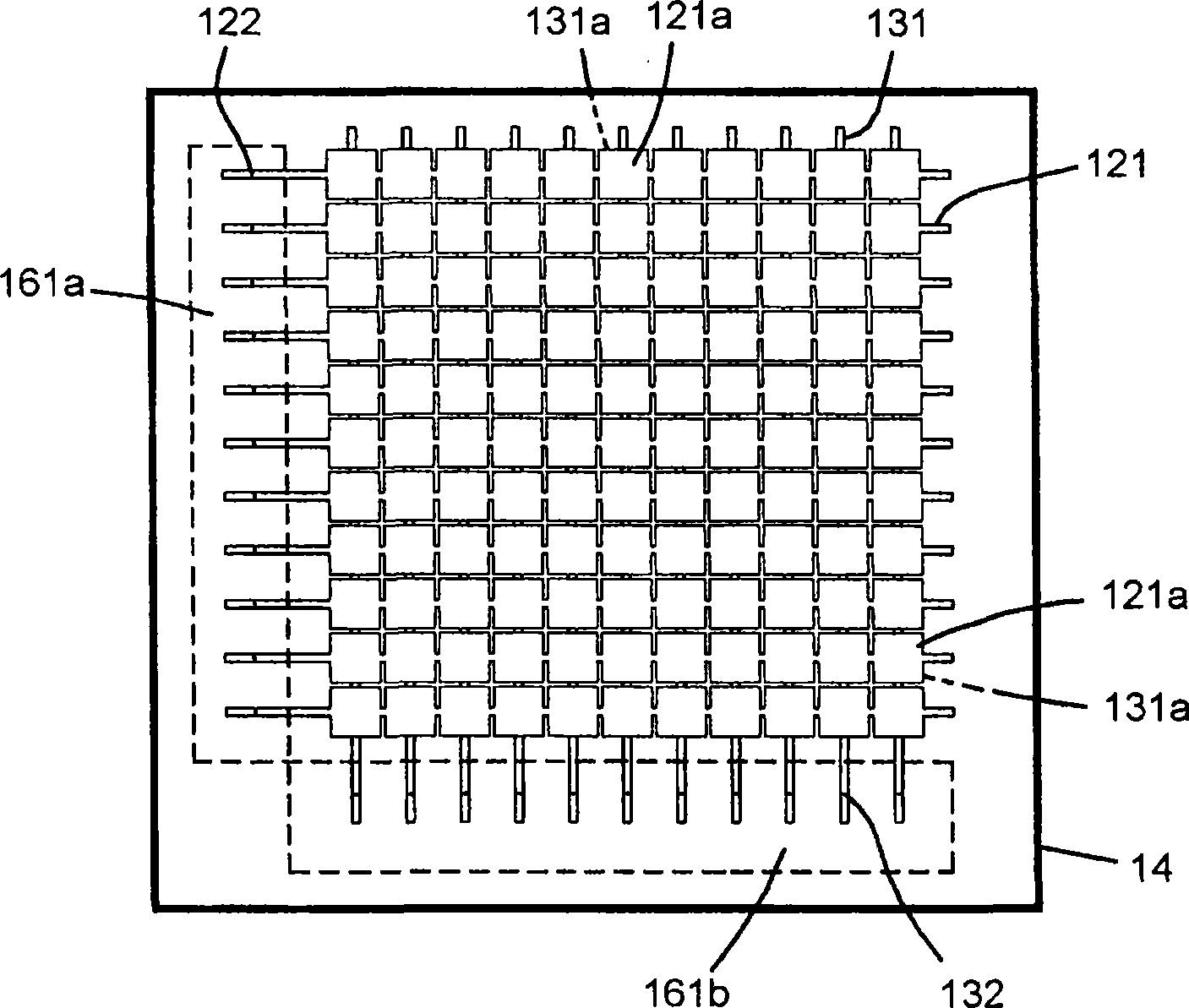

[0004] As for the structure of the capacitive touch panel, it slightly includes an x-axis sensing layer (x trace) and a y-axis sensing layer (y trace), so that the x-axis and y-axis sensing

layers are insulated within the touch panel body, and the The x-axis and y-axis sensing

layers are respectively grounded and connected to a

control circuit. During operation, when a finger or conductor touches or lightly slides over the surface of the touch panel, a

capacitive effect is generated at the moment the user's finger or conductor touches, Therefore, the

control circuit can determine the touch position of the finger or the conductor through the change of the capacitance value; since the capacitive touch panel can be input by the finger, it has the convenience of input operation, and its input operation does not need to go through the touch pressure, so it will not let The panel has the

disadvantage of being damaged by repeated stress and deformation, and this kind of touch panel has a simple structure, fewer components, high product yield, and is suitable for

mass production to reduce costs; in addition, this kind of touch panel also has multi-point Sensing performance, which means that this kind of touch sensing device has the performance of multitasking control, so it can be used in high-level control operations, for example, in the control of video games, it can make the virtual subject being controlled more Actions are more flexible or have more diverse performances...; However, although the capacitive

touchpad can be used for finger input, it is very convenient, but the accuracy of finger input sensing is not high, and it is easy to cause misoperation, resulting in use. It is troublesome, especially for the input of

character recognition, such as

Chinese characters with many strokes or complex shapes, the recognition rate is extremely low, and it is even difficult to reach a practical level, although the aforementioned problems can be solved by using a special However, it is still limited for use on a panel with a smaller area or for higher-precision point input. Moreover, the use of a special sensor pen often makes users feel very inconvenient in many occasions, such as When not carrying or losing pens

In addition, in recent years, some capacitive touch panels have changed to use light-transmitting insulating materials such as PET as the base material, and use low-impedance transparent

conductive materials such as silver glue as the sensing layer to form a transparent capacitive touch panel. Control board, so it is suitable to be arranged in front of the display screen of electronic products, so that users can lightly touch and press the desired position of the panel through the instructions on the screen screen, and then perform function input; this existing transparent

capacitor Type touch panel, the silver glue conductive material of the sensing layer is not completely transparent, and the sensing layers are respectively etched to form traces (Trace) of rhombus

grid pattern, so that transparent traces are formed on the working area of the touch panel. The stitched portion and the non-stitched portion (that is, the hollowed-out portion) with different light rates, because the stitched portion and the non-stitched portion with different light transmittances on the existing transparent capacitive touch panel are clearly separated, It will still cause uneven

refraction of the image light on the display screen at the bottom of the transparent touch panel, resulting in blurred and distorted images

Login to View More

Login to View More