Forming method of carbon fiber composite material grille

A composite material and molding method technology, used in household components, household appliances, other household appliances, etc., can solve problems such as excessive straightness of grille products, difficulty in demoulding, and cost reduction, and simplify the difficulty and variety of demoulding. Rich, easy pouring effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

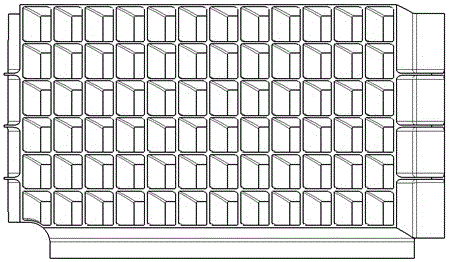

[0037] Embodiment 1: as figure 2 As shown, it is a composite material grid part molded by the present invention. The grid is composed of 80 grids with different sizes and specifications; Molding, demoulding is difficult, and the process is complicated; the dimensional accuracy of the product cannot be guaranteed when it is formed with a silicone rubber core mold.

[0038] The forming method of the carbon fiber composite grid of the present invention specifically comprises the following steps:

[0039] (1) Mandrel molding: firstly, the solidification temperature of the selected resin is 80°C, and the Tg is 123°C, so a low-melting point alloy with a melting point of 90°C is selected; the casting method is adopted, specifically: the mandrel mold and the gate are preformed Heat to 95°C, heat to 105°C after melting the low-melting point alloy, stir evenly, then slowly pour the melt into the mold along the gate until the gate is filled; then cool, demould, and cut off the gate wit...

Embodiment 2

[0046] Embodiment 2: The forming method of the carbon fiber composite grid of the present invention specifically comprises the following steps:

[0047](1) Mandrel molding: According to the use temperature of the product, select high-temperature curing epoxy resin, the curing temperature is 130°C, the post-processing temperature is 170°C, and the low-melting point alloy with a melting point of 145°C is selected, and directly processed by CNC machine tools Core mold; the height of the gate is at least 3cm higher than the upper surface of the core mold, and the position of the gate corresponds to the non-forming surface of the core mold;

[0048] (2) Paving of carbon fiber fabric: Lay the cut fabric on the mandrel, and use a special adhesive to assist the pasting; the vertical and horizontal ribs are paved on the flat plate for use;

[0049] (3) Mold closing: Assemble the mandrel prefabricated body, insert a piece of horizontal rib every time a mandrel is placed on the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com