Patents

Literature

102results about How to "Improve the level of production technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

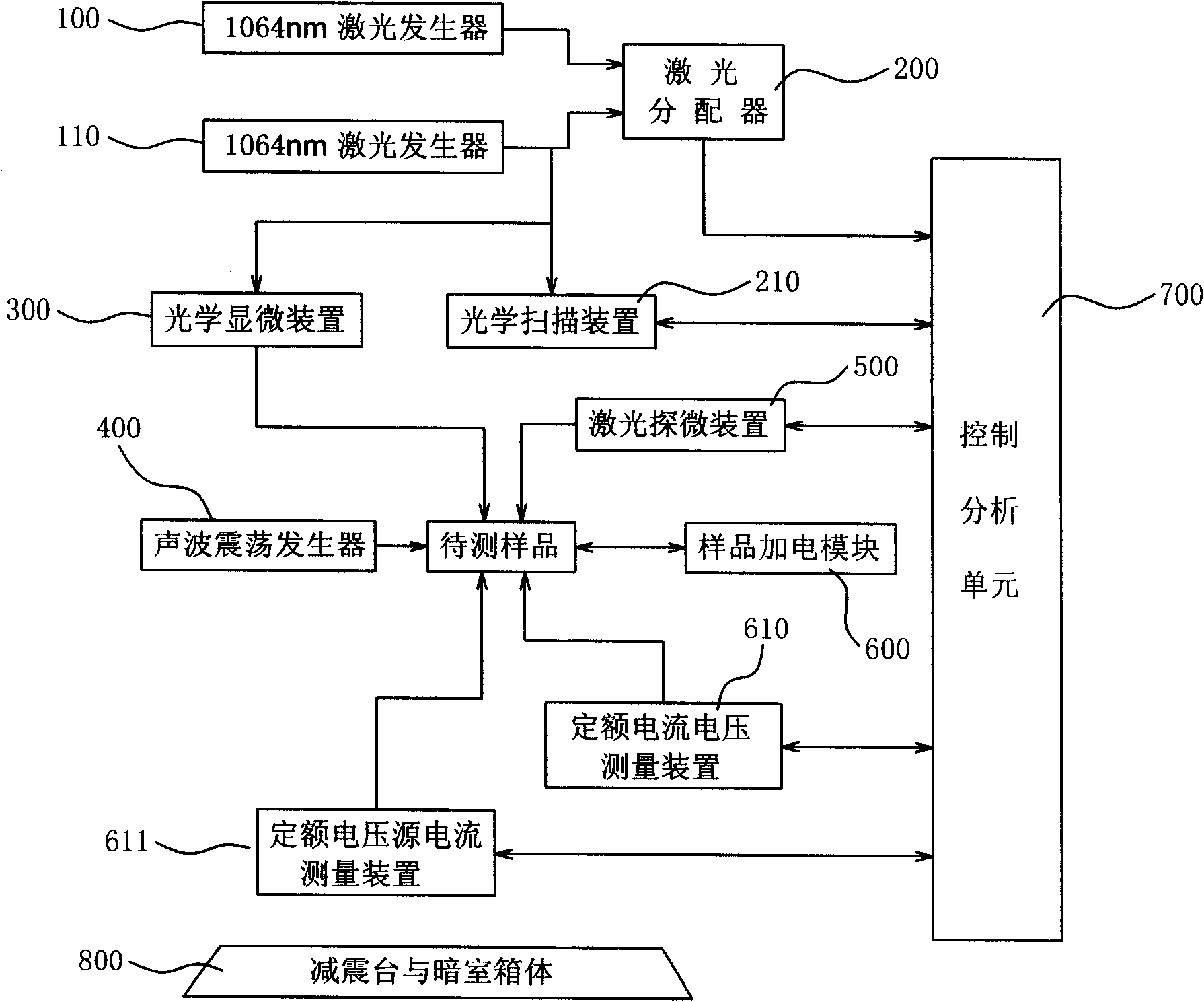

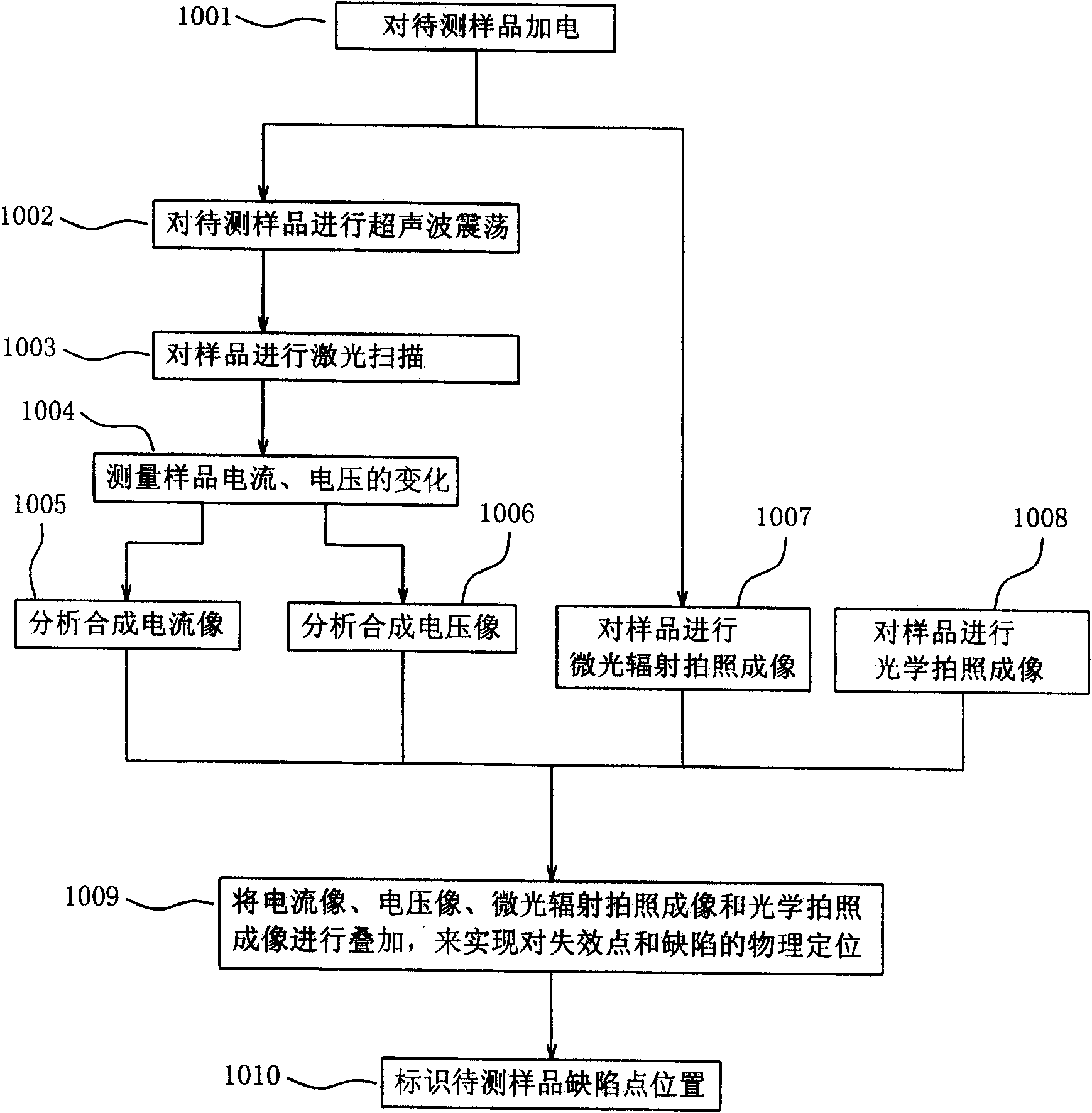

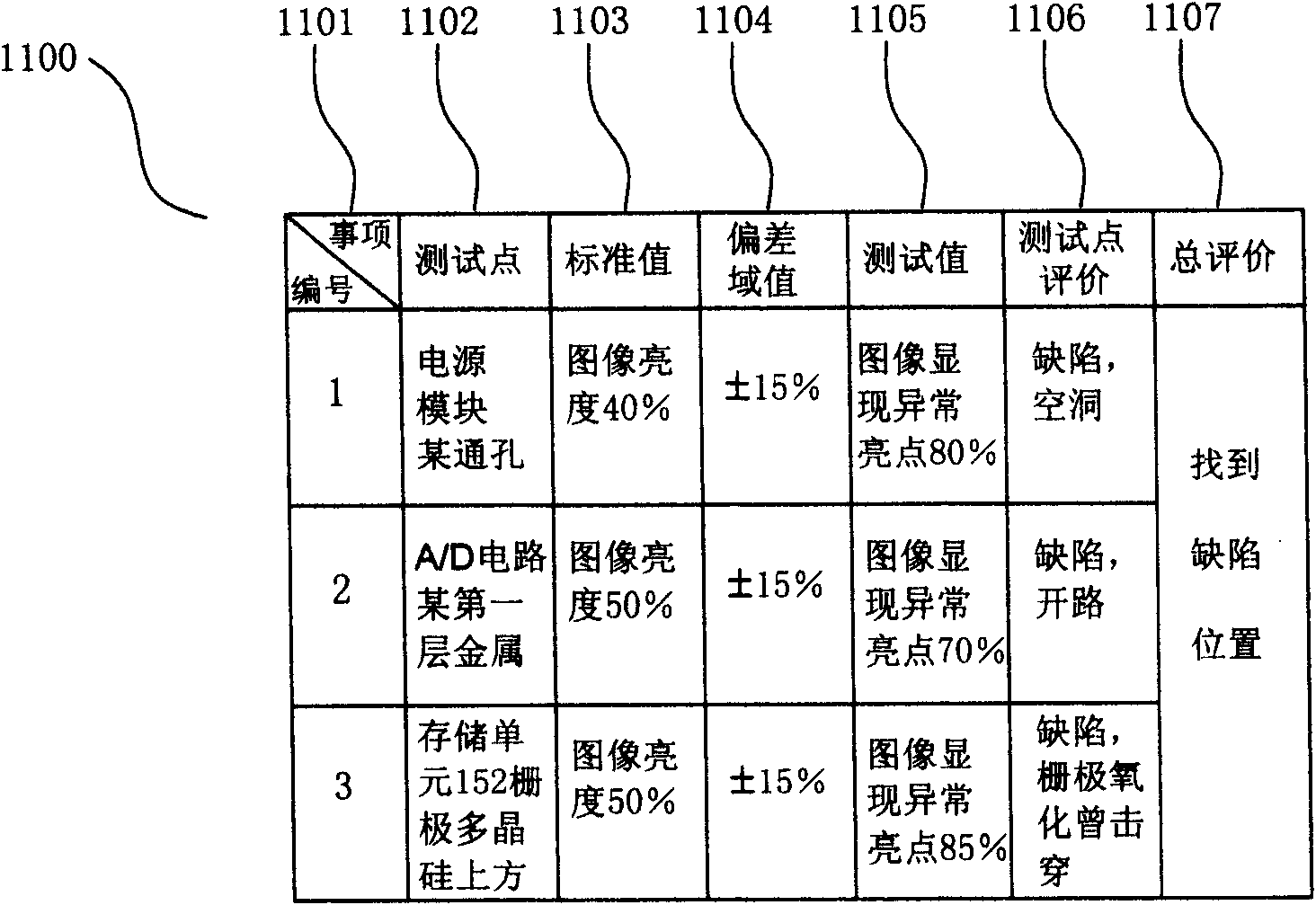

Location test system for defects of integrated circuit and implementation method thereof

InactiveCN101576565AImprove product qualitySpeed up research and developmentAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectronic circuit testingMeasurement deviceLaser scanning

The invention provides a location test system for defects of an integrated circuit and an implementation method thereof, belonging to the field of electronic test equipment, and relating to a system for locating and testing the defects of the integrated circuit and an implementation method thereof. The system mainly comprises a control analysis unit, a laser generator, a laser distribution device,a laser scanning device, an acoustic oscillation generator, an optical microscope device, a sample electrification module, a weak light detection device, a rated current voltage measurement device, arated voltage current measurement device, a damping platform, a darkroom case, and the like. Due to the adoption of the invention, the physical position of various defects of the integrated circuit can be located intuitively, and the defects of the integrated circuit can be found in time and accurately so as to improve the product quality, accelerate the speed of research and development and improve the production technique level.

Owner:SHANGHAI FALAB TEST

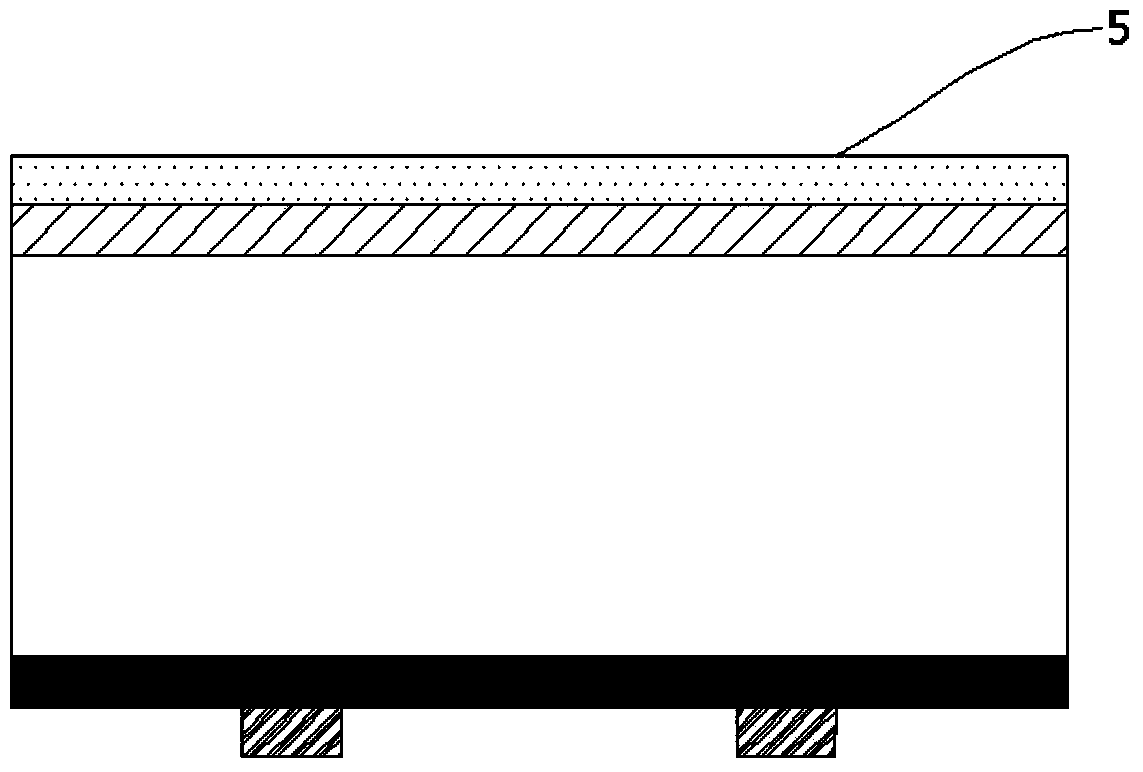

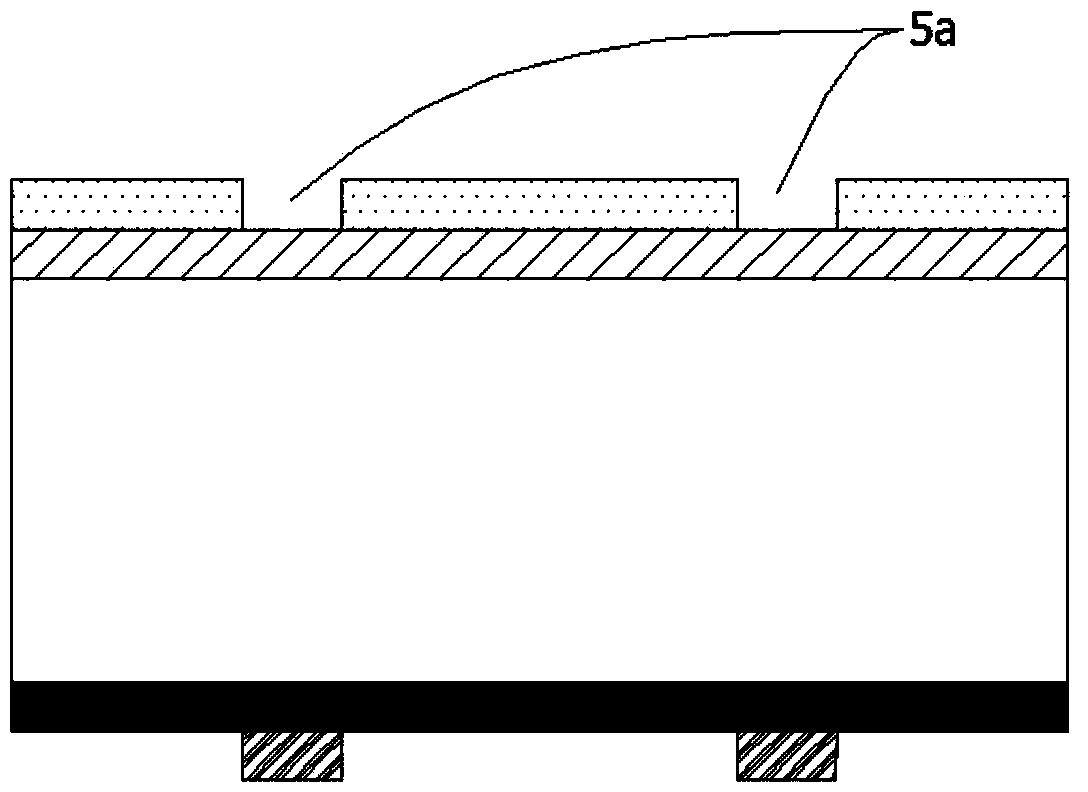

Improved copper electroplating method of crystal silicon solar battery

ActiveCN103726088AImprove the level of production technologyGuaranteed battery performance and reliabilityFinal product manufactureSemiconductor devicesSilicon nitrideEnergy level

The invention relates to an improved copper electroplating method of a crystal silicon solar battery. The silicon nitride layer on the surface of the conventional battery has many pin holes, and in the process of preparing copper (Cu) electrodes by an electroplating process, the Cu electrodes are easy to be adsorbed to the pin holes of the silicon nitride layer to lead to blur in appearance of the solar battery. Meanwhile, the copper electrodes are easy to seep into the silicon nitride layer and a silicon-based interface through the pin holes, and Cu as a deep energy level impurity with very fast diffusion rate entering into a pn junction affects the service life and generating efficiency of the battery, so that the reliability of the battery is reduced. A protective film covers the surface of the silicon nitride layer before Cu electroplating to prevent Cu from being adsorbed and seeped in the electroplating process, so that the reliability of the battery is guaranteed while the blur in appearance of the solar battery is avoided. The protective film can be removed after Cu electrode electroplating. According to the technological requirements of the crystal silicon batteries, the protective film can be still remained if parameters of the battery such as optical and electrical properties and reliability are not affected.

Owner:GUODIAN NEW ENERGY TECH INST +1

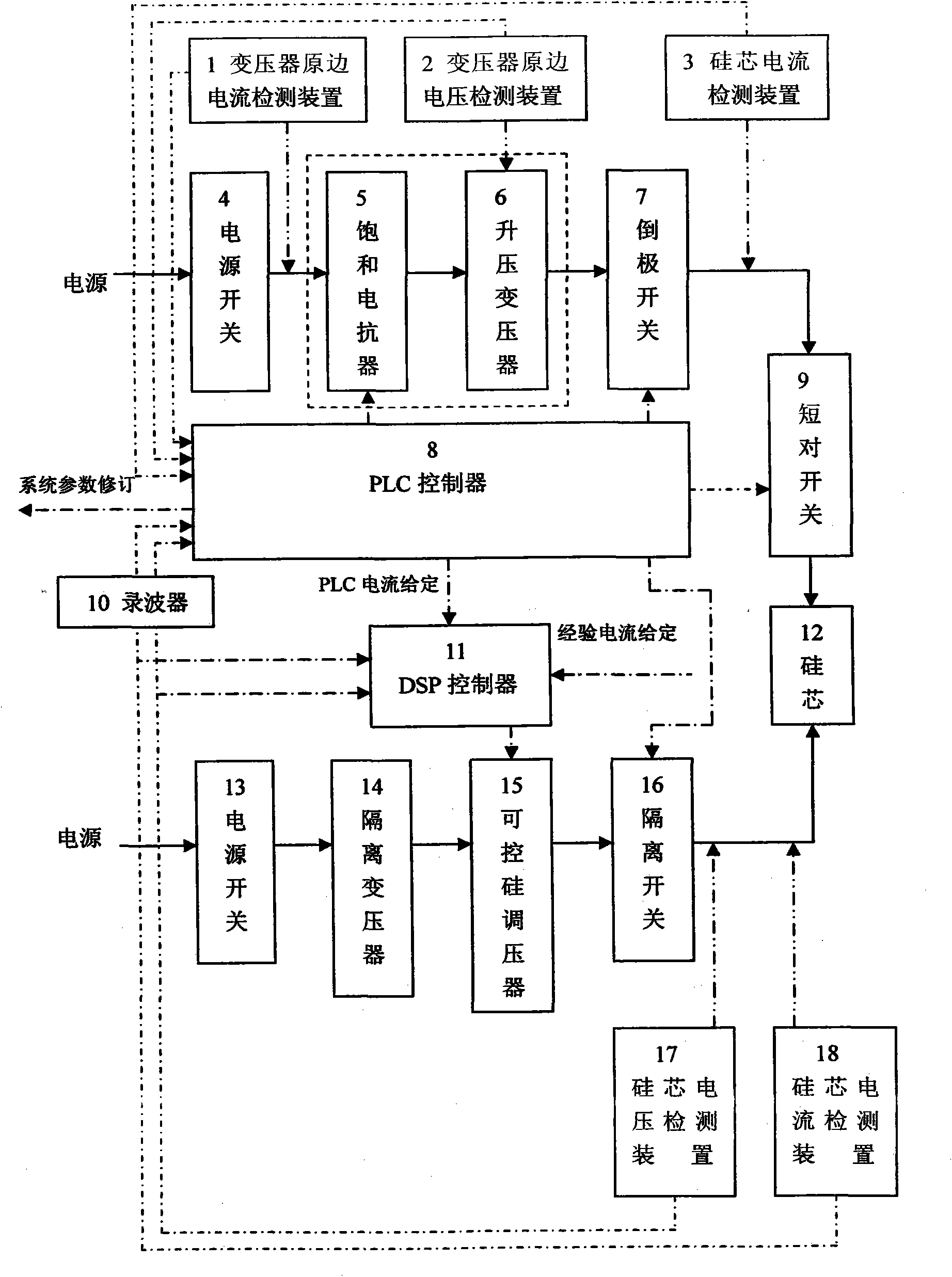

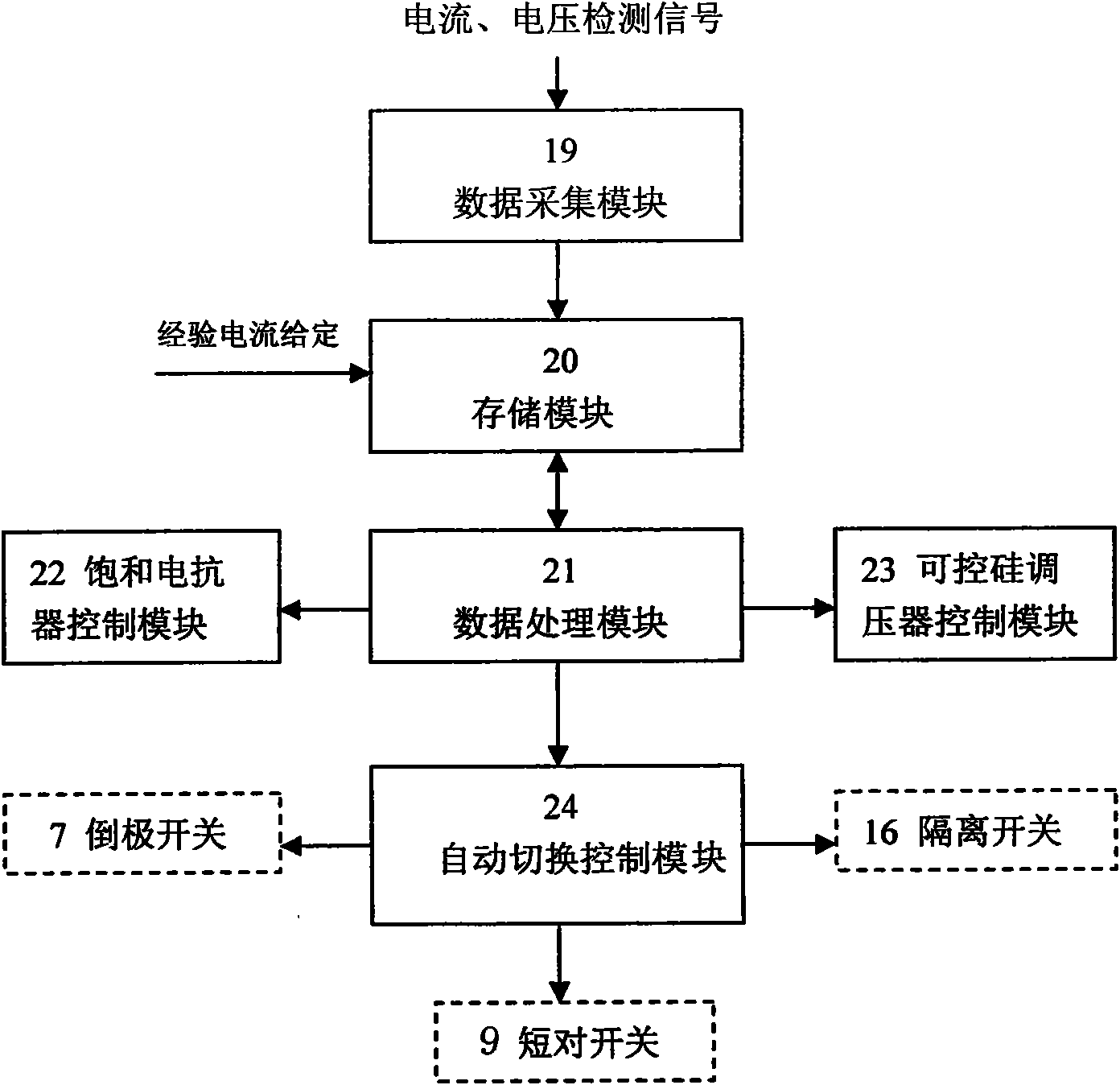

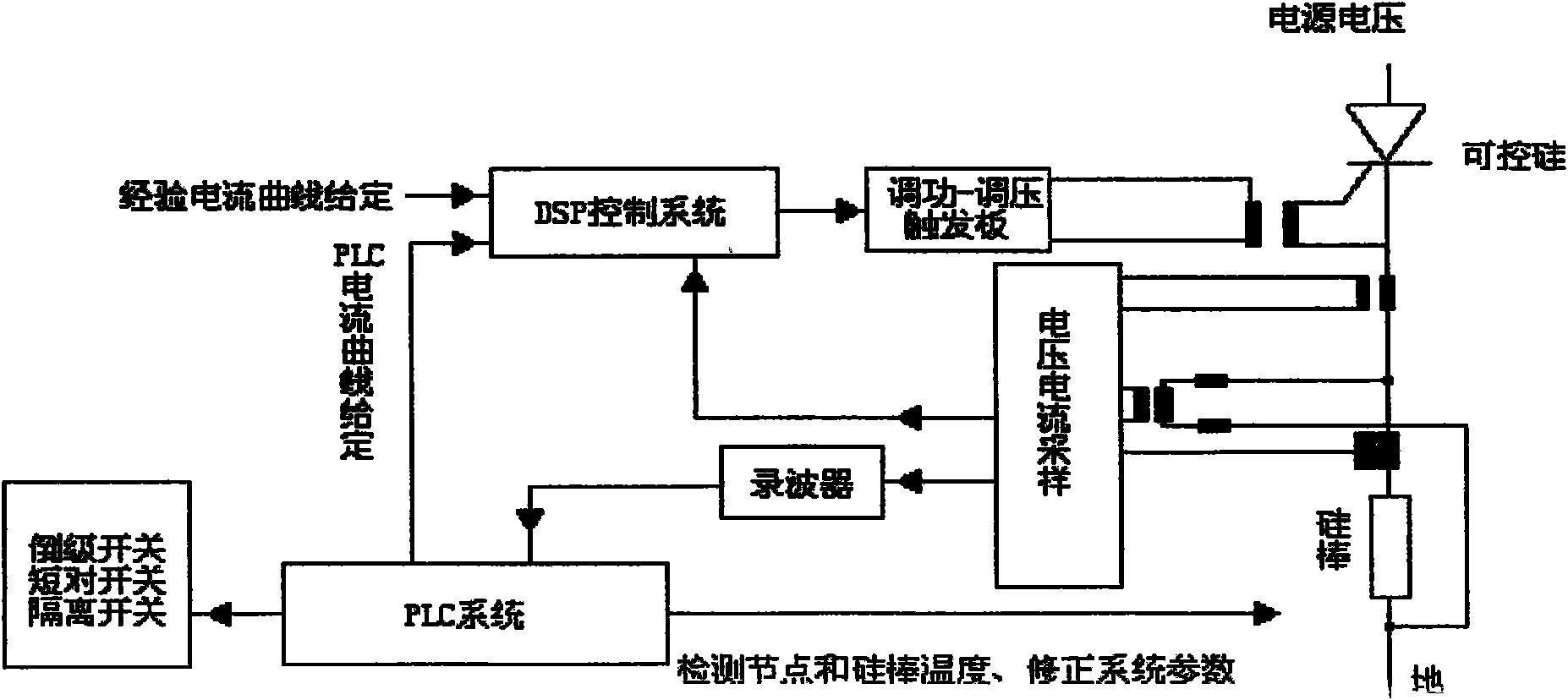

Automatic power regulation device for polysilicon reducing furnace

InactiveCN101597062AAutomatic Quick ConnectThe switching timing is stable and controllablePolycrystalline material growthSilicon compoundsSilicon-controlled rectifierPower switching

The invention discloses an automatic power regulation device for a polysilicon reducing furnace, comprising a silicon chip pre-heating device, a silicon chip constant-temperature heating device and controllers thereof, wherein, the silicon chip pre-heating device is provided with a power switch, a saturation resistor, a boosting transformer and a inverted pole switch which are connected in sequence, and the silicon chip pre-heating device is connected with a silicon chip by the inverted pole switch thereof; the silicon chip constant-temperature heating device is provided with a power switch, an isolation transformer, a silicon controlled rectifier and an isolating switch which are connected in sequence, and the silicon chip constant-temperature heating device is connected with the silicon chip by the isolating switch thereof; each controller is provided with a saturation resistor control module used for controlling the primary side voltage of the boosting transformer; a switch automatic switching control module is used for controlling the switching of the pre-heating device and the constant-temperature heating device, for controlling the breakdown sequence of the silicon chip, and for controlling the tapping position of the inverted pole switch on the secondary side of the boosting transformer, thereby controlling preheating current of the silicon chip; a control module of the silicon controlled rectifier is used for controlling the conduction angle of the controlled silicon, thereby controlling the constant-temperature heating current of the silicon chip; and the voltage regulator adopts wave splicing for voltage regulation.

Owner:DONGFANG ELECTRIC AUTOMATIC CONTROL ENG CO LTD

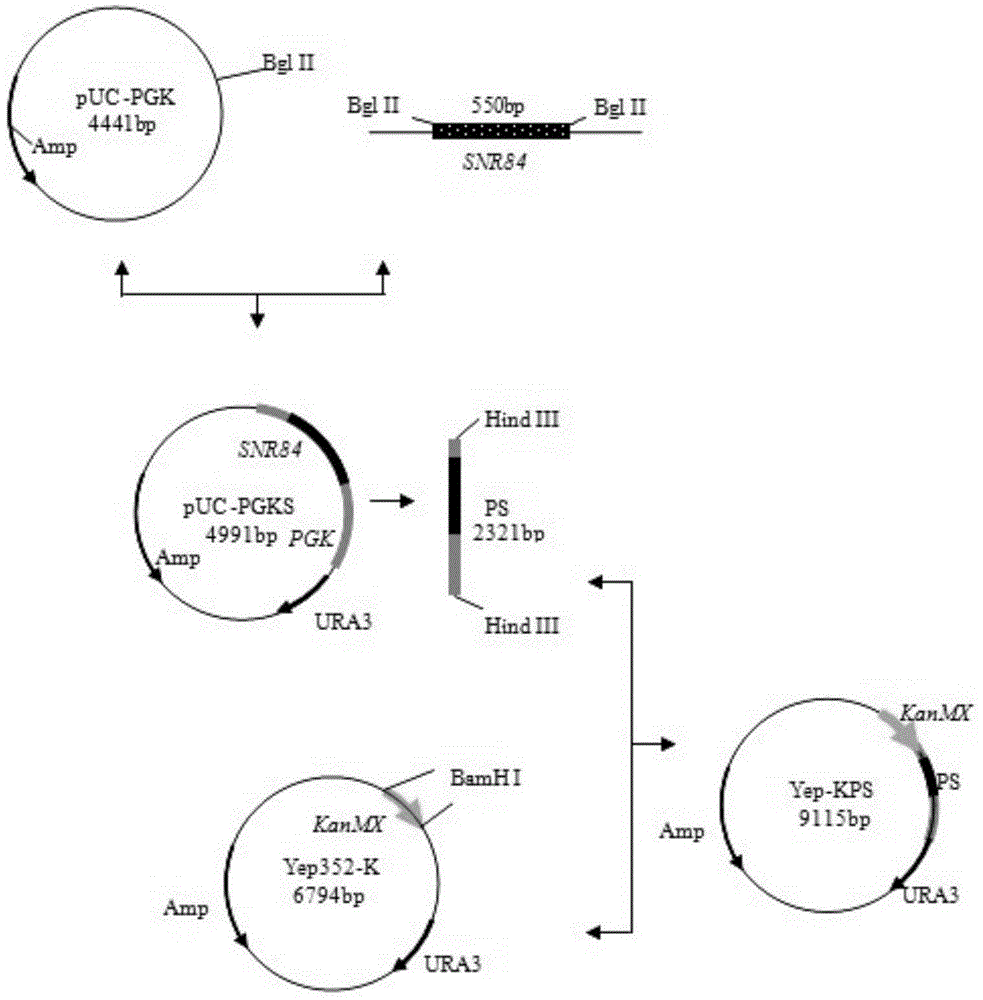

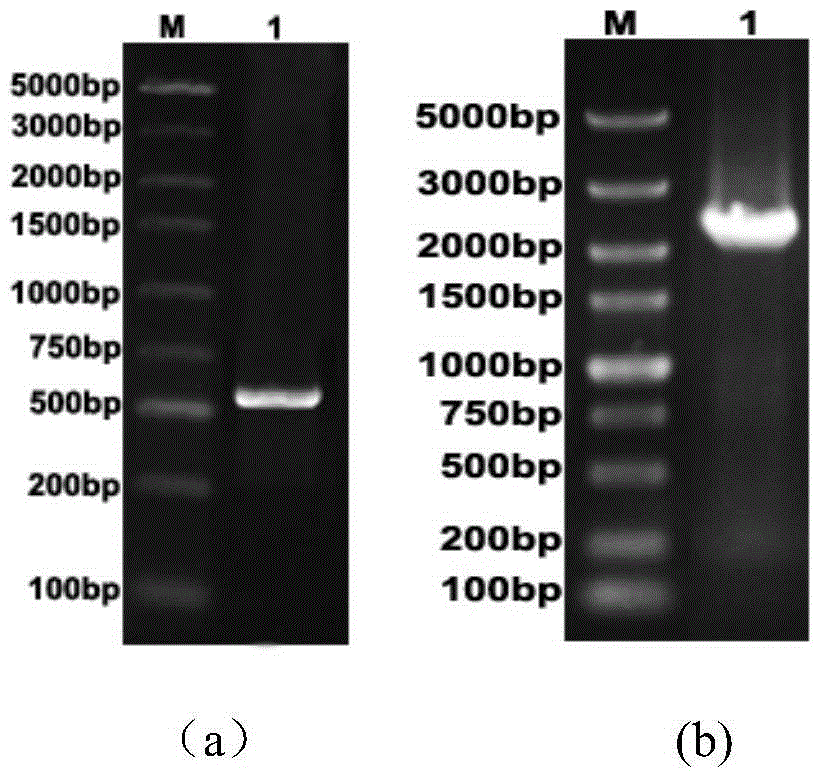

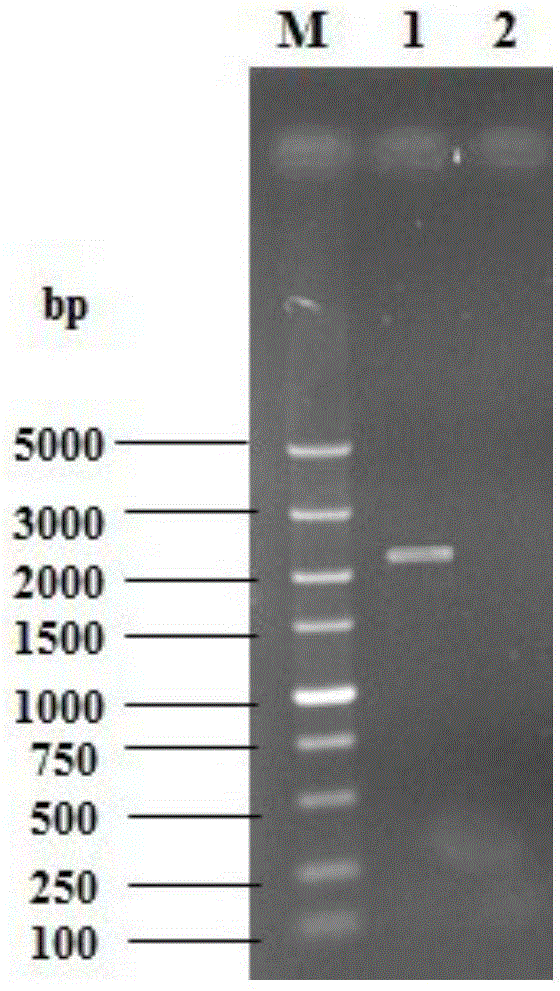

High-resistant yeast strain and preparation method thereof

ActiveCN104017742AOvercoming high temperature resistanceOvercome High Glucose ToleranceFungiPre-baking dough treatmentHeat shockBiotechnology

The invention discloses a high-temperature-resistant, high-sugar-resistant and freezing-resistant high-resistant yeast strain and a preparation method thereof. The preparation method comprises the following steps: over-expressing a complete sequence of H / ACA snoRNA (SNR84) by selecting and using a strong promoter PGK1 in a parent yeast strain to obtain the high-resistant yeast strain. The cell activity of the strain is remarkably improved in high-temperature, high-sugar and freezing environments in comparison with that of the parent strain. Saccharomyces cerevisiae are good in high-temperature resistance in heat shock treatment, high-sugar resistance in high-sugar dough and freezing resistance in frozen dough, the technical obstacle and the quality detect in a bread making process are overcome, and the application prospect is wide.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

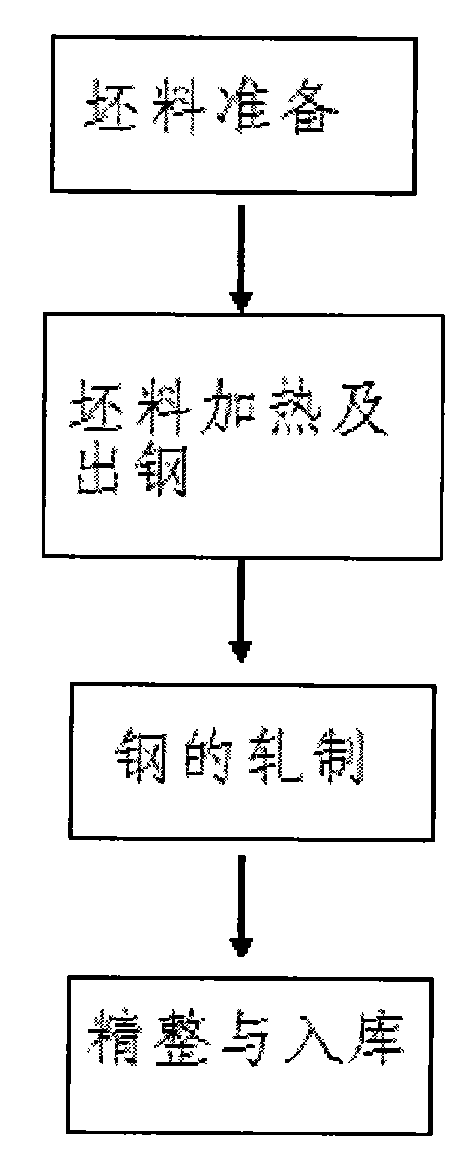

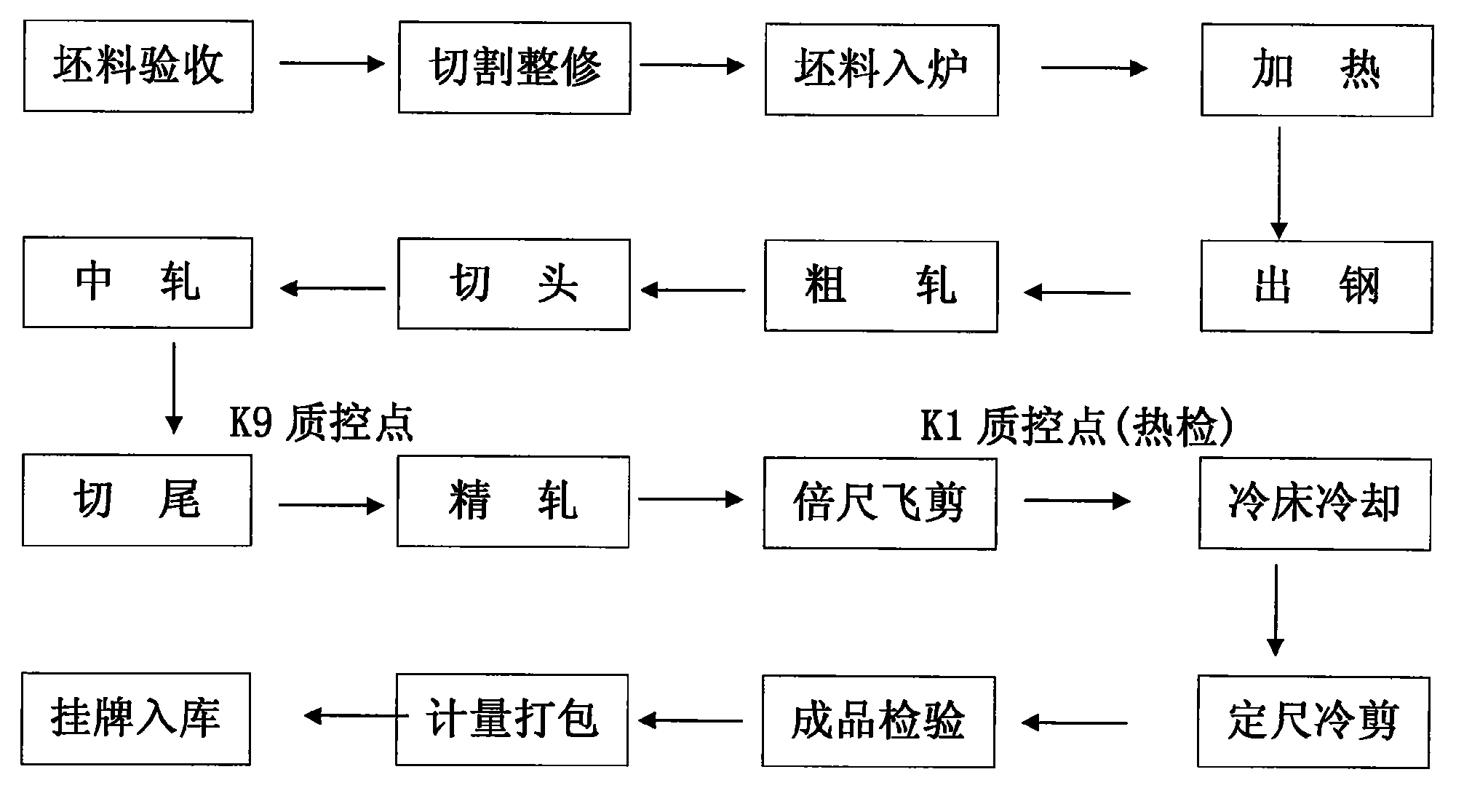

Steel rolling production process used in steel production

InactiveCN101596546AReduce product varietyImprove the level of production technologyCooling bedsMetal rolling arrangementsIntegrated productionEnergy resources

The invention discloses a steel rolling production process used in steel production, which comprises the following process flow: blank preparation, blank heating and steel tapping, steel rolling, finishing and warehousing; the steel rolling comprises the following steps: (1) test-rolling proof rolling; (2) checking a roller and replacing a groove; (3) guide installing; (4) rolling mill adjusting;(5) intermediate top cropping and end shearing, and carrying out finishing and shearing on billet after steel tapping by shearing equipment. In the invention, a double-roller rolling mill is used forrolling the billet, and a groove rolling method is also used with less product categories, thus being in favor of improving production technical level and performing professional strengths thereof, saving energy resource, reducing environmental pollution, effectively improving utilization ratio of equipment and production efficiency of steel rolling, and having the advantages of small production investment, simple process, low cost, high yield and energy saving and emission reducing, which is applicable to large-scale integrated production.

Owner:盐城市联鑫钢铁有限公司

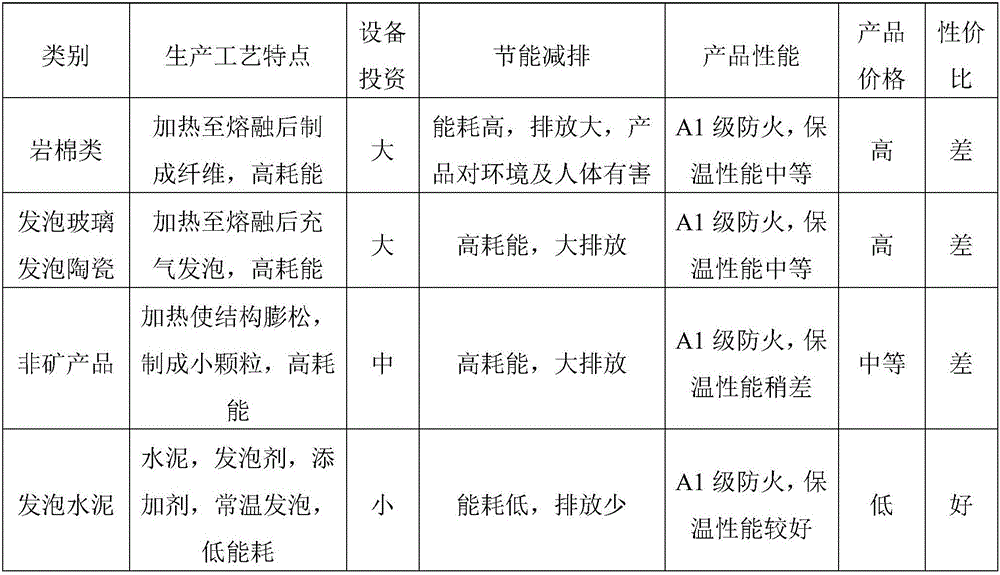

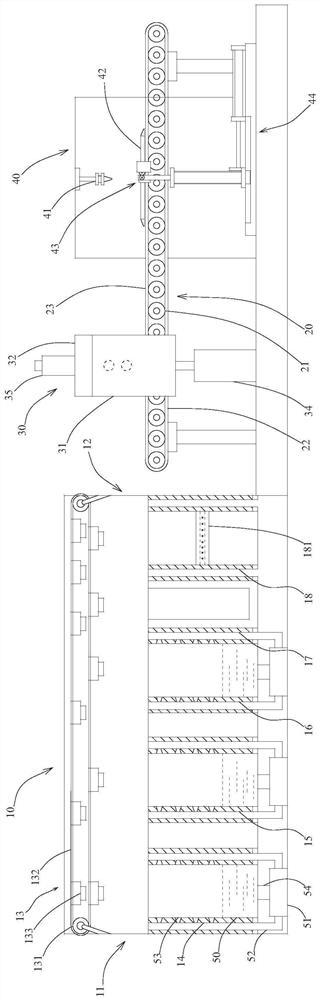

Multi-volume-weight magnesium oxysulfate foam insulation board as well as production equipment and process thereof

ActiveCN105818259AImprove the level of production technologyImprove reliabilityMixing operation control apparatusCeramic shaping plantsControl systemMaterials science

The invention relates to the field of cement, in particular to a multi-volume-weight magnesium oxysulfate foam insulation board as well as production equipment and a process thereof. The production equipment comprises a control system, a material storage system, a material batching system, a stirring system, a material distributing system, a material collecting system, a mould box and rail system, an operation system, a de-molding system, and a cutting and packaging system, wherein the material storage system, the material batching system, the stirring system, the material distributing system and the material collecting system are sequentially connected; and under the transfer of the operation system, the mould box and rail system connects the material collecting system with the de-molding system and the cutting and packaging system. The equipment and the process can simultaneously produce a plurality of magnesium oxysulfate foam insulation boards with different volume weights in a seamless manner, so that foamed inorganic magnesium oxysulfate products can be continuously, automatically and efficiently produced, and therefore, the reliability is high, the manufacturing cost is low and the production efficiency is high.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

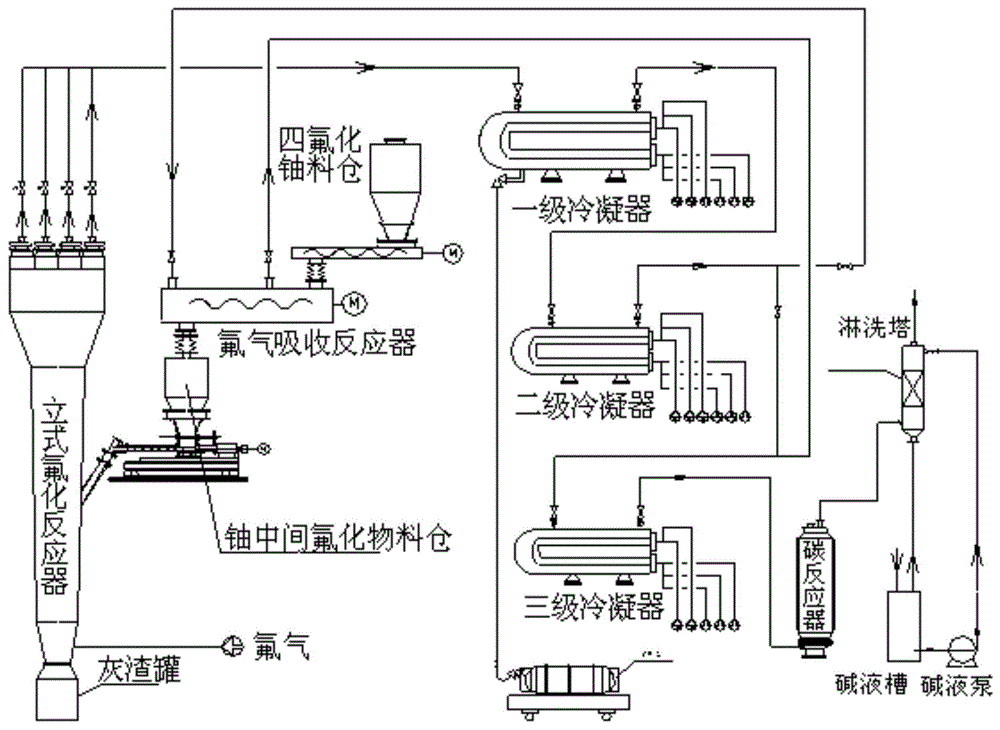

Fluorination technology for recovering fluorine gas

ActiveCN104628038AIncrease profitImprove absorption efficiencyUranium fluoridesUranium hexafluorideMaterial transfer

The invention discloses a fluorination technology for recovering fluorine gas. The method comprises the steps of fluorination and fluorine gas absorption. In the invention, a fluorine gas absorption reactor is abutted to a fluorination reactor, the solid material feeding end of absorption reactor is directly used as a system material inlet end, and the solid material inlet end of the fluorination reactor is substituted by the material outlet end of the fluorine gas absorption reactor, so a material transfer process is omitted. Compared with foreign fluorination technologies, the method has the advantages of short process flow and simple operation control. The technical scheme of the method adapts to the self characteristic of the technical route of uranium hexafluoride production technologies in China, and can be realized on the basis of original mature process flow without complex change.

Owner:THE 404 CO LTD CHINA NAT NUCLEAR

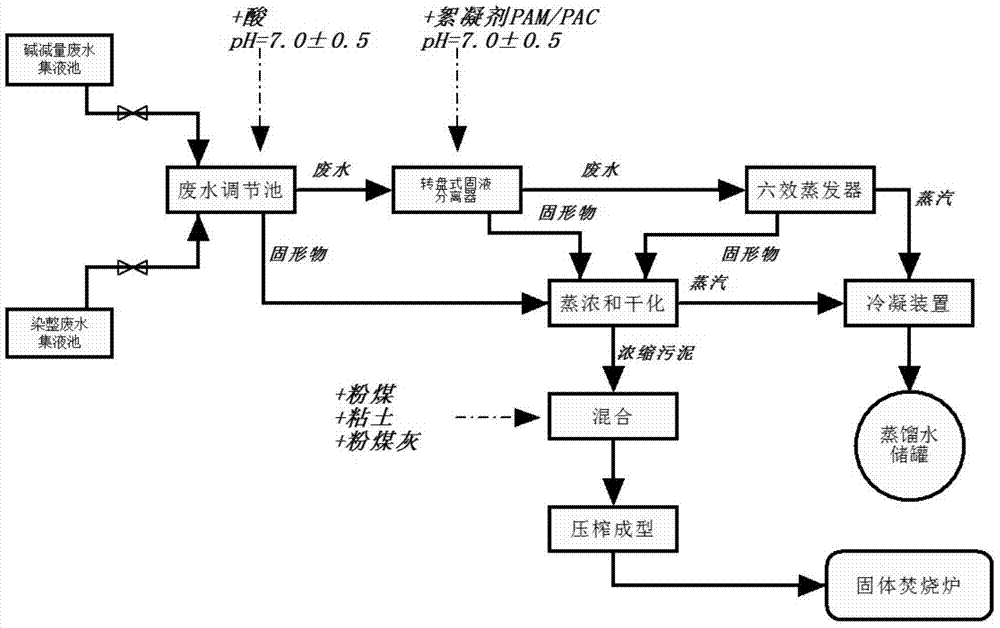

Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

InactiveCN103693792ASolve the technical bottleneck of zero emissionQuality improvementSludge treatment by de-watering/drying/thickeningBiofuelsFiberAluminium chlorohydrate

The invention discloses a wastewater zero discharge method in a manufacturing process of island superfine fiber synthetic leather. The method comprises the following steps: merging an alkali-minimization wastewater and a dyeing wastewater into a wastewater regulating reservoir, or merging the alkali-minimization wastewater into the wastewater regulating reservoir; adding acid to the wastewater regulating reservoir to form a solid matter; transferring the wastewater after the solid matter is cleaned into a turntable solid-liquid separator; adding a polyacrylamide flocculant and a polyaluminium chloride flocculant; evaporating the solid matter and the sludge obtained by solid-liquid separation in an evaporation tank, and simultaneously collecting distilled water in a condensation manner; transferring the wastewater from solid-liquid separation into a multi-effect evaporator to evaporate, and collecting distilled water by condensation; merging the residual residue in the evaporator into a sludge concentrating tank to continue to process. The production of the island superfine fiber synthetic leather is taken as a basic system, and is combined with collection, treatment and comprehensive utilization technologies of the production wastewater and the solid matter, the technical bottlenecks of wastewater zero discharge in the production process is solved, and the island superfine fiber synthetic leather which is friendly to environment and high in quality can be produced.

Owner:FUJIAN KELISHENG SUPERFINE FIBER

Multi-volume-weight foaming panel and production device and technology thereof

ActiveCN105881724AImprove the level of production technologyImprove reliabilityDischarging arrangementMixing operation control apparatusControl systemCement

The invention relates to the field of cement, in particular to a multi-volume-weight foaming panel and a production device and technology thereof. The production device comprises a control system, a storage system, a batching system, a stirring system, a material distributing system, a material collecting system, a die box and rail system, an operating system, a die stripping system and a cutting and packaging system. The storage system, the batching system, the stirring system and the material distributing system are sequentially connected with the material collecting system. Under transferring of the operation system, the material collecting system, the die stripping system and the cutting and packaging system are connected through the die box and rail system. According to the device and the technology, several kinds of inorganic foaming panels different in volume weight can be seamlessly produced at the same time, foaming inorganic products can be continuously, automatically and efficiently produced, reliability is high, the manufacturing cost is low, and the production efficiency is high.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

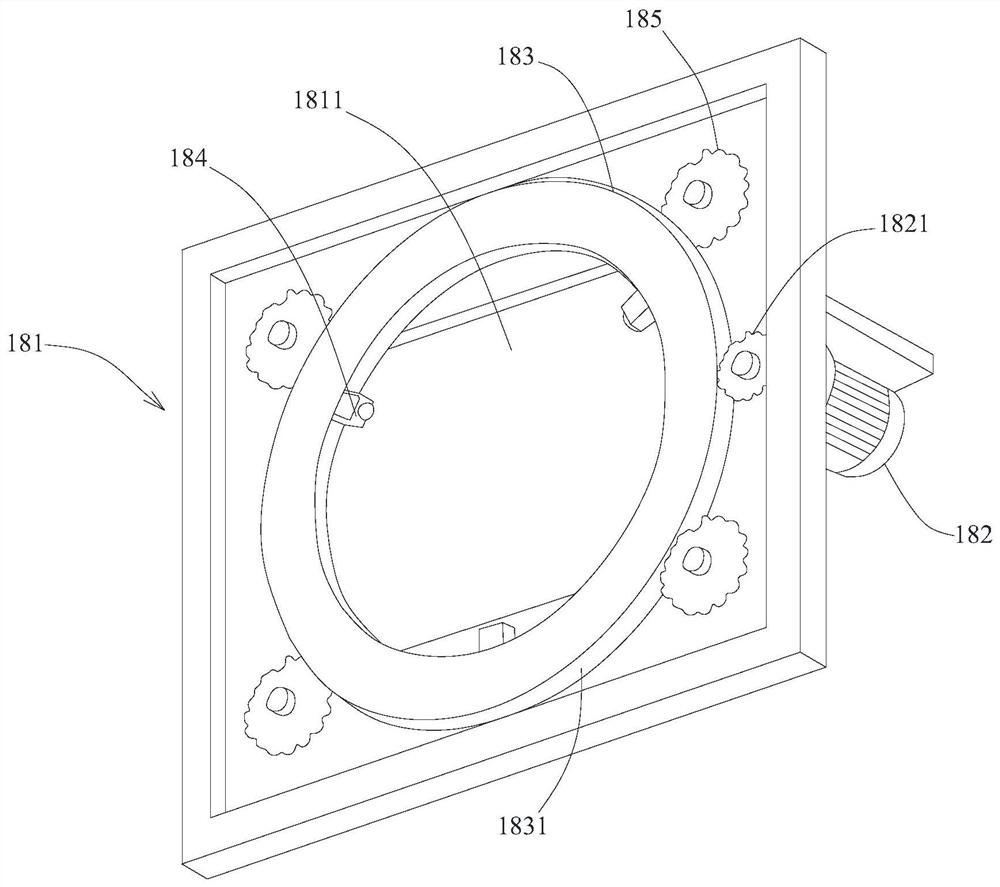

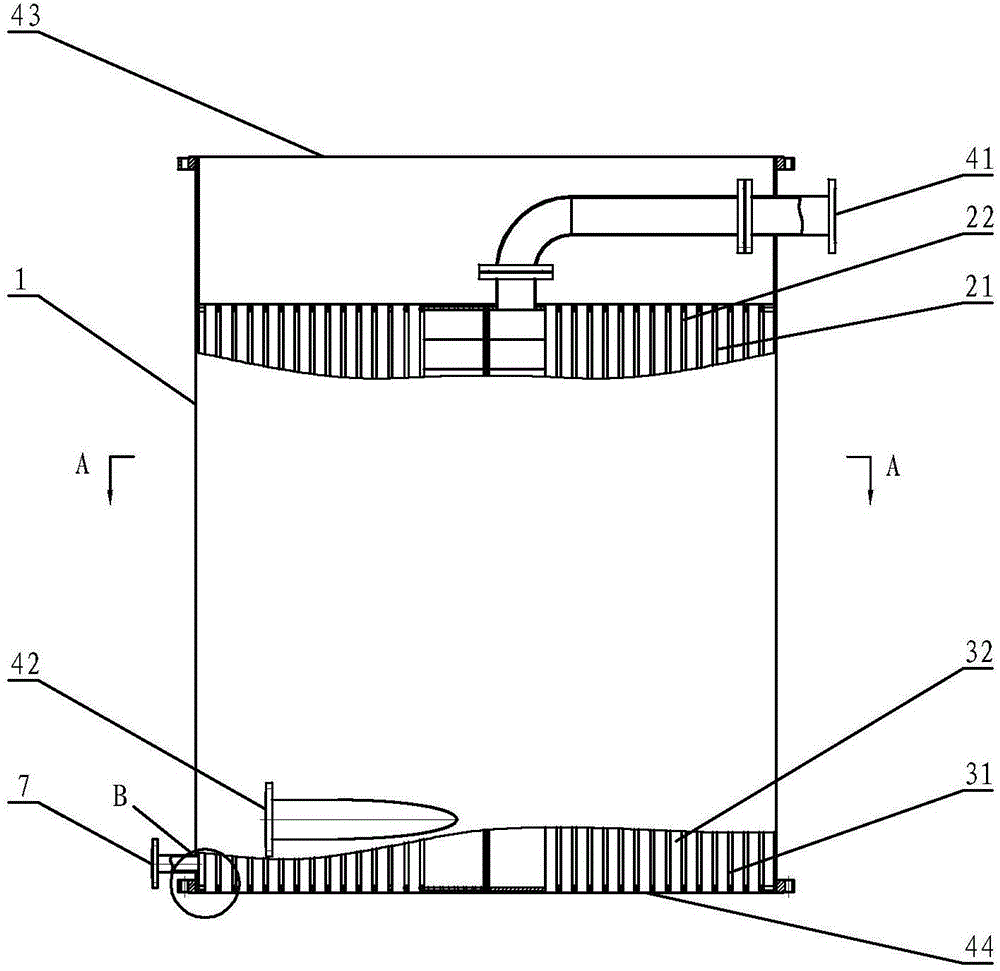

Structure of device for detecting tubeless steel ring gastightness

ActiveCN101451900AImprove production technologyImprove the level of production technologyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringAir tightness

A composition and detecting process for tubeless steel a gas-tight detecting device are provided. The machine body of the tubeless steel a gas-tight detecting device is comprised of an upper mainframe, a lower mainframe, a sink, a pressing plate, a tray, a matching control box component, an instrument component and a valve component, which are formed by connecting the components; in the process of the gas-tight detection for the tubeless steel ring, the method is mainly based on the work of pre-prepared operating procedures specific tubeless wheel and observation of the steps gas tightness. The technology program will not only further improve the tubeless wheel production technology, and improved tubeless wheel production technology level, the protection of tubeless steel product quality, reduce scrap rates and improve the economic efficiency of enterprises, have played a significant the role of filling in the domestic steel tubeless air tightness testing equipment and testing methods blank in our country to further standardize the tubeless wheel production technology and testing technology, also has a very active role in and of significant importance.

Owner:ZHEJIANG JINGU CO LTD

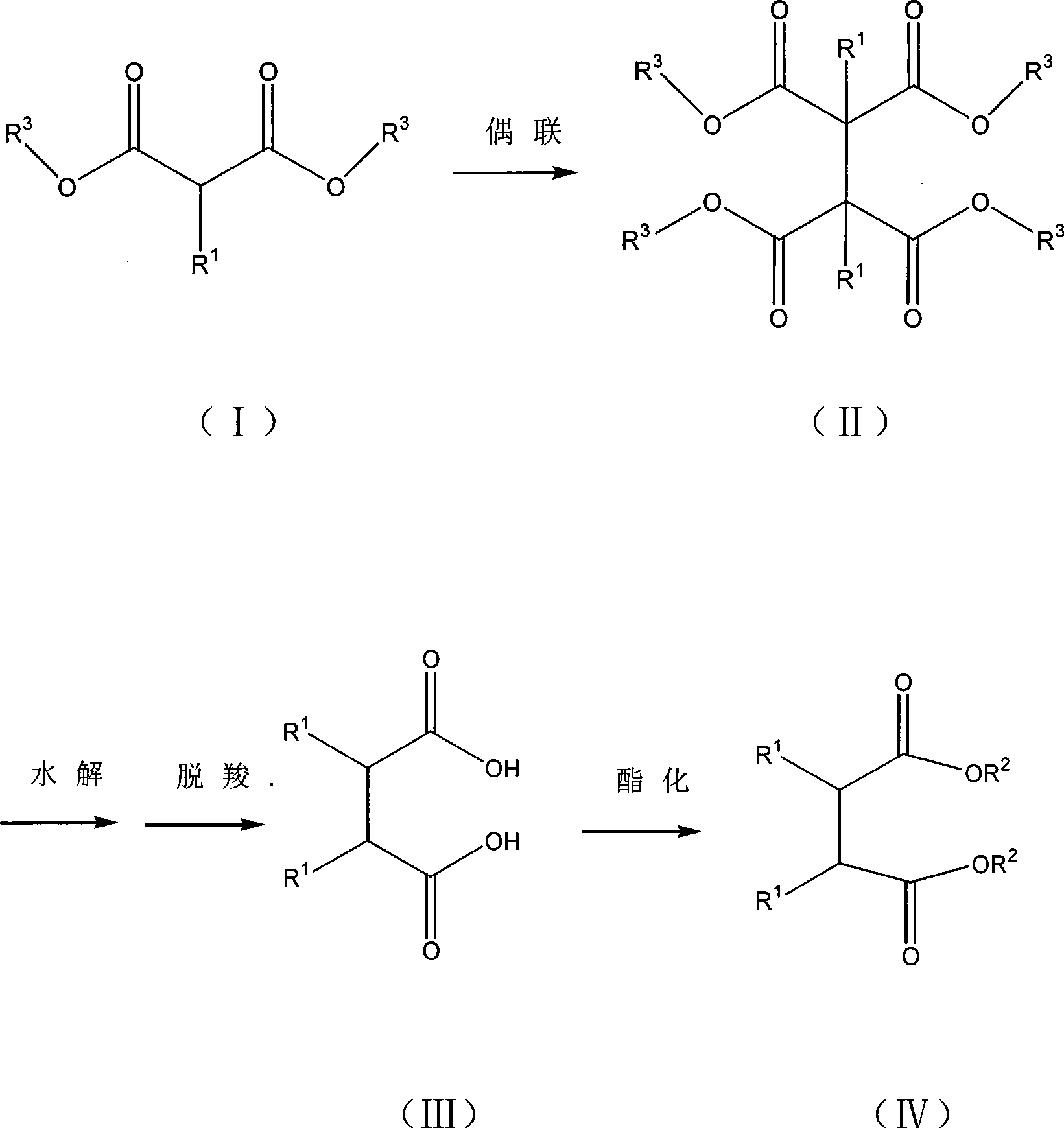

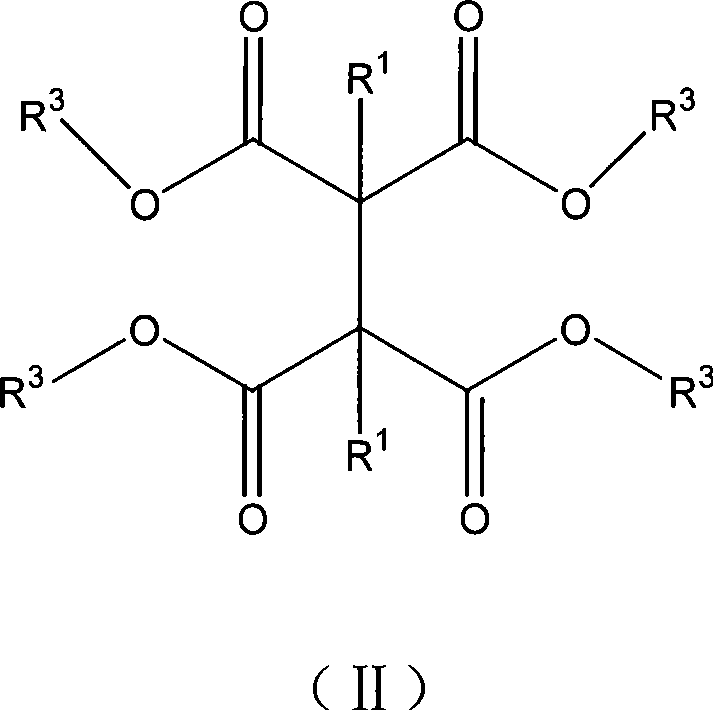

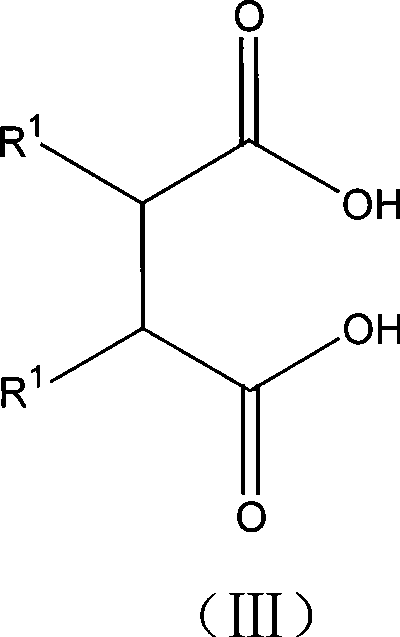

Method for preparing 2,3-dialkyl succinic acid and ester compounds thereof

ActiveCN101397246AImprove the level of production technologyEasy to industrializeCarboxylic preparation by ozone oxidationElectron donorSuccinic acid

The invention relates to a preparation method of 2, 3-dialkyl succinic acid and ester compounds thereof. 1, 2-dialkyl-1, 1, 2, 2-tetra (alkoxy carbonyl)ethane is prepared through the dimerization coupling reaction of 2-alkyl-malonic ester compounds, then the 2, 3-dialkyl succinic acid is prepared by carrying out hydrolysis and decarboxylation reaction, and the 2, 3-dialkyl succinate compounds are prepared by further esterification. The preparation method is conductive to the commercial production of the 2, 3-dialkyl succinate and can be used for preparing a Ziegler-Natta polypropylene catalyst as an internal electron donor compound. The preparation method can be used in the technical field of petrochemical polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing natural perfume nonanal

ActiveCN101597221AImprove the level of production technologyImprove conversion rateCarbonyl compound preparation by oxidationFlavorOrganic solvent

The invention belongs to a new process for synthesizing natural identical perfume nonanal. The method comprises the following steps: mixing and stirring 36 grams of trichloroiminocyanuric acid, 580 milliliters of trichloromethane, 33 grams of calcium oxide and 75 grams of nonanol; dripping 20 milliliters of trichloromethane solution containing 0.4 gram of trolamine while stirring the solution, keeping on stirring the solution at a temperature of 40 DEG C to react for 4 hours; adding 0.3 gram of trolamine and 15 grams of trichloroiminocyanuric acid into the solution, and keeping on stirring at 40 DEG C to react for 2 hours; removing solid from the reaction solution, washing the solution to neutrality by liquid, recovering organic solvent, distilling the obtained organic solvent by decompressing to 0.097MPa, and obtaining the fraction at boiling point of 102 DEG C, which is the final product. The method of the invention prepares the nonanal by the new process with high conversion rate, no pollution and easy industrial operation.

Owner:黄山科宏生物香料股份有限公司

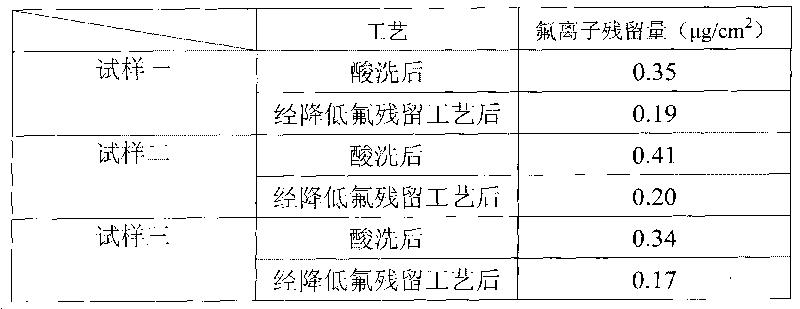

Technology for reducing fluorin residue on acid cleaned surface of zirconium alloy pipe

ActiveCN101698941AReduce fluorine residueExtended service lifeCleaning using liquidsManufacturing technologySoftened water

The invention relates to the field of a technology for reducing fluorin residue on the acid cleaned surface of a zirconium alloy pipe, comprising the following steps: sequentially rinsing the zirconium alloy pipe with NH4CO3 solution and NaOH solution; rinsing the zirconium alloy pipe with hot softened water, and washing the zirconium alloy pipe with cold softened water; and blowing and scrubbing the zirconium alloy pipe by directly blowing with high-pressure gas or blowing and beating the surface of a sponge block to lead the surface of the zirconium alloy pipe to have no moisture and water print remnant to complete the process of reducing the fluorin residue on the acid cleaned surface of the zirconium alloy pipe. The invention can effectively reduce the fluorin residue which mainly is zirconium fluoride complex on the acid cleaned surface of the zirconium alloy pipe, improves the service life of the zirconium alloy pipe, sufficiently meet the use requirement of the zirconium alloy pipe in nuclear power, improves the manufacture technology of the zirconium alloy pipe in China, and enhances the use safety of nuclear materials.

Owner:国核宝钛锆业股份公司 +1

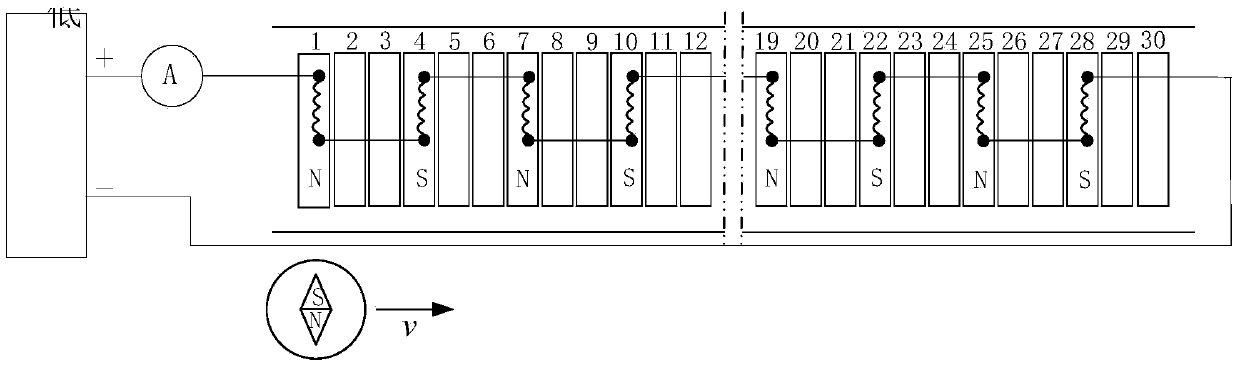

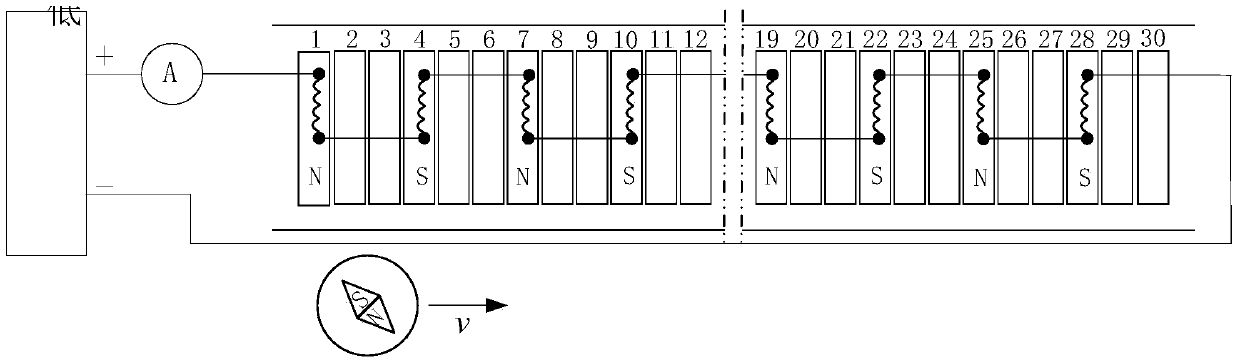

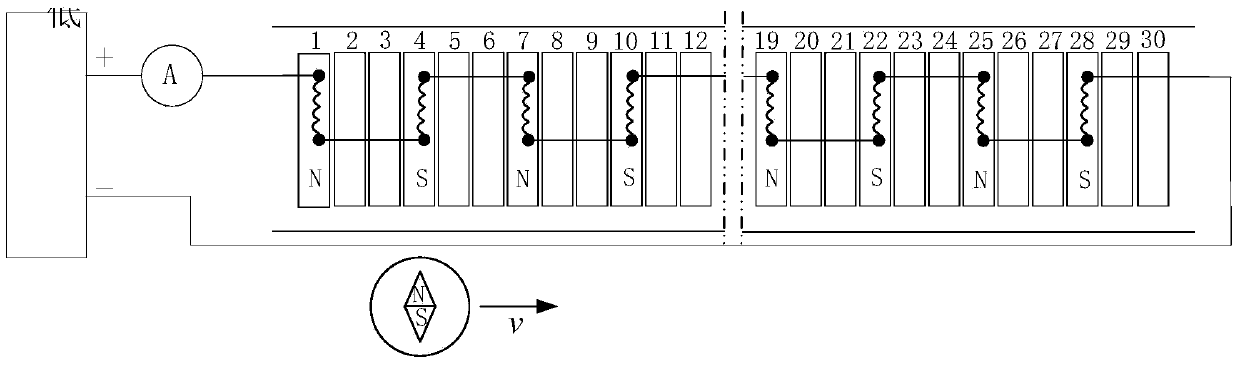

Method for detecting wiring of three-phase alternating current winding

InactiveCN103746487AImprove the level of production technologyImprove accuracyWindings conductor shape/form/constructionCurrent meterLow voltage

The invention relates to a method for detecting wiring of a three-phase alternating current winding, including a direct current single-phase detection method and an alternating current overall detection method. The direct current single-phase detection method applies low-voltage direct current to two ends of a winding of any phase of a primary three-phase winding of a motor, and moves a magnetic needle disc from one end of the winding of the phase to the other end of the winding of the phase at a uniform speed, if the magnetic needle disc passes through all coils of the winding of the phase, a magnetic needle rotate at a constant speed for p rounds along the same direction, and the number of pole-pairs of the motor is p, the wiring of the winding of the phase is judged to be definitely correct; and the alternating current overall detection method applies alternating current to the primary three-phase winding of the motor, horizontally places the magnetic needle disc in a position in or near the middle of one side of the three-phase winding to be fixed, and if the magnetic needle continuously rotates at a constant speed, overall wiring of the three-phase winding is judged to be correct, and a linear speed converted from the rotating speed of the needle is the speed of a moving magnetic field of the motor. The method for detecting wiring of the three-phase alternating current winding is simple to operate, visual and direct, and easy to realize.

Owner:XIJING UNIV

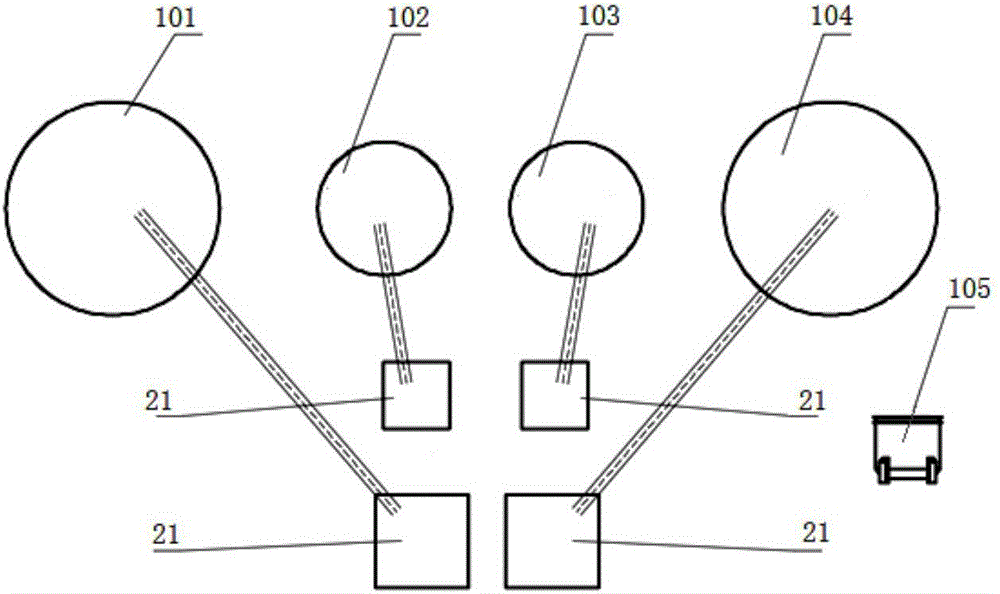

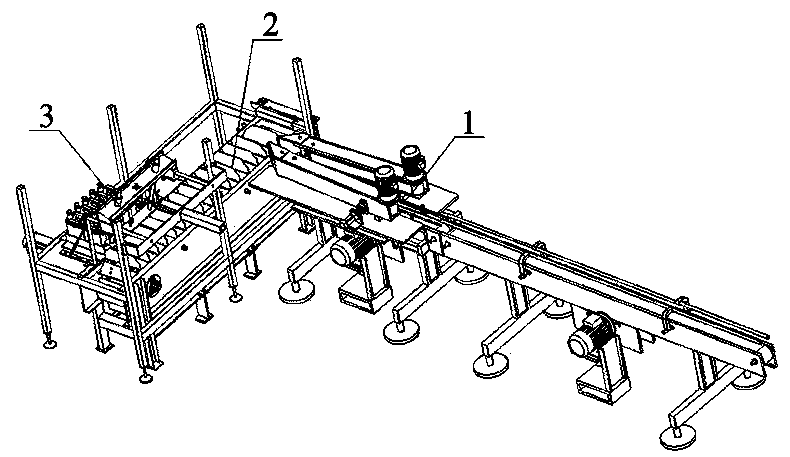

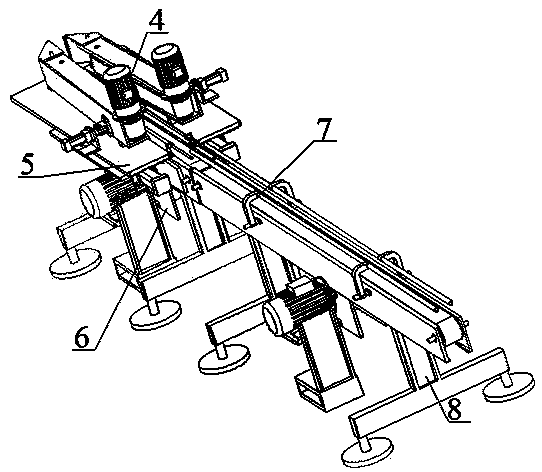

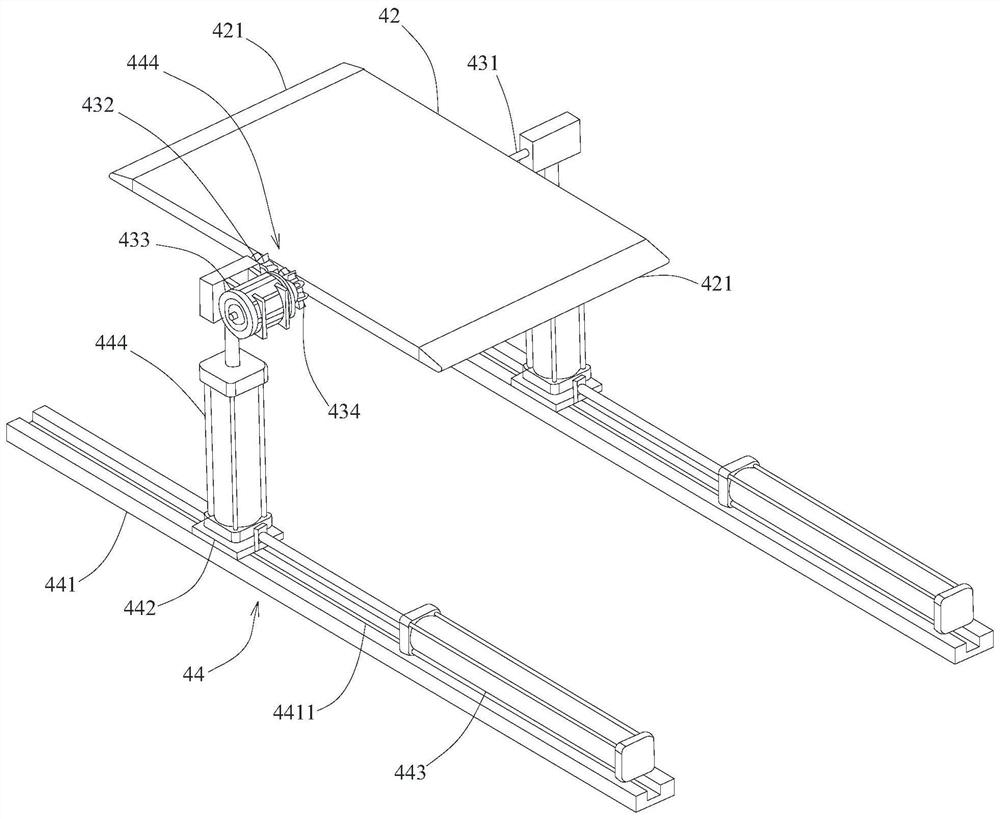

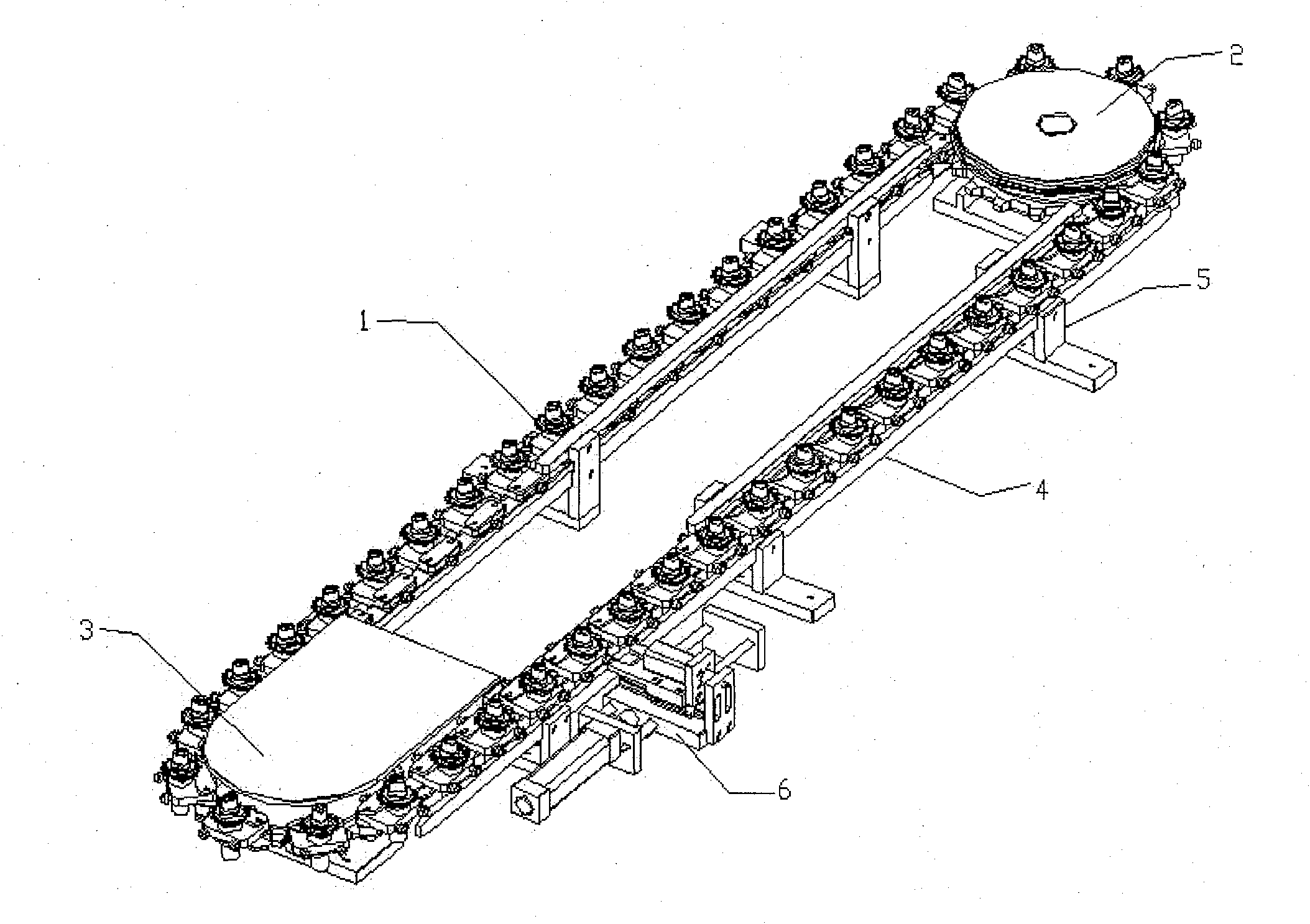

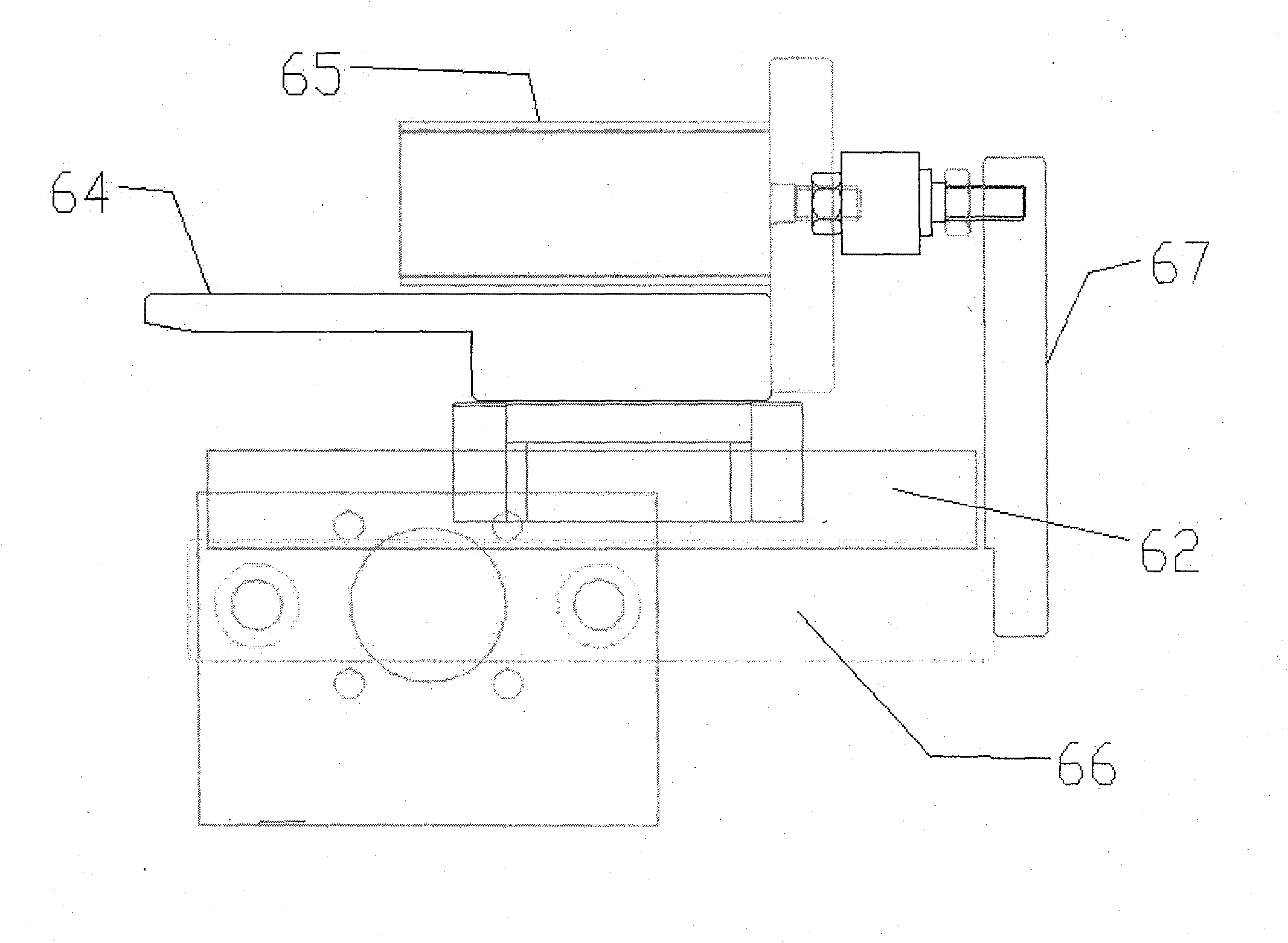

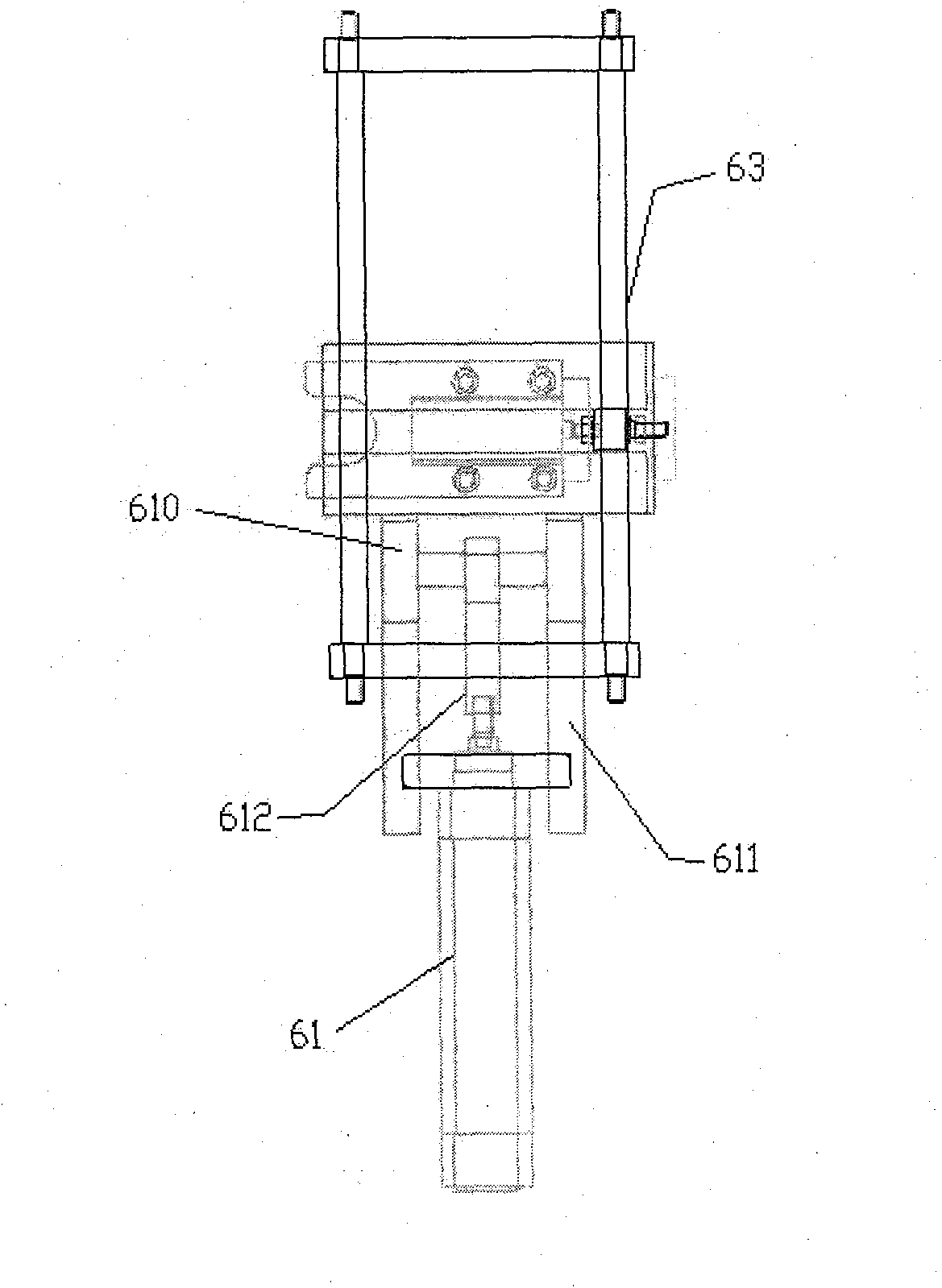

Forming device for laundry detergent encasement

The invention belongs to the technical field of industrial robot application and discloses a forming device for laundry detergent encasement. The forming device for laundry detergent encasement comprises a collecting arm mechanism, a chain plate conveying mechanism and a push mechanism. The front end of the collecting arm mechanism and the front end of the chain plate conveying mechanism are in vertical butt joint, and the push mechanism is arranged right above the chain plate conveying mechanism. Laundry detergent is collected by the collecting arm mechanism to be conveyed into the chain plate conveying mechanism according to production takt, the chain plate conveying mechanism conveys the laundry detergent into the push mechanism according to the production takt, and the laundry detergent, with the quality of one case, on the chain plate conveying mechanism is pushed and formed by the push mechanism. The forming device for laundry detergent encasement has positive significance to improving the automation degree, production efficiency and the production technology level of a laundry detergent production line.

Owner:安徽工业大学科技园有限公司

Aluminum panel surface uniform spraying line

PendingCN111715453AImprove spray uniformityHigh strengthPretreated surfacesCoatingsProcess engineeringMechanical engineering

The invention discloses an aluminum panel surface uniform spraying line, and belongs to aluminum panel production equipment. The aluminum panel surface uniform spraying line comprises a pre-washing device and a first conveying device, the pre-washing device comprises a pickling tank, an alkaline washing tank, a water washing tank, a drying box and a pre-spraying box which are sequentially mountedin the direction from the feeding end to the discharging end, a pre-spraying mechanism is arranged in the pre-spraying box, a uniform spraying device is further included in the spraying line, and is connected with the pre-washing device, the uniform spraying device comprises a second conveying device, a parallel spraying mechanism and an inclined spraying mechanism, one side of the parallel spraying mechanism is connected with the inclined spraying mechanism through the second conveying device, the other side of the parallel spraying mechanism is connected with the pre-spraying box through thefirst conveying device, the aluminum panel production automation degree and the production efficiency can be improved, meanwhile, the manual spraying tedious process can be avoided, manpower cost isreduced, and the aluminum panel production process level can be improved.

Owner:佛山市顺德区高士达建筑装饰材料有限公司

Supporting method of large-section tunnel in water-rich complicated geological mass

InactiveCN102808636AEfficient miningImprove the level of production technologyUnderground chambersDrainageEconomic benefitsInstability

The invention particularly provides a supporting method of a large-section tunnel in water-rich complicated geological mass and solves the problem that supporting of the large-section tunnel in the water-rich complicated geological mass fails to be achieved by the common supporting methods. The supporting method includes: arranging a micro-arc arched roof and an inverted-camber floor in the tunnel, and using anchor ropes and anchor bolts for combined supporting. The supporting problem of the large-section tunnel with rich-water roof and rheological property, expansibility and softness is solved, surrounding rock is controlled effectively, loss caused by instability of the tunnel is avoided, coal resources are exploited effectively, production technological level of enterprises is increased, and huge social and economic benefits are achieved.

Owner:DATONG COAL MINE GRP

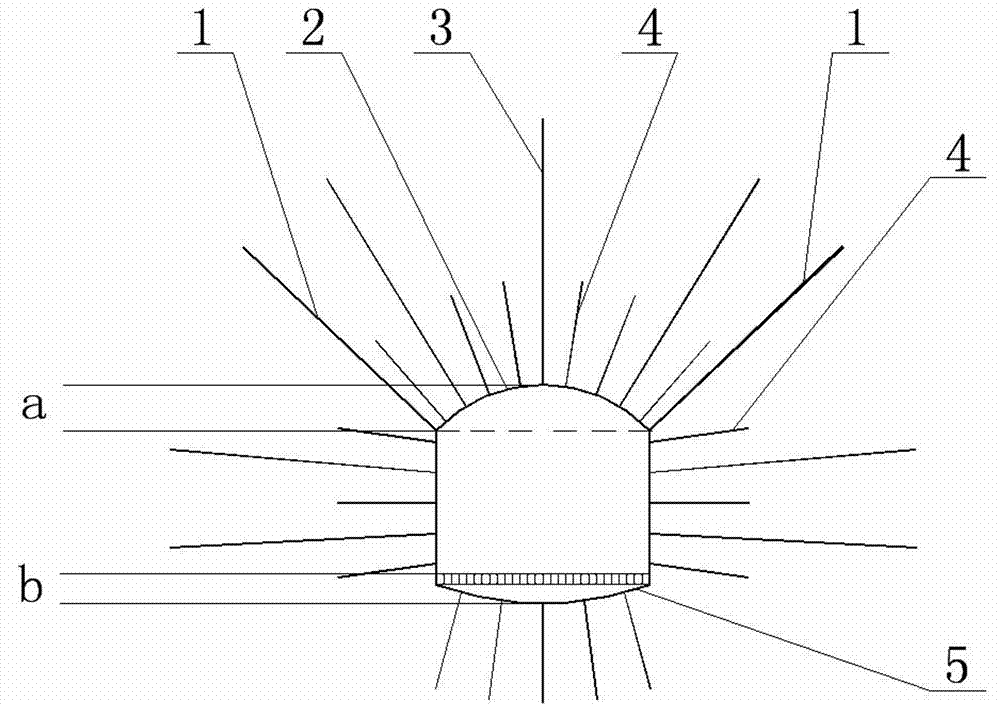

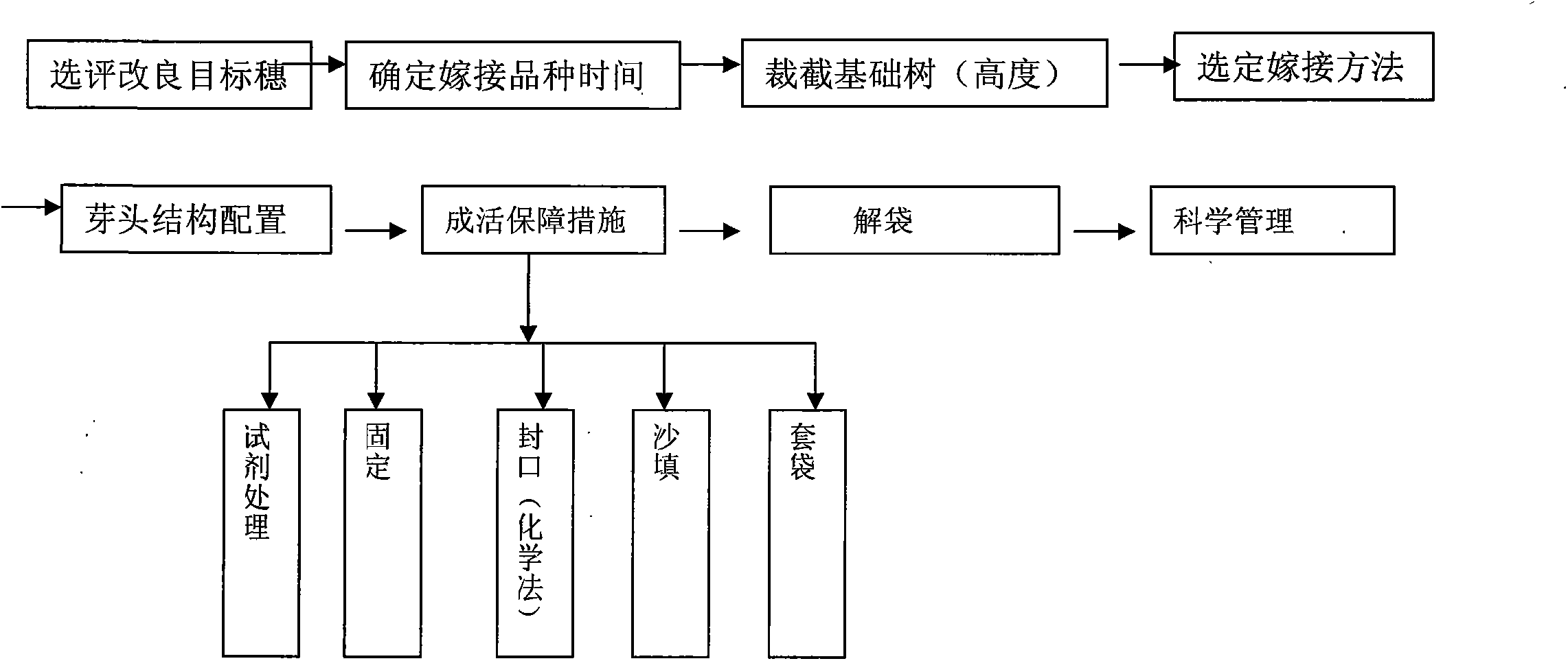

Quick and efficient fruit tree variety transformation technology

The invention discloses a quick and efficient fruit tree variety transformation technology. The technology comprises the following steps: (A) choosing an improving target panicle: choosing an improving target variety according to variety identification indicators, such as the high yield performance, resistance and adaptability of varieties, and varieties with excellent economic character performance after experiment in cultivation; (B) determining variety grafting time: determining grafting time according to different types of fruits, wherein the grafting time is 2-4 months; (C) cutting a base tree; (D) selecting a grafting method: selecting a tongue embedding connection method as the grafting method; (E) configuring a bud structure: grafting by adopting 3-head environment-friendly embedding configuration; (F) carrying out survival guarantee measures. Compared with the conventional fruit tree variety transformation methods, the transformation technology disclosed by the invention has the advantages that the transformation time can be shortened by more than 5 years, the survival rate reaches over 90%, the transformation cost is decreased by over 10 times, the economic benefit can be improved by over 6-10 times, and the social benefit is great.

Owner:SHAANXI UNIV OF TECH

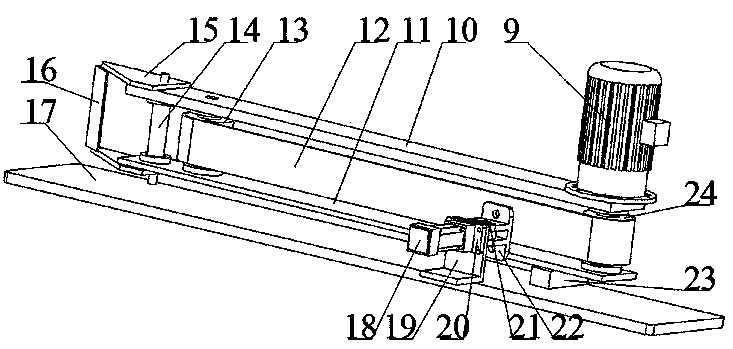

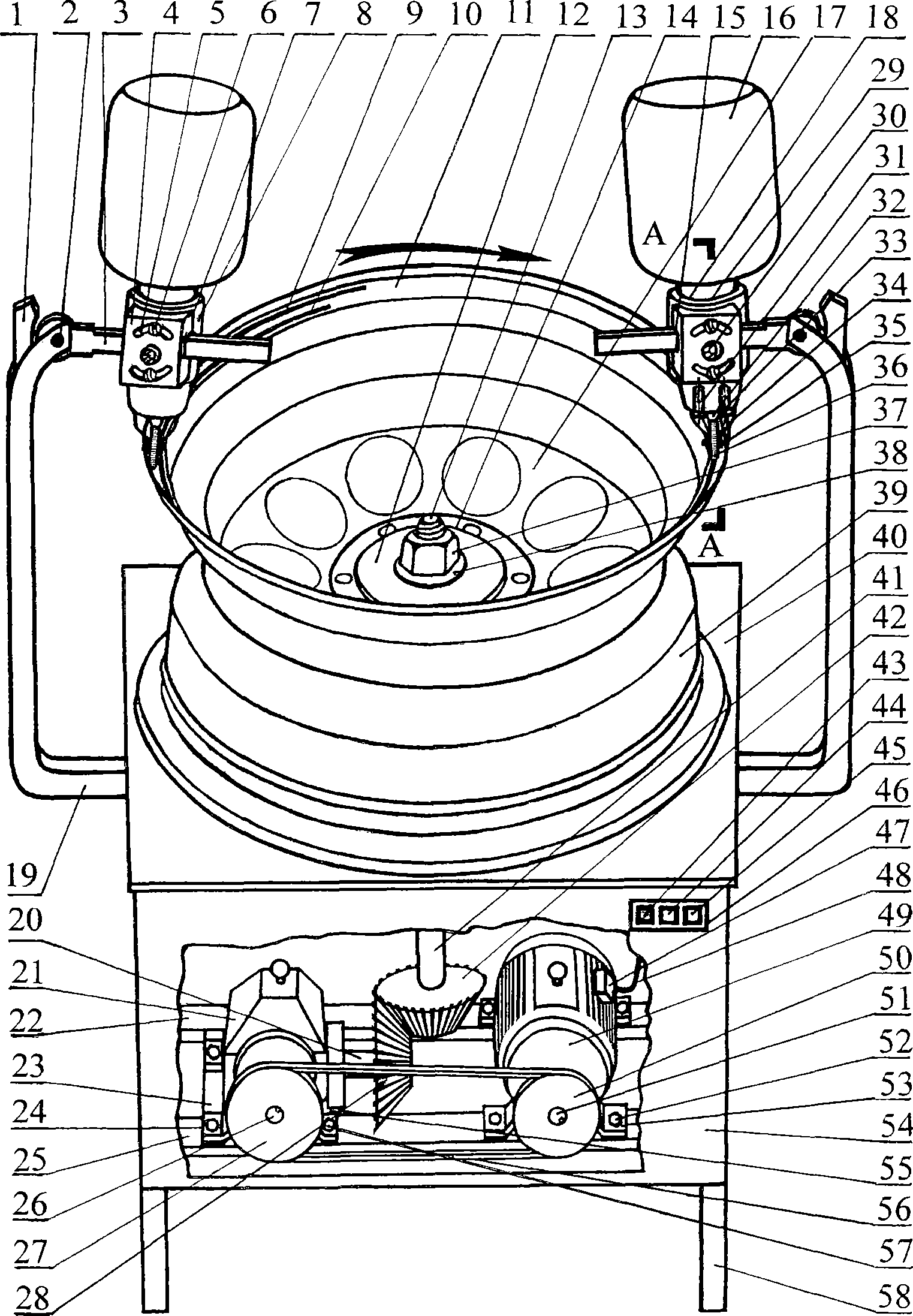

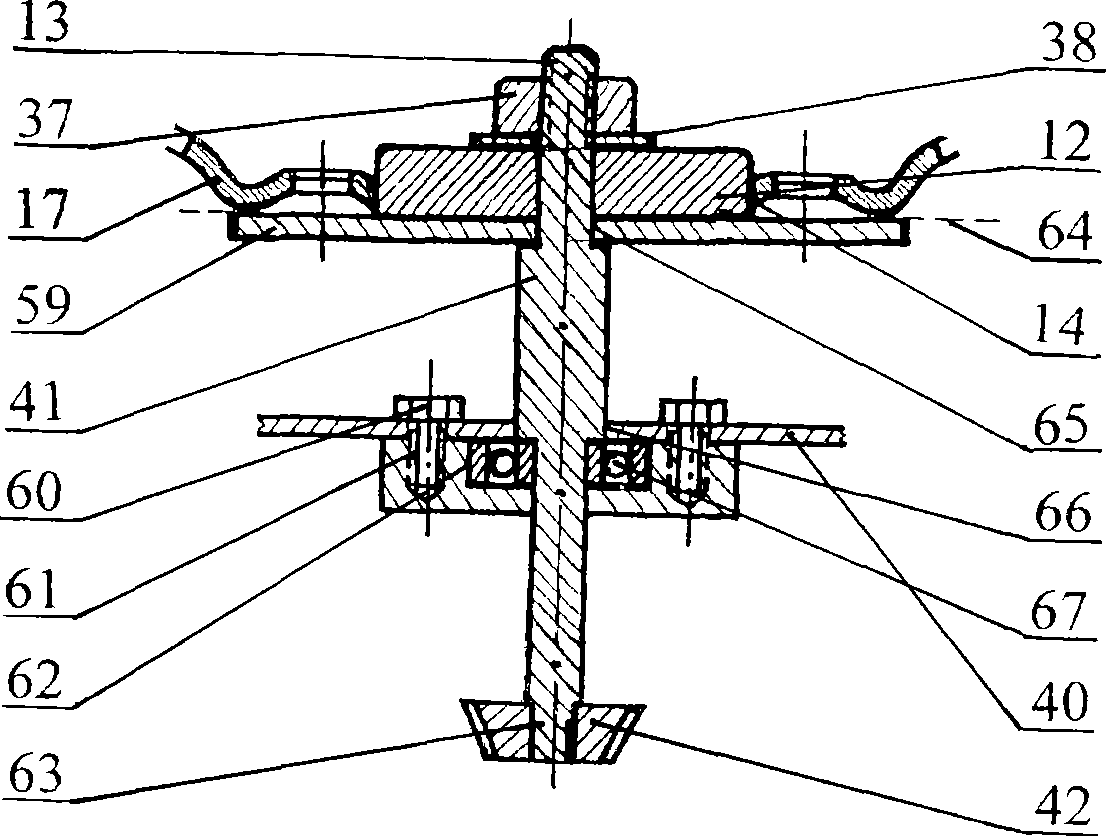

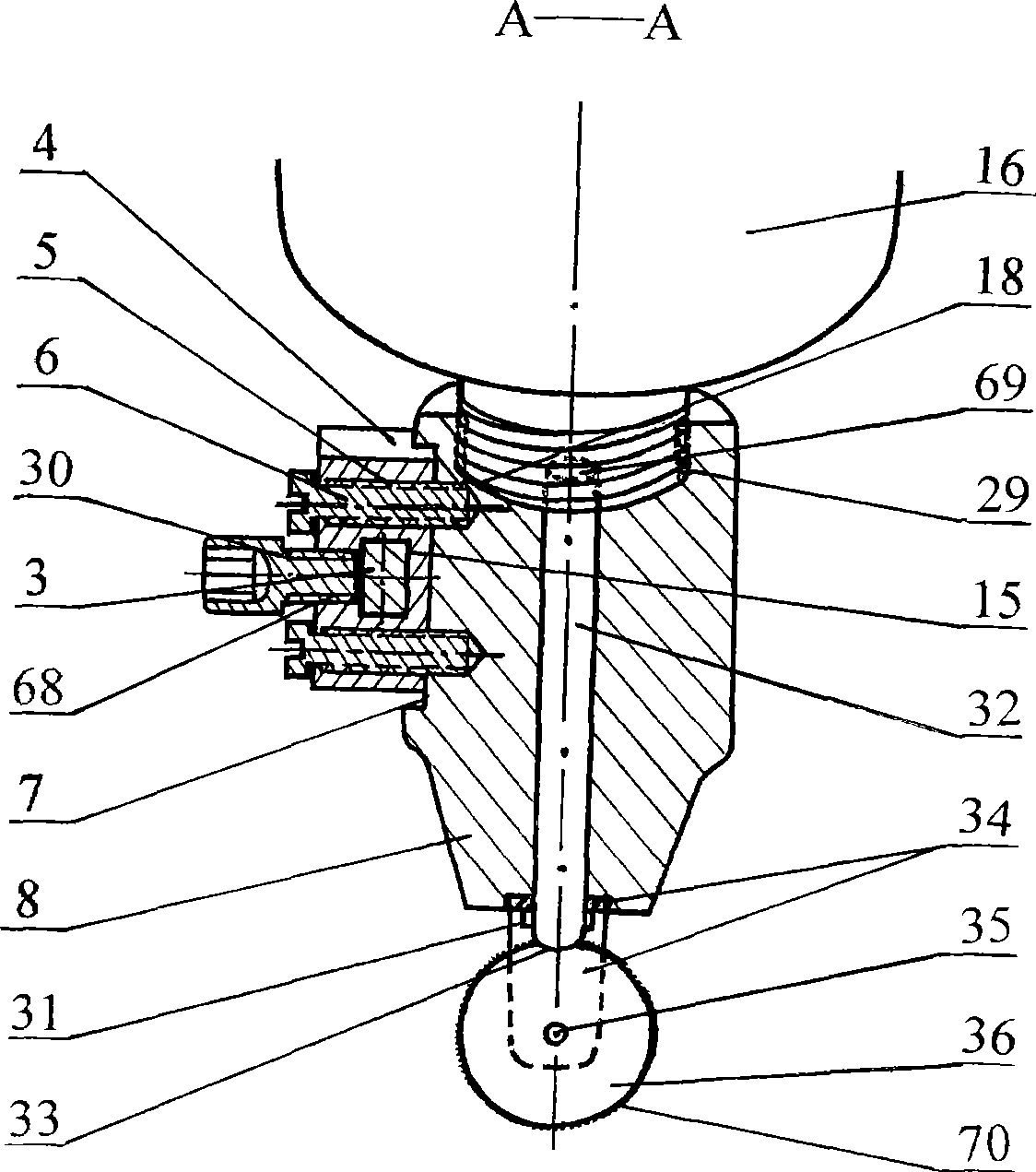

Improved operation process and device for drawing steel-ring appearance-line

InactiveCN101396944AImprove the level of production technologyUniform thicknessEmbossing decorationsSwitch boxEconomic benefits

The invention discloses an operating process for drawing appearance lines of a steel ring and an equipment structure thereof. The operating process for drawing the appearance lines of the steel ring and the equipment structure thereof are included. By the operating process for drawing the appearance lines of the steel ring, colorful appearance lines can be drawn out on a steel ring appearance surface; the lines of the appearance lines have uniform thickness, balanced spacing and good roundness, and the working efficiency for drawing the appearance lines is high. The body of the equipment comprises a line drawing device component, a cantilever frame component, a rotating disc component, a power device and a switch box, and a bench component, and then the line drawing device component is connected with the cantilever frame component, the cantilever frame component is connected with the bench component, the rotating disc component is connected with the bench component, and the power device is connected with the bench component, therefore, the equipment for drawing the appearance lines the steel ring are formed. The technical proposal creates necessary technical conditions for further promoting the production technology level of the steel ring, and perfecting production equipment and technique of the steel ring, and can also play a very active and effective role in meeting the market needs, enlarging the product markets and improving the economic benefit of the enterprises.

Owner:徐国林

Production process for embroidery

InactiveCN106757885AImprove the level of production technologyFull of three-dimensional senseEmbroidering machines apparatusComputer scienceL&D process

The invention discloses a production process for embroidery. The production process comprises the following process flows: first, embroidering a pattern manually, embroidering the profile of the pattern and general level-of-detail, then, scanning and imaging the embroidered pattern by a scanner, and inputting the image into a computer; performing computer embroidery plate-making on the acquired manually embroidered pattern which is acquired by Wilcom computer embroidery software, matching colours, and entering a large computer embroidery machine program, and matching colours of an embroidery frame, wherein the selected threads for the embroidery consist of thread bodies which at least contain a red thread, a green thread and a blue thread; then, starting a machine for producing; manually repairing the embroidery which is produced by a large computer embroidery machine, performing embroidery soft mounting, and packaging for leaving a factory.

Owner:木垒县哈萨克民族刺绣产品工程技术研究中心

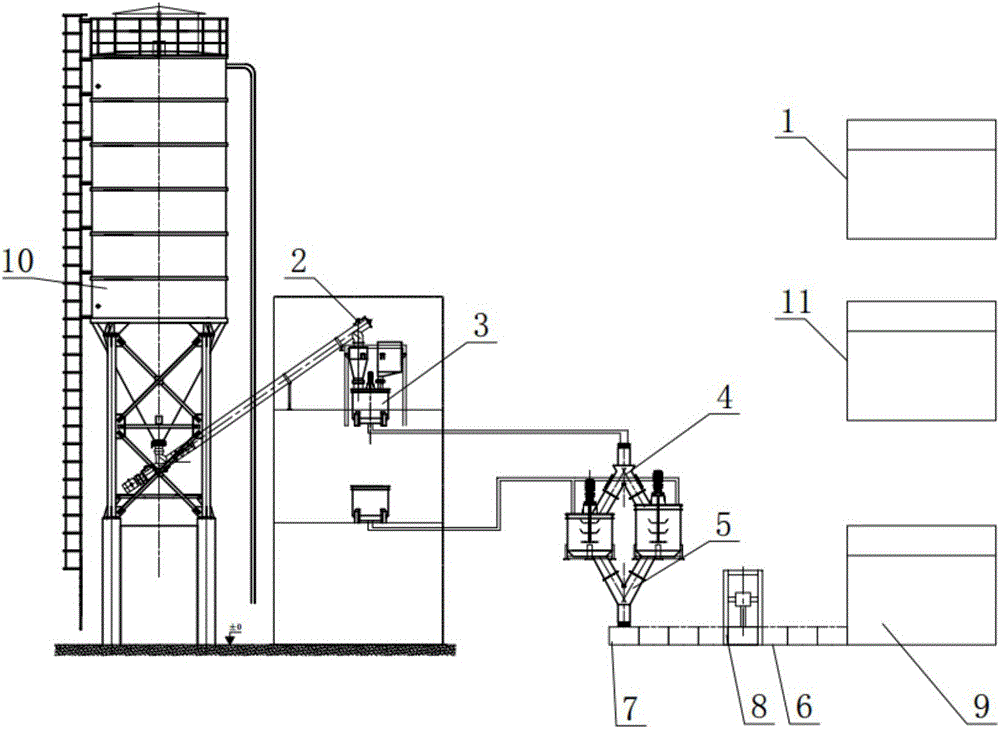

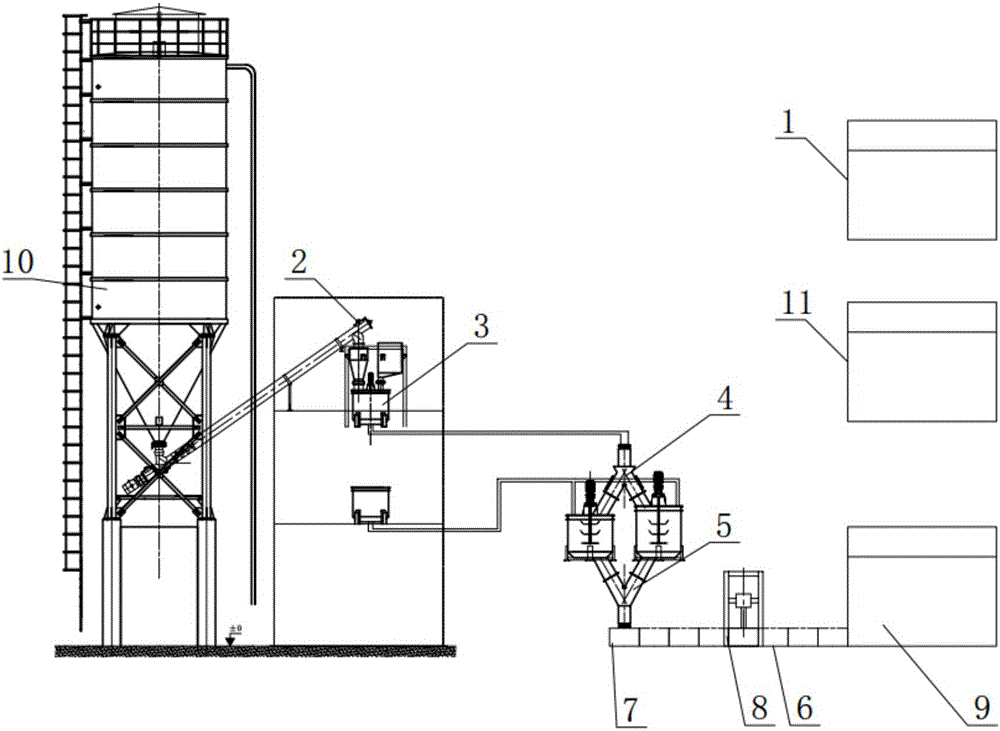

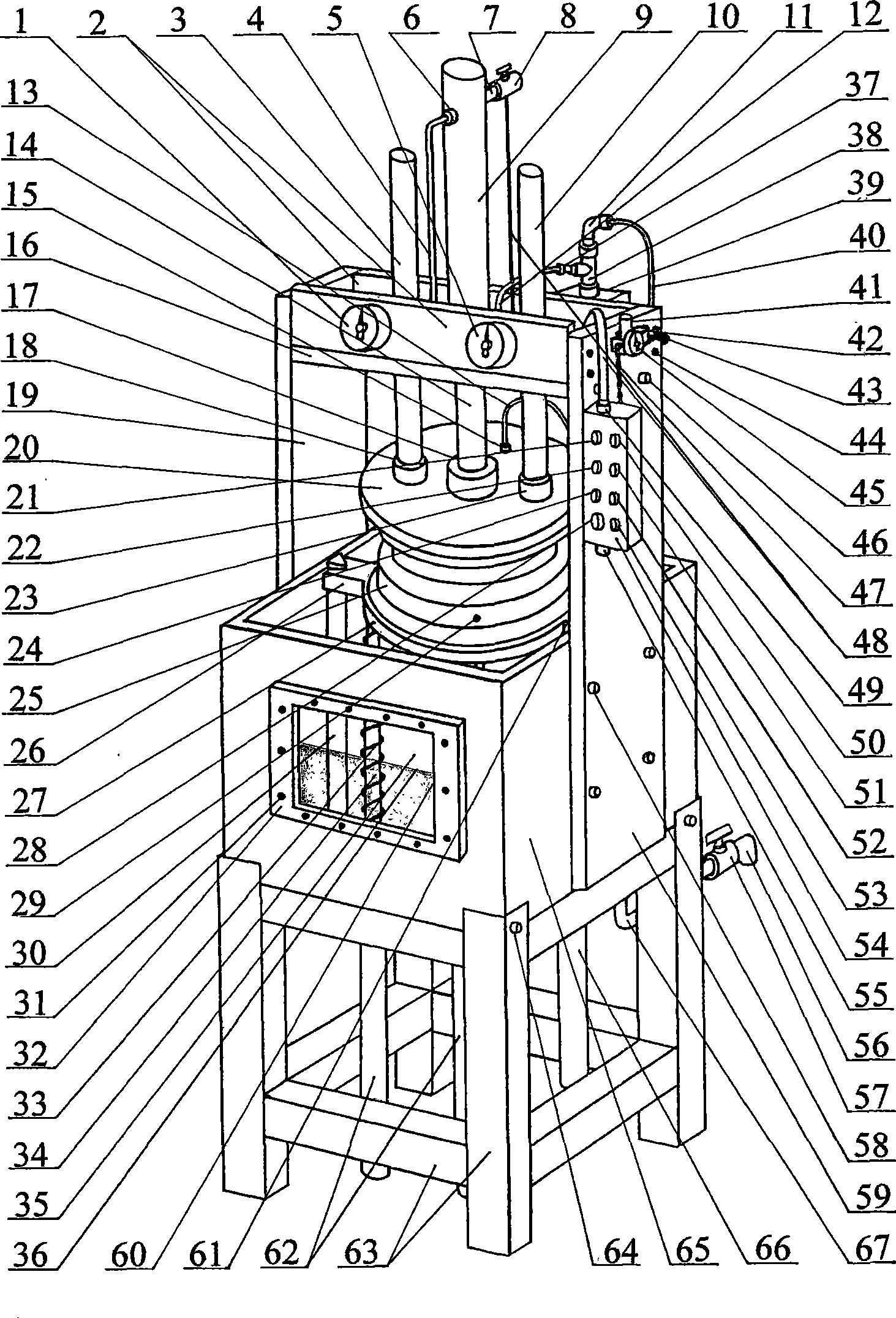

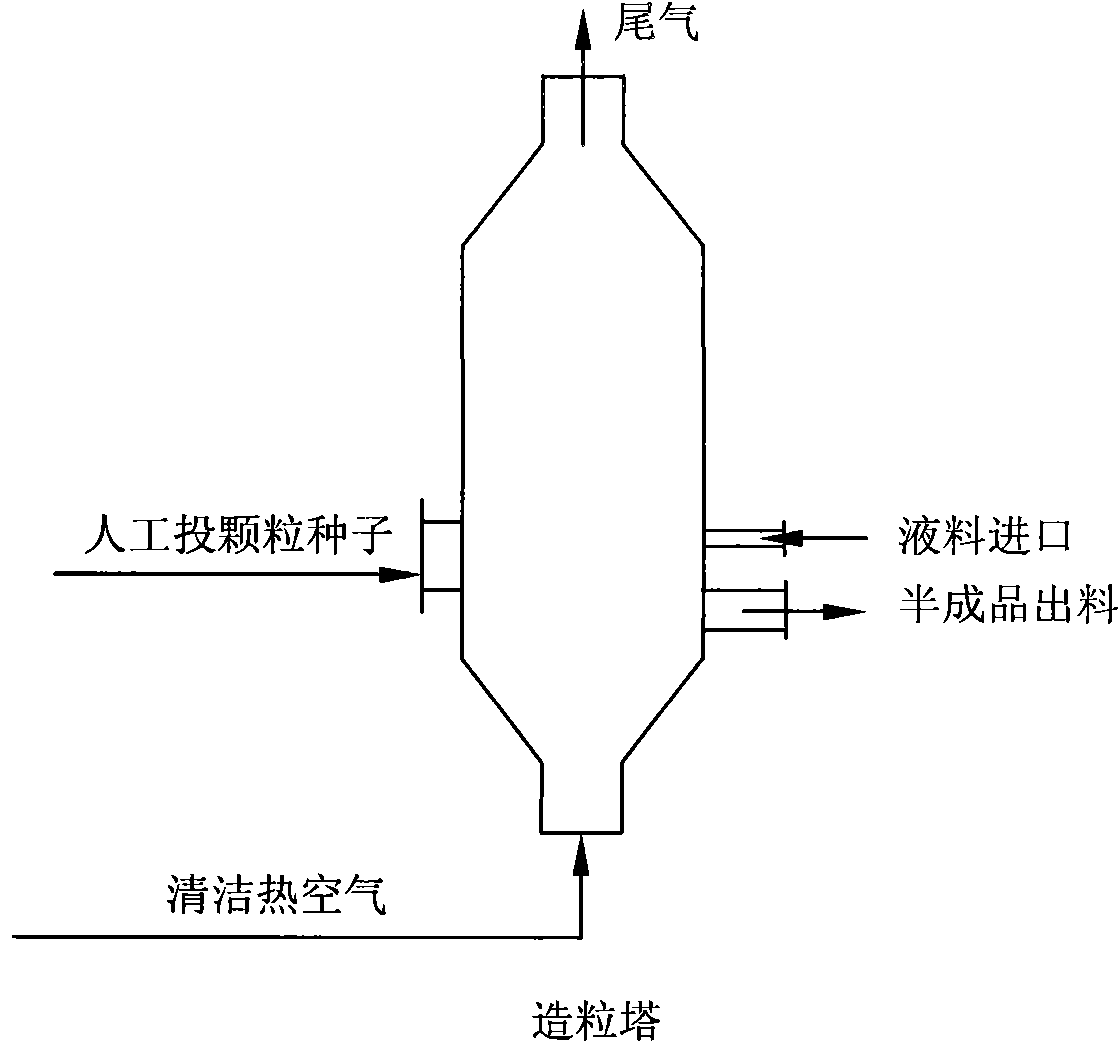

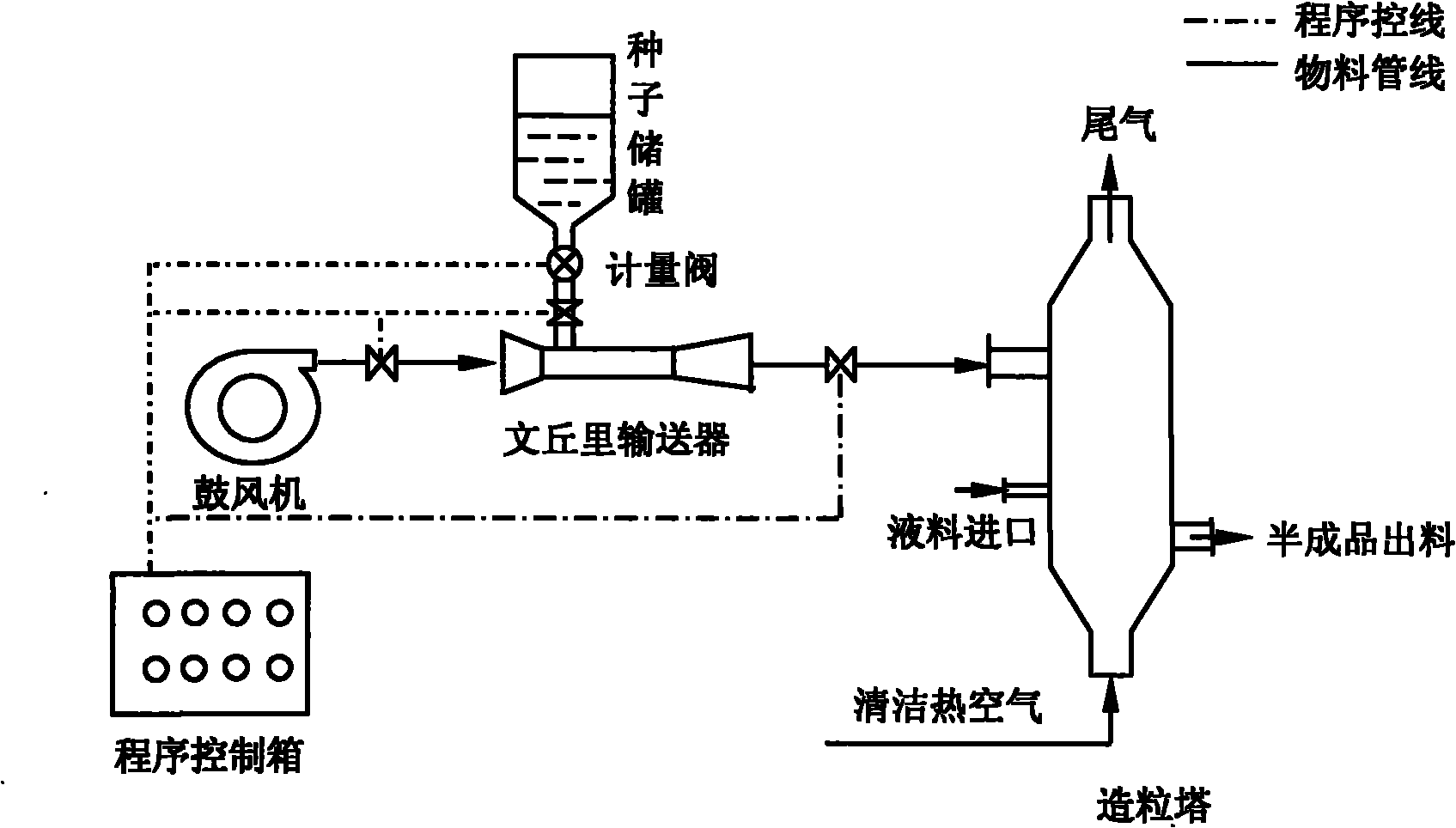

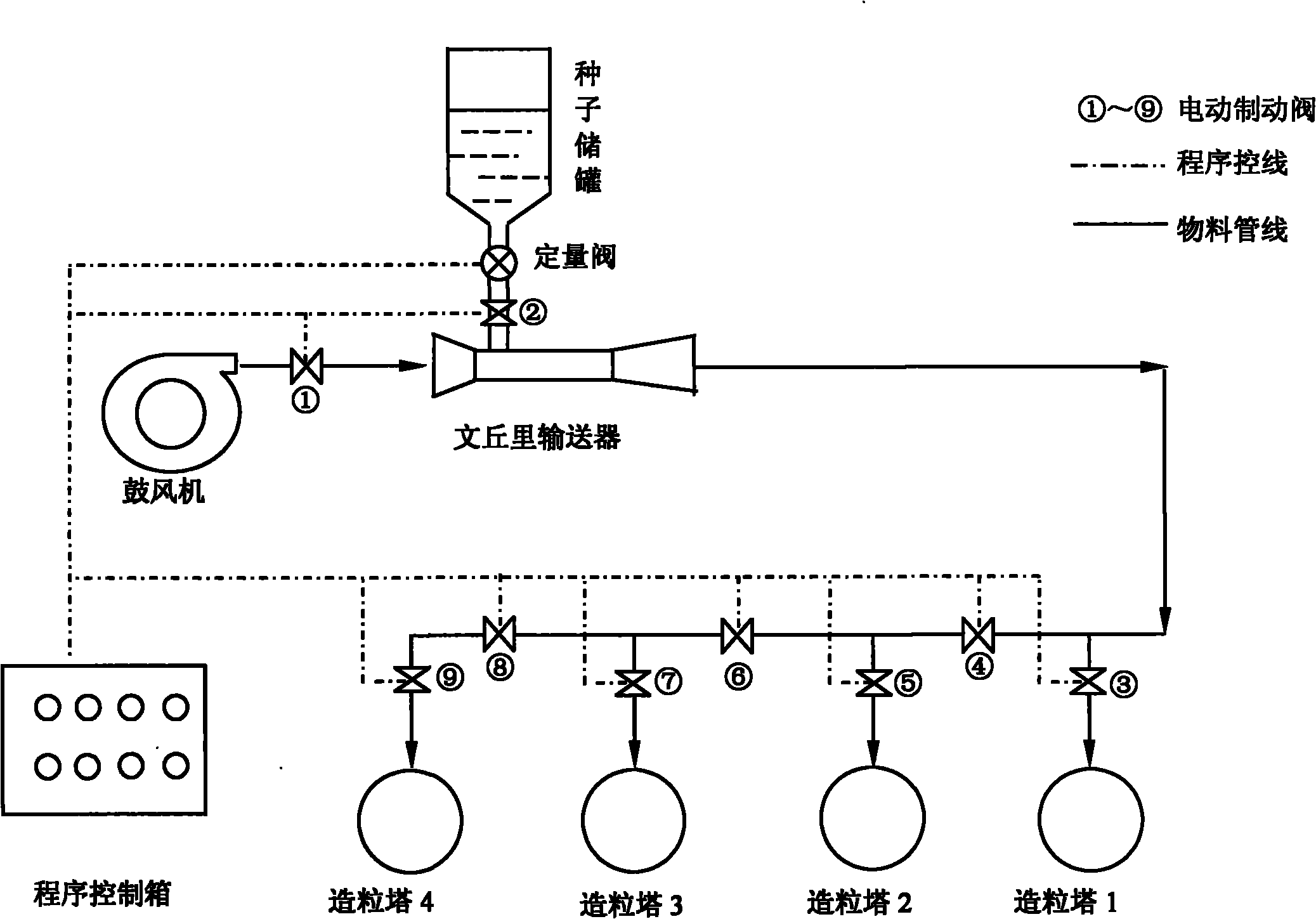

Charging system for the granulating preparation of sodium benzoate particle and operation process thereof

ActiveCN101766977AShorten feeding timeImprove the level of production technologyOrganic chemistryGranulation by powder suspensionProcess engineeringSodium benzoate

The present invention relates to a charging system for the granulating preparation of sodium benzoate particle and operation process thereof. The charging system comprises a granular seed storage tank and a granulating tower, a self-control charging system is arranged between the seed storage tank and the granulating tower. The self-control charging system consists of a granular seed metering valve, a blower, an electric brake valve, a program control cabinet and a Venturi conveyer. One end of the Venturi conveyer is connected with the blower, the other end of the Venturi conveyer is connected with the granulating tower, and a granular seed inlet is arranged near the blower and is connected with the granular seed storage tank. The outlet or inlet of each pipeline is provided with the electric brake valve. One or a plurality of granulating towers is or are provided. The operation time of each unit is controlled by an electric program and the seeds are in totally enclosed condition during the charging process. The invention changes the prior charging process of sodium benzoate, saves labor, saves the charging time of sodium benzoate particle, enhances the stability of product quality and improves the preparation environment of sodium benzoate particle.

Owner:TIANJIN DONGDA CHEM GRP

Orientation degree controllable extruded quick-cooked noodles and preparation method thereof

ActiveCN106071781ASimple preparation processReduce wasteFood ingredientsFood shapingEnzymeMonoglyceride

The present invention provides orientation degree controllable extruded quick-cooked noodles. The noodles are prepared from the following raw materials: 100 parts of flour, 1.2-30 parts of hydrophilic colloids, 0.02-0.1 part of an enzyme preparation, 0.2-0.4 part of dietary alkali, 0.5-2.5 parts of edible salt, 0-4 parts of monoglycerides and 0-15 parts of food ingredients. The preparation method comprises the steps of material mixing, blending, and extruding and shaping. In the blending process, the enzyme preparation is added. In the extruding process, a special shaping die device is used. With the help of the new extruding die device and using the enzyme adding and extruding technology, the orientation degrees and quick-cooking performances are controlled from the aspects of flour raw material selecting, hydrophilic colloid compounding, enzyme preparation controlling, food ingredient matching, extrusion operation parameter arranging, etc., so that the edible quality and product performance of the noodles are significantly better than those of the traditional noodles. Besides, the production operations are simple and feasible, and the orientation degree controllable extruded quick-cooked noodles are of great significances for the industrial development.

Owner:JIANGNAN UNIV

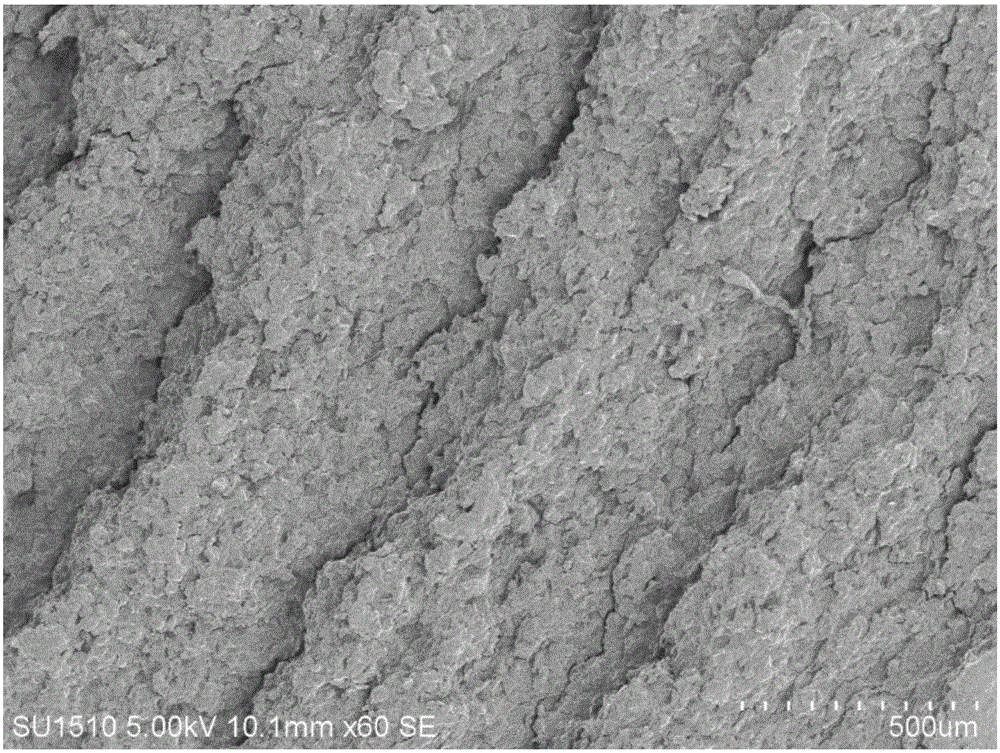

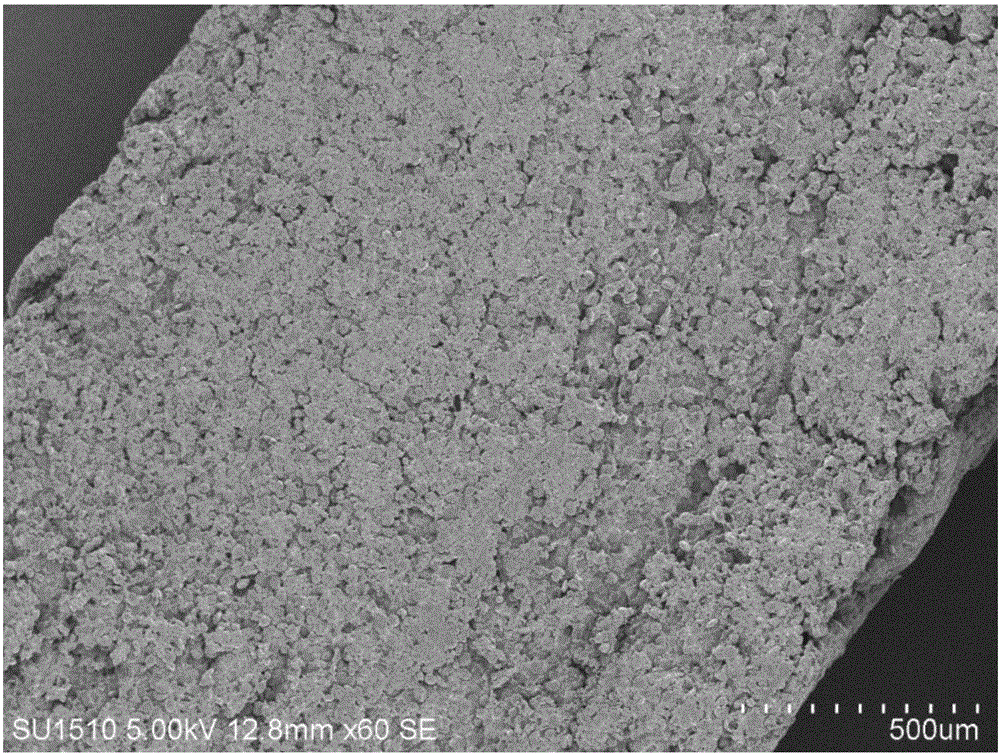

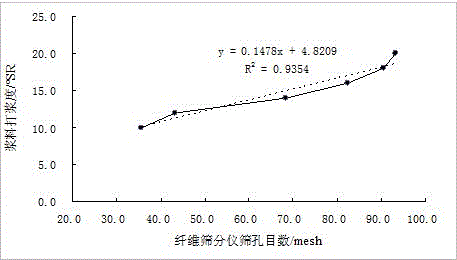

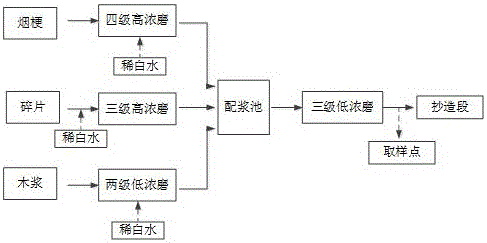

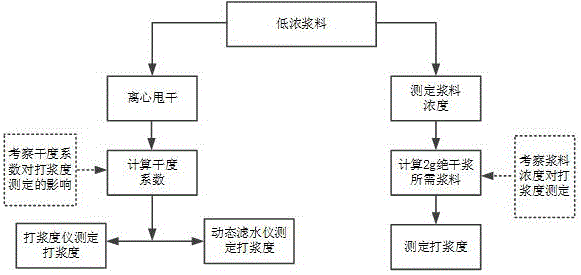

Method for correcting beating degree of tobacco pulp in pulping process

ActiveCN106360802AImprove product qualityImprove the detection accuracy of quality indicatorsTobacco preparationFiberWater baths

The invention relates to a method for correcting the beating degree of tobacco pulp in a pulping process. The method comprises the steps: weighing tobacco raw materials according to the formula of reconstituted tobacco raw materials in the pulping process of reconstituted tobacco pulp, and extracting in a constant-temperature water bath pot by using an aqueous solution for 30 minutes; pulping by a Wali beating machine method and measuring the beating degree by a GB / T 3332-2004 pulp beating degree measuring method and by using a Schober beating degree measuring instrument; measuring the fiber distribution of the pulp by a GB / T 2678.1-1993 paper pulp screening measuring method; establishing a working curve of the beating degree of the tobacco pulp and the 48-mesh passing fine fiber proportion x being more than or equal to 48 meshes, measuring the beating degree of the tobacco pulp DB dryness degree by a dryness degree coefficient method, measuring the fiber distribution of the spin-dried pulp by a paper pulp screening measuring method and measuring the 48-mesh passing fine fiber proportion x dryness degree being more than or equal to 48 meshes; calculating a beating degree correction value by a dryness degree coefficient method; and performing DB correction on the obtained beating degree correction, wherein due to the application of the DB correction, the qualification ratio of the reconstituted tobacco products is increased and the production cost of the reconstituted tobacco is reduced.

Owner:CHINA TOBACCO YUNNAN IND

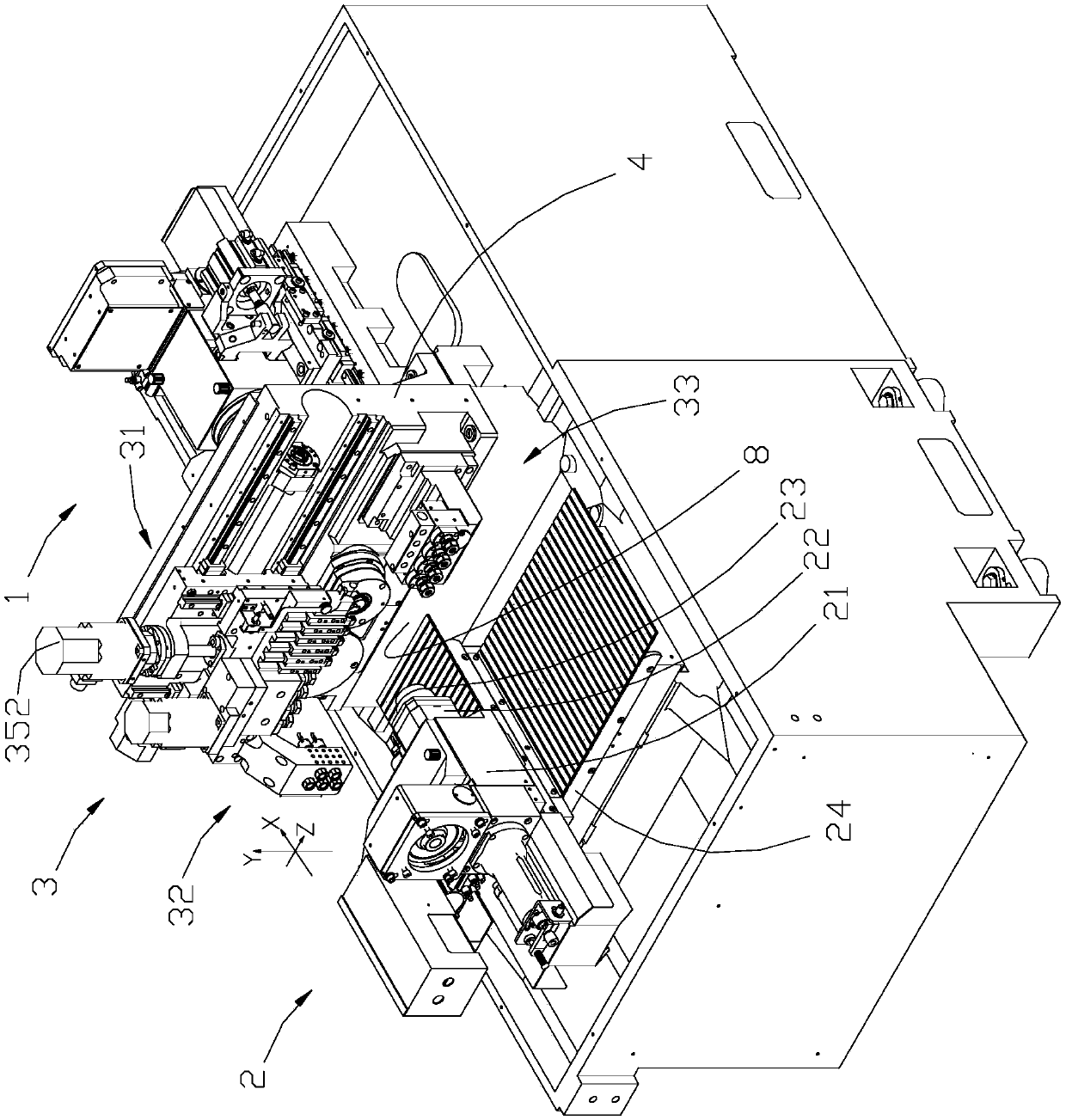

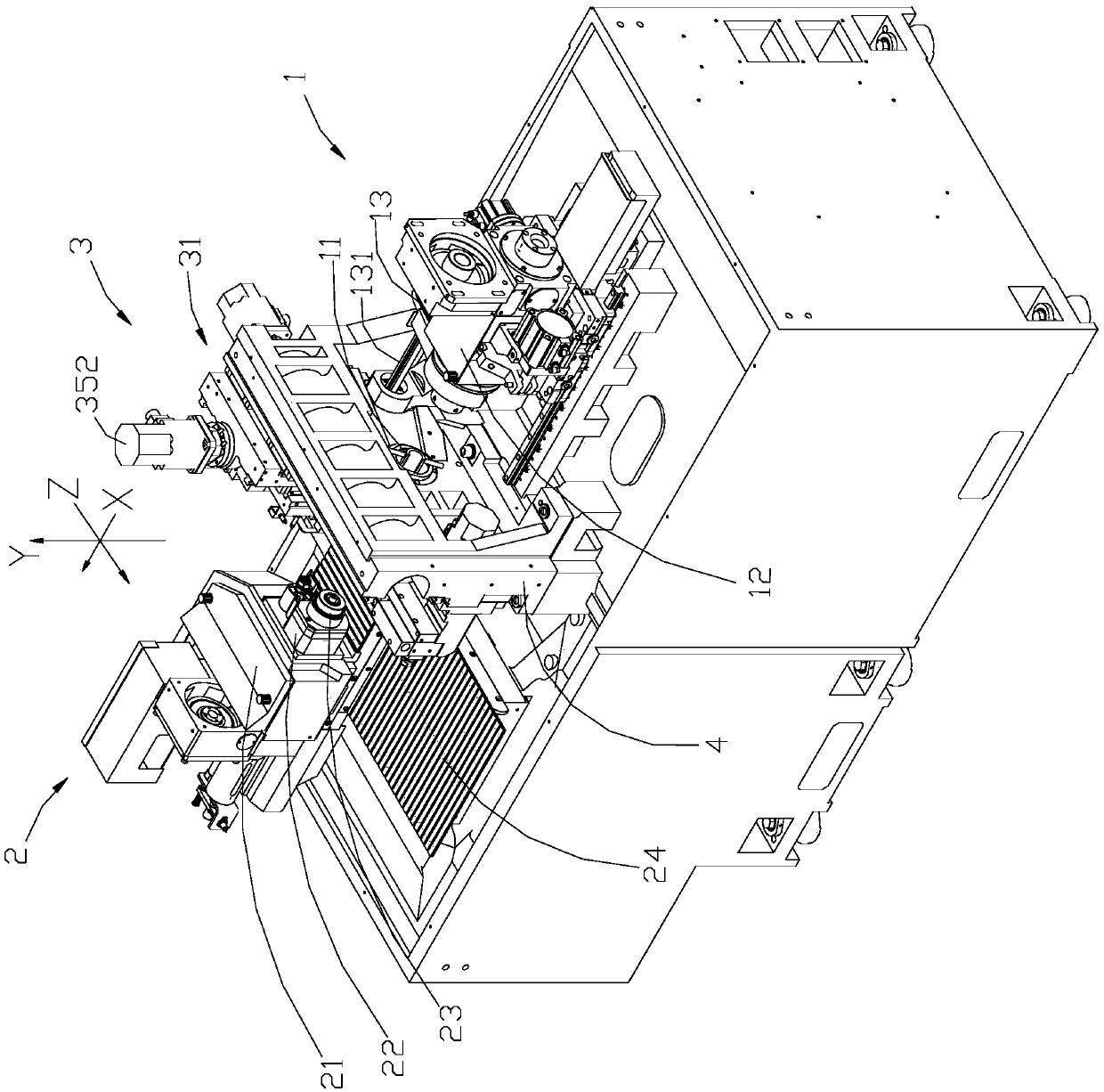

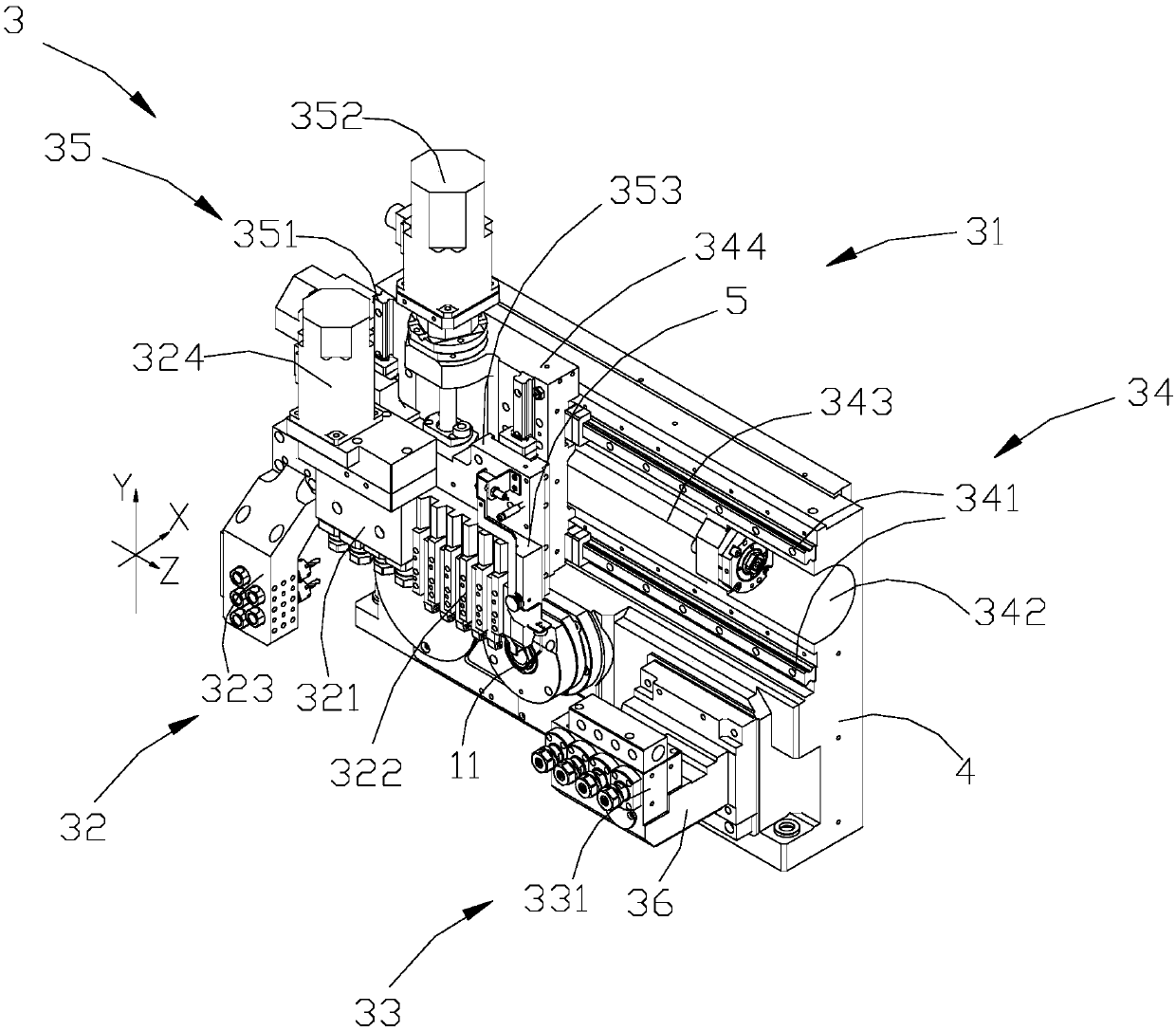

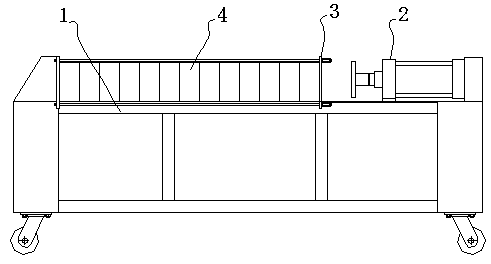

Dice machining centering machine and machining technology thereof

InactiveCN109623386ASolve the defect that the dice cannot be processed at one timeIncrease productivityOther manufacturing equipments/toolsComputer moduleMachining

The invention provides a dice machining technology. The dice machining technology comprises the steps that a bar is clamped through a main shaft module, and accordingly rotation telescopic movement inthe X-axis direction is conducted in the machining area; a main shaft tool rest enters the machining area through a moving device, accordingly, in the Z-axis direction and the Y-axis direction, the bar is rotated and telescopically moved in the X-axis direction in cooperation with the main shaft module, multi-shaft linkage is formed, and accordingly five faces of a dice are machined; an auxiliaryshaft module moves to the position coaxial to the main shaft module through a moving mechanism, synchronous rotation is conducted, the bar is cooperatively clamped, and clamping is conducted after the main shaft tool rest cuts off the bar; and the auxiliary shaft module moves in the X-axis direction, the Y-axis direction and the Z-axis direction through the moving mechanism and makes contact withan auxiliary shaft tool rest, multi-shaft linkage is formed, the cut-off face of the back of the dice is machined, one-time forming machining of the six faces of the dice is achieved in an integratedturning and milling manner, the production efficiency is greatly improved, and the production cost is reduced.

Owner:上海西码智能科技股份有限公司

Wood plate compressing densification and carbonization technology

InactiveCN103895082AGuaranteed straightnessReduce manufacturing costWood compressionWood charring/burningCarbonizationWood machining

The invention discloses a wood plate compressing densification and carbonization technology and belongs to the technical field of wood densification and modifying machining. The technology is characterized in that through a provided secondary releasing type pressing method program, a provided multi-time releasing type pressing method program and a provided follow-up type heat collecting pressing method program for producing compressing densification and carbonization wood plates and a straightening binding stacking gradual-change cooling method, the existing technology level can be improved, and the compressing densification and carbonization wood plates can be manufactured. The innovativeness and the practicability are that the shortcomings of the prior art are overcome, production efficiency is high, the straightness is guaranteed, and production cost is greatly lowered.

Owner:李启山 +1

Transmission mechanism of plastic bottle blowing machine

The invention relates to a transmission mechanism of a plastic bottle blowing machine, which mainly comprises a chain assembly. The chain assembly is provided with a front revolving wheel, a rear revolving wheel and a guide rail, the guide rail is provided with a guide rail bracket and a stepping mechanism, the chain assembly is formed via combination of a self-fabricated chain block, a heating base and a chain and is erected on the guide rail so as to freely slide on the guide rail, and the stepping mechanism comprises a positioning cylinder, a stepping cylinder, a linear guide rail pair, a guide rod, a positioning fork, a positioning cylinder and a sliding base, a positioning cylinder connection plate. Since a combination of a small gear and a large gear is adopted, linear force can be obtained rapidly in a moment. The manufacturing cost is low, the installation and debugging are simple, the effects of a servo motor or a stepper motor can be achieved, and high cost can be saved. Due to sliding of double guide rods, a clearance for left-right swinging can be reduced, the shaking of the chain can be avoided when the chain is pushed, and the accuracy can be improved.

Owner:董爱华

New process of freeze-drying procedure of riboflavin sodium phosphate for injection

InactiveCN104546465AImprove the level of production technologyReduce the rejection rate of light inspectionPowder deliveryOrganic active ingredientsChemistryElectric heating

The invention provides a new process of a freeze-drying procedure of riboflavin sodium phosphate for injection, and belongs to the technical field of biological medicine. The new process mainly solves the problems that in the freeze-drying process of riboflavin sodium phosphate for injection, penicillin bottles are seriously damaged, and the product rejection rate is high. The new process is low in cost, low in rejection rate and more stable in product quality. The process is mainly and technically characterized in that the temperature of products is decreased to -35 DEG C or lower, cold insulation is conducted for about 35 minutes, and it is ensured that the products are completely frozen; when the temperature of a condenser is decreased to -45 DEG C+ / -5 DEG C and the pressure is decreased to about 20 Pa through vacuumizing, the sublimation temperature of -10 DEG C is set, electric heating is started, and the temperature rising speed is controlled to be 0.5 DEG C per hour; when the temperature of the products reaches 40 DEG C, heat preservation is conducted for about 2.5 hours, the crystalline form of the products is plump, uniform and thin, and when the pressure in the box does not obviously increase any more, in the state that the pressure is 6 Mpa, all the products are pressed and plugged out of the box. The finished products produced through the process is more stable in quality, cost is obviously reduced, market prospects are good, and the new process is worthy of popularization.

Owner:HENAN FUREN HUAIQINGTANG PHARMA

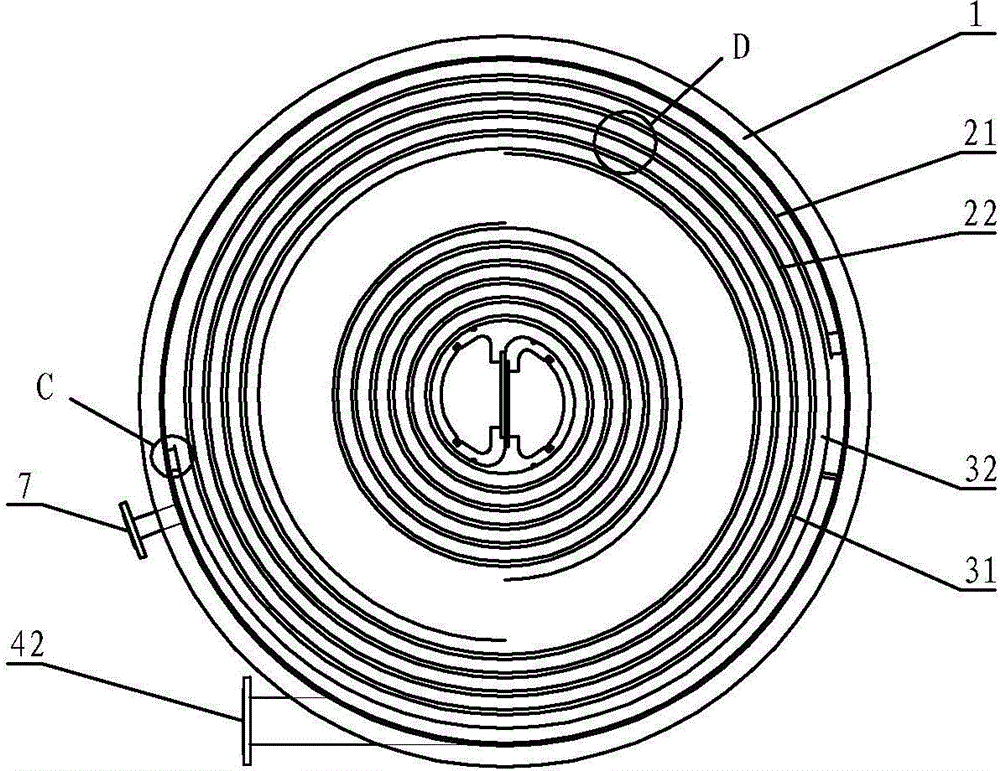

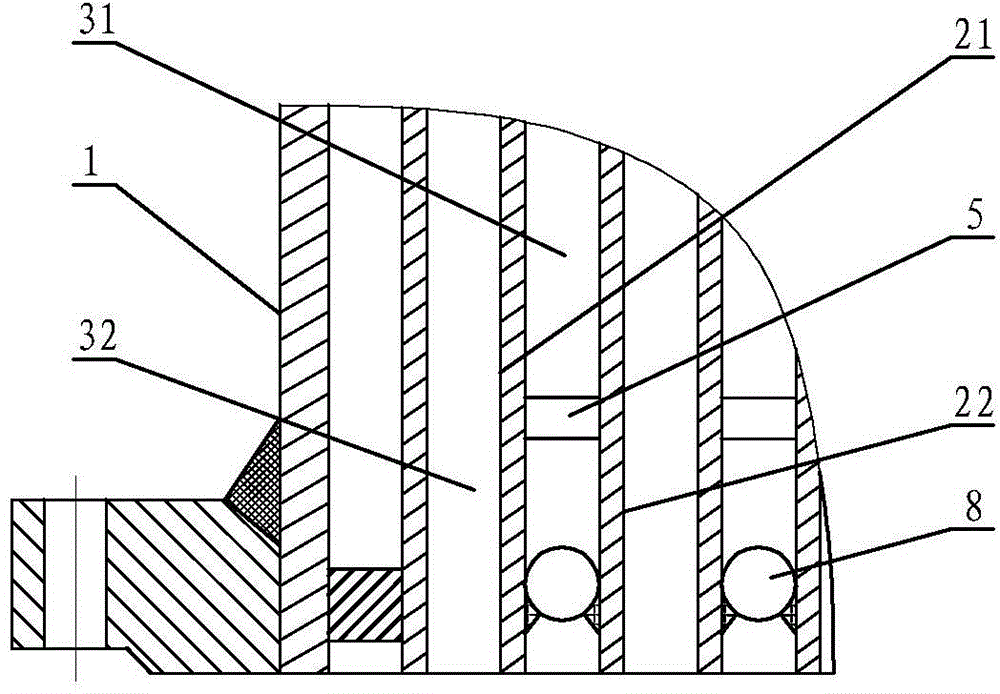

Spiral plate type vinyl chloride synthetic converter

InactiveCN104383859AImprove the level of production technologyAvoid Corrosion Leakage SituationsPreparation by halogen halide additionChemical/physical processesPtru catalystEngineering

The invention discloses a spiral plate type vinyl chloride synthetic converter. The converter comprises a vertical barrel-shaped shell as well as a first heat exchange plate and a second heat exchange plate which are double-spirally wound in the shell, wherein openings are formed at the two ends of the shell; a first channel and a second channel, which are double-spirally arranged, are formed between the first heat exchange plate and the second heat exchange plate; the upper and lower sides of the first channel are closed; a first opening is formed in the center of a spiral of the first channel and a second opening is formed in the edge of the spiral of the first channel; the center and edge of a spiral of the second channel are closed; the upper and lower sides of the second channel are open to form a third opening and a fourth opening; a catalyst is arranged on the side wall of the second channel. The converter has the advantages that as the spiral plate type structure is adopted, the structure size is reduced and the conversion rate is increased; due to a self-cleaning function of the spiral plate type structure, hot water scales are reduced, so that the service life and the repair cycle are prolonged and corrosion and leakage of pipelines are avoided; the vinyl chloride production technology level can be greatly improved; the market demands can be met.

Owner:SUZHOU CITY JINXIANG PRESSURE CONTAINER MFG CO LTD

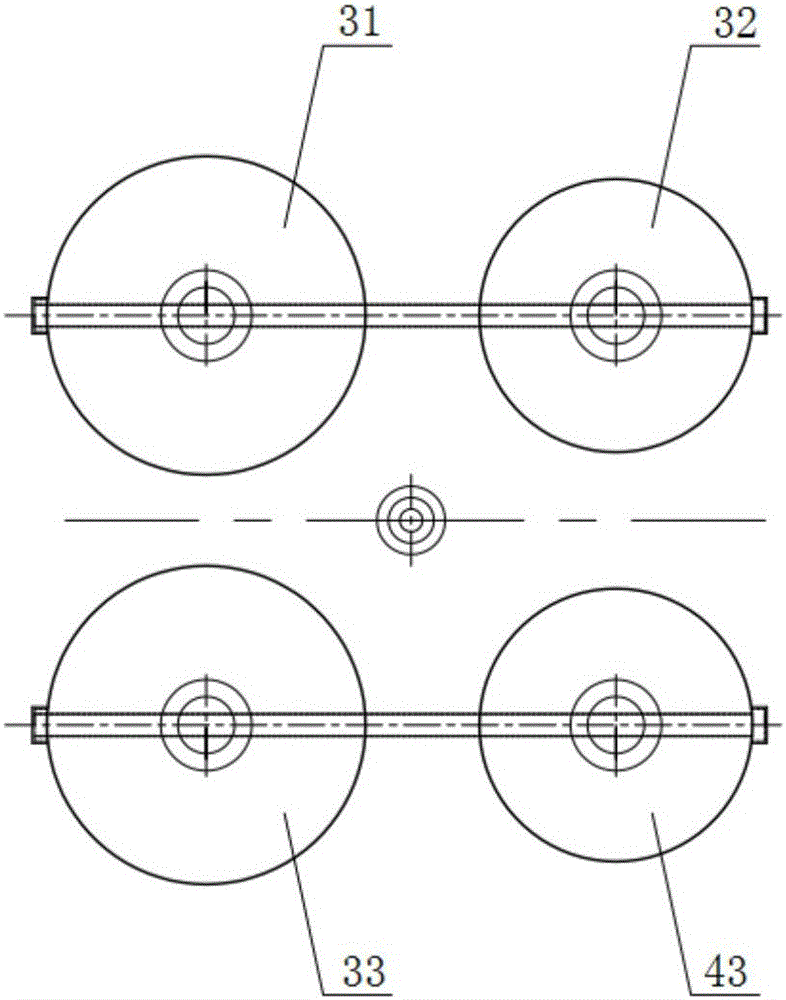

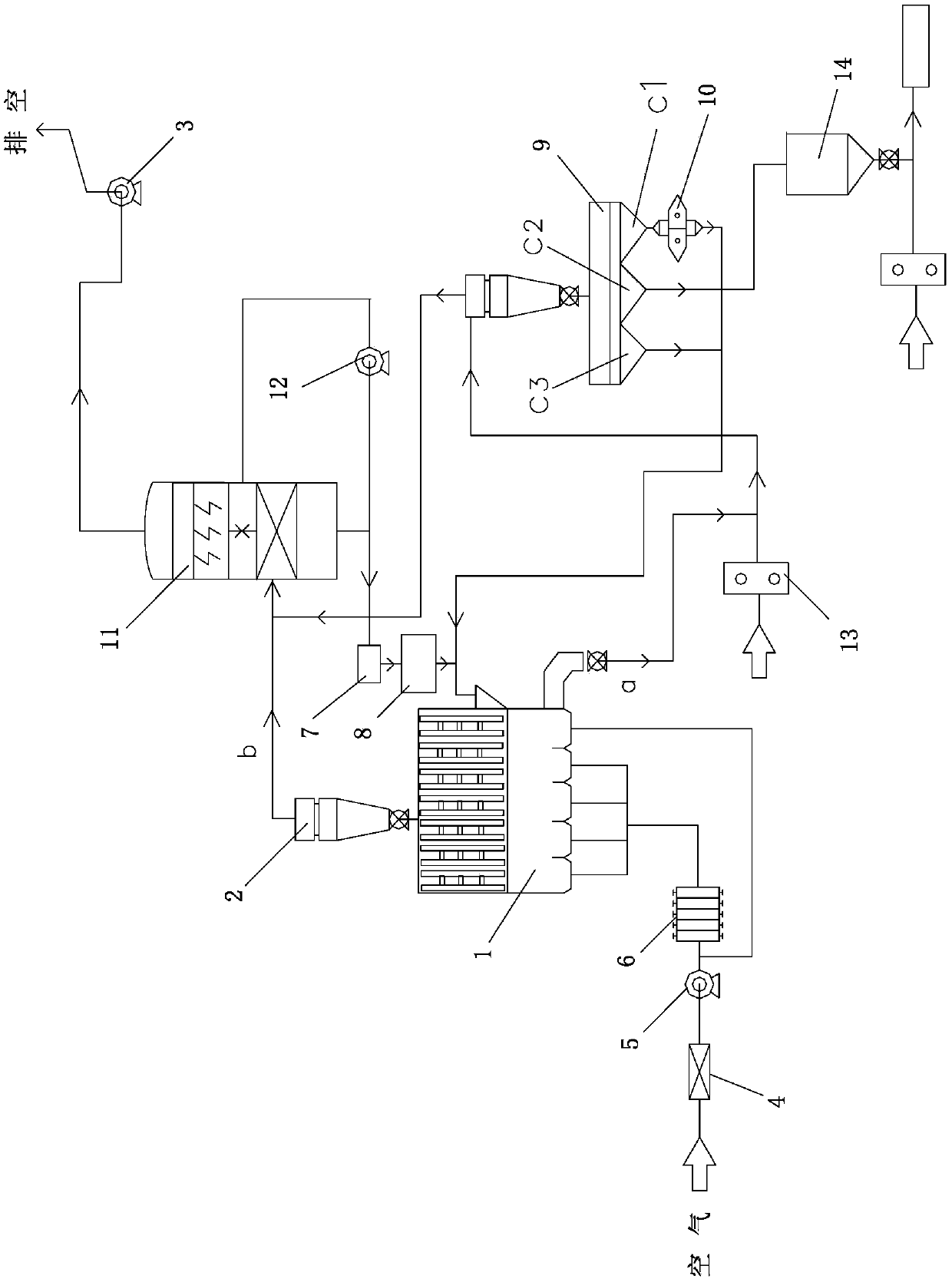

Device and method for continuous production of spherical sodium benzoate

ActiveCN106390855BImprove working environmentReduce labor costsGranulation by liquid drop formationCarboxylic acid salt preparationSlurryTower

The invention discloses a device for continuously producing spherical sodium benzoate and a method for continuously producing spherical sodium benzoate by using the device. The device comprises an air pretreatment system, a raw material system, a prilling system and a sieving system. A prilling method by using the device comprises the following steps: 1) injecting a sodium benzoate slurry into a slurry pool; 2) starting an induced draft fan, an air blower and an air heater, after purifying the air by a coarse filter, feeding purified air to a prilling tower, and blowing air upwards; 3) starting an atomizer, atomizing the sodium benzoate slurry in the slurry pool and then conveying atomized sodium benzoate slurry into the prilling tower for prilling so as to form spherical sodium benzoate particles; 4) carrying out separation treatment on the sodium benzoate particles in the prilling tower; 5) feeding the sodium benzoate particles through a discharge hole of the prilling tower into a classifying screen for sieving treatment, and evacuating and separating the sodium benzoate particles through a discharge hole of a cyclone separator; and 6) carrying out packaging treatment. By using the device, the production efficiency of the spherical sodium benzoate can be effectively improved, the environmental pollution is reduced, and the resources are saved.

Owner:WUHAN YOUJI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com