Micro-carbonized floor board

A floor and carbonization technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of moisture resistance, stability, moth resistance, poor anti-corrosion performance, floor deformation, floor insects, etc., to reduce hydrophilic performance, Improved moisture resistance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

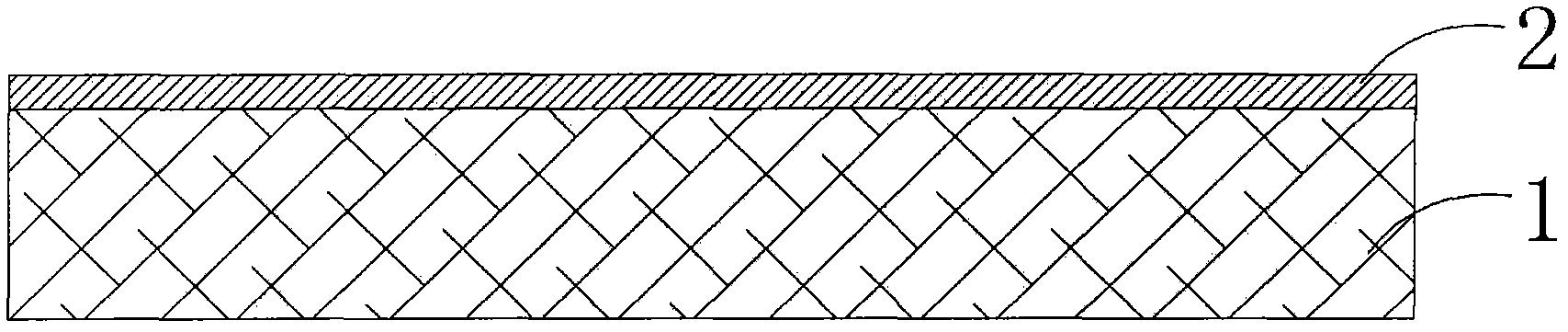

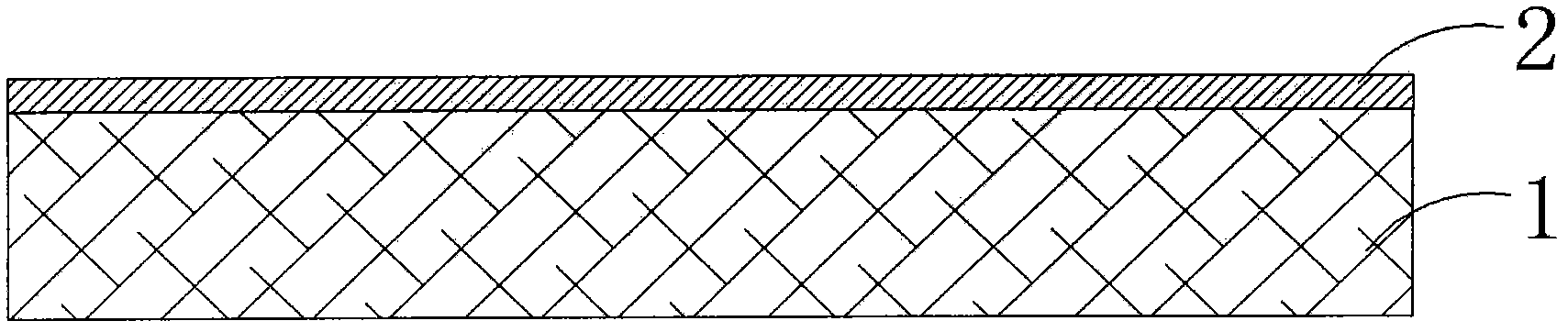

[0017] Examples, see attached figure 1 ; A micro-carbonized floor, including a floor body with a carbonized layer on the upper surface of the floor body.

[0018] The floor body is rectangular.

[0019] The carbonization layer is formed by deep carbonization of the surface of the plate at high temperature. Deep carbonization is carried out on the surface of the plate by high temperature to achieve the purpose of improving product performance and improving product stability.

[0020] The technological process of the present invention is as follows: first, the floor is planed; then, in a specific environment, the floor is subjected to a high-temperature carbonization process of about 200°, and only water vapor and high temperature are involved in the treatment process, without injecting any other chemical raw materials.

[0021] Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com