Composite tube liquid distribution device

A liquid distribution device, tubular technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, chemical/physical processes, etc. The effect of anti-deformation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

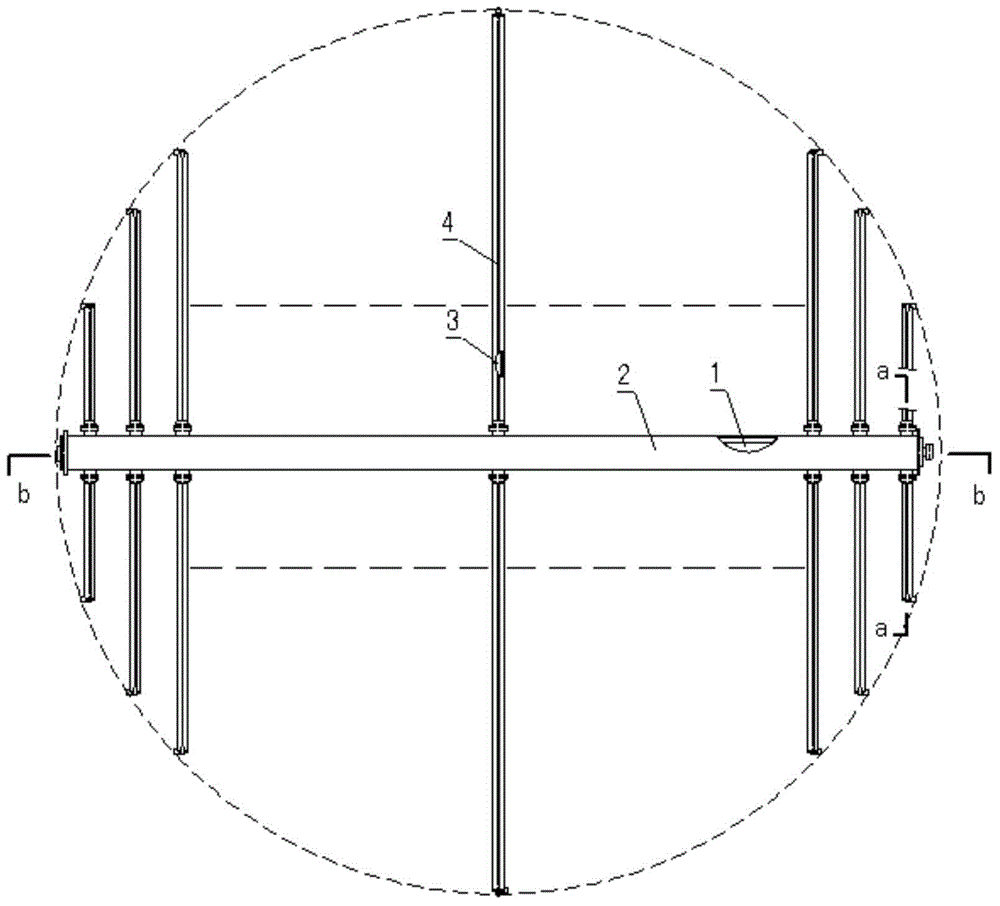

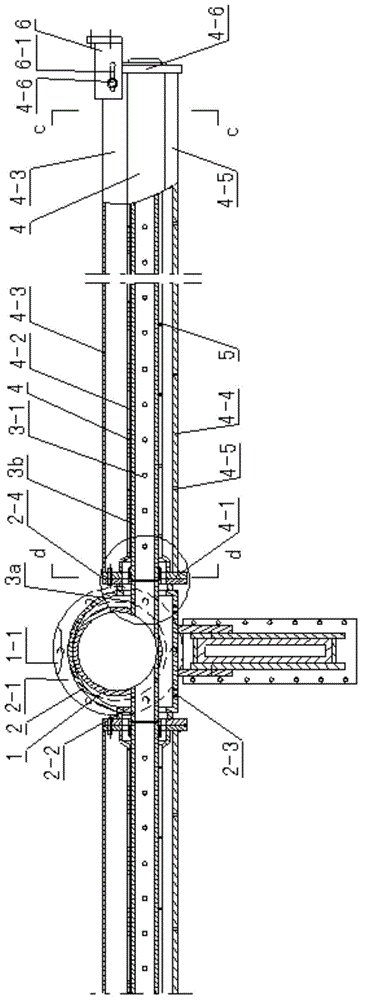

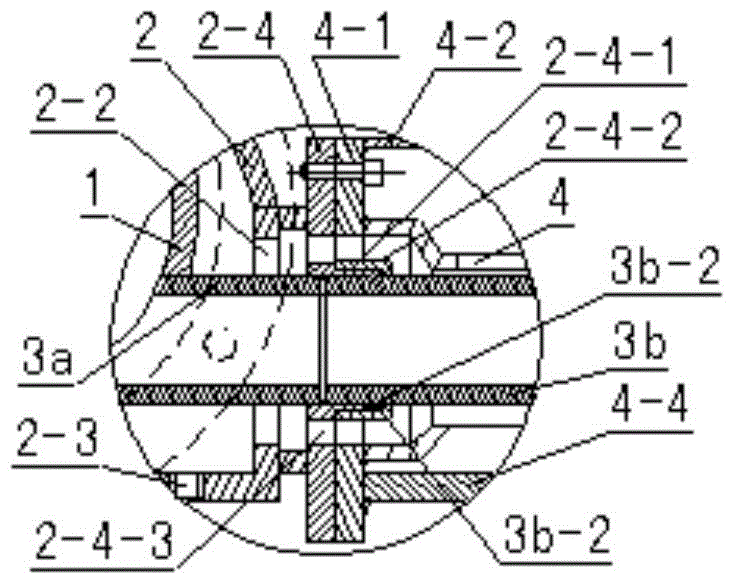

[0026] like figure 1 , 2 , 3, the embodiment shown in 4, is the composite pipe type liquid distribution device that is configured in the packed tower of nominal size tower diameter 12.5 meters, and embodiment comprises feed pipe 1 in the prior art and is respectively connected to feed pipe pipe There are parallel liquid distribution pipes on both sides of the body, the feed end of the feed pipe 1 is provided with a connecting flange 1-1, and the other end is provided with a blocking flange 1-2.

[0027] The feeding pipe 1 of the embodiment is equipped with a connecting pipe 2, and the two ends of the connecting pipe 2 are respectively provided with a connecting flange 1-1 and a sealing flange 1-2 corresponding to the welding connection with the feeding pipe, and the connecting pipe plane The bottom is provided with communicating pipe liquid distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com