Open hole packer staged fracturing method for horizontal well

A staged fracturing and packer technology, applied to wellbore/well valve devices, sealing/isolation, wellbore/well components, etc., can solve problems such as increasing the risk of tool running and fracturing construction operations , to achieve the effects of reducing fracturing construction time, improving drainage efficiency, and increasing drainage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

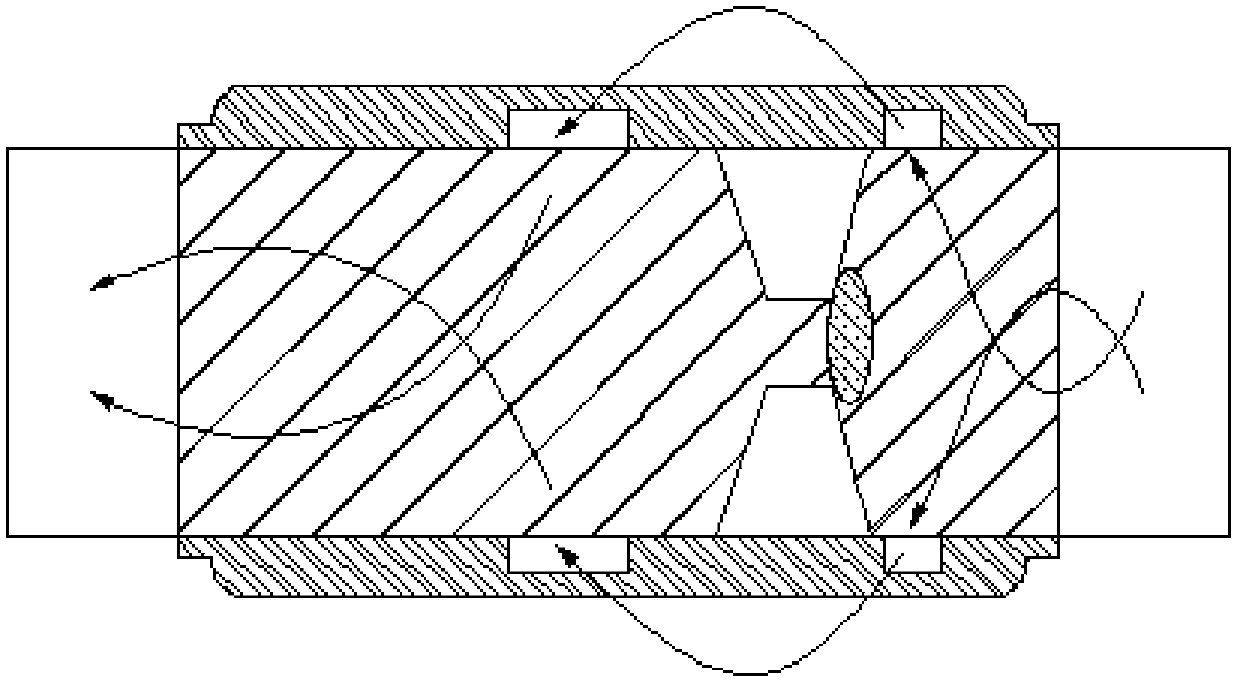

[0017] This embodiment provides a method for staged fracturing of an open-hole packer in a horizontal well, including the following steps:

[0018] Step 1: Wellbore preparation: adopt technical casing, scraping technical casing, and horizontal section to ensure that the hanging packer, open hole packer setting seal and fracturing sliding sleeve enter the well smoothly;

[0019] Step 2: Lowering the tool: Send the differential pressure sleeve, open hole packer, fracturing sleeve, suspension packer and back-insertion sleeve to the design position of the horizontal section with the drill pipe; An impact sliding sleeve is added between the separators;

[0020] The third step: throw the ball seat and seal the lost hand: set the open hole packer and hang the packer under different pressures to complete the lost hand;

[0021] Step 4: Tie-back: After the drill pipe is discarded, run the back-insertion string back-to-back to the back-insert, wellhead, and pressure test completion;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com