Aluminum alloy plate strip for lithium battery cover plate and preparation method of aluminum alloy plate strip

An aluminum alloy strip and lithium battery technology, applied in the field of aluminum alloy processing, can solve problems such as being unsuitable for manufacturing an integrated cover plate, increasing material manufacturing costs, increasing raw material costs, etc., achieving good mechanical properties, improving corrosion resistance, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

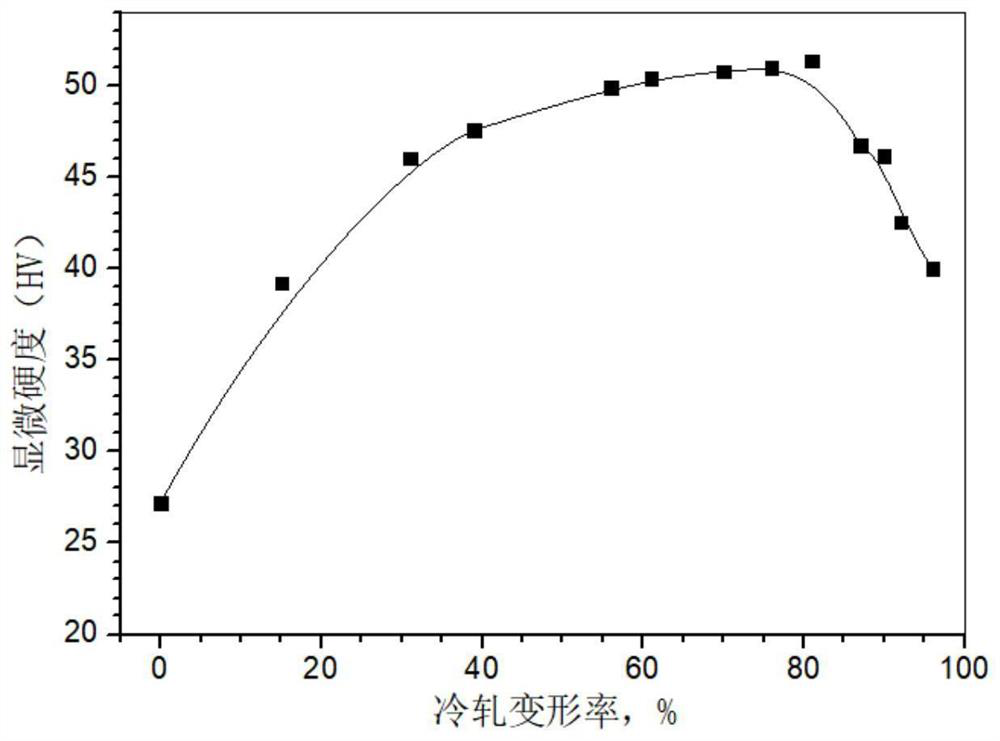

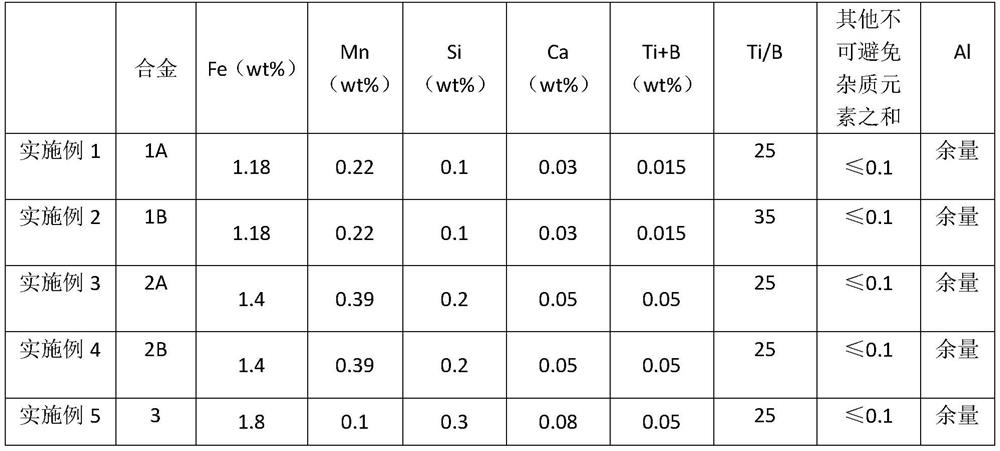

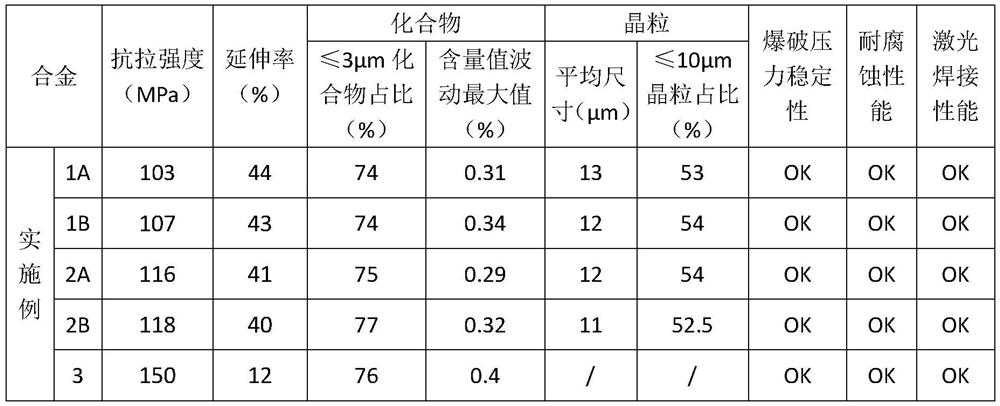

[0065] Pure aluminum, AlFe10, AlMn10, AlSi20, AlCa10, AlTi5B0.2 intermediate alloys are melted and cast into ingots (slabs) with the alloy composition given in Table 1, with a thickness of 490 mm; The heating rate of °C / h is raised to 580 °C for 20 hours, and then cooled to 500 °C with a cooling rate of 60 °C / h and kept for 5 hours; hot rolling is carried out, and the temperature of hot rolling is controlled at 270 °C; Rolled to 1.5mm, the cold rolling rate is 71%; for annealing treatment, the cold-rolled strip is heated to 350°C at a heating rate of 30°C / s and kept for 40s, and then cooled to below 100°C at a rate of 30°C / s; A fully annealed sheet and strip is obtained.

Embodiment 2

[0067] Melt and cast pure aluminum, AlFe10, AlMn10, AlSi20, AlCa10, AlTi5B0.2 master alloys into ingots with the alloy composition given in Table 1, with a thickness of 490mm; The heating rate is raised to 600°C for 12 hours, then cooled to 450°C at a cooling rate of 80°C / h and held for 10 hours; hot rolling is carried out, and the temperature of the hot final rolling is controlled at 270°C; the hot-rolled strip is cold-rolled to 1.5mm , the cold rolling rate is 71%; the cold-rolled strip is heated to 350°C at a heating rate of 15°C / s and kept for 40s, and then cooled to below 100°C at a rate of 30°C / s; a fully annealed strip is obtained .

Embodiment 3

[0069] Melt and cast pure aluminum, AlFe10, AlMn10, AlSi20, AlCa10, AlTi5B0.2 master alloys into ingots with the alloy composition given in Table 1, with a thickness of 490 mm; The heating rate is raised to 600°C for 12 hours, then cooled to 550°C at a cooling rate of 60°C / h and held for 7 hours; hot rolling is carried out, and the temperature of the hot final rolling is controlled at 270°C; the hot-rolled strip is cold-rolled to 1.5mm , the cold rolling rate is 89%; the cold-rolled strip is heated to 350°C at a heating rate of 50°C / s and kept for 40s, and then cooled to below 100°C at a rate of 30°C / s; a fully annealed strip is obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com