Wood plate compressing densification and carbonization technology

A wood plank and carbonization technology, which is applied in the direction of wood compression, charcoal burning/combustion, etc., can solve the problems of low utilization rate, increased cost consumption, environmental pollution, etc., to improve the production process level, reduce production costs, and ensure flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

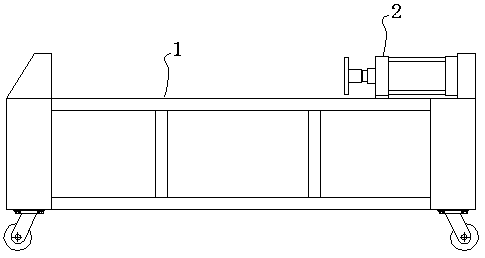

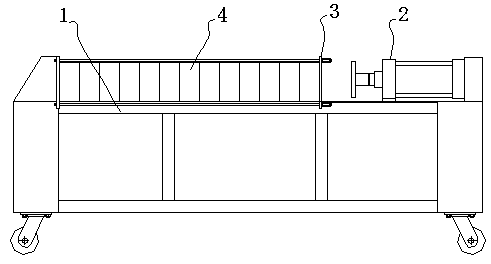

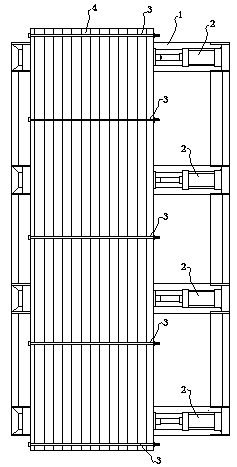

[0013] See attached figure 1 , a technology for compressing, densifying, shaping and carbonizing wood boards disclosed by the present invention is characterized in that: the moisture content of the wood boards to be compressed is lower than 8% but higher than 4%, and the density is lower than 0.4g / cm 3 Densify it by hot pressing to a density of 0.75g / cm 3 The production method of this compression densification setting and carbonized wood board is taken as an example, utilizes the far-infrared ray thermometer to measure these two kinds of wood boards between the upper and lower hot pressing boards of the hot press by the heat conduction speed of the hot pressing board to the middle of the wood board and through Pressure test to measure the heating softening point of wood boards with different densities, thicknesses, and heats to master the two parameters of heating softening temperature and time required for compressed and densified wood boards. After that, for moisture content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com