Patents

Literature

48results about How to "Uniform liquid distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

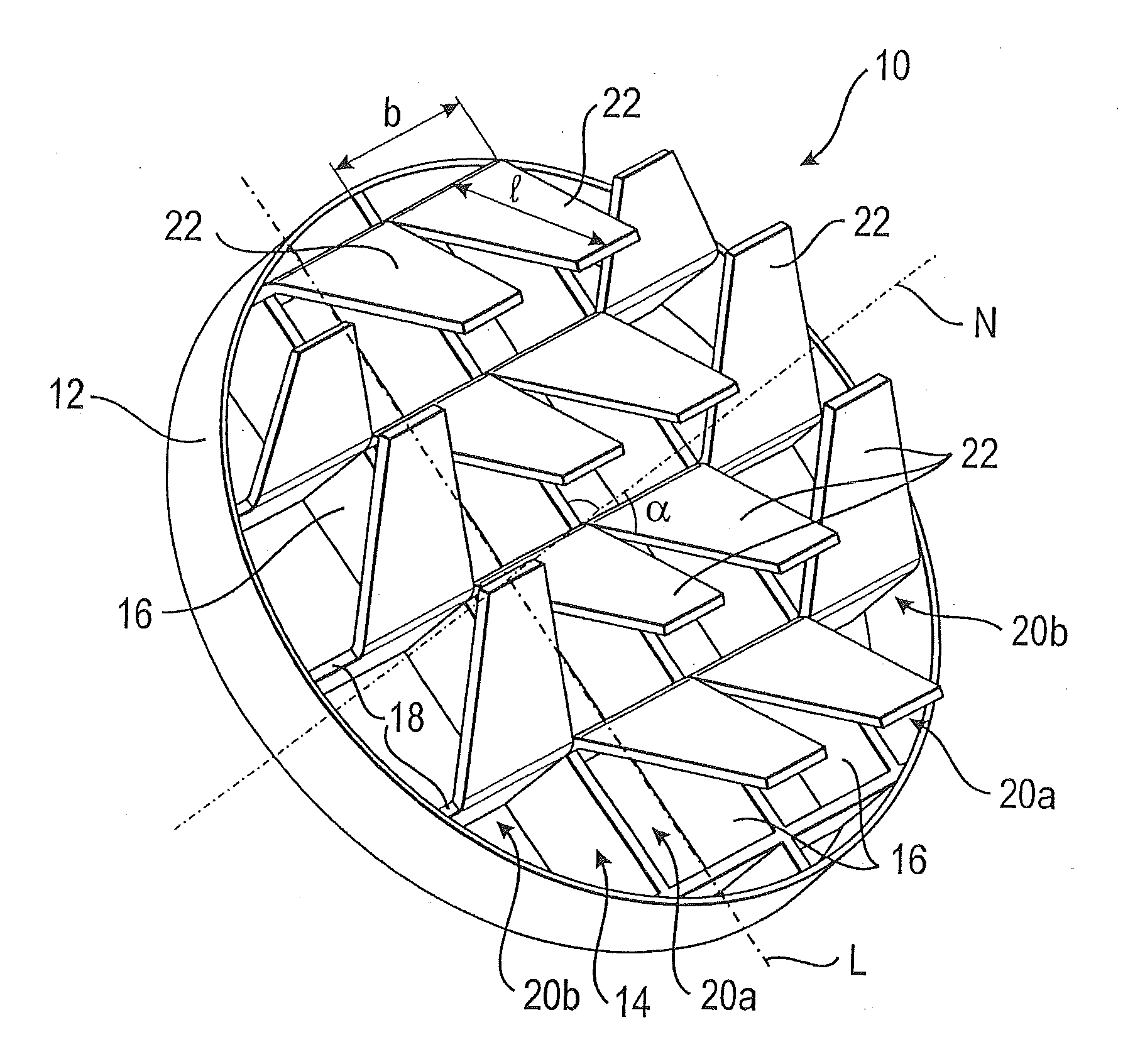

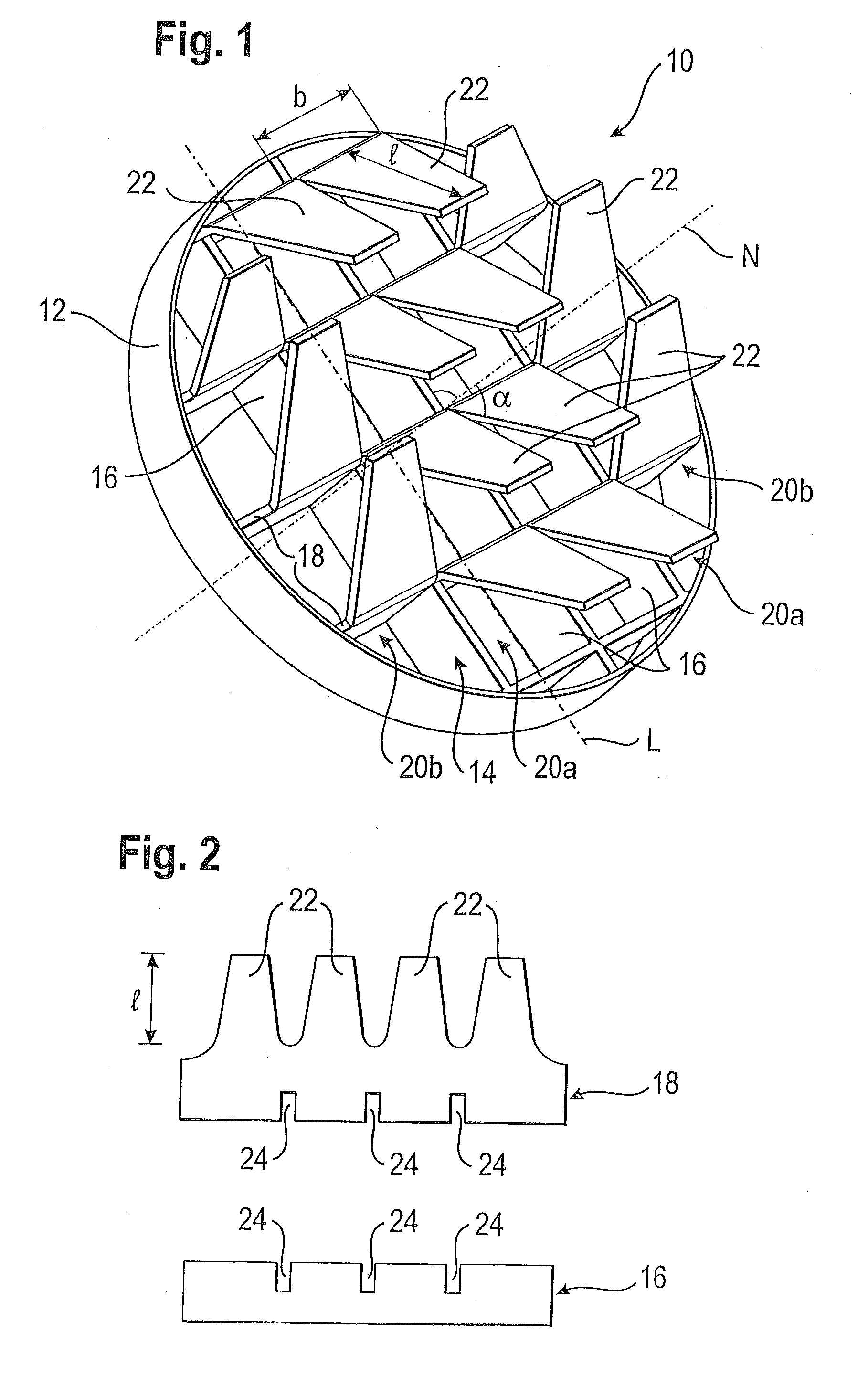

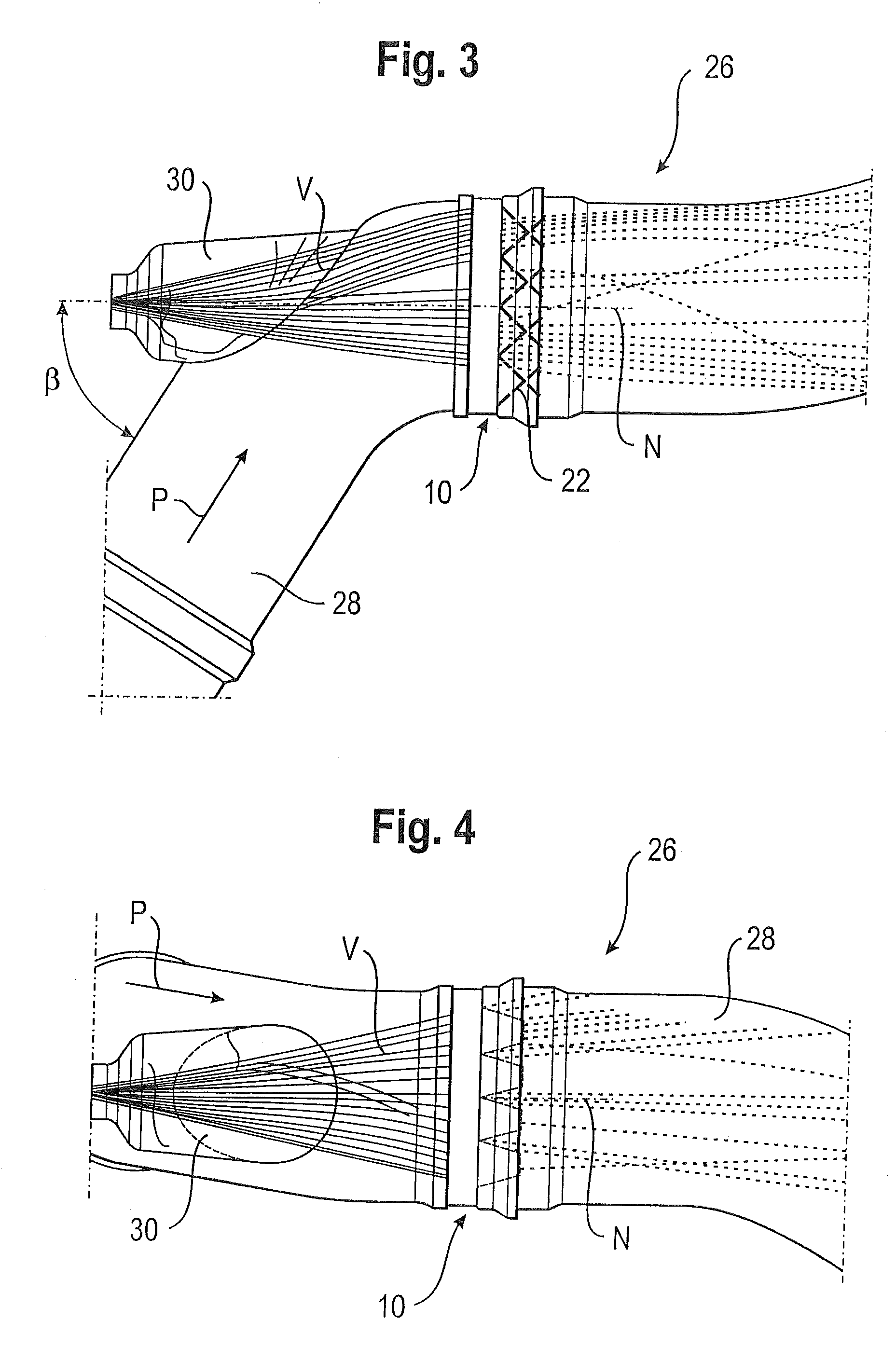

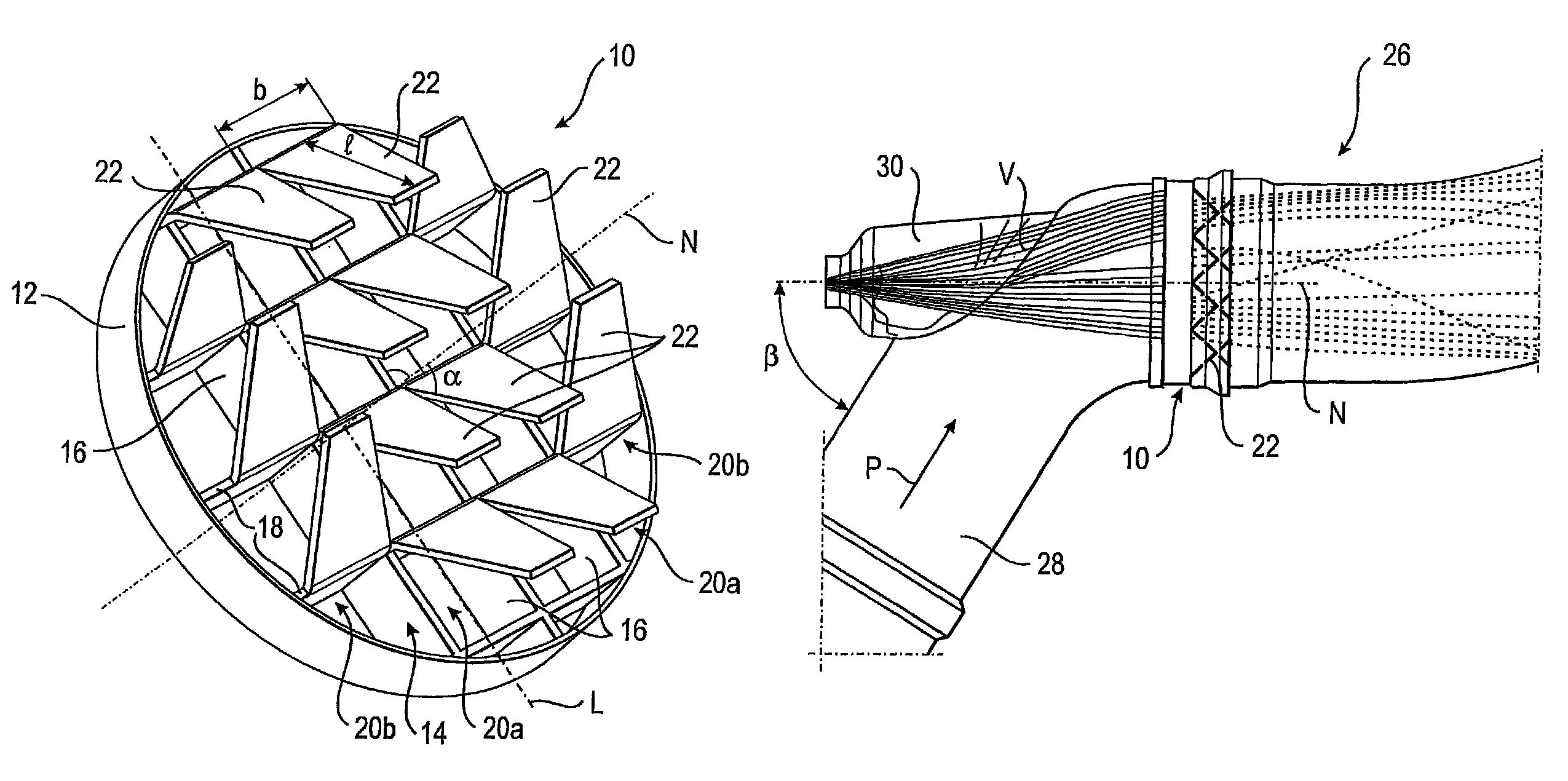

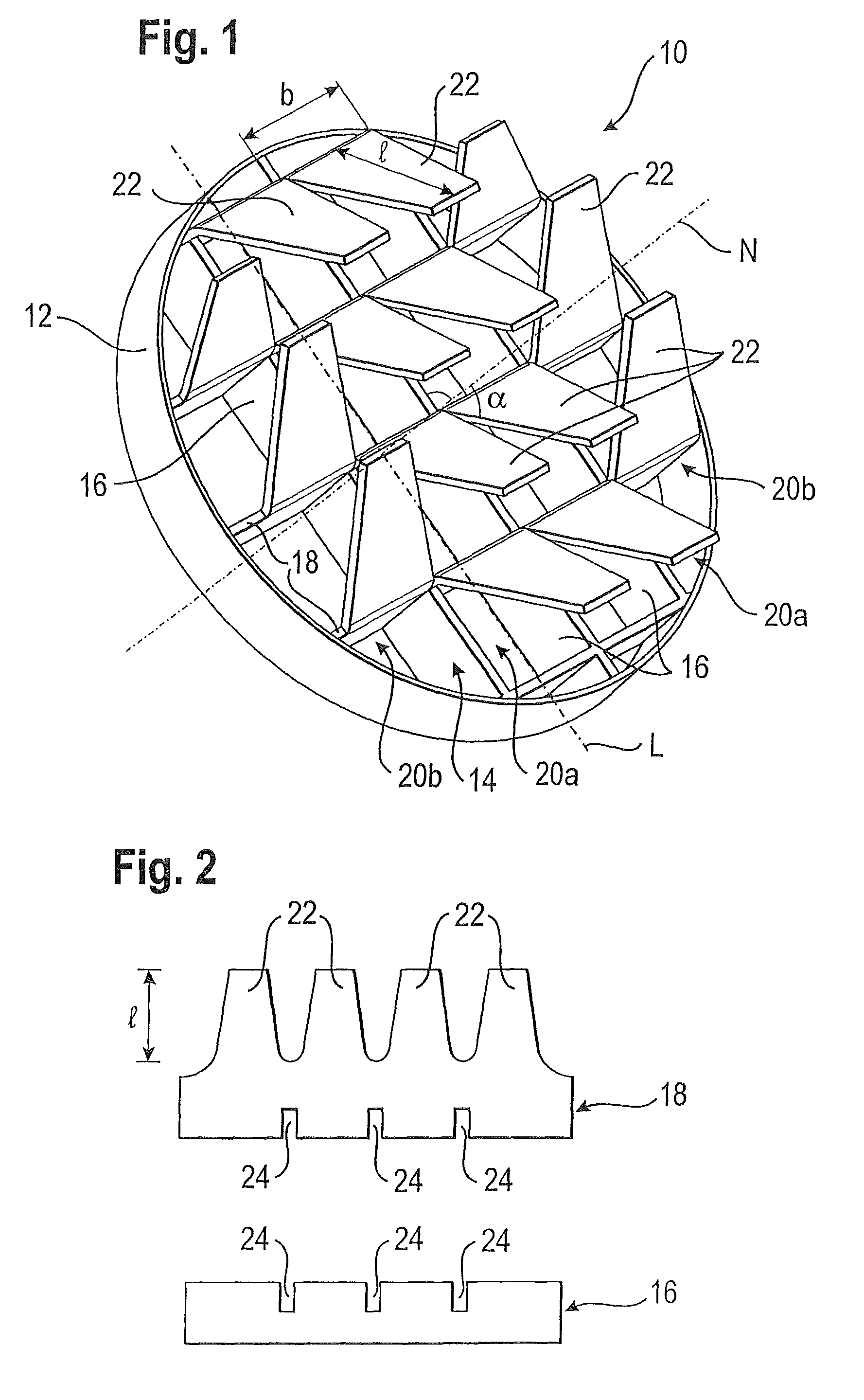

Mixing element and an exhaust system for an internal combustion engine

ActiveUS20100107617A1Well mixedStrong swirlInternal combustion piston enginesFlow mixersExternal combustion engineEngineering

A mixing element has a grid which includes a plurality of rows parallel to each other and a plurality of deflector elements which project from the grid and are inclined in relation to the grid plane normal. All deflector elements of one row are inclined in the same direction. The deflector elements of at least two immediately adjacent first rows are inclined in the same direction. The mixing element is used in an exhaust system of an internal combustion engine.

Owner:EMCON TECHNOLOGIES GERMANY (AUGSBURG) GMBH

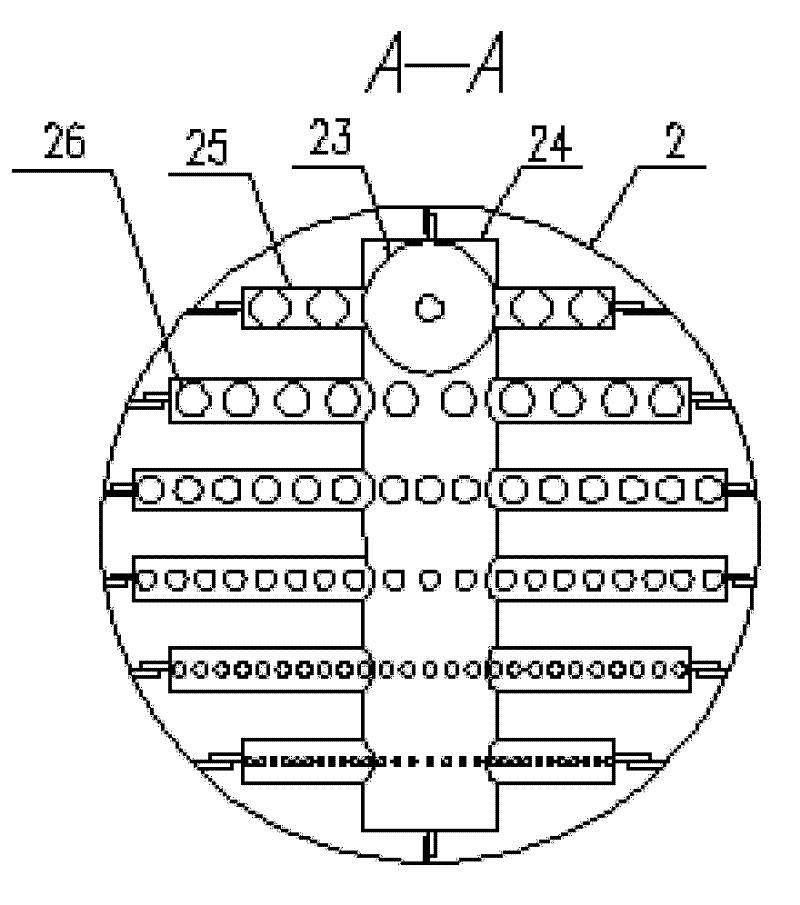

Oil-water separating device and method

ActiveCN101972559AWith deep separationAchieve deep separationNon-miscible liquid separationOil waterPolypropylene

The invention discloses oil-water separating device and method. The oil-water separating device comprises a swirler and a horizontal type agglutinating oil-water separator, wherein a bottom flow pipe of the swirler is in a U shape; the horizontal type agglutinating oil-water separator has the liquid uniform distributing function; an inlet liquid distributor, a rectifying sieve plate, a stainless steel plate ripple filler, a polypropylene gauze ripple filler, an outlet liquid collector, and the like are sequentially arranged in the horizontal type agglutinating oil-water separator, and the stainless steel plate ripple filler and the polypropylene gauze ripple filler are fixed by a limit grid plate; the U-shaped bottom flow pipe of the swirler and a filter screen arranged in the swirler can filter a small number of solid impurities contained in liquid so as to prevent the blockage of agglutinated fillers; the inlet liquid distributor and the outlet liquid collector ensure that the liquid is uniformly distributed; the rectifying sieve plate reduces the flow rate of the liquid to form lamellar flow; the stainless steel plate ripple filler provides a place for agglutinating and separating oil drops; and the polypropylene gauze ripple filler with an air floating device can further agglutinate and separate residual fine oil drops. The combination simultaneously has the effects of whirl, agglutination and air floatation and can realize the deep separation of oil and water.

Owner:TIANJIN UNIV

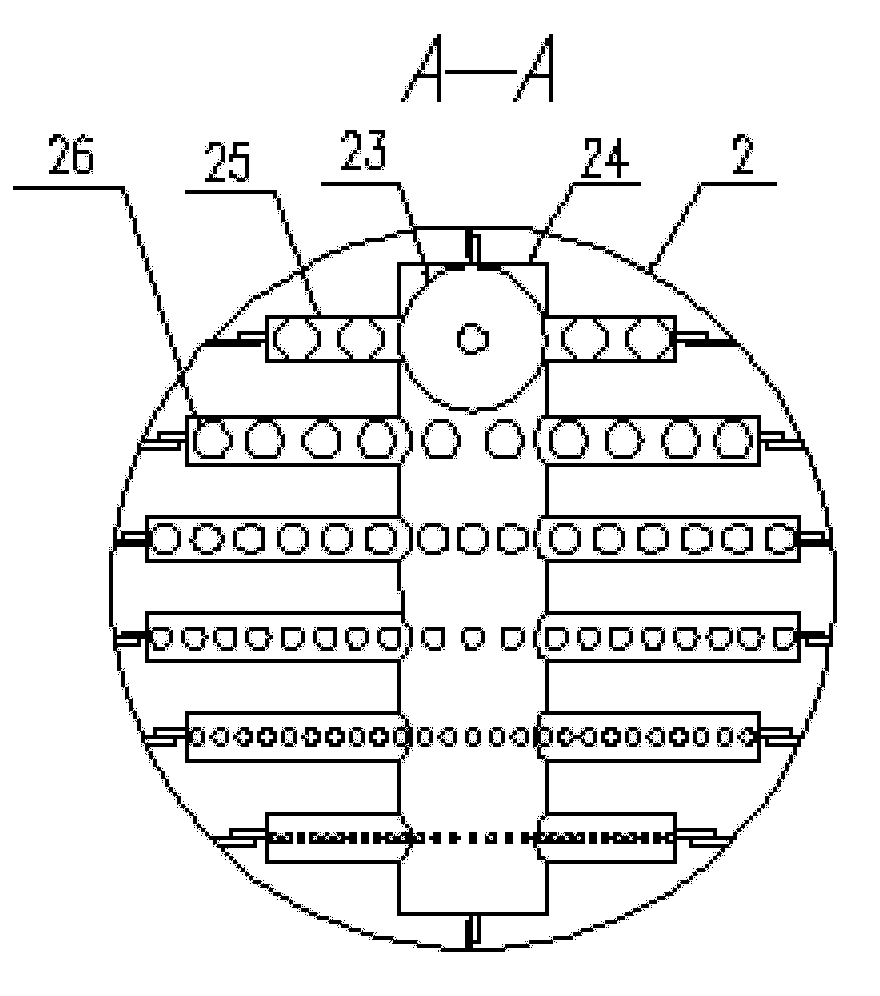

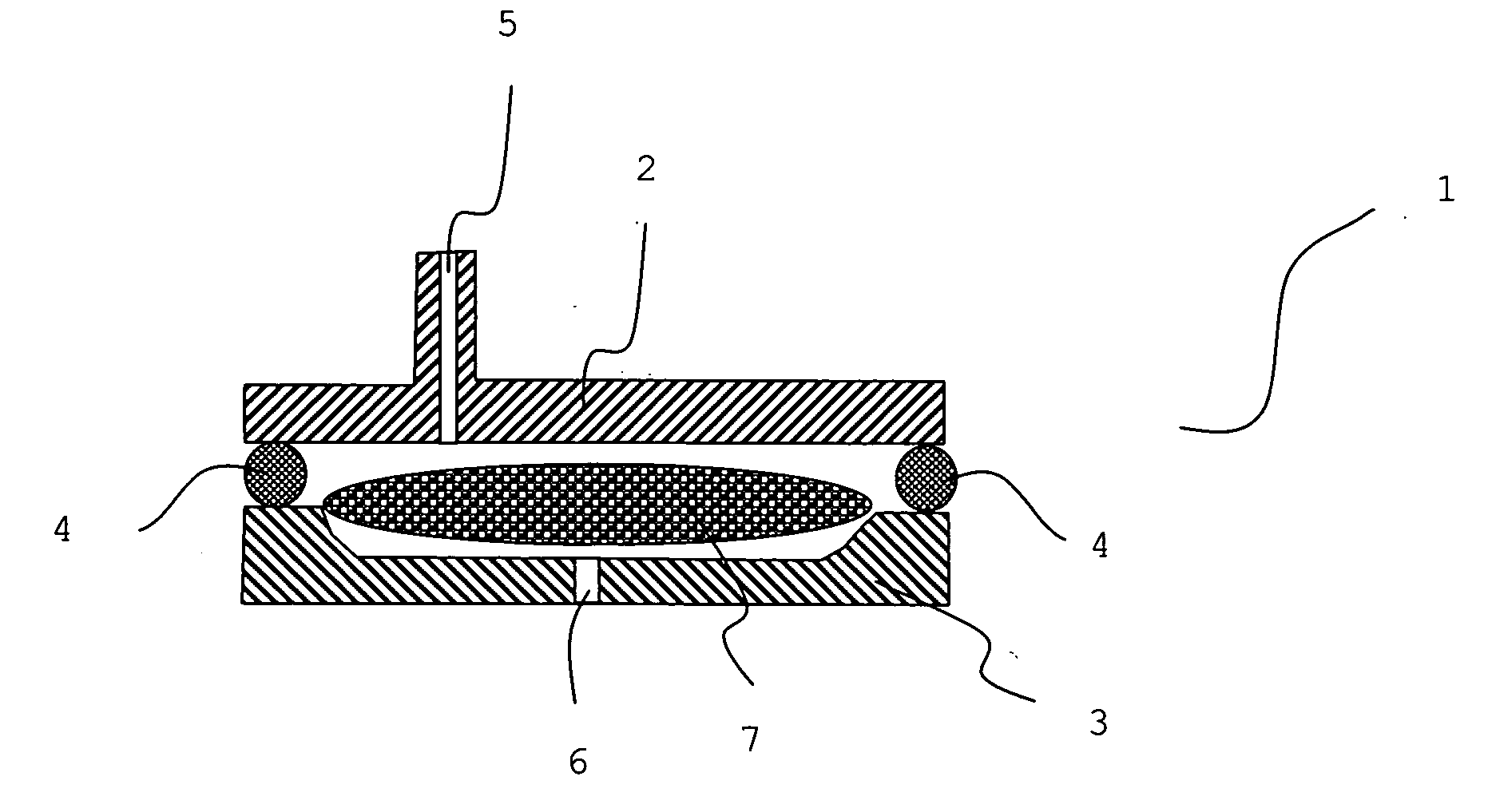

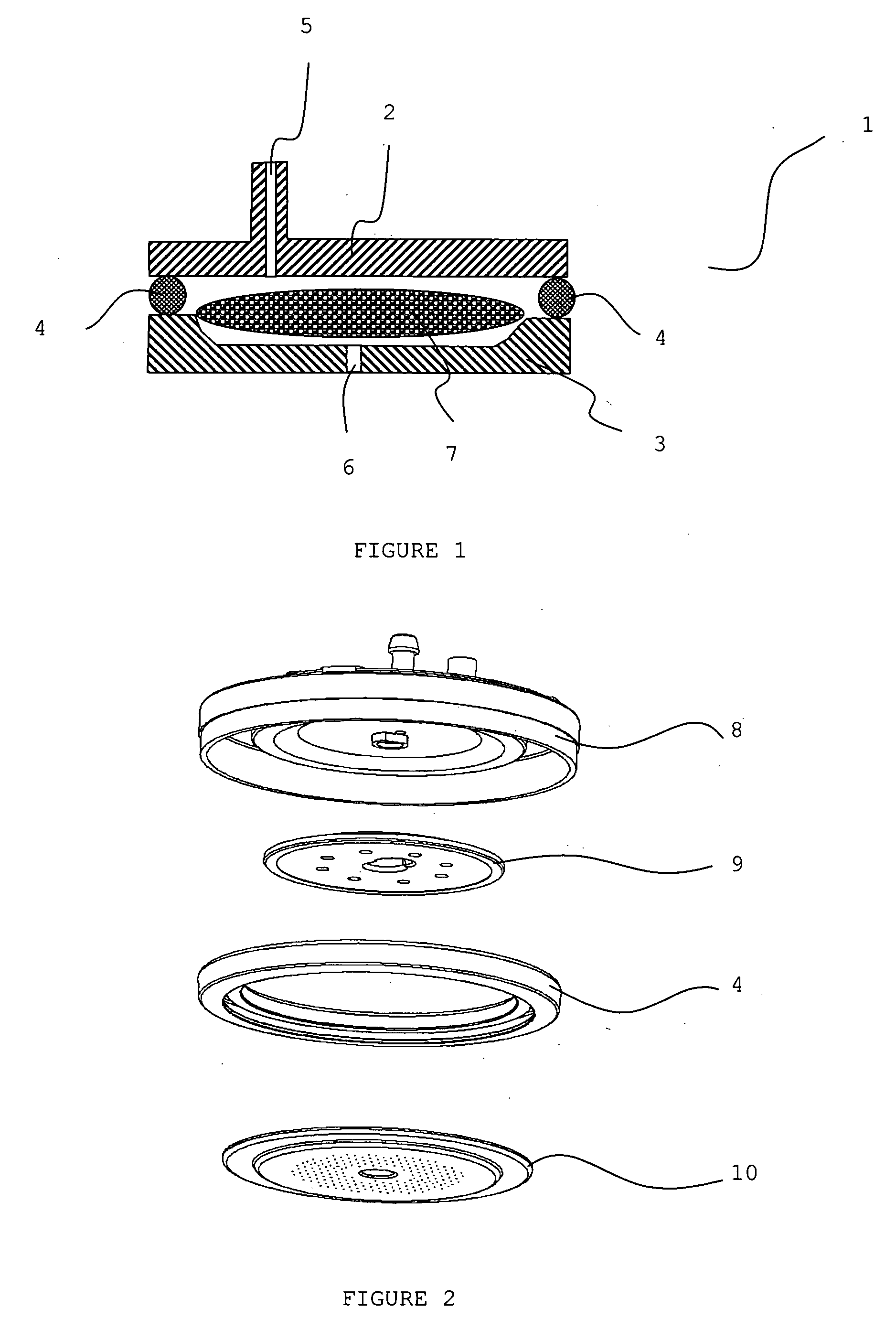

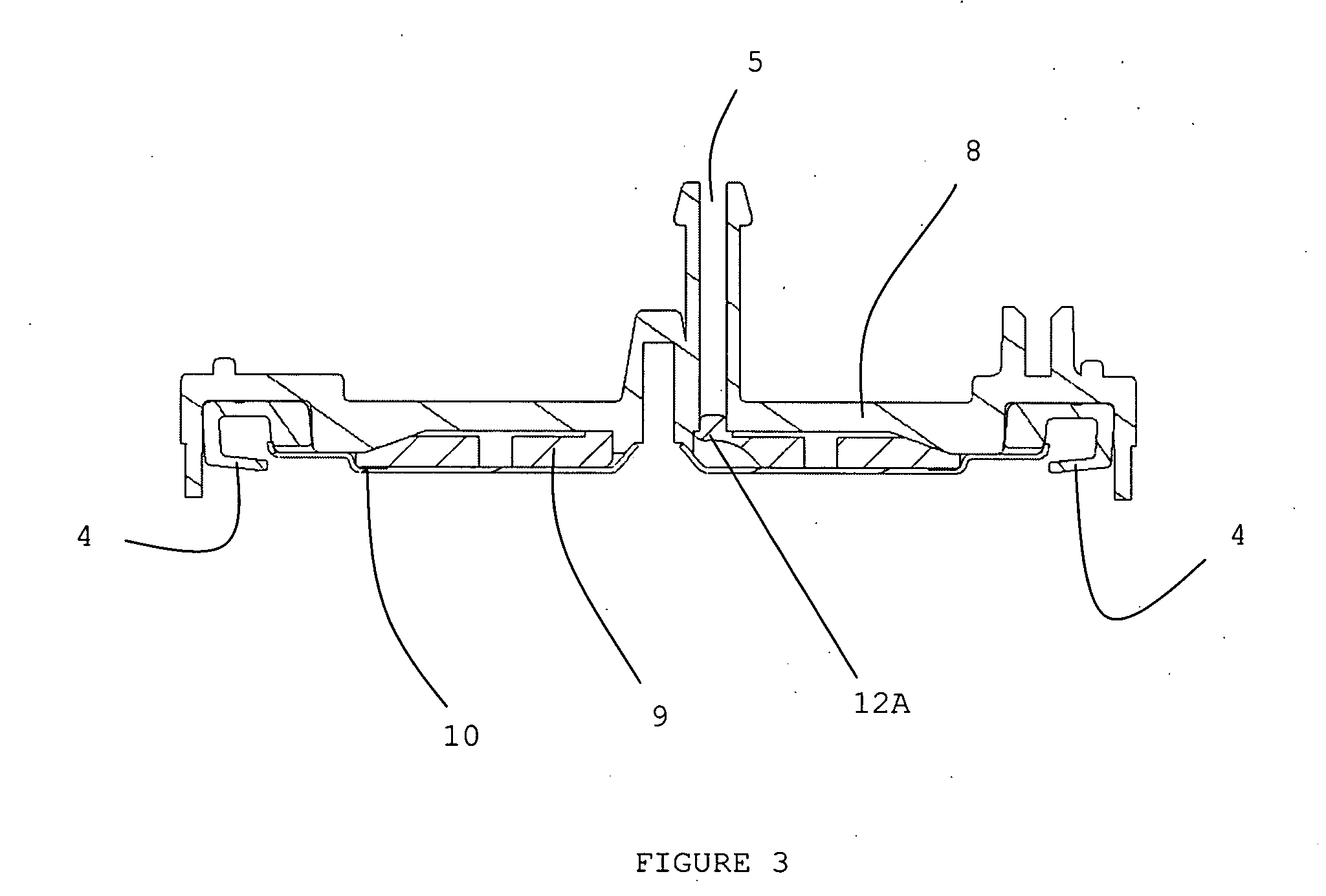

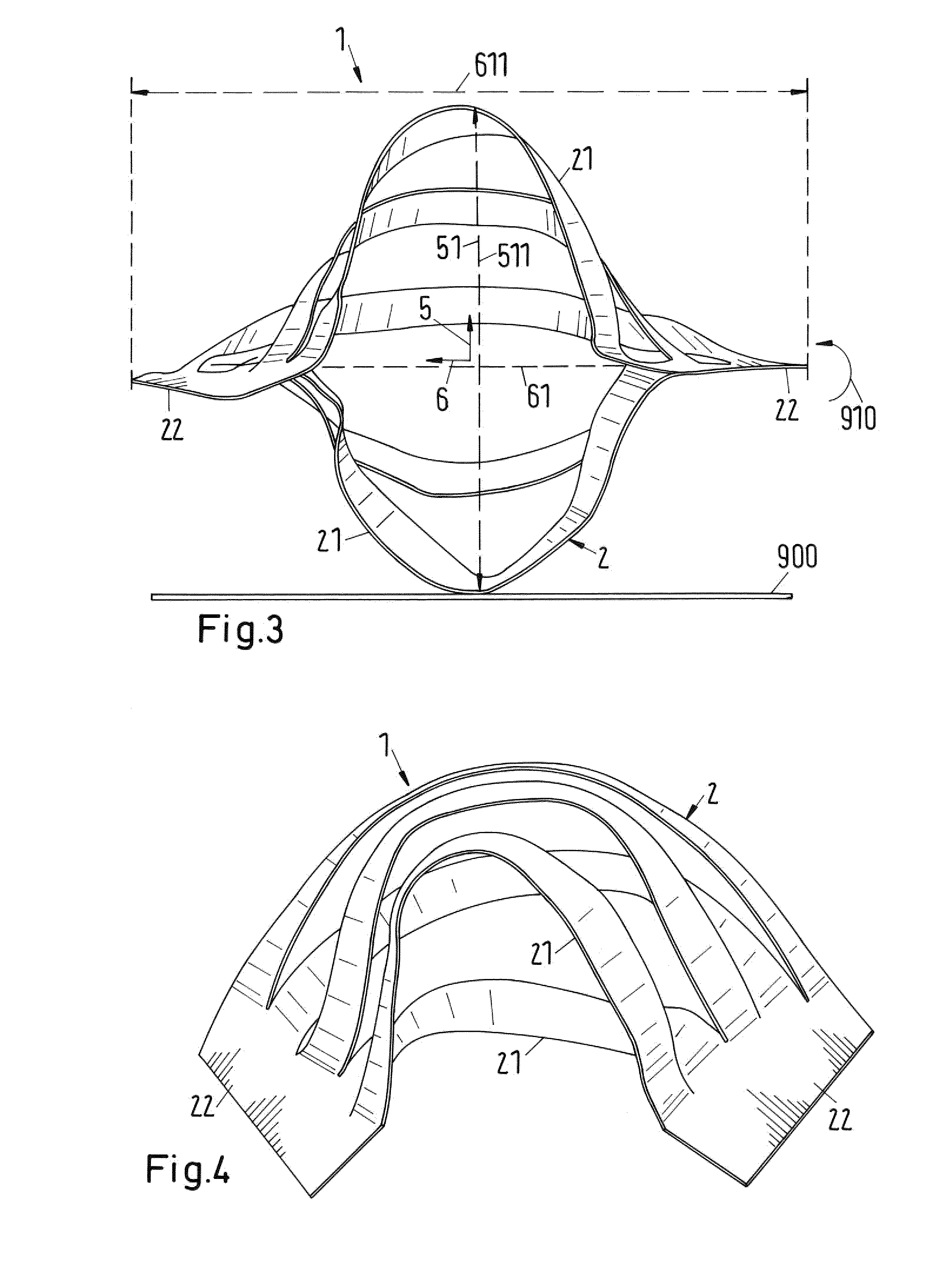

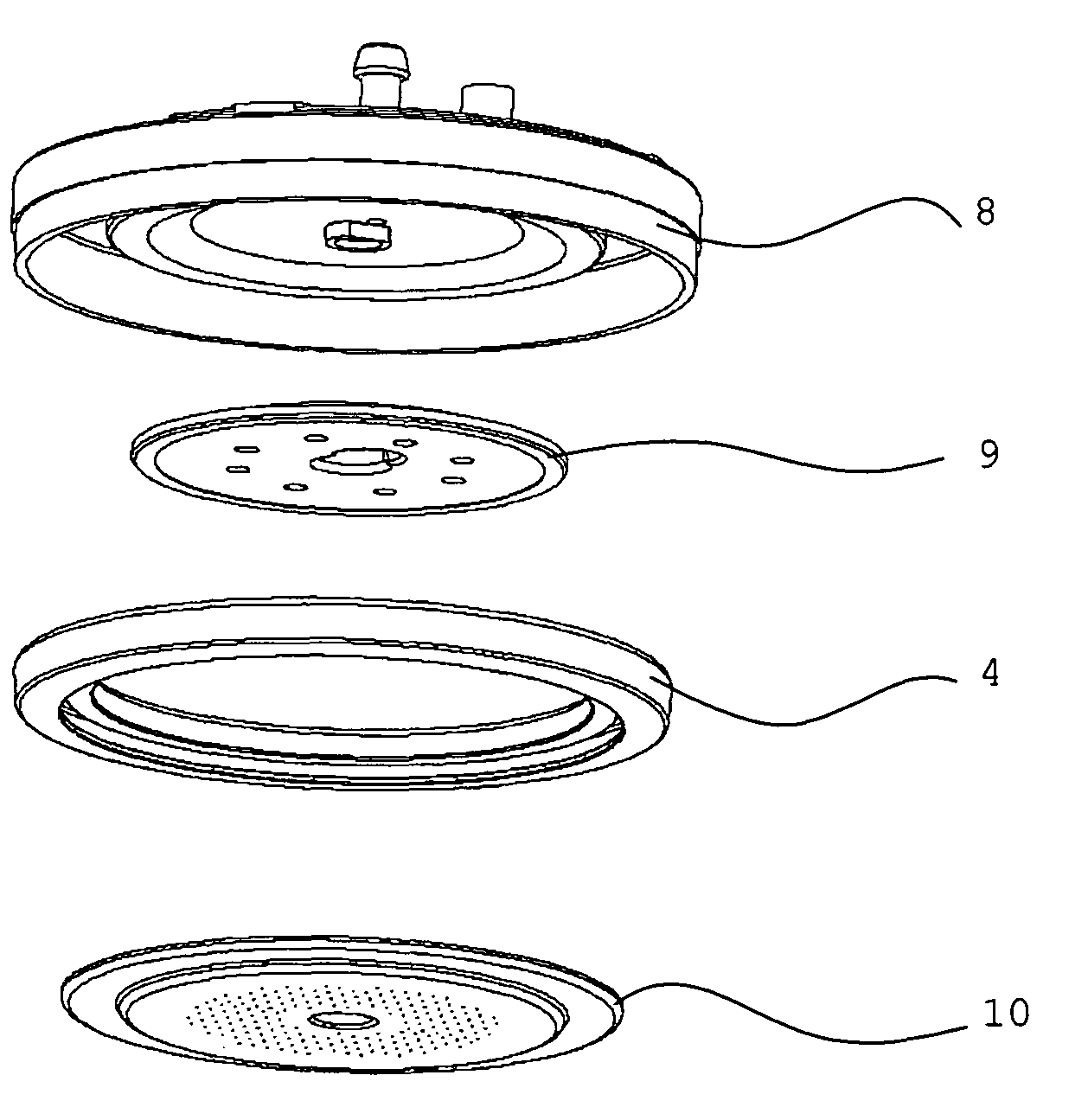

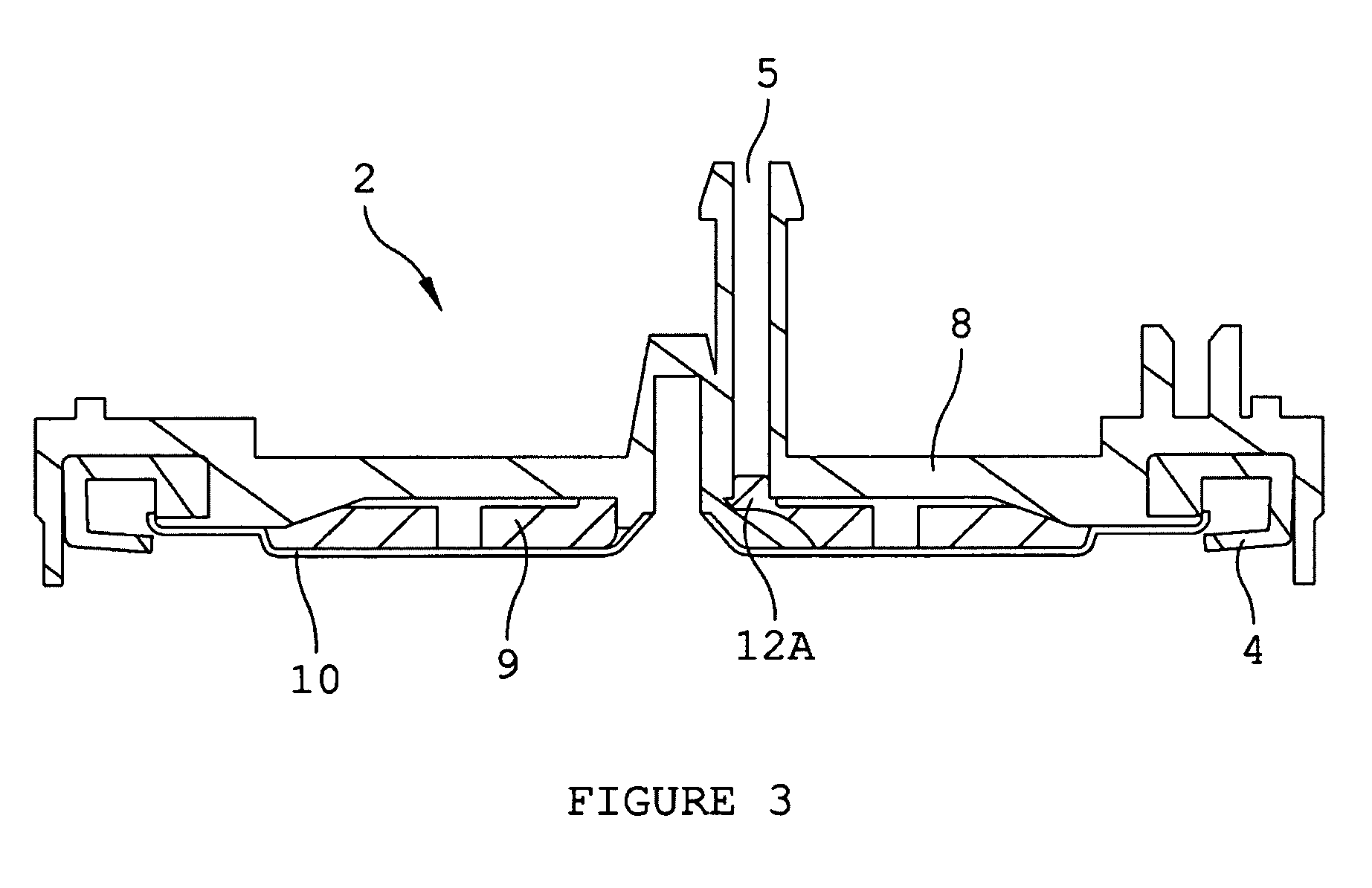

Apparatus for preventing unintended or premature release of liquid in a beverage brewing device and method thereof

InactiveUS20070084352A1Avoid premature releaseUniform liquid distributionBeverage vesselsEngineeringBiomedical engineering

An apparatus useful for preventing the release of residual liquid in a beverage brewing device prior to and after the brewing process, and for preventing the premature release of liquid during the heating process is disclosed. The apparatus includes a flexible member, a closing member and a recess. The apparatus is fabricated such that the pressure of the liquid being delivered to the brewing chamber displaces or depresses the closing member sufficiently into the recess to form a first fluid passage. The pressure of the fluid also creates a channel or cavity on a surface of the flexible member. The first fluid passage and the channel or cavity form a second fluid passages which provide fluid communication between the fluid inlet and the brewing chamber. Preferably, the flexible member, closing member and recess is formed as an integral unit.

Owner:ELECTRICAL & ELECTRONICS LTD

Mixing element and an exhaust system for an internal combustion engine

ActiveUS8607555B2Mixing valueEasy to produceInternal combustion piston enginesFlow mixersEngineeringInternal combustion engine

A mixing element has a grid which includes a plurality of rows parallel to each other and a plurality of deflector elements which project from the grid and are inclined in relation to the grid plane normal. All deflector elements of one row are inclined in the same direction. The deflector elements of at least two immediately adjacent first rows are inclined in the same direction. The mixing element is used in an exhaust system of an internal combustion engine.

Owner:EMCON TECHNOLOGIES GERMANY (AUGSBURG) GMBH

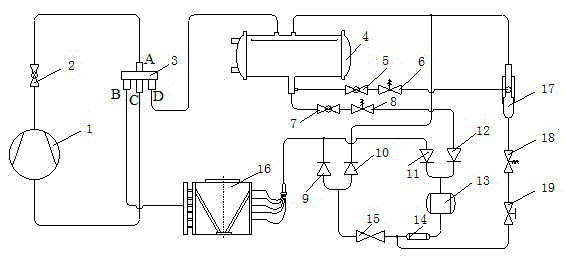

Air source falling film water chiller-heater unit

ActiveCN102853575AReduce chargeAvoid cloth liquid interferenceEvaporators/condensersFluid circulation arrangementBusiness efficiencyFour-way valve

The invention discloses an air source falling film water chiller-heater unit. The unit comprises a compressor, a four-way valve, a falling film heat exchanger, a reservoir, a drier, an expansion valve, an outdoor finned heat exchanger and an ejector, wherein the compressor, the falling film heat exchanger and the outdoor finned heat exchanger are connected with the four-way valve; the falling film heat exchanger is further connected with the reservoir and the ejector; the reservoir is connected with the drier; the ejector is connected with the drier and the expansion valve; and the expansion valve and the reservoir are connected with the outdoor finned heat exchanger. Due to the adoption of the air source falling film water chiller-heater unit, the interference of a gas-state refrigerant on a liquid distributor can be avoided, the structure of a liquid state distributor can be simplified, four layers or five layers are not required to be arranged, and uniform liquid distribution can be realized by adopting secondary liquid distribution; and under a heating working condition, air flow pressure drop can be reduced, the energy efficiency ratio of a system is increased, frequent impact of high-pressure and high-speed air flow on the liquid distributor can be avoided under the heating working condition, and the stability of a device is enhanced.

Owner:NANJING WUZHOU REFRIGERATION GRP

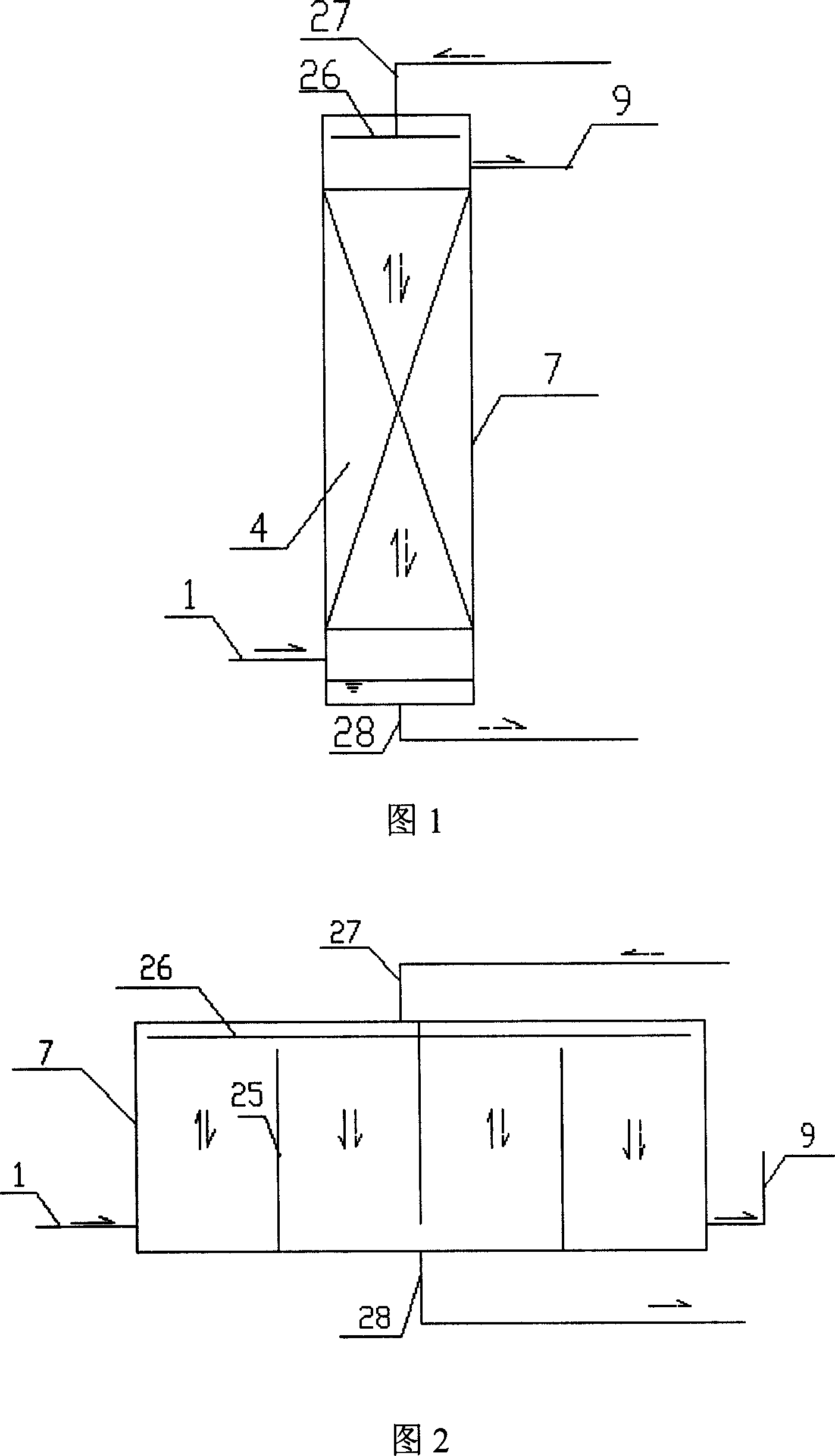

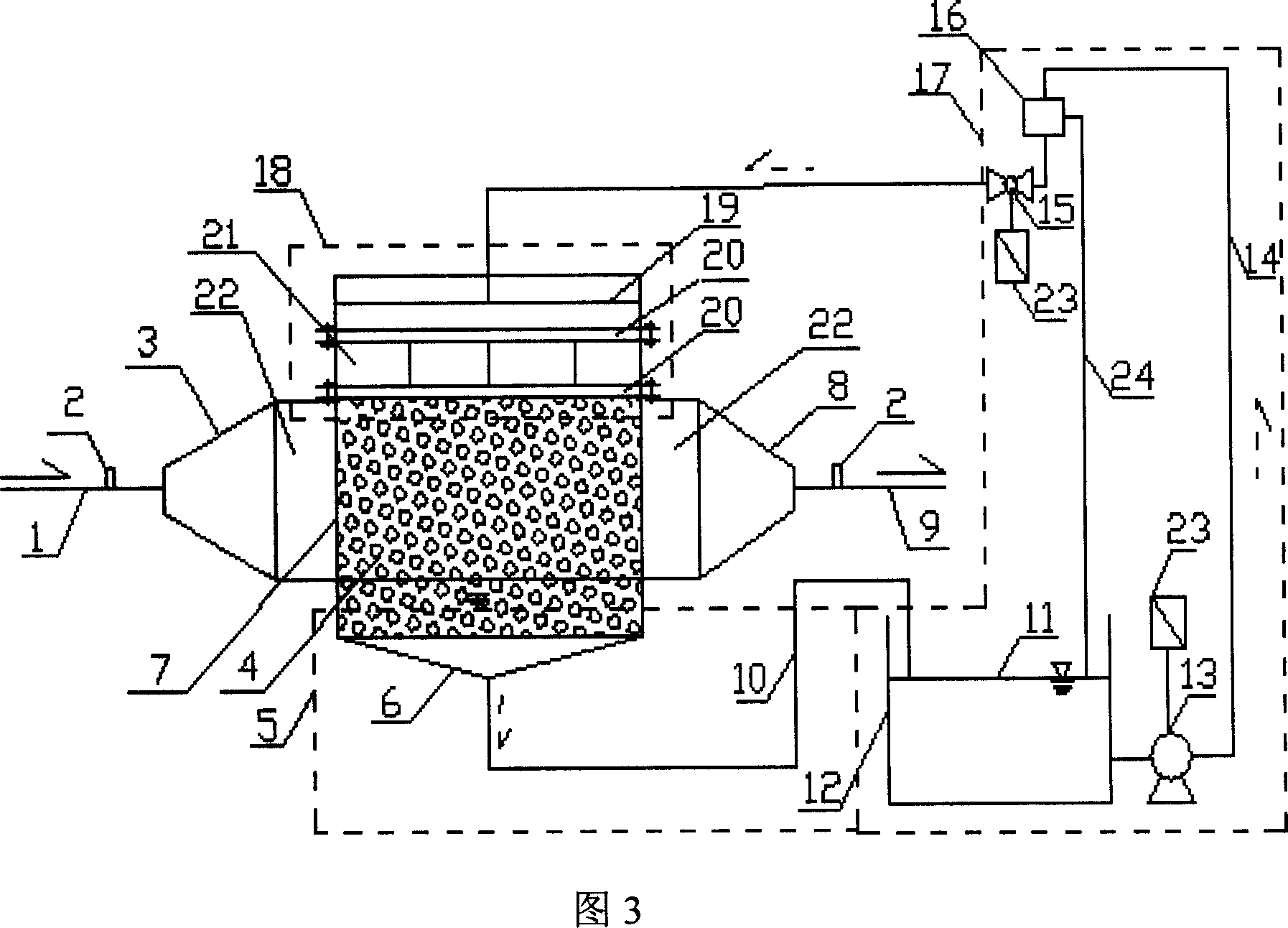

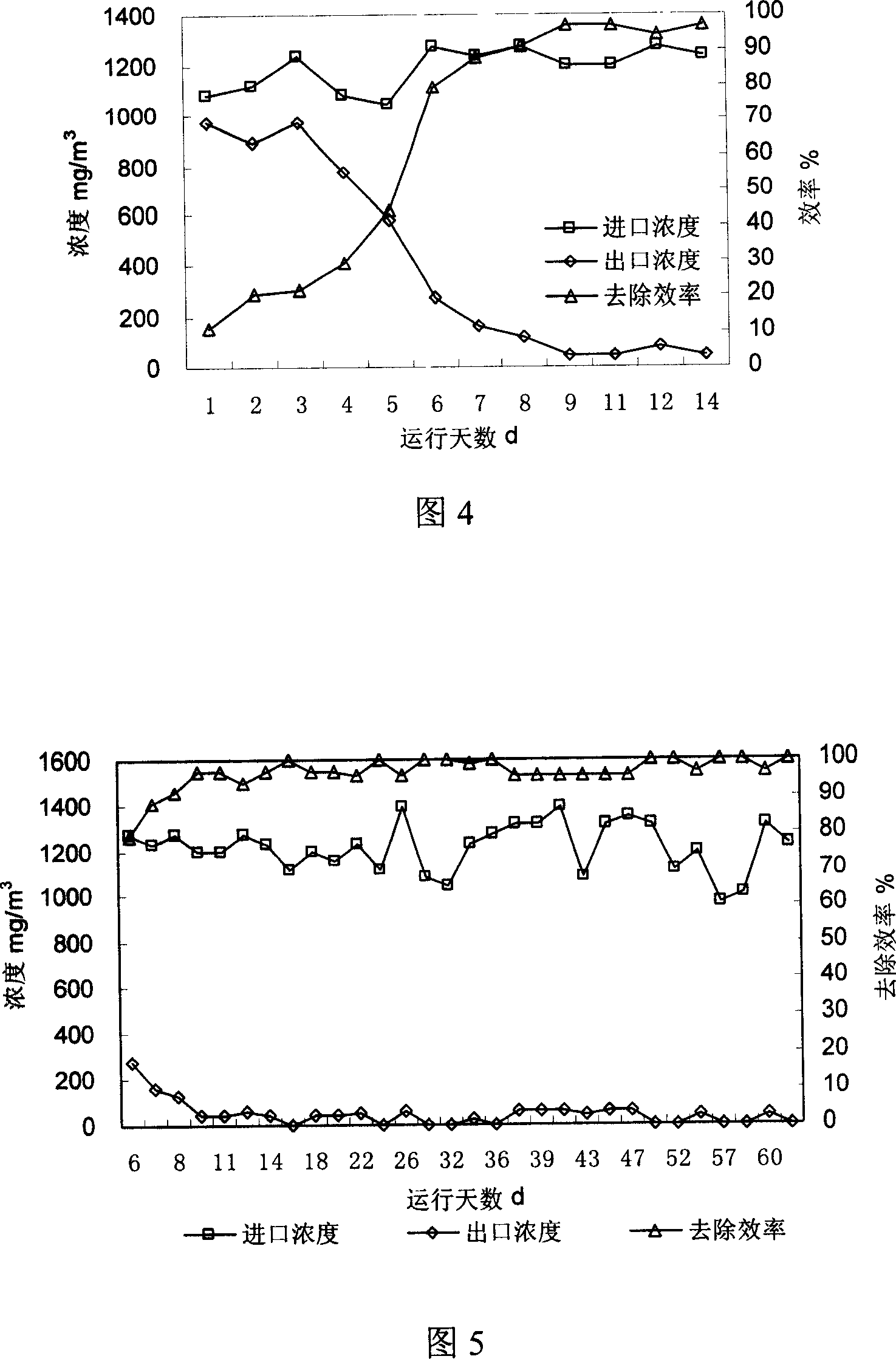

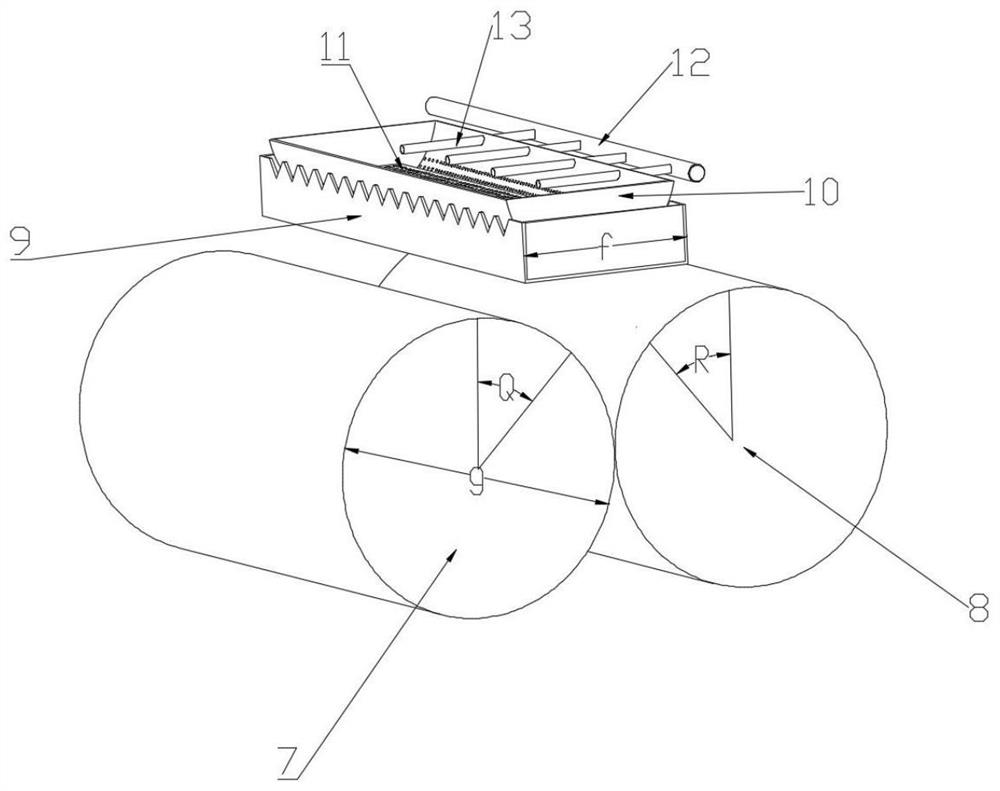

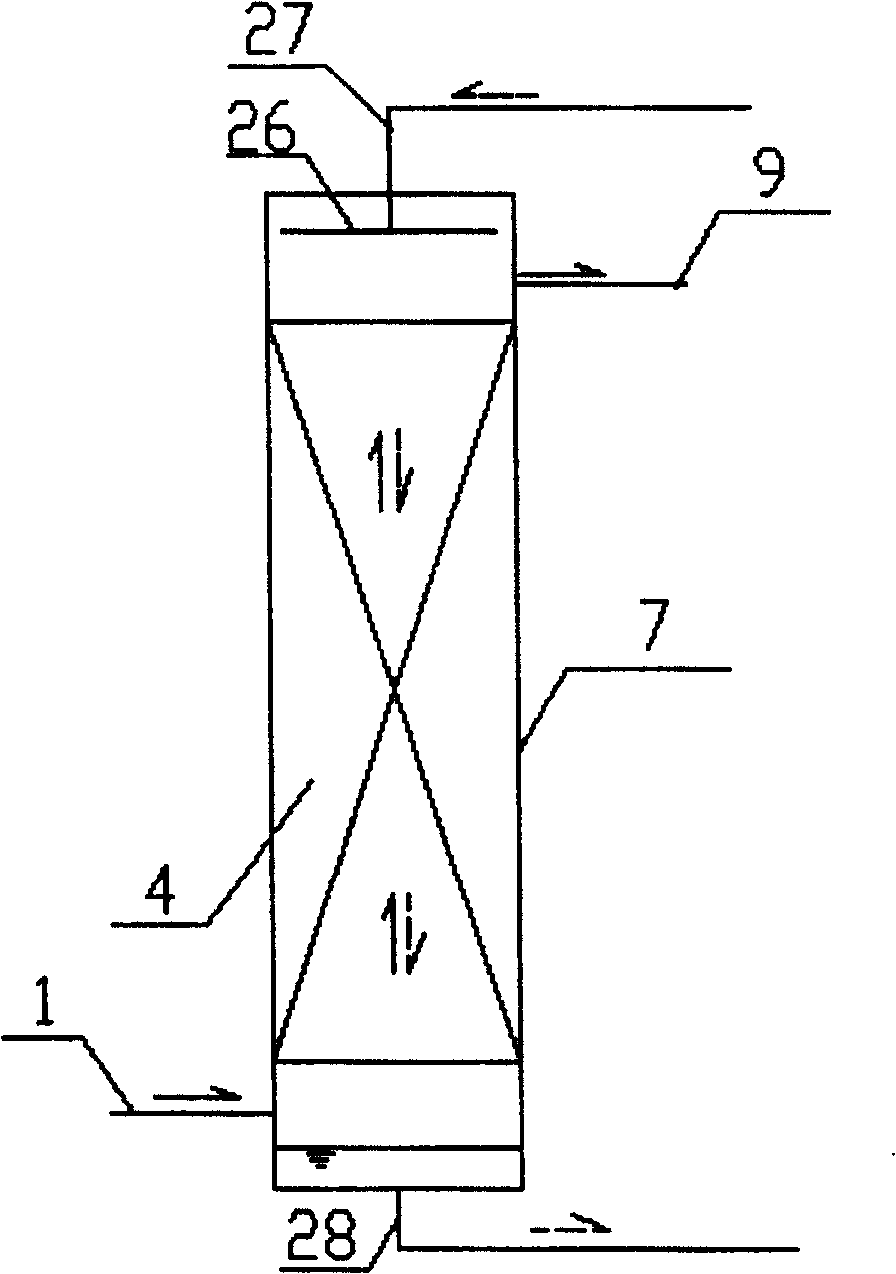

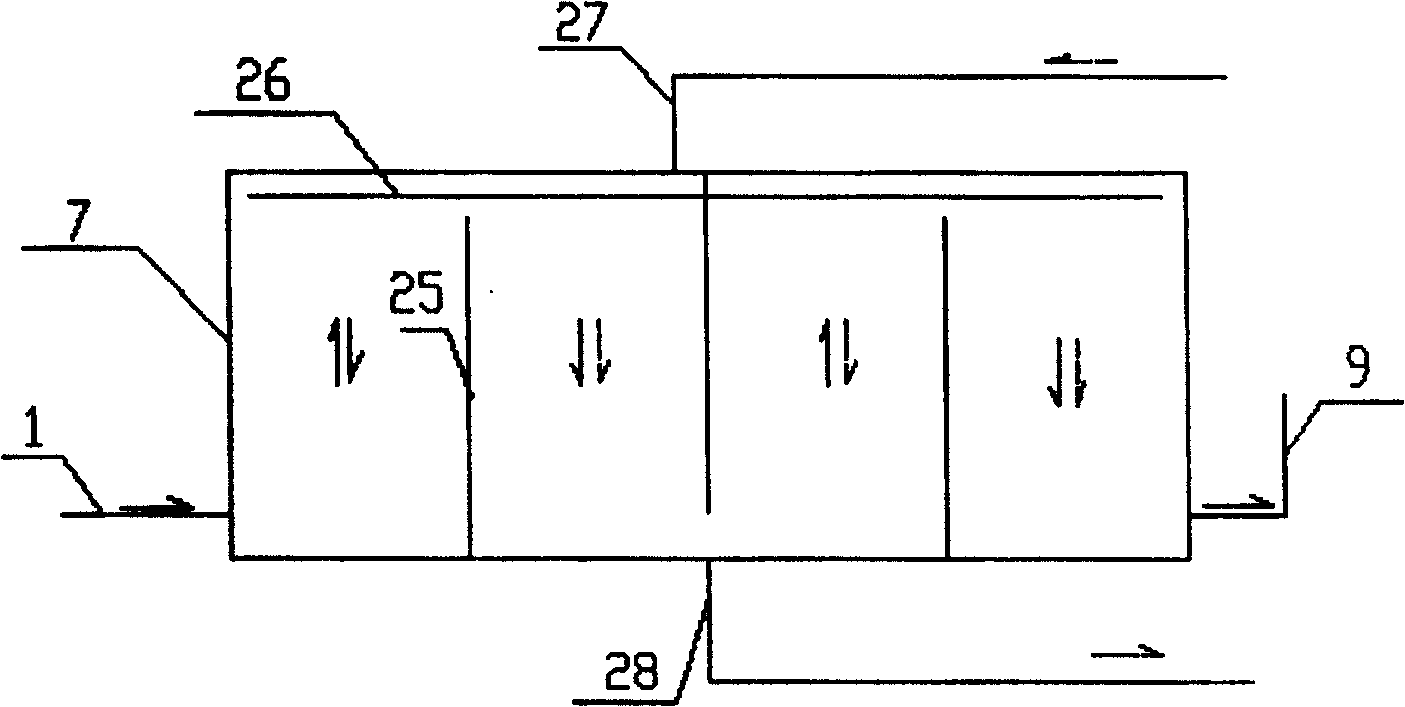

Bio-trickling device for processing volatile organic waste gas and method thereof

InactiveCN1994533AReduce flow heightIncreased load removal capacityDispersed particle separationAir quality improvementForming gasNutrient solution

The invention relates to a biological drop filter and relative method for treating volatile organic waste gas, wherein it comprises that: feeding volatile organic waste gas into gas inlet tube (1) and main body (7) of reactor to be degraded and purified to be discharged from ventilate tube (9); the nutriment (11) enters into main body (7) via the nutriment distributor (18); the invention is characterized in that: the entrance of volatile organic waste gas is along the horizontal central line of main body 97); the nutriment (11) flows along the main body (7) from up to down, to form gas-liquid alternative contact in the main body (7). The invention can strengthen the biological degrade ability, with small area.

Owner:BEIJING UNIV OF TECH

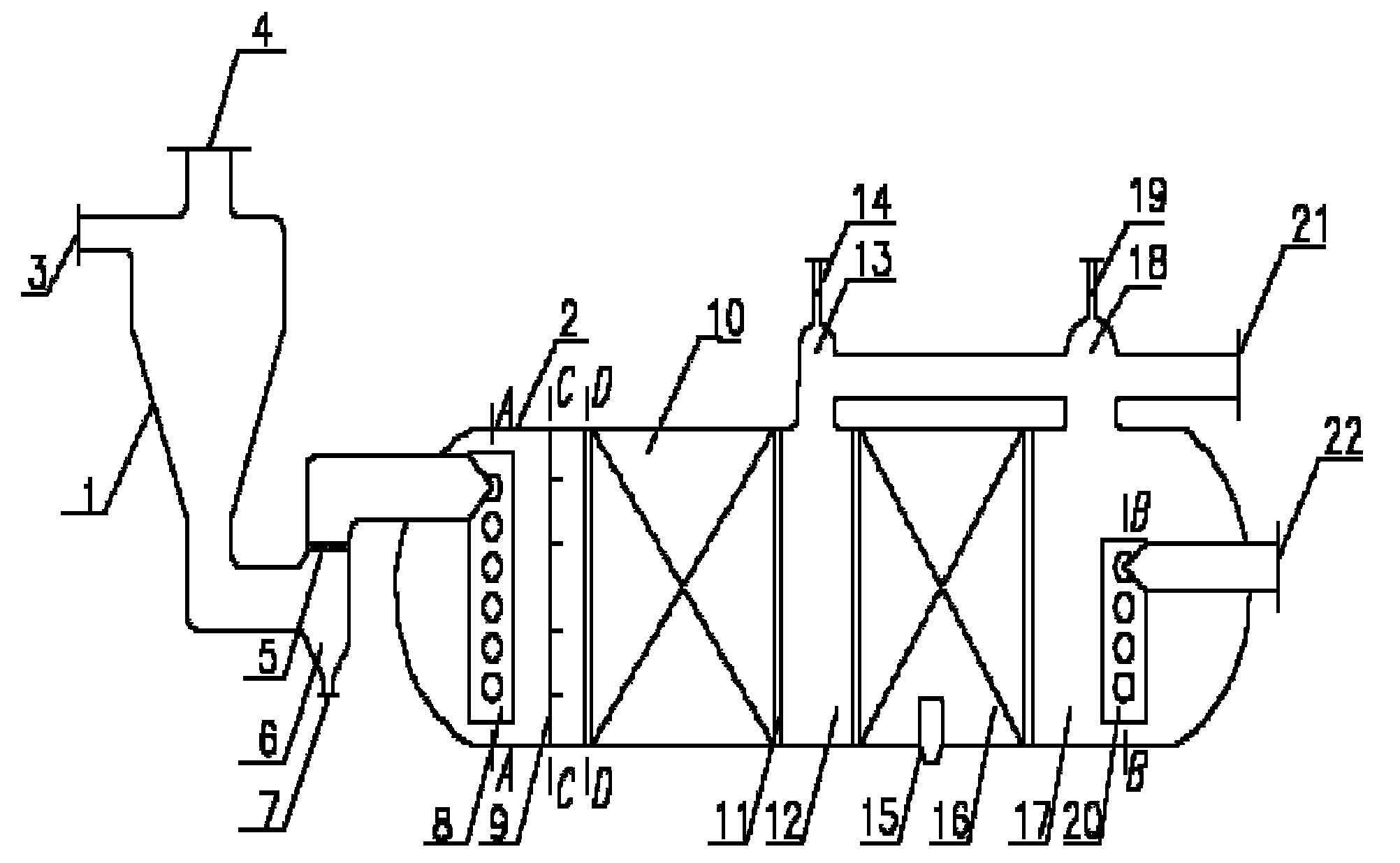

Oil-water separating device and method

ActiveCN101972559BWith deep separationAchieve deep separationNon-miscible liquid separationOil waterPolypropylene

The invention discloses oil-water separating device and method. The oil-water separating device comprises a swirler and a horizontal type agglutinating oil-water separator, wherein a bottom flow pipe of the swirler is in a U shape; the horizontal type agglutinating oil-water separator has the liquid uniform distributing function; an inlet liquid distributor, a rectifying sieve plate, a stainless steel plate ripple filler, a polypropylene gauze ripple filler, an outlet liquid collector, and the like are sequentially arranged in the horizontal type agglutinating oil-water separator, and the stainless steel plate ripple filler and the polypropylene gauze ripple filler are fixed by a limit grid plate; the U-shaped bottom flow pipe of the swirler and a filter screen arranged in the swirler canfilter a small number of solid impurities contained in liquid so as to prevent the blockage of agglutinated fillers; the inlet liquid distributor and the outlet liquid collector ensure that the liquid is uniformly distributed; the rectifying sieve plate reduces the flow rate of the liquid to form lamellar flow; the stainless steel plate ripple filler provides a place for agglutinating and separating oil drops; and the polypropylene gauze ripple filler with an air floating device can further agglutinate and separate residual fine oil drops. The combination simultaneously has the effects of whirl, agglutination and air floatation and can realize the deep separation of oil and water.

Owner:TIANJIN UNIV

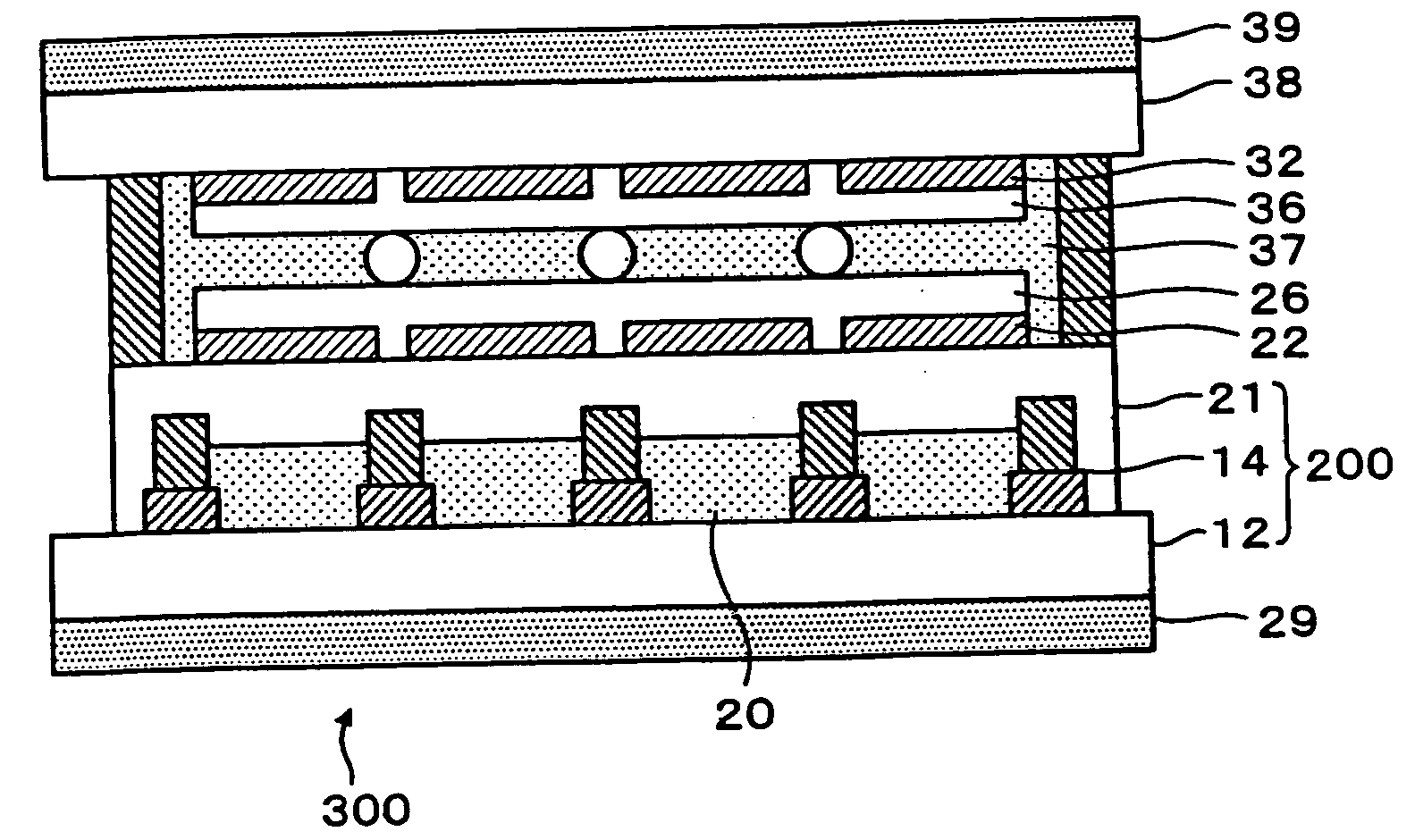

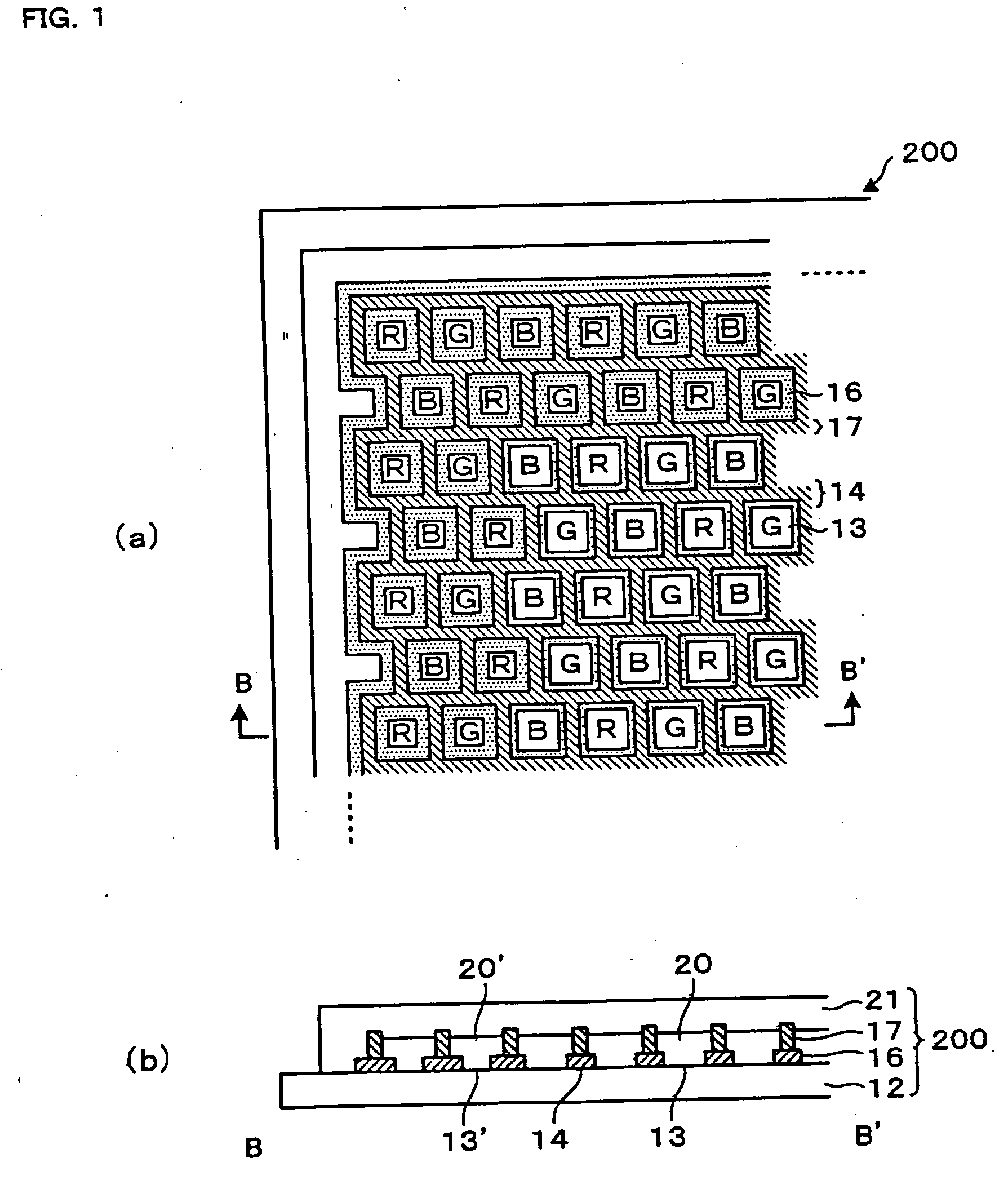

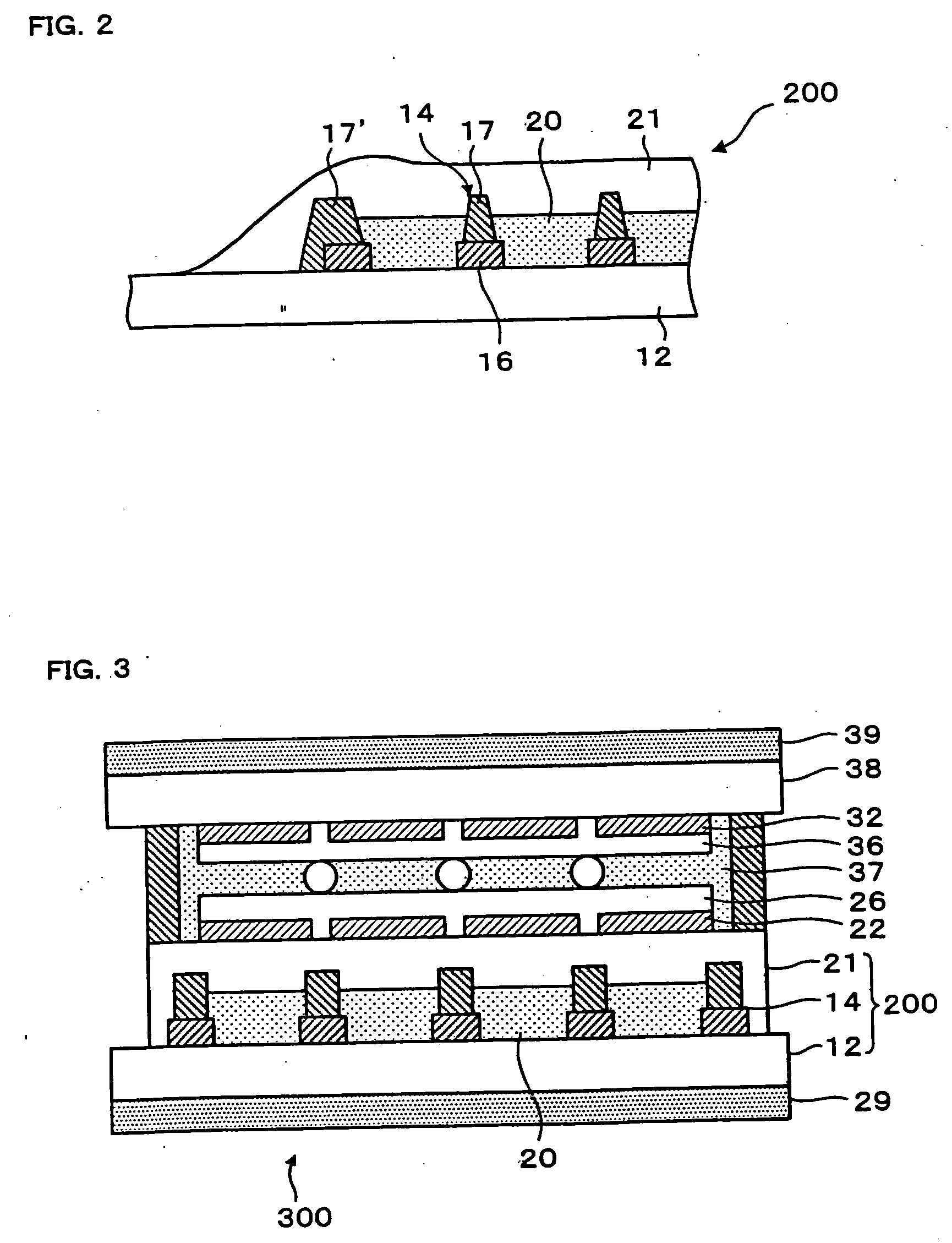

Color filter and electro-optical device

InactiveUS20050174043A1Difference in qualityUniform liquid distributionAddress electrodesSustain/scan electrodesTectorial membraneColor gel

Owner:KATEEVA

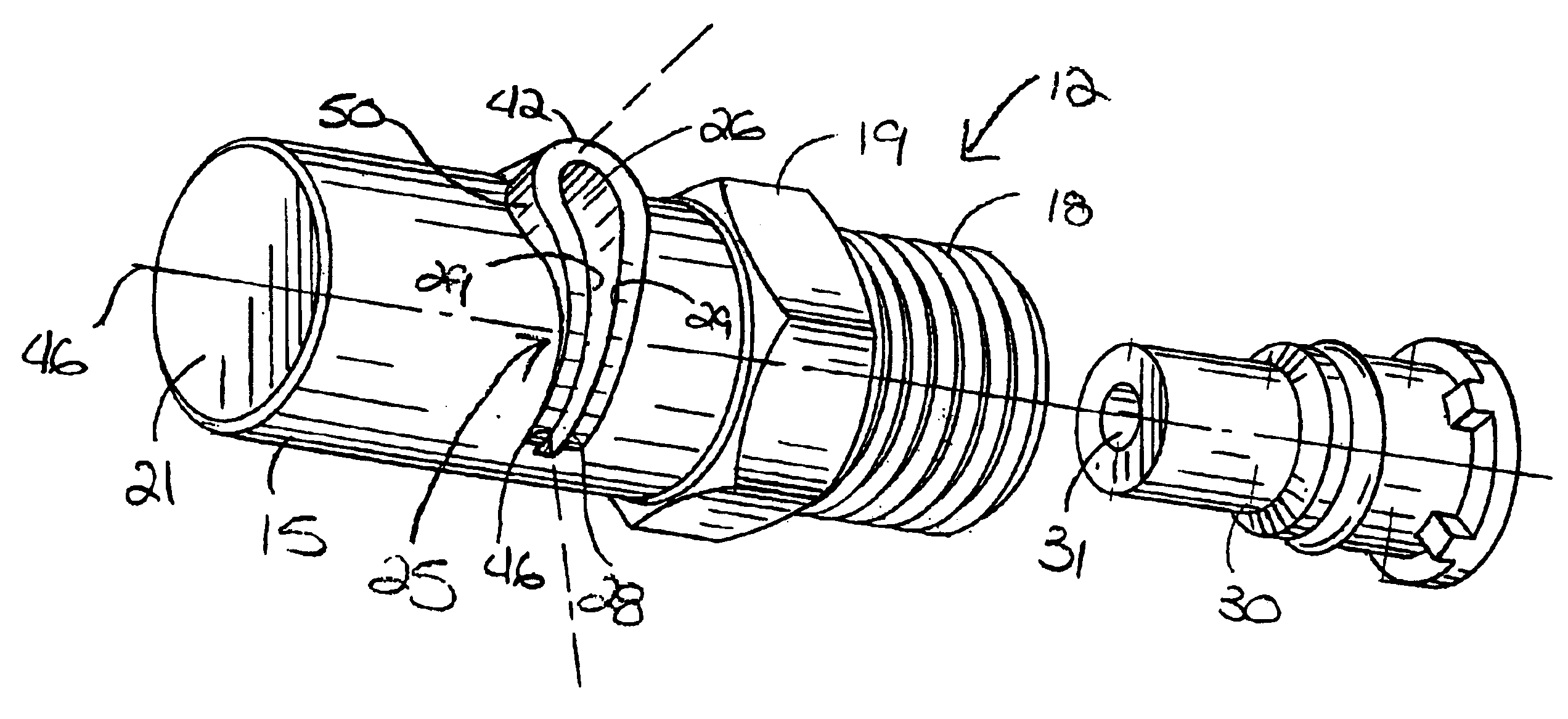

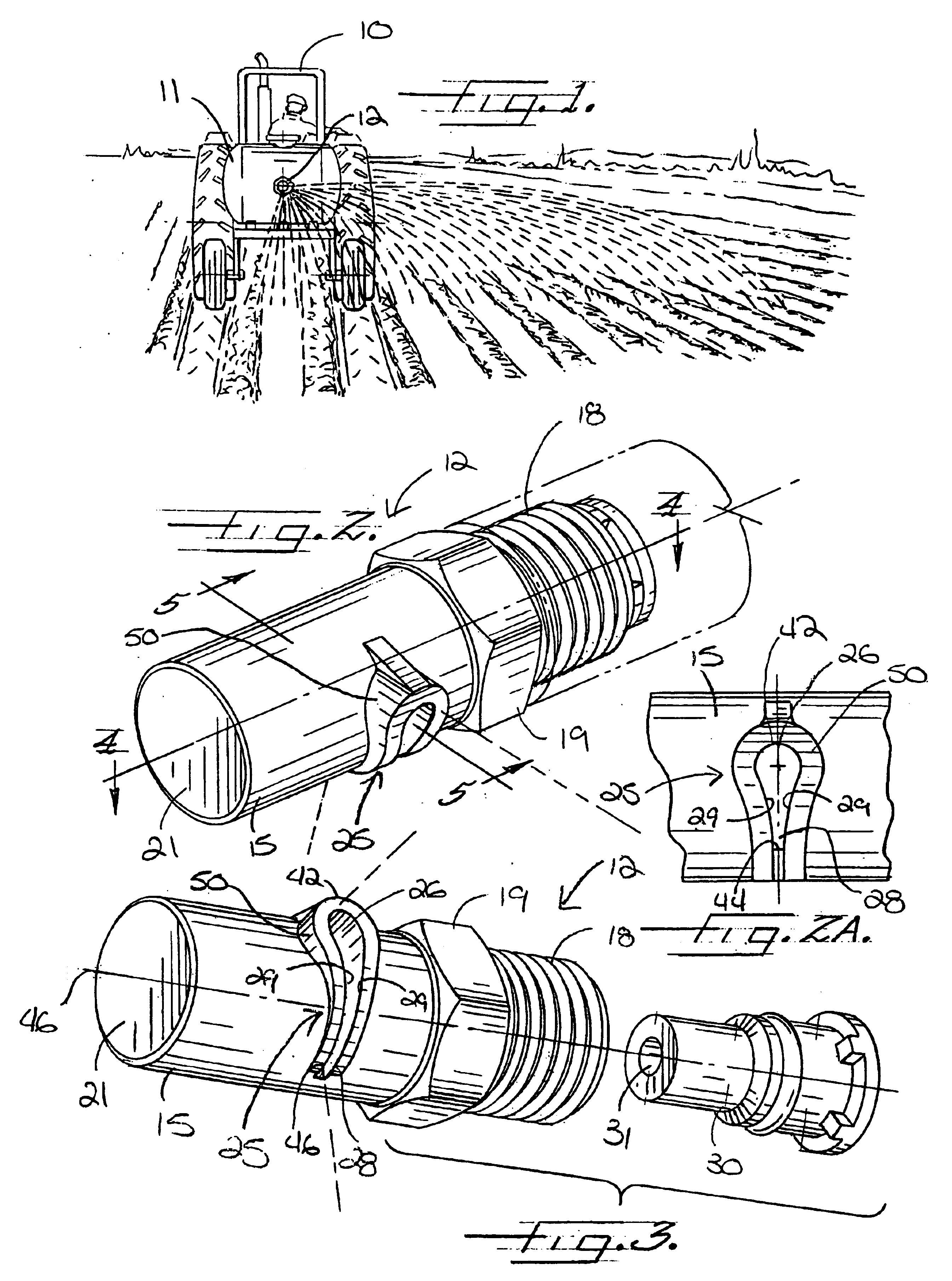

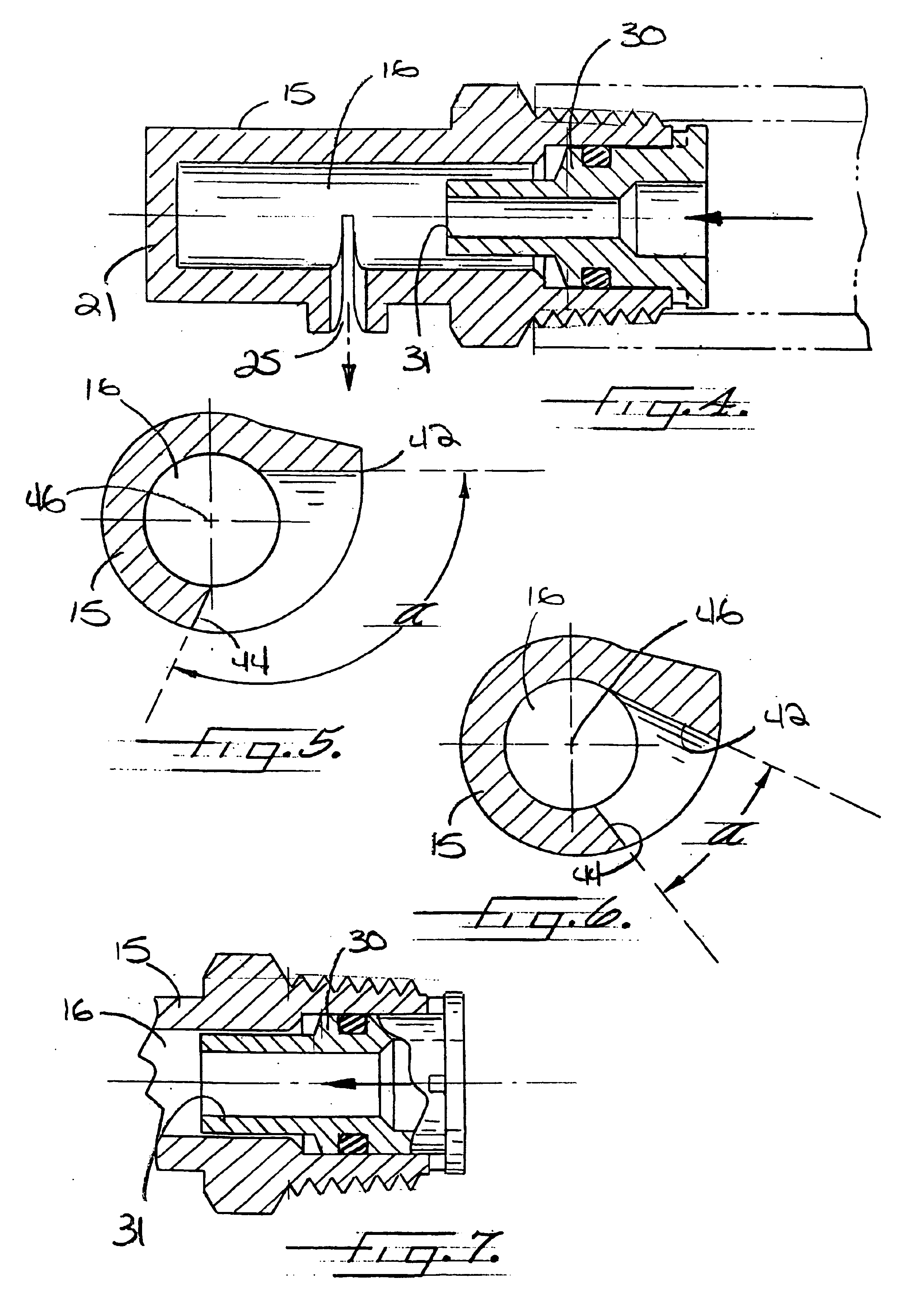

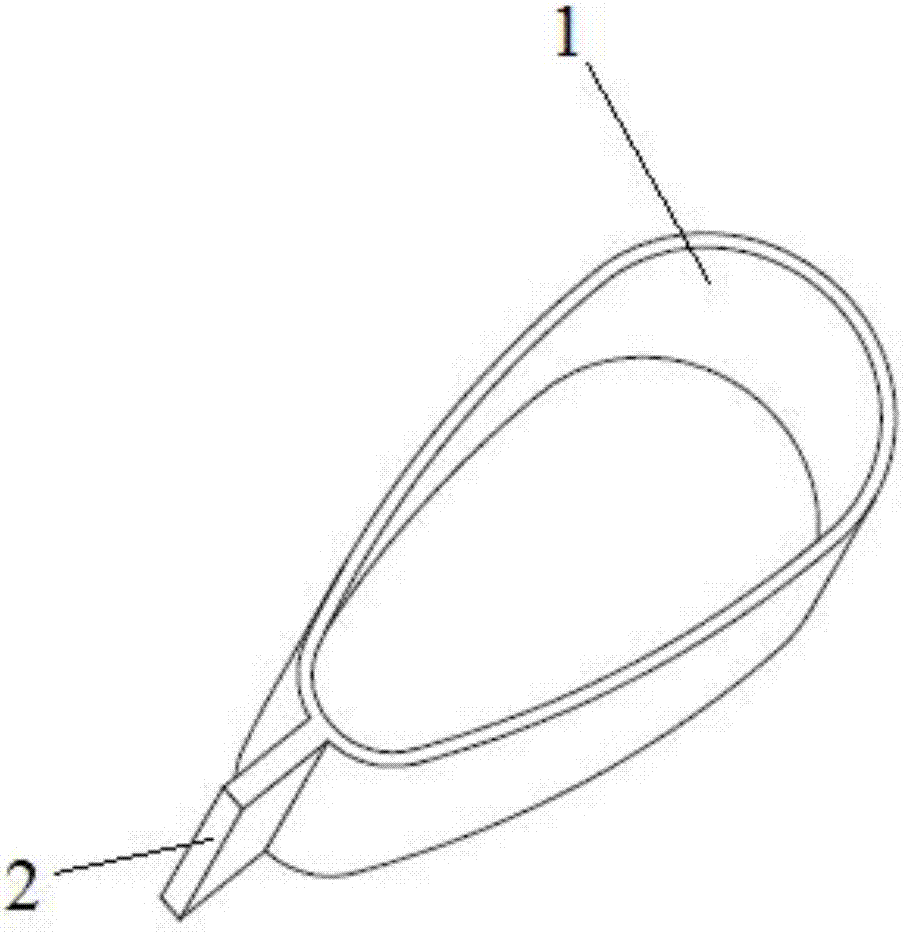

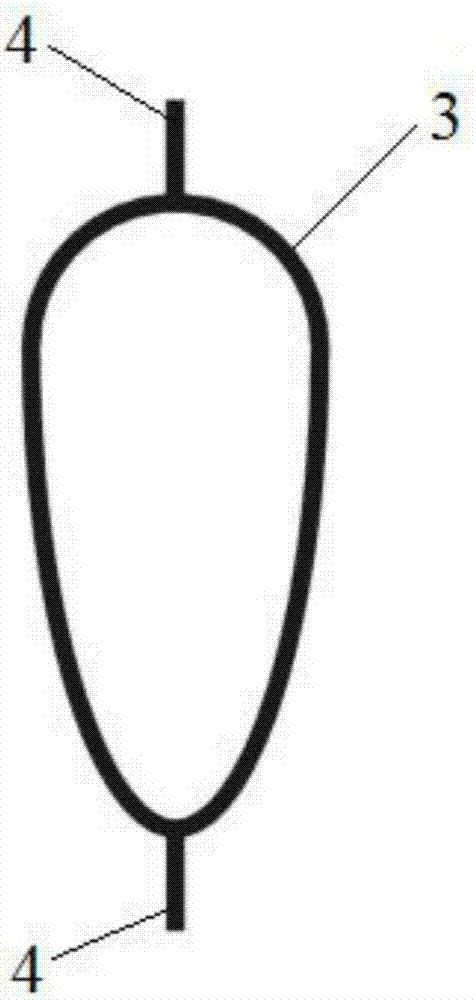

Lateral spray nozzle

ActiveUS6866211B2Uniform liquid distributionEasy constructionSpray nozzlesFire rescueEngineeringNozzle

A spray nozzle for directing a wide lateral spray curtain with substantially uniform liquid distribution throughout the length of the spray curtain is provided. The nozzle includes a nozzle body defining an elongated internal flow passage. The nozzle body includes an inlet end for connection to a pressurized liquid supply, a downstream end wall and a side wall. A discharge orifice is provided in the side wall of the nozzle body between the inlet end and the downstream end wall. The discharge orifice communicates with the internal flow passage of the nozzle body. The discharge orifice has a generally inverted teardrop configuration comprising a relatively larger area upper portion and a relatively smaller area lower portion arranged below the upper portion.

Owner:SPRAYING SYST

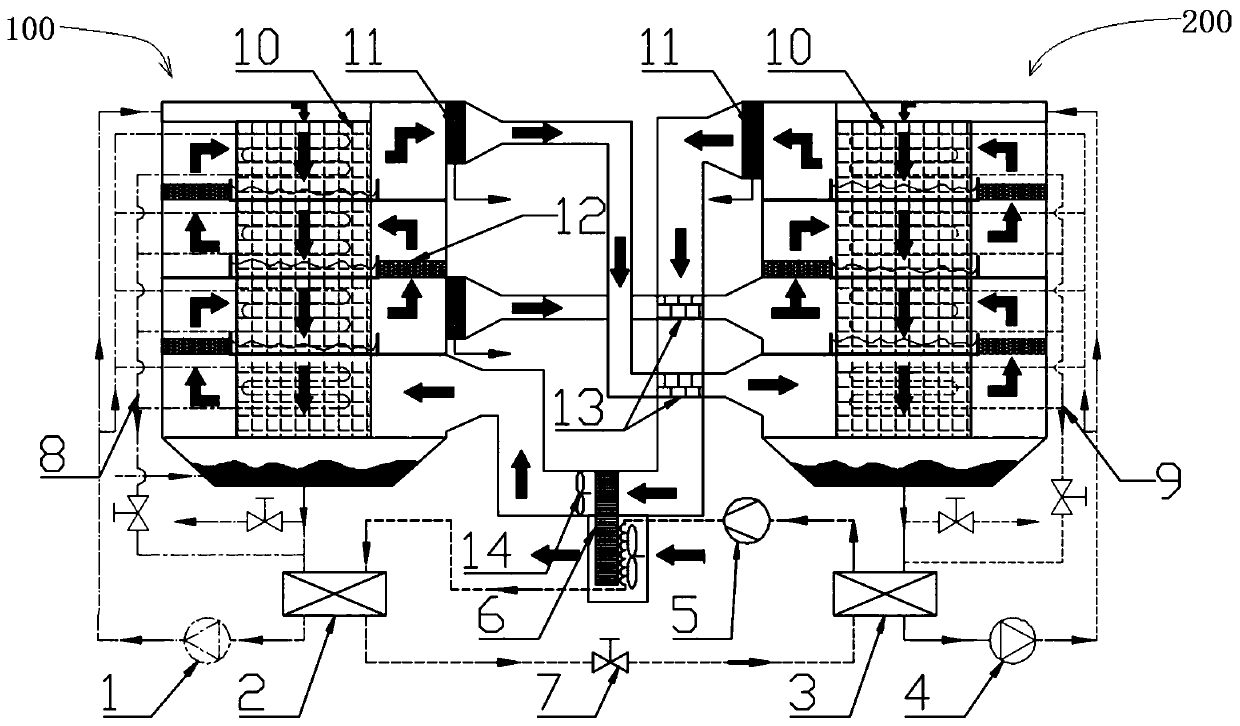

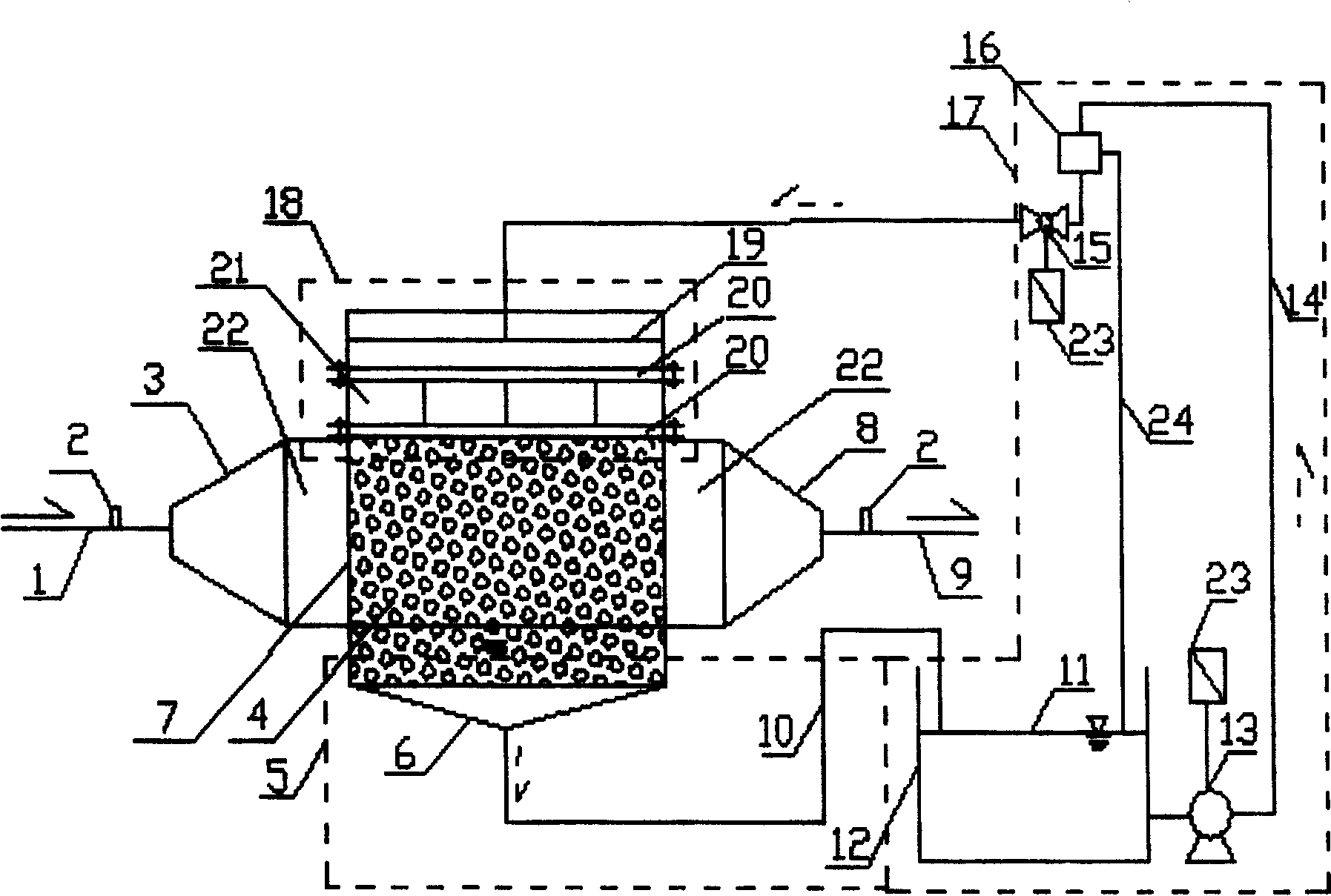

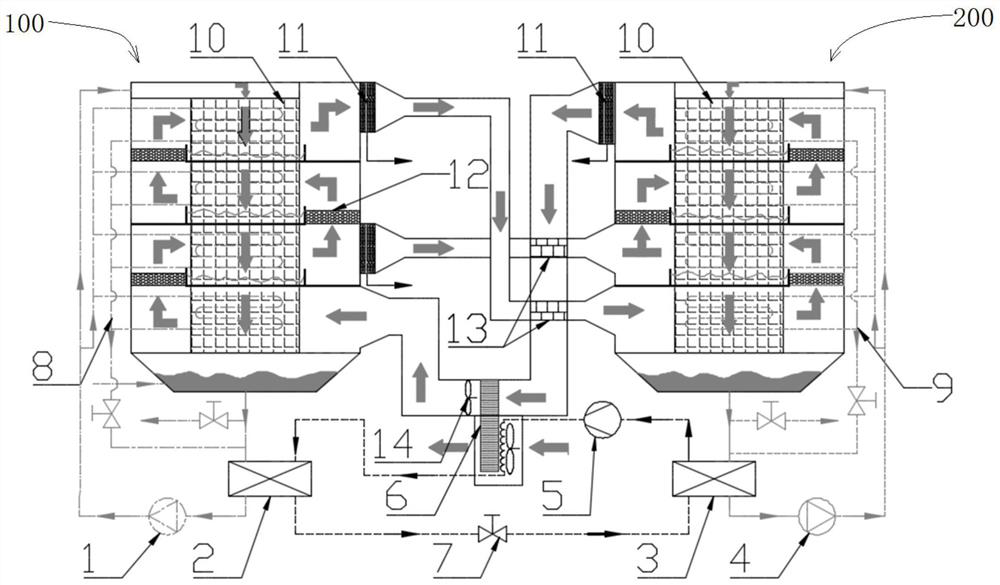

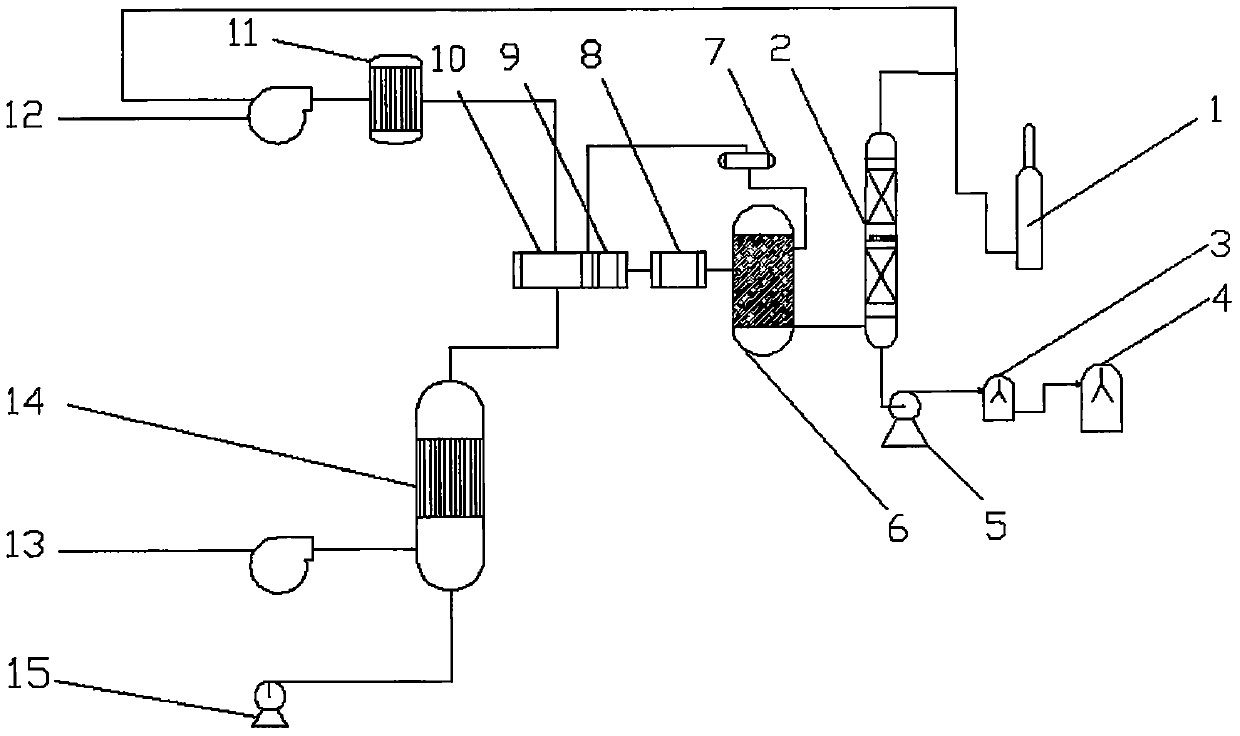

System and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer

ActiveCN110498462AIncrease temperatureHigh trafficGas treatmentSpecific water treatment objectivesLiquid wasteDistributor

The invention provides a system and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer. The system comprises an absorber, wherein the absorber is connected with a condenser, the condenser is connected with a waste liquid circulating pump, and the waste liquid circulating pump is connected with a liquid distributor of the absorber and a heater in the absorber; the system also comprises an analyzer, wherein the analyzer is connected with an evaporator, the evaporator is connected with a clean water pump, and the clean water pump is connected with a liquid distributor of the analyzer and a cooler in analyzer; an air outlet of the absorber is connected with an air inlet of the analyzer; an air outlet of the analyzer is connected with an air inlet of the absorber; and an air channel between the air outlet of the analyzer and the air inlet of the absorber is provided with a circulating fan and an adsorber. According to the invention,air can be utilized as a mass transfer medium to realize water migration in industrial waste liquid under the condition of a low temperature, and the system operates under normal pressure and is suitable for treatment of corrosive liquid which is crystallized easily and scaled easily, so that a series of pretreatment procedures such as precipitation, oil removal, pH value adjustment and the likerequired by conventional waste liquid treatment are greatly reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

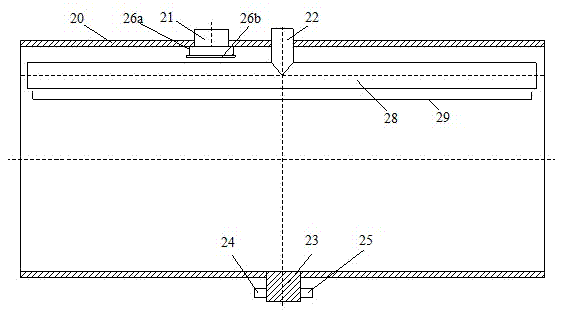

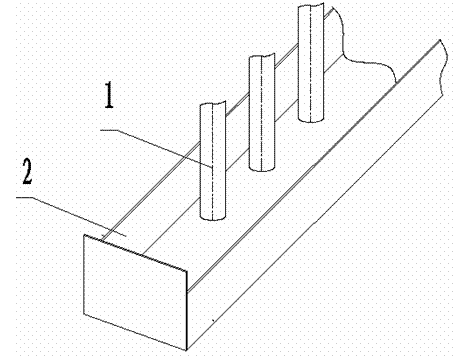

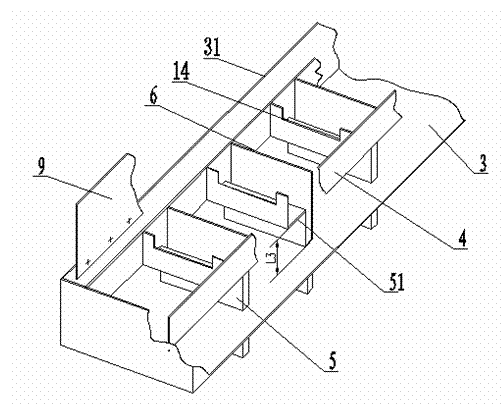

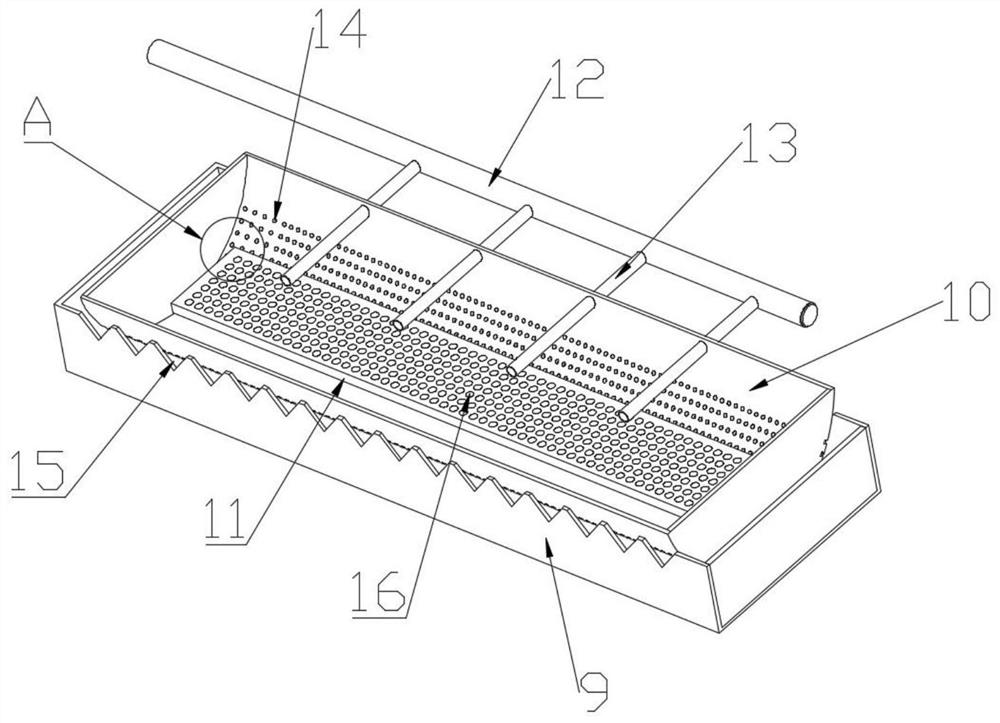

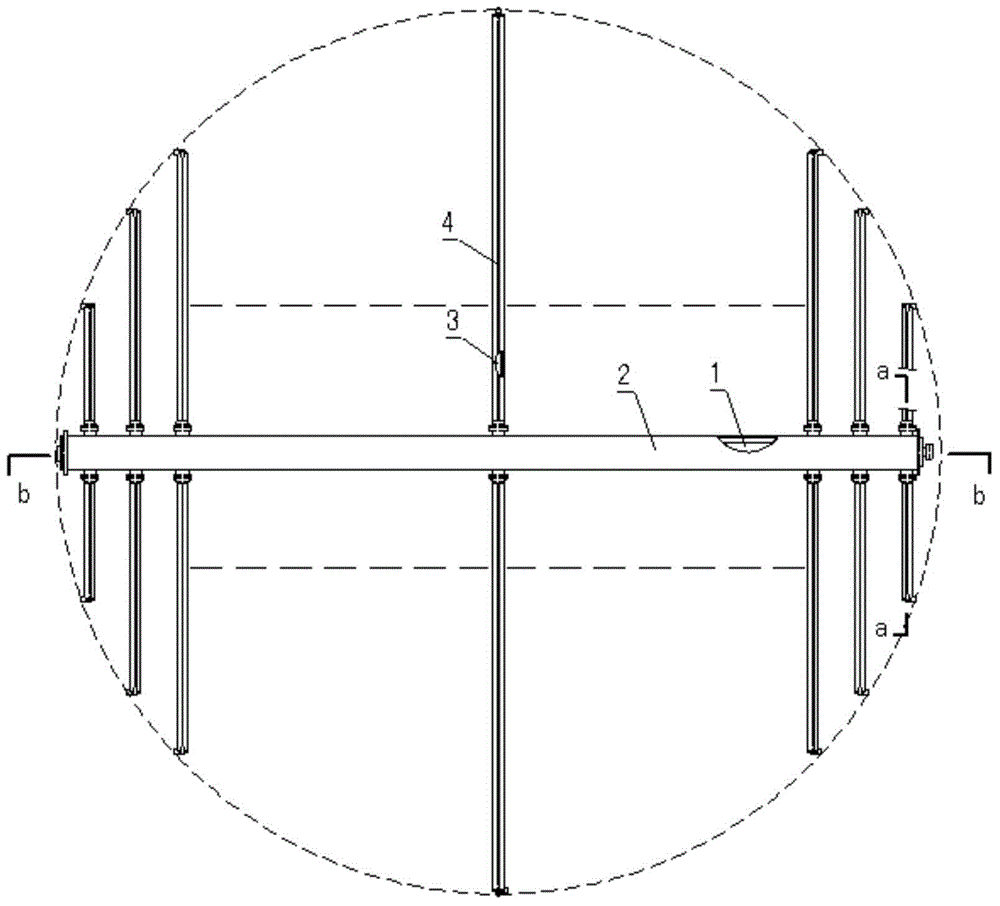

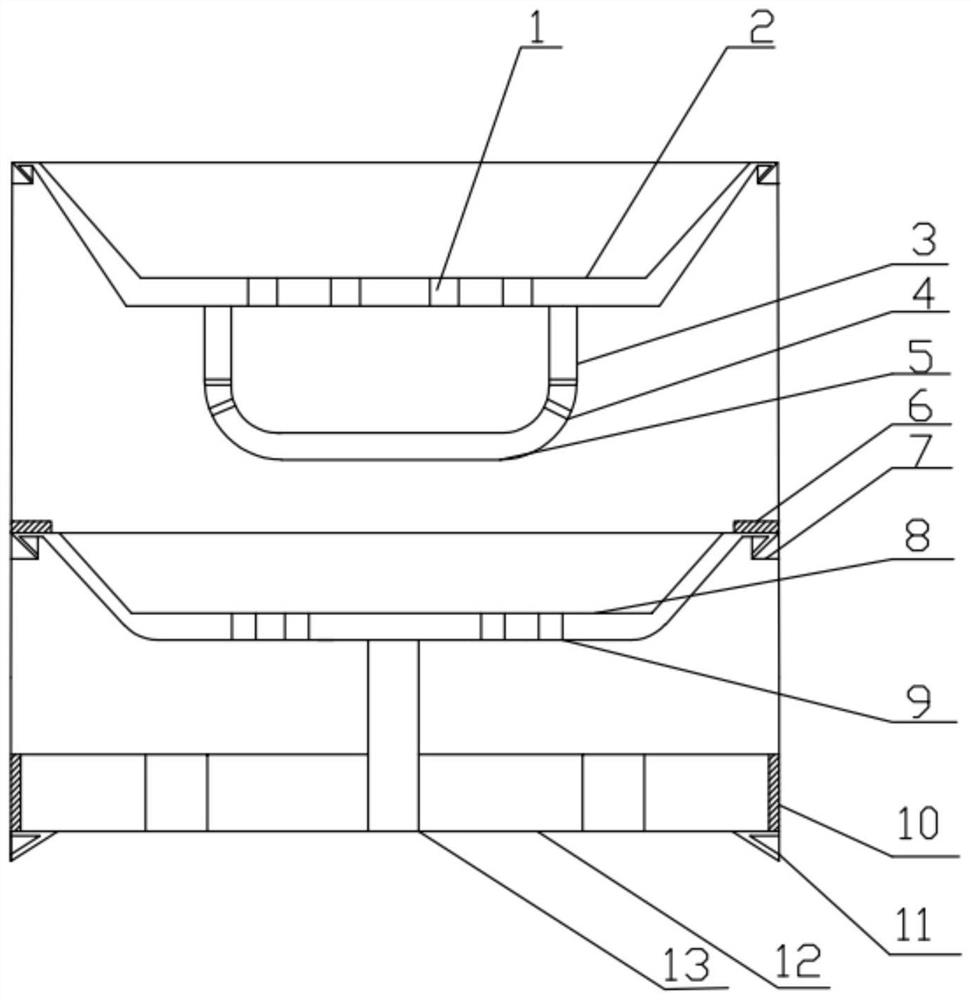

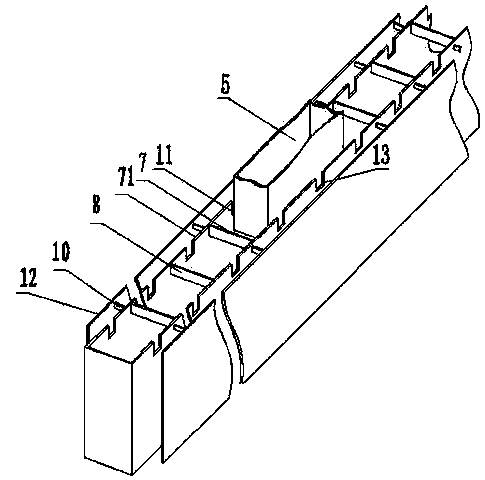

Full overflow tank type liquid distributor

ActiveCN103028355AAvoid cloggingAvoid shockDispersed particle separationChemical/physical/physico-chemical processesBuffer tankDistributor

The invention discloses a full overflow tank type liquid distributor which comprises liquid distribution pipes, a buffer tank, a primary tank, liquid distribution boxes, secondary tanks, baffles, connecting plates, liquid receiving boxes and liquid guide plates, and is characterized in that the primary tank is internally provided with two longitudinal partitions parallel to two walls of the primary tank, and a designed quantity of transverse partitions; identical gaps are formed among the longitudinal partitions and the two side walls of the primary tank; the transverse partitions are arranged between the two longitudinal partitions and are perpendicular to the longitudinal partitions; a double right-angle folded plate is arranged between every two adjacent transverse partitions; each liquid distribution box combined by two wide-top and narrow-bottom rectangular cross sections is formed between each double right-angle folded plate and each transverse partition; a concave overflow port is formed at the upper edge of each double right-angle folded plate; the widths of the liquid distribution boxes and the buffer tank are identical; and liquid outflow modes of the primary tank and the secondary tanks are overflow modes, that is the outflow direction of liquid is opposite to the sedimentation directions of material granules.

Owner:天津市创举化工设备有限公司

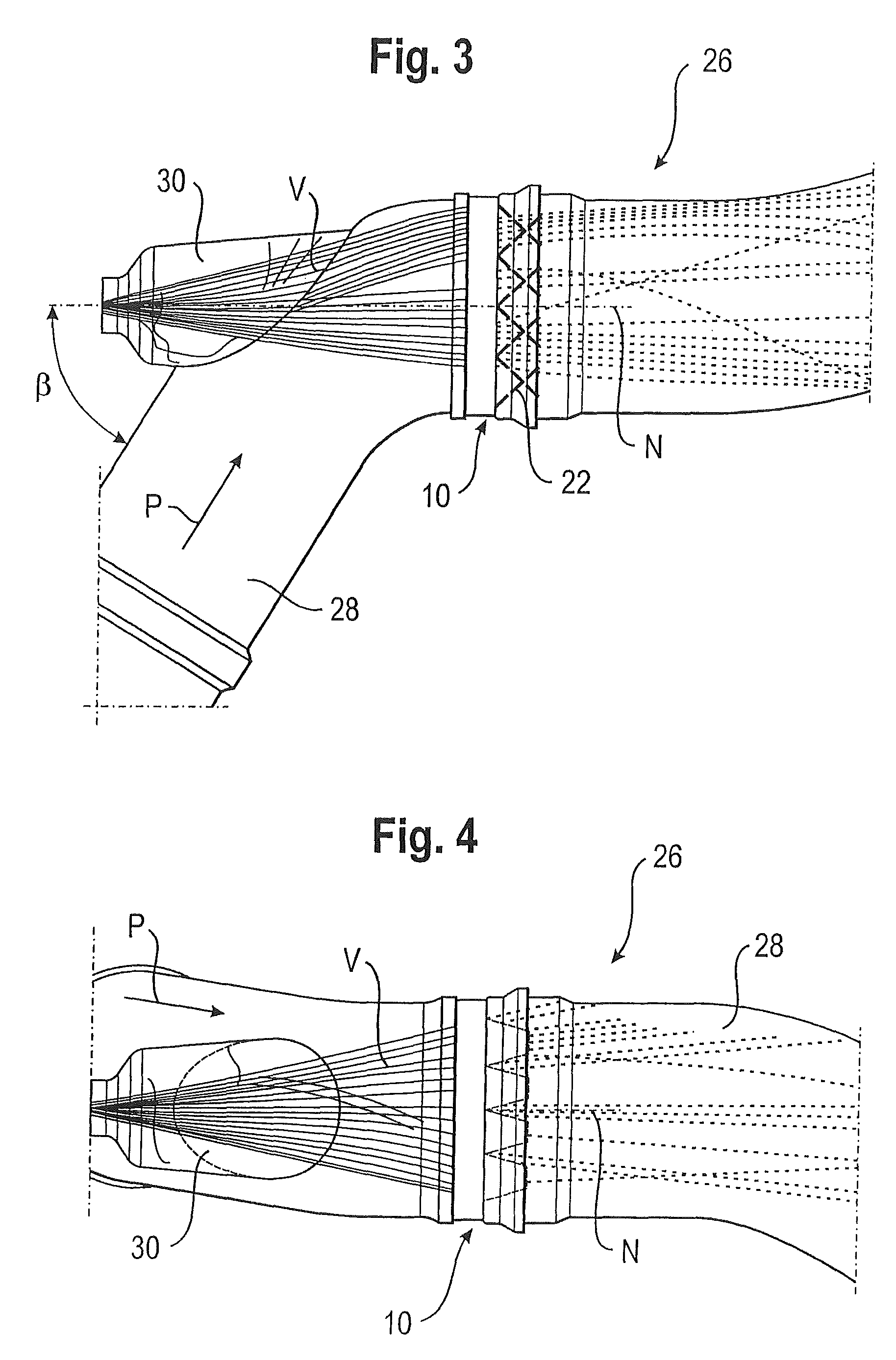

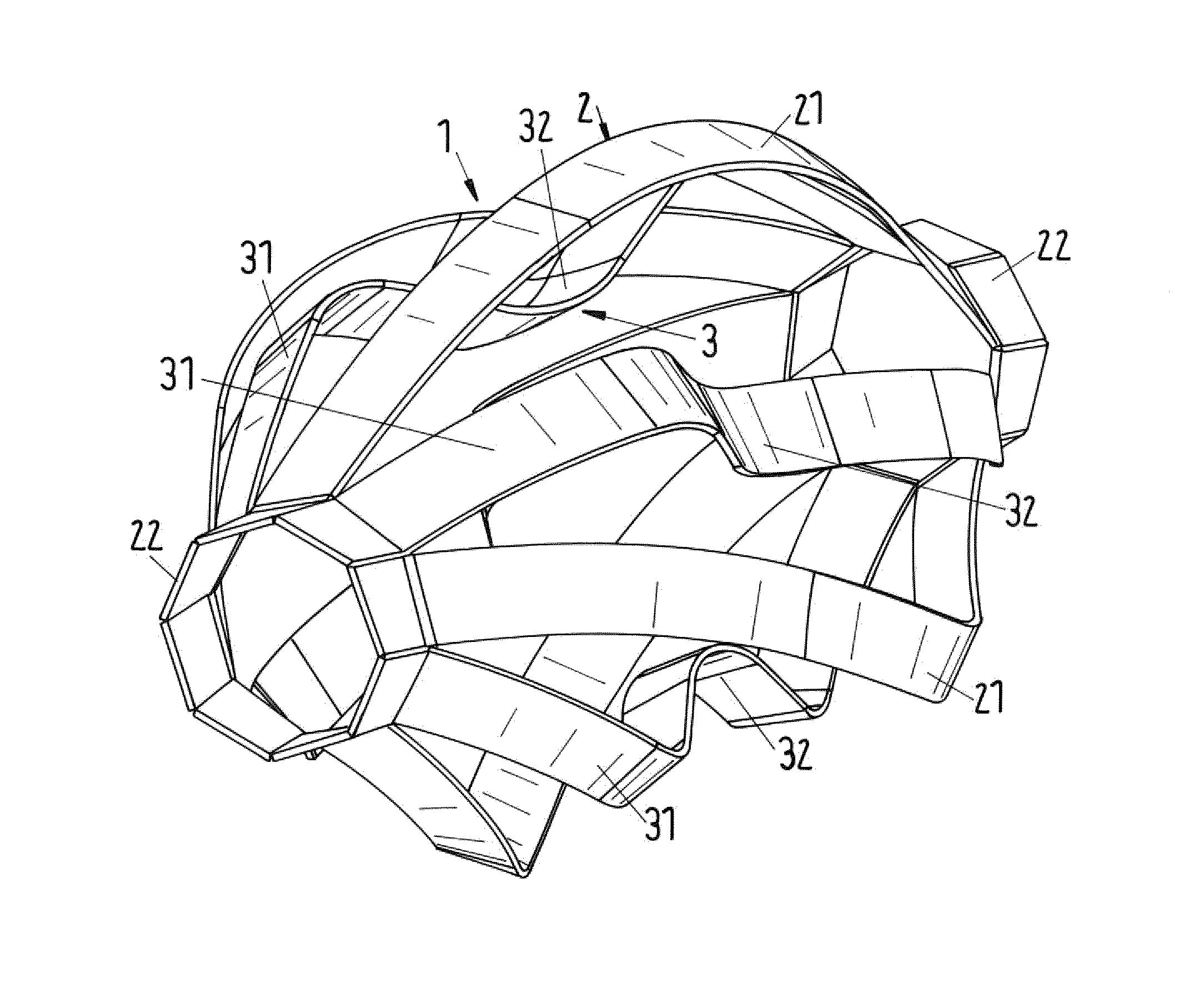

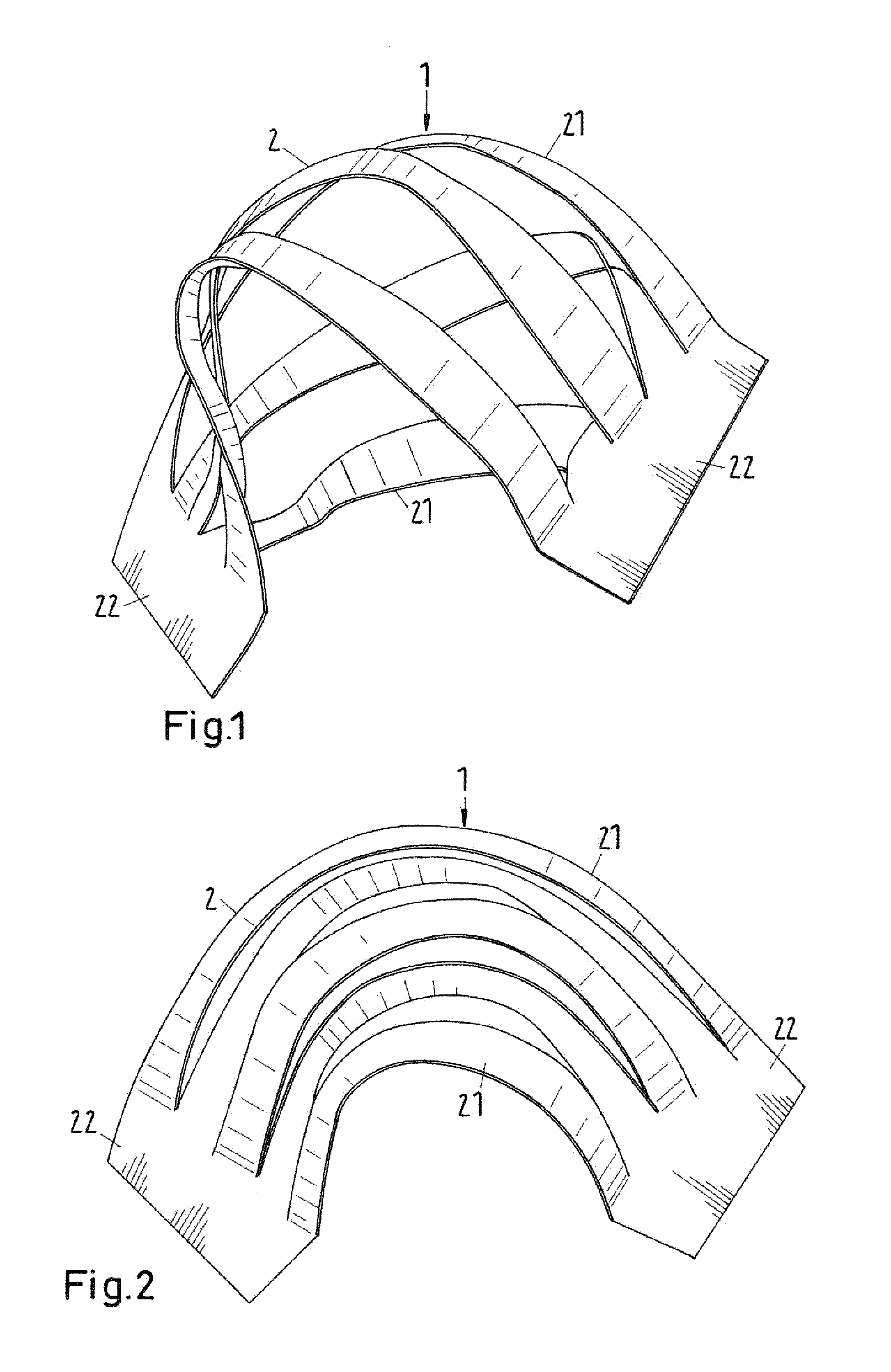

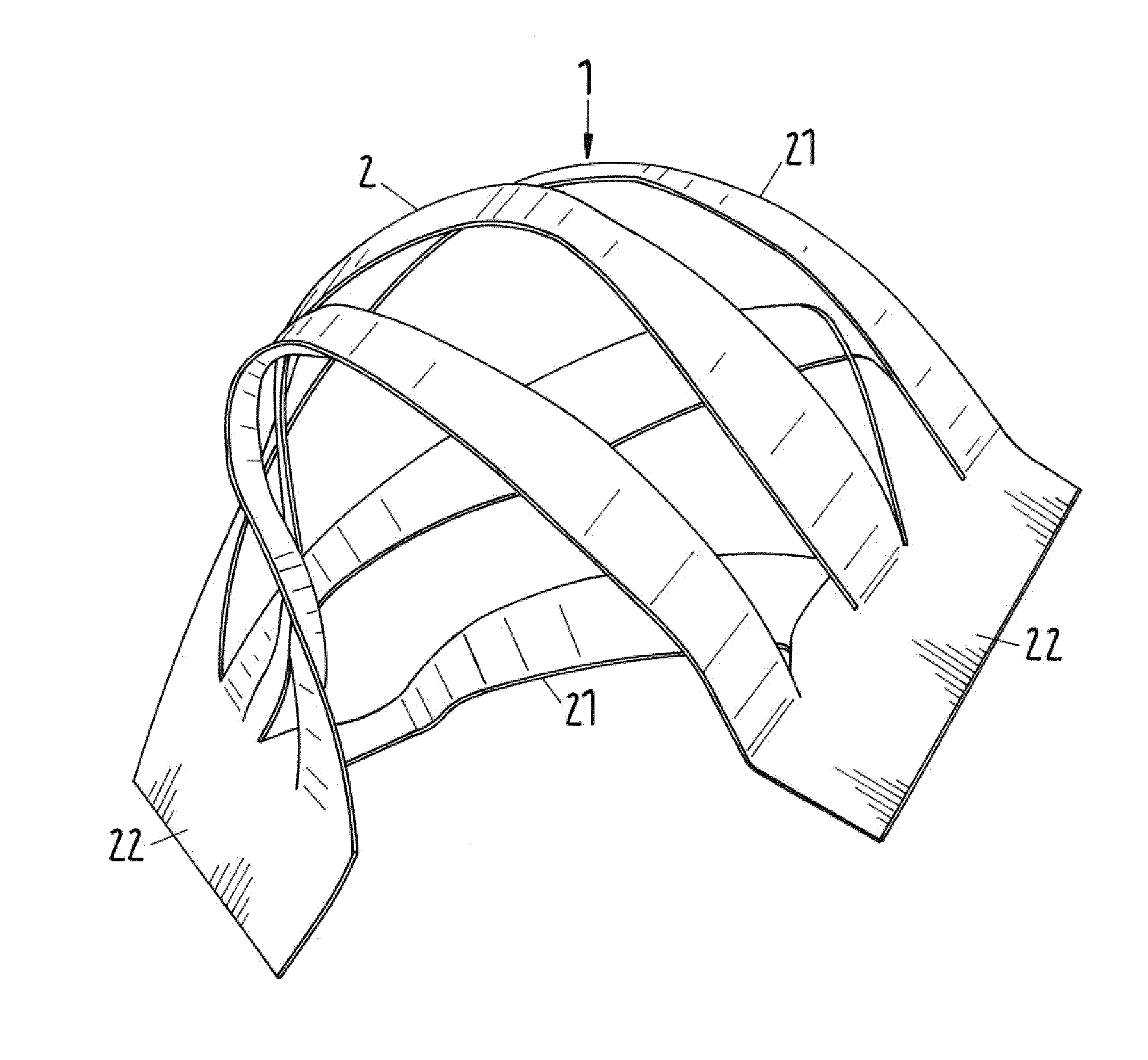

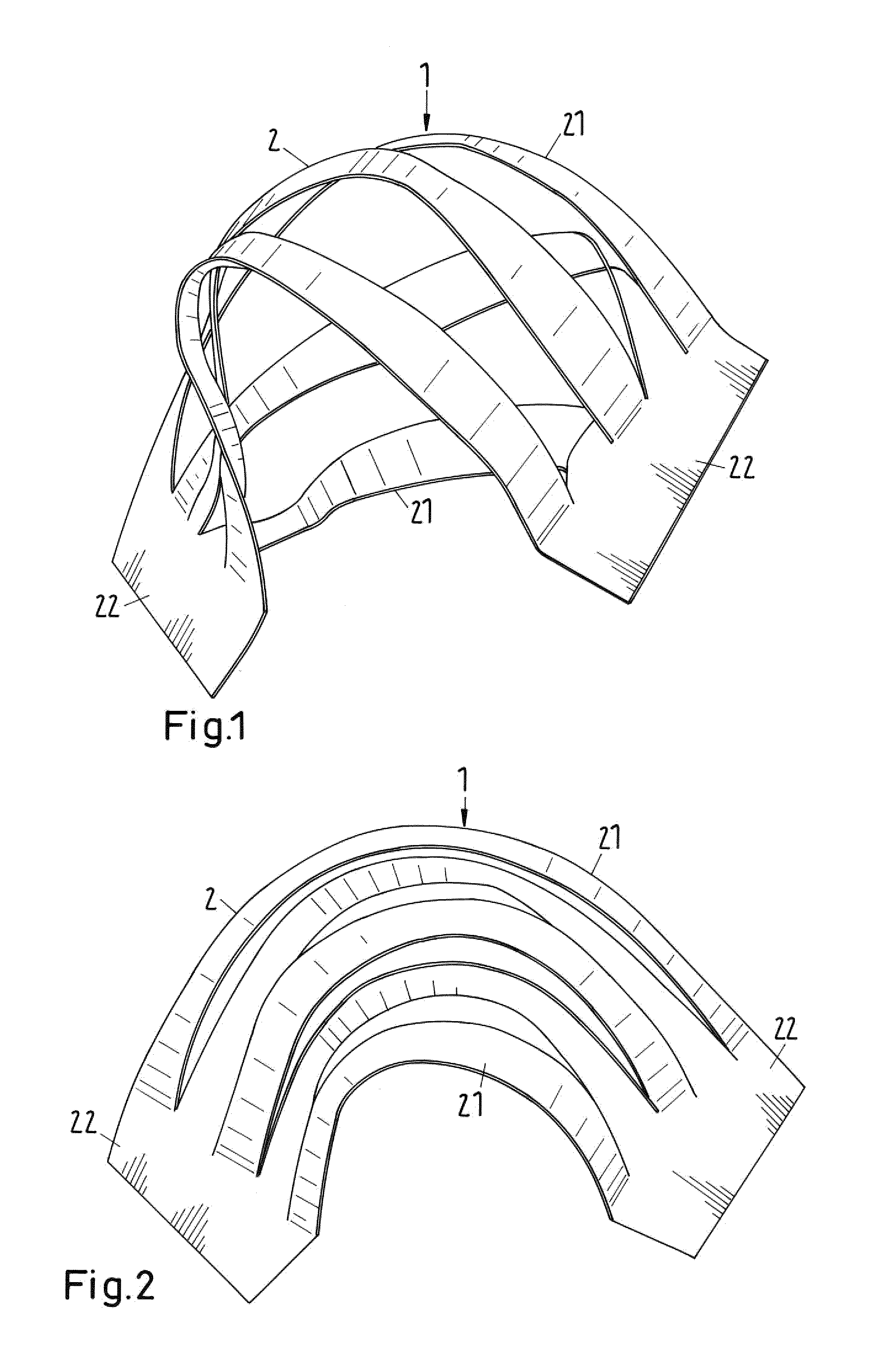

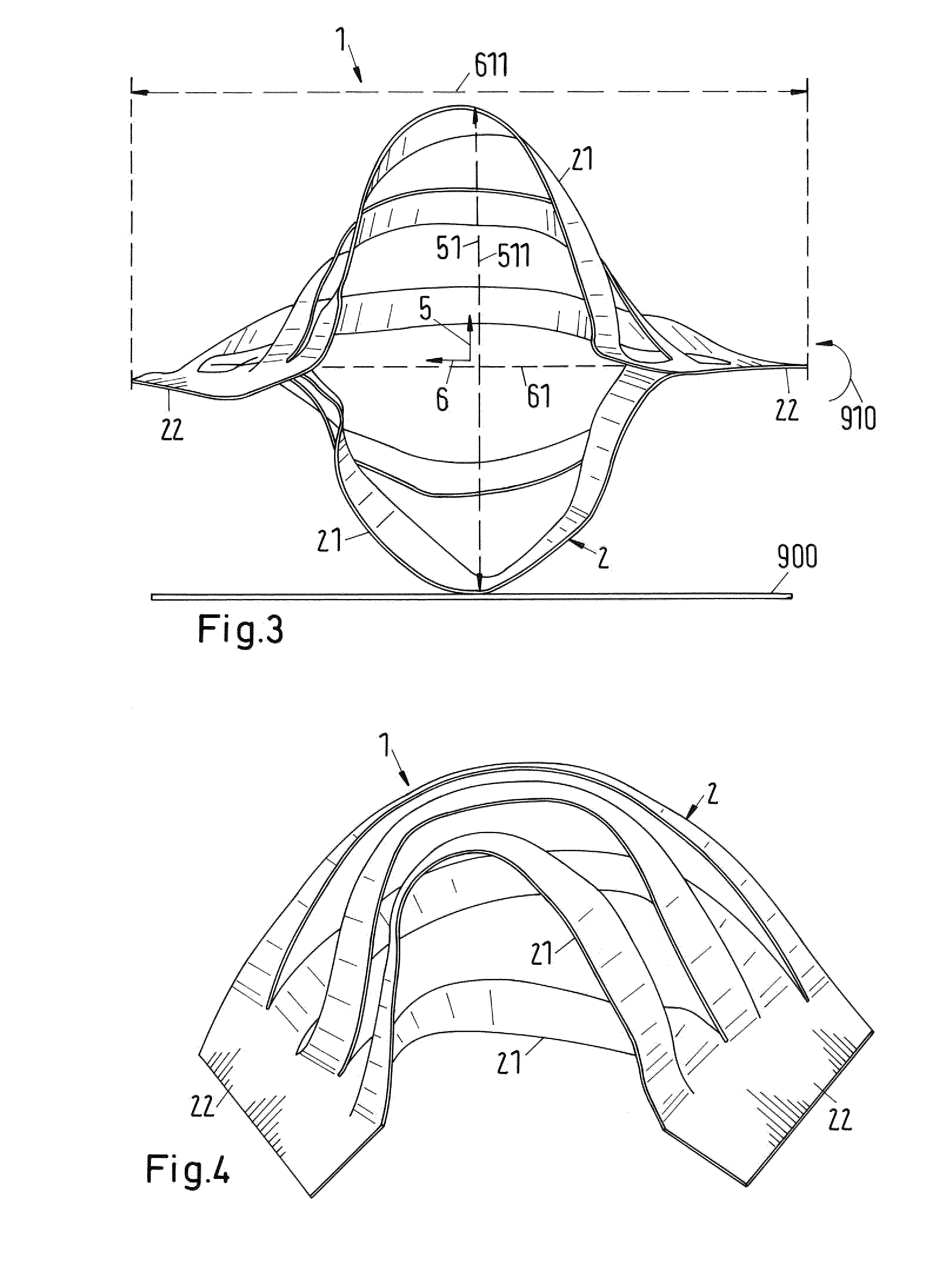

Packing element, method to produce it and a column or reactor comprising said element

ActiveUS9452412B2Improve distributionEasily and rapidly packedMixing methodsTransportation and packagingChemical reactionProject area

A packing element (1) for use in mass and / or heat transfer processes through which at least one liquid may flow, wherein the packing element (1): has an outer surface (2) comprising three or more outer arched rib elements (21) and two outer connecting edge elements (22), optionally has an inner surface (3) comprising optional inner arched rib elements (31), wherein the element 1 is substantially spherical or substantially ellipsoidal, and wherein the outer connecting edge elements (22) and the outer arched rib elements (21) and optional inner arched rib elements (31) are embodied such that the total projected area (4) of the packing element (1) when viewed in any direction (7), preferably a radial direction (5) or optional axial direction (6), is partially open due to the presence of an open projected area (41), wherein it is open to an extent that ranges from about 15 to about 50, preferably about 17 to about 40, more preferably about 18 to about 35, most preferably about 20 to about 30% of the total projected area (4). The invention further relates to a method for producing said element (1). The present invention further relates also to a column or reactor comprising a bed of said elements (1), a method to prepare said bed, and the use of the element (1) or column or reactor in a mass transfer and / or heat transfer process and / or in a chemical reaction.

Owner:SULZER MANAGEMENT AG

Apparatus for preventing unintended or premature release of liquid in a beverage brewing device and method thereof

InactiveUS7861645B2Avoid premature releaseUniform liquid distributionBeverage vesselsEngineeringBiomedical engineering

An apparatus useful for preventing the release of residual liquid in a beverage brewing device prior to and after the brewing process, and for preventing the premature release of liquid during the heating process is disclosed. The apparatus includes a flexible member, a closing member and a recess. The apparatus is fabricated such that the pressure of the liquid being delivered to the brewing chamber displaces or depresses the closing member sufficiently into the recess to form a first fluid passage. The pressure of the fluid also creates a channel or cavity on a surface of the flexible member. The first fluid passage and the channel or cavity form a second fluid passages which provide fluid communication between the fluid inlet and the brewing chamber. Preferably, the flexible member, closing member and recess is formed as an integral unit.

Owner:ELECTRICAL & ELECTRONICS LTD

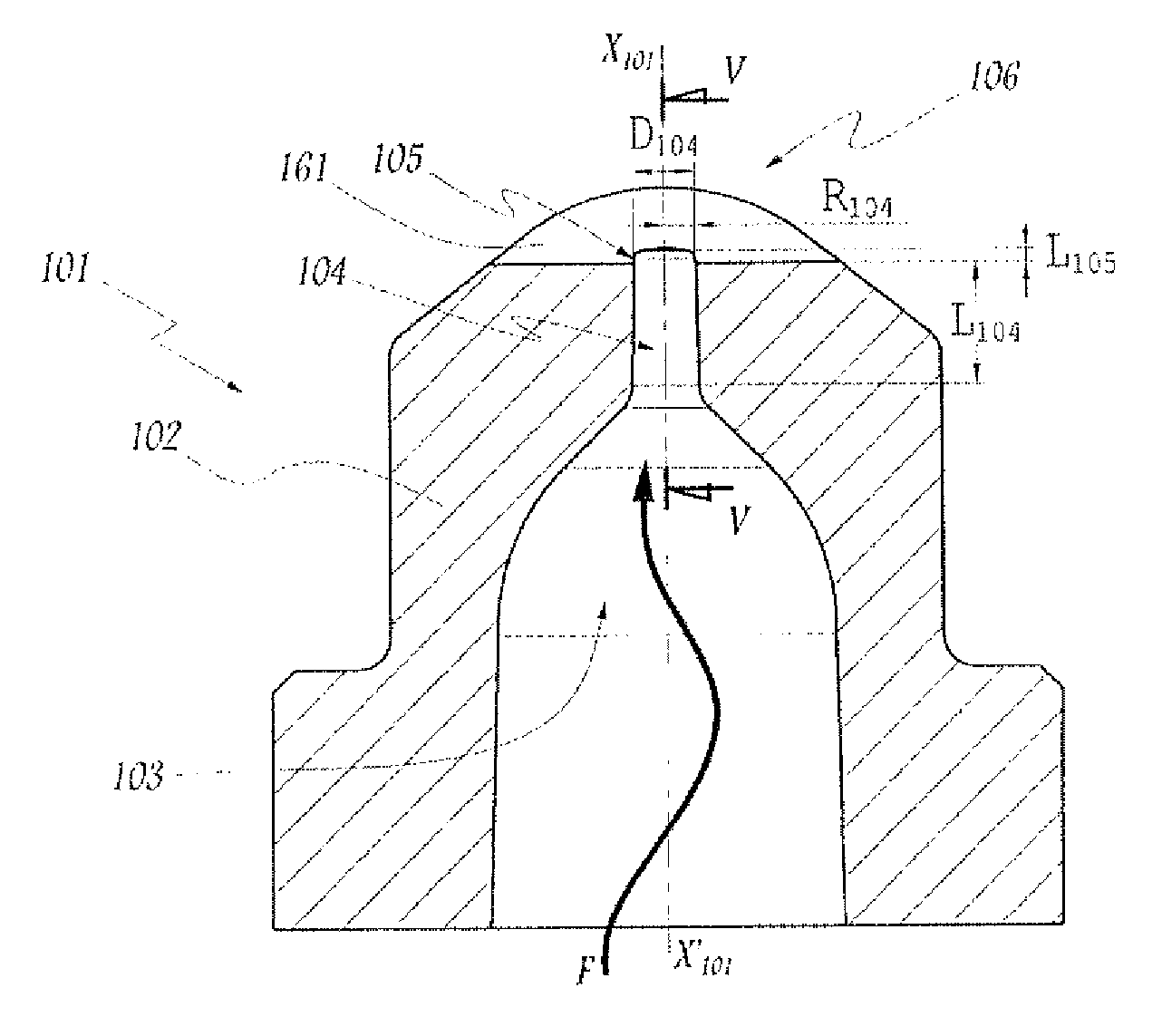

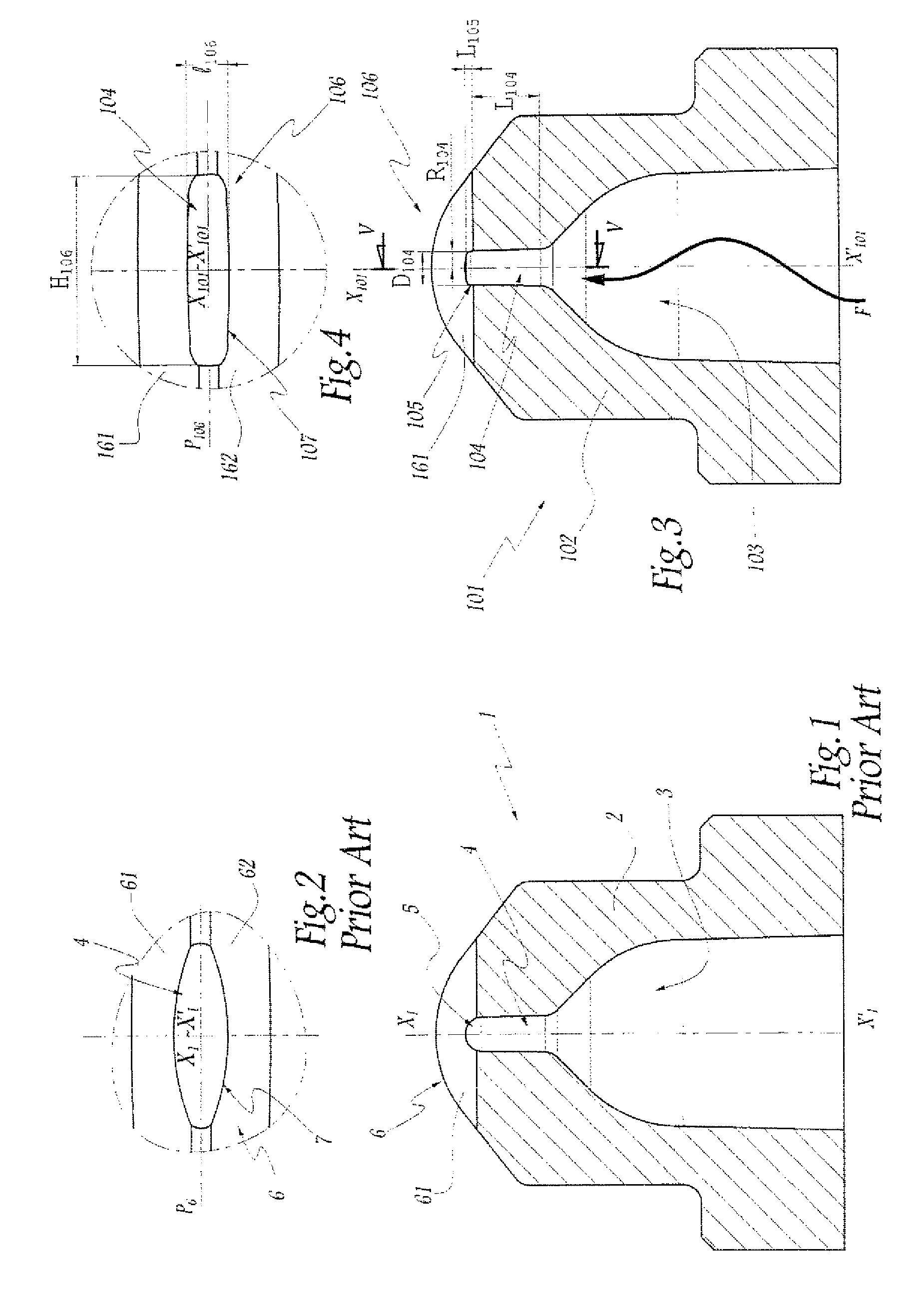

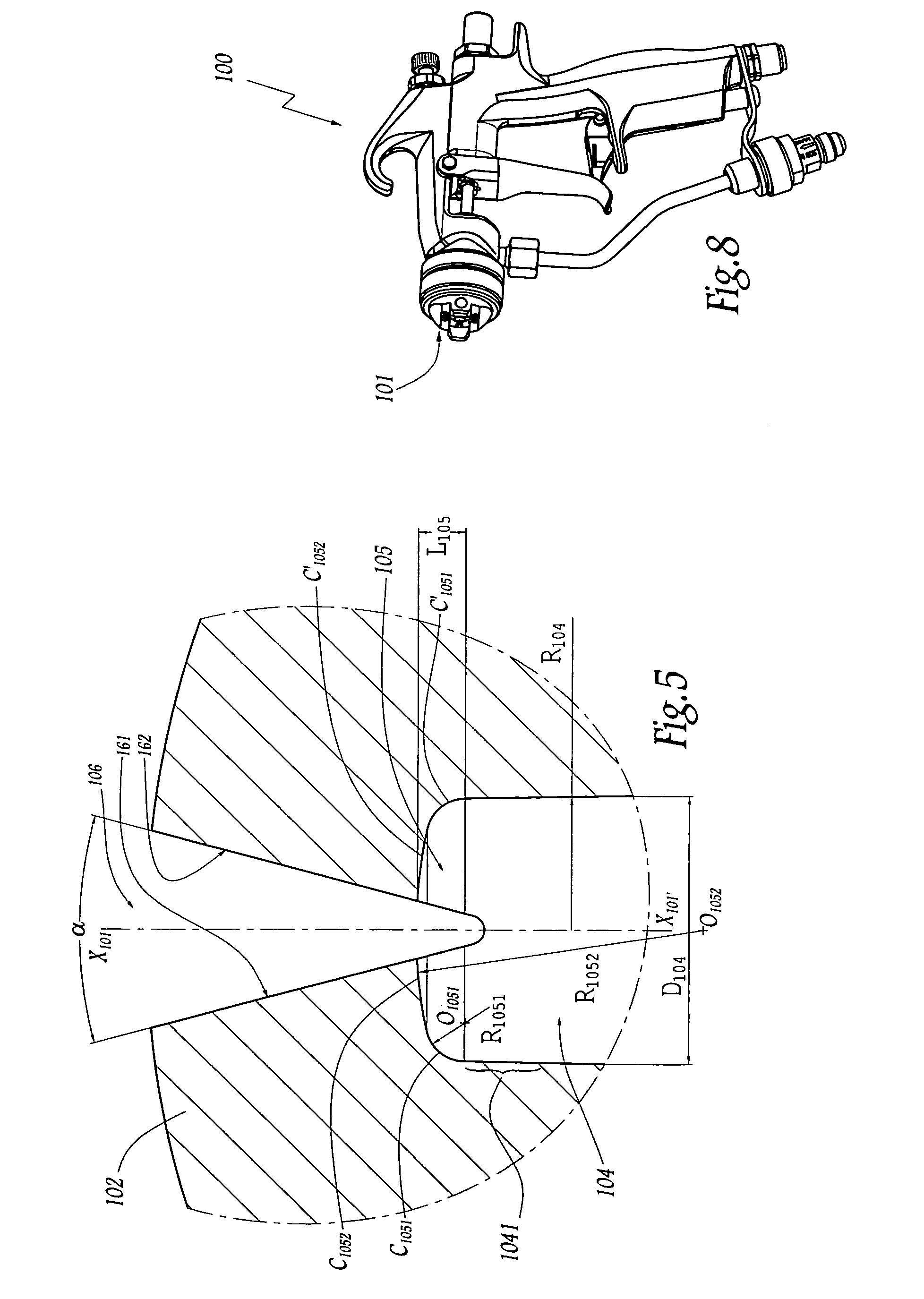

Spray nozzle for liquid and device for spraying liquid comprising such a nozzle

InactiveUS8590816B2Easy to useImprove spray qualitySpray nozzlesFire rescueSpray nozzleMechanical engineering

A spray nozzle includes a tubular channel extending along a longitudinal axis, a slot formed by two approximately plane surfaces converging in a direction of the channel and located on either side of a plane including the longitudinal axis of the channel, and a dome connecting the channel and the slot wherein a length of the dome represents less than 50% of a largest transverse dimension of the channel and a plane cross section of the dome is symmetric and it is defined by at least two different circular arcs.

Owner:EXCEL IND INC

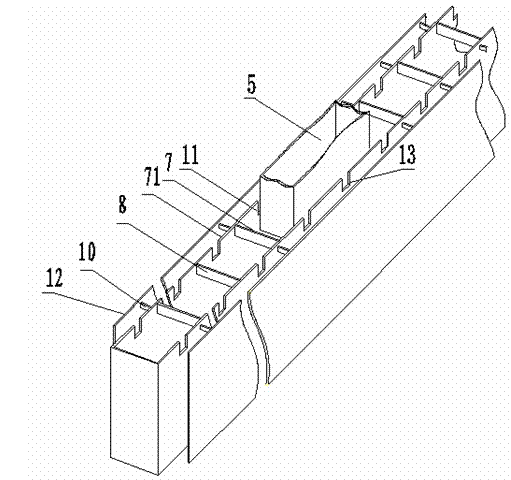

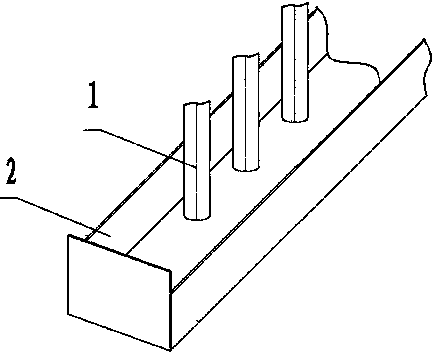

Two-stage groove type distributing device provided with pressure stabilizing plate and used for thin-layer drying equipment

PendingCN112028157AGuaranteed uniformityImprove work efficiencyWater distributersSolution crystallizationEngineeringStructural engineering

The invention discloses a two-stage groove type distributing device provided with a pressure stabilizing plate and used for thin-layer drying equipment. A two-stage distributing mechanism comprises arectangular overflow groove, a U-shaped main groove, a flow stabilizing plate, a liquid conveying header pipe and liquid conveying pipes; the rectangular overflow groove is formed in the upper end ofa drying rotary column; the U-shaped main groove is formed in the upper end of the rectangular overflow groove; the flow stabilizing plate is arranged in the U-shaped main groove; a liquid conveying header pipe is arranged on one side of the U-shaped main groove; the plurality of liquid conveying pipes are arranged between the liquid conveying header pipe and the U-shaped main groove; and one endof each liquid conveying pipe penetrates into the U-shaped main groove; According to the two-stage distributing mechanism, on one hand, mother liquor descending kinetic energy is relieved, so that thetwo-stage d distributing mechanism is prevented from being directly impacted by large-flow mother liquor; on the other hand, feed liquid splashing caused by sharp fluctuation of the liquid level is avoided, the distribution uniformity of the mother liquor is effectively improved; and a complete, uniform and stable liquid film can be rapidly formed on the outer surface of a drying rotary column under the action of the gravity and surface tension of the mother liquor and the centrifugal force of the drying rotary column.

Owner:江苏固环环境科技有限公司

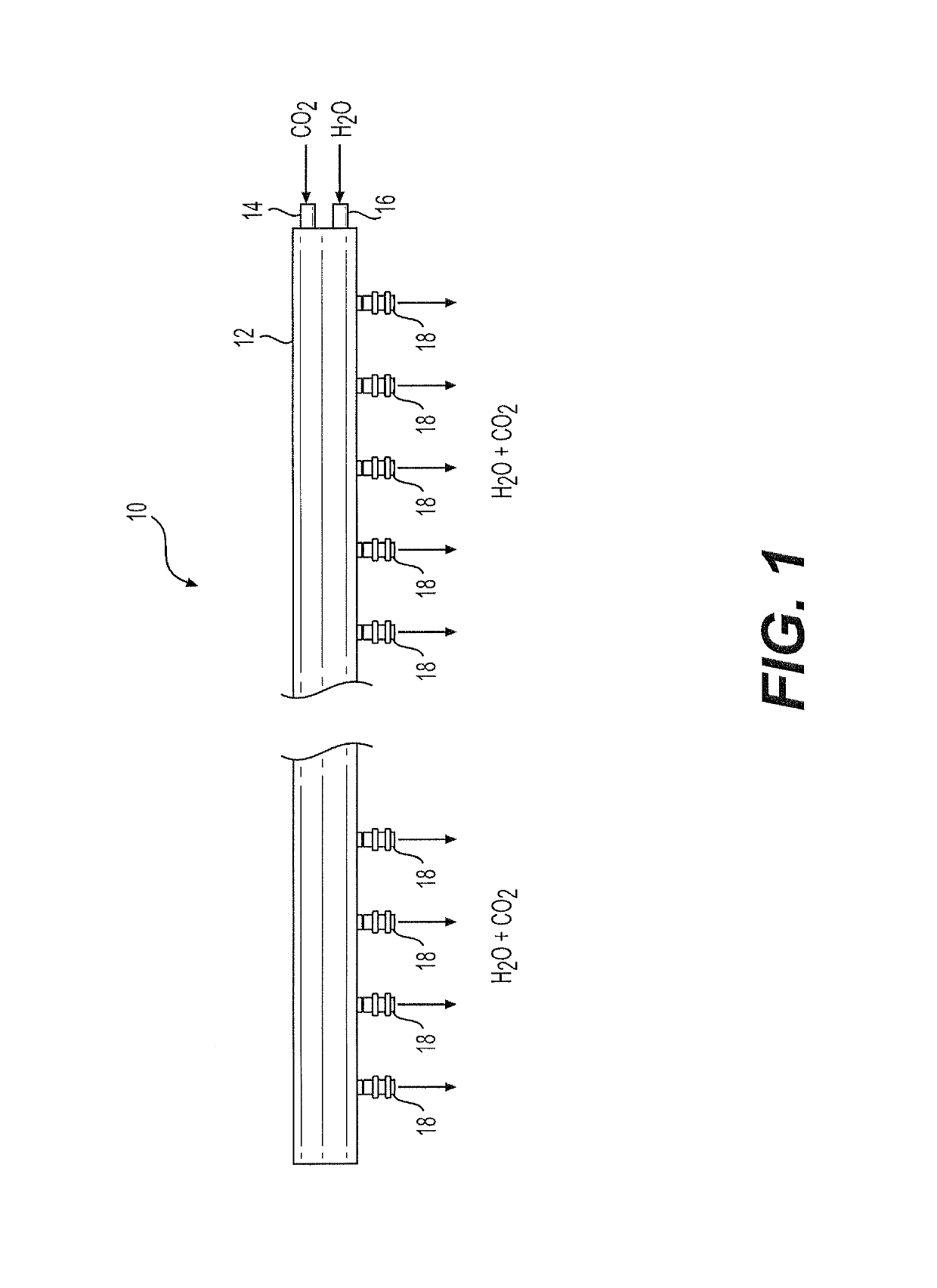

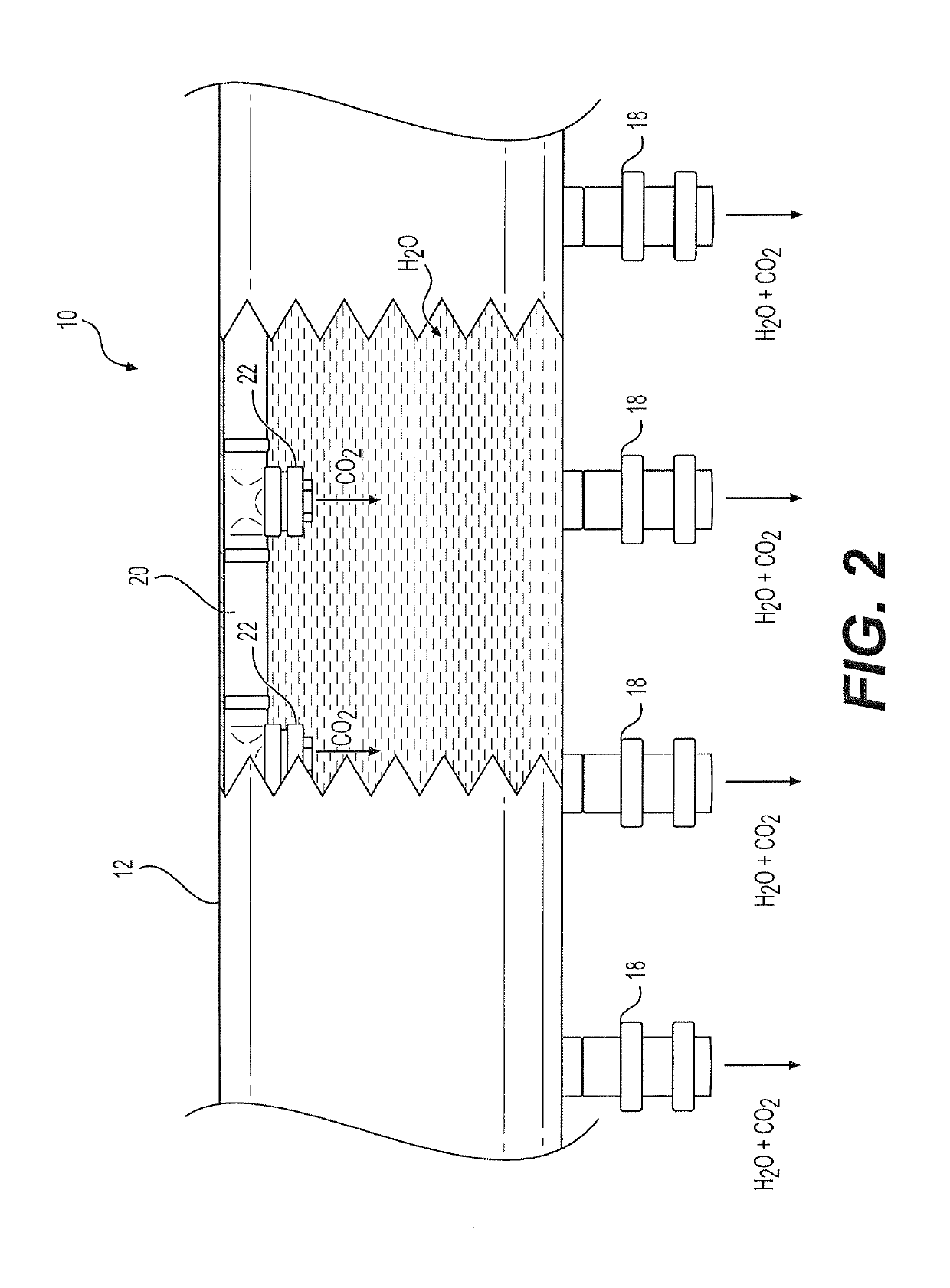

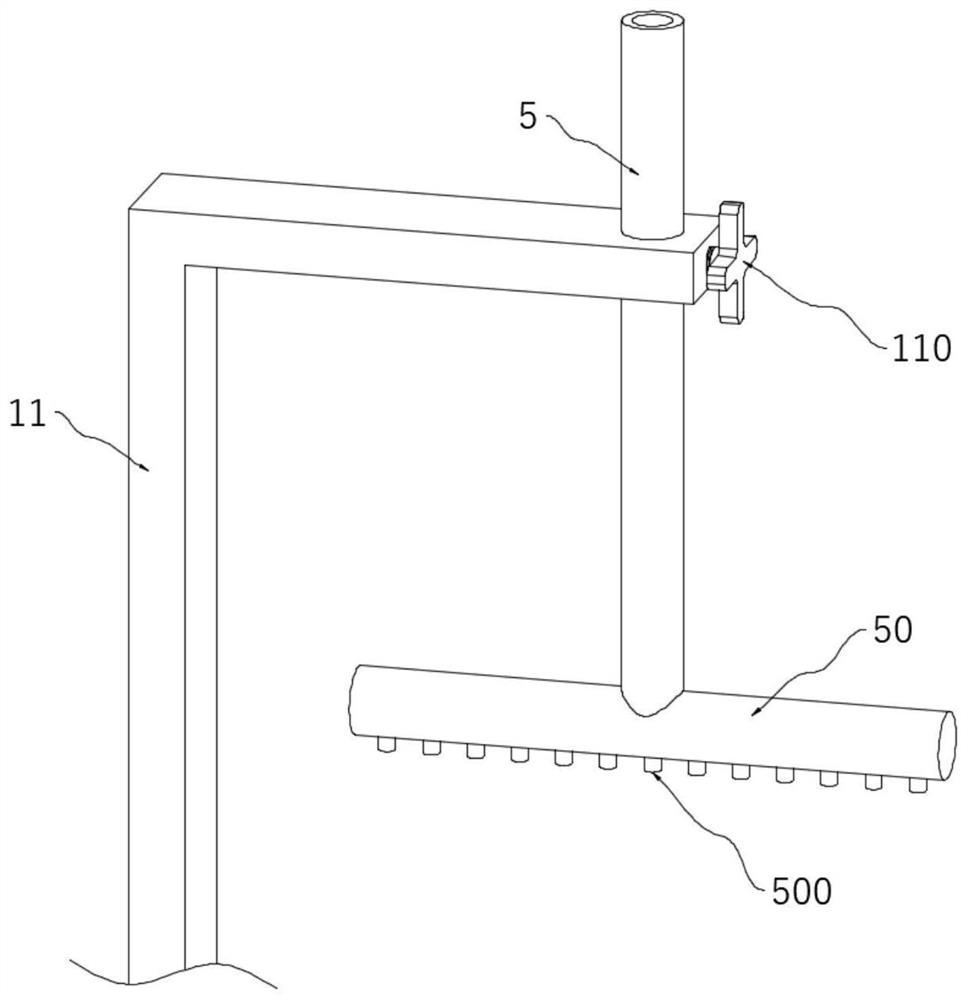

Drip irrigation system

ActiveUS10251336B1Increase pressureUse minimizedClimate change adaptationWatering devicesWater flowDrip irrigation

The drip irrigation system allows for the irrigation of soil with carbon dioxide-infused water. The drip irrigation system includes a pipe having first and second inlets. The first inlet is adapted for receiving pressurized carbon dioxide gas, and the second inlet is adapted for receiving water under pressure. A plurality of drip nozzles are mounted to the pipe, such that each drip nozzle is in fluid communication with an interior of the pipe. An inner tube is mounted in the interior of the pipe and is in fluid communication with the first inlet for receiving the pressurized carbon dioxide gas. The pressurized carbon dioxide is expelled through a plurality of ports of the inner tube to mix with the water flowing within the interior of the pipe. This mixture forms water infused with carbon dioxide, which is then released, in the forms of drops, by the plurality of drip nozzles.

Owner:UNITED ARAB EMIRATES UNIVERSITY

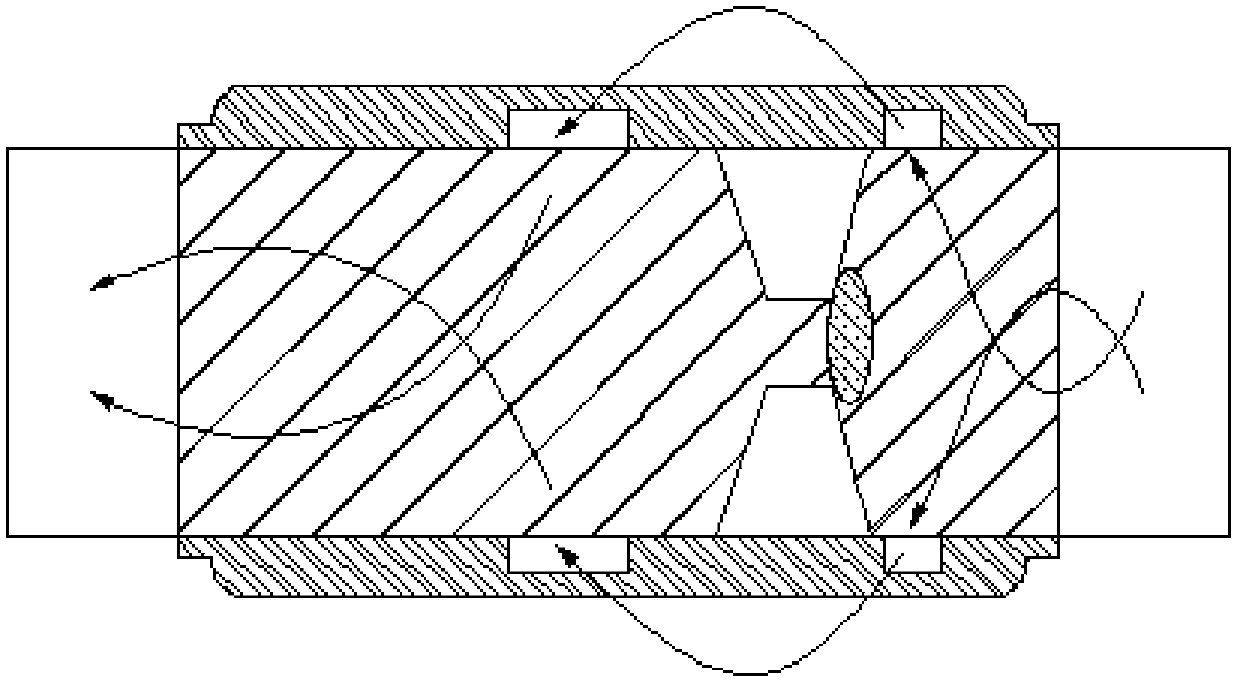

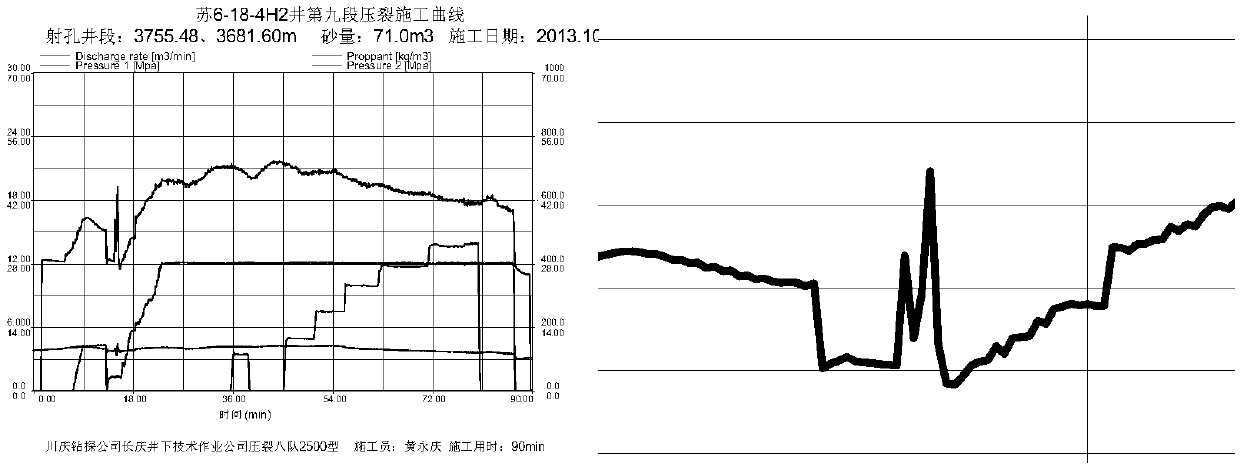

Open hole packer staged fracturing method for horizontal well

InactiveCN109812250AReduce usageShorten the timeFluid removalWell/borehole valve arrangementsHorizontal wellsDifferential pressure

The invention relates to the field of horizontal wells, in particular to an open hole packer staged fracturing method for a horizontal well. The method comprises following steps: step one, shaft preparation; step two, tool lowering: a differential pressure sliding sleeve, an open hole packer, a fracturing sliding sleeve, a suspending packer and a back inserting tube are fed to the design positionsof a horizontal section by adopting a drill pipe; an impact sliding sleeve is added between the two packers during tool lowering; step three, ball injection and setting to finish release; step four,tie-back; step five, fracturing construction: fracturing balls matched with a fracturing sliding sleeve ball seat from small to large are fed respectively, when the fracturing balls are sent to the impact sliding sleeve, pins of a ball injection sliding sleeve are sheared off, and injection holes in the impact sliding sleeve are opened; a setting ball moves downwards through a ball seat of the impact sliding sleeve, and when the setting ball moves to a common fracturing sliding sleeve ball seat, the pins are sheared off under the pressure action, the fracturing sliding sleeve is opened, and fracturing construction of the stage is performed. With the adoption of the method, a reservoir can be exposed to a greater degree, the discharge area is increased, the number of fracturing stages is optimized, and the recovery ratio is increased.

Owner:张家志 +10

Semielliptical falling film heat exchange tube with uniform flow guiding fins

PendingCN107966063ASave cloth liquidIncrease the heat exchange areaTubular elementsHeat transfer tubeEllipse

Owner:DONGHUA UNIV

Packing Element, Method to Produce it and a Column or Reactor Comprising Said Element

ActiveUS20150069663A1Improve distributionEasily and rapidly packedMetal-working feeding devicesTransportation and packagingMechanical engineeringHeat transfer process

A packing element (1) for use in mass and / or heat transfer processes through which at least one liquid may flow, wherein the packing element (1): has an outer surface (2) comprising three or more outer arched rib elements (21) and two outer connecting edge elements (22), optionally has an inner surface (3) comprising optional inner arched rib elements (31), wherein the element 1 is substantially spherical or substantially ellipsoidal, and wherein the outer connecting edge elements (22) and the outer arched rib elements (21) and optional inner arched rib elements (31) are embodied such that the total projected area (4) of the packing element (1) when viewed in any direction (7), preferably a radial direction (5) or optional axial direction (6), is partially open due to the presence of an open projected area (41), wherein it is open to an extent that ranges from about 15 to about 50, preferably about 17 to about 40, more preferably about 18 to about 35, most preferably about 20 to about 30% of the total projected area (4). The invention further relates to a method for producing said element (1). The present invention further relates also to a column or reactor comprising a bed of said elements (1), a method to prepare said bed, and the use of the element (1) or column or reactor in a mass transfer and / or heat transfer process and / or in a chemical reaction.

Owner:SULZER MANAGEMENT AG

Bio-trickling device for processing volatile organic waste gas and method thereof

InactiveCN100431671CReduce flow heightIncreased load removal capacityDispersed particle separationAir quality improvementForming gasEnvironmental engineering

Owner:BEIJING UNIV OF TECH

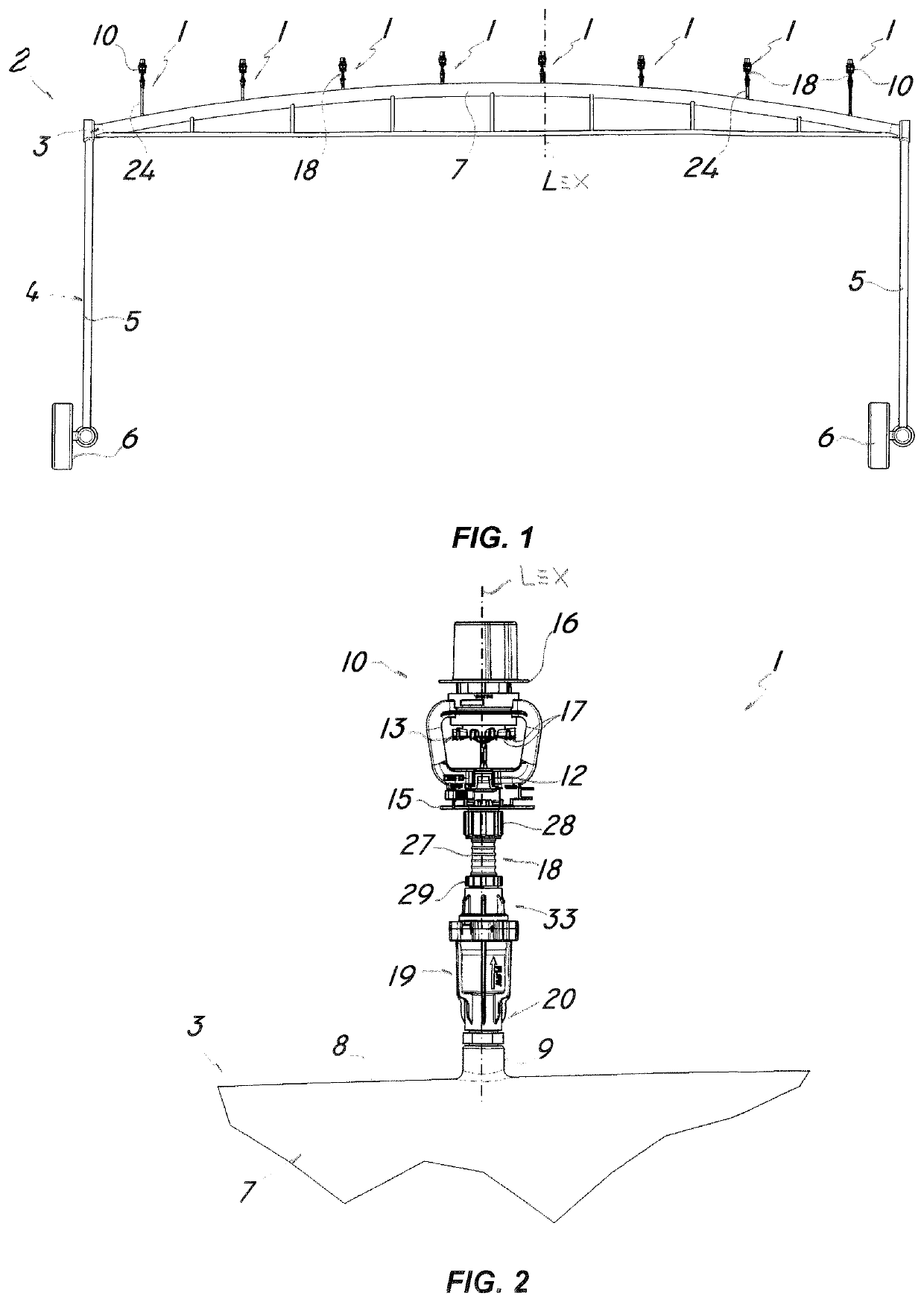

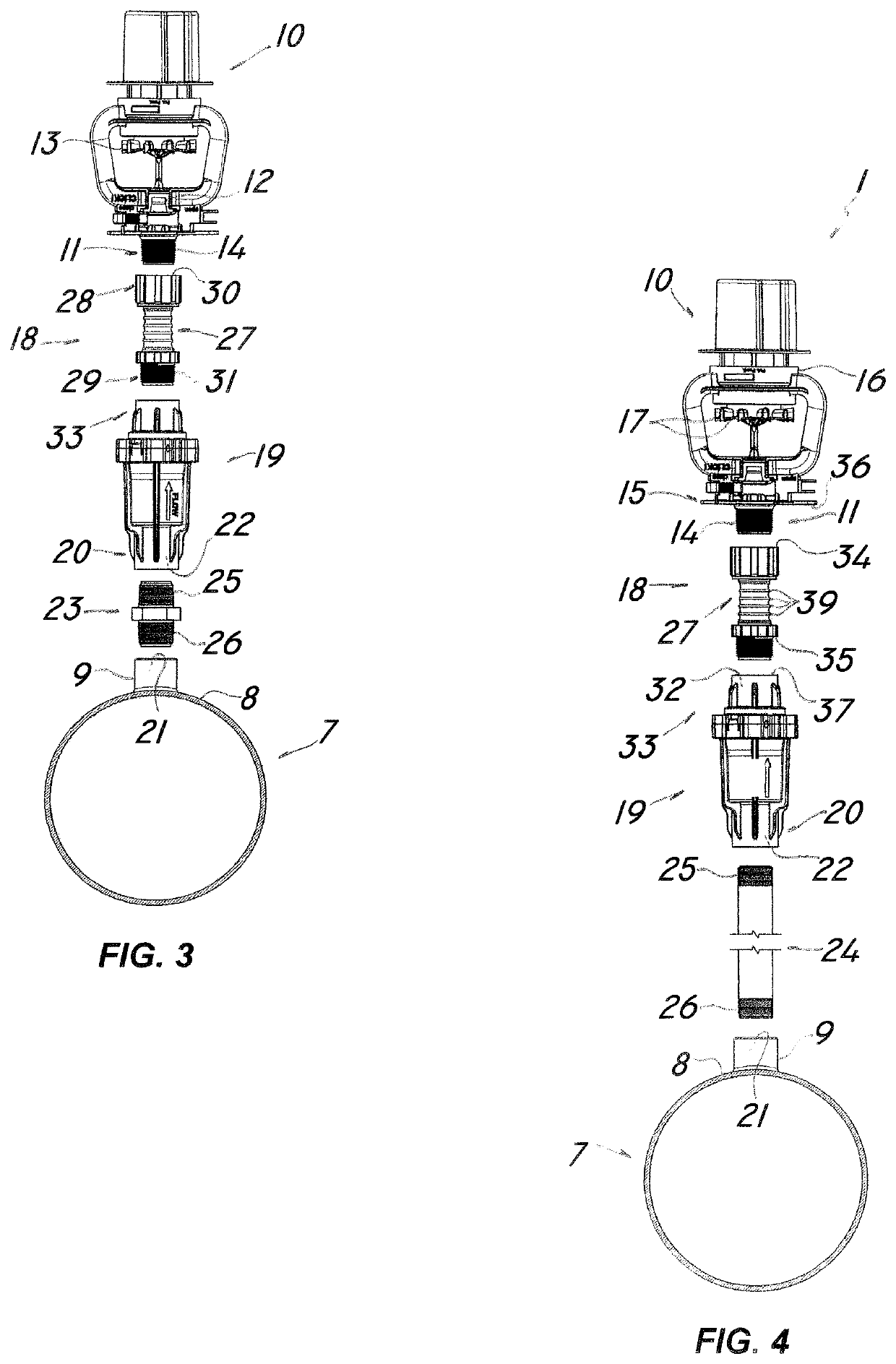

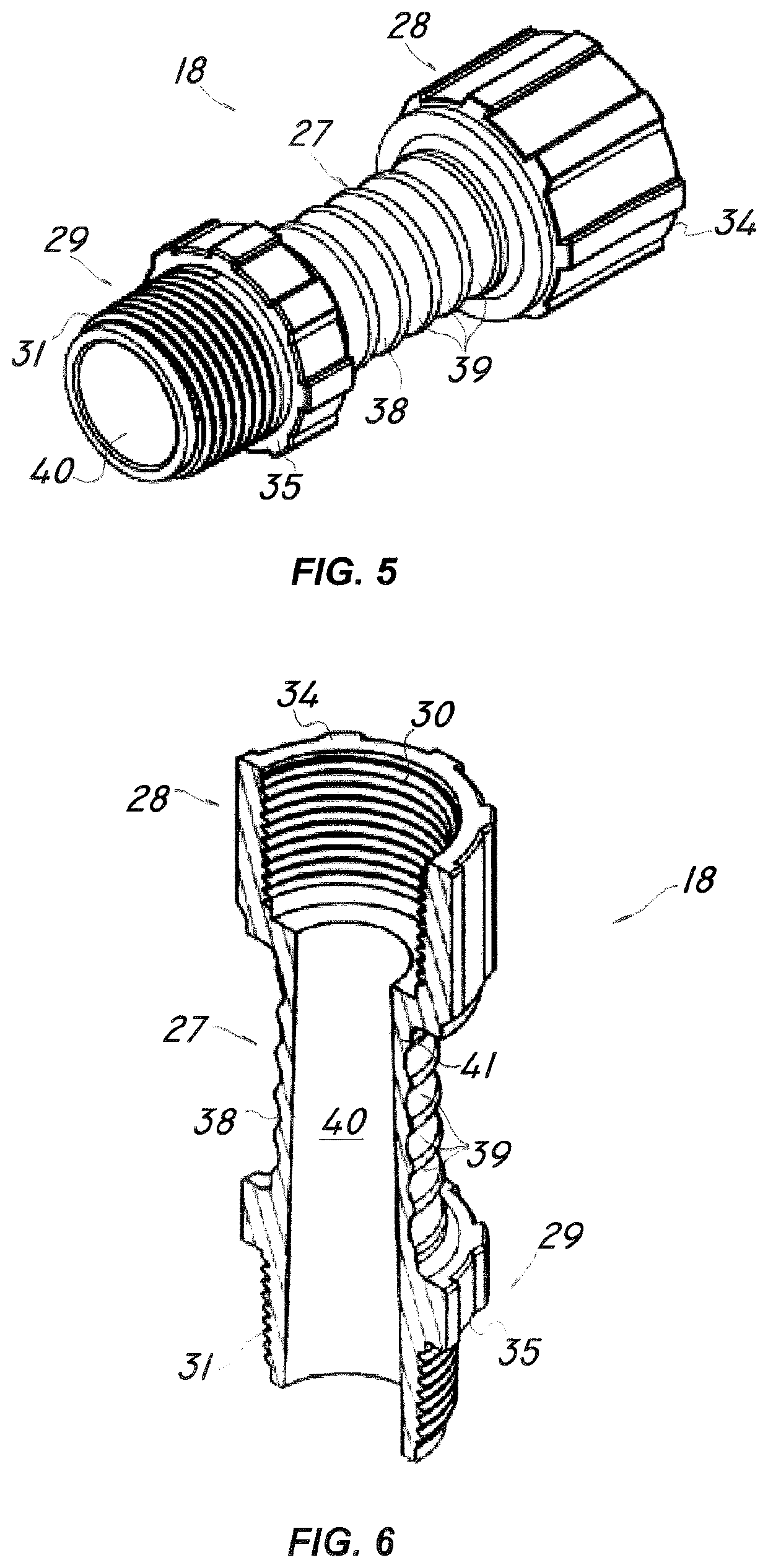

Diffuser assembly for diffusing a liquid in irrigation plants, and irrigation plant comprising a plurality of diffuser assemblies

ActiveUS11311896B2Improve efficiencyCost-effectiveMovable spraying apparatusAdjustable jointsElastomerThermoplastic elastomer

A diffuser assembly for diffusing a liquid in irrigation plants has a supply conduit includes a diffuser with a nozzle adapted to direct a jet of liquid along a longitudinal axis, at least one deflector facing the nozzle for radially spraying the jet outwards, and a connection device for ensuring fluid connection of the diffuser to the supply conduit of the plant. The diffuser is mounted onto the irrigation plant with the axis extending in a substantially vertical direction and with the nozzle facing up, and the deflector is configured to rotate about the longitudinal axis, thereby causing oscillations in the assembly. The connection device includes a tubular body with end joints that connect to the diffuse, and the supply conduit and the body is monolithic with the joints and is made of a thermoplastic elastomeric base material. Furthermore, the body has an outer surface with annular folds, which imparts elasticity and damp the oscillations induced by the deflector. A pivot or linear irrigation plant includes a plurality of those diffuser assemblies.

Owner:KOMET AUSTRIA GMBH

An industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer

ActiveCN110498462BNo secondary pollutionAchieve moisture purificationGas treatmentSpecific water treatment objectivesCirculator pumpProcess engineering

The invention proposes an industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer. The system includes an absorber connected to a condenser connected to a waste liquid circulation pump connected to an absorber The liquid distributor of the resolver and the internal heater of the absorber; the resolver, which is connected to the evaporator, and the evaporator is connected to the clean water pump, and the clean water pump is connected to the liquid distributer of the resolver and the internal cooler of the resolver; the air outlet of the absorber is connected to the resolver The air inlet of the resolver, the air outlet of the resolver is connected to the air inlet of the absorber, and the air channel between the air outlet of the resolver and the air inlet of the absorber is provided with a circulating fan and an adsorber. The invention can use air as the mass transfer medium to realize the migration of water in the industrial waste liquid under the condition of relatively low temperature. A series of pretreatment processes such as precipitation, oil removal, and pH adjustment required for liquid disposal.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

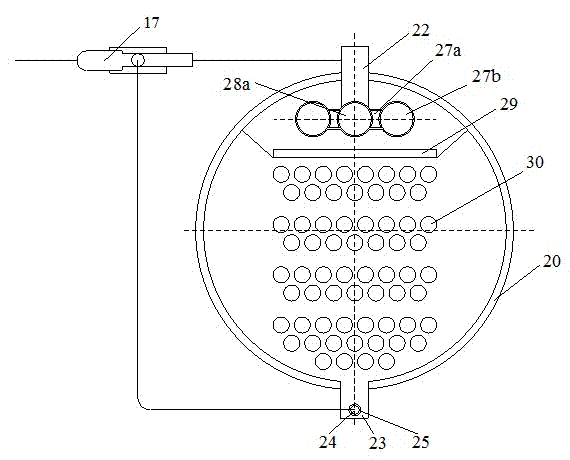

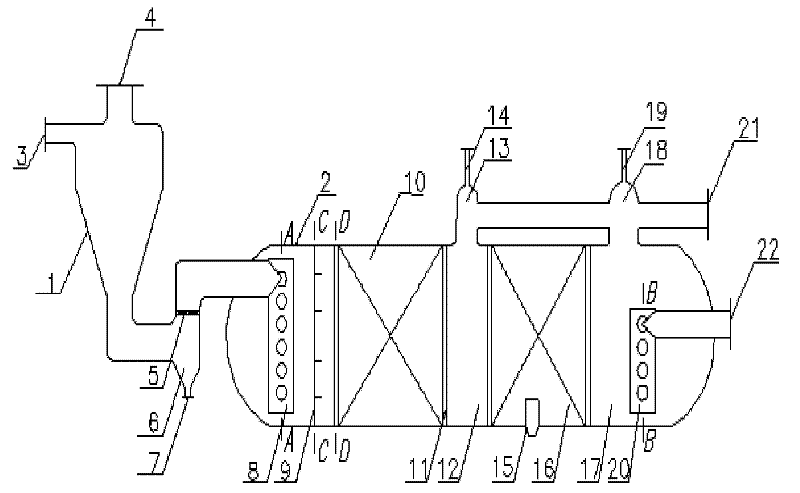

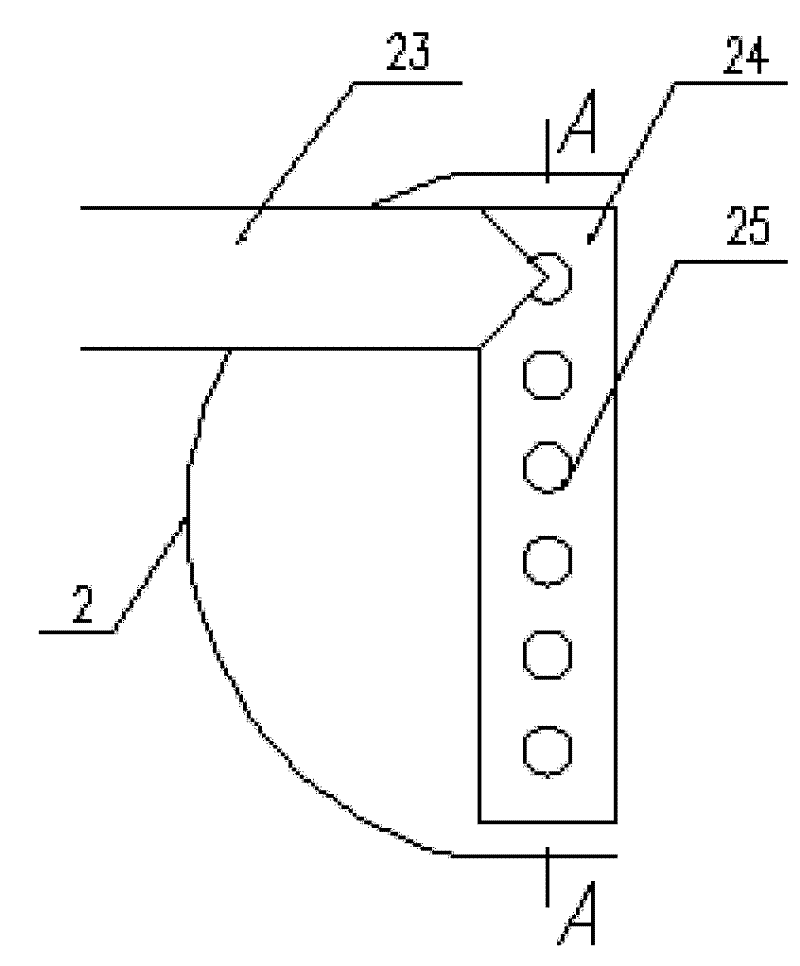

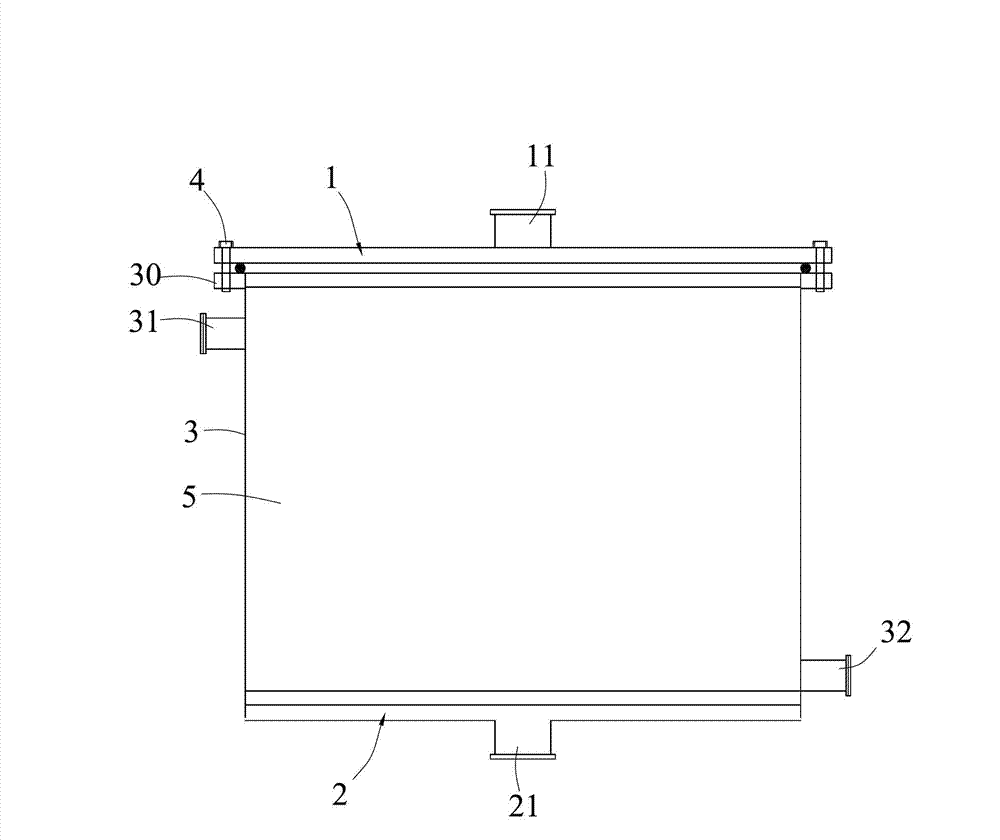

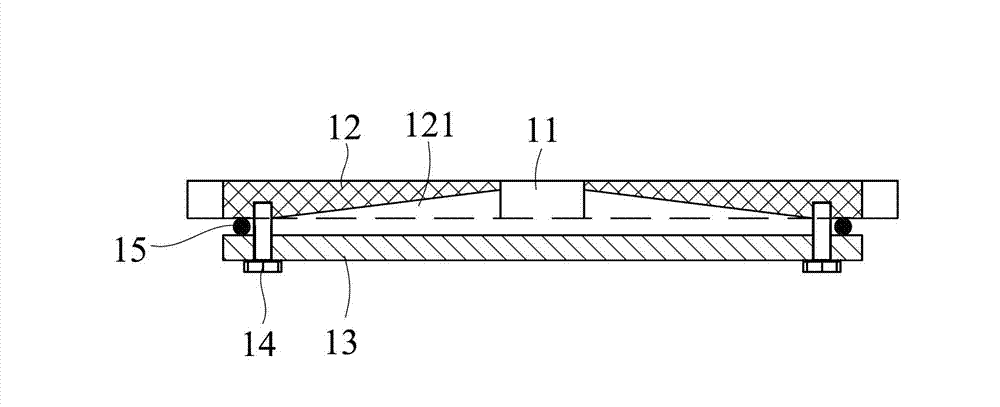

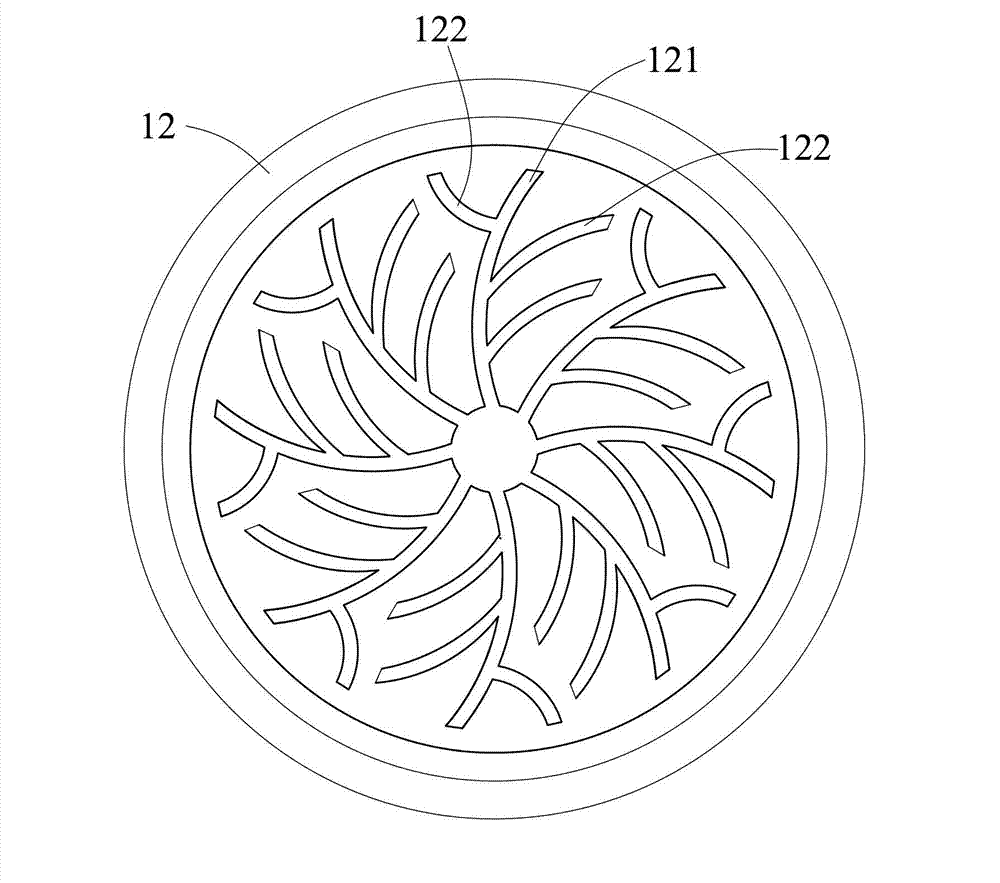

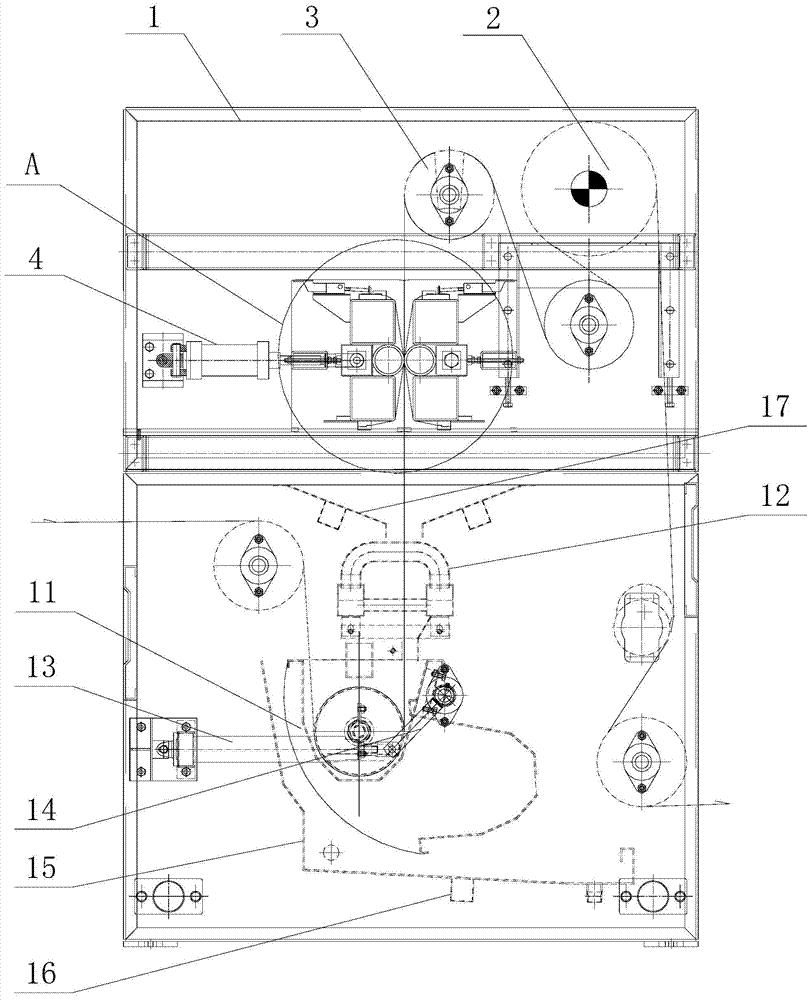

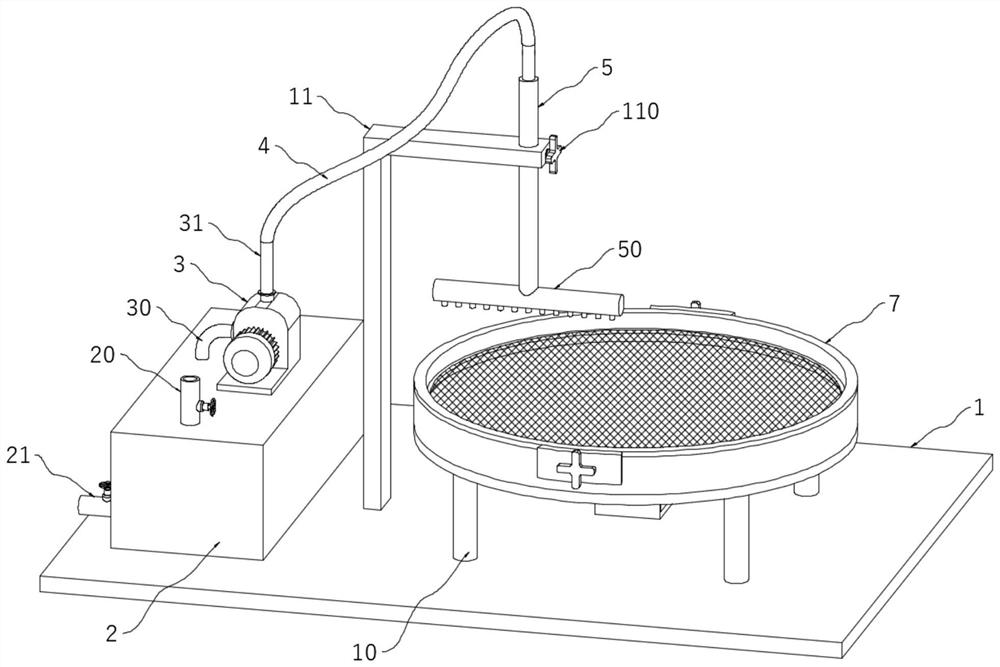

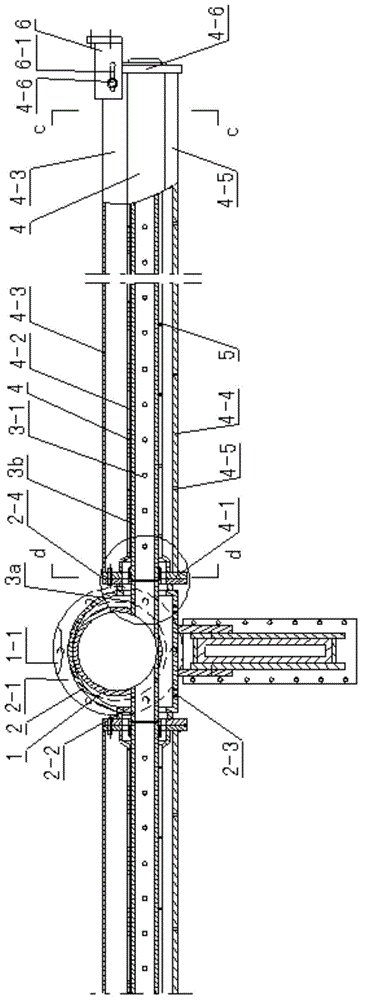

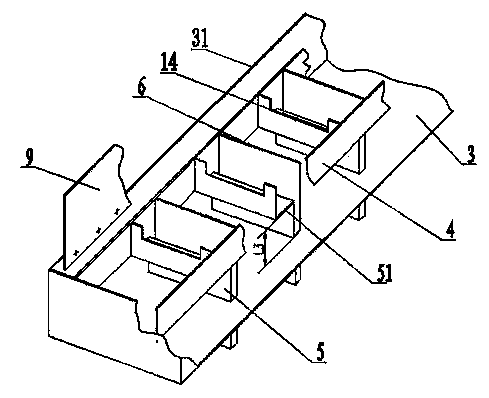

Integrated unit operating device for water treatment

ActiveCN103086473ACompact structureLiquid channel shortWater/sewage treatment by ion-exchangeWater/sewage treatment by sorptionWater treatment systemIon exchange

The invention discloses an integrated unit operating device for water treatment, belonging to the technical field of water treatment and solving the technical problems of complex structure, long liquid-flowing passage, nonuniform liquid distribution, short service life and high regeneration cost of the existing unit operating device. The integrated unit operating device comprises a tank body, wherein the tank body is sequentially provided with a liquid distribution device, a filler layer and a liquid-collecting device from top to bottom; the liquid distribution device comprises a liquid distribution trough plate and a liquid distribution filter plate; the liquid-collecting device comprises a liquid-collecting trough plate and a liquid-collecting filter plate; the liquid distribution trough plate is provided with a liquid inlet passage located in the center of the liquid distribution trough plate and a liquid distribution guiding trough extending from the liquid inlet passage to the edge of the liquid distribution trough plate; and the liquid-collecting trough plate is provided with a liquid outlet passage located in the center of the liquid-collecting trough plate and a liquid-collecting guiding trough extending from the liquid outlet passage to the edge of the liquid-collecting trough plate. The integrated unit operating device is applied to a water treatment system, such as water treatment equipment using an ion exchange and chromatographic technology.

Owner:浙江晶泉水处理设备有限公司

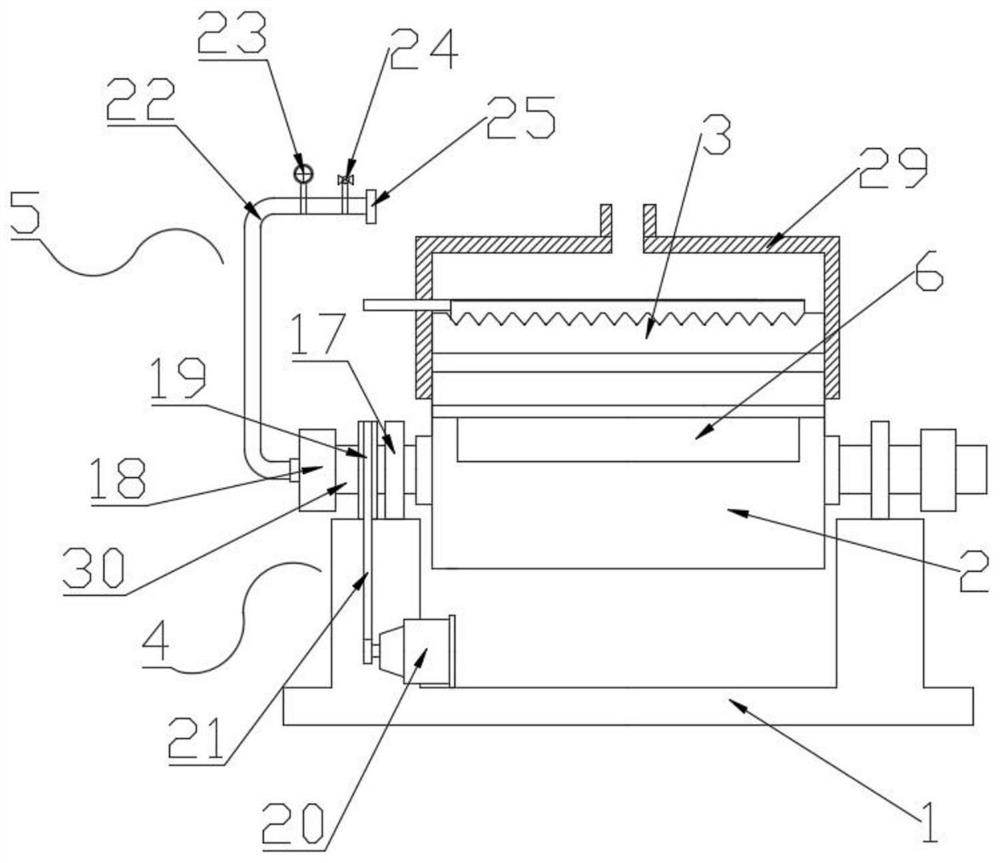

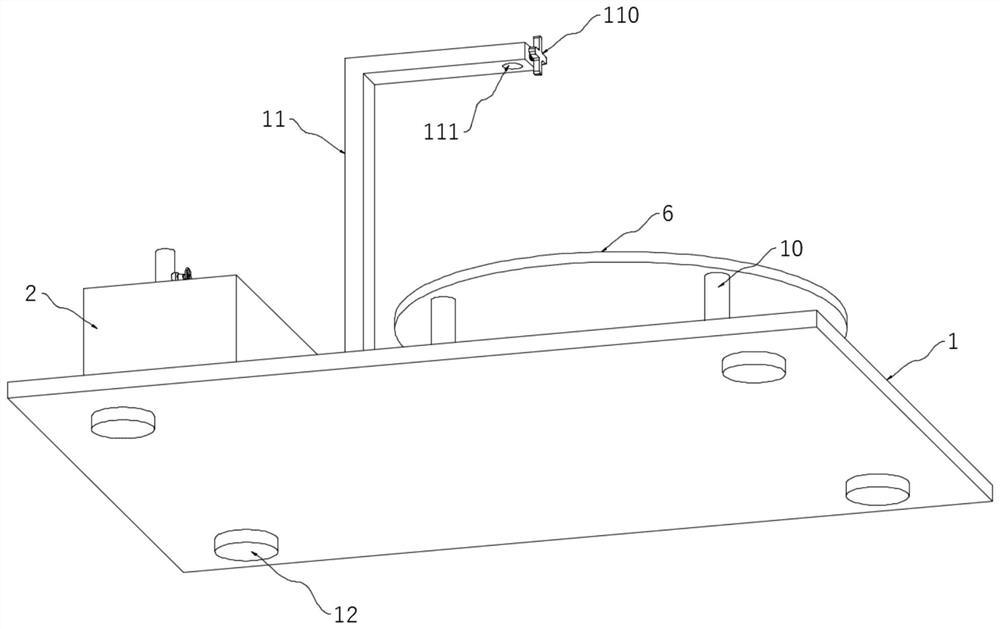

A high liquid feeding machine for cloth processing

The invention discloses a high liquid feeding machine for cloth processing, which comprises a horizontally arranged frame, inside the frame there are driving rollers and a plurality of driven rollers for feeding and guiding the cloth, and inside the frame are arranged There is a liquid scraping device, the liquid scraping device includes a first cylinder symmetrically arranged on both sides of the frame, a first support and a second support are symmetrically arranged at one end close to the telescopic end of the first cylinder, along the length direction of the first support There is a groove, and an inflatable air bag is arranged in the groove, and a stainless steel plate for wrapping the air bag is arranged on the first support, and the structure of the first support and the second support is exactly the same, wherein the first support and the second support The telescopic end of a cylinder is connected, the second support is fixed to the frame, and a scraping gap is formed between the first support and the stainless steel plate on the second support; the invention not only has compact structure, low cost, simple operation, and easy control of cloth The liquid volume is high, the equipment has high working efficiency and long service life, which greatly improves the quality of the product.

Owner:宜兴市华东印染机械厂

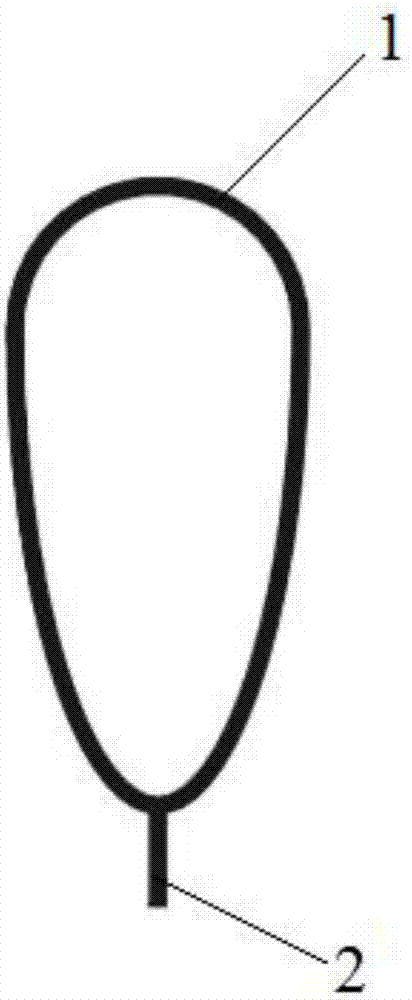

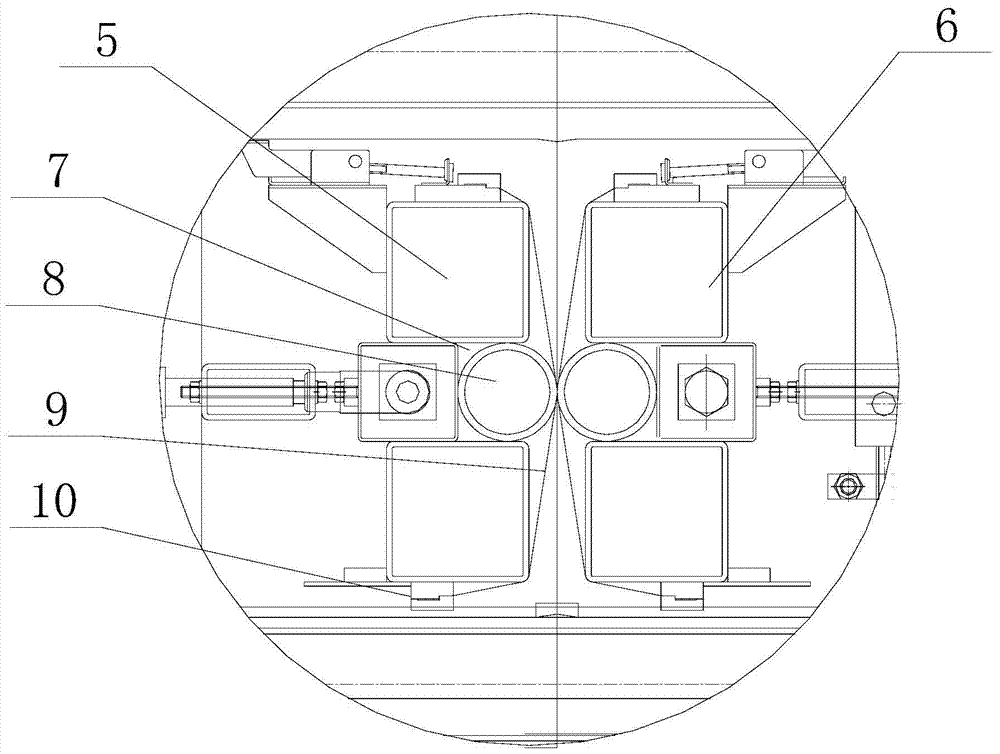

Subcutaneous tumor cell inoculation device capable of improving dispersity and use method thereof

PendingCN113105999AImprove dispersionAvoid accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringAnatomy

The invention relates to the technical field of cell inoculation devices, in particular to a subcutaneous tumor cell inoculation device capable of improving dispersity and a use method thereof. The subcutaneous tumor cell inoculation device comprises a fixed base, a liquid storage tank is arranged at the position, close to the left end, of the top of the fixed base, and an L-shaped fixed plate is arranged at the position, close to the right side of the liquid storage tank, of the top of the fixed base; a center pipe is movably connected to the position, close to the right end, of the top of a horizontal plate of the L-shaped fixing plate, four supporting columns distributed in an annular array are arranged at the position, close to the right end, of the top of the fixing base, a supporting plate is jointly supported by the top ends of the four supporting columns, a servo motor is arranged in the middle of the bottom of the supporting plate, and a carrier fixing mechanism is arranged on the top of the supporting plate. According to the subcutaneous tumor cell inoculation device capable of improving the dispersity, the reticulate carrier can be fixed through the carrier fixing mechanism, and the carrier fixing mechanism is driven by the servo motor to rotate at a constant speed, so that liquid can be uniformly distributed on the surface of the reticulate carrier, and the dispersity of inoculated cells is improved.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

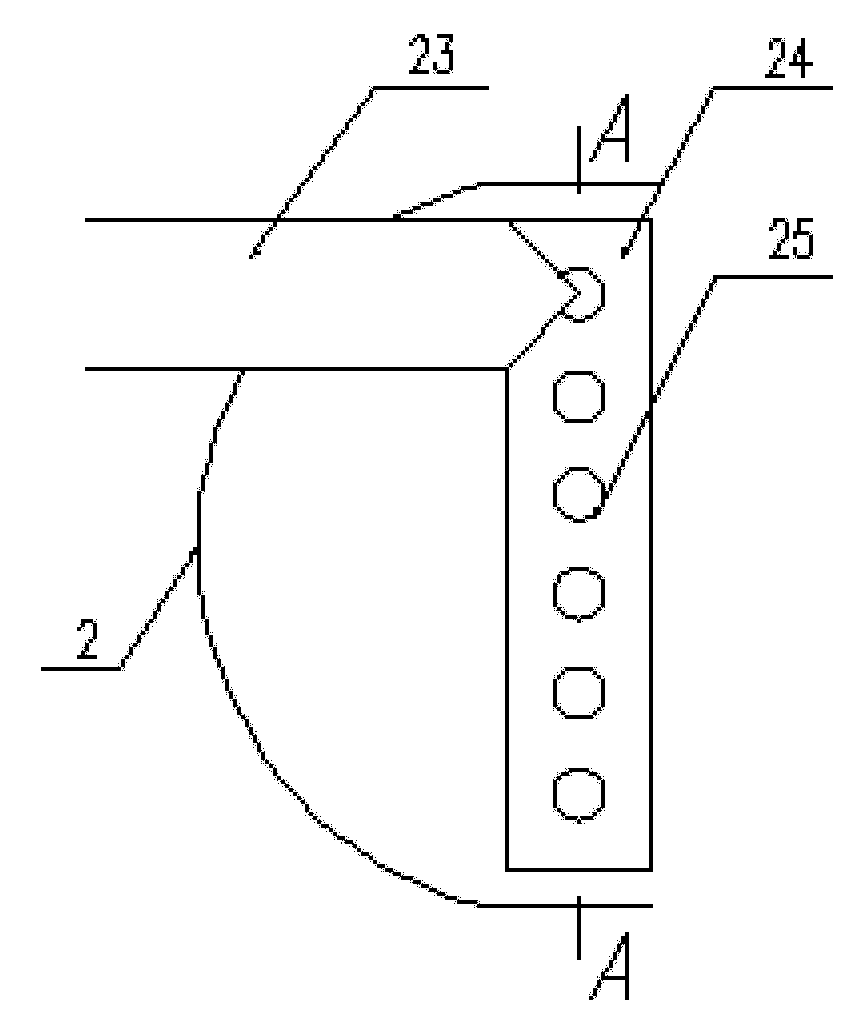

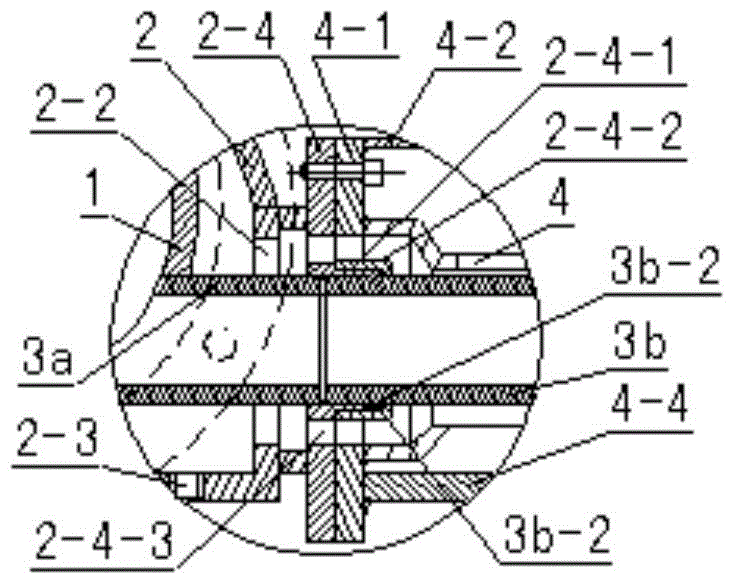

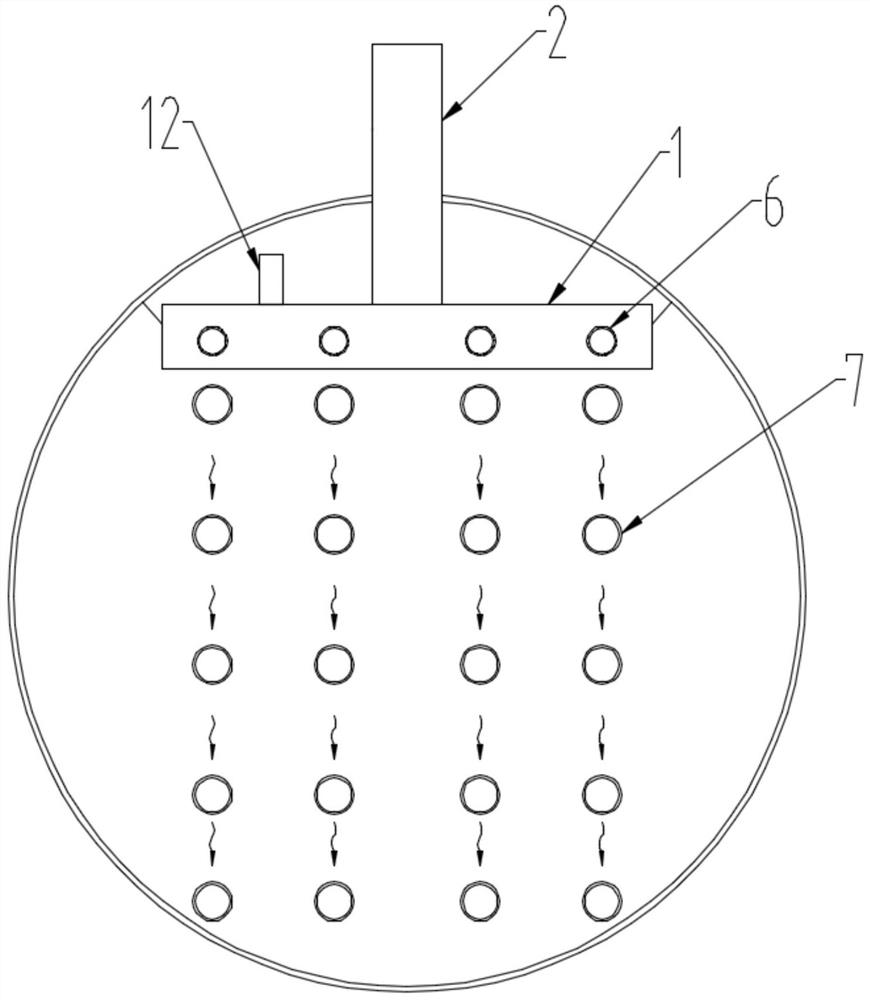

Composite tube liquid distribution device

ActiveCN103908936BMeet the requirements of steady-state flowAnti-deformationChemical/physical/physico-chemical processesEngineeringLiquid tank

Owner:TIANJIN UNIVTECH CO LTD

Methanol preparation equipment

InactiveCN107556159AReduce power consumptionReduce consumptionOrganic compound preparationHydroxy compound preparationFlame arresterReboiler

The invention discloses a methanol preparation equipment, comprising an incineration device, an absorption tower connected with the incineration device and a tail gas fan, a circulation pump and a reactor connected with the absorption tower, a configuration tank connected with the circulation pump, and a configuration tank The connected finished product tank, flame arresting filter, mixer, superheater installed on the mixer, tail gas heater, air fan, reboiler and methanol pump; the methanol pump and air fan are connected to the reboiler, and the tail gas The blower is connected to the tail gas heater, the reboiler and the tail gas heater are connected to the mixer; the superheater is connected to the reactor through a flame arresting filter. The invention adopts frequency conversion technology to reduce the power consumption of the fan, the system resistance is small, the operation cycle is long, the alcohol consumption is low, the reactor is evenly heated and has a long life, the cooling speed is fast, the occurrence of side reactions is greatly reduced, and the thermal load is controlled in sections. Improve absorption efficiency and reduce circulating water consumption.

Owner:天津市富宇精细化工有限公司

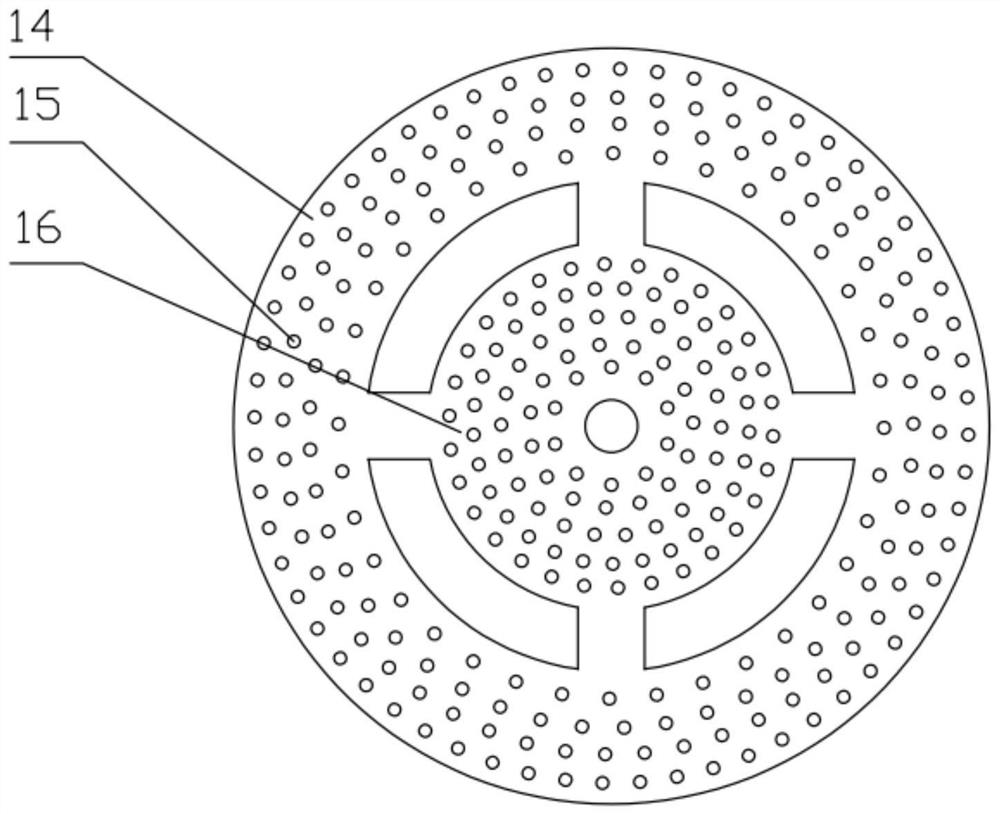

A liquid distributor of magnetic control composite material

ActiveCN112717832BAvoid backflow phenomenonAvoid blockageFeed devicesFiltrationMechanical engineering

The invention discloses a liquid distributor of magnetic control composite material. The liquid inlet chamber of the present invention is installed on the inner wall of the top of the cylinder; the slow flow filter chamber is connected to the bottom of the liquid inlet chamber; the liquid separation chamber is installed on the inner wall of the cylinder, and the liquid separation chamber has a liquid leakage hole; the liquid distribution chamber Connected with the liquid distribution chamber, fan-shaped areas are arranged inside the liquid distribution chamber, and drainage channels are formed between adjacent fan-shaped areas. At the same time, the fan-shaped areas divide the liquid distribution chamber into an inner ring road and an outer ring road. There is an external magnetic field device between the inner wall along the circumferential direction and the bottom of the cylinder. The slow flow filter chamber of the present invention has the effect of preliminary slow flow and filtration, and the liquid separation chamber has the effect of stabilizing the flow again, which improves the liquid distribution effect of the distributor. The specific situation determines whether deformation occurs, and realizes intelligent control while facilitating uniform distribution, and the invention is easy to install, reduces the cost of disassembly and assembly, and is convenient for operation and later repair.

Owner:ZHEJIANG UNIV OF TECH

Full overflow tank type liquid distributor

ActiveCN103028355BAvoid cloggingAvoid shockDispersed particle separationChemical/physical/physico-chemical processesBuffer tankEngineering

The invention discloses a full overflow tank type liquid distributor which comprises liquid distribution pipes, a buffer tank, a primary tank, liquid distribution boxes, secondary tanks, baffles, connecting plates, liquid receiving boxes and liquid guide plates, and is characterized in that the primary tank is internally provided with two longitudinal partitions parallel to two walls of the primary tank, and a designed quantity of transverse partitions; identical gaps are formed among the longitudinal partitions and the two side walls of the primary tank; the transverse partitions are arranged between the two longitudinal partitions and are perpendicular to the longitudinal partitions; a double right-angle folded plate is arranged between every two adjacent transverse partitions; each liquid distribution box combined by two wide-top and narrow-bottom rectangular cross sections is formed between each double right-angle folded plate and each transverse partition; a concave overflow port is formed at the upper edge of each double right-angle folded plate; the widths of the liquid distribution boxes and the buffer tank are identical; and liquid outflow modes of the primary tank and the secondary tanks are overflow modes, that is the outflow direction of liquid is opposite to the sedimentation directions of material granules.

Owner:天津市创举化工设备有限公司

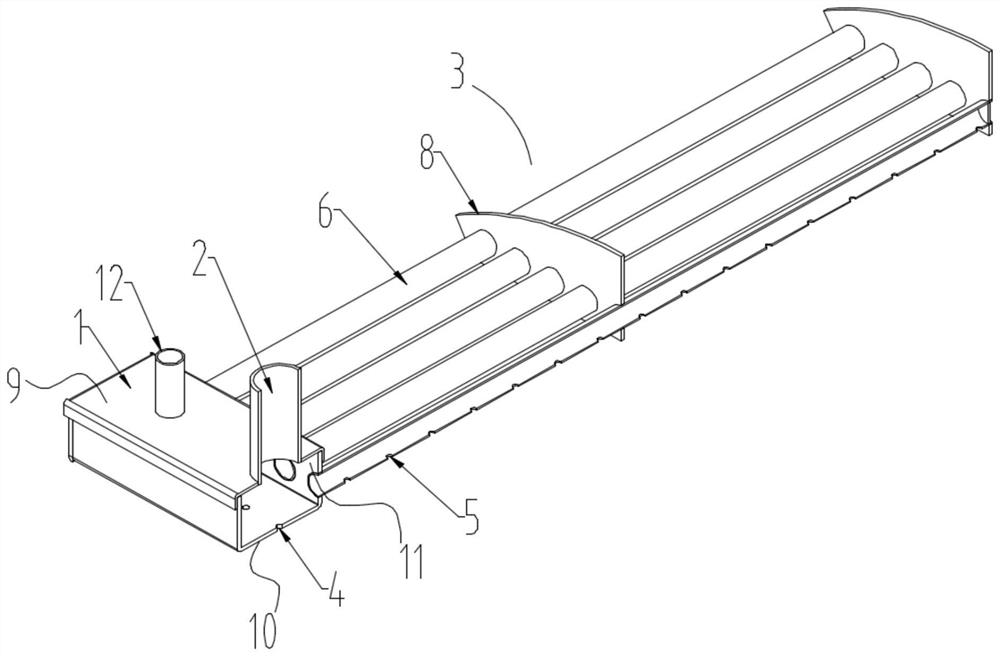

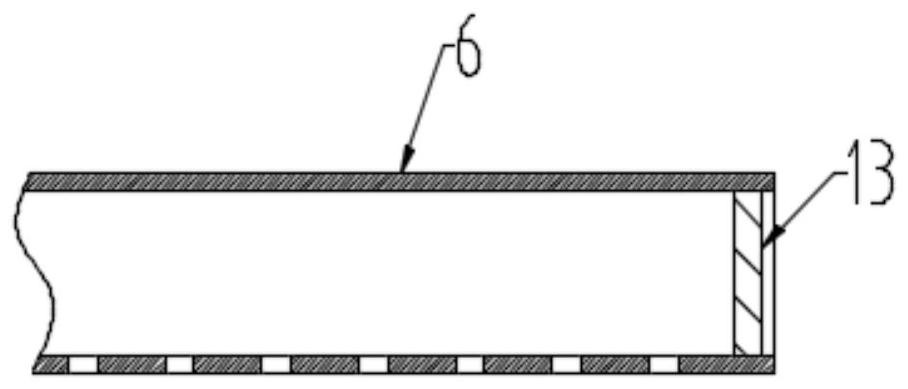

Liquid distributor and falling-film-type heat exchanger

PendingCN112097544AIncrease profitImprove heat transfer effectSpace heating and ventilation detailsStationary conduit assembliesLiquid stateEngineering

The invention provides a liquid distributor and a falling-film-type heat exchanger. The liquid distributor comprises two or more liquid distribution structures and a liquid inlet pipe; the two or moreliquid distribution structures mutually communicate; the liquid inlet pipe is arranged on one of the two or more liquid distribution structures, and a liquid refrigerant flows in through the liquid inlet pipe and then is shunted into other liquid distribution structures in the two or more liquid distribution structures; and other liquid distribution structures in the two or more liquid distribution structures are provided with liquid distribution holes, and the liquid distribution holes are configured to be able to distribute liquid to heat exchange tubes. According to the liquid distributor,the multi-cavity design is adopted, a high-flow-speed refrigerant only impacts the liquid level in the first liquid distribution structure, the liquid levels in the other liquid distribution structures are stable, the liquid distributor can uniformly distribute the liquid, the liquid is uniformly distributed on the surfaces of the heat exchange tubes, the utilization rate of the heat exchange tubes is high, and the heat exchange effect is good; and distribution pipes arranged at intervals in a multi-connection mode are adopted for liquid distribution, the circulation sectional area of a vaporrefrigerant is increased, the flow speed of the vapor refrigerant is reduced, and the vapor-liquid entrainment phenomenon is relieved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com