Laser weld of laser transmitting member containing alkaline earth metal salt of anthrapyridone acid dye

An alkaline earth metal salt and laser welding technology, which is applied in the fields of benzo-azabenzanthrone dyes, thin material processing, transportation and packaging, etc., can solve the problem of poor appearance of the welded part, and achieve beautiful appearance and fastening Strong, laser penetration, laser welding and good stability

Inactive Publication Date: 2008-01-30

ORIENT CHEM INDS

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the appearance of the welded part will be deteriorated due to color fading of the member prepared from the laser-transmissive colored thermoplastic resin composition.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1-1

[0070]

example 1-2

[0072]

[0073] Compound Example 1-3

[0074]

[0075] Compound Example 1-4

[0076]

example 1-5

[0078]

[0079] Compound Example 1-6

[0080]

[0081] Compound Example 1-7

[0082]

[0083] Compound Example 1-8

[0084]

[0085] Compound Example 1-9

[0086]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

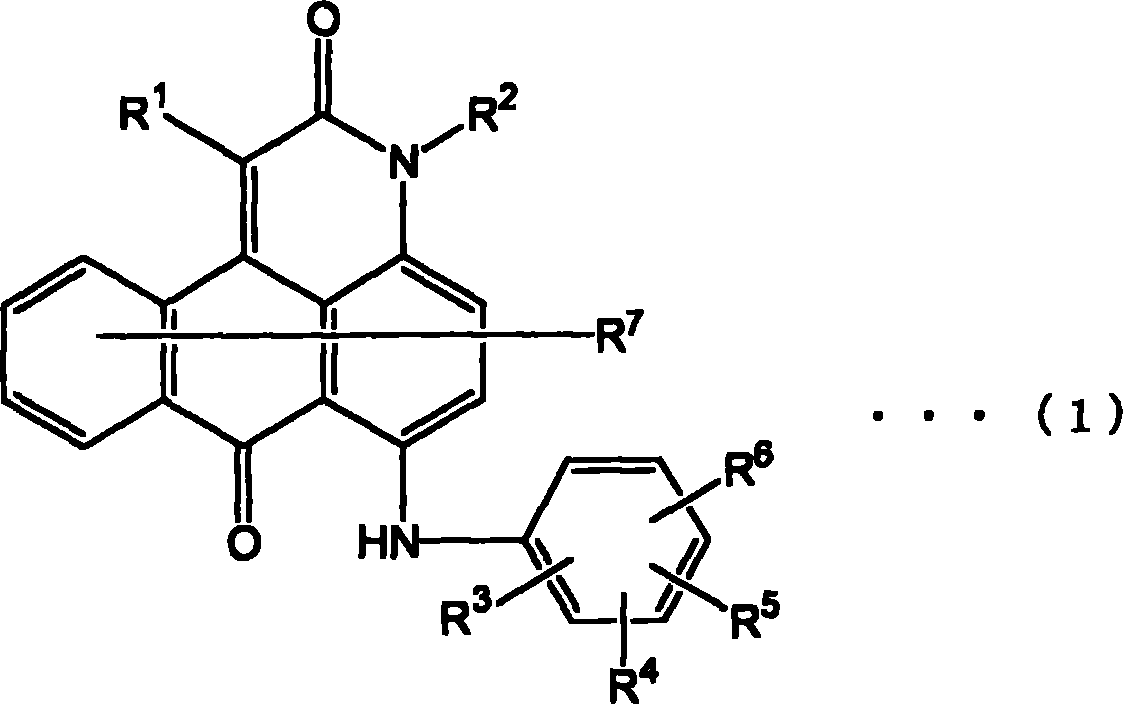

A laser-welded article comprises: a laser-transmissible workpiece made from a laser-transmissible colored resin composition including a resin and an alkaline earth metal salt of an anthrapyridone-type acidic dye represented by the following chemical formula [in the chemical formula, R 7 is allowed to be the group presented by chemical formula (2) and at least one of R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , R 9 , and R 10 is SO 3 M 1 / 2 that M is an alkaline earth metal] and a laser-absorptive workpiece putting the laser-transmissible workpiece together, wherein the workpieces are welded at the put position thereof by irradiated laser towards the laser-transmissible workpiece that transmits therethrough and is absorbed into the laser-absorptive workpiece.

Description

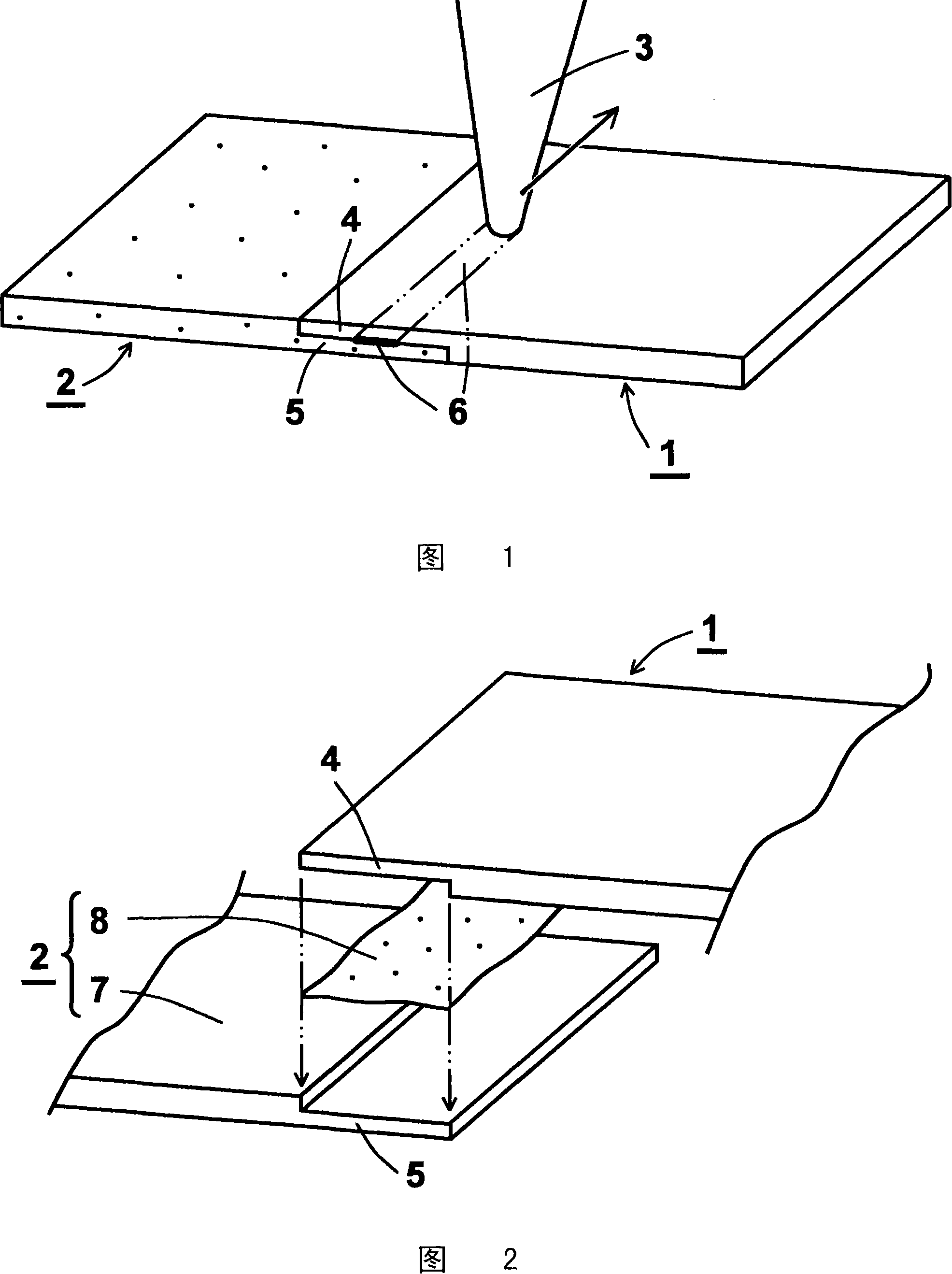

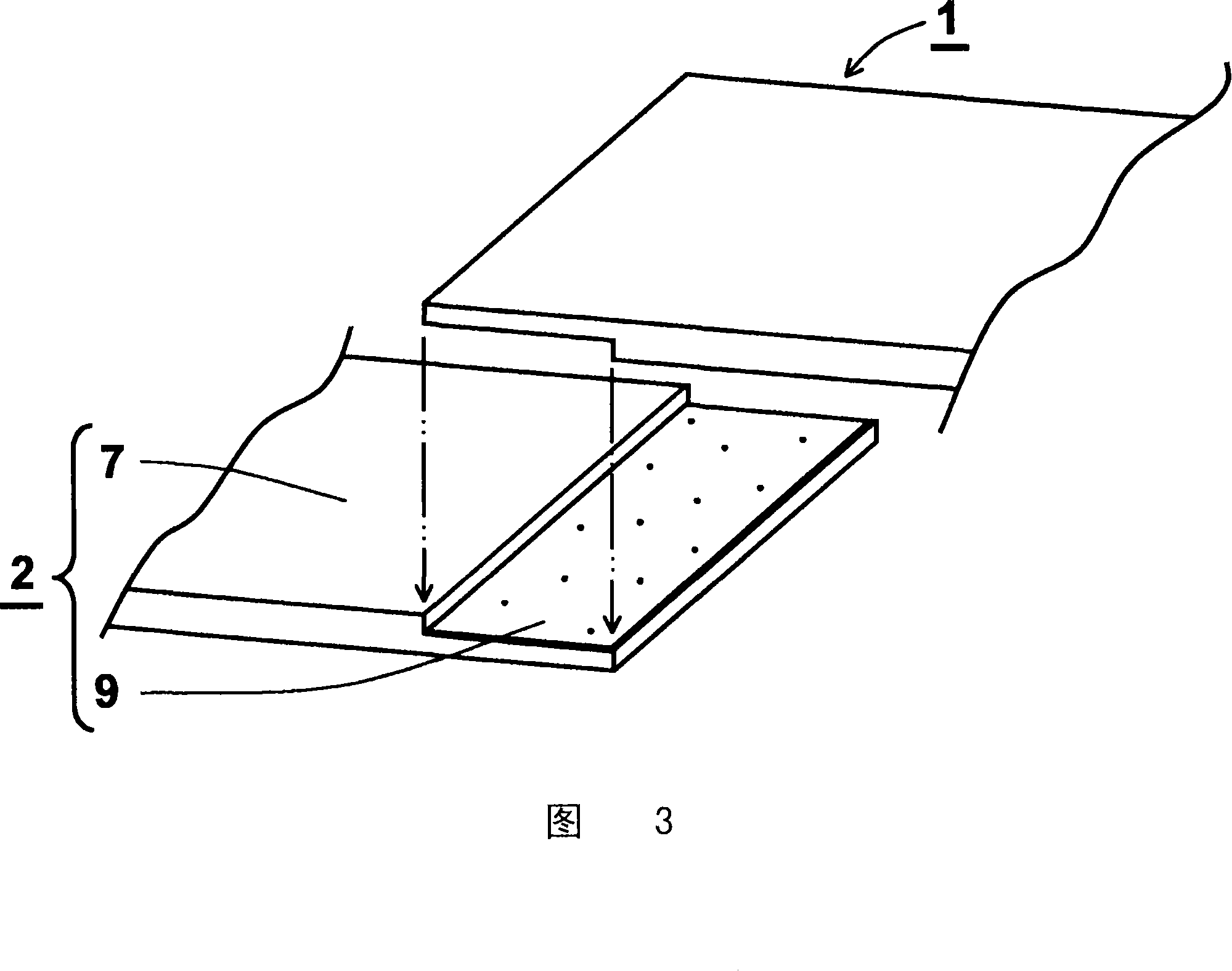

technical field [0001] The present invention relates to a laser welded body prepared from a laser penetrating member and a laser absorbing member and a laser welding method for the laser welded body. It is prepared from a laser penetrating colored resin composition of an alkaline earth metal salt. Background technique [0002] It is well known to join members made of thermoplastic synthetic resin materials by laser welding. [0003] Such laser welding can be performed, for example, as follows. As shown in Figure 1, a laser-transmitting member is used on one member, and a laser-absorbing member is used on the other member, and then the two are butted. When the laser-absorbing member is irradiated with laser light from one side of the laser-transmitting member, the laser light transmitted by the laser-transmitting member is absorbed in the laser-absorbing member, thereby generating heat. Through this heat generation, the laser-absorbing member melts centering on the laser-a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C65/16C09B5/14C08K5/3432B29K81/00

CPCB29C66/43B29C65/1616B29K2995/0027B29C65/1635B29C65/1683B29C65/1654B29C66/71B29C65/1696B29C65/1677B29C65/168B29C66/7332B29C65/1674B29K2995/0022B29C66/14C09B5/14C08K5/0041B29C66/12841B29C66/1282B29K2995/002B29K2101/12B29C66/128B29C66/836B29C66/73771B29C66/73775B29C66/73921Y10T428/192B29K2081/06B29K2081/04B29K2077/00B29K2067/00B29K2059/00B29K2023/00B29C65/16C08K5/3432B29K2081/00

Inventor 菅原修治畑瀬芳辉岡西俊泰

Owner ORIENT CHEM INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com