Patents

Literature

420results about "Wood damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Wood drying method

InactiveCN101236048ADrying using combination processesDrying solid materials without heatPulp and paper industryEquilibrium moisture content

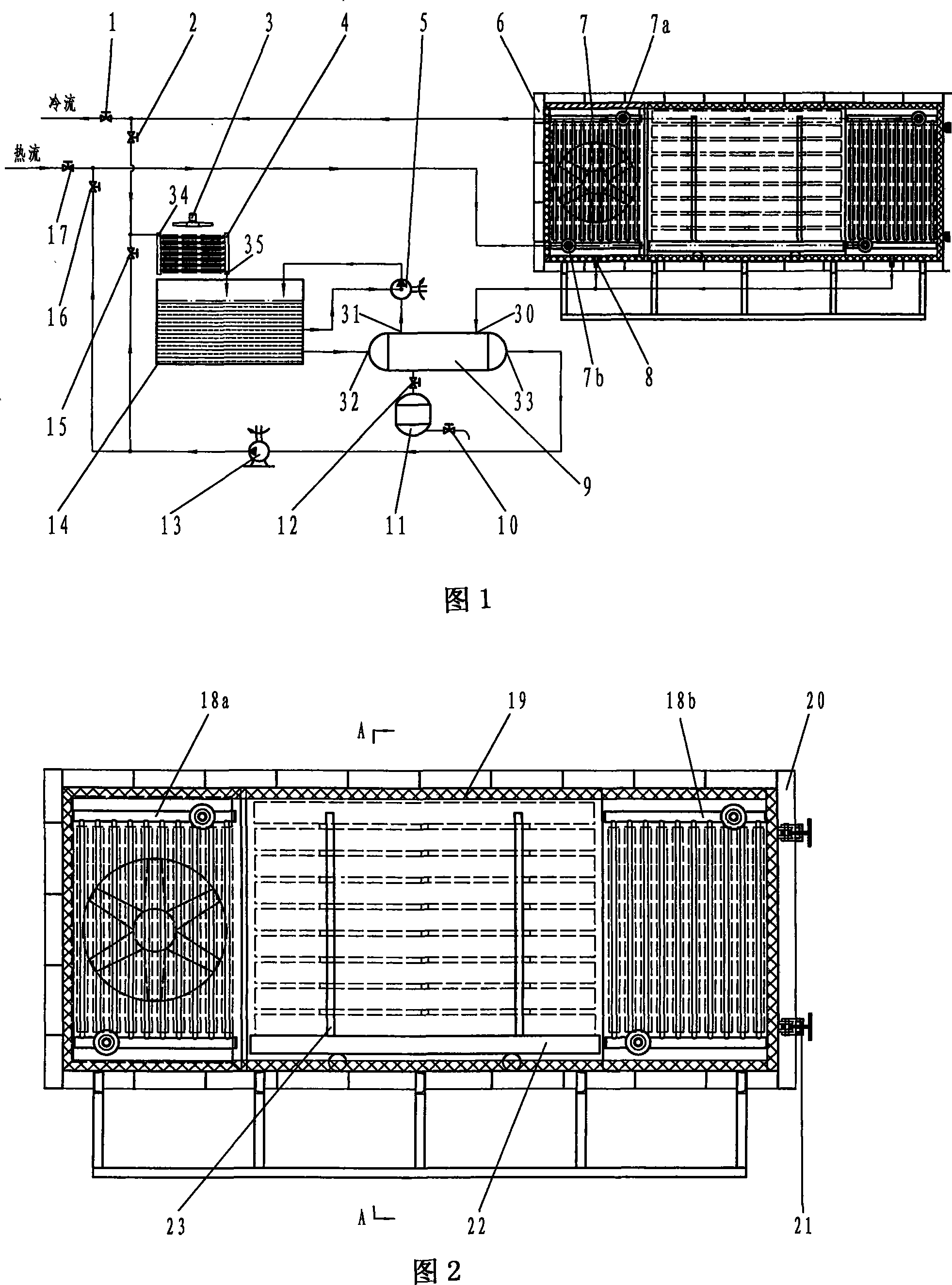

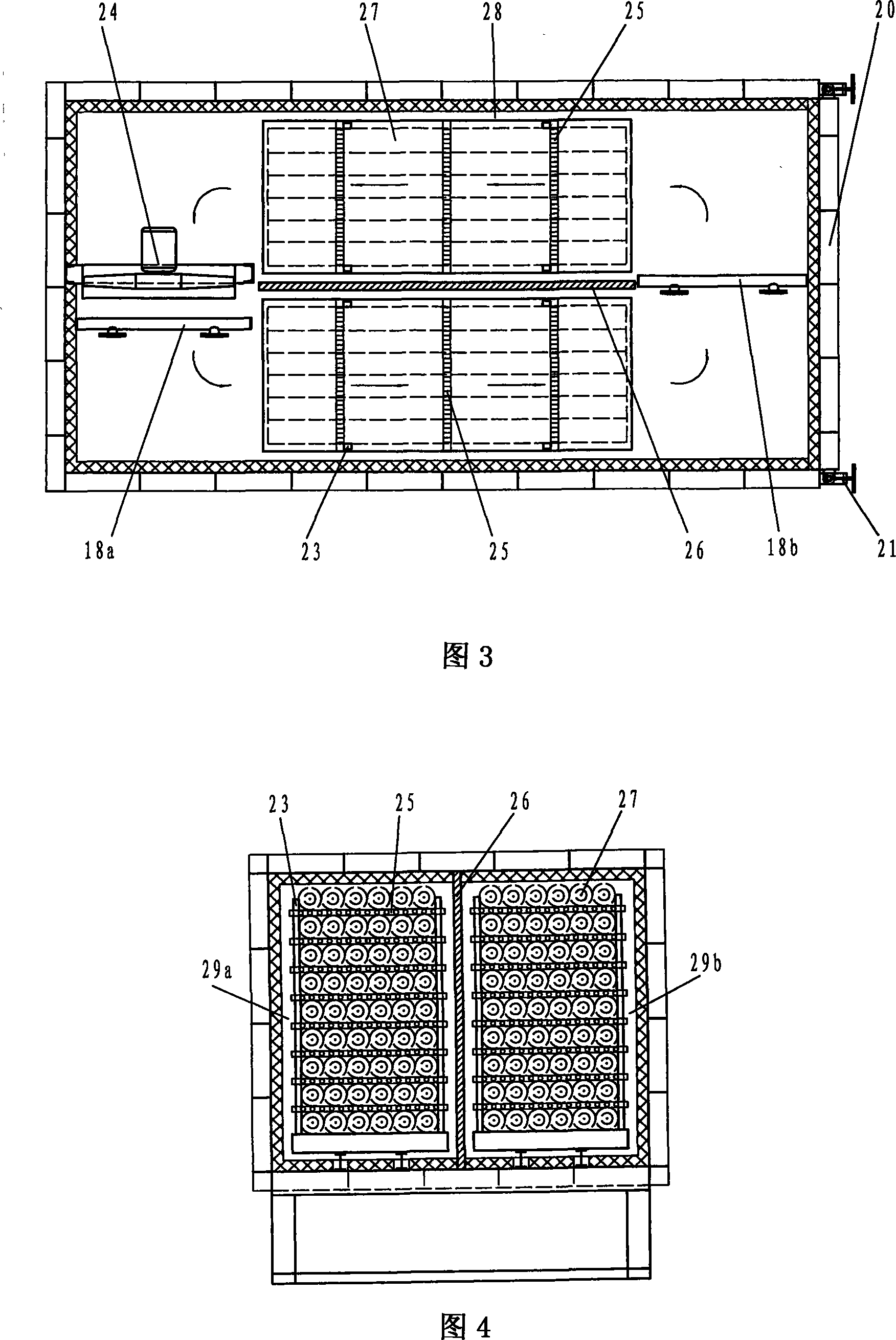

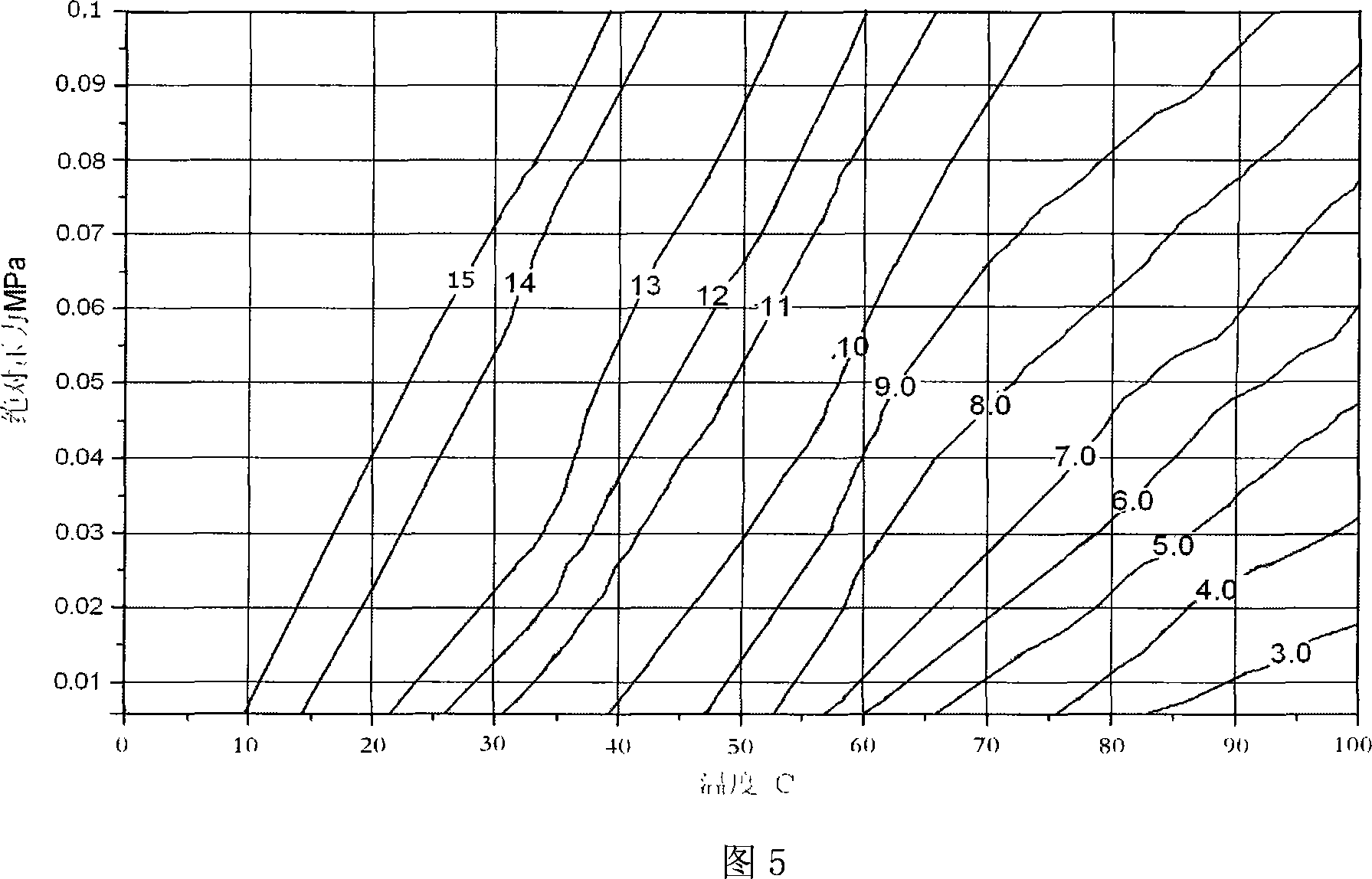

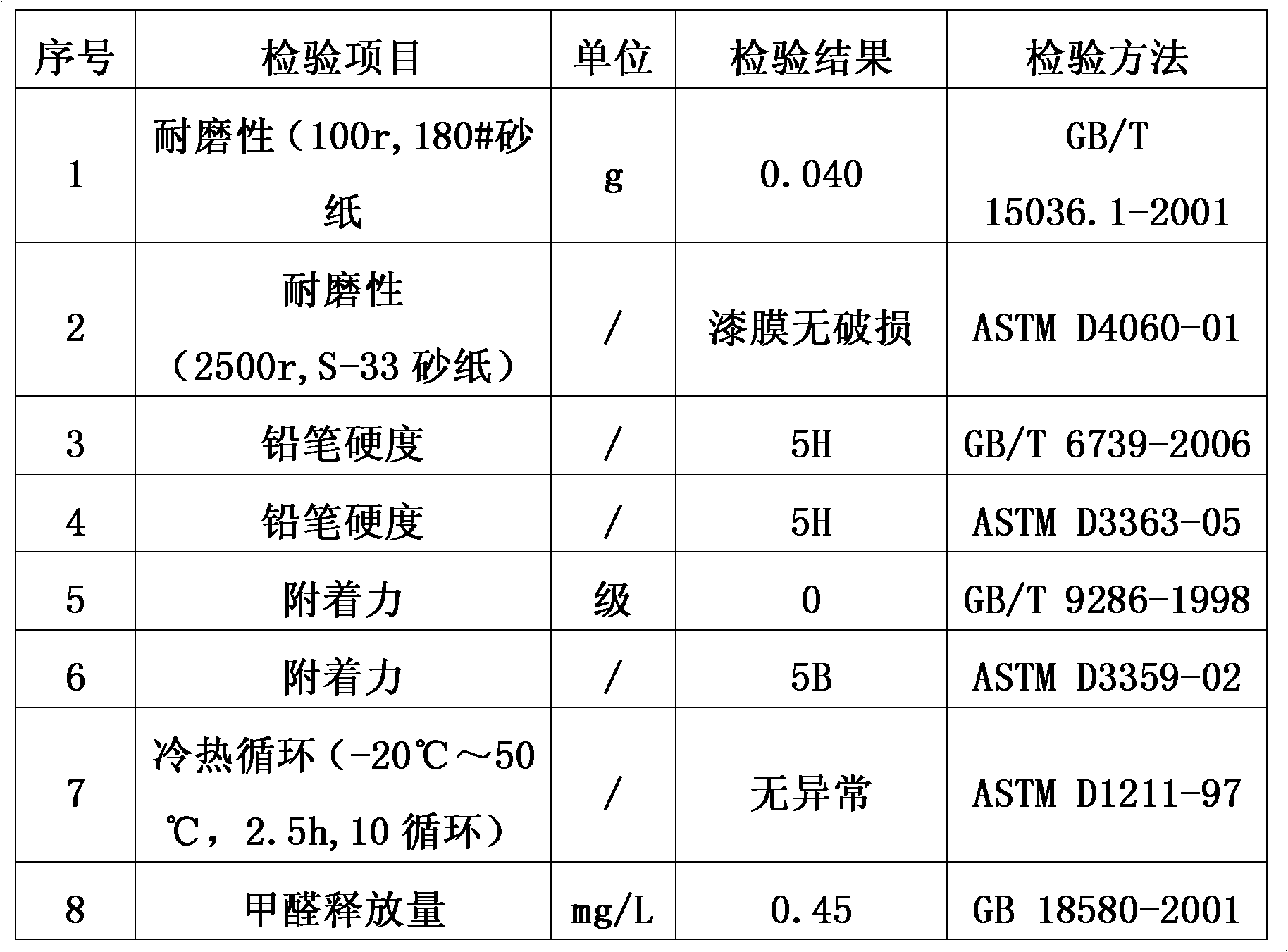

The invention discloses a method of log vacuum drying, which is adaptable to drying process of logs with minor diameter. The method comprises carrying out reheating to-be-dried wood, then keeping the reheating to-be-dried wood under vacuum circumstance, enabling drying media to flow along the longitudinal direction of the to-be-heated wood, controlling the temperature and value of absolute pressure according to corresponding graphs of previously determined medium temperature, the absolute pressure and equilibrium moisture content, charging cooling water in a heat exchange system when the final moisture content of the wood meeting the qualification and thereby realizing rapidly cooling and discharging, wherein the to-be-dried wood is log with minor diameter or plates and the ratio of the length of the to-be-dried wood and the average diameter or thickness is 5-15. The method of the invention enables the wood to be uniformly heated, and obviously shortens the time for the procedures of preheating the wood and drying, thereby largely increasing the production efficiency of drying the wood.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY +1

Method for producing high-emulation three-dimensional (3D) wood floor and high-emulation 3D wood floor

ActiveCN101885200AThree-dimensionalUnique wood grain printing effectWood treatment detailsWood dampingPulp and paper industrySubstrate surface

The invention discloses a method for producing a high-emulation 3D wood floor and the high-emulation 3D wood floor. The method comprises the following steps of: processing the surface of a base material to form a convex-concave three-dimensional surface; transferring wood grain on a rubber covered roller by using a steel roller with the wood grain, printing the wood grain on a substrate for 2 to 3 times by using the rubber covered roller, and coating finish on the substrate surface for 1 to 2 times; and printing the wood grain on the substrate for 2 to 3 times; and finally, coating finish on the substrate surface for 2 to 5 times. The wood floor produced by the method has high-emulation 3D wood grain layering and visual effects; the wood grain is clear and very vivid; and the produced floor voids repeated wood grain and has a good footfeel and the smooth and soft surface.

Owner:ZHEJIANG SHIYOU TIMBER

High temperature water heat processing method for timber

ActiveCN1876343AImprove water absorptionSmall water absorptionWood treatment detailsWood dampingMetallurgyIncrease size

Owner:HUNAN TAOHUAJIANG BAMBOO SCI & TECH CO LTD

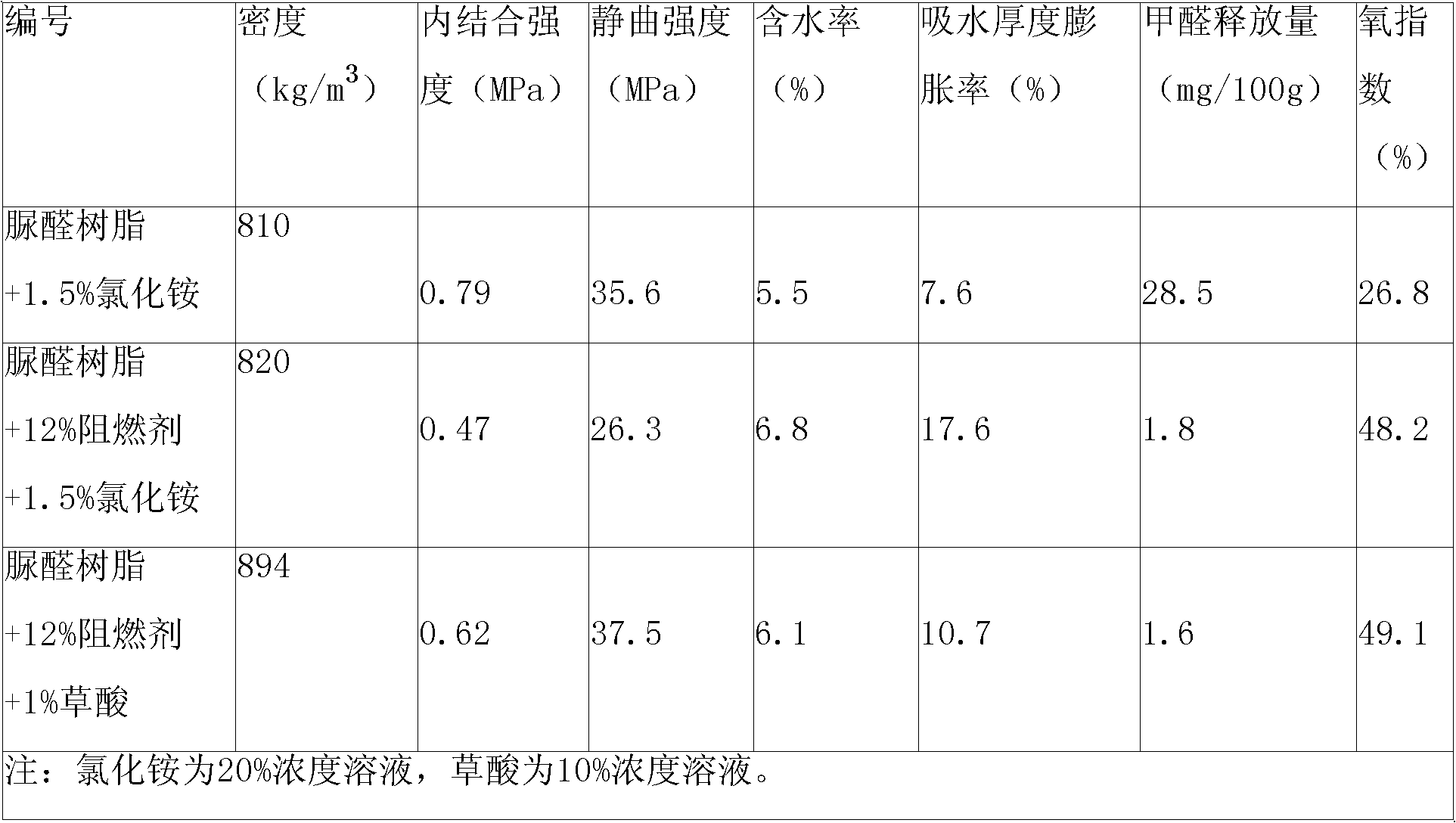

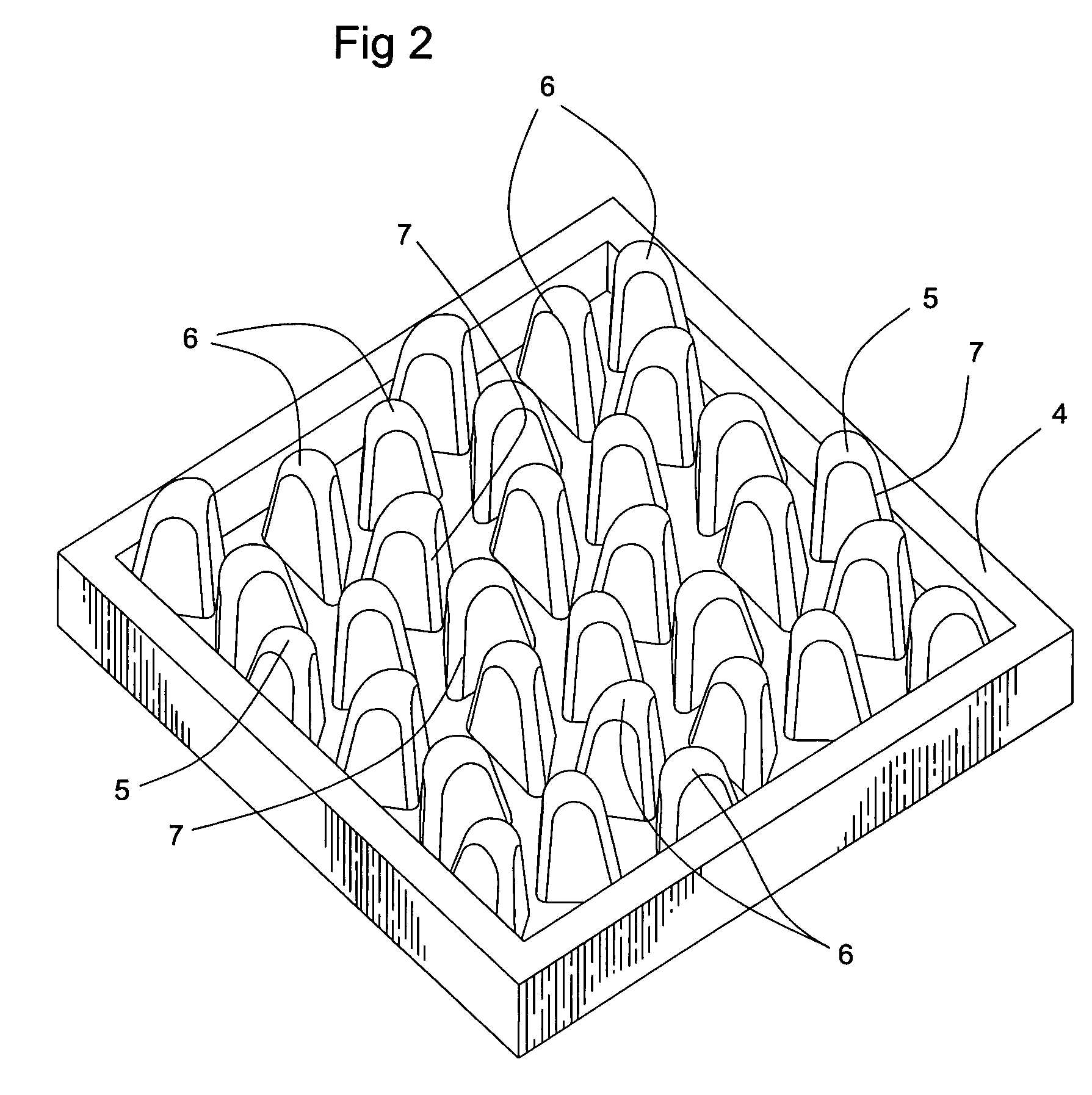

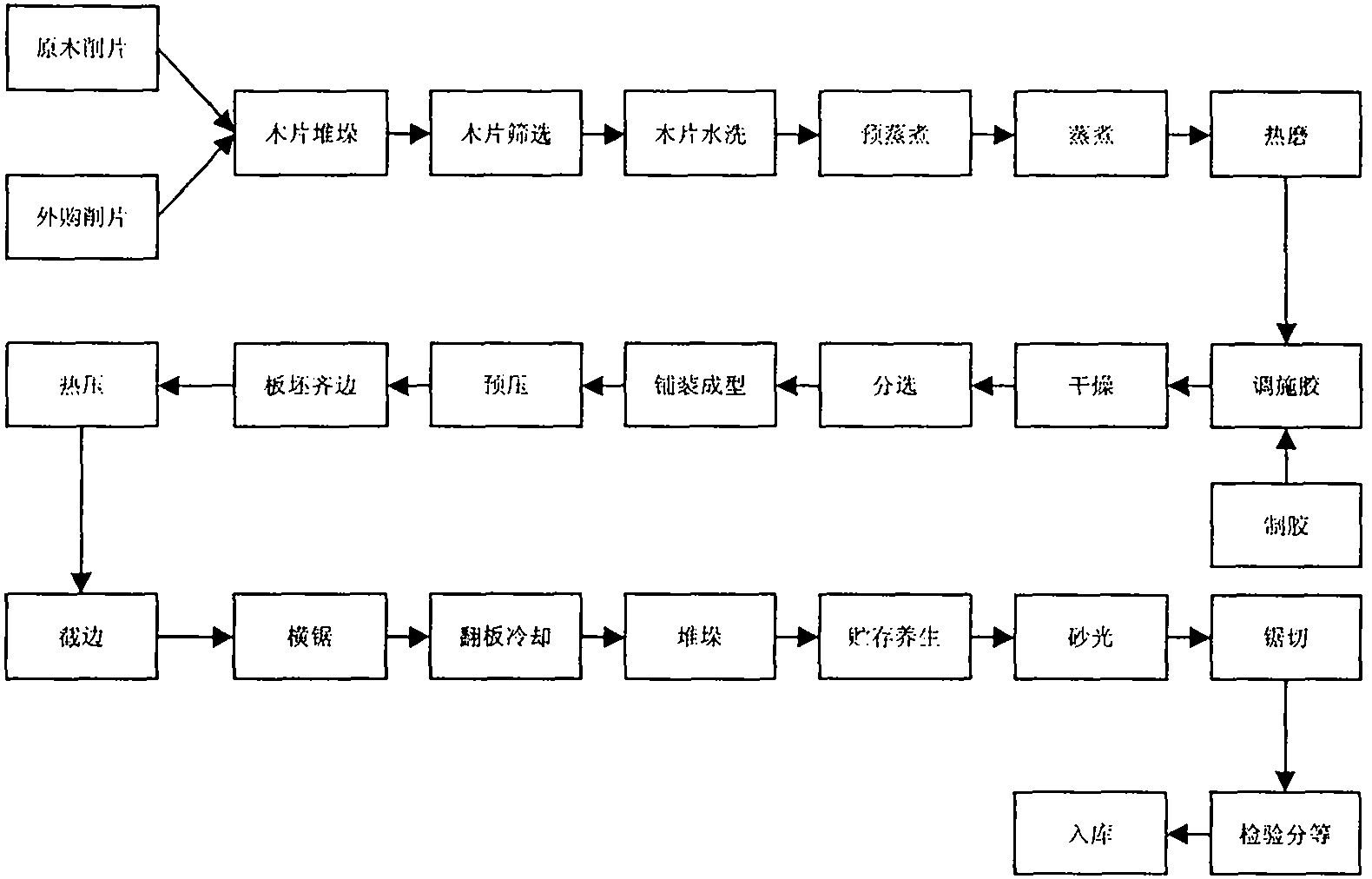

Manufacturing method of environment-friendly antiflaming middle and high density fiberboard

The invention relates to a manufacturing method of an environment-friendly antiflaming middle and high density fibreboard, solving the problem of high fibreboard production cost and poor fire resistance and environmental protection in the prior art. The invention comprises the following technical steps: hot grinding wooden or non-wooden materials into fibre; applying expansion N-P fire retardant of which the solid content is 35-60% and the pH value is 7-8 for fire retardant treatment, wherein the application amount of the fire retardant accounts for 10-15 wt% of absolute dry fibre; applying urea resin, waterproof agent and curing agent, wherein the urea resin application amount accounts for 10-14 wt% of the absolute dry fibre, the waterproof agent application amount accounts for 1-3 wt% of the absolute dry fibre, and the curing agent application amount accounts for 0.5-2 wt% of urea resin; then, drying, paving, prepressing, hot-pressing, cutting edges, sanding, separating and the like to obtain the fibreboard after inspection. The invention has simple production technology and low cost, the fibreboard not only has favorable physical-mechanical property but also has antiflaming and environment-friendly characteristics.

Owner:ZHEJIANG FORESTRY ACAD

Wood heat treatment method

ActiveCN101224593AReduce defects such as crackingReduce the degree of strength lossWood dampingOxygen contentEqualization

The invention provides a thermal processing method of timber and belongs to the technical field of the heat treatment of timber. The specific procedures are: (1) the timber is placed in a heat treatment chamber by yard; (2) the temperature and oxygen content of the first stage are set, namely, the temperature is 80-150 DEG C and the oxygen content is 12-21%, the treatment time maintains 0.5-1.5 hours for each centimeter thickness of the timber; (3) the temperature and oxygen content of the second stage are set, namely, the temperature is 150-200 DEG C and the oxygen content is 6-12%, the treatment time maintains 0.5-2 hours for each centimeter thickness of the timber;(4) the temperature and oxygen content of the third stage are set, namely, the temperature is180-260 DEG C and the oxygen content is 2-6%, the treatment time maintains 1.5-2 hours for each centimeter thickness of the timber; (5) the fourth stage is a cooling and equalization treatment stage, the indoor temperature is lowered to less than 100 DEG C, then equalization treatment on the water ratio of the timber is carried out in the way of spray-steaming, then the temperature is lowered to 40-50 DEG C after the water ratio of timber meets the product requirement, and the treated timber is taken out. The method can prominently reduce the problems of the prior art that the strength loss is serious with a great deal of defects.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

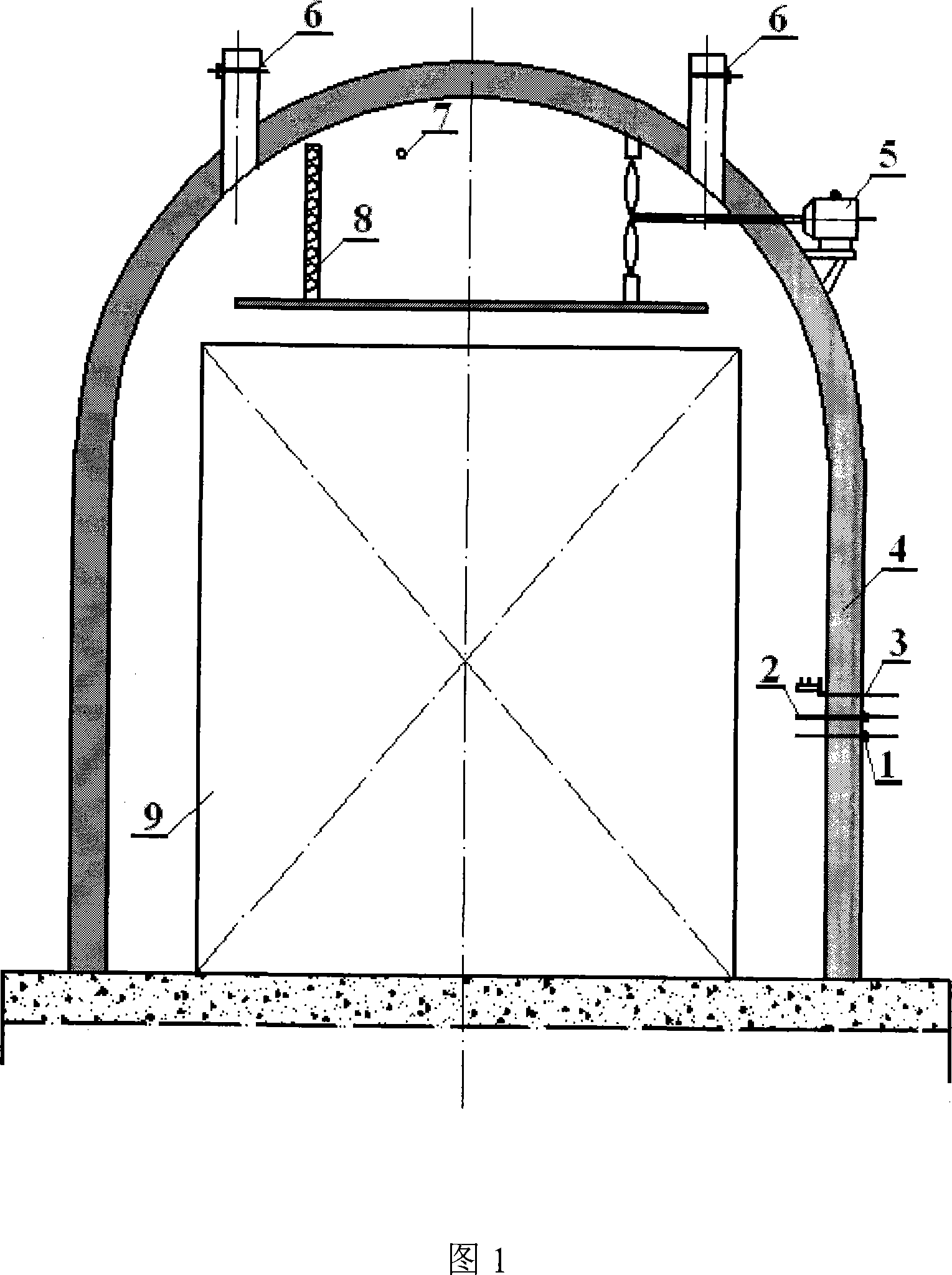

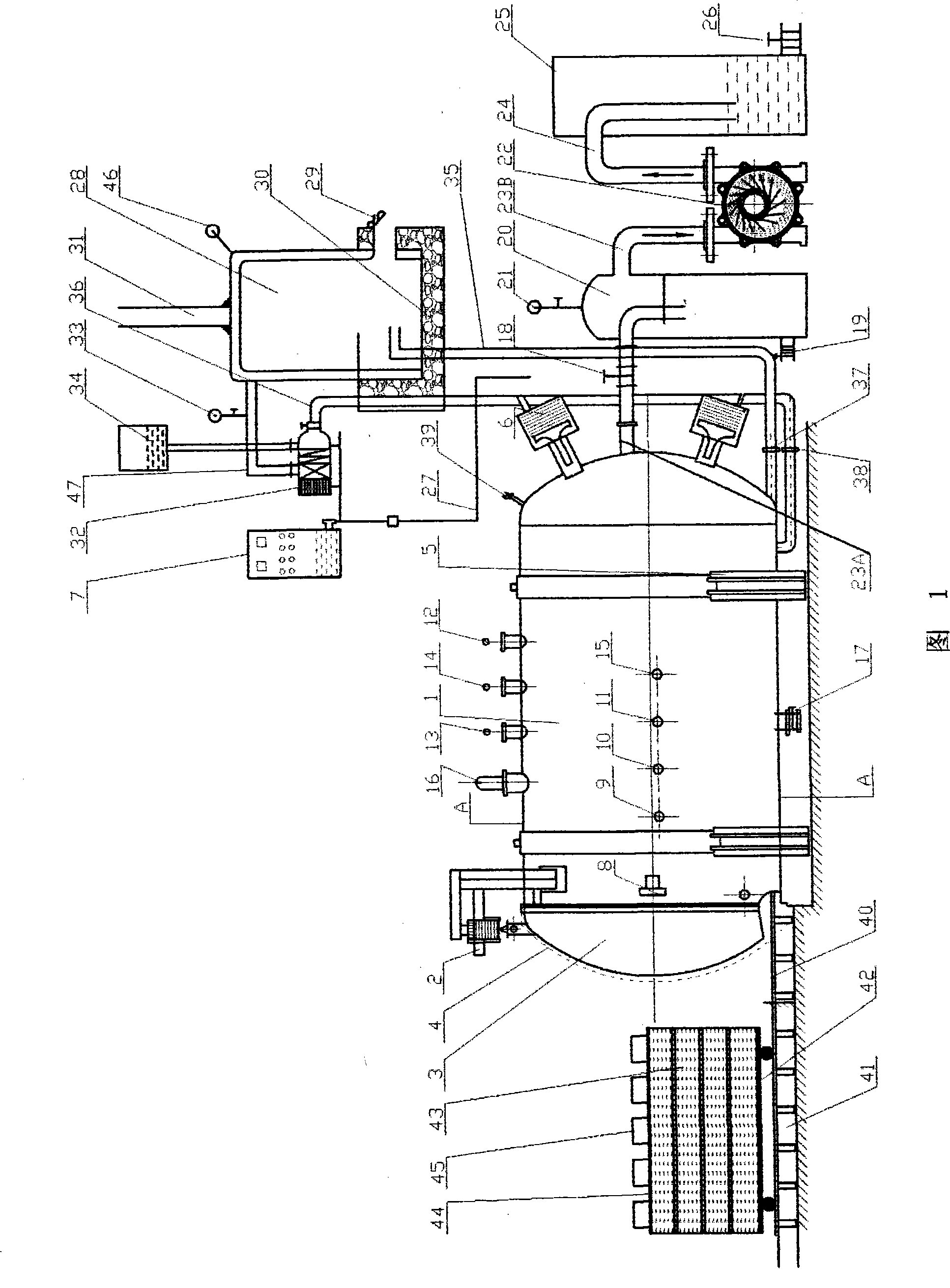

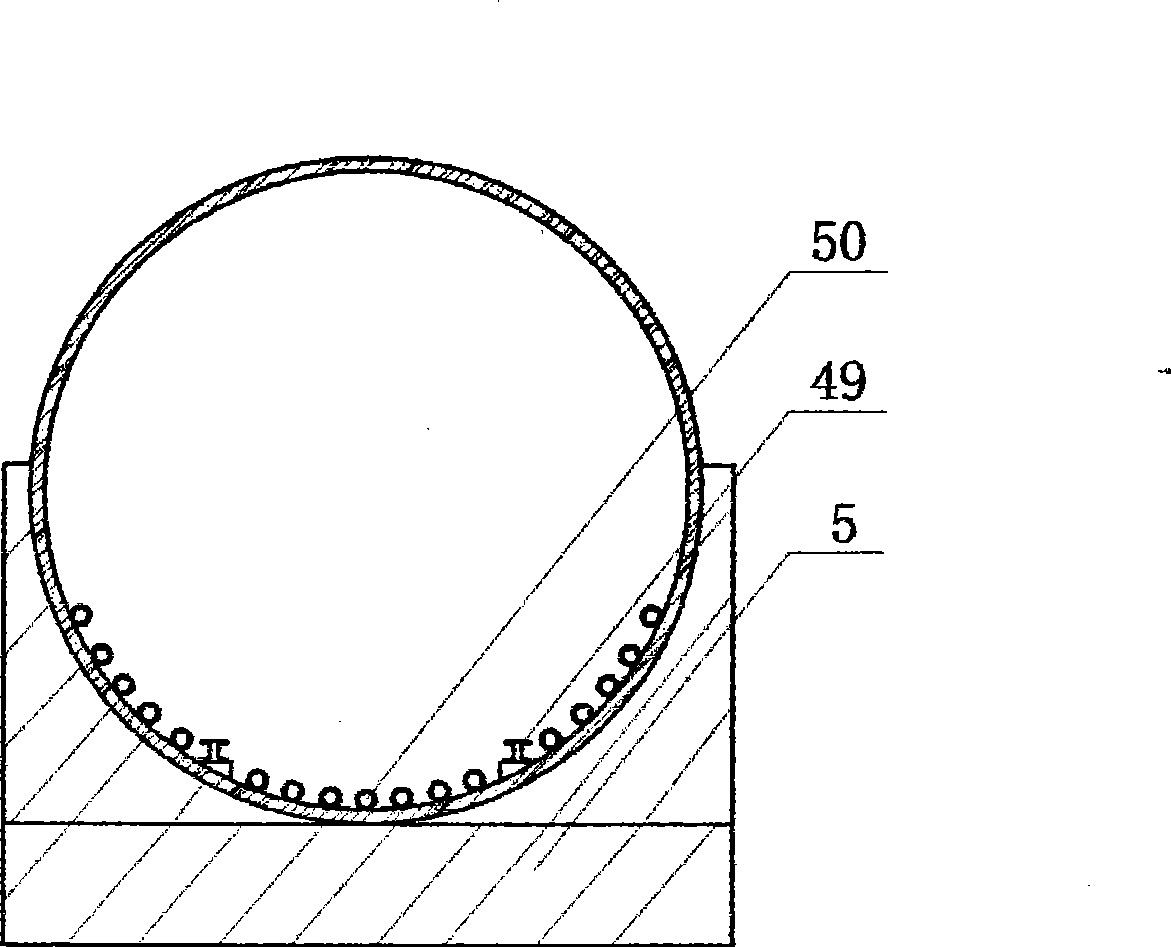

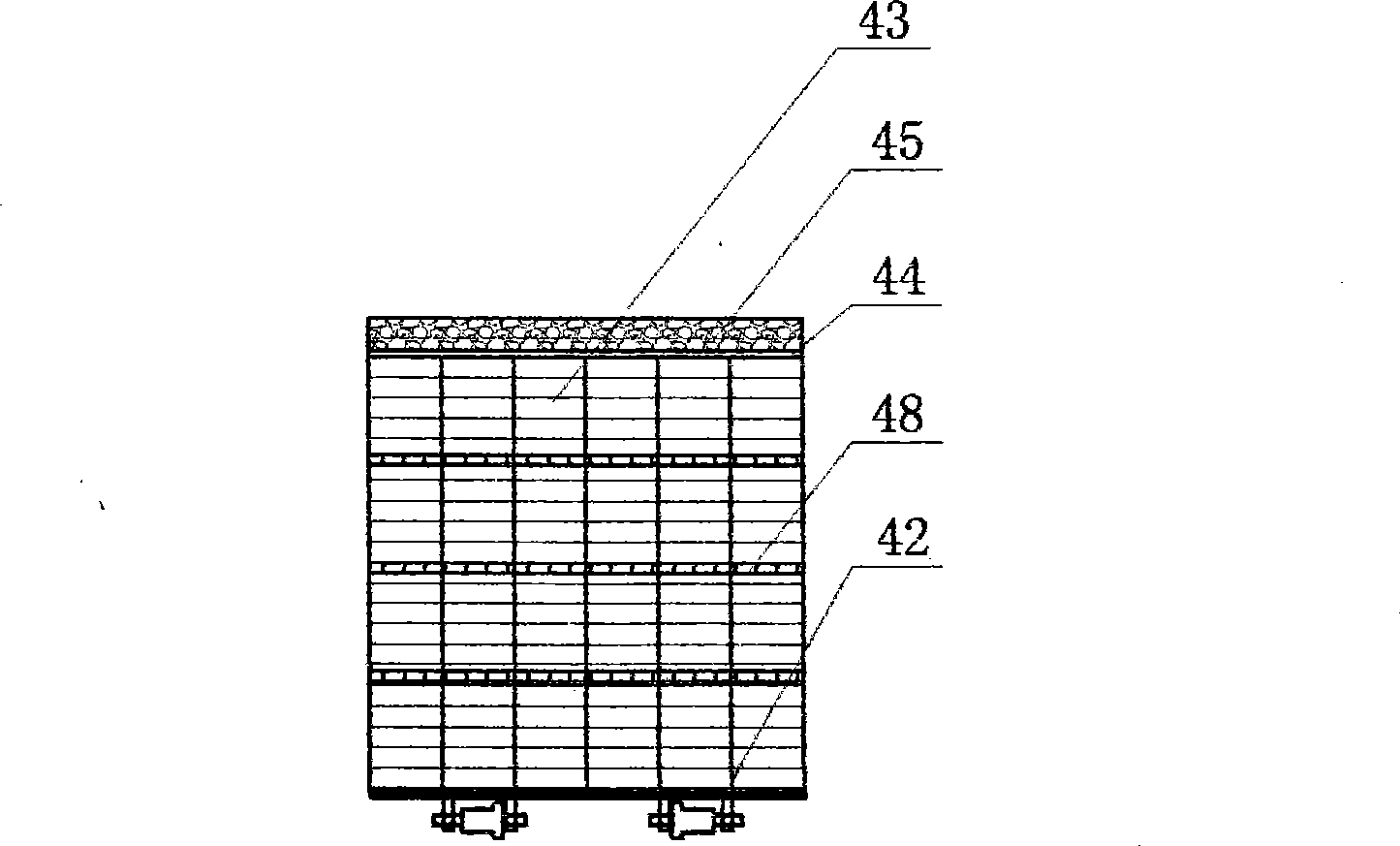

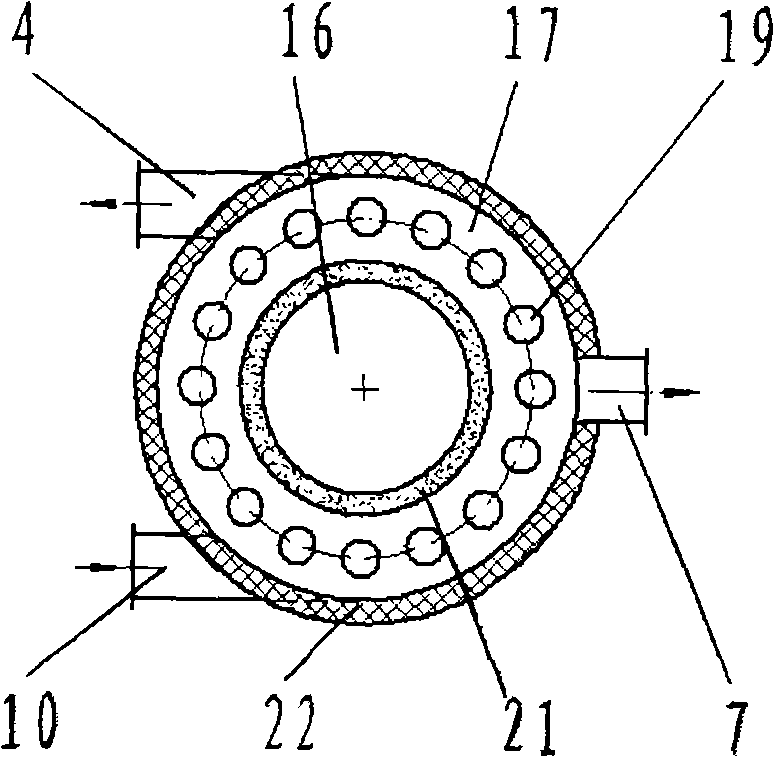

Microwave vacuum device for drying and charring lumber

ActiveCN101439529AConsistent heating inside and outsideDry evenlyWood treatment detailsWood dampingAir cycleFurnace temperature

The invention relates to a wood microwave vacuum drying and charring device and a drying and charring method thereof. The device comprises one charring tank (box) with a tank door (3), a tank door opener (2) and a charring chamber (1), a vacuum system, and one or more microwave sources (6) generating the microwave, a heat-conducting oil furnace system and a material preparation and feed system. The drying and charring method comprises the following steps: A. rising the temperature inside the tank to 30-50 DEG C, and then to 80-130 DEG C at the rate of 2-8 DEG C / h; B. preserving the temperature for 2-100 hours; C. vacuumizing the tank for 4-100 hours; D. starting a hot recycle pump to control the oil furnace temperature, the oil flow rate and the pressure inside the tank for 4-100 hours: E. turning off the microwave source and a heat source, opening an intake and exhaust valve (39) to discharge the pressure inside the tank to 0 and lower the temperature to 70-130 DEG C, and then closing the intake and exhaust valve (39); and F. starting a vacuum pump (22) to lower the temperature inside of the tank by air circulation and removing the wood from the tank when the temperature decreases to 30-70 DEG C. The device and the method help char the wood evenly, shorten the production cycle by 60% compared with the conventional method, and lower the energy consumption by 70%, thus greatly reducing the production cost.

Owner:罗玉成

Method for blending and setting wood

ActiveCN101596730AAlleviate the prominent contradiction between supply and demandExpand the scope of useWood compressionWood treatment detailsPulp and paper industryDistortion

The invention relates to the technique field of wood processing treatment, in particular to a method for blending and setting wood. The method for blending and setting wood comprises steps of sorting treatment, softening process, blending and deforming, setting, temperature reduction and humidifying, and cooling and health preserving. The method solves the problems existing in the existing traditional wood blending and distortion technique that wood utilization ratio is low, obtained products have poor size stability and high recovery rate of radius of curvature and is easy to crack, deform, decay and go moldy, etc.

Owner:ZHEJIANG SHIYOU TIMBER

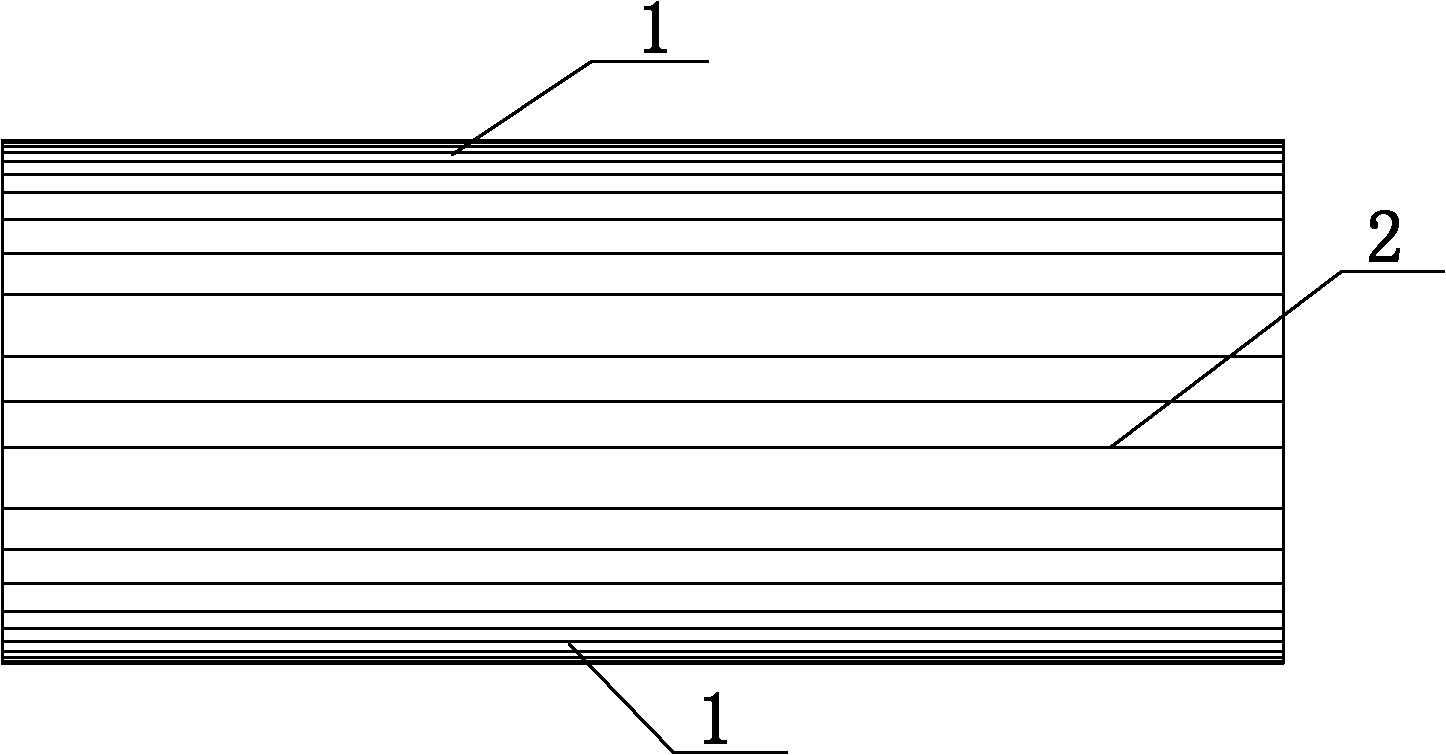

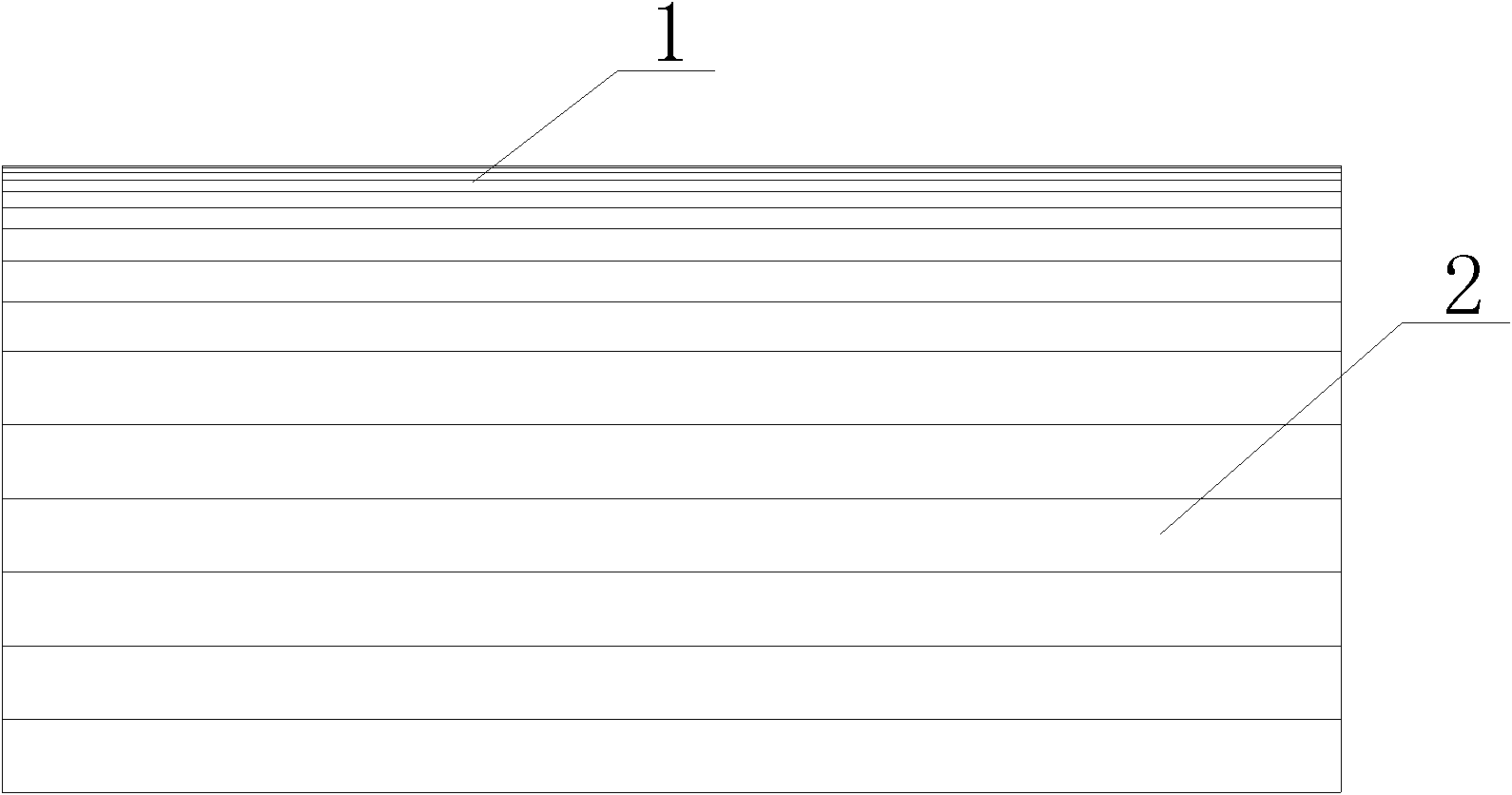

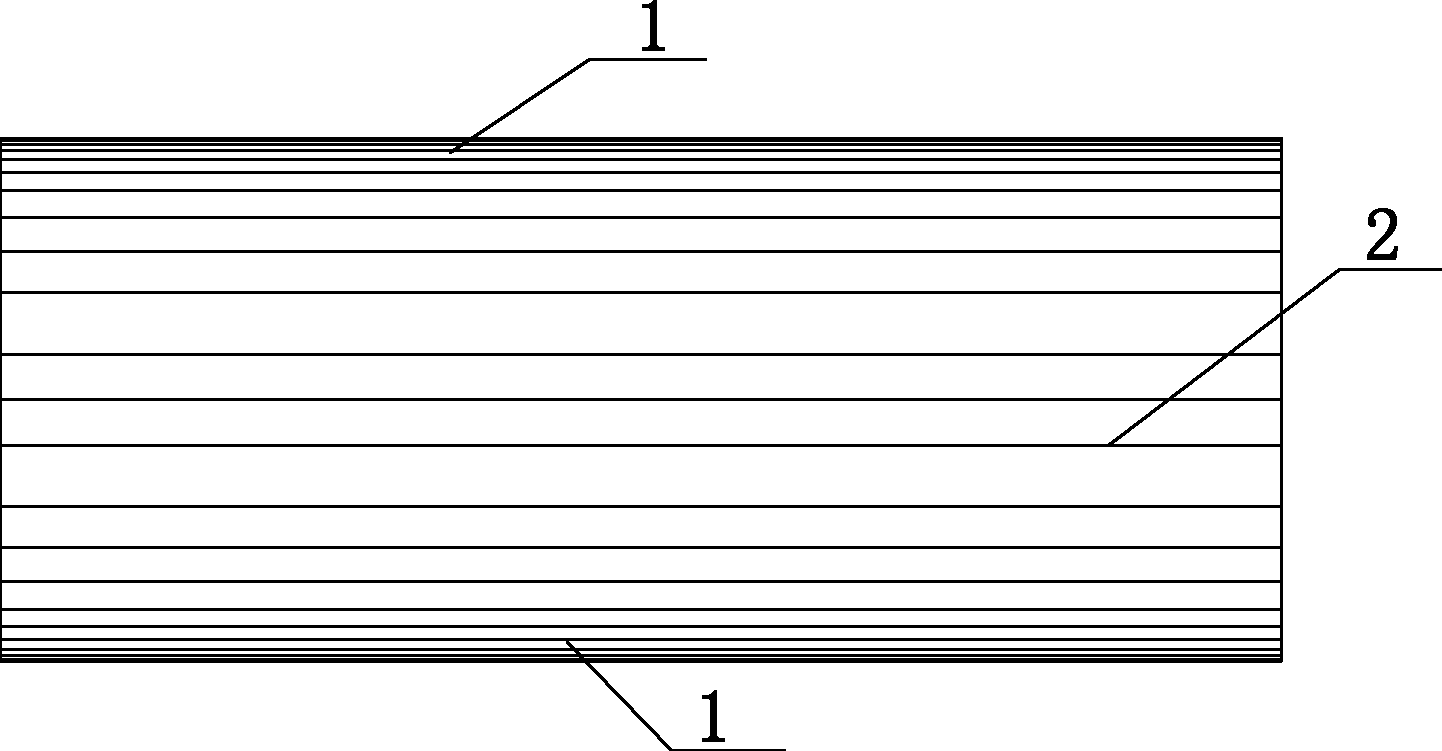

Surface reinforced solid wood section material, floor board and manufacturing method thereof

ActiveCN101603623AReduce pollutionStable moisture contentWood compressionFurniture partsSolid woodVolumetric Mass Density

Owner:ZHEJIANG SHIYOU TIMBER +1

Method for processing wood and wood manufactured by same

InactiveCN101623887AShort processing timeShort processing cycleWood treatment detailsWood dampingHeat lossesSuperheated steam

The invention relates to a method for processing wood, which belongs to the technical field of heat treatment of wood. The method comprises the steps of sequentially carrying out decompressing, preheating, high-temperature pressurizing and humidifying on wood placed into a container. Because the higher equilibrium water content is maintained in the process of processing the wood by the method, the manufactured wood overcomes the dry defects of cracking, shrinkage, and the like. The manufactured wood has reinforced size stability, strength and bending strength; the cracking generation proportion, the hygroscopicity and the water absorption performance of the wood are greatly reduced; and the weather and corrosion resistance of the wood is improved. The wood manufactured by the method reaches the standard of carbonized wood SB / T 10508-2008. The superheated steam with large specific heat and heat transfer coefficient is used as a heat transfer medium by the method and has small medium transfer resistance, short processing time and less heat loss; and the method saves energy sources and has low wood processing cost.

Owner:WUXI YUSHENG KITCHEN & BATH APPLIANCE

Manufacturing method of surface compressed plate

InactiveCN101664948AHigh densityHigh strengthWood compressionWood treatment detailsPolymer scienceVolumetric Mass Density

The invention relates to a manufacturing method of a surface compressed plate, in particular to solving the technical problem of providing a manufacturing method of a surface compressed plate featuring high surface layer density, high strength, low probability of deformation, simple technology, strong operability and lighter color. The technical scheme for solving the problem is as follows: the method comprises the following steps: (1) drying and controlling the water content between 20% and 30%; (2) rolling and controlling the compression ratio between 10% and 30%; (3) impregnating surface layer, namely soaking one or two sides of the plate into light-color water-soluble low molecular weight phenolic resin adhesives at a concentration of 10-25%; (4) softening by steam and controlling thesoftening temperature between 120 DEG C and 140 DEG C and time between 20min and 60min; and (5) compressing surface layer and controlling the compression ratio between 15% and 50%, the hot pressing temperature between 160 DEG C and 180 DEG C and the unit pressure between 1.5MPa and 4.5MPa. The method is suitable for such fields as furniture manufacturing, indoor decoration and the like.

Owner:ZHEJIANG FORESTRY UNIVERSITY

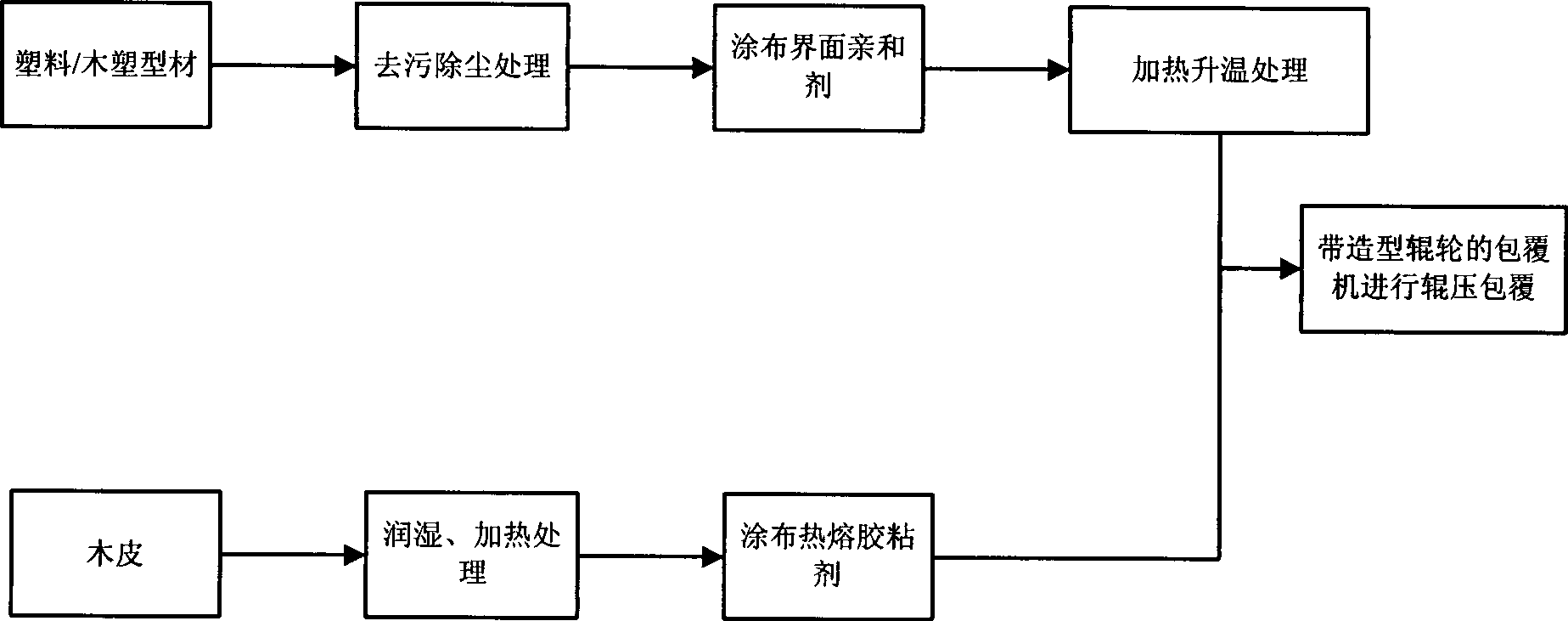

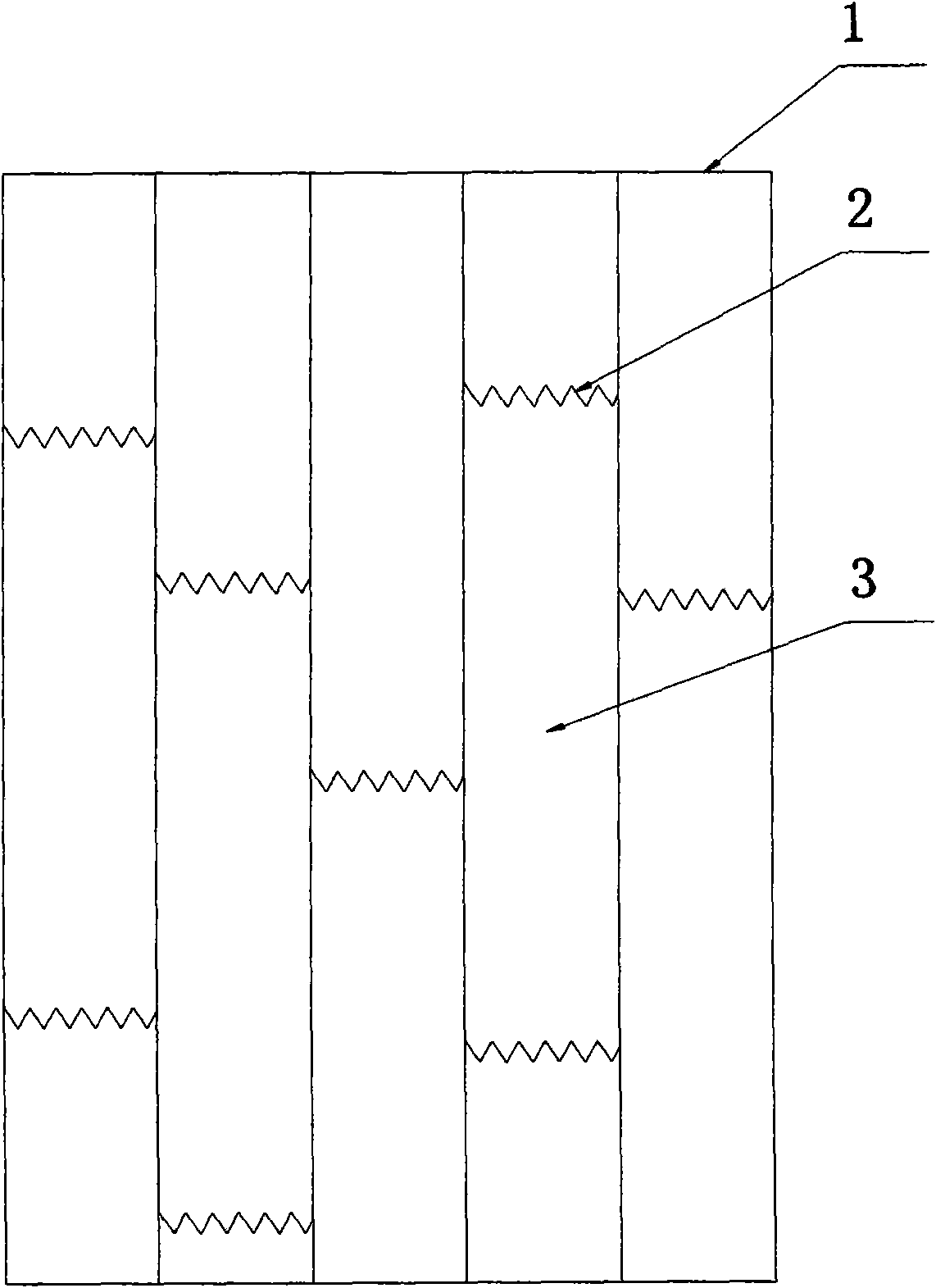

Composite section material for coating wood surface on surface of plastic/wood-plastic sectional material and manufacturing method therefor

InactiveCN101367220AFast curingIncrease productivityWood veneer joiningWood dampingEngineeringMechanical engineering

The invention provides a composite sectional material covering bark on the surface of a plastic / wood plastic sectional material and a manufacture method thereof, in order to overcome the defects of slow solidification speed, easy defect generation of glue films and unstable bonding caused by the mode of applying single cold glue to single side for bonding a plastic surface and a wood layer in the prior art. The method comprises the following steps: A. carrying out stain and dust removal treatment to the surface to be covered of the plastic / wood plastic sectional material; B. applying hot melt adhesive to the inner surface of the bark, and applying interface affine agent to the surface to be covered of the plastic / wood plastic sectional material which is subjected to the step A; and C. rolling and covering the bark on the surface of the plastic / wood plastic sectional material through a forming roll of a covering machine, so that the inner surface of the bark and the surface to be covered of the plastic / wood plastic sectional material can be bonded together. With the manufacture method, the bonding power between the surface of the bark and the surface of the plastic / wood plastic sectional material can be greatly improved, and the glue film has excellent quality, so that the plastic / wood plastic sectional material and the bark can be firmly bonded.

Owner:北京市森诺家具材料有限公司

Enhanced high-temperature heat treated wood and manufacturing method thereof

InactiveCN104985657AGood dimensional stabilityReduce moisture absorptionWood treatment detailsThermal wood treatmentPulp and paper industryResin adhesive

The invention discloses enhanced high-temperature heat treated wood and a manufacturing method thereof. The manufacturing method comprises the following steps that 1, high-temperature heat treatment is performed, wherein man-made forest wood serves as raw materials, and high-temperature heat treatment is performed on the man-made forest wood to obtain heat treated wood; 2, impregnation enhancing treatment is performed, wherein the heat treated wood obtained by the step 1 is impregnated in resin adhesives to obtain impregnated wood; 3, solidification forming treatment is performed, wherein solidification forming treatment is performed on the impregnated wood obtained by the step 2 to obtain the enhanced high-temperature heat treated wood. According to the manufacturing method, not only can the mechanical properties of the wood be improved, but also the size stability of the wood can be improved, green and environmental protection are achieved, and the prepared enhanced high-temperature heat treated wood takes the man-made forest wood as the raw materials and is high in mechanical strength and good in size stability.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

Alpine ash wedge joint board and making method thereof

The invention discloses an alpine ash wedge joint board, which is formed by mutual jointing of alpine ash wedge joint boards. Alpine ash wedge joint slices are rectangle alpine ash wood blocks with equal width and equal thickness; the short-edge end surfaces of the wedge joint slices are provided with finger gears with same rack shapes and rack saws; the racks are jointed to form long wedge jointstrips; and the long wedge joint strips are jointed by glue in parallel to form the wedge joint board. The making method thereof includes the steps of ventilating and airing fresh alpine ash logs; arranging the logs into a kiln and drying; arranging the logs at a ventilating and dry location for airing; fixing the width and length of the base materials, then polishing and sorting by colors; tenoning and longitudinally jointing the tenons; jointing the boards, sanding and cutting the edge; then returning to the kiln and drying; and discharging out of the kiln, inspecting, packaging and warehousing. The invention better solves the problems that the wood is easy to be shrunk and deformed when drying, the water contents of the base materials are not uniform and the anti-bending strength of thewedge joint board materials is low, etc, when processing the alpine ash wedge joint board, thereby stabilizing the quality of the alpine ash wedge joint board; moreover, the invention solves the technical problem that the alpine ash wood is not easy to be processed into the wedge joint board meeting the product requirements and strength, saves energies and protects the environment, has very largepopularization value, and contains tremendous economic and social benefits.

Owner:李磊

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

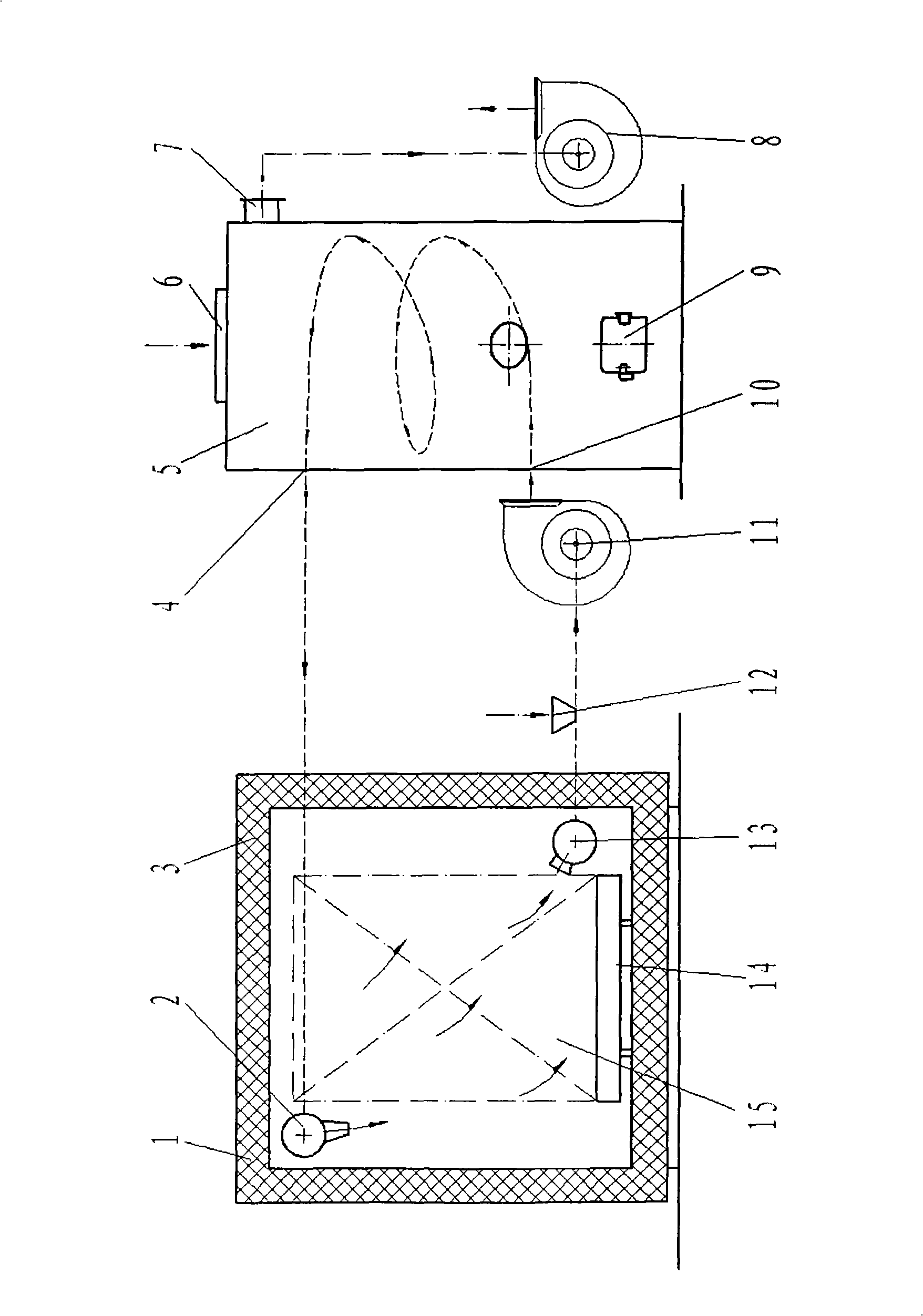

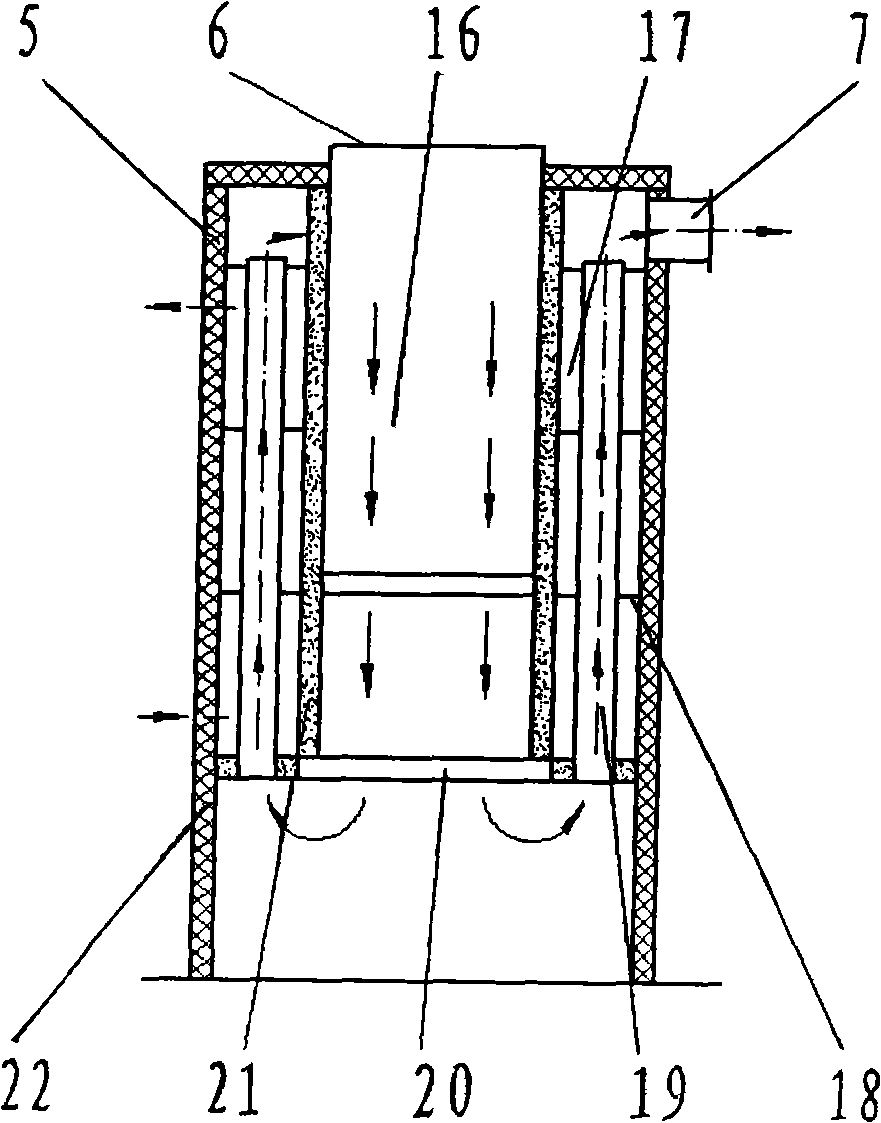

Wood high-heat treatment device and technological process thereof

InactiveCN101491908AImprove thermal efficiencyBurn fullyWood treatment detailsWood dampingCombustionWood machining

The invention relates to a device and a technical method for the high-temperature thermal treatment of timber. The device adopts a structure that: the air outlet of a reverse combustion-type combustion-heat exchange integral hot blast stove is communicated with the air inlet of a gas ejector pipe, the air outlet of the gas ejector pipe is communicated with the air inlet pipe of a return pipe through a log pile in a logging truck, the air outlet pipe of the return pipe is connected with one end of a heat supply fan through a humidifying device, the other end of the heat supply fan is connected with the air inlet of the reverse combustion-type combustion-heat exchange integral hot blast stove, and the smoke outlet of the reverse combustion-type combustion-heat exchange integral hot blast stove is connected with an induced draft fan; and a machine body of the high temperature thermal treatment device is provided with a machine body heat-preservation layer, and the top of the reverse combustion-type combustion-heat exchange integral hot blast stove is provided with a charging hole. The technical method comprises the steps of piling, ignition, process control, conditioning treatment, temperature reduction and discharge and the like. The device and the method have that advantages that: residues of timber processing are used as fuel, the heat exchange of a thermal treatment cyclic medium is carried out through the reverse combustion-type combustion-heat exchange integral hot blast stove at a time, the thermal efficiency is high, the combustion is complete and no pollution is produced.

Owner:NANJING FORESTRY UNIV

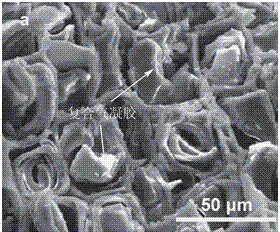

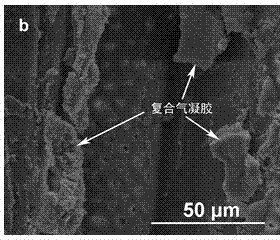

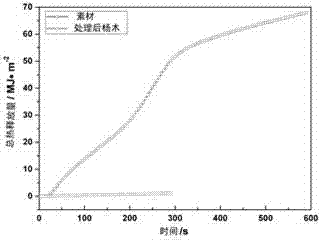

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Storage packaging material for tobacco material and preparation and using method thereof

ActiveCN101041394ARich tasteTo achieve the effect of adding fragranceTobacco preparationFlexible coversEngineeringTobacco leaf

The invention discloses a storing and packaging material for tobacco material and the preparing and using method. The natural wood with aroma is dipped into alcoholic drink liquid for 1-180 days and after drying and balancing the material is obtained. The packaging container can be manufactured by normal method again for store tobacco leaf or tobacco rag. The invention fills in the blank of cigarette technology. The packaging container is used to form storing condition with little breath and in storing process the aroma component in packaging material is distributed into tobacco leaf uniformly and continuously to achieve the aroma effect. The technology application can enrich the cigarette taste and improve the cigarette suction quality. It is provided with low cost and convenient operation. There is no need to change the prior silk making process and it is easy to be realized. It has good applicable prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

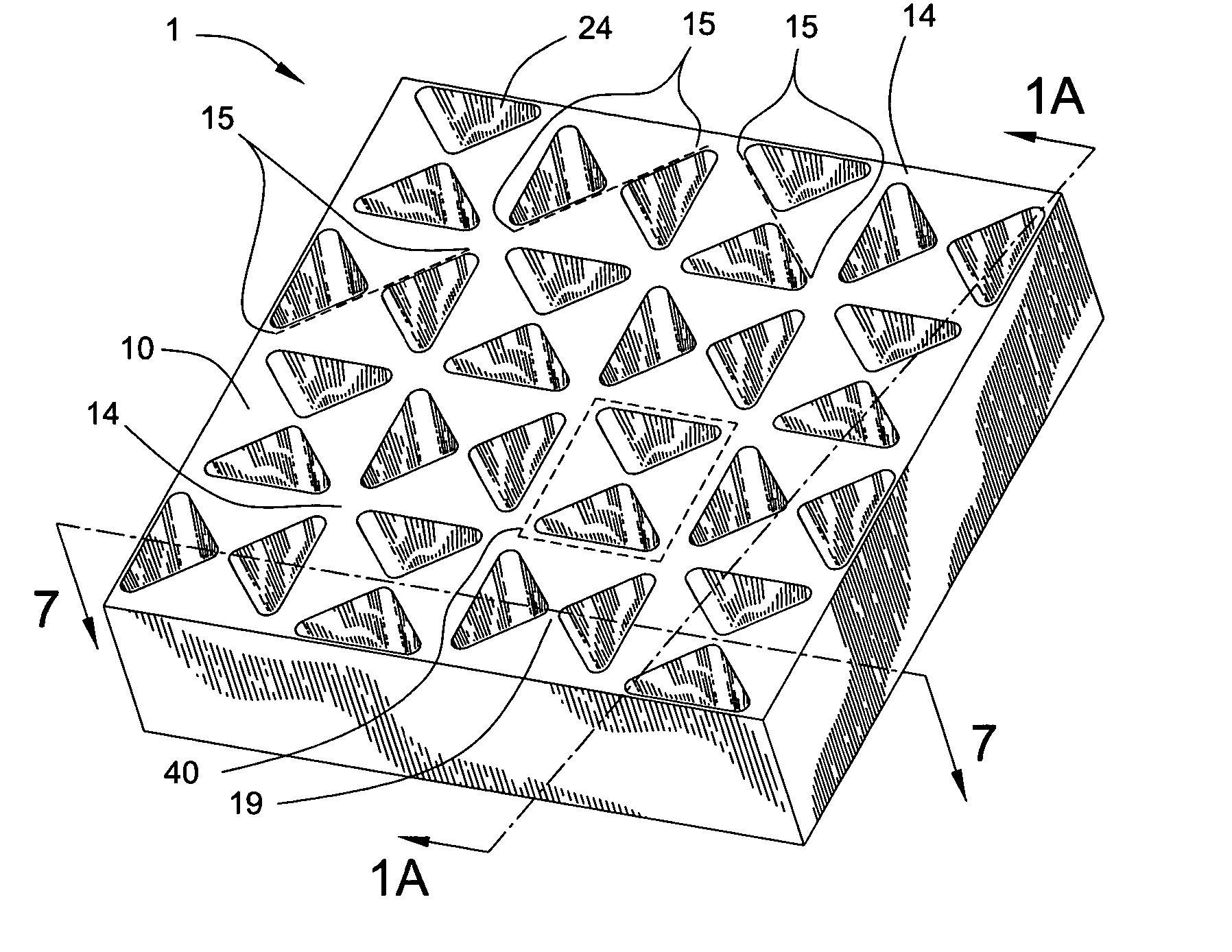

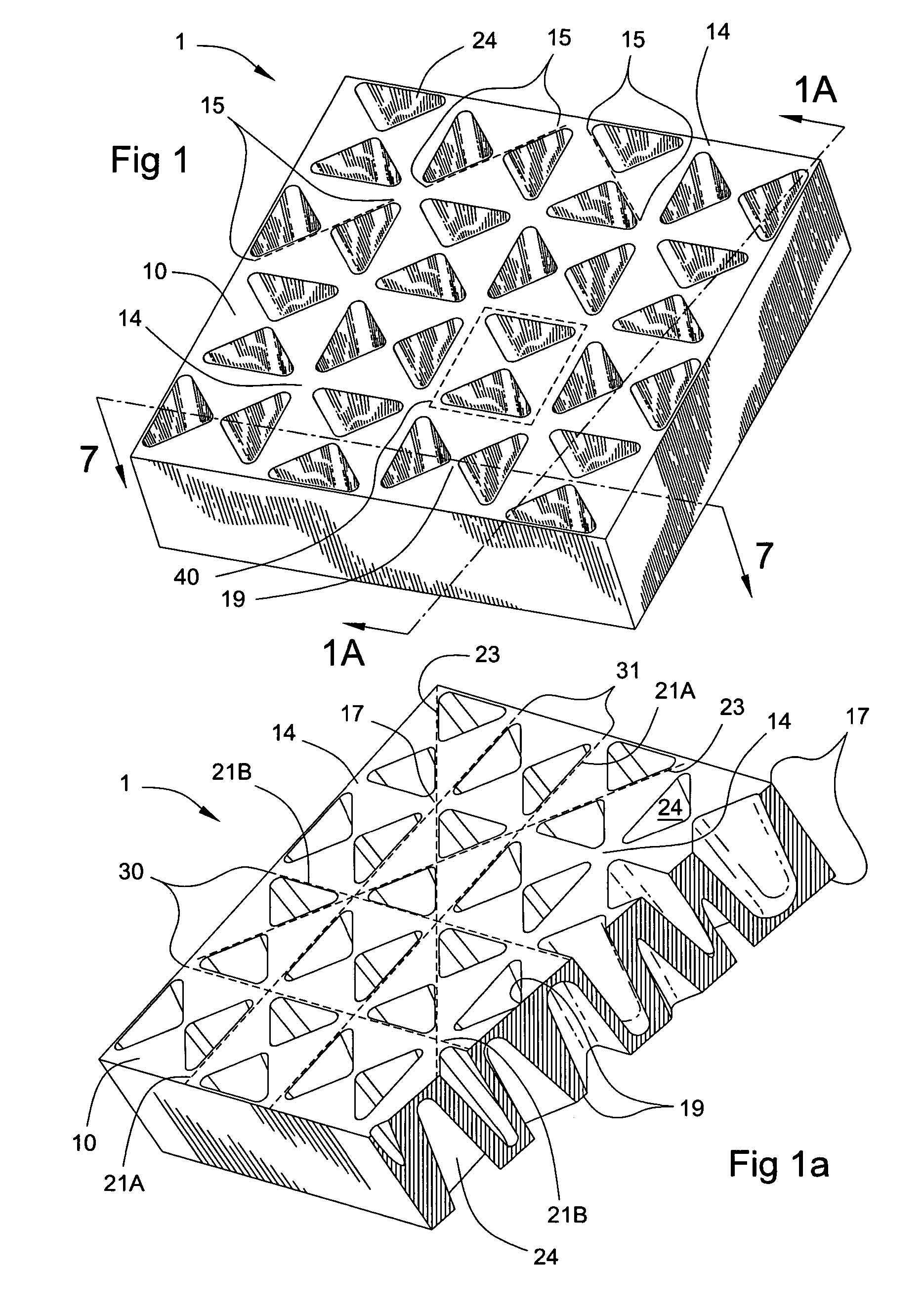

High strength low density multi-purpose panel

ActiveUS7021017B2Economical and practicalHigh strengthConstruction materialDoor/window protective devicesCruciformEngineering

A high strength low density multi-purpose panel. The preferred panel is made of a plurality of boxes, organized into rows and columns, and each preferably including four alternately inverted voids. The voids are preferably triangular in cross-section and rounded at their apex and corners. The box sides are preferably four solid panels. Cross panels, extending between opposite corners and between the faces of each box, intersect at each box center, resulting in an X-shaped cross in each box. Each box is rotated ninety degrees with respect to each adjacent box. Each box shares sides with four adjacent boxes and corners with four cater-corned boxes. The common sides create perpendicular sets of parallel braces running the panel's length and width. The shared corners align and join the X-shaped cross panels with the X-shaped cross panels of their cater-cornered neighbors, creating diagonal braces that run across the entire panel.

Owner:HERRON INTPROP HLDG L L C

Processing method of high-strength E0 grade middle-high density plate

InactiveCN101863062AStable productionEasy to controlWood treatment detailsWood dampingFiberHigh density

The invention relates to a processing method of a high-strength E0 grade middle-high density plate, comprising the following steps of: controlling the pressure and the time in the stewing and softening working procedure based on the traditional processing method; controlling the pressure of a grinding chamber in the hot rolling work procedure; mixing phenolic resin adhesive with paraffin and a liquid formaldehyde tapping agent in the sizing work procedure; and controlling the dried fiber water-containing rate, the hot-pressing temperature, hot-pressing factors, the density control and other conditions and innovating. The invention particularly provides a preparation method for improving the phenolic resin adhesive, thereby having the specific advantages that the phenolic resin adhesive isstable in the production process and is easy to control and the contents of free aldehyde and free phenol of adhesive liquid are low. The formaldehyde release quantity of a fiber board produced by using modified phenolic resin reaches the European E0 standard; various indexes reach national standard; and the invention has favorable weather resistance and can be used outdoors.

Owner:DONGYING ZHENGHE WOOD IND

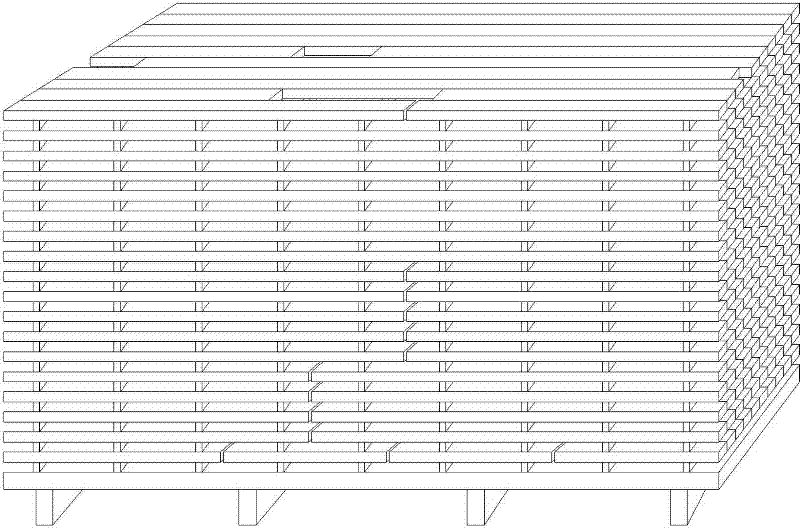

Eucalypt artificial wood drying method

The invention belongs to a timber drying method for eucalyptus planted forests. The method comprises the following steps: selecting materials; measuring initial moisture content, in which, sawtimbers are detected to obtain moisture contents and the sawtimbers of different moisture contents are respectively dried; stacking, in which, reasonable circulation of airflow inside a kiln is ensured and the capacity of the kiln is fully utilized to prevent timber warping and end checking; placing a moisture content check plate inside the kiln, in which, the moisture content check plate of dried timber inside the same kiln is determined according to requirements to check the moisture content of the check plate; and controlling the temperature and humidity inside the kiln according to the drying standards of different eucalyptus species. The timber drying method has the advantages of preventing eucalypti from crimpling in the process of drying and ensuring drying quality of eucalypti.

Owner:国际竹藤网络中心

Manufacturing technique of cortices assembled and adhered clad plate

InactiveCN101081524AFast softening speedInterpenetrate and moisten wellOther plywood/veneer working apparatusWood treatment detailsComposite plateUltimate tensile strength

The technological process of producing composite plate of spliced bark includes the following steps: sorting bark material, softening, cold pressing of bark and spliced board or hot splicing and curing, ageing, mechanical forming and trimming, sanding, dedusting, etc. During the production process, 10 % concentration alkali solution is added to speed the softening of bark, and eliminate partial starch and saccharide for preventing moth, and the ageing step can moisten bark mutually and volatile partial water. The composite plate of spliced bark made with waste bark as main material has certain strength, tight combination, low cost, natural bark grains and other advantages.

Owner:陈战

Fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby

ActiveCN102626941AImprove permeabilityNo burstDrying using combination processesWood compressionPulp and paper industryMoisture

The invention relates to a fast-growing wood surface reinforcing manufacturing method and sections manufactured thereby, belonging to the field of functional improvement on wood and wood processing. The technical scheme comprises the following steps of (1) drying step: drying fast-growing wood till a moisture content of 5-12%; (2) carbonizing step: carbonizing the fast-growing wood; (3) surface reinforcing step: compacting and reinforcing the surface of the fast-growing wood; and (4) thermally processing and fixing step: thermally processing and fixing the fast-growing wood at the temperature of 180-220 DEG C. The problems are solved that in the conventional technical scheme, the production process is complicated, the production cost is high, the wood yield is low, obtained sections are poor in texture and color and luster and poor in product stability, and the like; compared with the prior art, the fast-growing wood surface reinforcing manufacturing method has the advantages of simple process, no addition of any chemical in the production process, environment-friendly production, high production efficiency, capability of realizing large-scale flow-line production, low wood loss, high wood yield, low production cost and the like; and the obtained fast-growing wood surface-reinforced sections have the advantages of hard surfaces and soft middle parts or bottoms, high size stability, high corrosion resistance, clear texture, plump color and luster, good decorative effect and the like.

Owner:福建秦朝木业科技有限公司

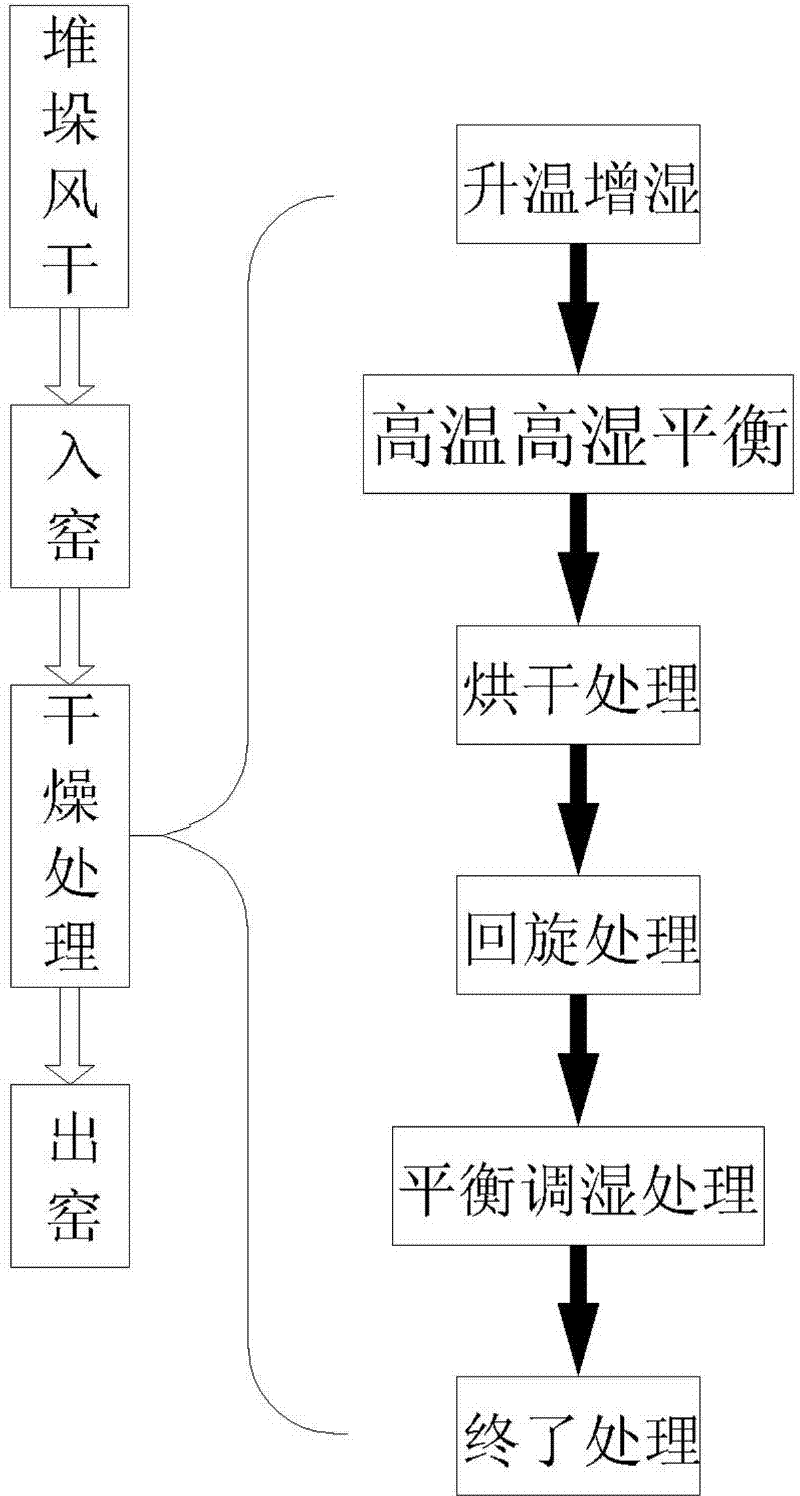

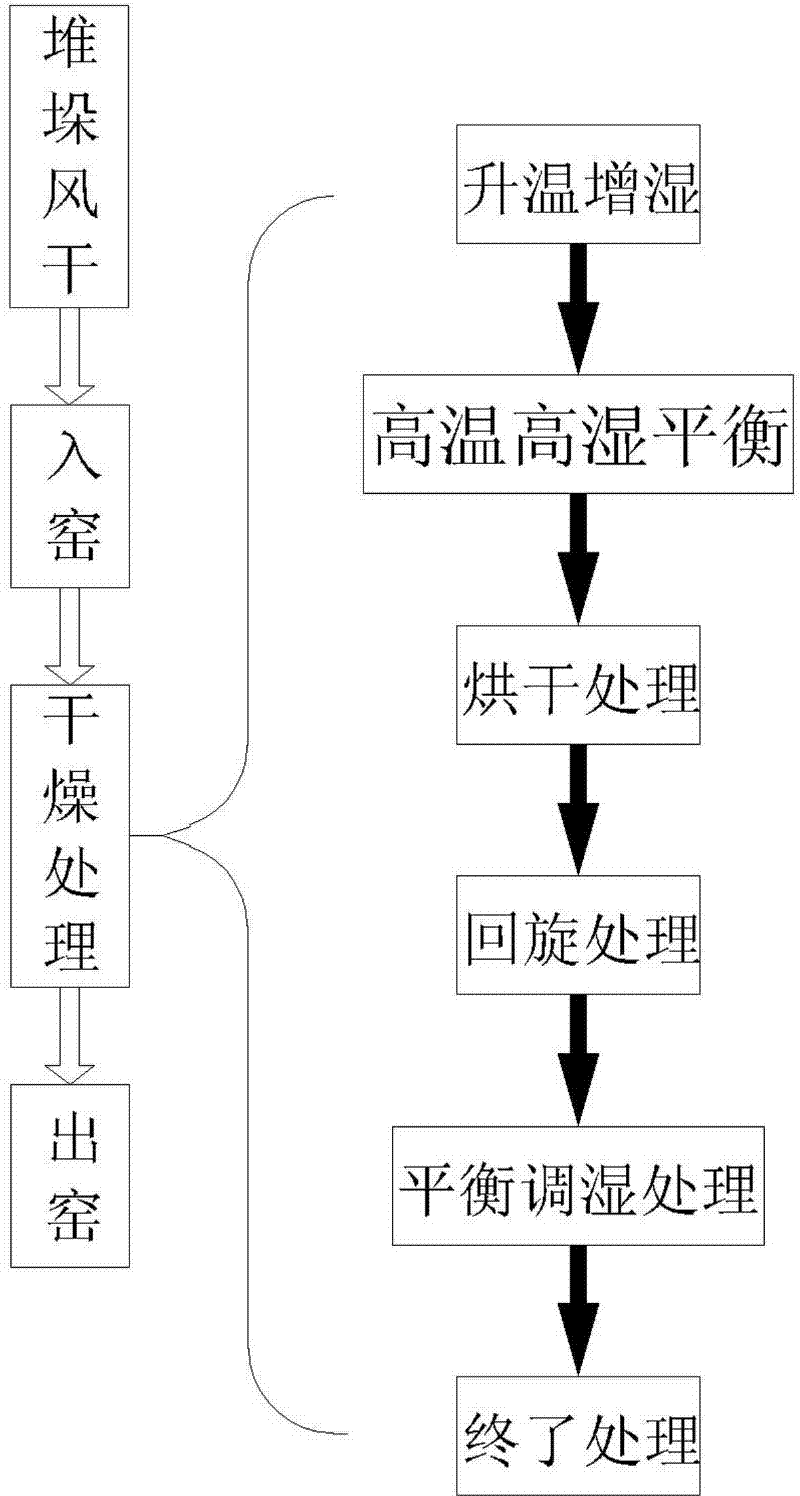

Rotary drying method for timbers

The invention provides a rotary drying method for timbers. The method comprises the following steps of: stacking the timbers and airing the timbers till the water content is about 30 percent; stacking the aired timbers, putting the timbers in a timber drying kiln, preheating, raising the temperature, humidifying, preserving heat and moisture, drying and dehydrating, finally treating and carrying out balanced humidification and rotary treatment many times. The method has the keys that a drying medium in a kiln is kept to form rotary vortex, and the water content of the timbers is not reduced in one step and is kept in rotary decline; by the rotary method, the internal stress of the timbers is dispelled in time, drying stress and surface hardening are eliminated, plasticizing deformation is prevented in the drying stage of the timbers, the defects of air shrinking, bending, deforming, cracking and the like are not caused, the degradation loss of the timbers is reduced to be below 6 percent, the drying period is shortened by about 20 percent, energy can be saved by about 15 percent, and limited timber resources are utilized more effectively; and the method has strong universality, is suitable for various different timbers, and can be widely applied to drying kilns with high automation degree.

Owner:GUANGDONG YIHUA TIMBER IND

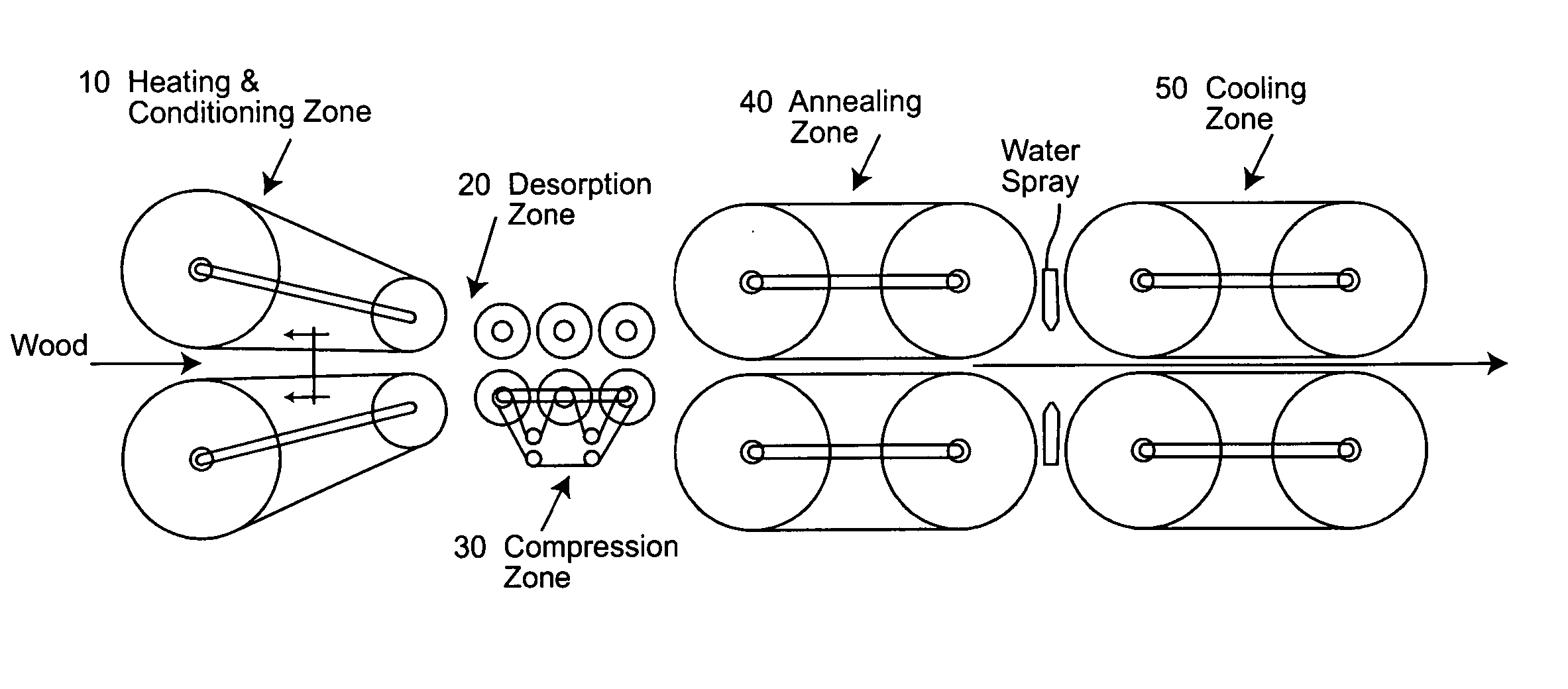

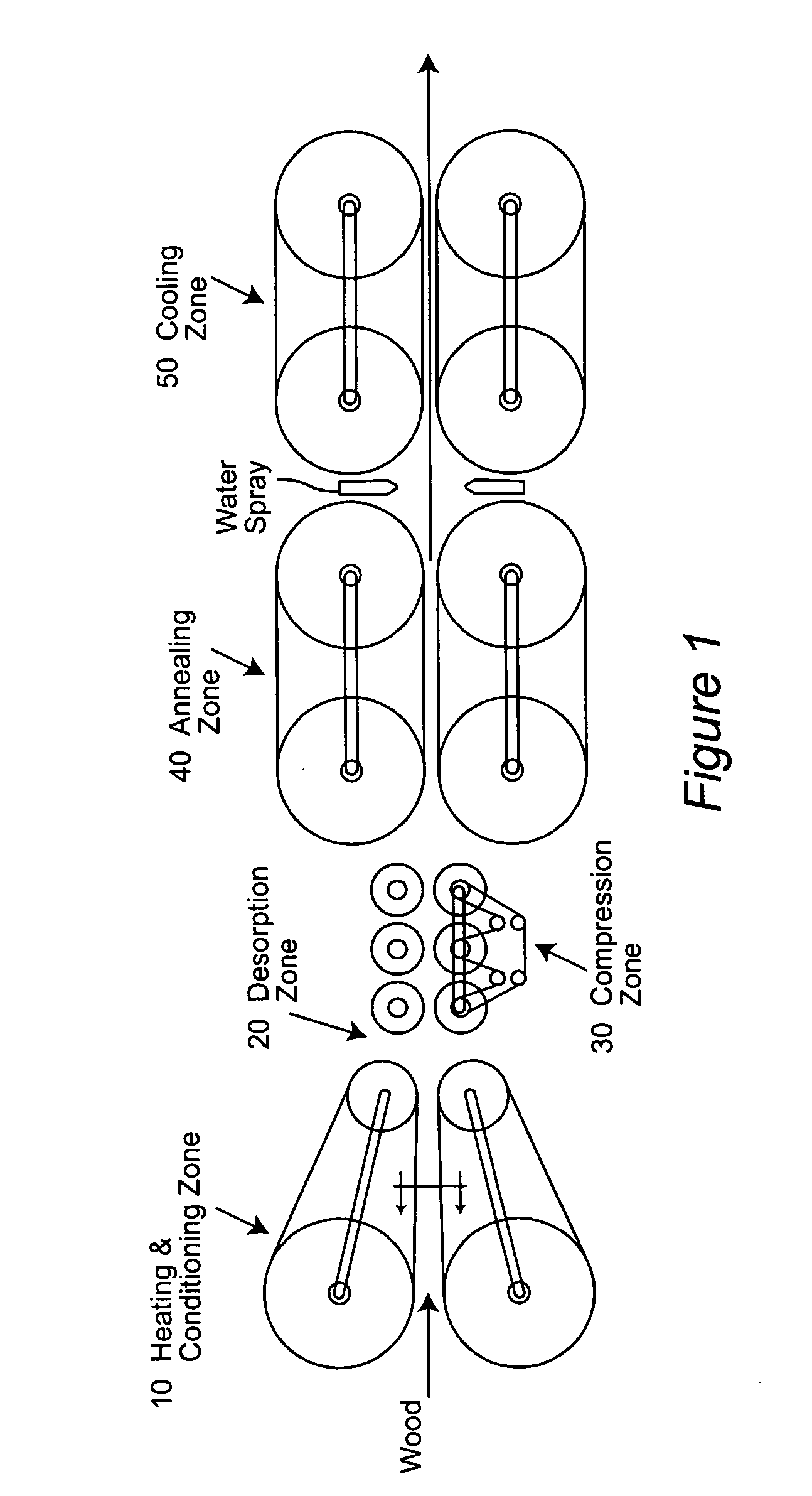

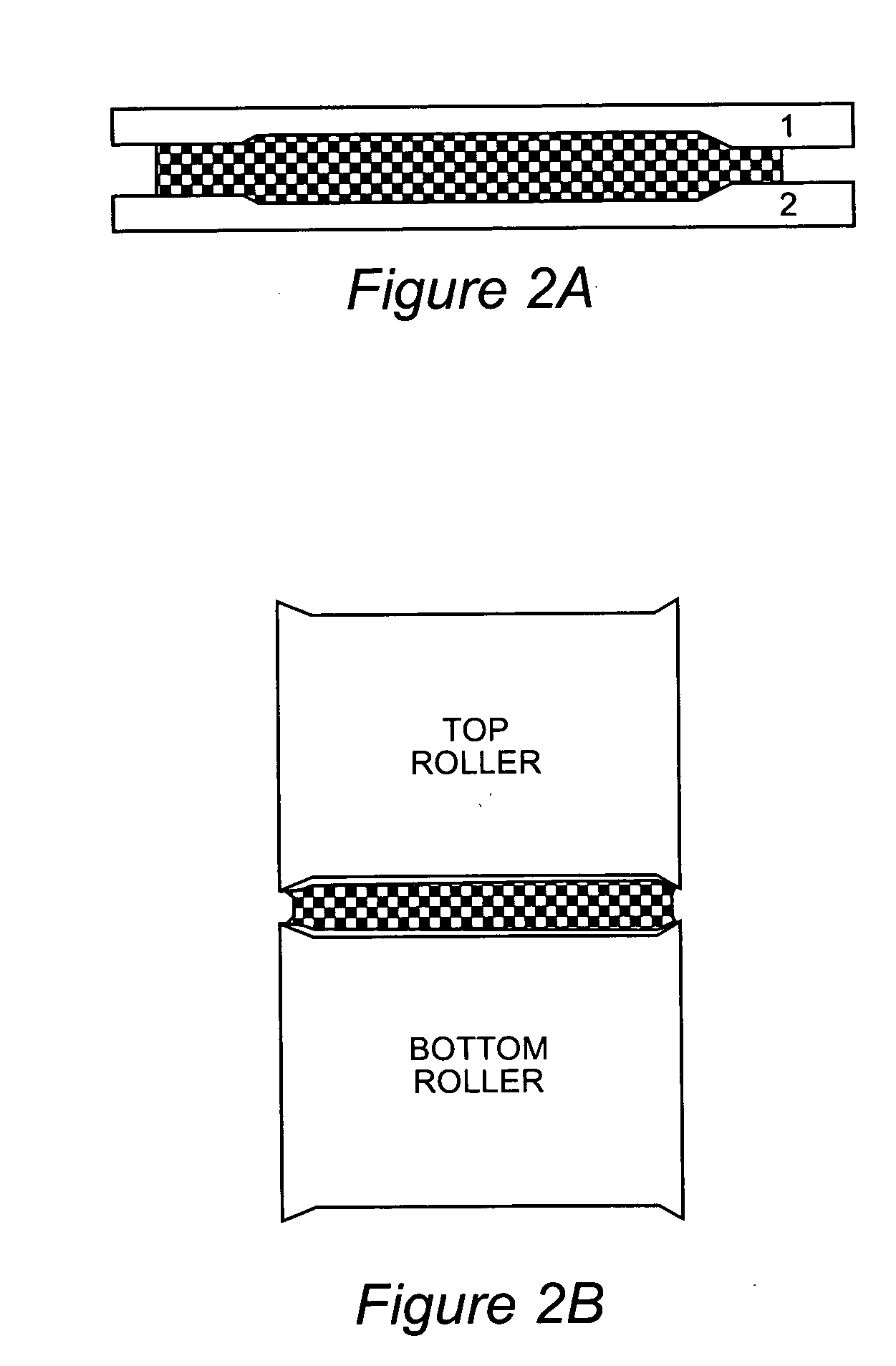

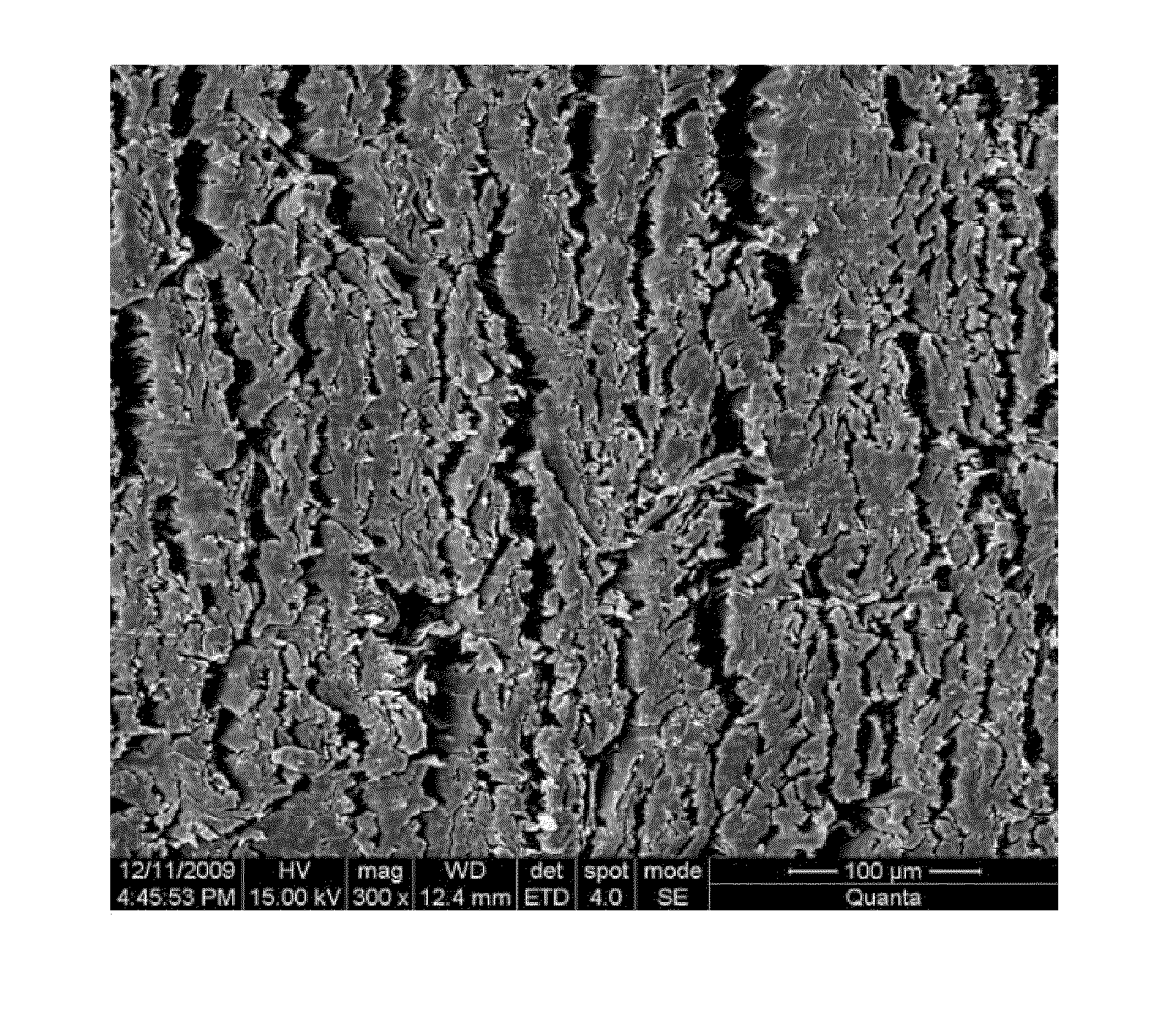

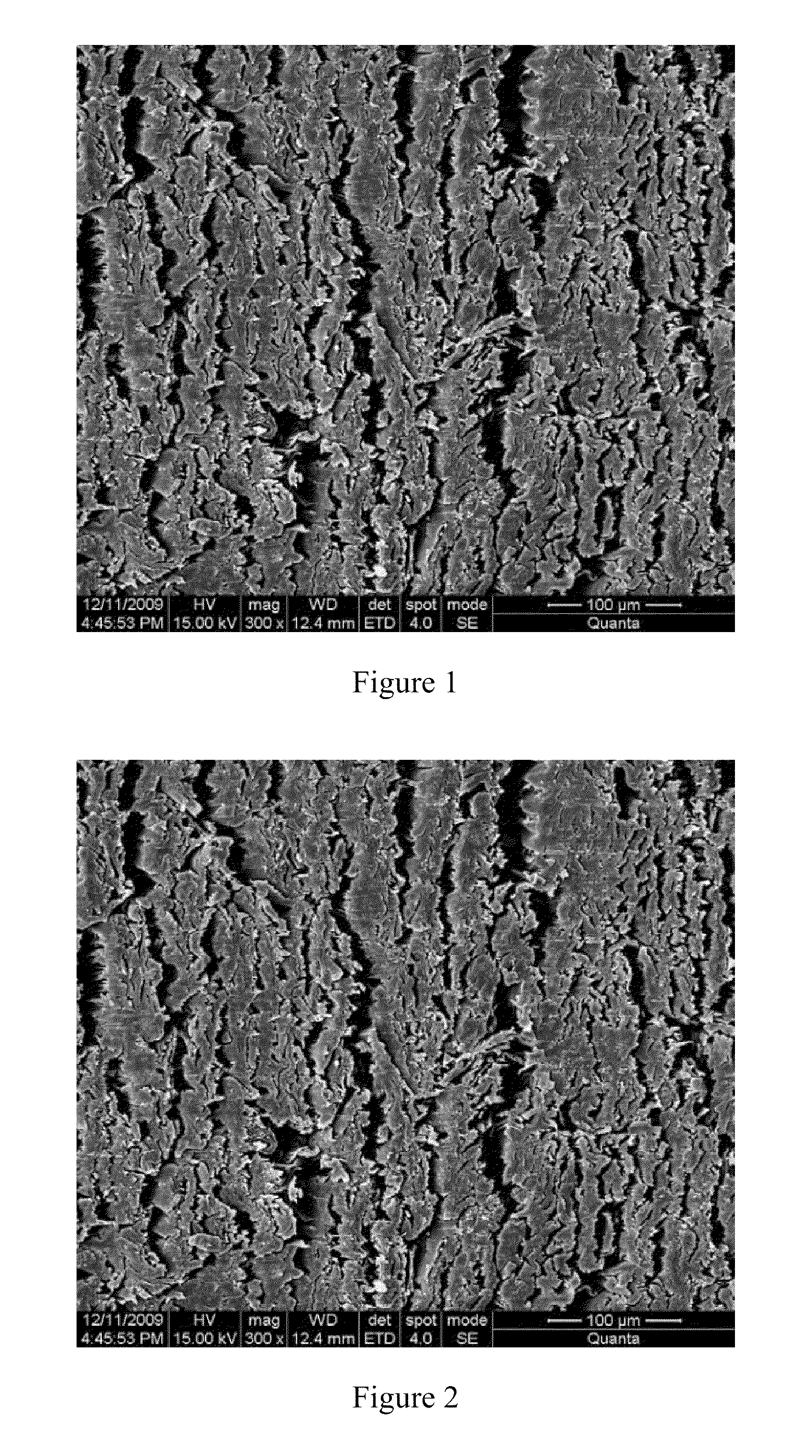

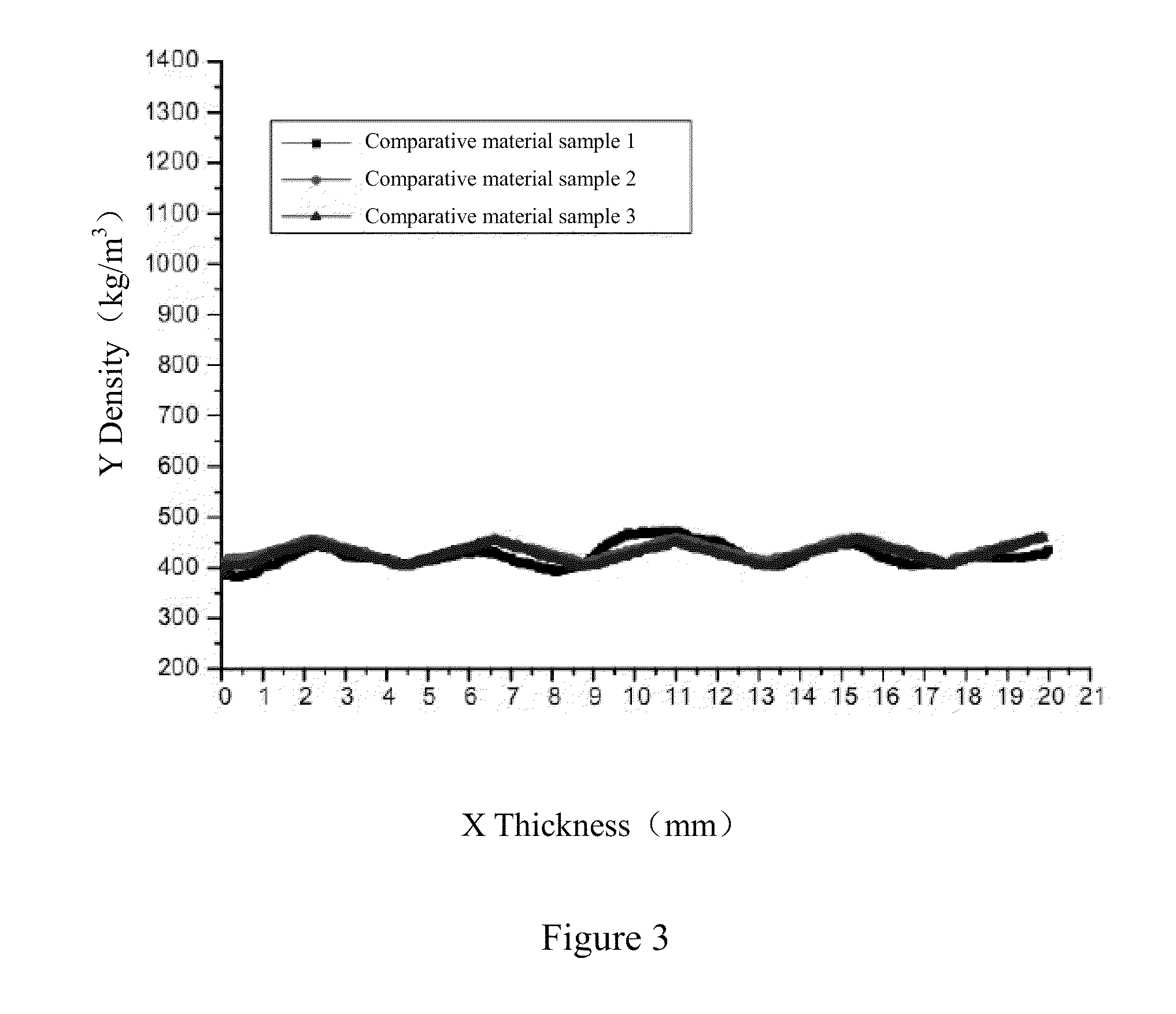

Viscoelastic thermal compression of wood

ActiveUS20050006004A1High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Pine drying method

ActiveCN104511953AUniform moisture contentAvoid deformationWood treatment detailsDrying gas arrangementsWood machiningEngineering

The invention discloses a pine drying method, and belongs to the field of timber processing. The method comprises the following steps: selecting pine sheets with the thickness of 25-35mm and the water content of 40-45% before drying, putting the pine sheets in a kiln, stacking, using division bars between layers of the pine sheets, making a pine water content drying reference according to the dimension of the stack of the pine sheets, the flow velocity of a drying medium and the water content of the sheets, setting a wet and dry bulb temperature according to the water content drying standard, starting a system in the drying kiln to carry out automatic heating and steam injection to a preset required range, cooling the pine sheets, and discharging the cooled pine sheets from the kiln to obtain a finished product. The method allows the water content of the timber to be balanced in the drying process by adopting the pine drying reference and using automatic steam injection, prevents the deformation, cracking and bending of the sheets in the drying process, and realizes an optimal drying state through multi-time automatic steam injection, humidity elimination and adjustment.

Owner:柳州林道轻型木结构制造有限公司

Wood drying technique

InactiveCN101231132AGuaranteed machining accuracyReduce energy consumptionDrying solid materials with heatWood dampingTreatment effectPulp and paper industry

The invention discloses a wood drying technology, which comprises a moist heat treatment, a drying step, a finishing step and a cooling step, wherein, the finishing step and the cooling step are combined to a finishing-cooling step. The invention adopts the progressive combination drying technology, namely, the moist heat treatment is controlled by a time base, and is controlled by a water-content coefficient base after the drying step, and the finishing-cooling step is a balancing water-content coefficient base. As the finishing step and the cooling step are combined to a finishing-cooling step, the wood drying technology of the invention assures the finishing treatment effect, and also saves energy and shortens drying period. The adoption of the progressive combination drying technology, namely, different base control method is adopted at different stage, assures machining accuracy, and the good versatility suits for various wood.

Owner:金国庆

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764ASolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumLacquer

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualification rate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

Method of using eucalyptus to make formaldehyde-free veneer laminated lumber

InactiveCN102528880ASolve the problem of reasonable and efficient useImprove use valueWood veneer joiningWood dampingFormaldehyde freeEngineering

The invention discloses a method of using eucalyptus to make formaldehyde-free veneer laminated lumber, which solves the problem that veneer laminated lumber made of eucalyptus is easy to deform and warp by means of drying, carbonizing and assembling of eucalyptus, softening of eucalyptus veneers and scientific and reasonable assembly. The veneer laminated lumber made of eucalyptus is stable in structure and not easy to warp, construction of planted forests can be promoted while wooden products having higher use value can be provided for the society, and reasonable and efficient utilization of small-diameter eucalyptus is achieved, which is significant in current situation of wood resource shortage and supply-demand contradiction.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Type of wood section material and its manufacturing method

ActiveUS20110262727A1Easy to useLow densityThermal wood treatmentWood layered productsWood machiningCarbonization

The present invention relates to a type of wood section material manufacturing method, especially with respect to soft wood section material and its manufacturing method. It belongs to wood processing field. This invention is achieved by the following technical plans: a type of wood section material manufacturing method includes the following steps: (1) wood preparation; (2) drying; (3) Polishing; (4) Hot pressing, which is to use two hot pressing boards with 140-200° C. to firmly press two surfaces of panel blank material; (5) Pre-carbonization, which pre-carbonize the panel blank material under 160° C. and 200° C.; (6) Carbonization, which carbonize the panel blank material between 200° C. and 225° C.; (7) Cooling; and (8) Moisture content control. This invention is particularly suitable to make wooden floor boards and office furniture.

Owner:TU DENGYUN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com