Patents

Literature

57results about How to "Improve Laser Welding Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition for laser welding and molded article

ActiveUS20070129475A1Transmittance be uniformHigh welding strengthLamination ancillary operationsLaminationChemistryPlasticizer

A laser weldable PBT-series resin composition and a molded product thereof are provided, in which the composition is weldable uniformly and has high welding strength even when the composition comprises a polybutylene terephthalate (PBT) as a base. The laser weldable resin composition comprises 1 to 50 parts by weight of (B) an elastomer (such as a polystyrene-series thermoplastic elastomer or a polyester-series thermoplastic elastomer), 5 to 100 parts by weight of (C) a polycarbonate-series resin, 1 to 10 parts by weight of (D) a plasticizer (e.g., an aromatic polycarboxylic acid ester, and an acrylic plasticizer), and 0 to 100 parts by weight of (E) a filler or reinforcing agent (such as a glass fiber), relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin (a homopolyester or a copolyester). The molded product prepared from the resin composition has a small light transmittance fluctuation range depending on sites to be irradiated of the molded product. Thus, the molded product can be bonded to a counter part article uniformly by a laser welding.

Owner:POLYPLASTICS CO LTD

Polybutylene terephthalate resin composition for fusion bonding with laser and molded article

InactiveUS20050165176A1Improve Laser Welding PerformanceImprove welding strengthPolytetramethylene terephthalatePolymer science

A laser weldable PBT-series resin composition comprises a polybutylene terephthalate (PBT)-series resin (A), and at least one resin (B) selected from the group consisting of a polycarbonate-series resin (b1), a styrenic resin (b2), a polyethylene terephthalate-series resin (b3) and an acrylic resin (b4). The PBT-series resin (A) may be a PBT homopolyester, or a PBT-series copolymer modified with not more than 30 mol % of a copolymerizable monomer (e.g., a bisphenol compound or an adduct thereof with an alkylene oxide, and an asymmetrical aromatic dicarboxylic acid). The ratio (weight ratio) of the resin (B) relative to the PBT-series resin (A) [the former / the latter] is about 0.1 / 1 to 1.5 / 1. The resin composition may comprise a glass fiber. The resin composition is excellent in laser weldability, and can improve in welding strength of a shaped article formed from the resin composition.

Owner:WIN TECH POLYMER LTD

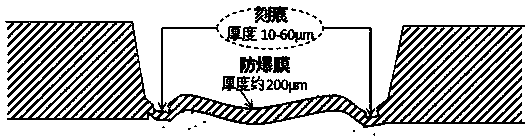

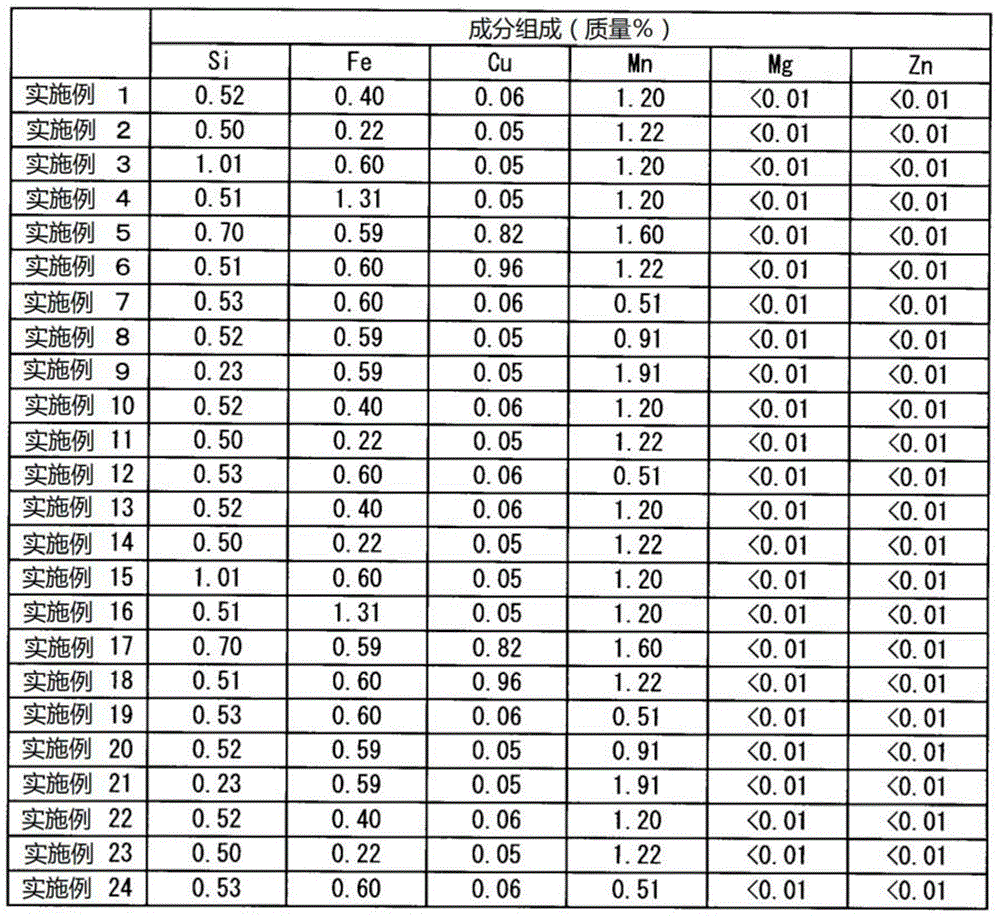

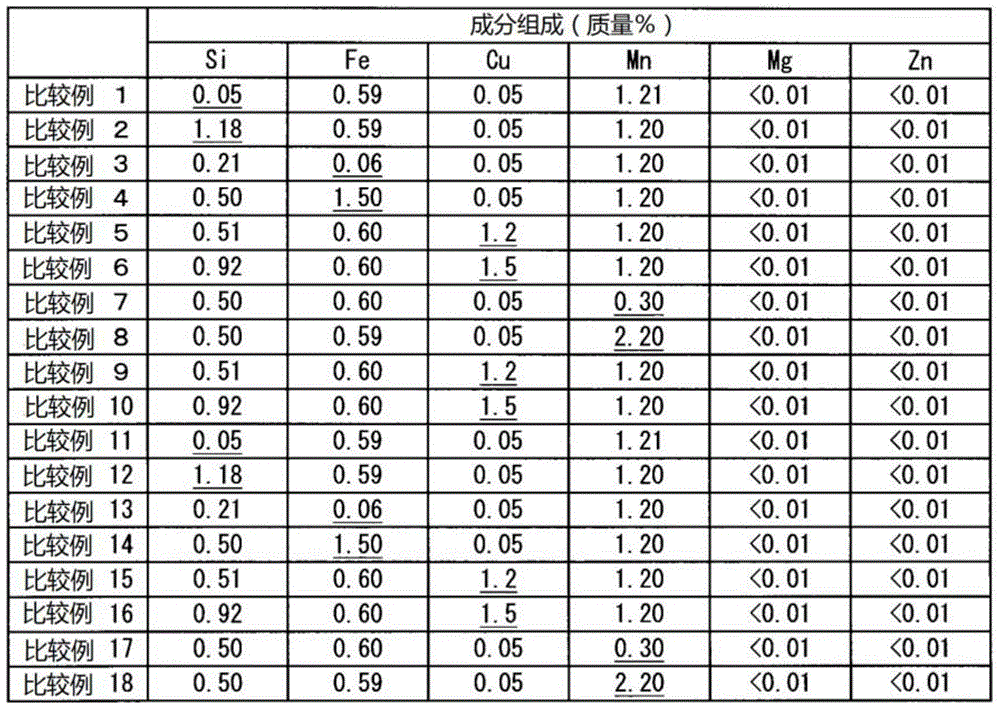

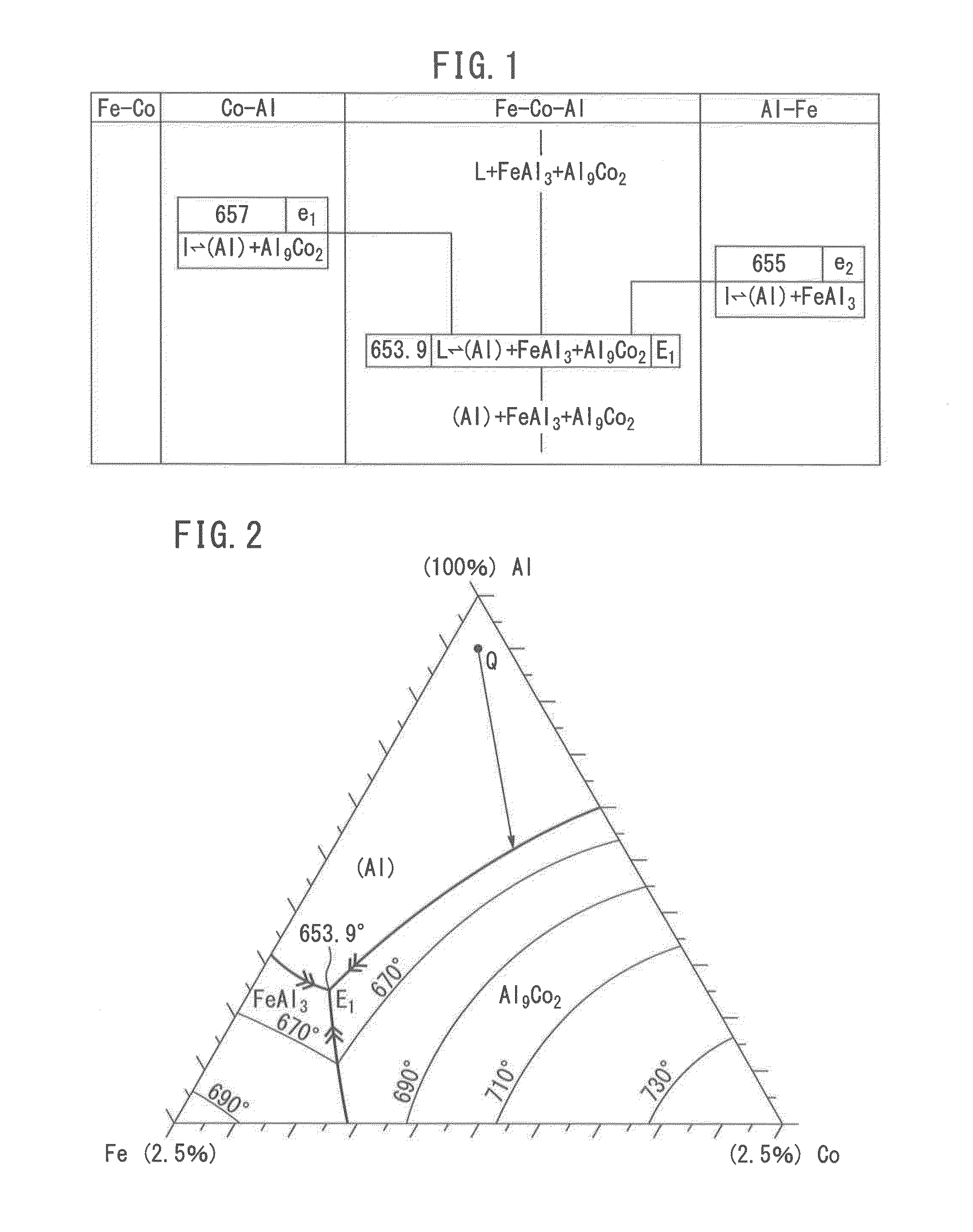

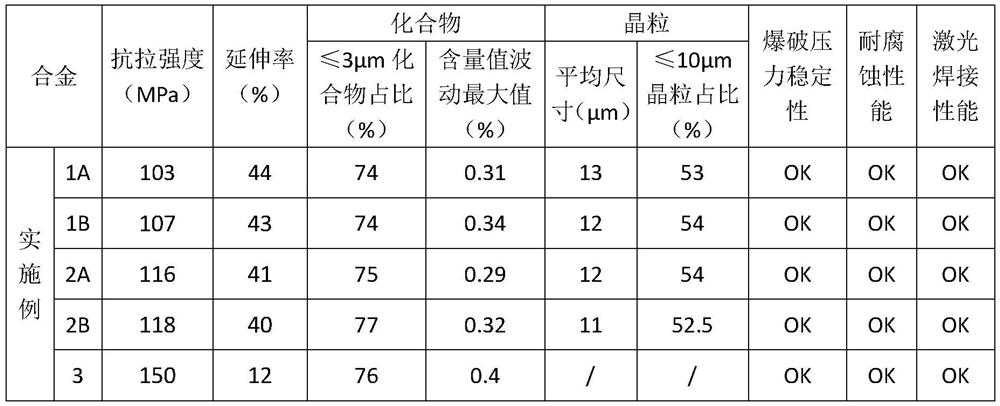

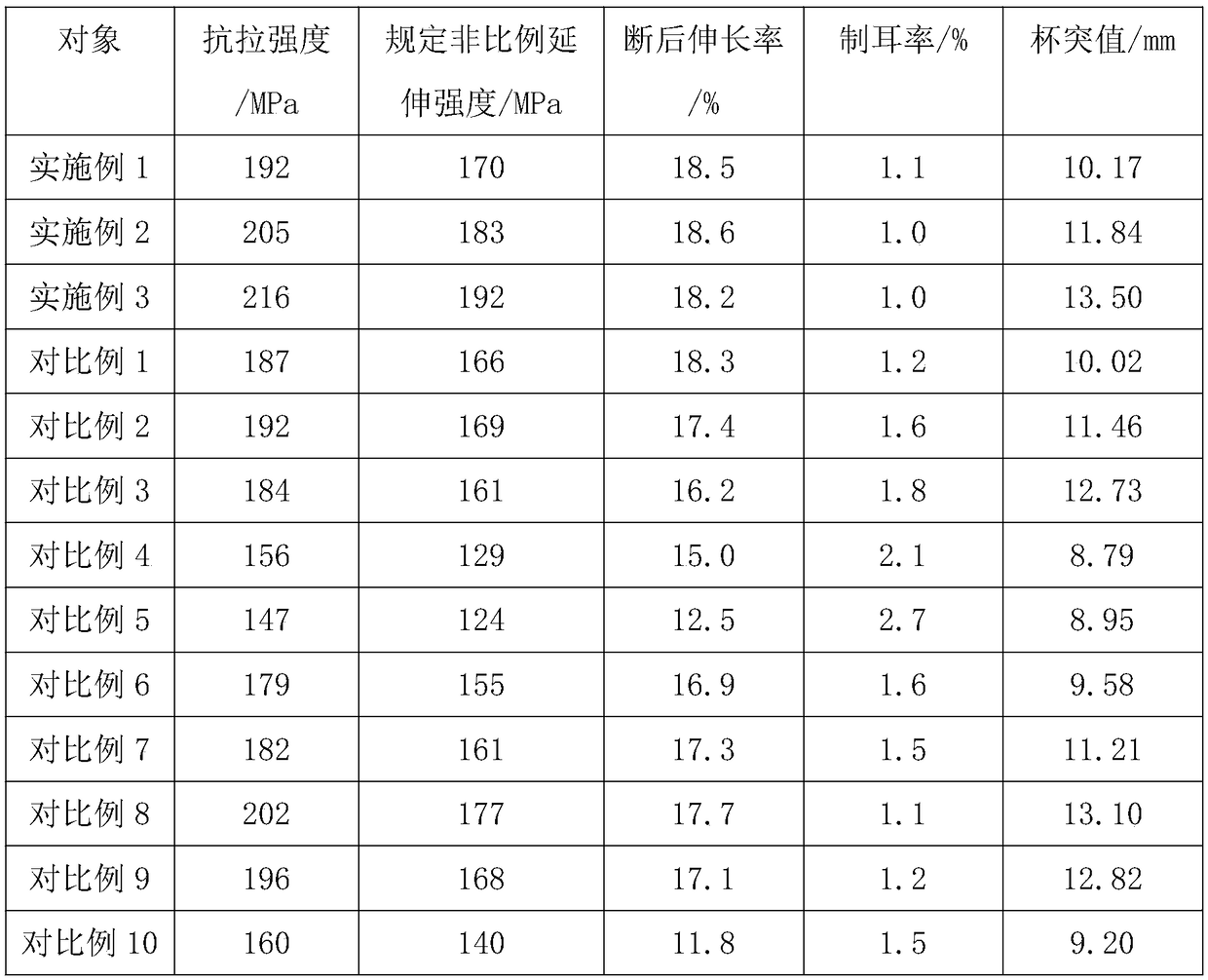

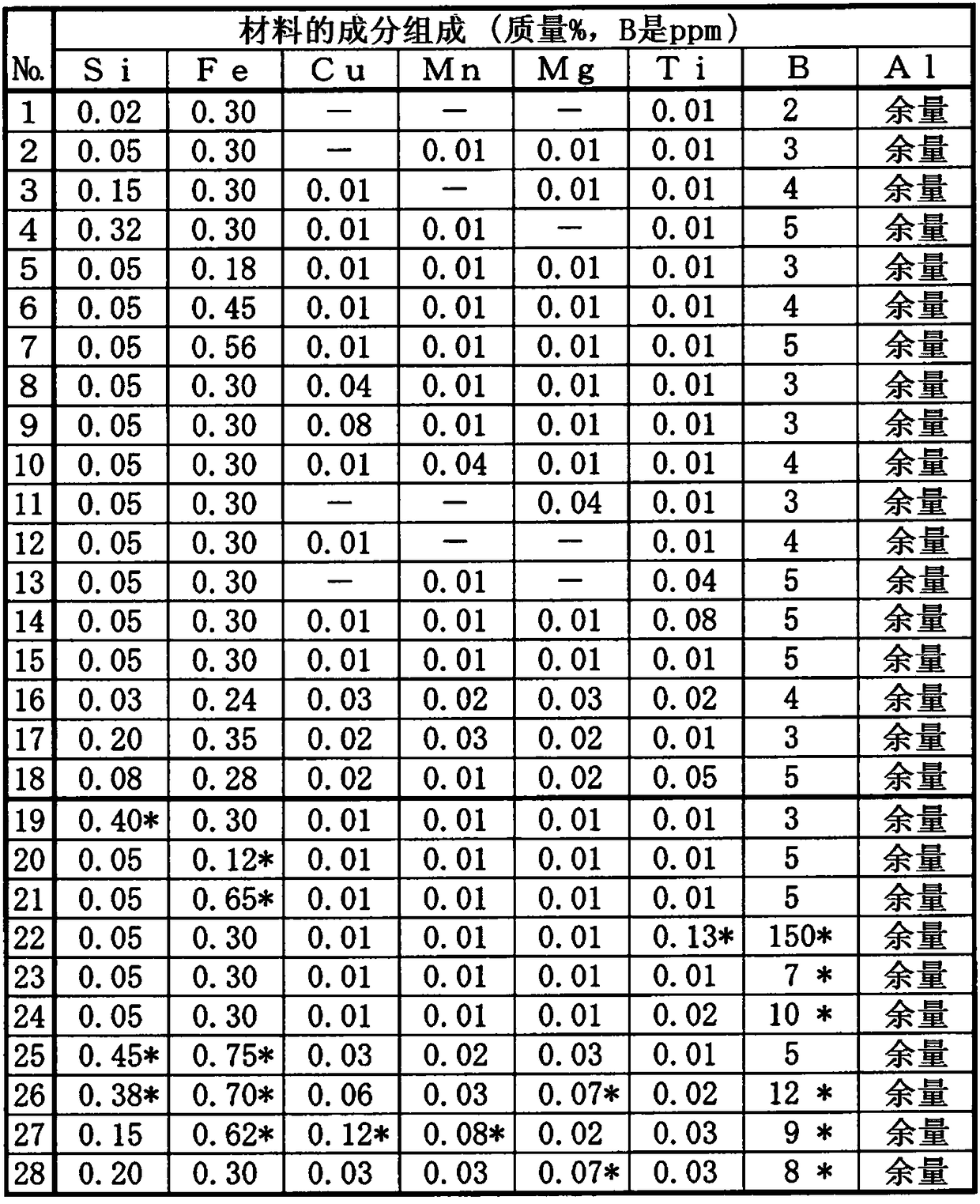

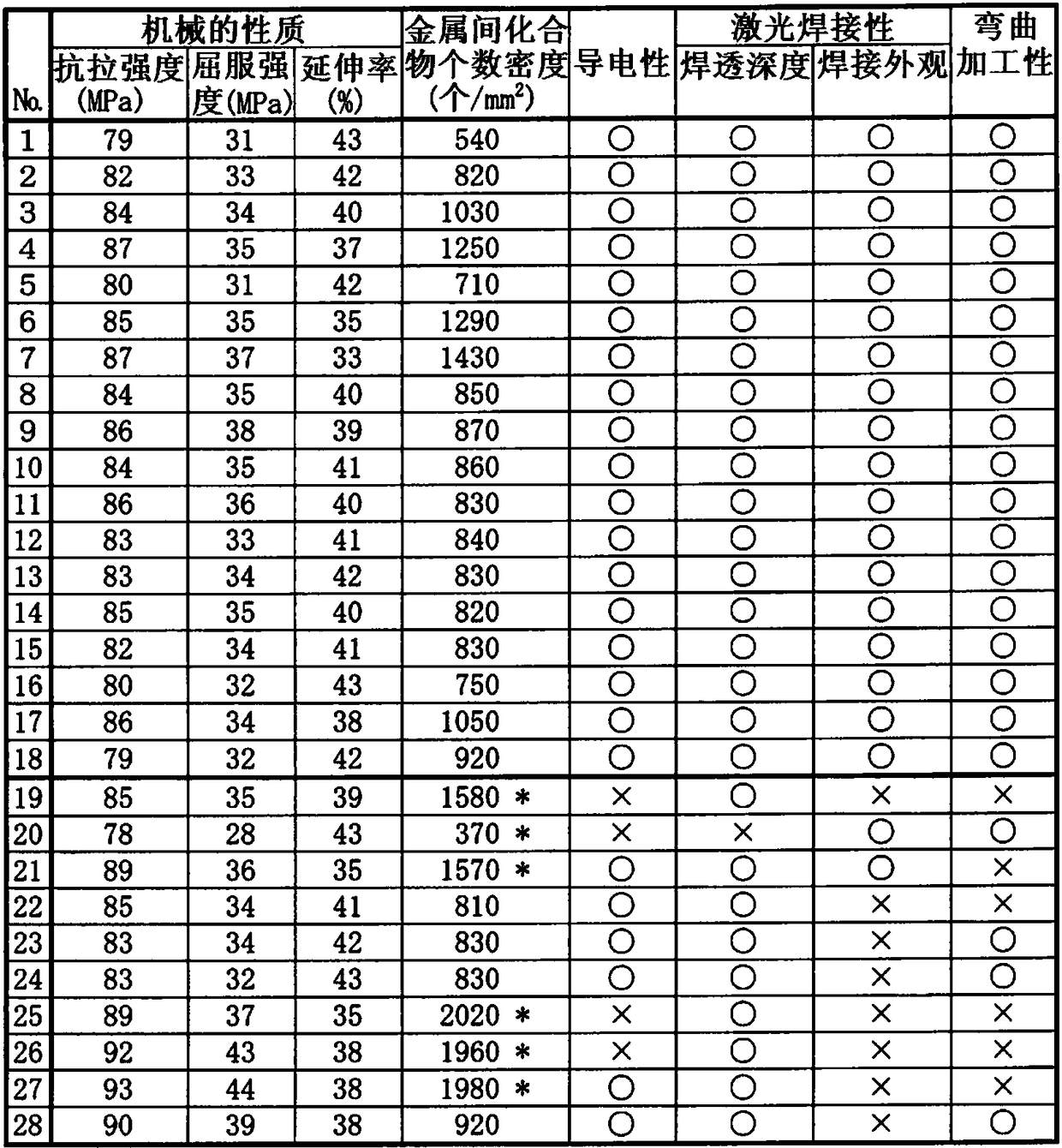

Aluminum alloy strip for integrated battery cover plate and preparing method of aluminum alloy strip

InactiveCN107604212AImprove deep drawing performanceImprove Laser Welding PerformanceCell component detailsDetonationAluminium alloy

The invention discloses an aluminum alloy strip for an integrated battery cover plate and a preparing method of the aluminum alloy strip. The aluminum alloy strip comprises components including 1.2%-1.5% of Fe, 0.25%-0.5% of Mn, 0.05%-0.2% of Si, 0.005%-0.1% of Ti, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.05% of Mg, smaller than or equal to 0.05% of Zn and the balance aluminum and inevitable impurities. Through component design and technology control, the characteristics that when an Al-Fe-Mn alloy is machined to a certain degree, softening happens, and a high laser absorbing rate and a low heat conductivity coefficient are achieved are utilized, during downstream manufacturing, the battery cover plate and an anti-explosion port are directly integrally punched and formed, annealing and welding are avoided, an anti-explosion sheet is uniform in thickness and stable in performance, the anti-explosion sheet and cover plate welding procedure and leakage, instable detonation pressure and other hidden danger caused by welding are reduced, and the preparing method of the aluminum alloy strip for the battery cover plate is novel.

Owner:CHINALCO RUIMIN +1

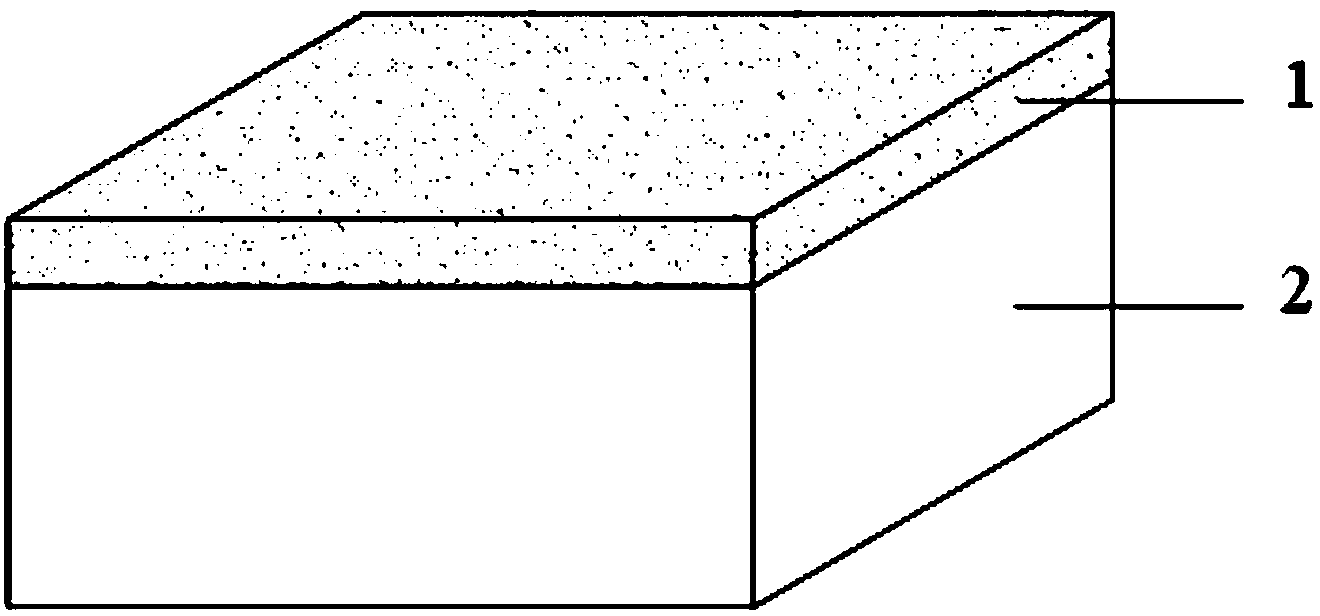

Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

ActiveCN103367270AImprove thermal conductivityReduce bloatSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationCarbide silicon

The invention discloses an aluminum silicon carbide composite material with a laser welding layer and a preparing method of the aluminum silicon carbide composite material. The composite material is composed of the laser welding layer and an aluminum silicon carbide layer, the laser welding layer is composed of pure aluminum or aluminum alloy comprising silicon and aluminum, the volume fraction of the silicon in the aluminum alloy is a, the volume fraction of the aluminum in the aluminum alloy is b, the a is greater than 0 and less than or equal to 30%, and the b is greater than or equal to 30% and less than 100%. The aluminum silicon carbide layer is composed of silicon carbide and pure aluminum or aluminum alloy, and the volume fraction of the silicon carbide ranges from 30% to 70%. The preparing method comprises the steps that silicon carbide pelleting powder is prepared firstly, then silicon carbide preformed parts are prepared, and the aluminum silicon carbide composite material with the laser welding layer is prepared in the vacuum pressure impregnation method finally. The aluminum silicon carbide composite material is good in weldability and gas tightness, high in heat conductivity, low in coefficient of thermal expansion, simple in preparing method, efficient and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

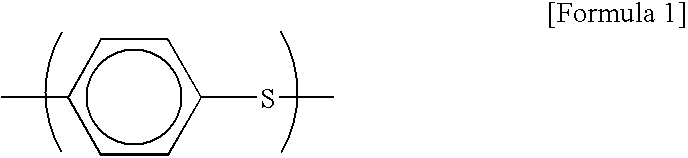

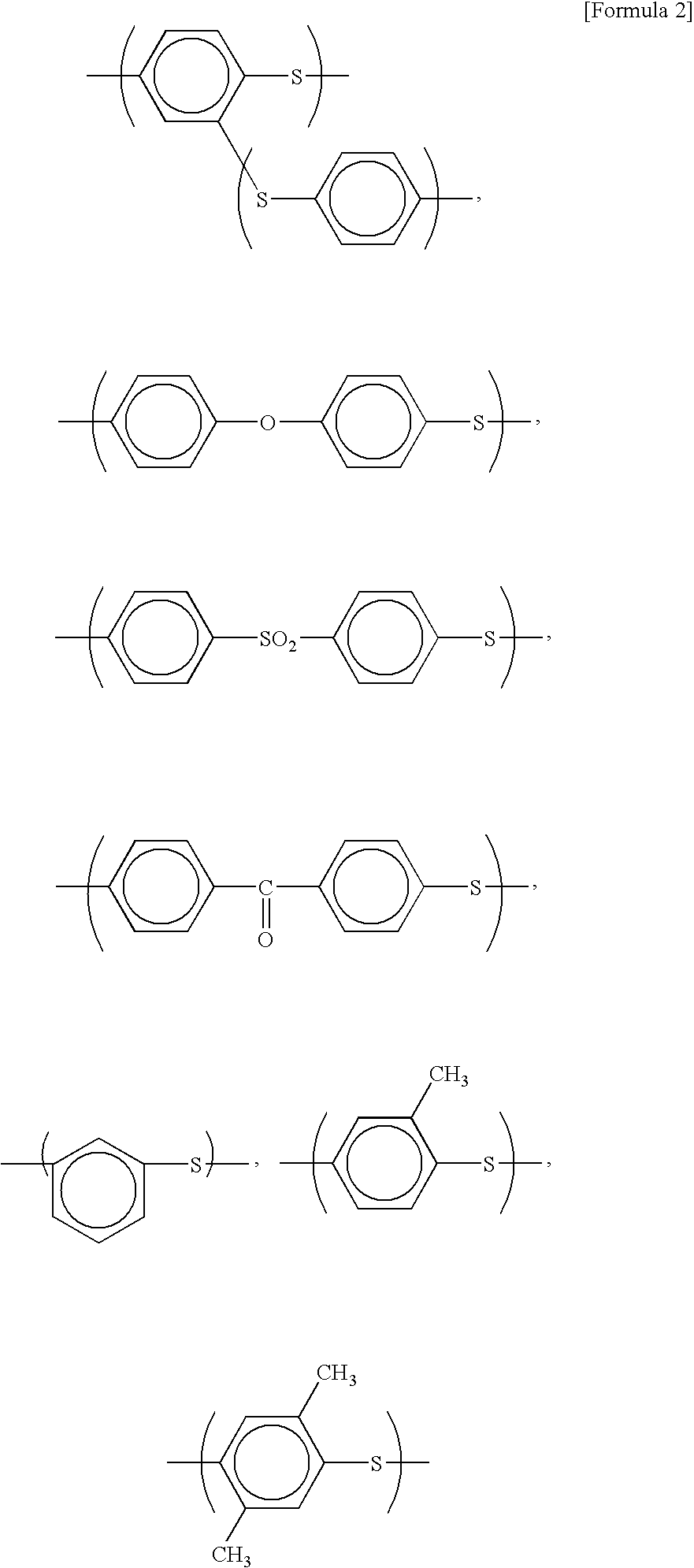

Polyphenylene sulfide resin compositions

InactiveUS20070021549A1Avoid breakingReduce heat resistance requirementsSpecial tyresGlass fiberHeat deflection temperature

A polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 12 μm or lager and has a crystallization temperature during cooling of 205° C. or lower. Also provided is a polyphenylene sulfide resin composition which comprises 100 parts by weight of a polyphenylene sulfide resin (A) and, compounded therewith, 1 to 100 parts by weight of glass fibers (B) having a single-fiber diameter of 10 to 12 μm, excluding 12 μm, has a crystallization temperature during cooling of 205° C. or lower and a chloroform-extractable content of 0.5 wt. % or lower, and gives a 2 mm-thick molded product which has a transmittance of 15% or higher for laser beam having a wavelength of 940 nm and a heat distortion temperature of 230° C. or higher under a load of 1.82 MPa.

Owner:TORAY IND INC

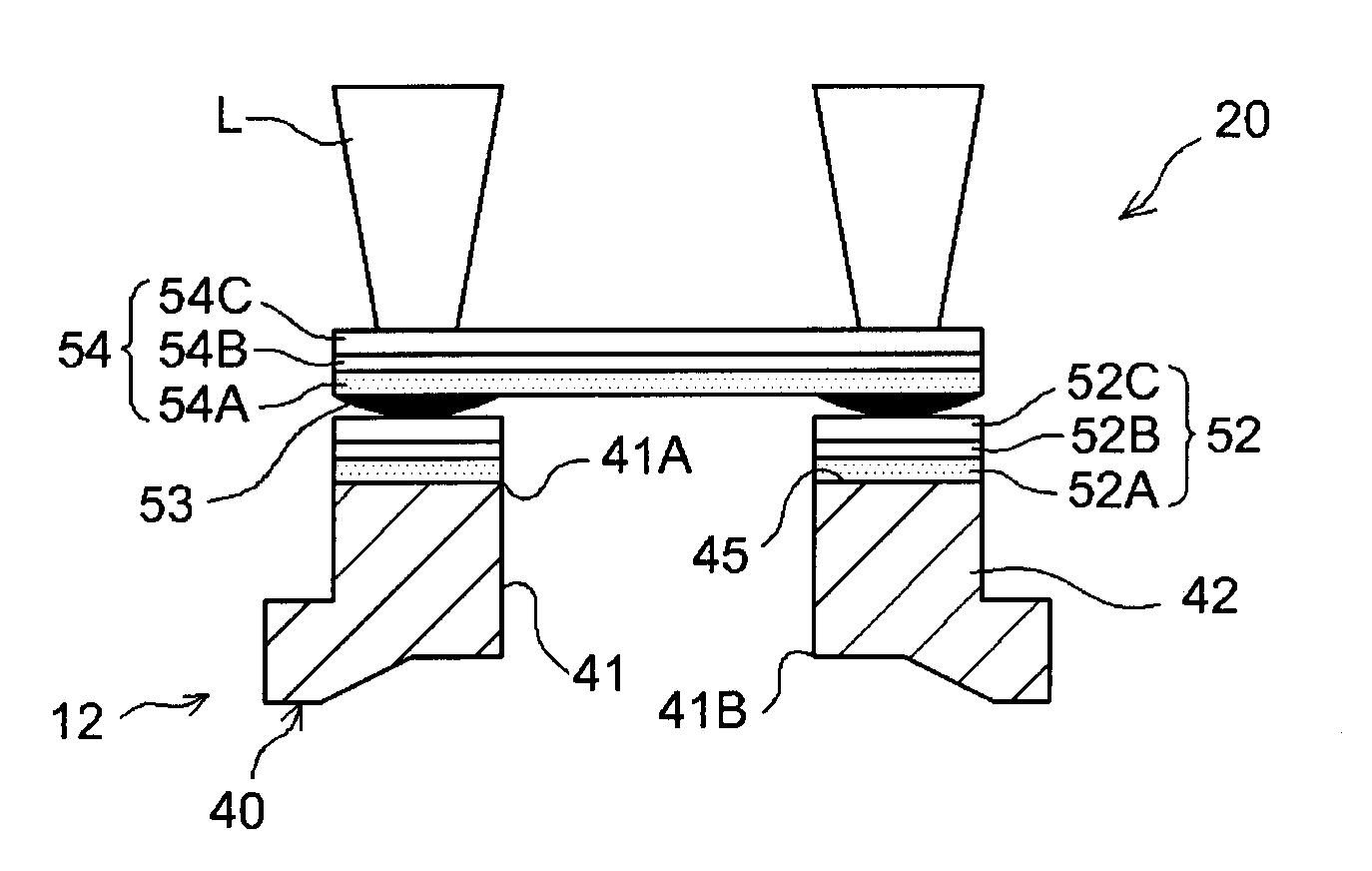

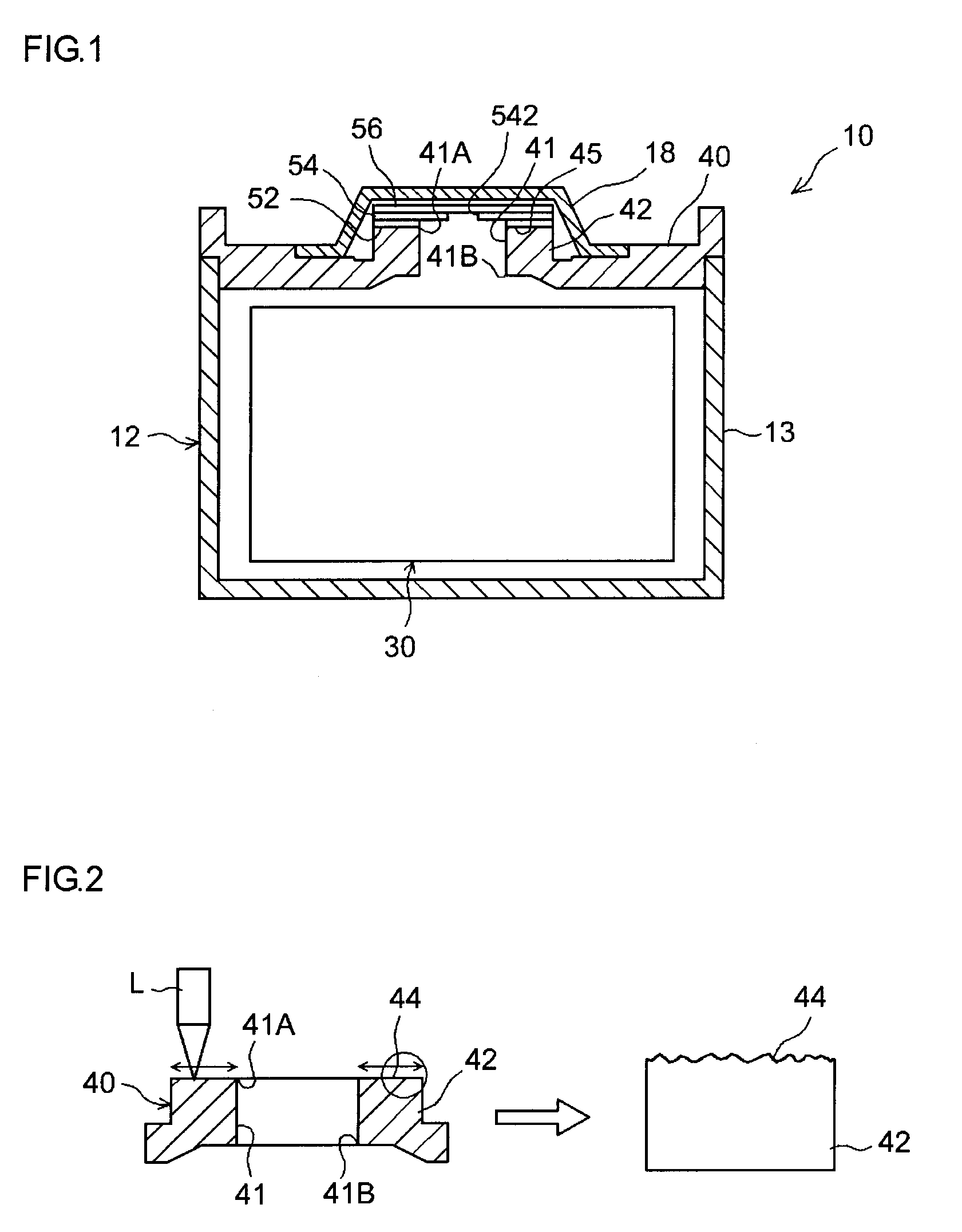

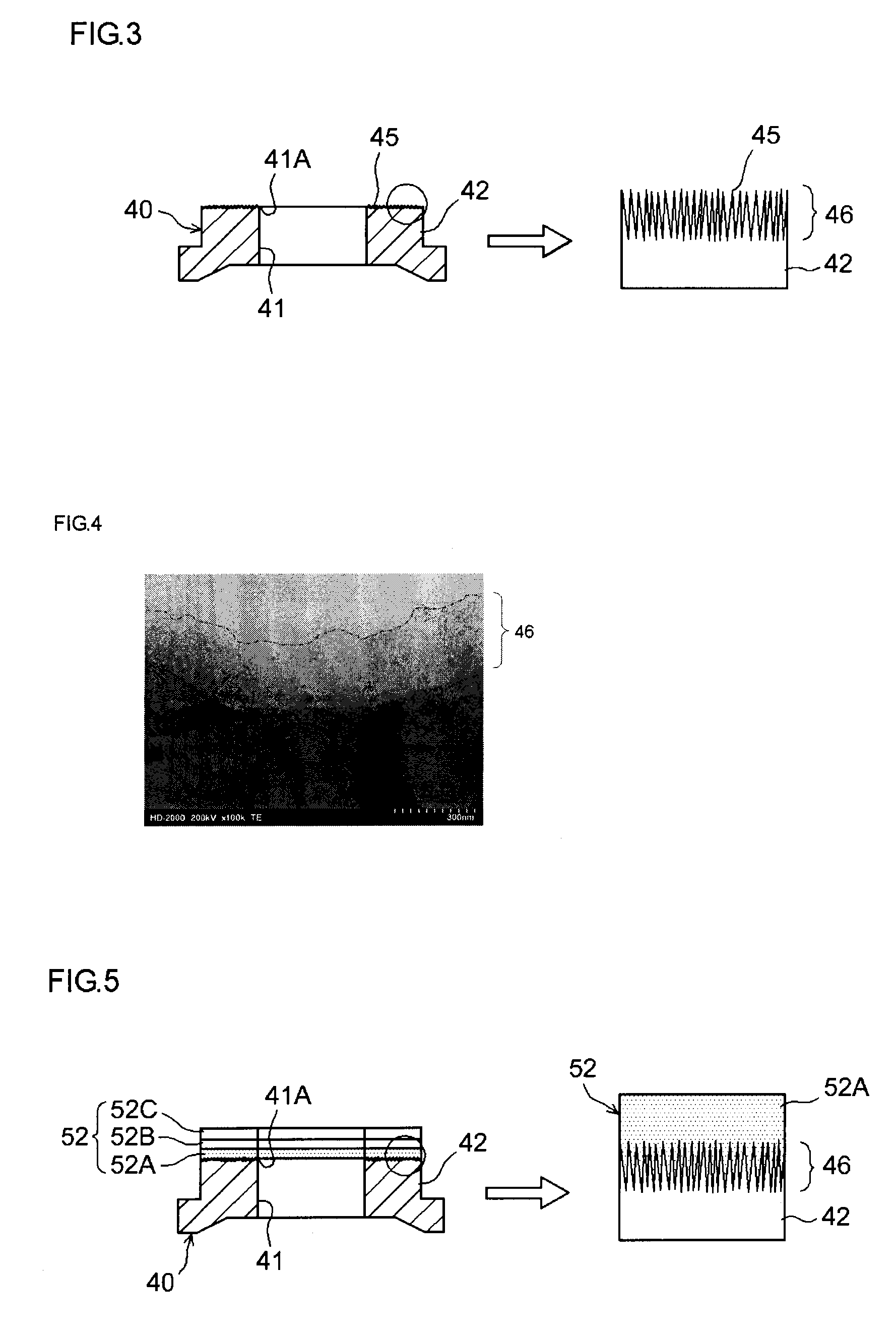

Sealed type cell manufacturing method

ActiveUS20110027645A1Improve solderabilityGood weldabilityLarge-sized flat cells/batteriesFinal product manufactureEngineeringAlloy

A cell assembly (20) is formed by arranging an electrode body and electrolyte in an external case (12) having a through hole (41). A laser is applied to an annular portion (formed by Al or Al-based alloy) surrounding an opening end (41A) of the through hole (41) toward outside the case so as to form a welded base (45). A sealing film (54) is welded to the surface of the welded base directly or via a base film (52) welded in advance, so as to temporarily seal the through hole (41). The cell assembly (20) in the temporarily sealed state is subjected to initial charge and then a hole is opened through the film (54) so as to form a gas discharge passage for communication between inside and outside of the case (12), thereby discharging an excessive gas from the case (12) outside.

Owner:TOYOTA JIDOSHA KK

Resin composition for laser welding and molded article

ActiveUS8052830B2Uniform light transmittanceHighly uniform weldabilityLamination ancillary operationsLaminationElastomerPolytetramethylene terephthalate

A laser weldable PBT-series resin composition and a molded product thereof are provided, in which the composition is weldable uniformly and has high welding strength even when the composition comprises a polybutylene terephthalate (PBT) as a base.The laser weldable resin composition comprises 1 to 50 parts by weight of (B) an elastomer (such as a polystyrene-series thermoplastic elastomer or a polyester-series thermoplastic elastomer), 5 to 100 parts by weight of (C) a polycarbonate-series resin, 1 to 10 parts by weight of (D) a plasticizer (e.g., an aromatic polycarboxylic acid ester, and an acrylic plasticizer), and 0 to 100 parts by weight of (E) a filler or reinforcing agent (such as a glass fiber), relative to 100 parts by weight of (A) a polybutylene terephthalate-series resin (a homopolyester or a copolyester). The molded product prepared from the resin composition has a small light transmittance fluctuation range depending on sites to be irradiated of the molded product. Thus, the molded product can be bonded to a counter part article uniformly by a laser welding.

Owner:POLYPLASTICS CO LTD

Laser weldable polybutylene terephthalate-series resin composition, and shaped article

InactiveUS20070135587A1Improve Laser Welding PerformanceImprove welding strengthLamination ancillary operationsSynthetic resin layered productsPolytetramethylene terephthalatePolymer science

A laser weldable PBT-series resin composition comprises a polybutylene terephthalate (PBT)-series resin (A), and at least one resin (B) selected from the group consisting of a polycarbonate-series resin (b1), a styrenic resin (b2), a polyethylene terephthalate-series resin (b3) and an acrylic resin (b4). The PBT-series resin (A) may be a PBT homopolyester, or a PBT-series copolymer modified with not more than 30 mol % of a copolymerizable monomer (e.g., a bisphenol compound or an adduct thereof with an alkylene oxide, and an asymmetrical aromatic dicarboxylic acid). The ratio (weight ratio) of the resin (B) relative to the PBT-series resin (A) [the former / the latter] is about 0.1 / 1 to 1.5 / 1. The resin composition may comprise a glass fiber. The resin composition is excellent in laser weldability, and can improve in welding strength of a shaped article formed from the resin composition.

Owner:POLYPLASTICS CO LTD

Aluminum alloy sheet for electric cell case, having excellent moldability, heat dissipation, and weldability

InactiveCN104204249AFast heat conductionGood formabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsLithiumImpurity

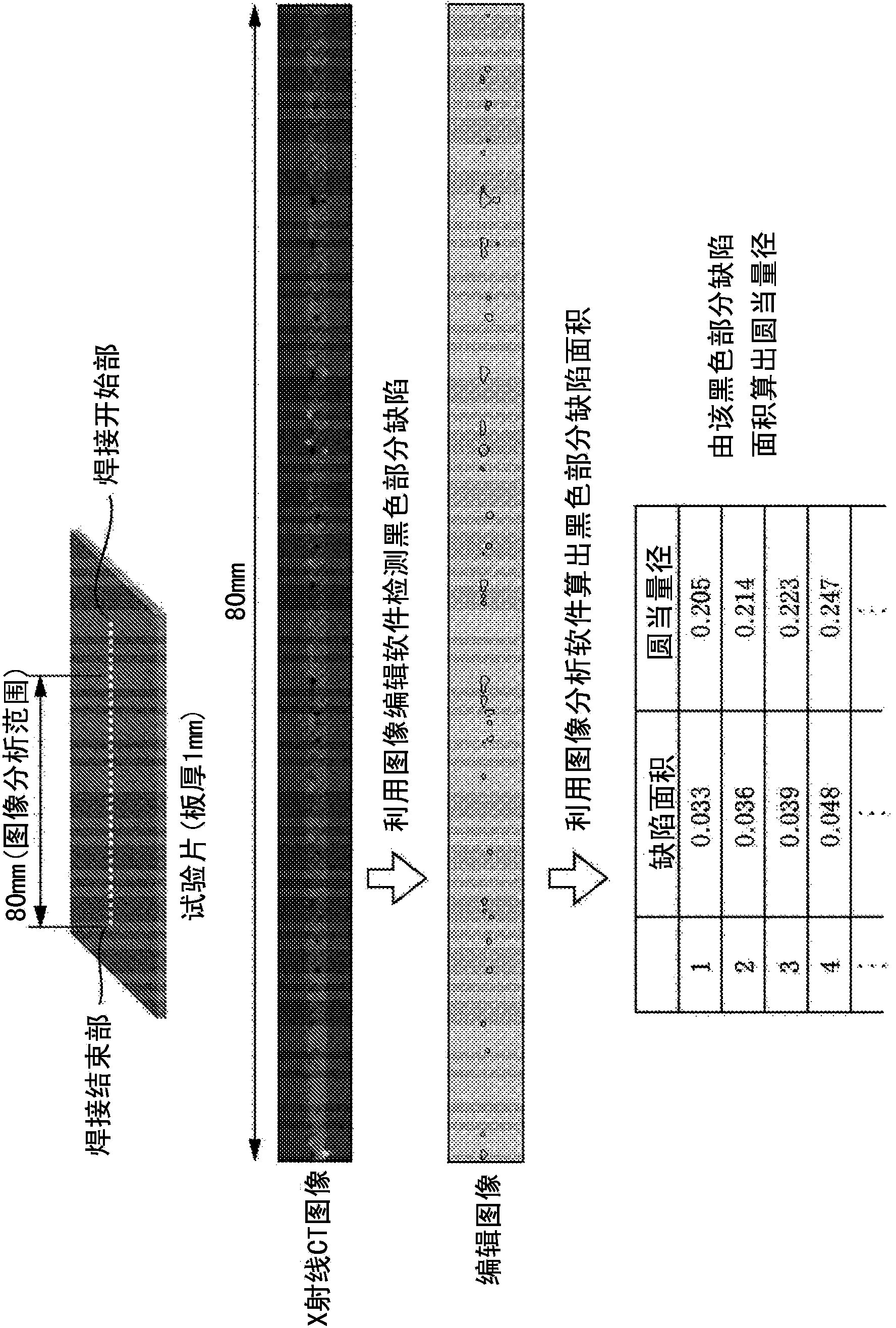

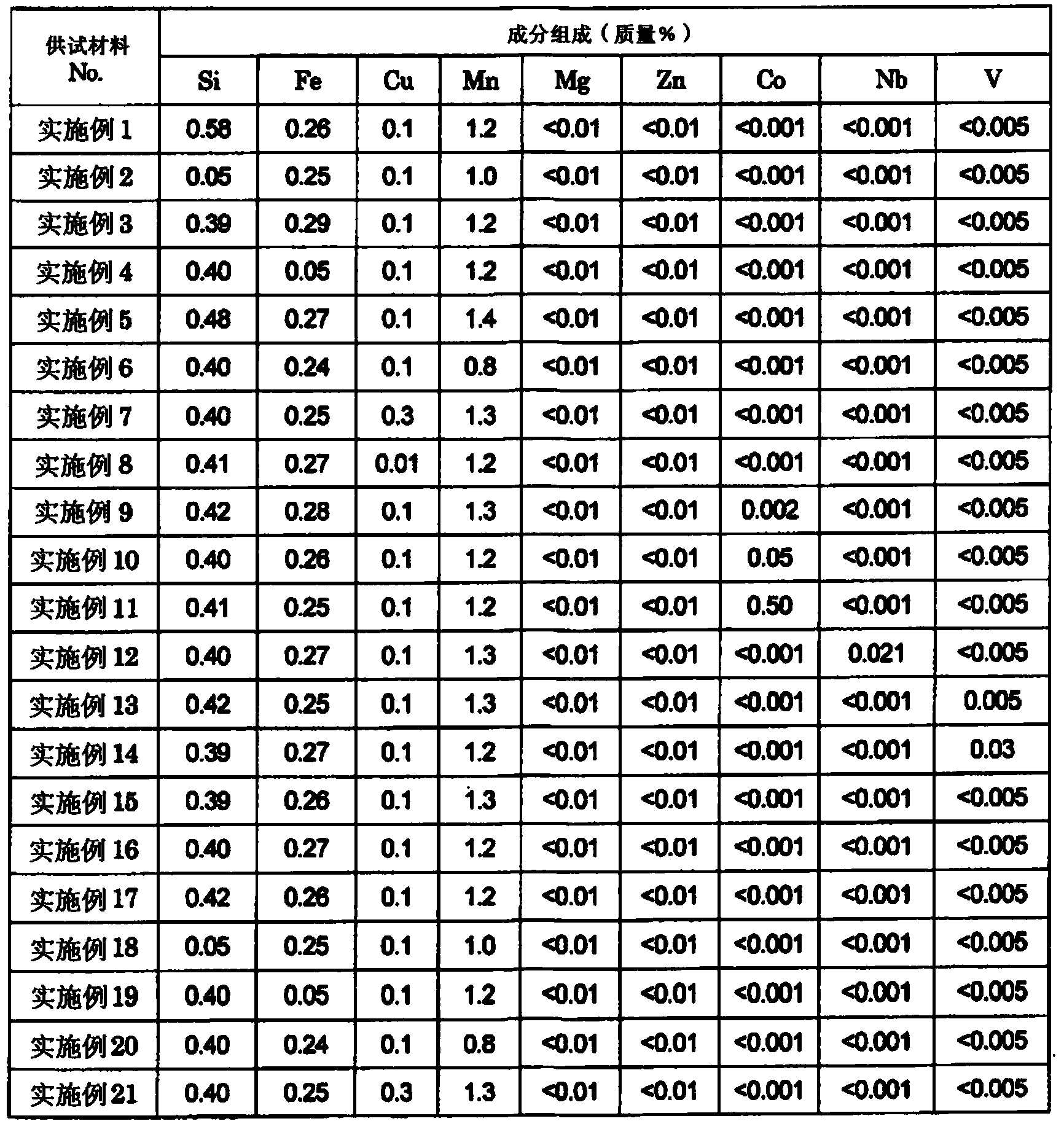

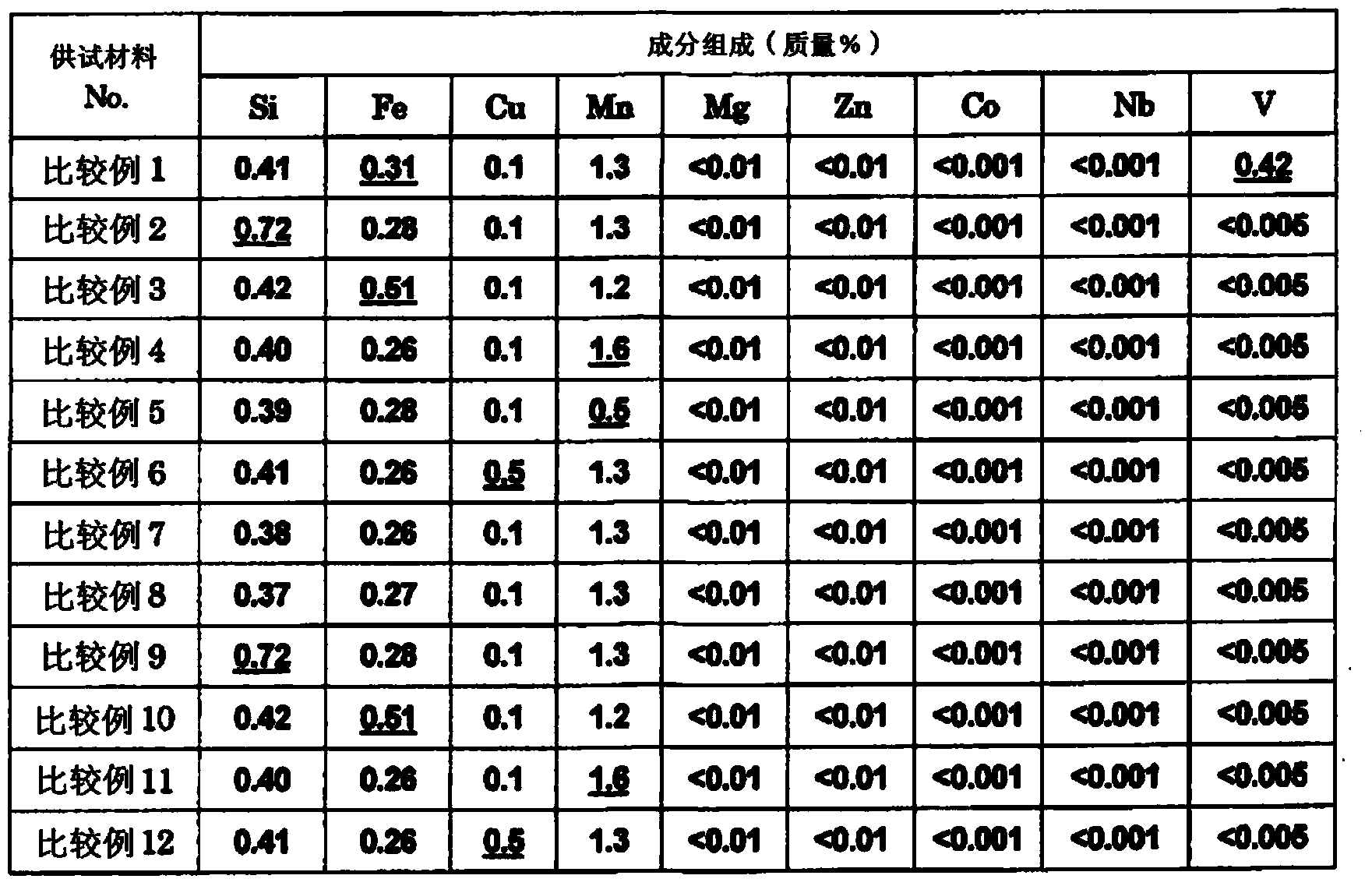

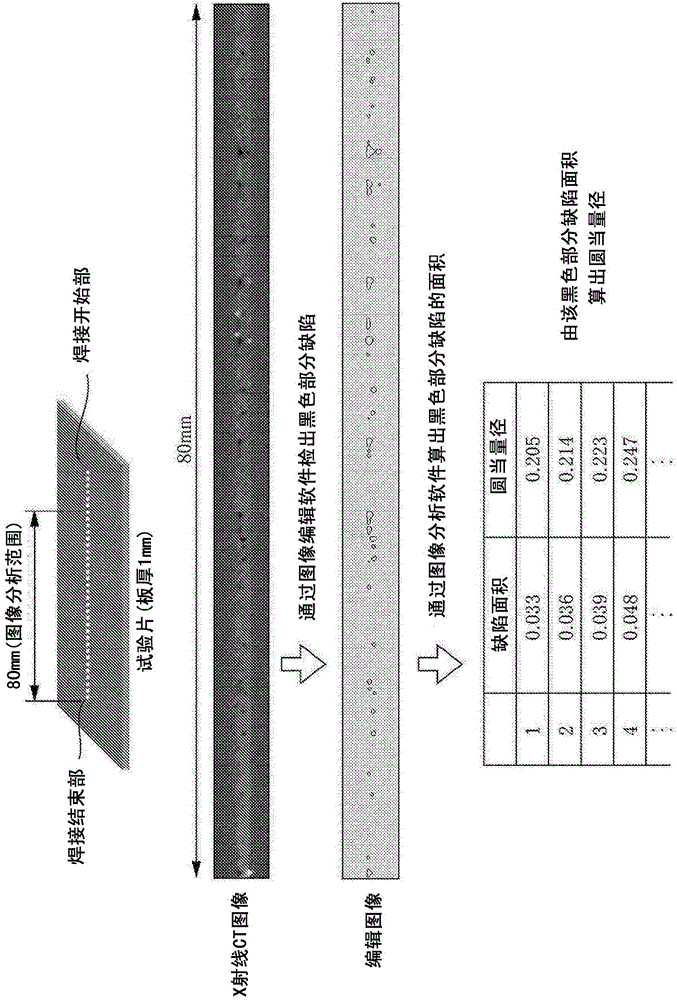

Provided is a 3000 series aluminum alloy sheet having heat-dissipating characteristics applicable to large lithium ion cell containers, and also having excellent moldability, shape-freezing properties, and laser weldability. The aluminum alloy sheet is a cold-rolled, annealed material having a component composition of, by mass, 0.05 to less than 0.3% Fe, 0.6 to 1.5% Mn, and 0.05 to 0.6% Si, with the balance being Al and impurities, the impurities being, by mass, less than 0.35% Cu and less than 0.05% Mg; and displaying an IACS electrical conductivity exceeding 45%, a 0.2% proof stress of 40 to less than 60 MPa, and an elongation value of 20% or more. Alternatively, the aluminum alloy sheet may be an as-cold-rolled material displaying an IACS electrical conductivity exceeding 45%, a 0.2% proof stress of 60 to less than 150 MPa, and an elongation value of 3% or more. To further increase the electrical conductivity, one or more of, by mass, 0.001 to 0.5% Co, 0.005 to 0.05% Nb, and 0.005 to 0.05% V may be included.

Owner:NIPPON LIGHT METAL CO LTD

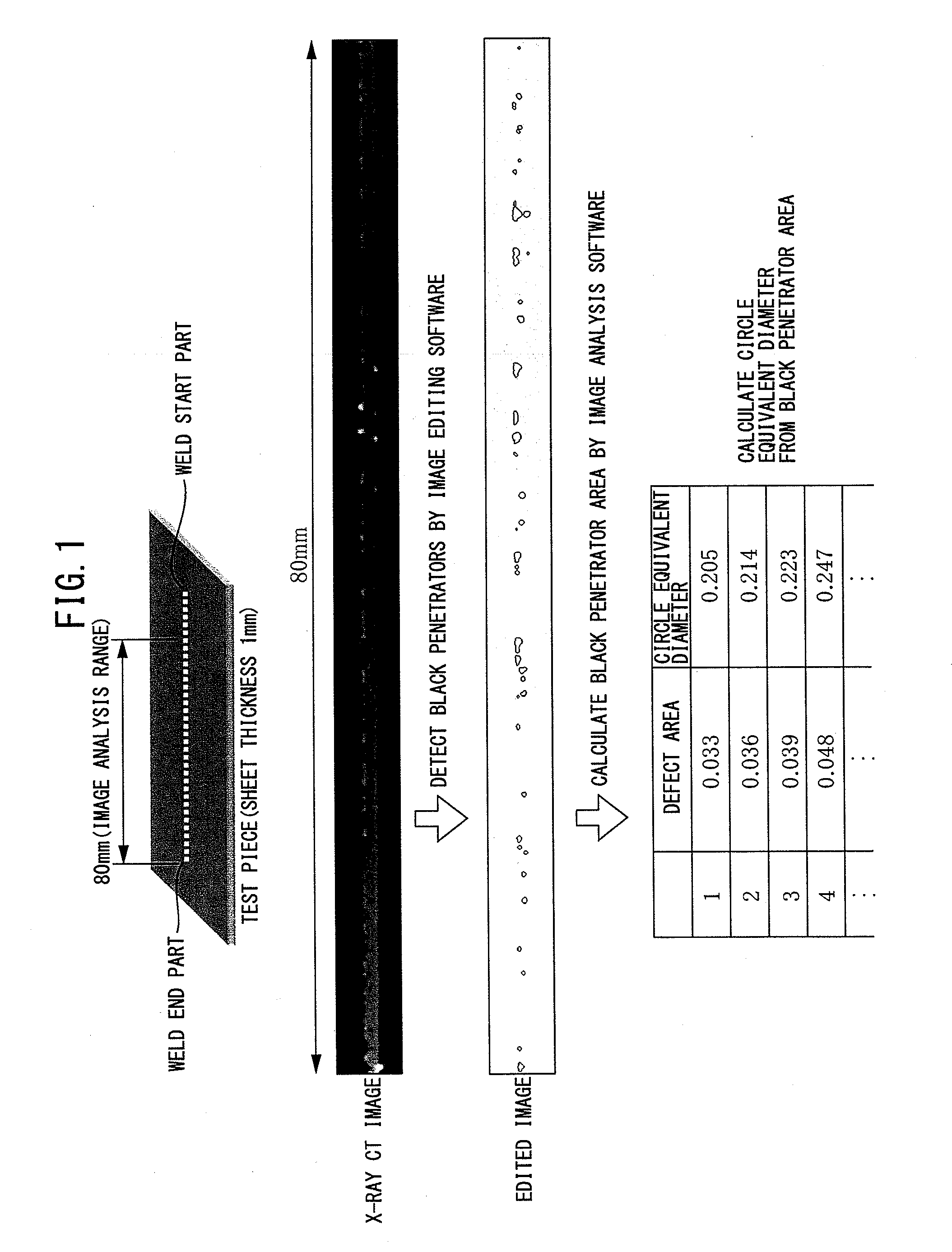

Battery-case aluminium alloy plate exhibiting excellent moulding properties, heat-dissipation properties, and welding properties

InactiveCN104838025AFast heat conductionGood formabilitySecondary cellsJackets/cases materialsLithium-ion batteryElectrical resistivity and conductivity

Provided is a 3000 series aluminium alloy plate which exhibits heat-dissipation characteristics applicable to large lithium ion battery containers, and which also exhibits excellent moulding properties, shape fixability, and laser welding properties. This aluminium alloy plate is a cold-rolled annealed material which has: a component composition including over 0.2 mass% but less than 1.4 mass% of Fe, 0.5-2.0 mass% of Mn, over 0.2 mass% but not more than 1.1 mass% of Si, 0.05-1.0 mass% of Cu, and less than 0.05 mass% of Mg, the remainder comprising Al and impurities; a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 30 MPa but less than 85 MPa; and an elongation value of at least 10%. Otherwise, this aluminium alloy plate is a cold-rolled material which has: a conductivity of over 45% IACS; a metallographic structure in which the number of second phase particles having an equivalent circular diameter of at least 2 µm is less than 1800 / mm2; a 0.2% proof stress of at least 90 MPa but less than 180 MPa; and an elongation value of at least 3%.

Owner:NIPPON LIGHT METAL CO LTD

New energy power battery shell and cover aluminum alloy material preparing method

InactiveCN109371291AGood mechanical propertiesGood stamping performanceJackets/cases materialsElectrical batteryPower battery

The invention discloses a new energy power battery shell and cover aluminum alloy material preparing method, and relates to the technical field of new energy batteries. The method comprises the firststep of smelting, the second step of refining, drossing and online gas removal, the third step of semicontinuous casting, the fourth step of saw cutting, face milling and homogenizing, the fifth stepof rolling, the sixth step of annealing and the seventh step of cleaning, finishing and straightening. A new energy power battery shell and cover aluminum alloy is excellent in comprehensive performance; through integrity improvement and optimization on the aluminum alloy components and content and the preparing technology, the application performance of a prepared new energy power battery shell and cover product is obviously improved, substantive breakthrough is particularly achieved in the aspects of tensile strength, regulated non-proportion extension strength, percentage elongation after fracture, stability, punching performance and welding performance indexes, the application occasion and field are wide, and the active demand of the new energy market for high-performance power batterycover and shell products can be greatly met.

Owner:合肥天沃能源科技有限公司

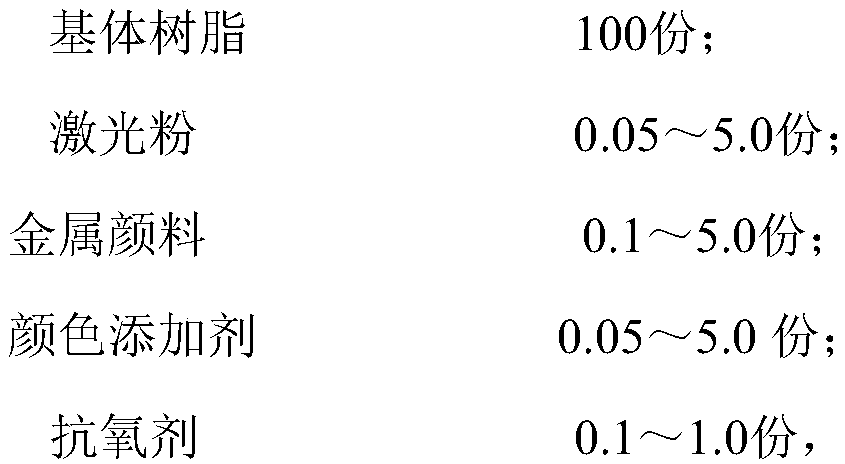

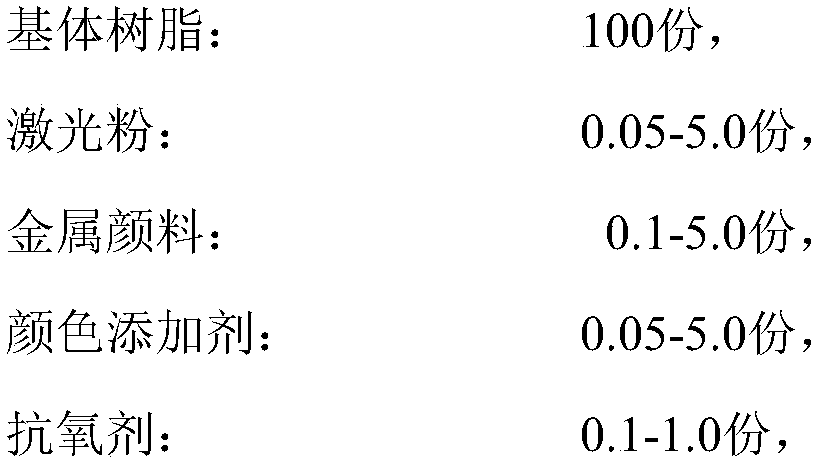

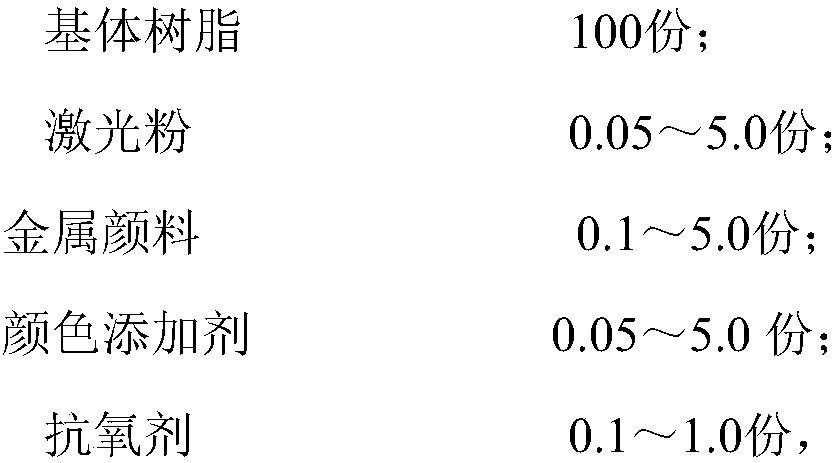

Resin composition applicable to laser welding and with high metal texture and preparation method thereof

The invention relates to the field of automotive materials, in particular to a resin composition applicable to laser welding and with high metal texture and a preparation method thereof. The resin composition comprises, by weight, 100 parts of matrix resin, 0.05-5.0 parts of laser powder, 0.1-5.0 parts of metal pigment, 0.05-5.0 parts of pigment additive and 0.1-1.0 part of antioxidant. The preparation method includes: sufficiently mixing the matrix resin, the laser powder, the metal pigment, the pigment additive and the antioxidant in a low-speed mixer, feeding into a double-screw extruder through a metering device, performing screw conveying, shearing and mixing to allowing the materials to sufficiently melt and mix, and performing extrusion, drawing, cooling and grain-sized dicing to obtain the resin composition applicable to laser welding. The prepared resin composition with high metal texture can have excellent laser welding performance.

Owner:HASCO VISION TECHNOLOGY CO LTD

Aluminium alloy plate for battery case and its manufacturing method

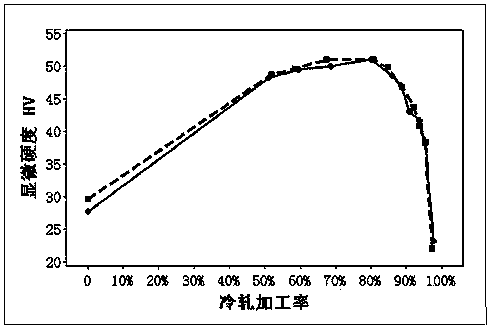

ActiveCN1497051ASmall amount of expansion deformationImprove Laser Welding PerformanceTemperature and pressureAluminium alloy

Provided is an aluminum alloy plate for a battery case which is excellent in moldability and laser weldability and shows little swelling deformation, even when temperature and pressure inside the case are increased after repetitive charging and discharging. The aluminum alloy plate is a plate material of an aluminum alloy comprising >1.0% and <1.5% Mn, >0.3% and <0.8% Mg, >0.3% and <0.6% Cu, 0.05-0.25% Si, 0.2-0.5% Fe and the balance being Al and impurities, wherein the relation: 3Cu(%) C22C 21 / 00 1 9 1 2003 / 10 / 17 1497051 2004 / 5 / 19 100500901 2009 / 6 / 17 2009 / 6 / 17 2009 / 6 / 17 Sumitomo Light Metal Industries, Co., Ltd. Japan Tanaka Hiroki Nagai Yasunori Ito Tomoyasu pan peikun jing zhiqiang 72003 Japan 2002 / 10 / 18 2002-303856 Japan 2003 / 7 / 15 2003-274451

Owner:SUMITOMO LIGHT METAL INDS LTD

Preparation method of black flame-retardant PBT composite material capable of being welded by laser

ActiveCN112795146AImprove Laser Welding PerformanceImprove temperature resistanceFire retardantRevolutions per minute

The invention relates to a preparation method of a black flame-retardant PBT composite material capable of being welded by laser. The preparation method comprises the following steps: adding a raw material I into a main side feeding port of a double-screw extruder, adding a raw material II into a fourth section side feeding port of the double-screw extruder, extruding and granulating, controlling the rotating speed of a screw machine of the double-screw extruder to be 180-600 revolutions per minute and the extruding temperature of the double screws to be 235-275 DEG C, and preparing the black flame-retardant PBT composite material capable of being welded by laser; the length-diameter ratio of the twin-screw extruder is 40: 1; the raw material I is a mixture of 70-90 parts by mass of PBT resin A, 8-10 parts by mass of a flame retardant and 0.3-1.5 parts by mass of black powder, and the raw material II is a mixture of 10-20 parts by mass of PBT resin B and 0.2-3 parts by mass of potassium N-butylpiromate; the prepared black flame-retardant PBT composite material capable of being welded by laser has excellent laser welding capacity and good temperature resistance, is halogen-free and flame-retardant, meets the requirements of ROHS and Reach regulations, and can be used for producing black parts with flame-retardant requirements.

Owner:上海日之升科技有限公司

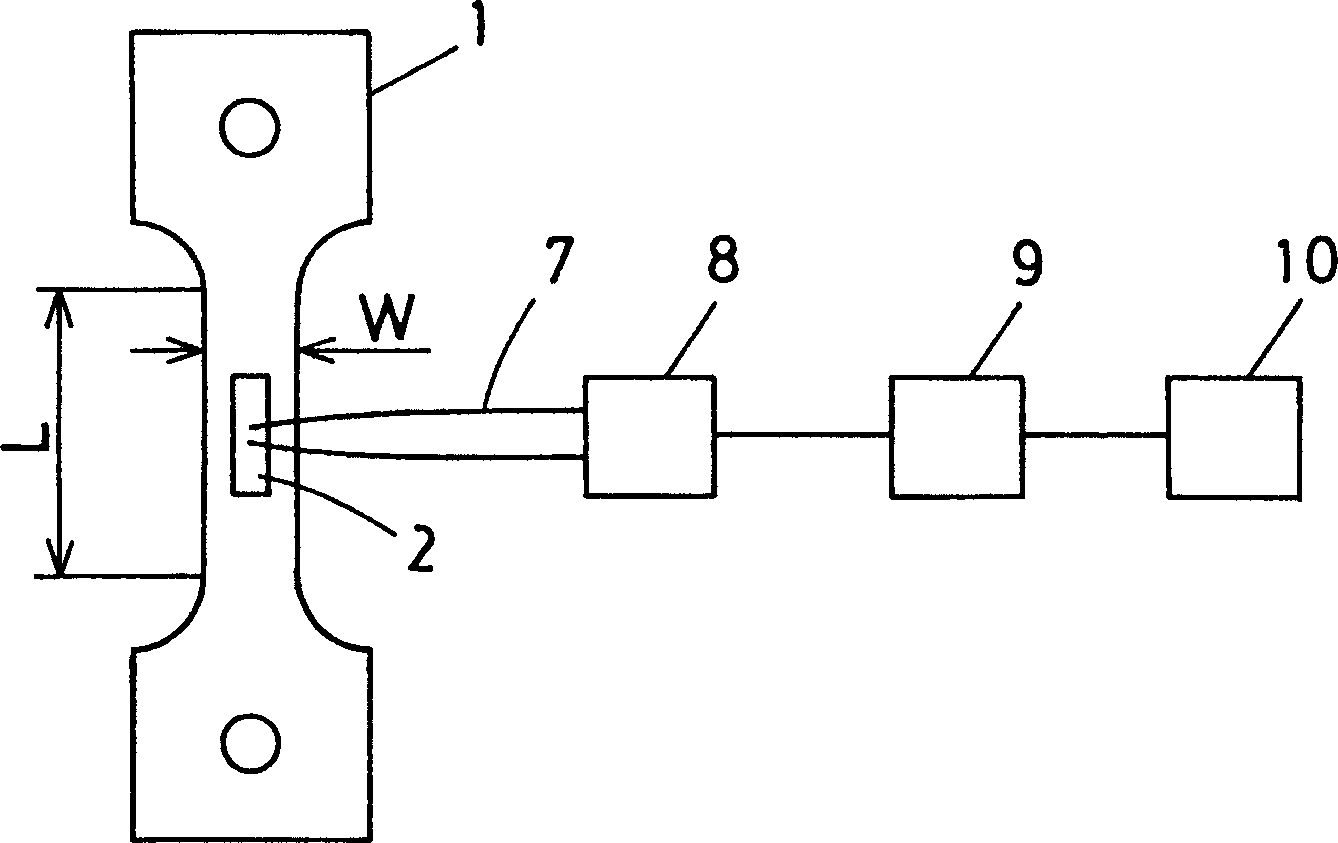

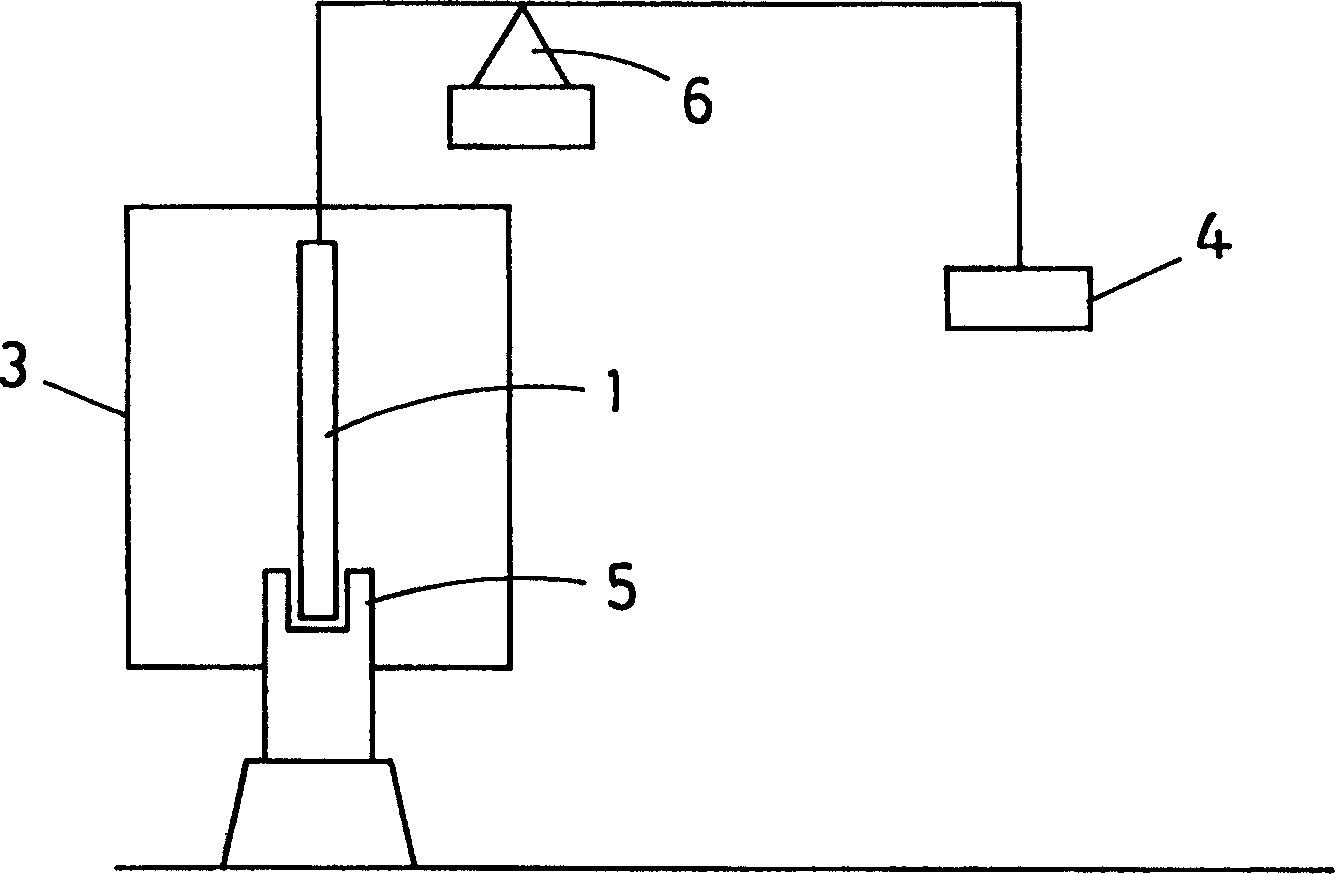

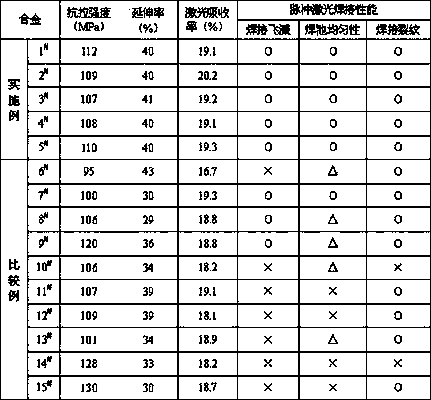

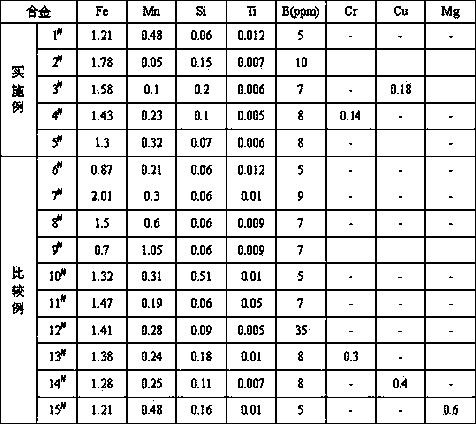

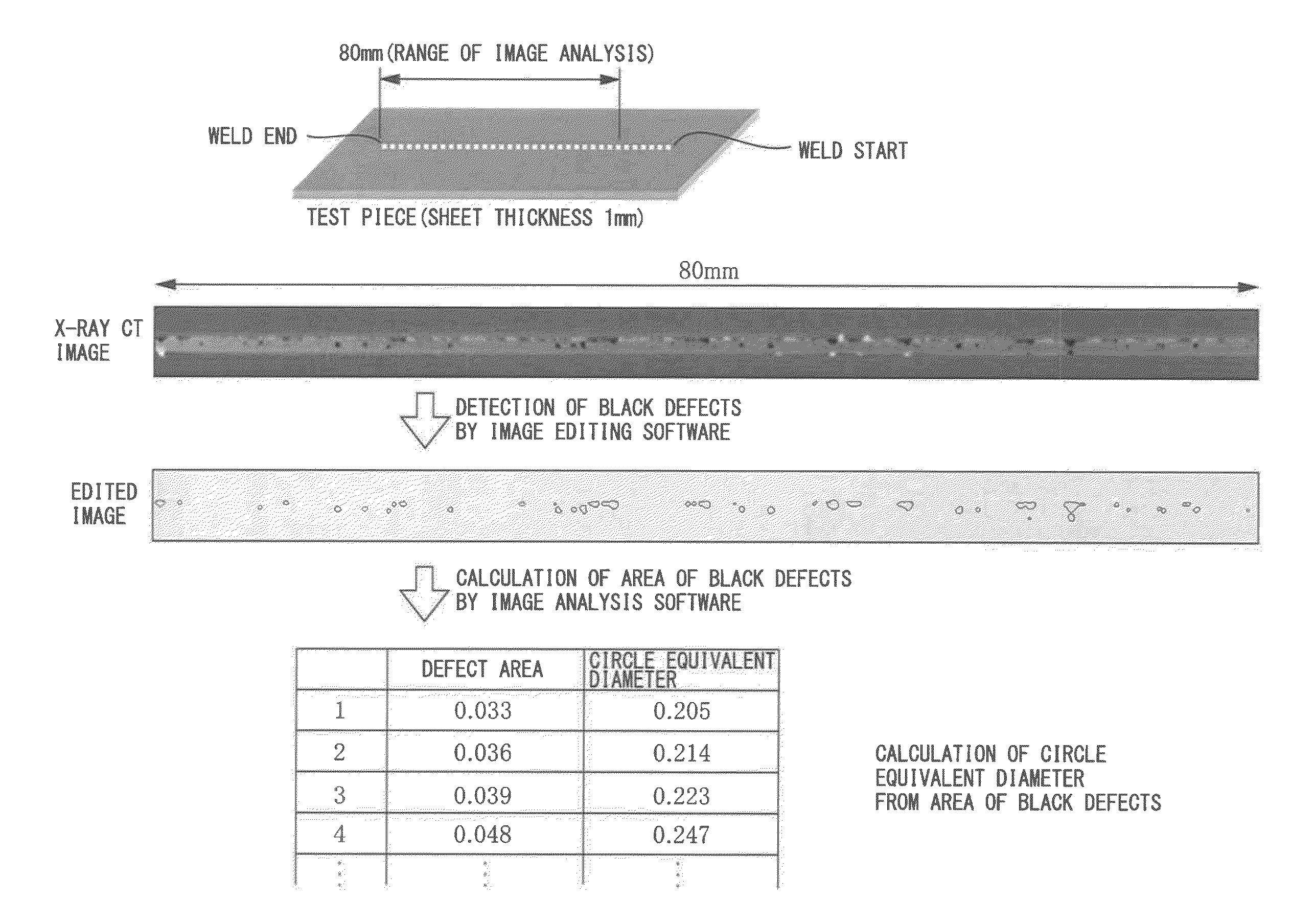

Aluminium alloy plate with excellent laser welding performance and preparation method thereof

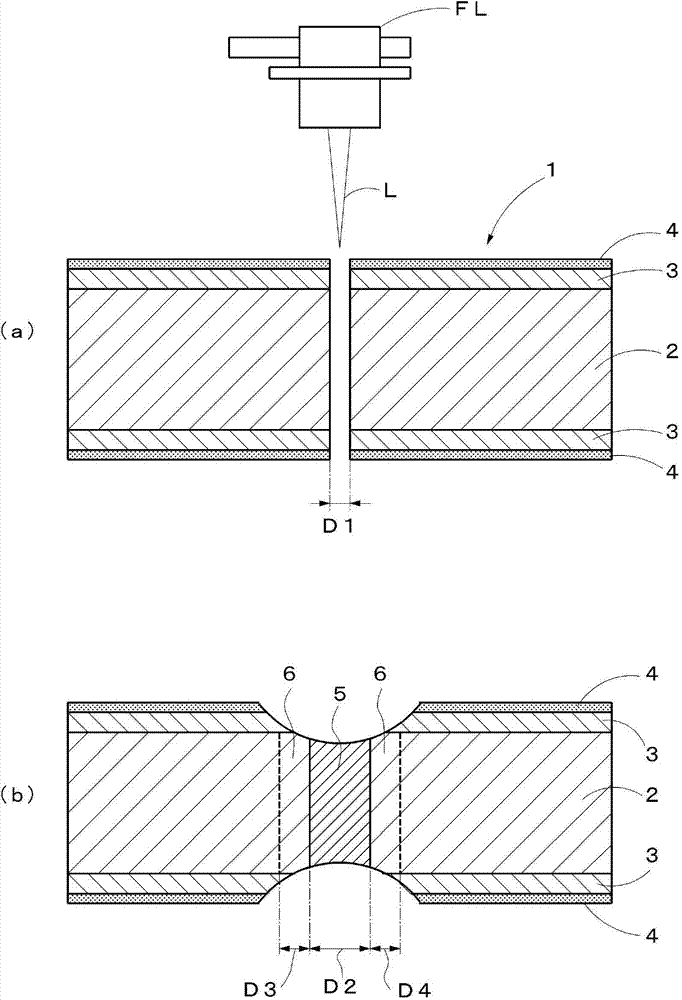

ActiveCN103361521AImprove Laser Welding PerformanceHighlight substantive featuresLithium-ion batteryMechanical property

The invention relates to an aluminium alloy plate with excellent laser welding performance and a preparation method thereof. The aluminium alloy plate comprises the following components: 1.2-1.8 wt% of Fe, 0.05-0.5 wt% of Mn, Ti being less than or equal to 0.012 wt%, B being less than or equal to 10 ppm and the balance Al and unavoidable impurities; or the aluminium alloy plate also comprises one or more components selected from less than 0.2 wt% of Si, less than 0.2 wt% of Cu and less than 0.15 wt% of Cr. Nd:YAG pulse laser absorptivity by the aluminium alloy plate reaches more than 18.8%. The alloy sheet has excellent laser welding performance. Even if fusion depth by pulse laser welding exceeds 0.4mm, there is no abnormal welding pool, splashing or crack. Meanwhile, the aluminium alloy plate has good mechanical performance and formability and can meet manufacturing requirements of lithium ion battery shells of different capacities and specifications.

Owner:CHINA ALUMINUM INT ENG CORP

Laser-weldable resin composition and molded product

InactiveUS8008387B2Improve Laser Welding PerformanceDeterioration of propertyImpression capsLamination ancillary operationsPolytetramethylene terephthalateOligomer

A laser-weldable polybutylene terephthalate-series resin composition having a high laser weldability is provided. The resin composition comprises (A) a polybutylene terephthalate-series resin and (B) a fatty acid-series compound (e.g., a C12-36 fatty acid ester, and a metal salt of a C12-36 fatty acid), and if necessary (C) a cyclic polyester oligomer (e.g., a cyclic polyalkylene terephthalate oligomer). In the resin composition, the proportion of the fatty acid-series compound (B) may be usually about 0.01 to 1.0 part by weight relative to 100 parts by weight of the polybutylene terephthalate-series resin (A).

Owner:WIN TECH POLYMER LTD

Aluminum alloy plate for battery cases, which has excellent moldability and weldability

InactiveUS20150159243A1High heat conductivityGood molding effectSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsChemical compositionHigh intensity

Provided is a 1000-series aluminum alloy plate which has high strength applicable to large-size lithium ion battery cases and also has excellent moldability and excellent laser weldability. An aluminum alloy plate produced from a DC cast slab. The aluminum alloy plate has such a chemical composition comprising 0.01 to 0.4 mass % of Si, 0.01 to 0.5 mass % of Fe, 0.002 to 0.3 mass % of Co and a remainder made up by Al and impurities, wherein the content of Cu, which is contained as an impurity, is limited to less than 0.2 mass %. The aluminum alloy plate has a metallic structure in which the number of second phase particles each having an equivalent circle diameter of 3 μm or more is 110 particles / mm2 or more and less than 1000 particles / mm2. A cold-rolled and annealed plate produced from the aluminum alloy plate has an elongation value of 30% or more.

Owner:NIPPON LIGHT METAL CO LTD

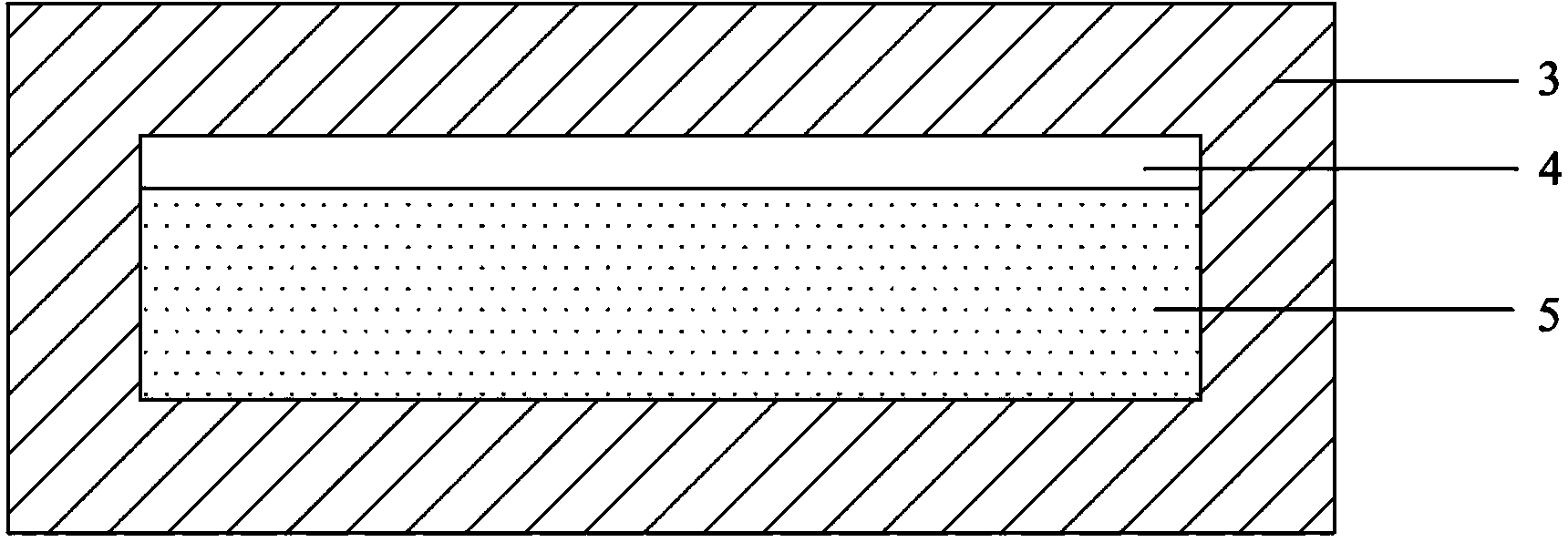

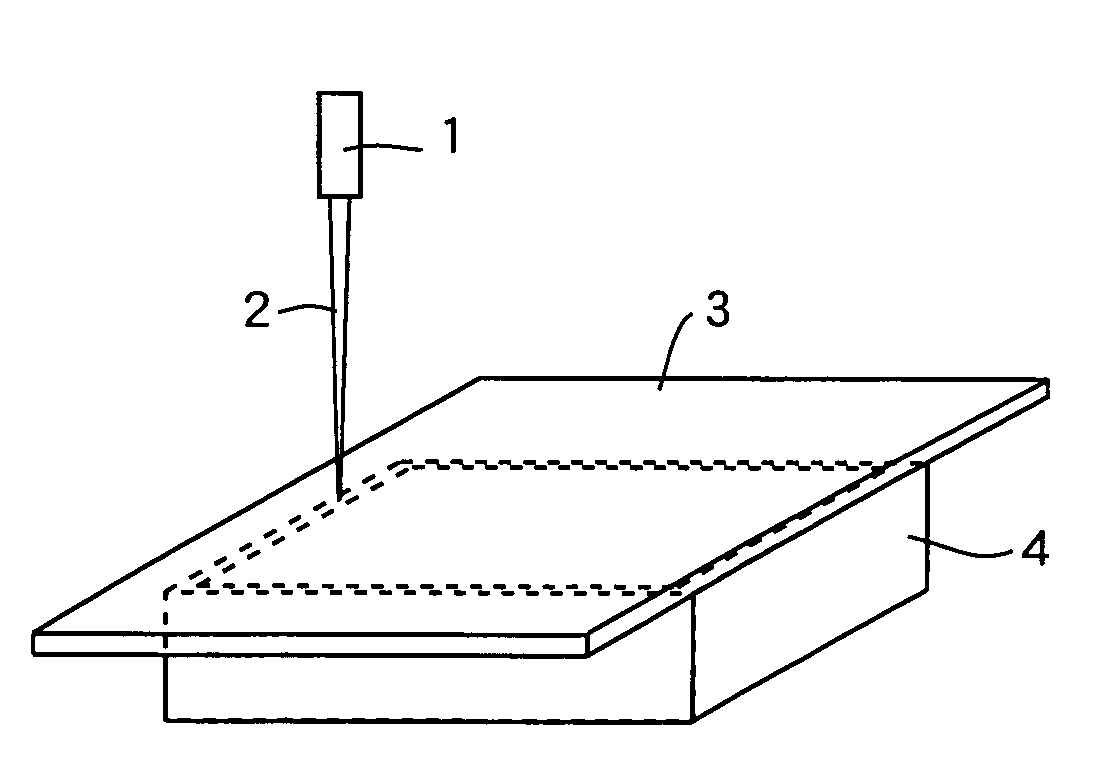

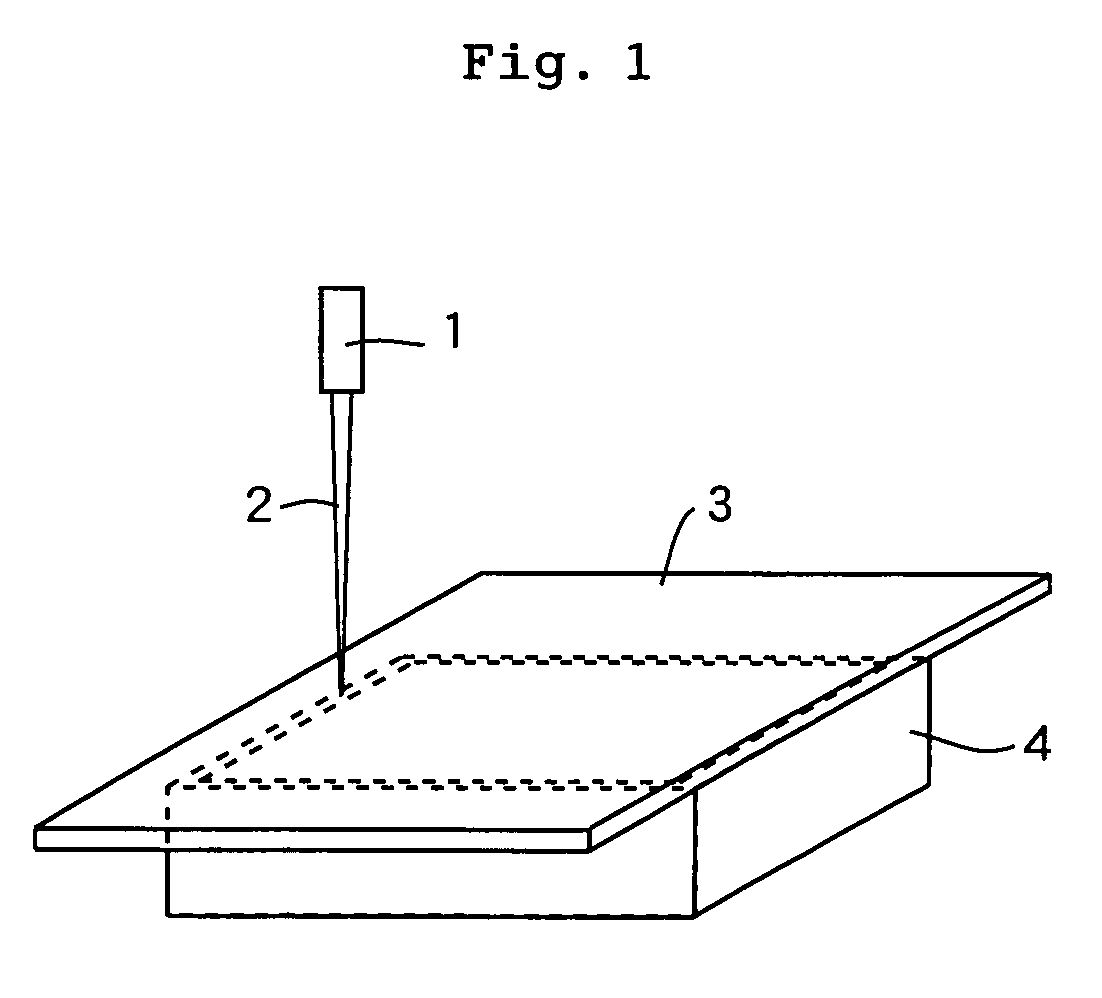

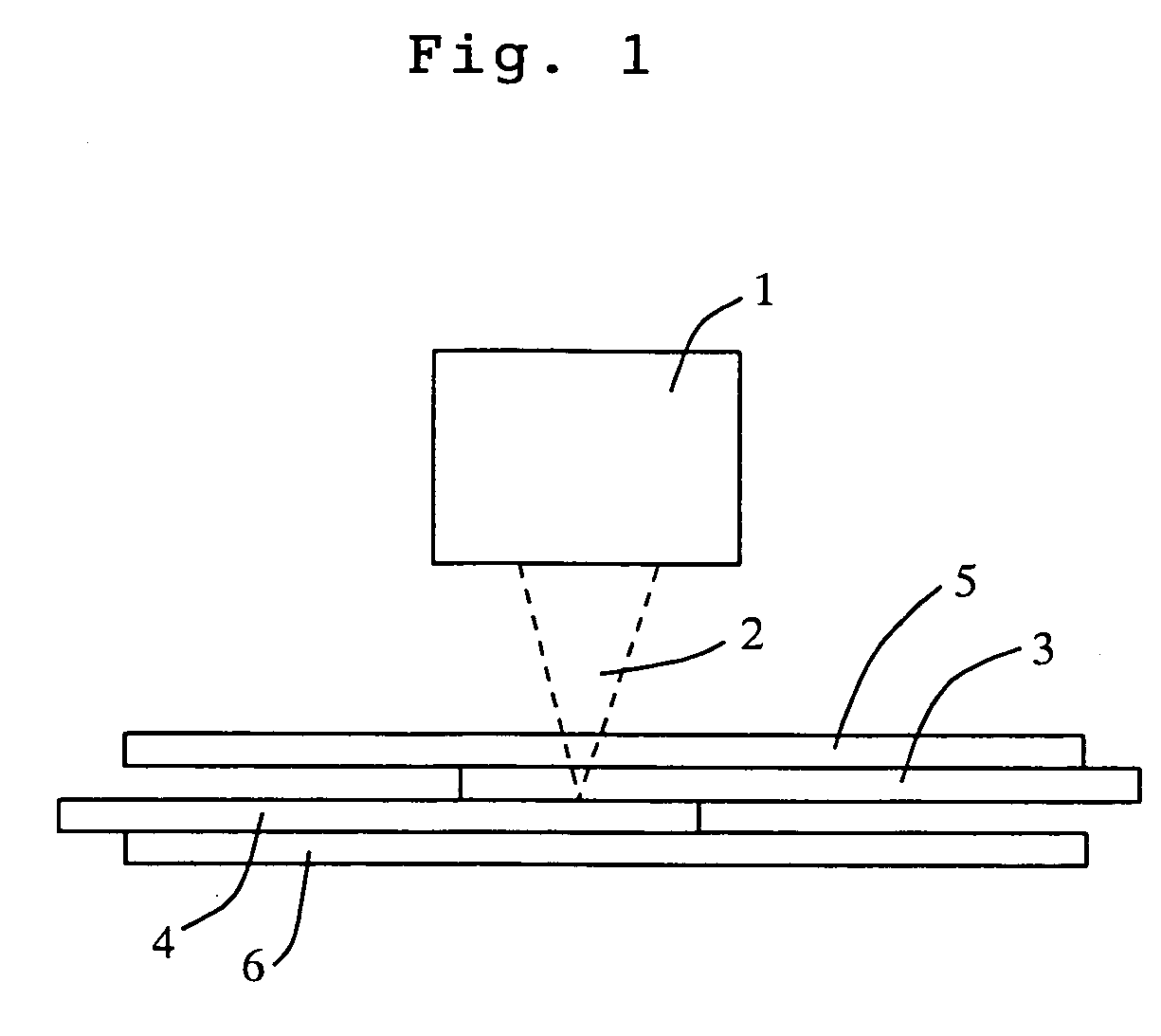

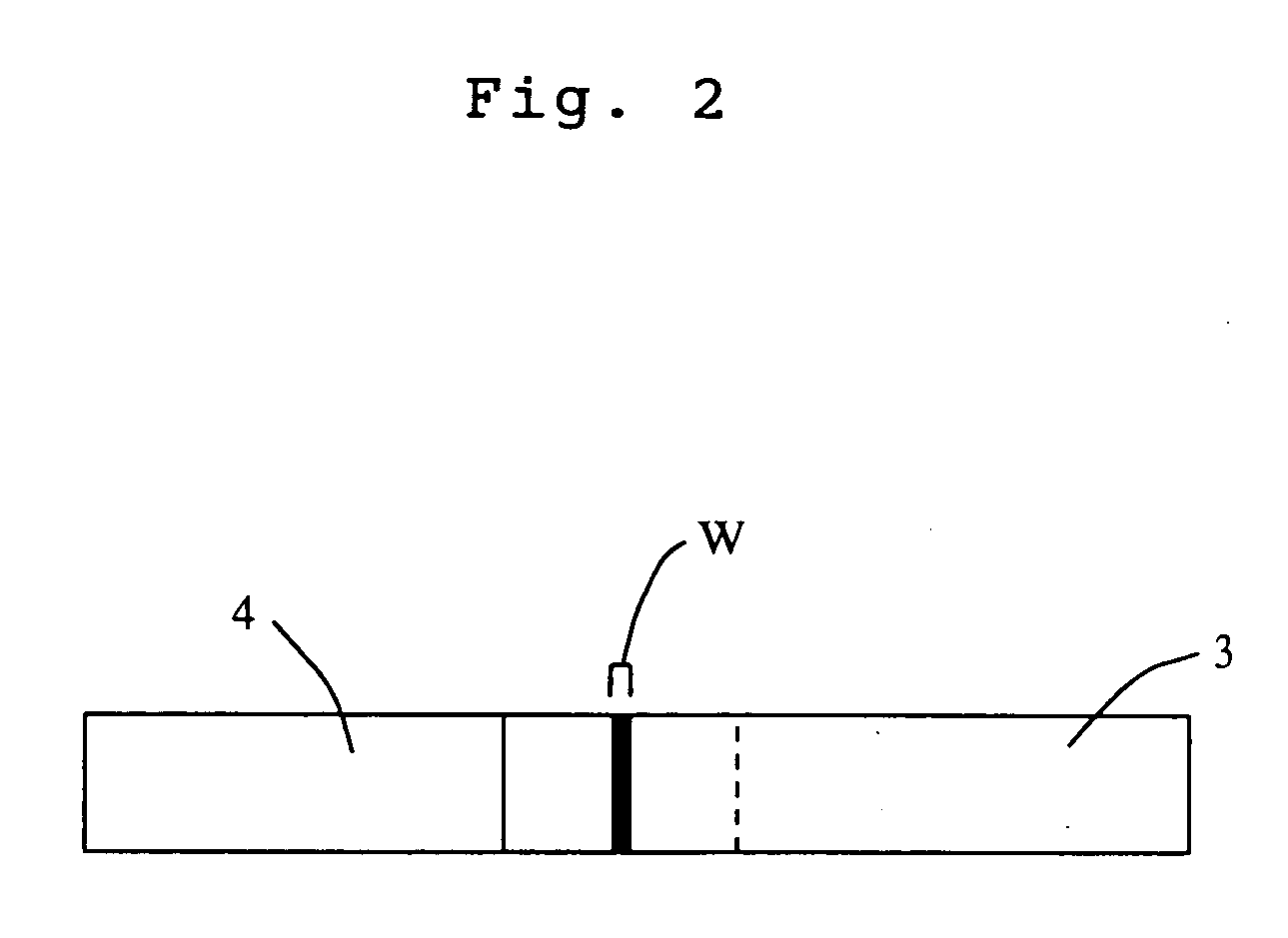

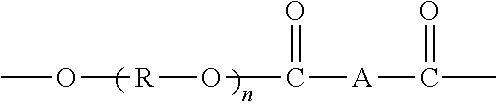

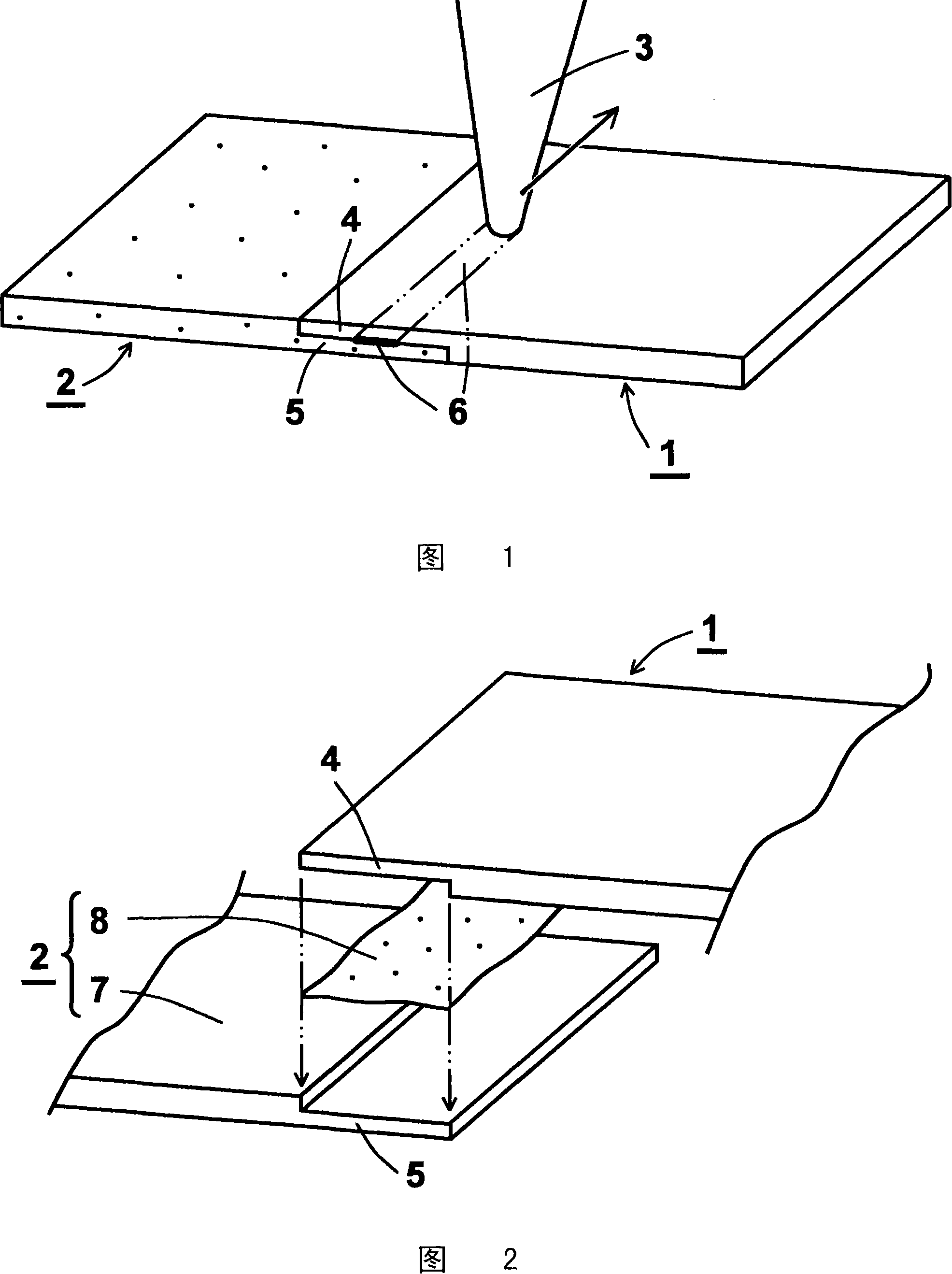

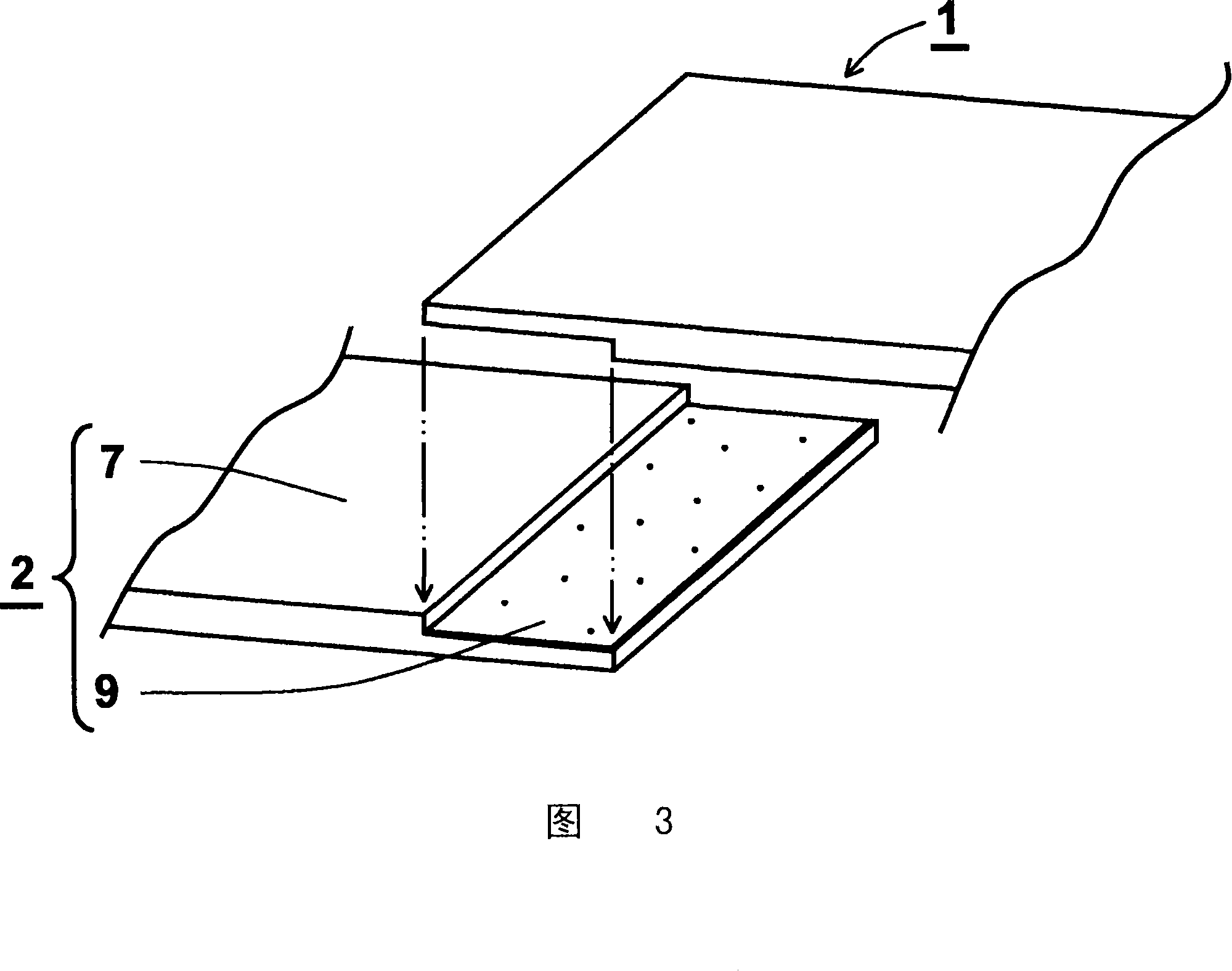

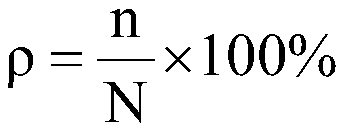

Metal member,terminal,electric wire connection structure and method of manufacturing terminal

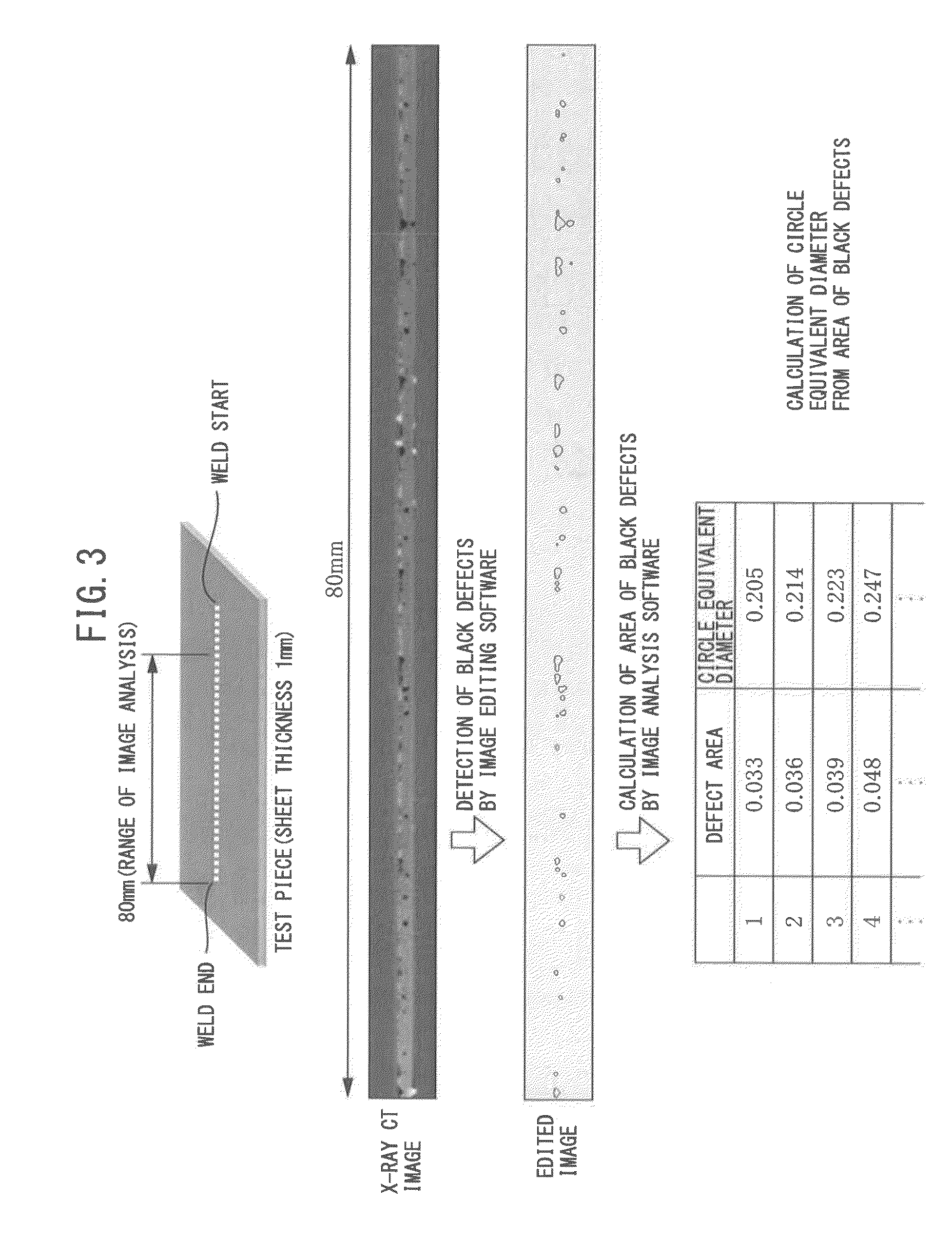

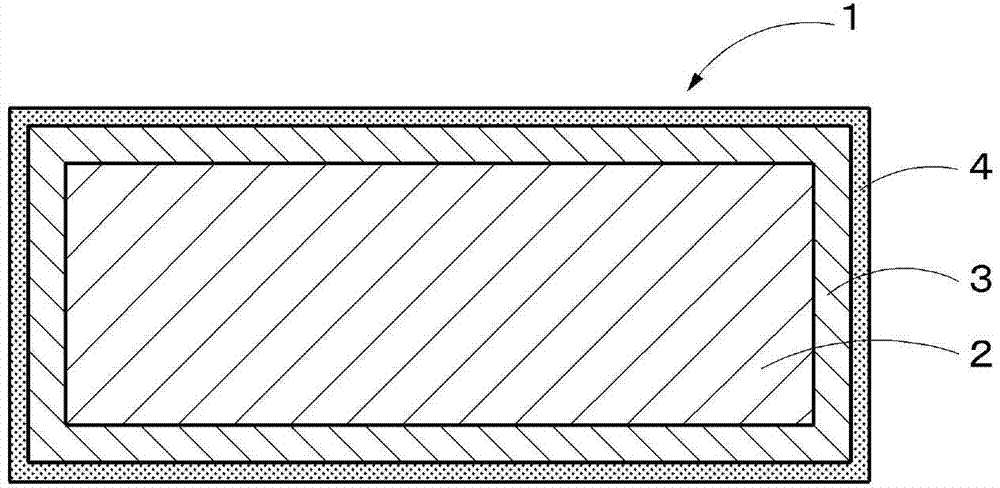

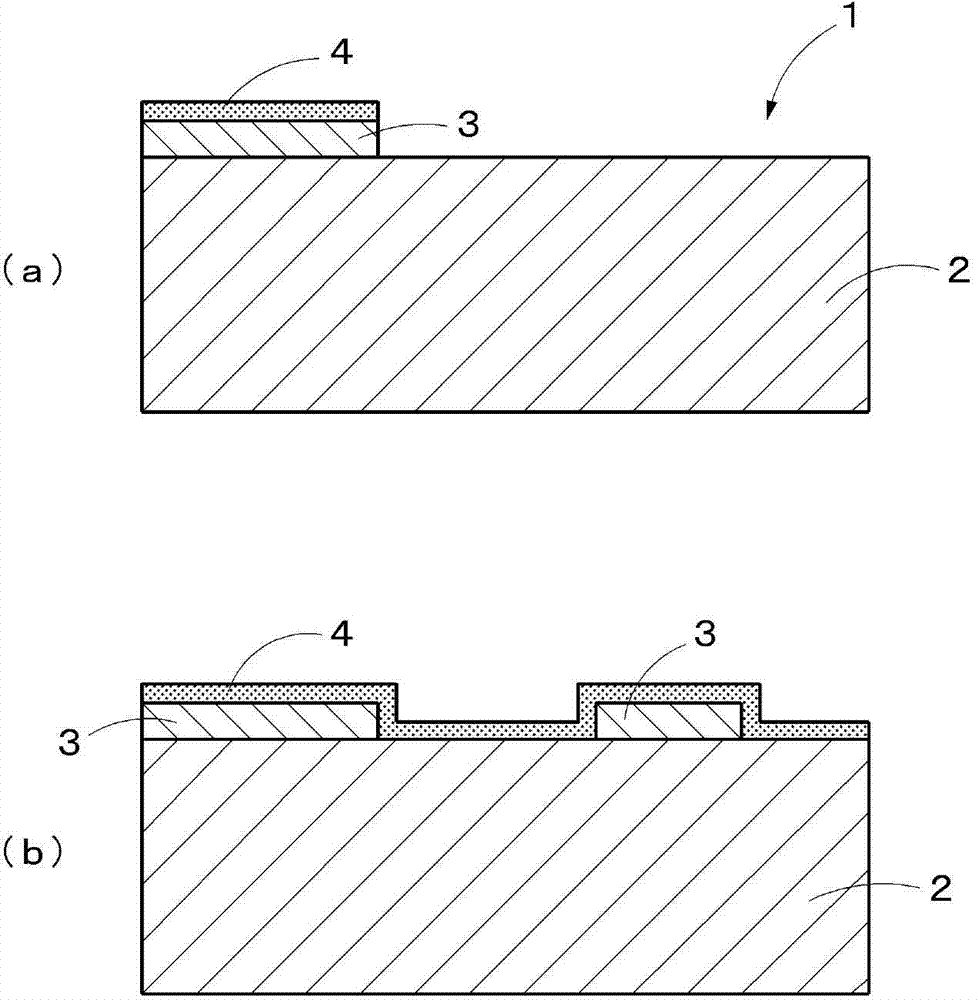

ActiveCN104126033AImprove Laser Welding PerformanceShrink the HAZContact member manufacturingCoupling contact membersCapacitanceHeat-affected zone

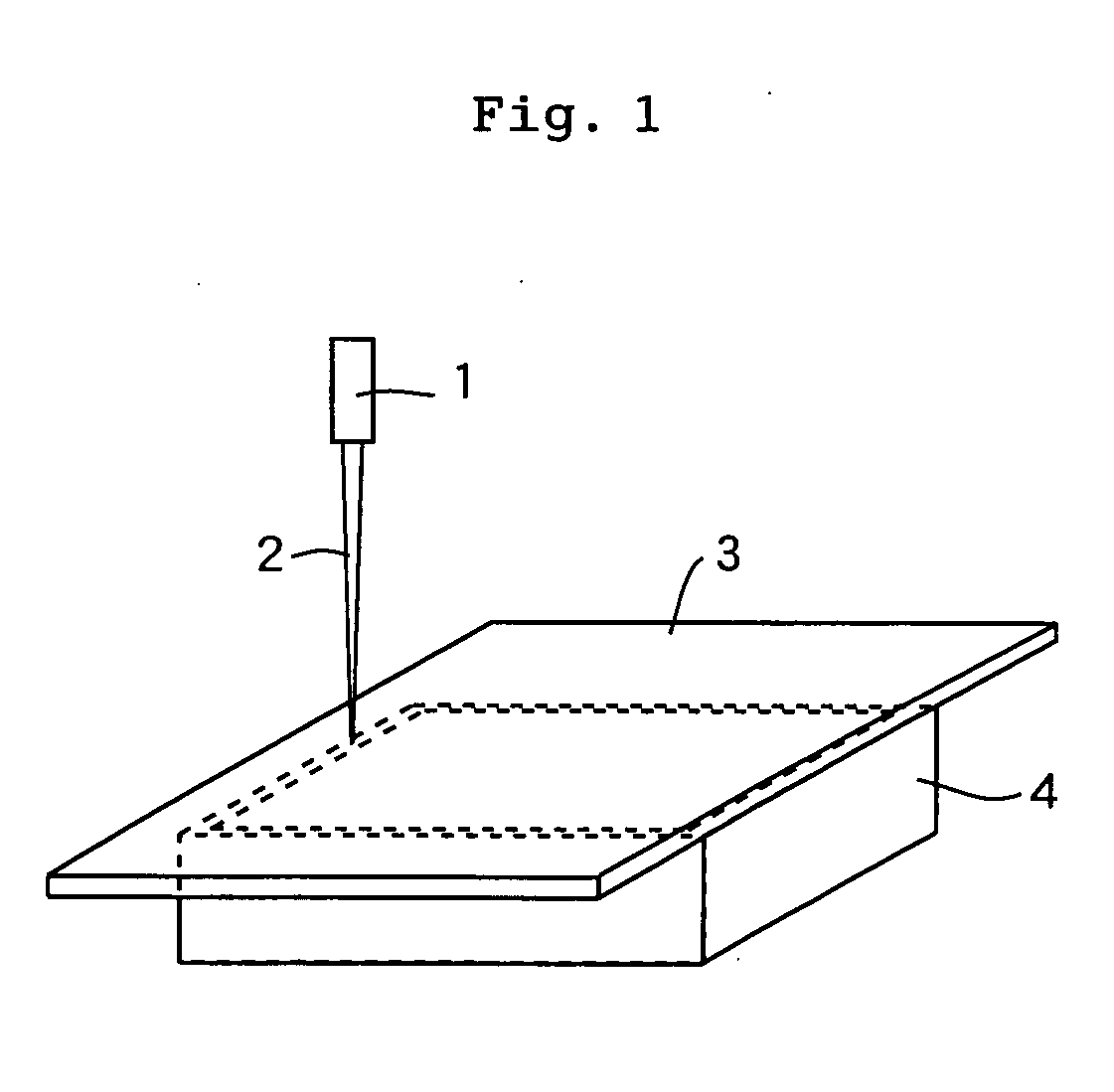

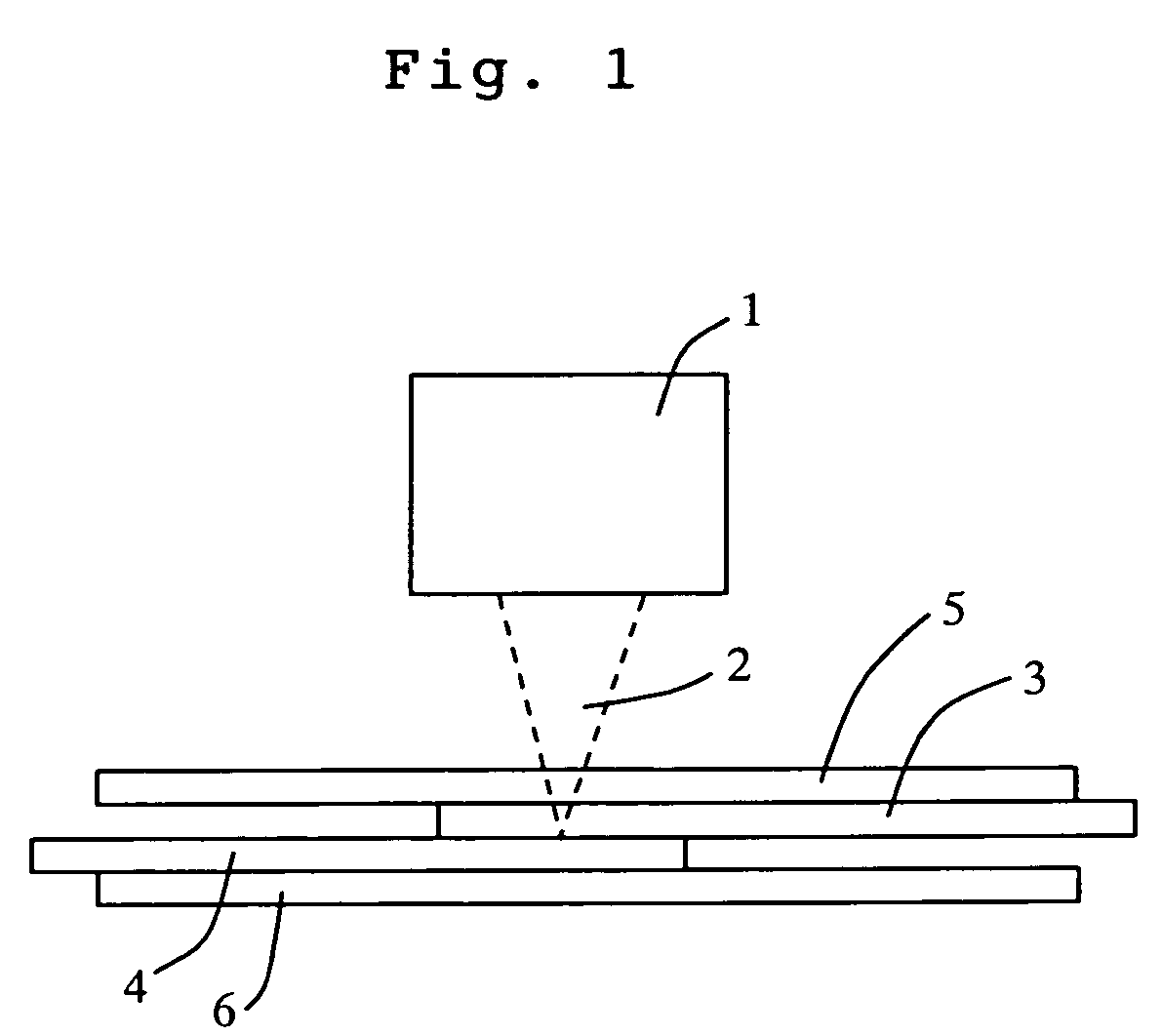

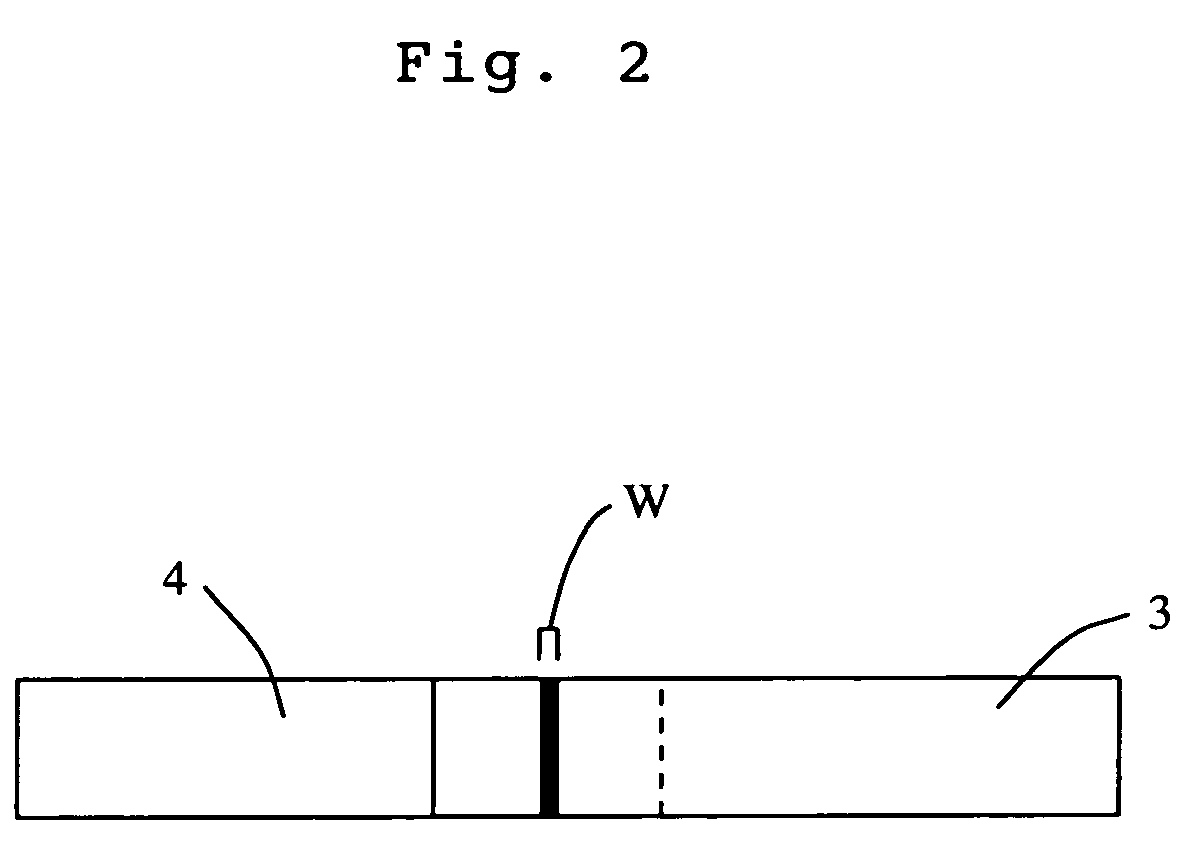

Provided are: a metal member which has improved copper and copper alloy laser weldability, and a small heat-affected zone; a terminal and an electric wire connection structure formed using the metal member; and a method for manufacturing the terminal. As shown, for example, in fig. 1, this metal member (1) has: a base material (2) comprising copper or a copper alloy; a white metal layer (3) provided on a part of or the entirety of the base material (2); and an oil film (4) provided on the white metal layer. In the metal member (1), the thickness of the white metal layer is 0.01-0.80 µm, the arithmetic average roughness (Ra) of the surface of the white metal layer is 0.6-1.2 µm, and moreover the electrical double layer capacitance of the oil film is 1.5-7.0 µF / cm2.

Owner:FURUKAWA ELECTRIC CO LTD +1

Polybutylene terephthalate resin composition

ActiveCN112469781AGood alkali resistanceImprove thermal shock resistanceSynthetic resin layered productsVehicle componentsPolytetramethylene terephthalateElastomer

A polybutylene terephthalate resin composition is characterized by containing (B) 0-30 parts by mass of an elastomer, (C) 0.3-4 parts by mass of an epoxy compound, (D) 15-80 parts by mass of a reinforcing filler, and (E) 1-15 parts by mass of a master batch including a thermoplastic resin and a silicone compound having a weight-average molecular weight of 10000-80000, with respect to (A) 100 partsby mass of a thermoplastic resin including polybutylene terephthalate resin.

Owner:MITSUBISHI ENG PLASTICS CORP

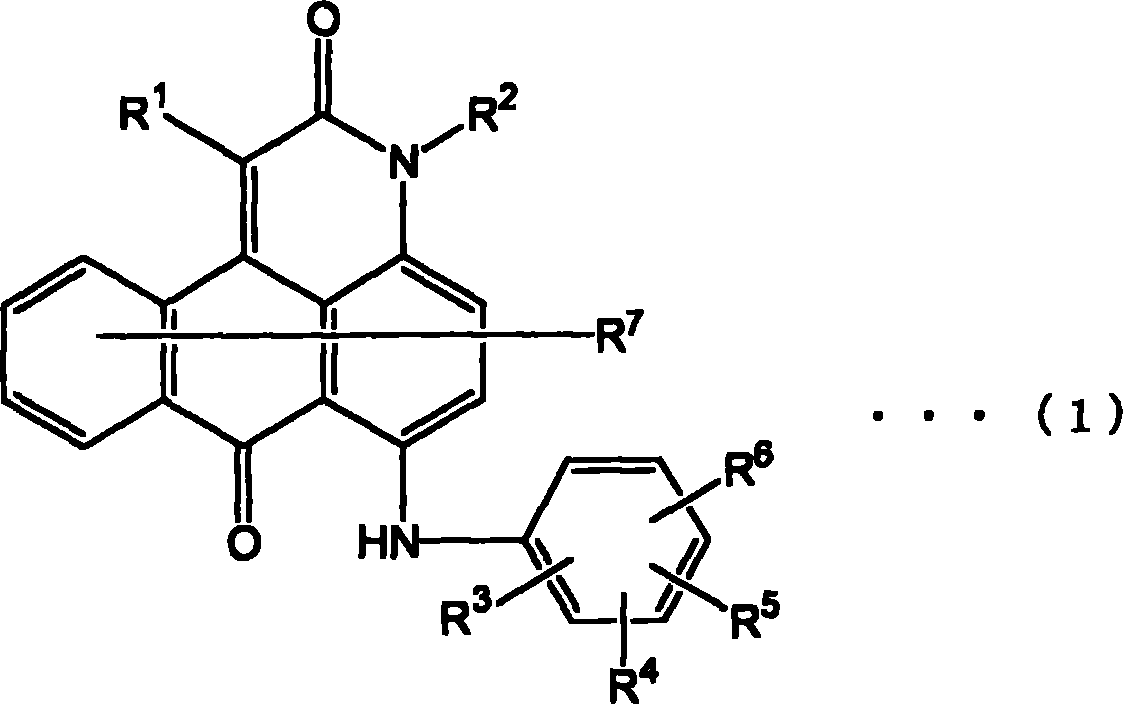

Laser weld of laser transmitting member containing alkaline earth metal salt of anthrapyridone acid dye

InactiveCN101115610ABeautiful appearanceHigh tensile strengthBenz-azabenzanthrone dyesThin material handlingAlkaline earth metalAcid dye

Owner:ORIENT CHEM INDS

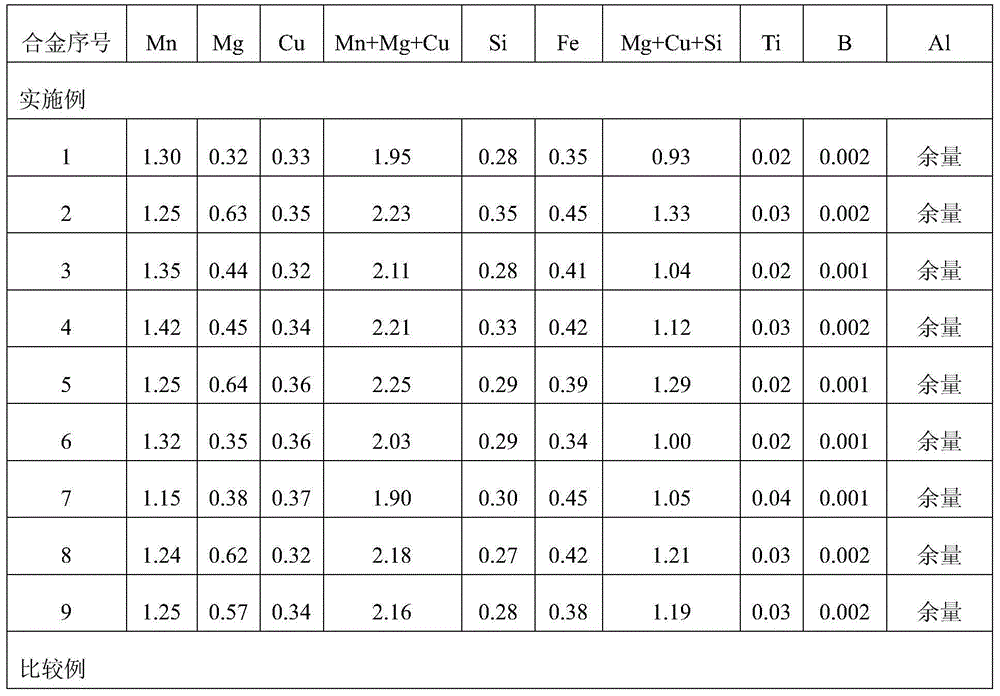

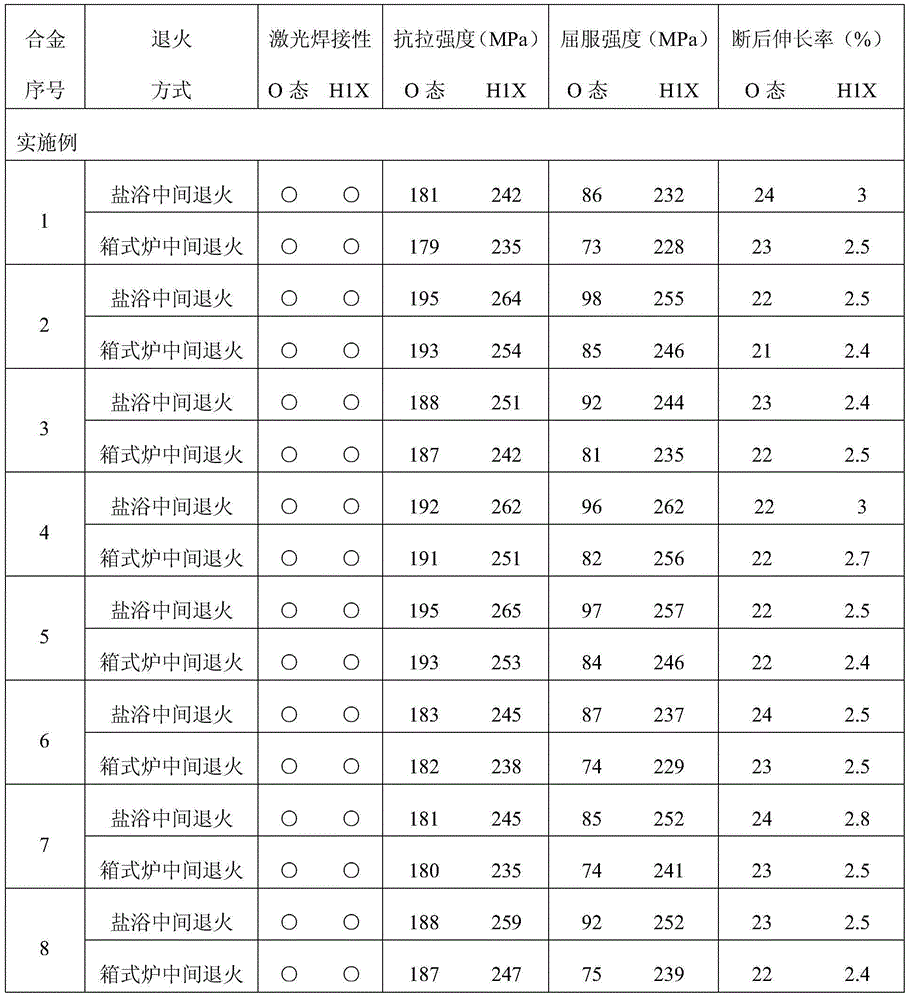

High-strength aluminum alloy used for lithium ion battery shell and having excellent laser welding performance

ActiveCN103981401AImprove Laser Welding PerformanceImprove performanceCell component detailsLithium electrodeDeep drawing

The invention relates to a high-strength aluminum alloy used for a lithium ion battery shell and having excellent laser welding performance. The high-strength aluminum alloy comprises the components: 1.0-1.5 wt% of Mn, 0.2-1.0 wt% of Mg, 0.3-0.399 wt% of Cu, 0.251-0.4 wt% of Si, 0.2-0.6 wt% of Fe, less than 0.05 wt% of Ti, less than 0.005 wt% of B, and the balance Al and inevitable impurity elements, wherein Mn (wt%)+Mg (wt%)+Cu (wt%)>=1.8 wt%, and Mg (wt%)+Cu (wt%)+Si (wt%)<=1.4 wt%. Aluminum alloy sheet materials having the alloy components have excellent laser welding performance and good thinning-deep drawing formability, moreover, the tensile strength of an O-state sheet material is not less than 170 MPa, the tensile strength of an H1X-state sheet material is not less than 230 MPa, and the aluminum alloy sheet materials are suitable for manufacture of the lithium ion battery shell.

Owner:CHINA ALUMINUM INT ENG CORP

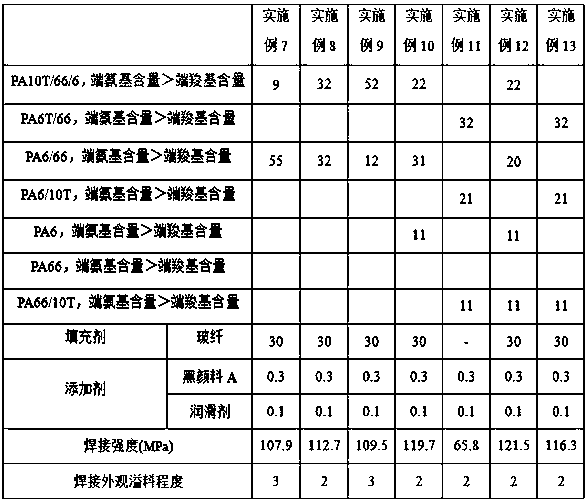

Polyamide composite material and preparation method thereof

ActiveCN110845843AImprove the cosmetic defect of excessive overflowImprove appearance defectsPolymer sciencePolyamide

The invention discloses a polyamide composite material which comprises the following components in parts by weight: A) 20-80 parts of a compound of at least one polyamide E and at least one of polyamide I, polyamide II and polyamide III, wherein the content of amino terminal group in the polyamide E, the polyamide I, the polyamide II and the polyamide III is greater than the content of terminal carboxyl; and B) 0-35 parts of a filler. The polyamide composite material disclosed by the invention has the advantages of good laser welding effect and the like.

Owner:SHANGHAI KINGFA SCI & TECH +3

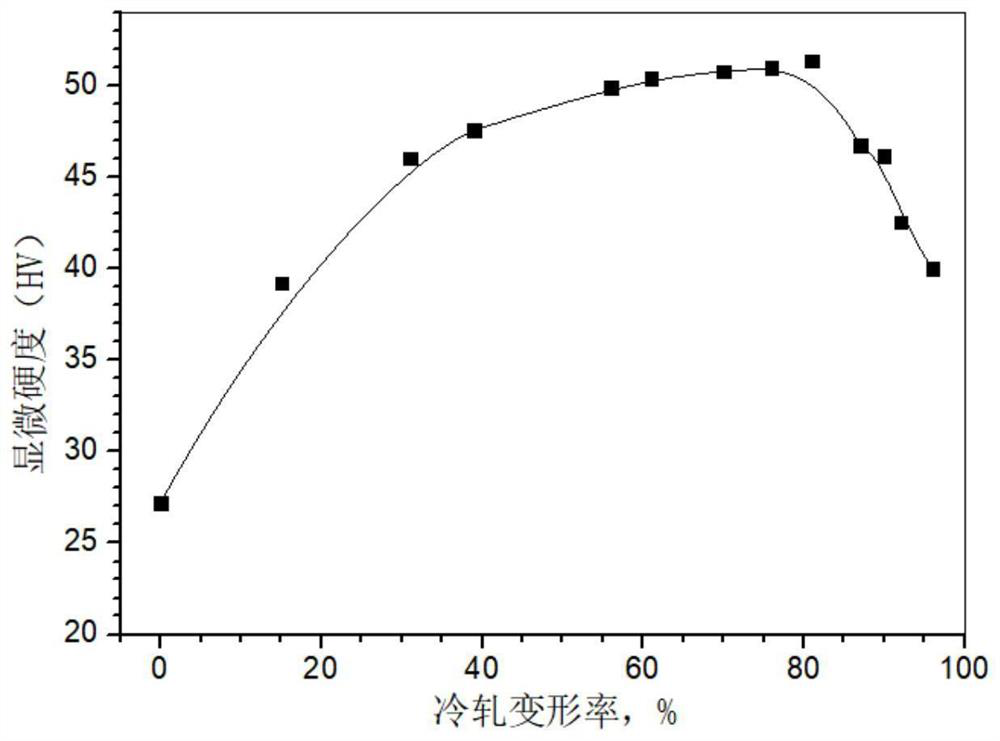

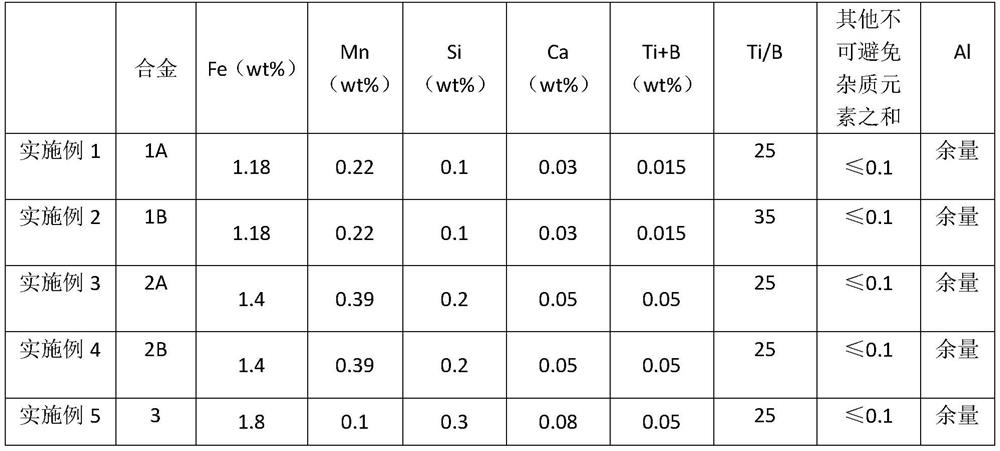

Aluminum alloy plate strip for lithium battery cover plate and preparation method of aluminum alloy plate strip

InactiveCN113088764AGuaranteed process softeningHigh strengthCell component detailsMaterials scienceLaser soldering

The invention discloses an aluminum alloy plate strip for a lithium battery cover plate and a preparation method of the aluminum alloy plate strip. The aluminum alloy plate strip comprises the following components of, in percentage by mass, 1.18 wt%-1.8 wt% of Fe, Mn less than or equal to 0.395 wt% 0.03 wt%-0.08 wt% of Ca, 0.1 wt%-0.3 wt% of Si and the balance Al and inevitable impurities, wherein Fe + Mn is less than 2 wt%, Fe / Mn is more than or equal to 2.5, Mn + Si is less than 0.6 wt%, and (Fe + Mn + Ca) / Si is more than or equal to 2.5. According to the aluminum alloy plate strip for the lithium battery cover plate and the preparation method of the aluminum alloy plate strip, the alloy has good mechanical performance, forming performance and laser welding performance at the same time, especially the performance stability of a material can be improved, and a prepared explosion-proof valve has stable explosion pressure.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

Aluminum alloy sheet for battery case use excellent in formability, heat dissipation, and weldability

InactiveUS20150167126A1Improve conductivityGood molding effectJackets/cases materialsWelding/cutting media/materialsLithium-ion batteryLarge size

An aluminum alloy sheet having a heat dissipation characteristic that is applicable to a large-size lithium ion battery container, excellent in formability and shape freezability and excellent in laser weldability is provided. An aluminum alloy sheet comprising a cold rolled, annealed material containing Fe: 0.05 to less than 0.3 mass %, Mn: 0.6 to 1.5 mass %, and Si: 0.05 to 0.6 mass %, has a balance of Al and impurities Cu: less than 0.35 mass % and Mg: less than 0.05 mass %, has a conductivity exceeding 45% IACS, has a 0.2% proof strength of 40 to less than 60 MPa, and displays a 20% or more value of elongation is also provided. An aluminum alloy sheet comprising an as-cold-rolled material having a conductivity exceeding 45% IACS, a 0.2% proof strength of 60 to less than 150 MPa, and displaying 3% or more value of elongation is also provided.

Owner:NIPPON LIGHT METAL CO LTD

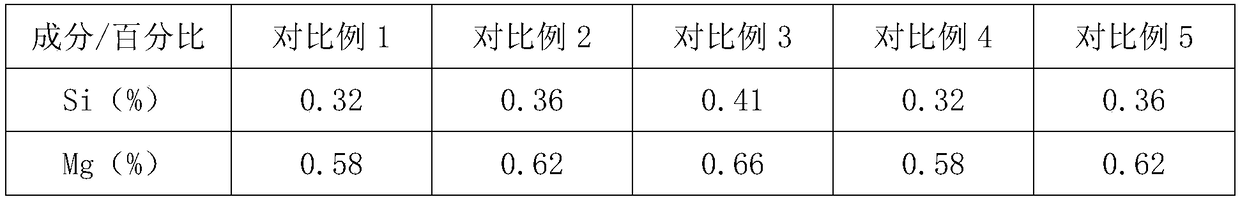

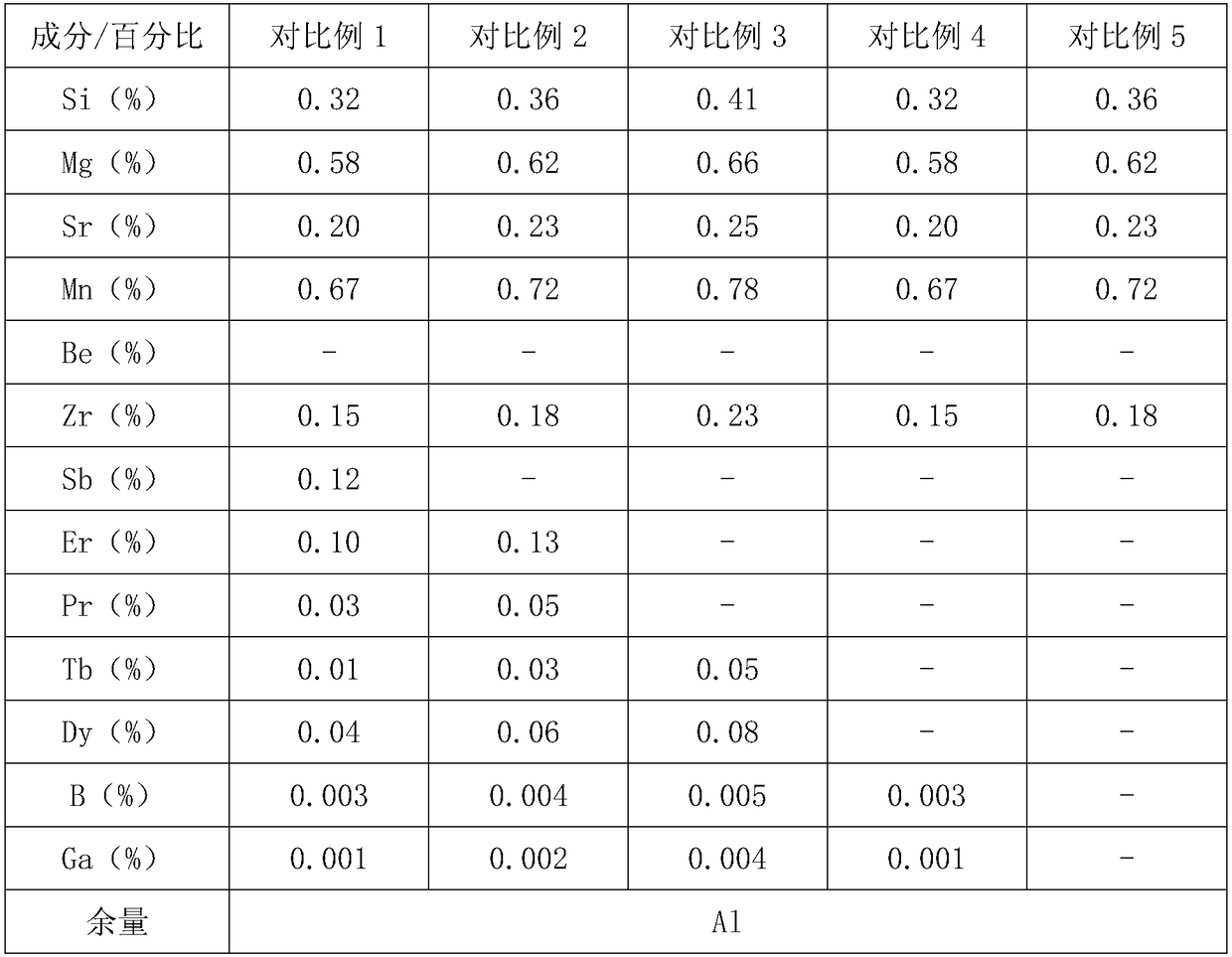

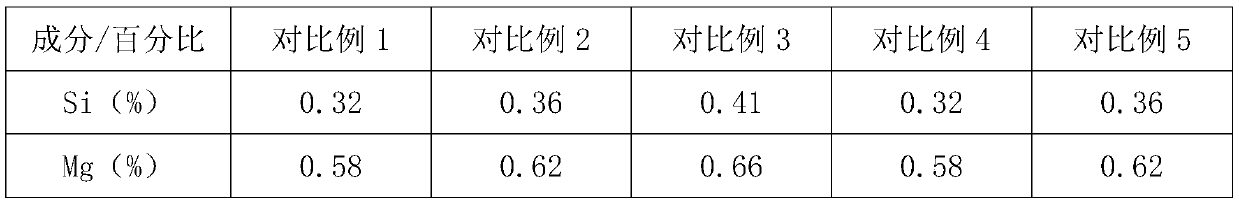

Aluminum alloy material for new energy power battery shells and covers and application of aluminum alloy material

InactiveCN109371294AImprove mechanical propertiesHigh outburstJackets/cases materialsPower batteryNew energy

The invention discloses an aluminum alloy material for new energy power battery shells and covers and application of the aluminum alloy material, and relates to the technical field of new energy batteries. The aluminum alloy material is composed of following element components including Si, Mg, Sr, Mn, Be, Zr, Sb, Er, Pr, Tb, Dy, B, Ga and Al. An aluminum alloy for the new energy power battery shells and covers is excellent in comprehensive performance; the components, content and preparation process of the aluminum alloy are overall improved and optimized, the application performance of prepared new energy power battery shell and cover products is improved remarkably, substantive breakthroughs are achieved especially on the index aspects of tensile strength, prescribed non-proportional extension strength, percentage elongation after fracture, stability, punching performance and welding performance, and the application occasion and field are wide; and the active demands of the new energy market for high-performance power battery cover and shell products can be greatly met.

Owner:合肥天沃能源科技有限公司

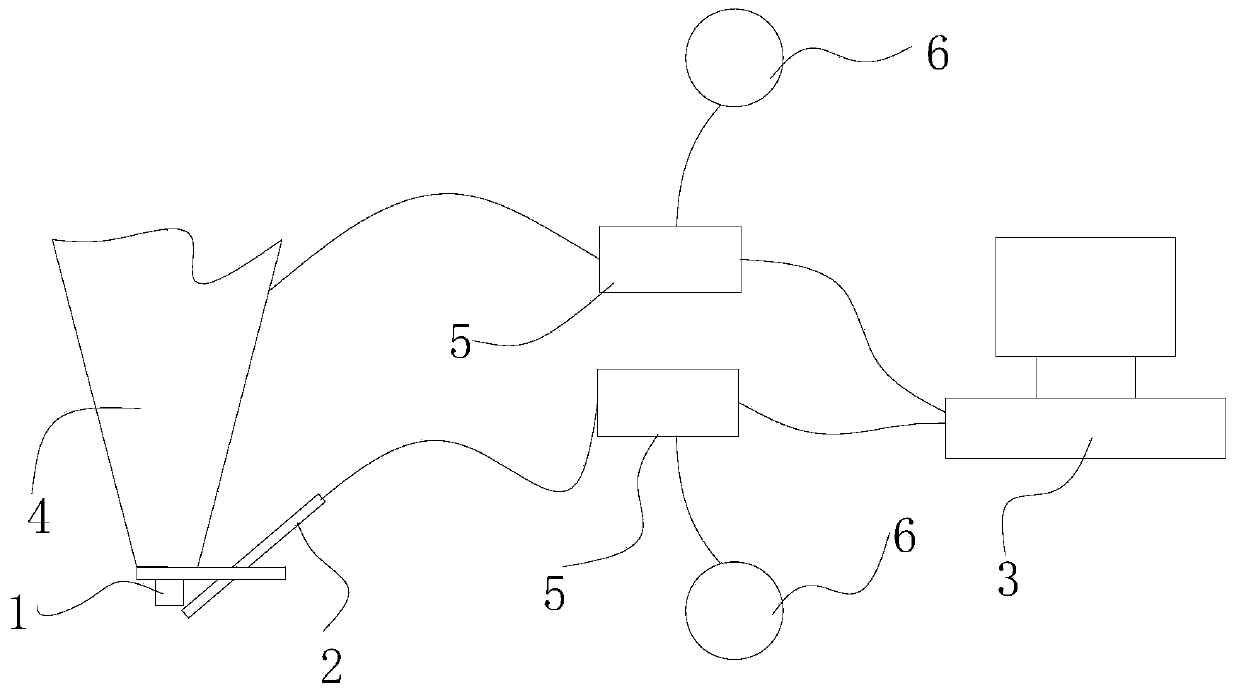

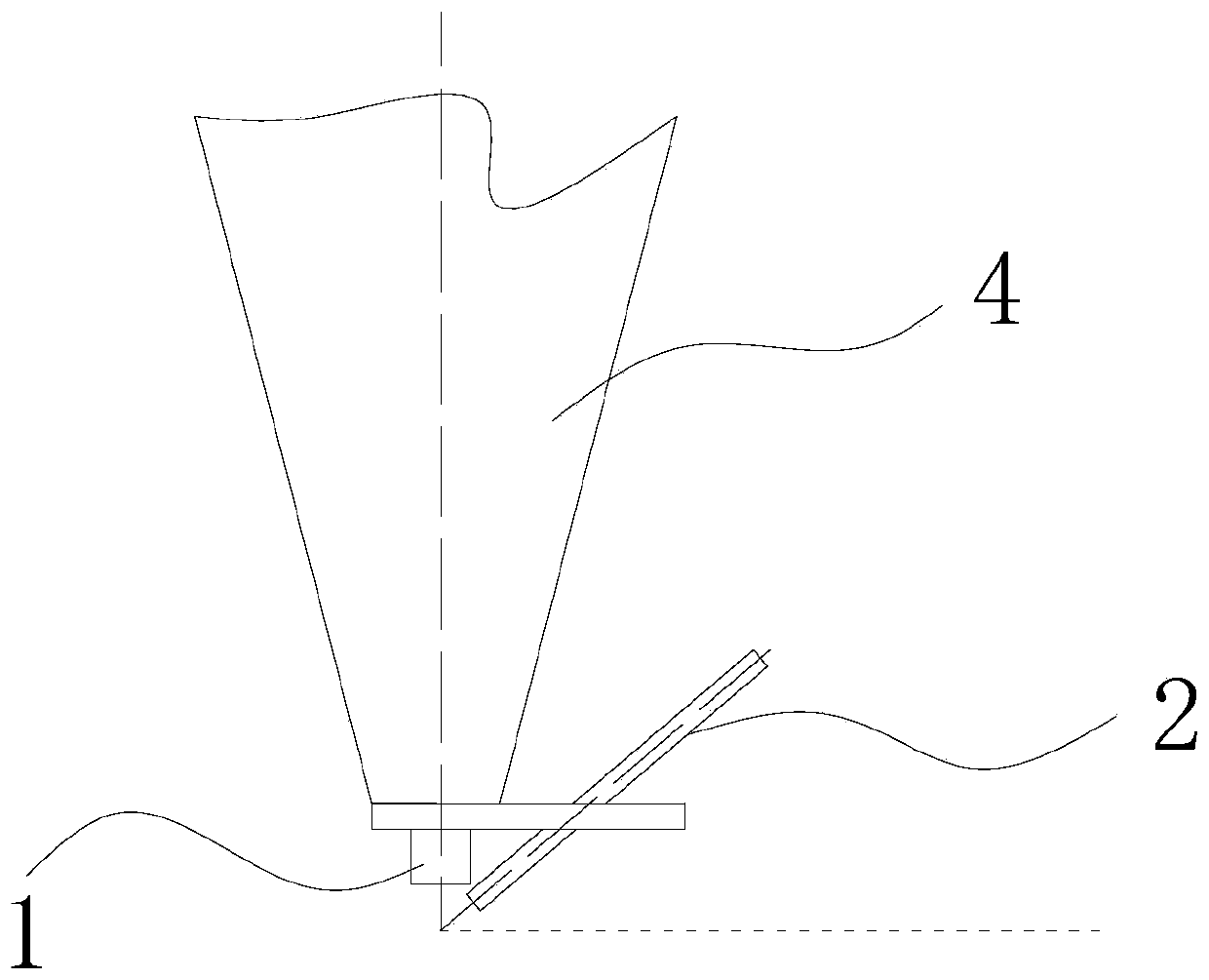

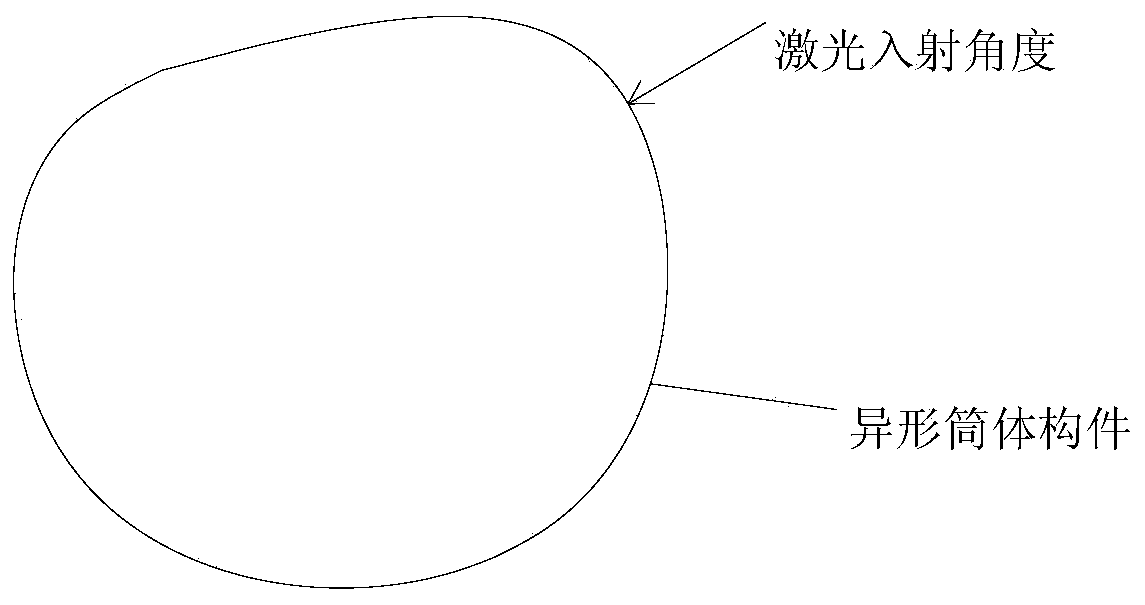

Laser welding assembly of special-shaped cylinder component, laser welding machine and welding method

ActiveCN111151881AUniform stressGuaranteed stabilityMetal working apparatusLaser beam welding apparatusShielding gasEngineering

The invention relates to a laser welding assembly of a special-shaped cylinder component, a laser welding machine and a welding method. The laser welding assembly comprises a coaxial gas nozzle, a side gas nozzle and a control module; the coaxial gas nozzle is arranged on a welding head of the laser welding machine, is coaxial with the welding head, and is used for spraying shielding gas with certain force to a to-be-welded part on the special-shaped cylinder component; the side gas nozzle is arranged on one side of the welding head and is used for spraying the shielding gas with certain forceto the to-be-welded part; and the control module is connected with the control ends of the coaxial gas nozzle and the side gas nozzle, and is used for adjusting the strength of the coaxial gas nozzleand the side gas nozzle for spraying the shielding gas according to a preset motion path as well as gravity and surface tension of molten pools at different welding positions. According to the laserwelding assembly of the special-shaped cylinder component, the laser welding machine and the welding method, the stability of molten pool structures is ensured, forming consistency of obtained weld joints is greatly improved, the perforation phenomenon is not likely to occur, and finally high-quality weld joint forming is obtained.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Copper alloy material for resistance member, manufacturing method therefor, and resistor

ActiveCN110168119AAccurate measurementImprove Laser Welding PerformancePolishing machinesResistorsElectrical resistance and conductanceManganese

Provided are: a copper alloy material for a resistance member having favorable laser weldability, said copper alloy material being capable of easily obtaining a correct measured value in the measurement of electrical resistivity; and a method for manufacturing the copper alloy material. The copper alloy material for a resistance member is a rolled sheet having a thickness t of 0.04 mm or more whenmeasured using a contact-type film thickness gauge, and the copper alloy material comprises 2-14 mass% of manganese with the remainder comprising copper and unavoidable impurities. Further, when theroughness curve in a direction orthogonal to the rolling direction is acquired using a contact-type surface roughness measurement technique, the sheet surface of the rolled sheet has a maximum heightRz of 0.3-1.5 mu m, an average length of roughness curve elements RSm of 0.03-0.15 mm, and a value of a parameter A of 0.002-0.04.

Owner:FURUKAWA ELECTRIC CO LTD

Flame-retardant polyester composition as well as preparation method and application thereof

PendingCN114015205AImprove laser transmittanceImproved uniformity of laser transmittanceLaser solderingPolymer chemistry

The invention discloses a flame-retardant polyester composition which comprises the following components in parts by weight: 100 parts of polyester resin; 10 to 30 parts of an epoxy polymer; 10 to 45 parts of a flame retardant; and 10-500 ppm of tetrahydrofuran or derivatives thereof based on the total weight of the flame-retardant polyester composition. According to the flame-retardant polyester composition, the epoxy polymer and the tetrahydrofuran are compounded, so that the laser welding property of the flame-retardant polyester composition can be improved.

Owner:SHANGHAI KINGFA SCI & TECH +2

Preparation method of aluminum alloy material for new energy power battery shells and covers

InactiveCN111321325AGood mechanical propertiesGood stamping performanceRoll force/gap control deviceTemperature control devicePower batteryAluminium alloy

Owner:合肥博康金属技术有限公司

Aluminum alloy plate for bus bars, which has excellent laser weldability

InactiveCN108350533AImprove conductivityEasy to processCurrent conducting connectionsSmall-sized cells cases/jacketsMetallurgyBus

This aluminum alloy plate for bus bars contains Si, Fe, Ti and B respectively in specific amounts, with the balance being made up of Al and unavoidable impurities. With respect to this aluminum alloyplate for bus bars, the number density of intermetallic compounds having maximum lengths of 2 mum or more is 400-1500 compounds / mm2 in a cross-section of 1 / 4 of the plate thickness; and the electricalconductivity is 58-62% IACS.

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com