Rotary drying method for timbers

A drying method and wood technology, applied in the direction of humidity control wood, wood processing equipment, manufacturing tools, etc., can solve the problems of wood degradation, failure to meet the needs of industry development, loss of use value, etc., to achieve the removal of surface hardening and shorten the drying cycle , the effect of preventing plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

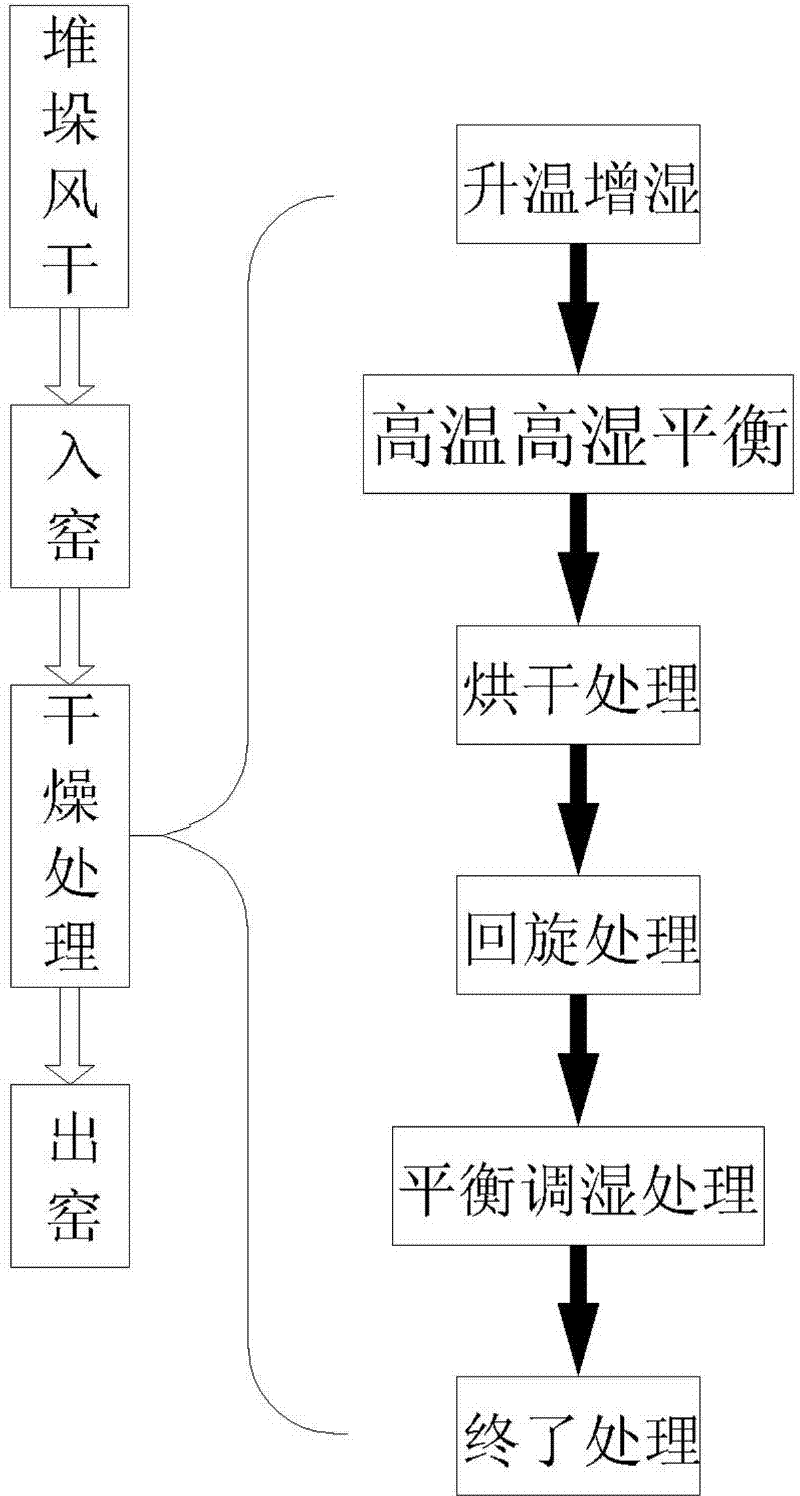

[0021] Such as figure 1 As shown, a wood rotary drying method, a wood rotary drying method, sequentially includes stacking air-drying treatment, kiln-in treatment, drying treatment and kiln-out treatment, wherein the above-mentioned drying treatment includes the following steps:

[0022] (1) Heating and humidification: set the target temperature at 40°C to 85°C, the equilibrium moisture content (EMC) at 15% to 18%, and increase the temperature by no more than 5°C per hour, and start the fan at the same time to dry the medium in the kiln A whirling vortex is formed, the fan frequency is 50Hz, and it rotates once every 1 to 2 hours, with an interval of 5 minutes. When the temperature reaches 45°C, it should be maintained for 1 to 2 hours for every 5°C increase to heat the shell surface, main equipment parts and wood surface in the drying room, and avoid drying on these solid surfaces under subsequent high temperature and high humidity working conditions. Condensation occurs. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com