A high liquid feeding machine for cloth processing

A cloth and liquid machine technology, which is used in textile processing machine accessories, textile material processing, textiles and papermaking, etc., can solve the problems of difficult to control the amount of liquid in the cloth belt, easy to produce stains on rubber rollers, and large gap error between rubber rollers. To achieve the effect of convenient operation, increased use range, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

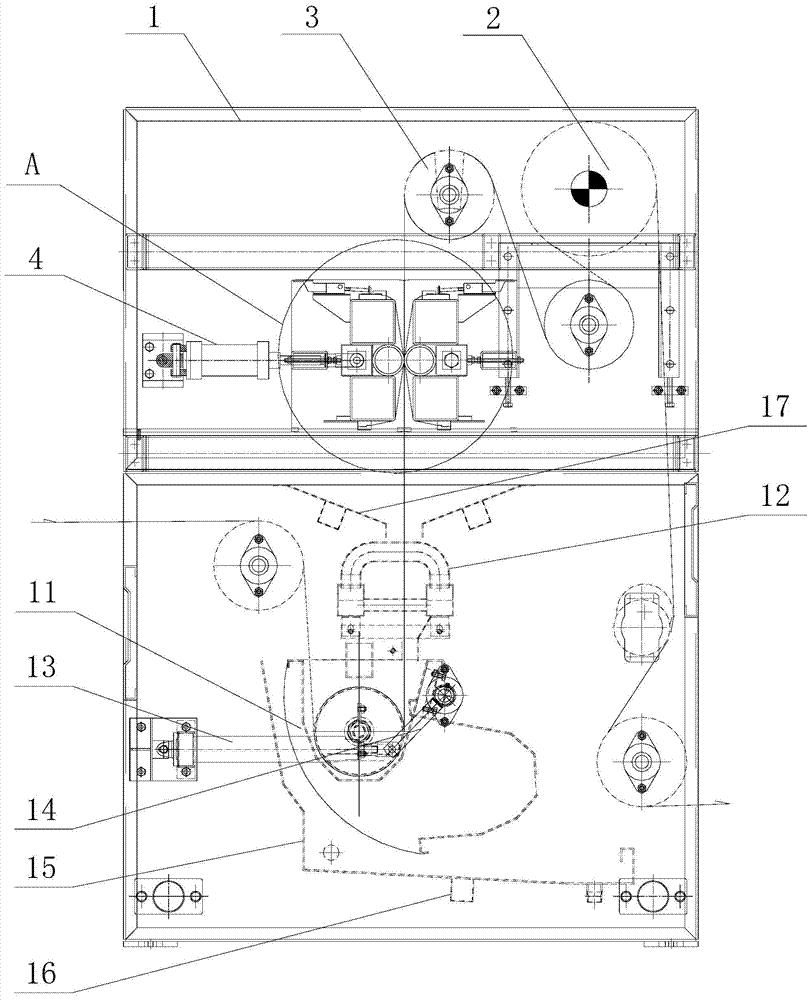

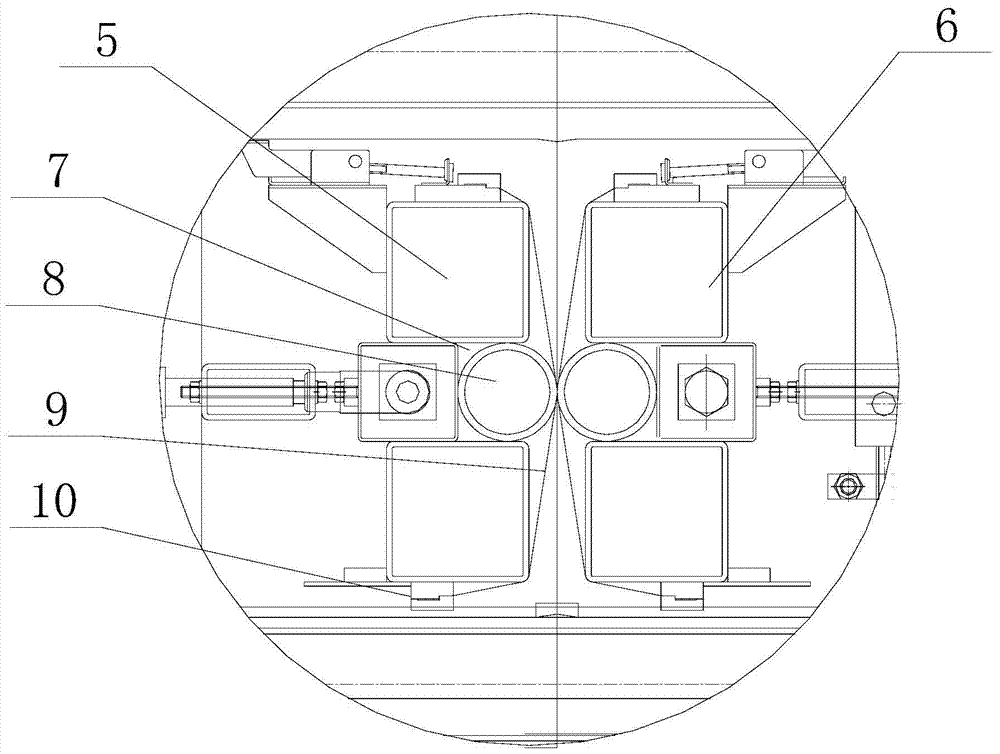

[0020] A high liquid feeding machine for cloth processing provided in this embodiment includes a horizontally arranged frame 1, and inside the frame 1 are provided a driving roller 2 and a plurality of driven rollers 3 for conveying and guiding the cloth. A liquid scraping device is provided inside the frame 1, and the liquid scraping device includes a first cylinder 4 symmetrically arranged on both sides of the frame 1, and a first support 5 and a second support 6 are symmetrically provided at one end close to the telescopic end of the first cylinder 4, A groove 7 is provided along the length direction of the first support 5, an inflatable air bag 8 is arranged in the groove 7, a stainless steel plate 9 for wrapping the air bag 8 is provided at the first support 5, and the first support 5 and the The structure of the second support 6 is exactly the same, wherein the first support 5 is connected with the telescopic end of the first cylinder 4, the second support 6 is fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com