Inner hole machining method for molybdenum alloy thin-walled long pipe

A processing method, molybdenum alloy technology, applied in the field of molybdenum alloy processing, can solve the problems of molybdenum alloy tube breakage, poor processing performance of molybdenum alloy, low precision and efficiency, and achieve the effects of improving efficiency, reducing vibration, and reducing the number of broken wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

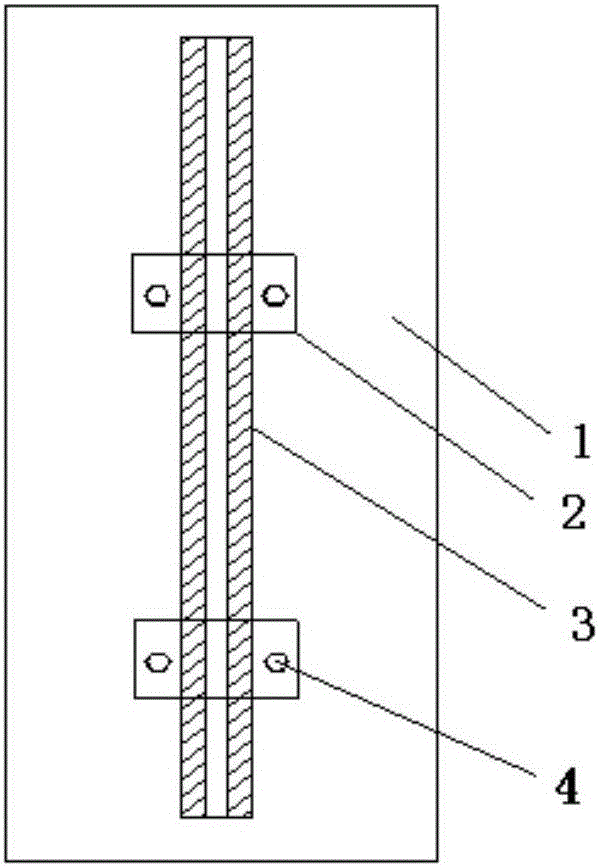

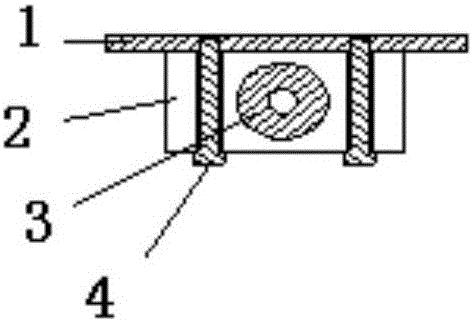

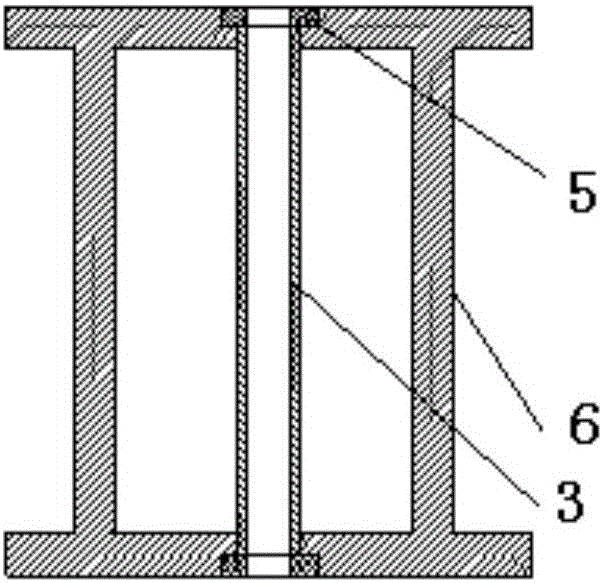

Image

Examples

Embodiment 1

[0041] In this embodiment, the inner hole processing of the molybdenum alloy thin-walled long tube with a length of 700 mm and a wall thickness of 1 mm is realized, and the inner diameter of the inner hole is 18 mm. This method is a compound processing method combining gun drilling, wire cutting and honing, which includes the following steps:

[0042] (1) Datum machining of the outer circle of the molybdenum alloy rod

[0043] The molybdenum alloy rod is clamped by the center frame, and the molybdenum alloy rod is turned to ensure that the straightness of the outer circle is not greater than 0.05mm; the center frame is used for clamping so that the molybdenum alloy rod is evenly stressed and the cutting process is reduced. Medium vibration, increase the axial clamping force;

[0044] (2) Gun drill wire hole

[0045] The molybdenum alloy rod is clamped by "V" type iron, and the molybdenum alloy rod is drilled with a gun drill; the blade surface of the gun drill bit is coated ...

Embodiment 2

[0057] The difference from Example 1 is that the surface of the cutting edge of the gun drill bit is coated with TiN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com