Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

A technology of laser welding and aluminum silicon carbide, which is applied in the manufacture of ceramic products, other household appliances, semiconductor/solid-state devices, etc., can solve the problems that the airtightness of the weld seam is difficult to meet the requirements and the cost of the production process is high, and achieve high airtightness , low cost, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

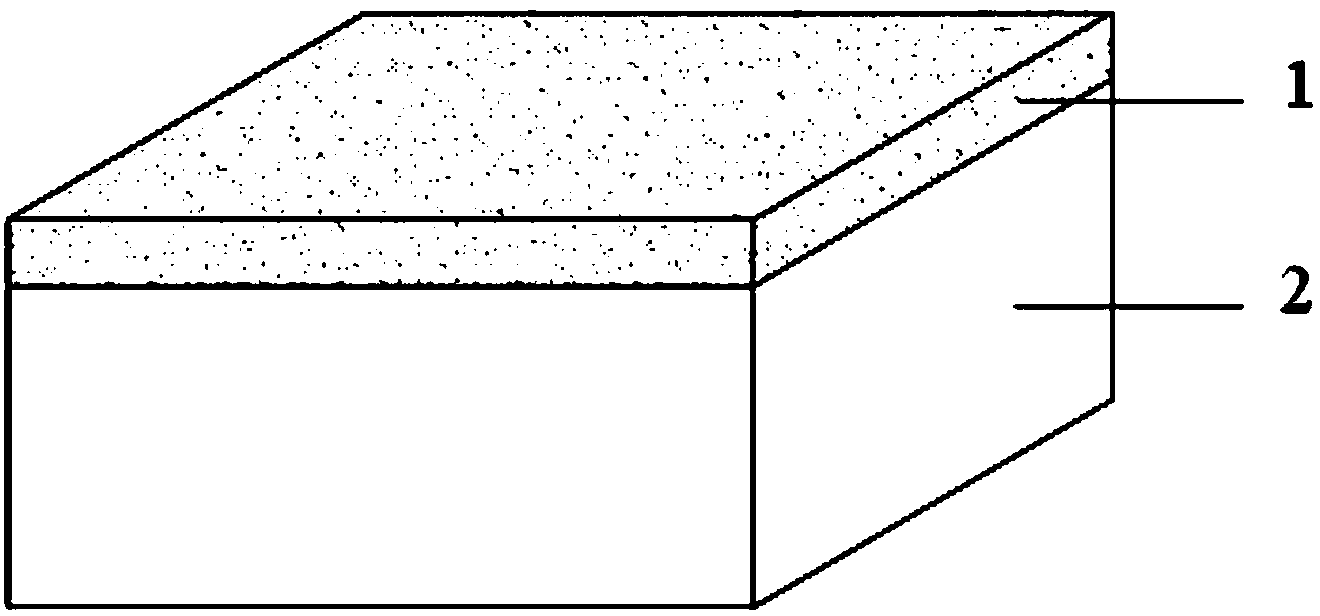

[0033] A kind of aluminum silicon carbide composite material (referred to as composite material) with laser welding layer of the present invention, such as figure 1 As shown, the composite material has a layered structure, which is composed of a laser welding layer 1 and an aluminum silicon carbide layer 2. The laser welding layer 1 is 6063 aluminum alloy (which can be regarded as pure aluminum), and the thickness of the laser welding layer 1 is 0.3 mm. The silicon carbide layer 2 is composed of silicon carbide and 6063 aluminum alloy, wherein the volume fraction of silicon carbide is 58%, the volume fraction of 6063 aluminum alloy is 42%, and the thickness of the aluminum silicon carbide layer 2 is 9.0mm.

[0034] A method for preparing the above-mentioned aluminum silicon carbide composite material with a laser welding layer of the present invention, comprising the following steps:

[0035] (1) Preparation of silicon carbide granulated powder: Weigh 30g of silicone resin (ie...

Embodiment 2

[0041] A kind of aluminum silicon carbide composite material with laser welding layer of the present invention, such as figure 1 As shown, the composite material has a layered structure and is composed of a laser welding layer 1 and an aluminum silicon carbide layer 2. The laser welding layer 1 is a high-silicon aluminum alloy. The volume fraction of silicon in the high-silicon aluminum alloy is 30%, and the volume fraction of aluminum The score is 70%. The thickness of the laser welding layer 1 is 2.5mm, the aluminum silicon carbide layer 2 is composed of silicon carbide and high-silicon aluminum alloy, the volume fraction of silicon carbide is 67%, the volume fraction of high-silicon aluminum alloy is 33%, and the aluminum silicon carbide layer 2 The thickness is 7.0mm.

[0042] A method for preparing the above-mentioned aluminum silicon carbide composite material with a laser welding layer of the present invention, comprising the following steps:

[0043] (1) Preparation ...

Embodiment 3

[0048] A kind of aluminum silicon carbide composite material with laser welding layer of the present invention, such as figure 1 As shown, the composite material has a layered structure, consisting of a laser welding layer 1 and an aluminum silicon carbide layer 2. The laser welding layer 1 is 4047 aluminum alloy, in which the volume fraction of silicon is 13%, and the thickness of the laser welding layer 1 is 1.5mm , the aluminum silicon carbide layer 2 is composed of silicon carbide and 4047 aluminum alloy, the volume fraction of silicon carbide is 43%, the volume fraction of 4047 aluminum alloy is 57%, and the thickness of the aluminum silicon carbide layer 2 is 8.0mm.

[0049] A method for preparing the above-mentioned aluminum silicon carbide composite material with a laser welding layer of the present invention, comprising the following steps:

[0050] (1) Preparation of silicon carbide granulated powder: Weigh 30g of silicone resin (ie, binder), 180g of starch (ie, pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com