Aluminium alloy plate for battery case and its manufacturing method

An aluminum alloy plate and battery case technology, which is applied in the field of aluminum alloy plates for battery cases, can solve the problems of lack of battery case characteristics, increased case weight, failure or damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The aluminum alloy ingots having the compositions shown in Table 1 were homogenized and hot-rolled by a usual method, and then cold-rolled. Next, after maintaining at 450° C. in a salt bath for 90 seconds, air-cooled intermediate annealing was performed, and then final cold rolling was performed at the reduction rate shown in Table 2 to form an aluminum alloy plate with a thickness of 0.6 mm as a test material. In addition, the forming ratio of the cold rolling before the intermediate annealing was appropriately adjusted in consideration of the forming ratio and the final thickness of the final cold rolling.

[0027]Tensile tests, forming tests, laser welding tests, and creep tests were performed on the obtained test materials by the methods described below.

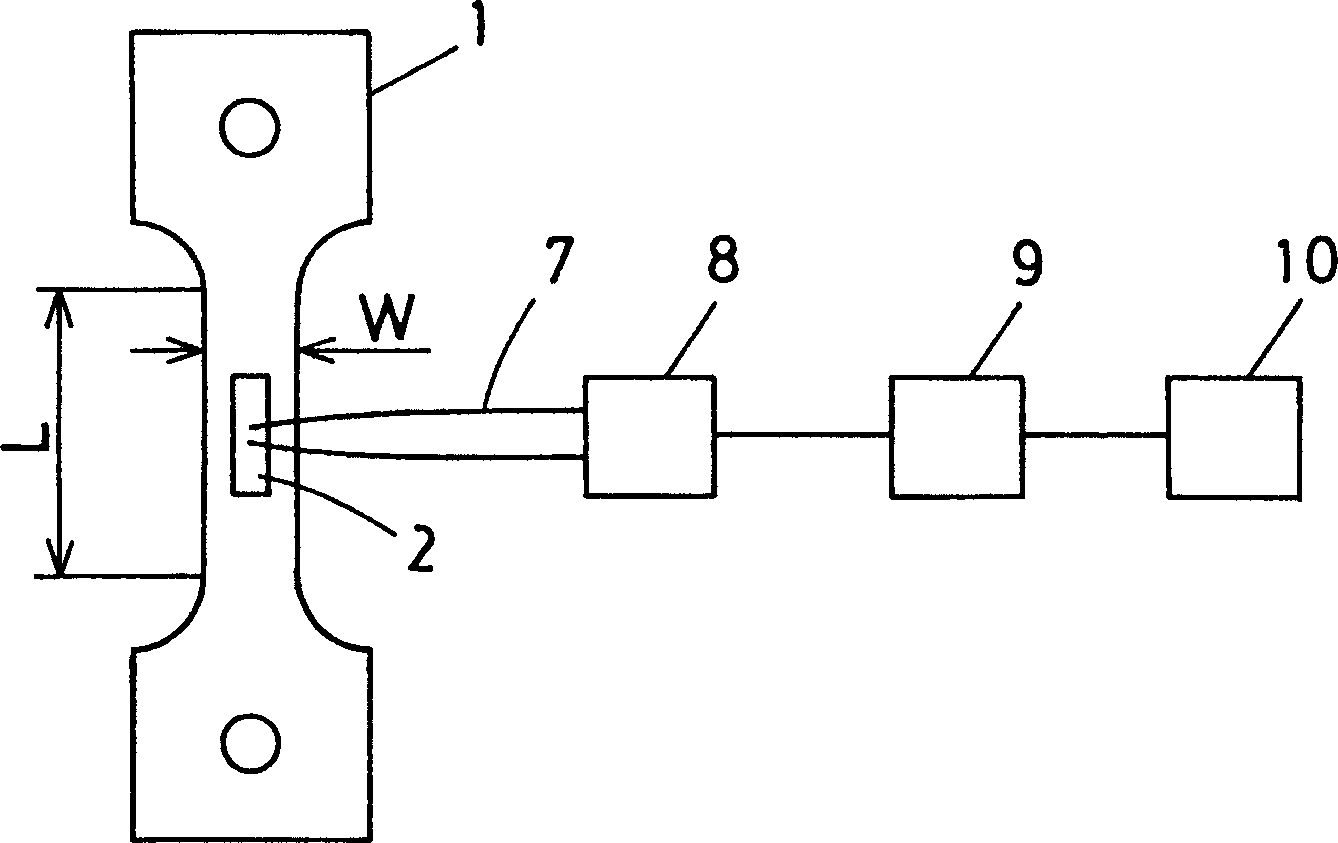

[0028] Tensile test: Using a JIS No. 5 test piece, a tensile test was performed at room temperature according to JIS Z2241 to obtain tensile properties.

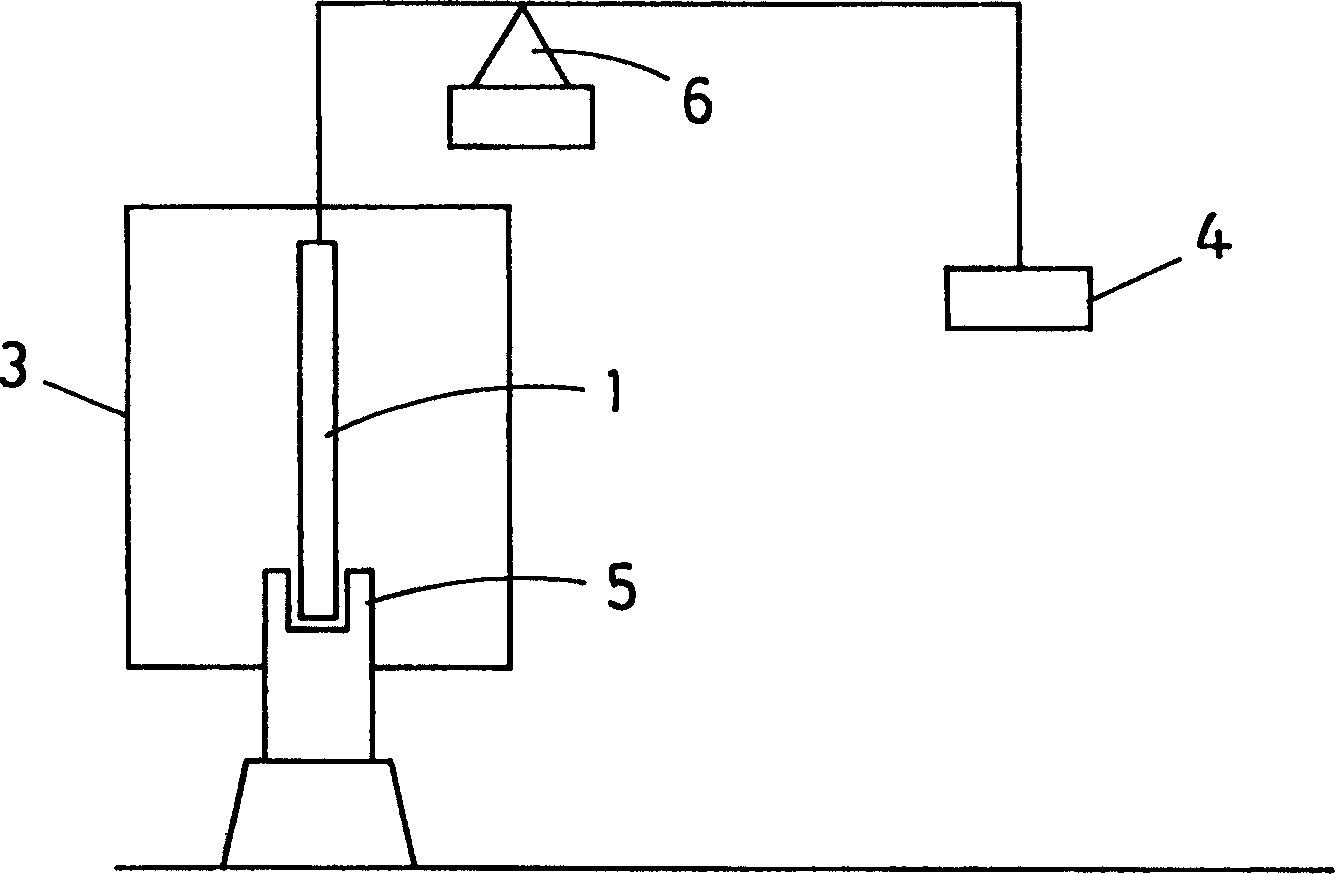

[0029] Forming test: The thinning and drawing rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| creep strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com