Valve tri-eccentric seal surface milling processing special numerical control combination machine

A combined machine tool and triple eccentric technology, used in metal processing machinery parts, milling machines, milling machine equipment, etc., can solve the problems of low work efficiency, difficult to ensure accuracy, and difficult to ensure processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

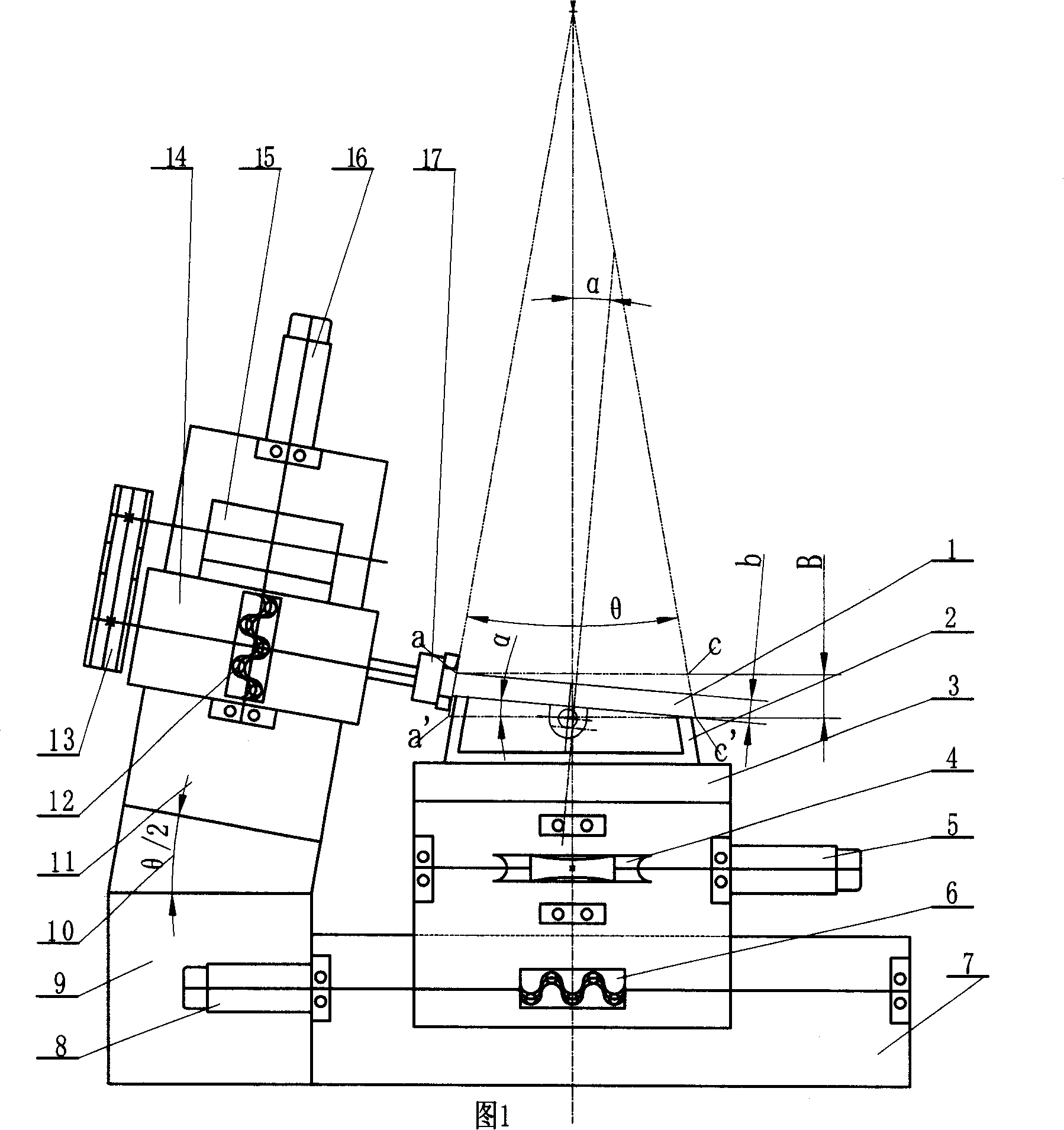

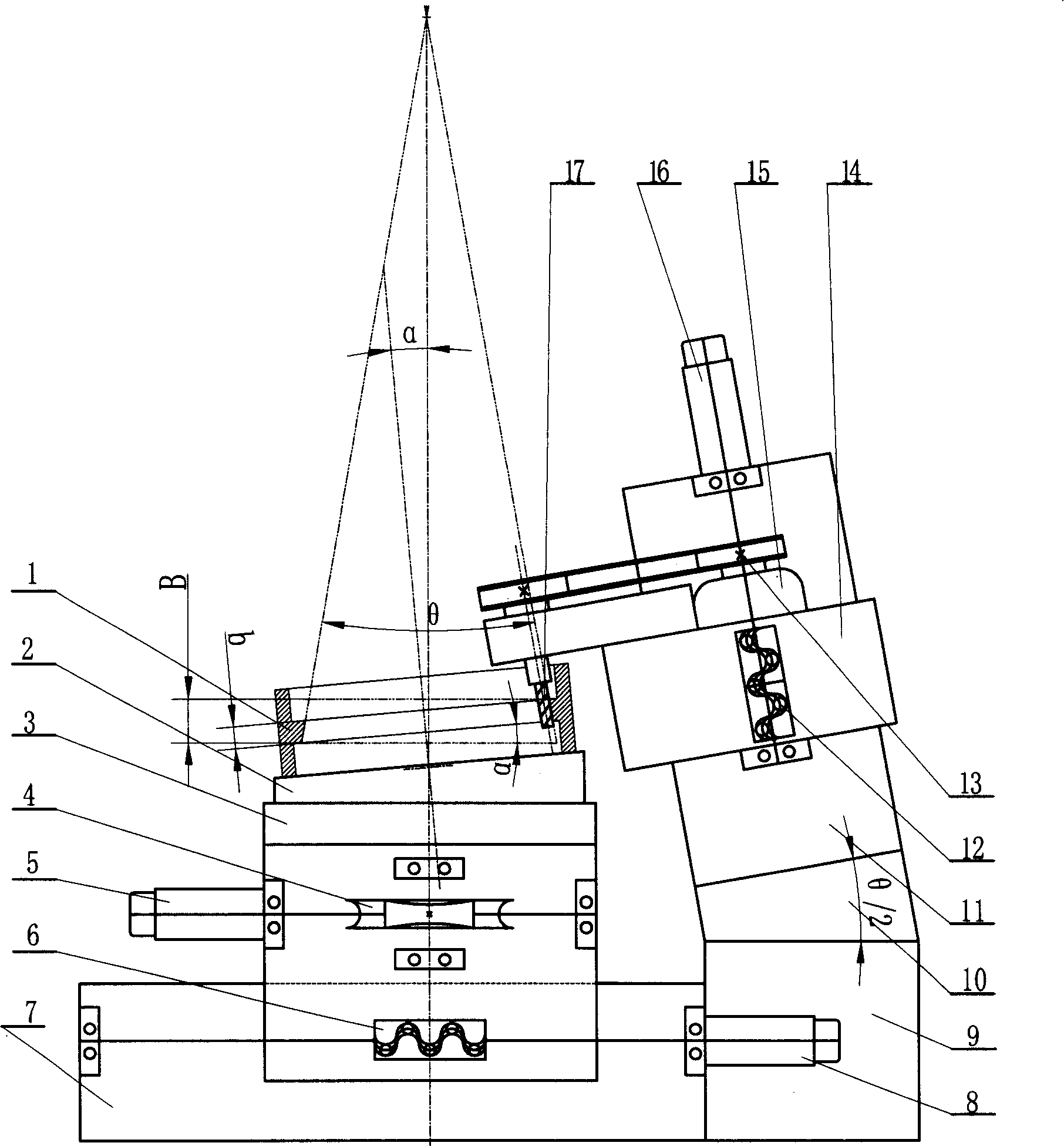

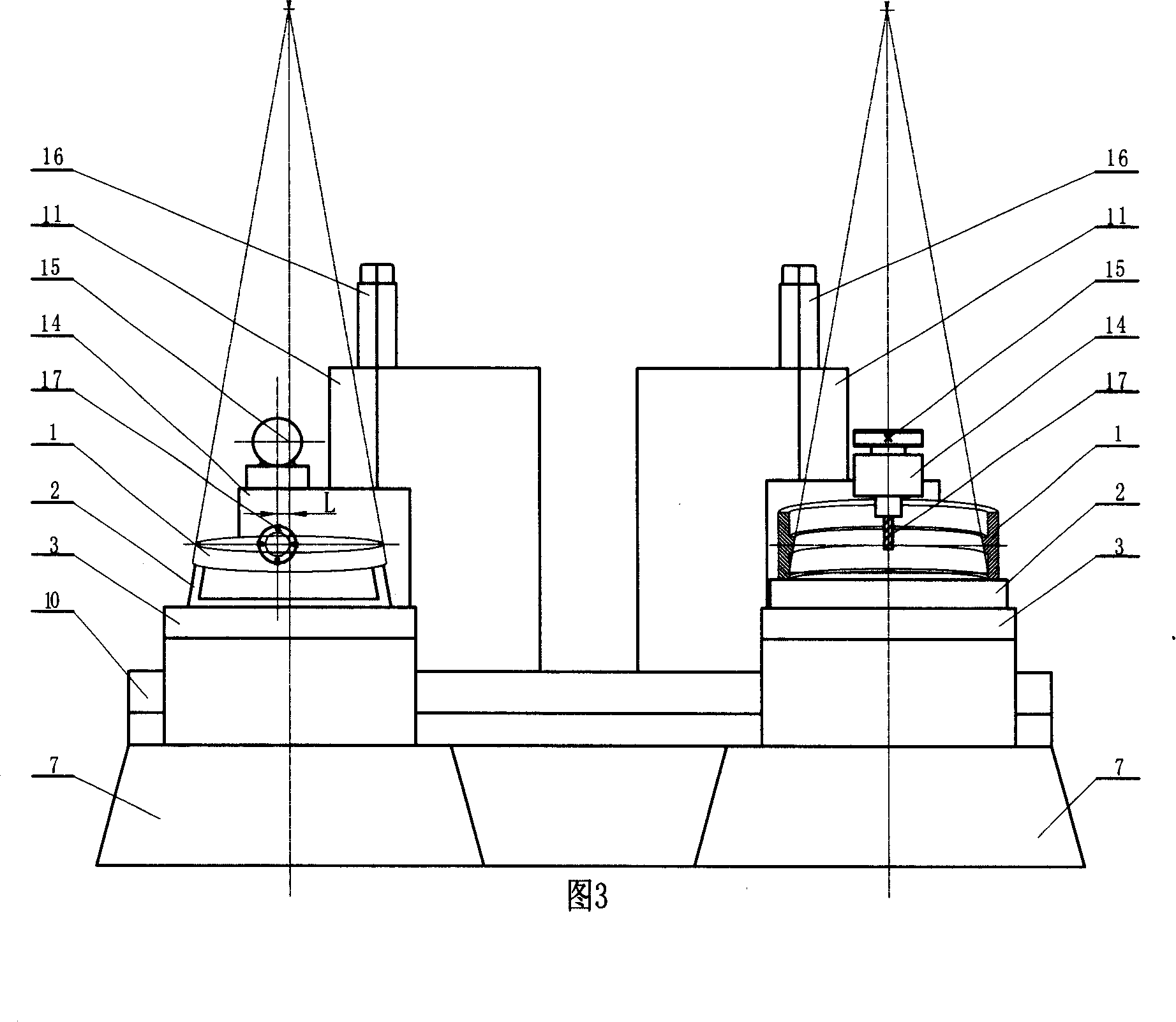

[0010] The present invention will be further described below in conjunction with accompanying drawing.

[0011] See Figures 1, 2, and 3. This special combined machine tool consists of a rotary table 3, a sliding table 7, a common side base 9, a common slope plate 10, a column 11, a spindle servo motor 15, and stepping motors 5, 8, and 16. And main components such as transmission parts ball screw 6,12, synchronous belt transmission 13, workbench turbine pair 4 and milling power head 14 and milling cutter 17 are formed. Among them by Figure 1, figure 2 It can be seen that the two groups of rotary tables 3 with identical structures are driven by the stepping motor 5 through the turbine pair 4 to make a 360° rotation in any direction, and the rotary tables 3 are placed on the respective slide tables 7, and the slides The stepper motor 8 drags the rotary table through the ball screw 6 of the slide table to move longitudinally along the guide rail on the slide table. It can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com