Air source falling film water chiller-heater unit

A cold and hot water unit, falling film technology, applied in the direction of refrigerators, refrigeration components, compressors, etc., can solve the problem of not being able to give a schematic diagram of the flow chart of the heat pump air conditioning system, the design of the refrigerant inlet position is unreasonable, and the liquid distribution is not considered Avoid problems such as adverse consequences of the device, and achieve the effects of avoiding liquid distribution interference, simple structure, and avoiding frequent impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

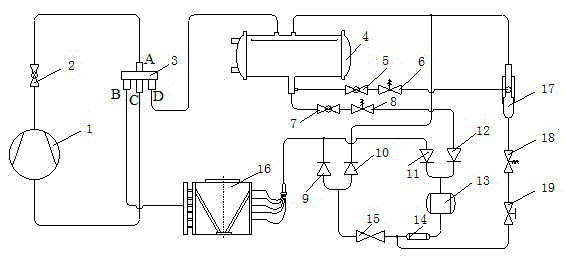

[0032] Such as figure 1As shown, an air source falling film chiller and hot water unit includes: a compressor 1, a four-way valve 3, a falling film heat exchanger 4, a liquid receiver 13, a dryer 14, an expansion valve 15, and an outdoor fin Heat exchanger 16, ejector 17, compressor 1, falling film heat exchanger 4 and outdoor fin heat exchanger 16 are all connected to four-way valve 3, and falling film heat exchanger 4 is also connected to liquid reservoir 13. The ejector 17 is connected, the liquid reservoir 13 is connected with the dryer 14, the ejector 17 is connected with the dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com