Patents

Literature

163results about How to "Ensure drilling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

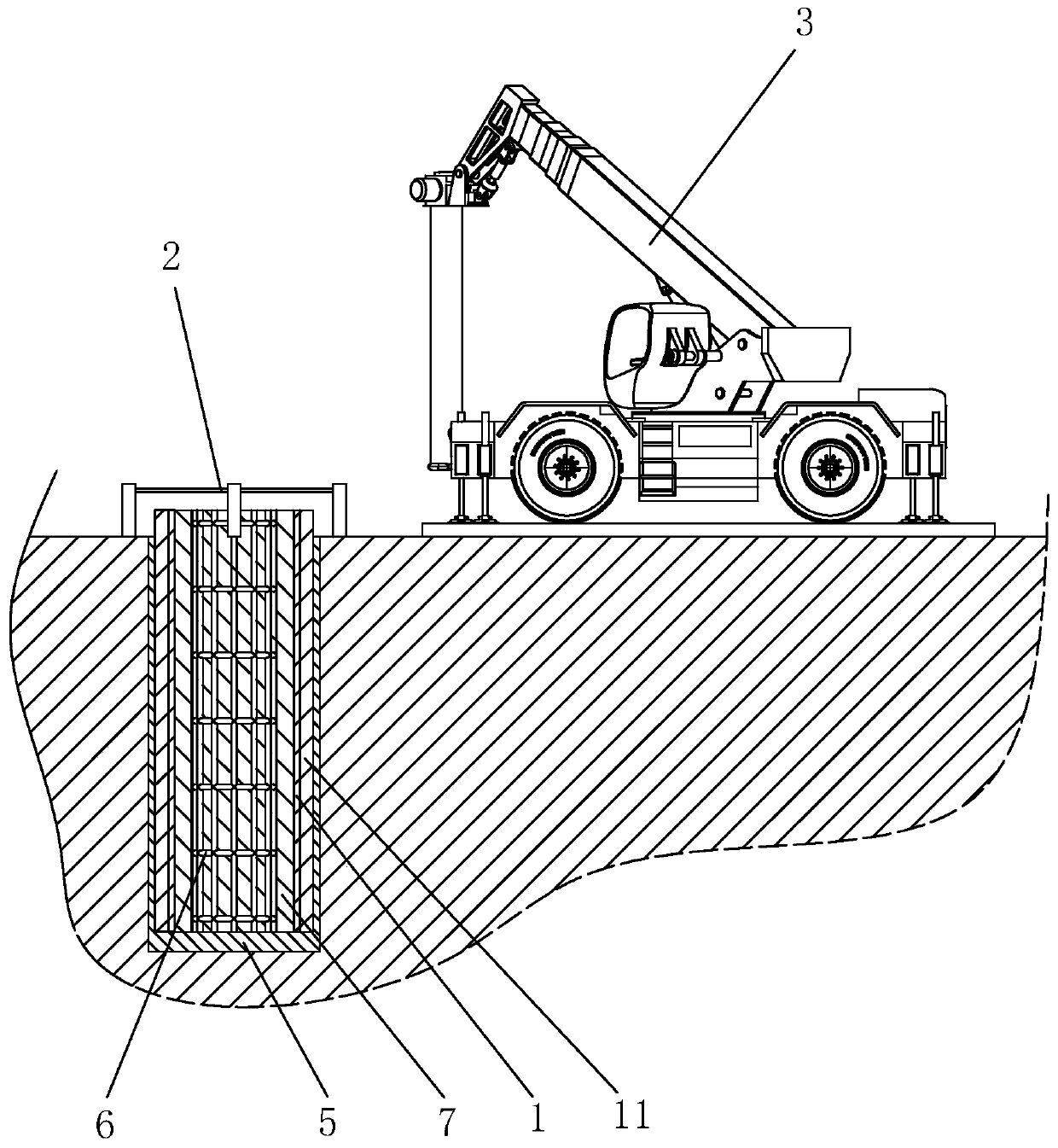

Ground-surface fixed-point deep hole layered grouting construction method

ActiveCN106640120AGuaranteed implementabilityAvoid the problem of difficult liftingUnderground chambersTunnel liningSleeve valveDeep hole

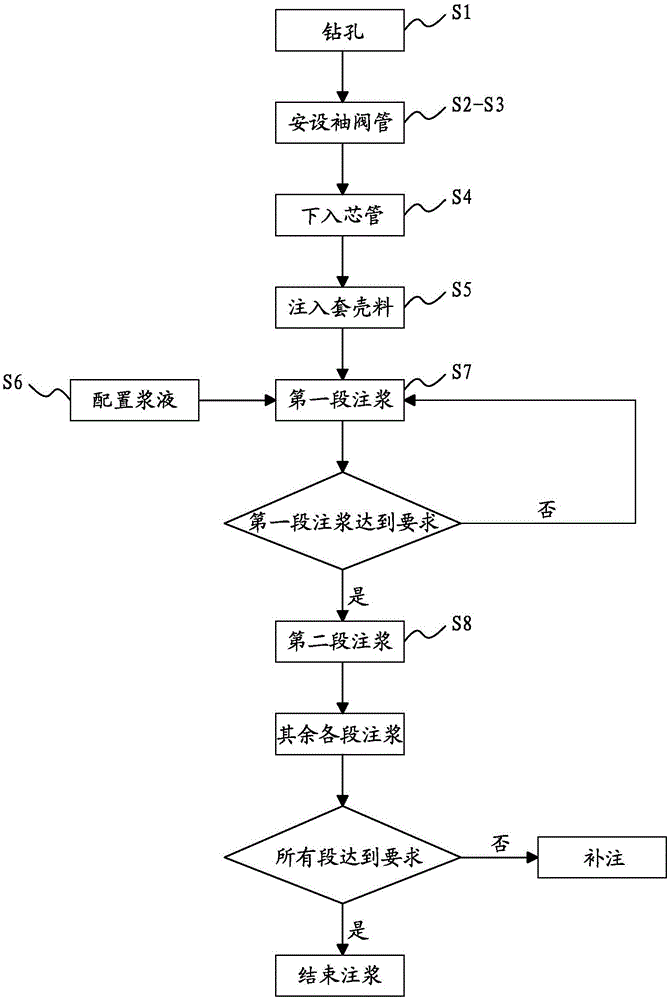

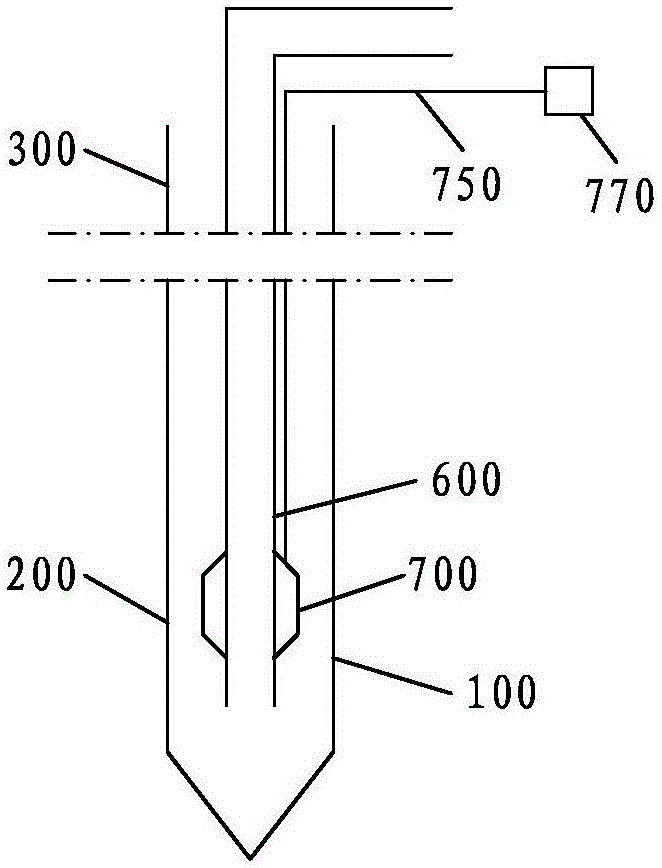

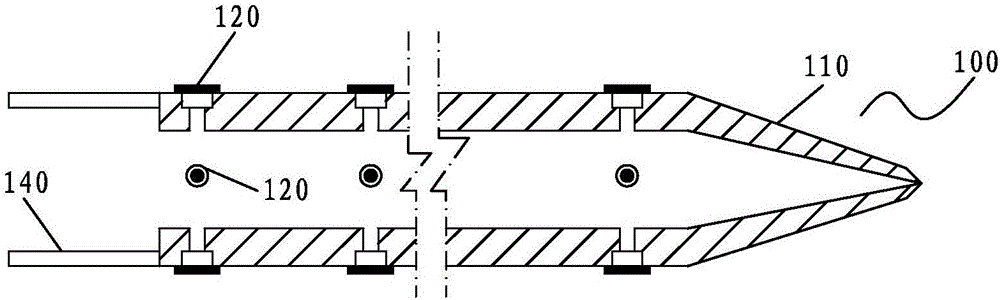

The invention discloses a ground-surface fixed-point deep hole layered grouting construction method. The method comprises the steps that vertical drilling is conducted from the ground surface of a construction area to the interior of the area needing to be grouted, wherein the hole depth is set to range from 80 meters to 150 meters; after the depth of a finished hole reaches the designed depth, a type-I sleeve valve tube (100) is put into the tail end of the drilled hole, designed grouting segments, put into the drilled hole, of a type-II sleeve valve tube (200) are connected segment by segment, and non-designed grouting segments, put into the drilled hole, of a type-III sleeve valve tube (300) are connected segment by segment; after the sleeve valve tubes are installed, a casing shell material is injected into a gap formed between the outer walls of the sleeve valve tubes and the inner wall of the drilled hole for hole sealing; after hole sealing is completed and solidifying is achieved, grouting core pipes (600) are put into the drilled hole; the tail end of the first grouting core pipe (600) penetrates through a stop-grouting plug (700) to be connected with the stop-grouting plug (700), and the other grouting core pipes (600) are connected segment by segment and then put into the sleeve valve tubes till the stop-grouting plug (700) is put into the bottoms of the sleeve valve tubes; a grouting pipe is connected to the core pipe end, grouting liquid is prepared, and then grouting operation starts through the grouting core pipes (600).

Owner:北京瑞威世纪铁道工程有限公司

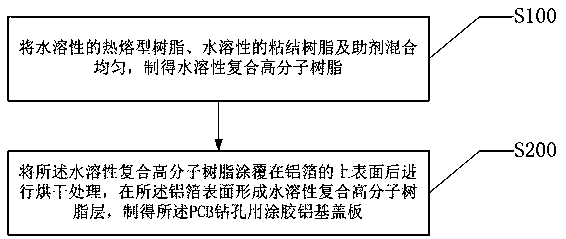

Gluing aluminum-based cover plate for PCB drilling and preparing method thereof

InactiveCN110281308AReduce the temperatureExtended service lifePretreated surfacesCoatingsSolubilityWater soluble

The invention provides a gluing aluminum-based cover plate for PCB drilling and a preparing method thereof. The gluing aluminum-based cover plate for PCB drilling comprises aluminum foil and a water-soluble composite molecular resin layer arranged on the upper surface of the aluminum foil. The water-soluble composite molecular resin layer material comprises water-soluble hot melting resin, water-soluble bonding resin and an assistant. According to the invention, the toughness of the water-soluble composite molecular resin layer is proper, in the drill needle falling process, the guide effect is achieved, and the drilling precision is improved; meanwhile, the hot melting resin in the water-soluble composite molecular resin layer achieves the effect of lubricating a drill bit and cooling the drill needle during drilling, the hole wall roughness is effectively improved, wire winding is reduced, the drill bit temperature is reduced, the service life of the drill needle is prolonged, and in addition, the water-soluble composite molecular resin layer is good in water solubility, easy to treat after drilling, not prone to being attached into holes of a PCB and capable of ensuring drilling quality.

Owner:烟台柳鑫新材料科技有限公司

Inner hole machining method for molybdenum alloy thin-walled long pipe

ActiveCN105750843ARealization of inner hole processingBrittleHoning machinesBoring/drilling machinesAlloyLinearity

The invention belongs to the technical field of molybdenum alloy machining, and discloses an inner hole machining method for a molybdenum alloy thin-walled long pipe of a reactor. The method is a combined machining method in which gun drilling, linear cutting and honing are organically combined, and comprises the following steps: (1) outer circle reference machining of a molybdenum alloy bar, (2) gun drilling of a threading hole, (3) linear cutting of an inner hole and (4) honing finish machining of the inner hole. The linearity of the machined inner hole of the molybdenum alloy thin-walled long pipe is higher than 0.03 mm, the cylindricity of the inner hole is higher than 5 [mu]m, and the roughness of the inner hole is better than 0.2 [mu]m.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

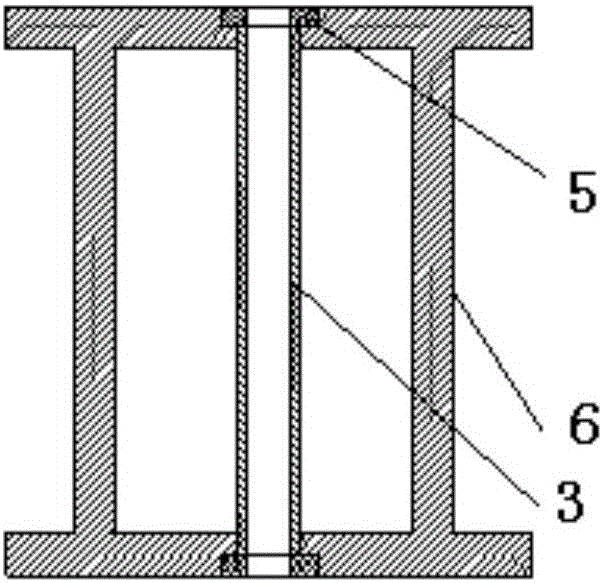

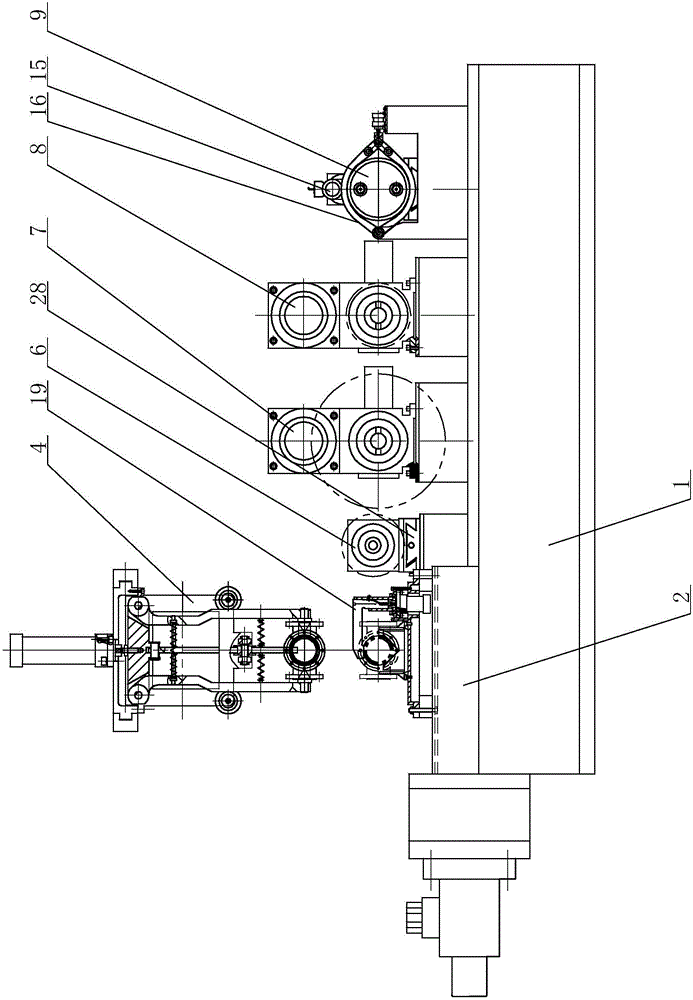

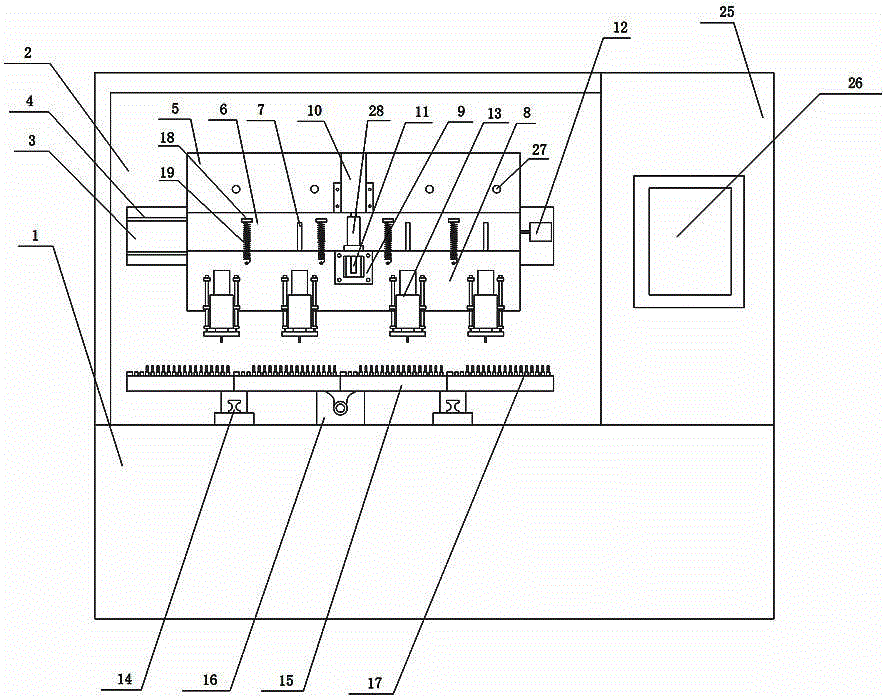

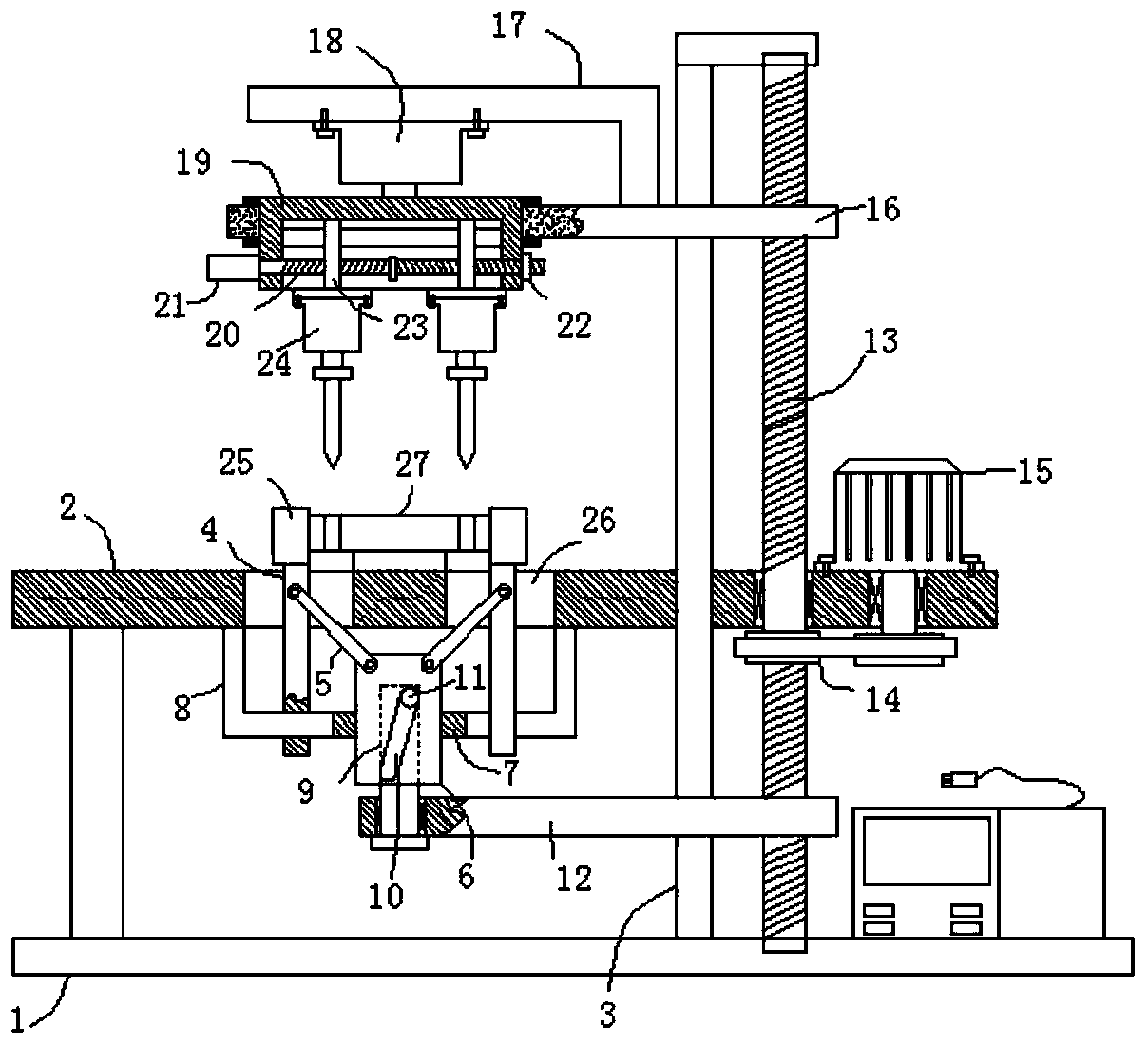

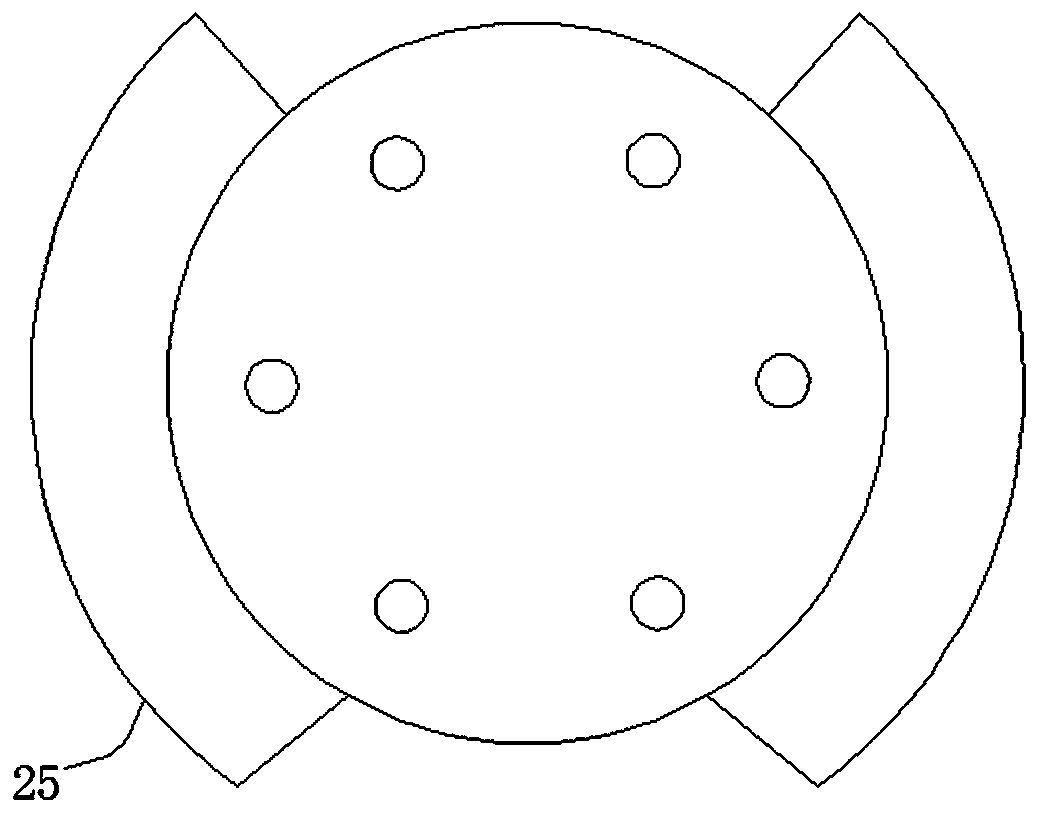

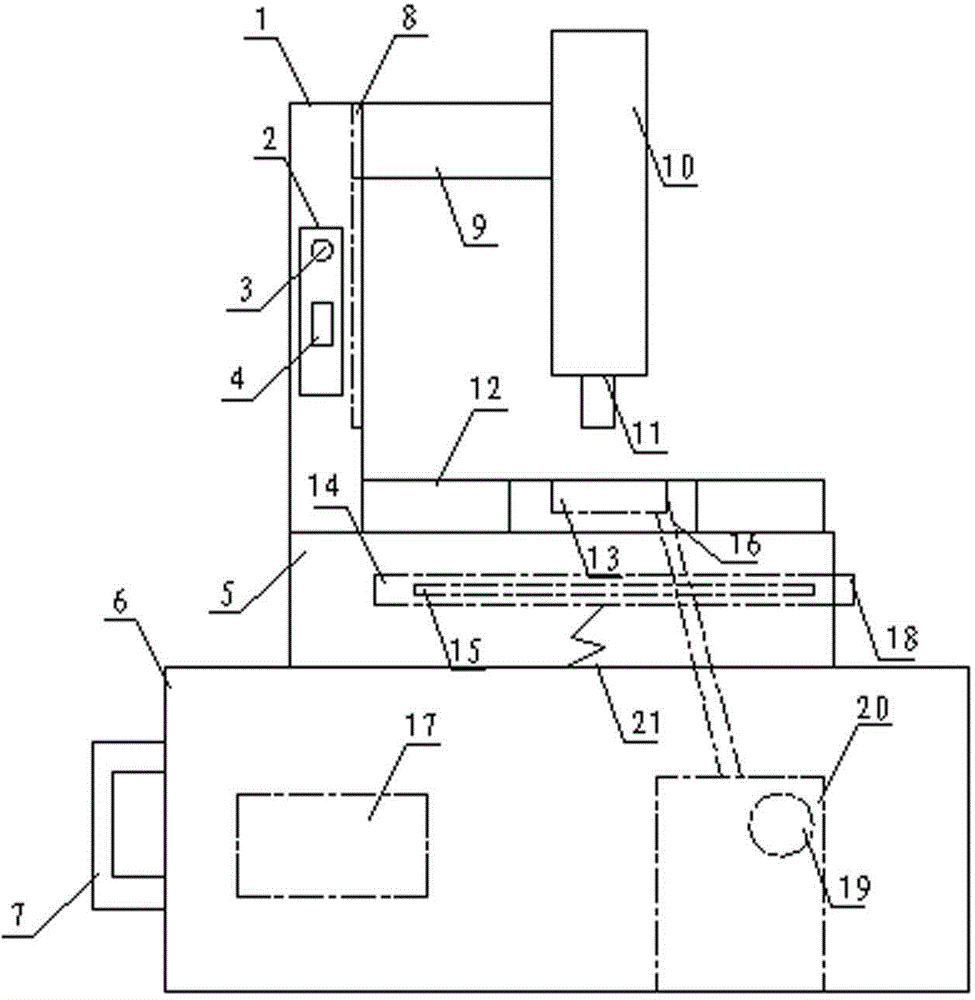

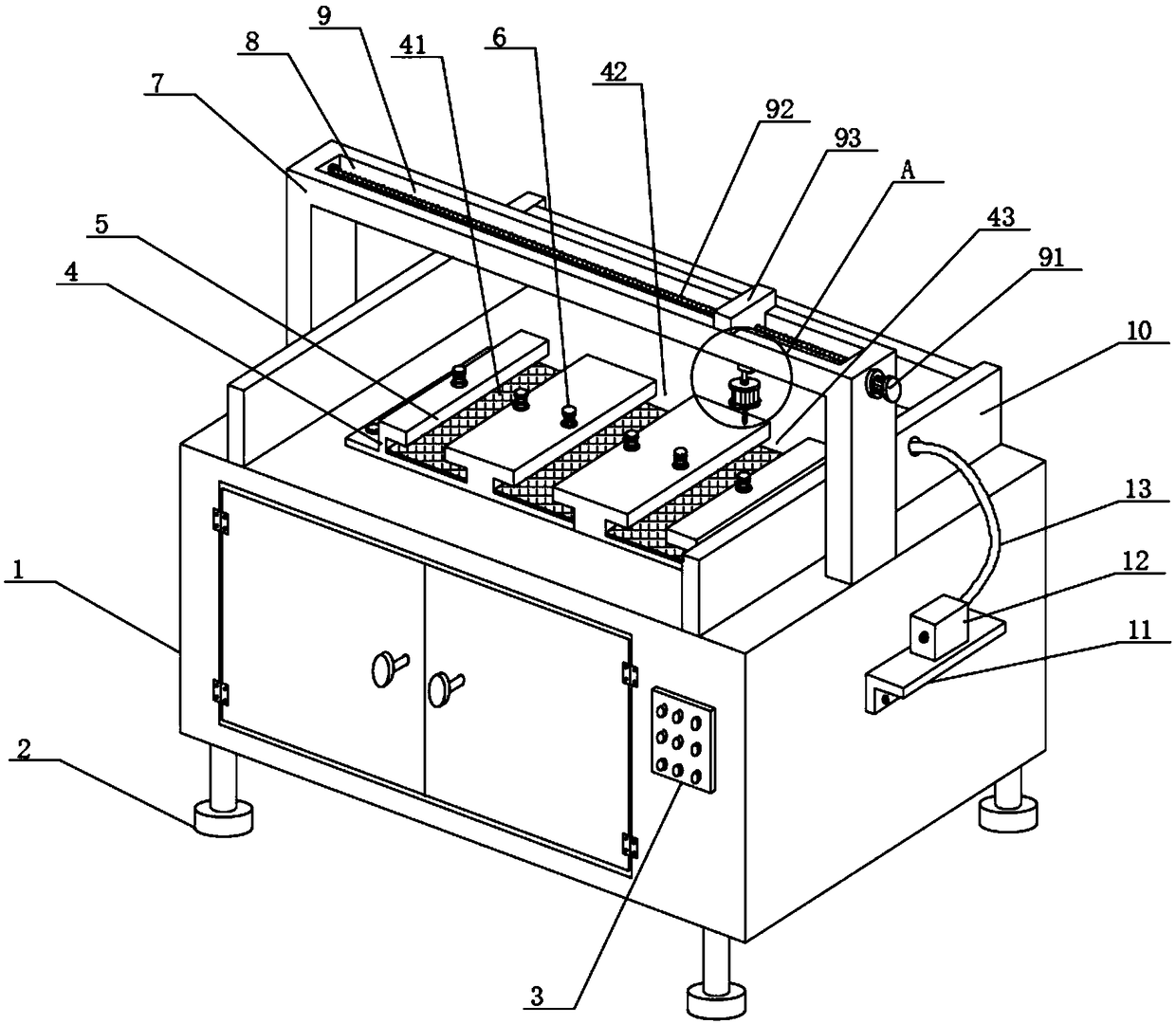

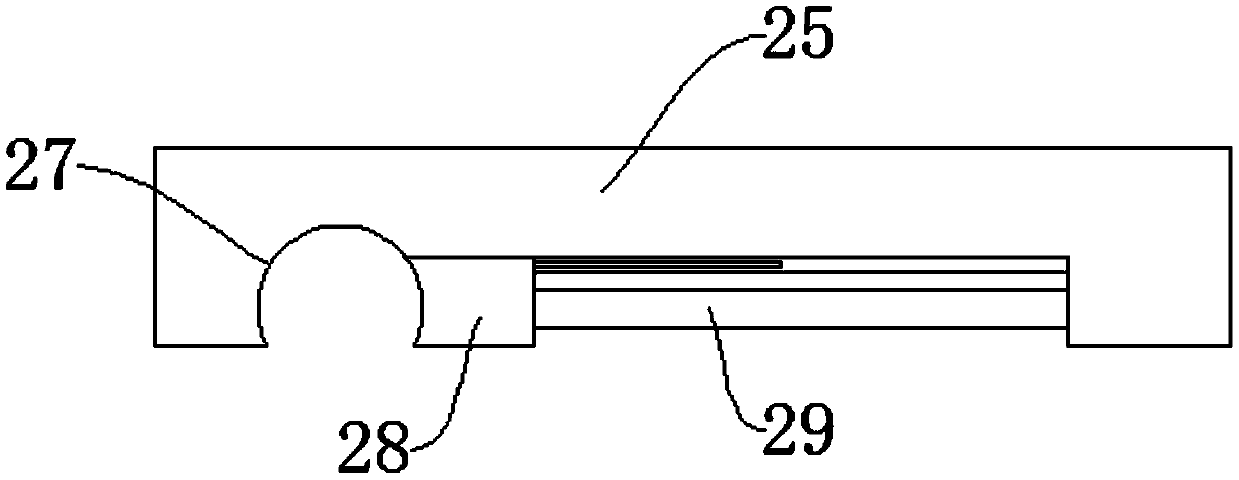

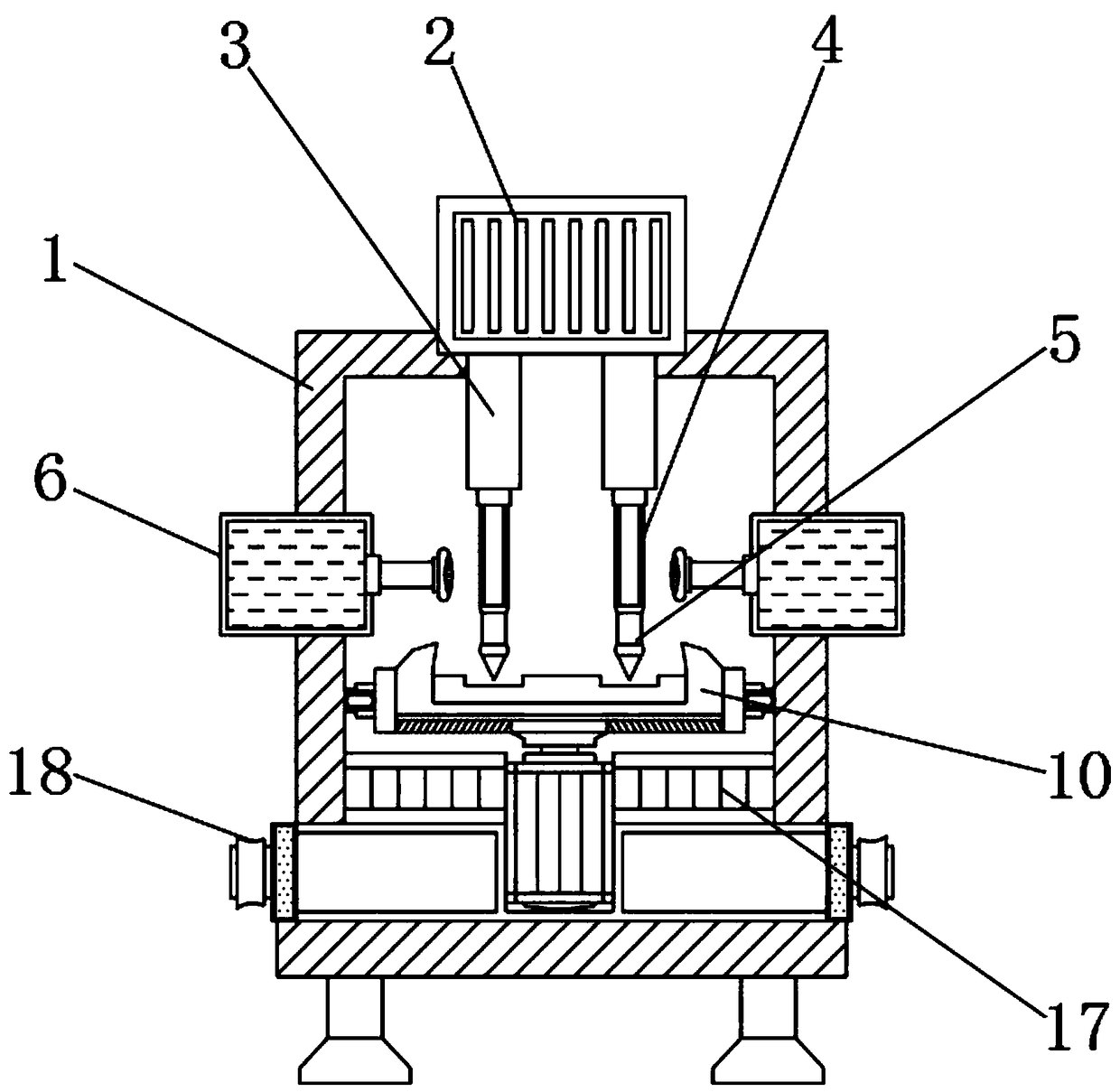

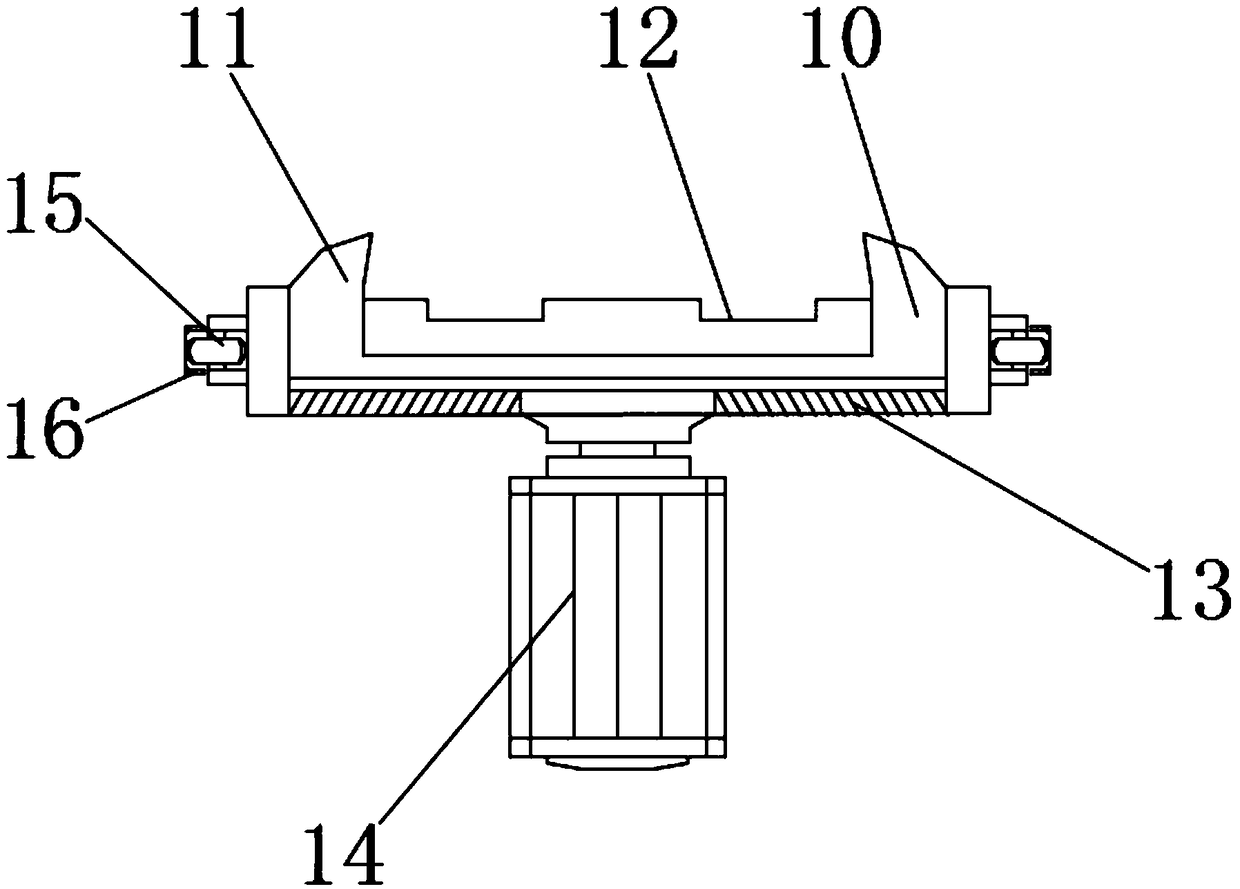

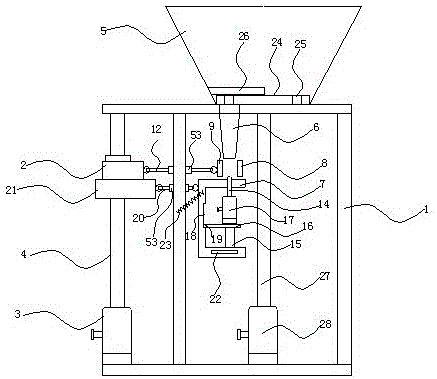

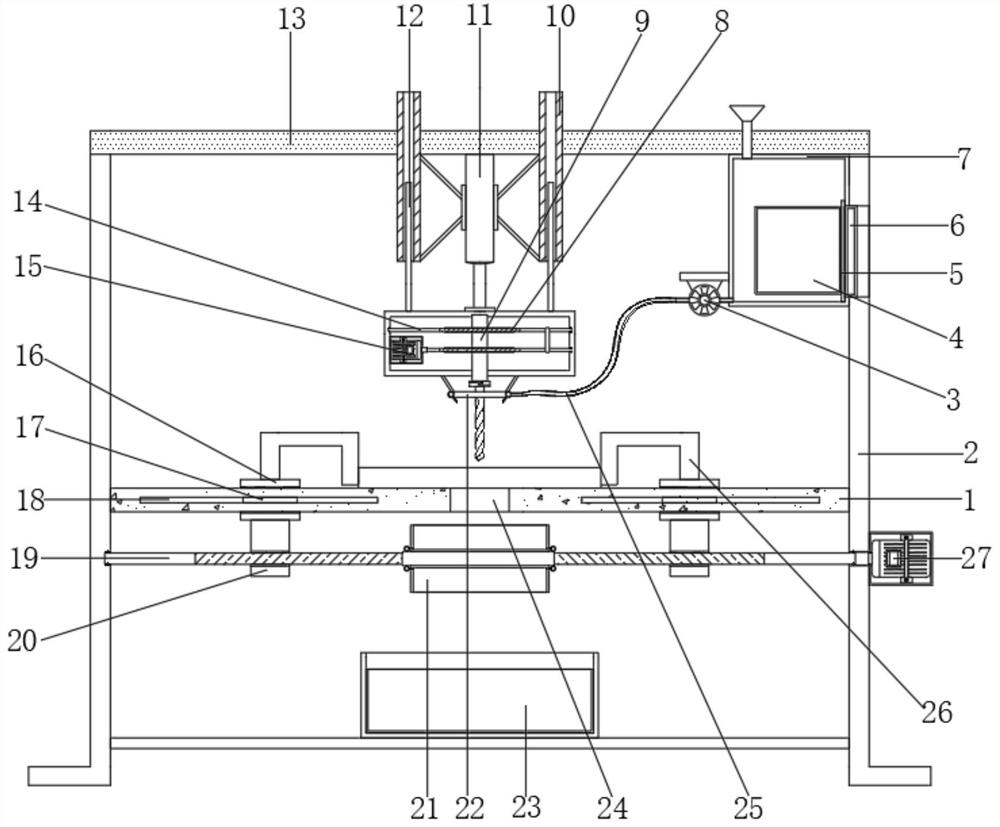

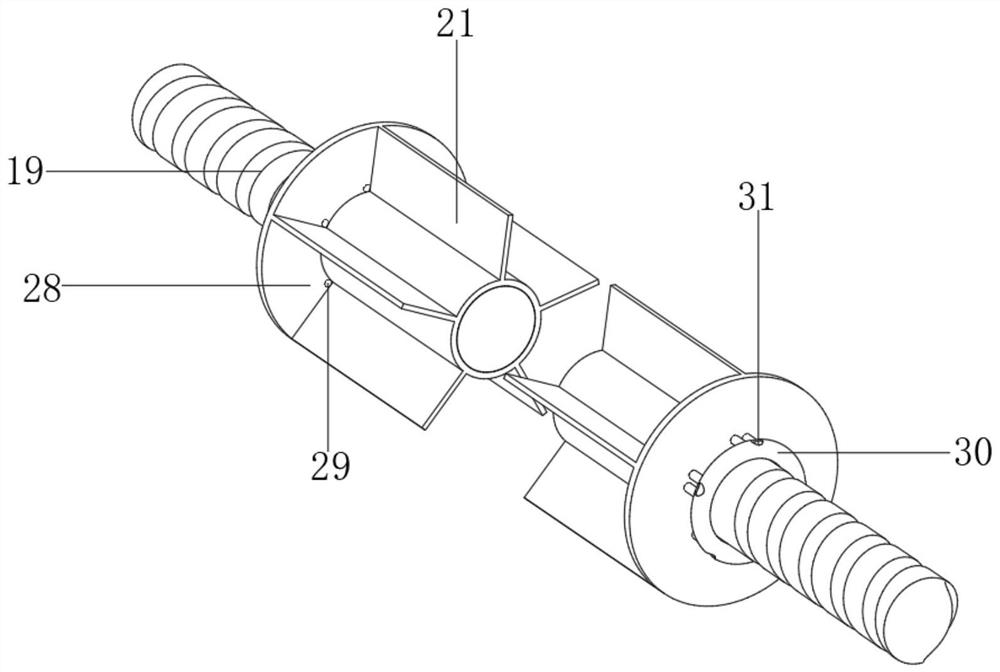

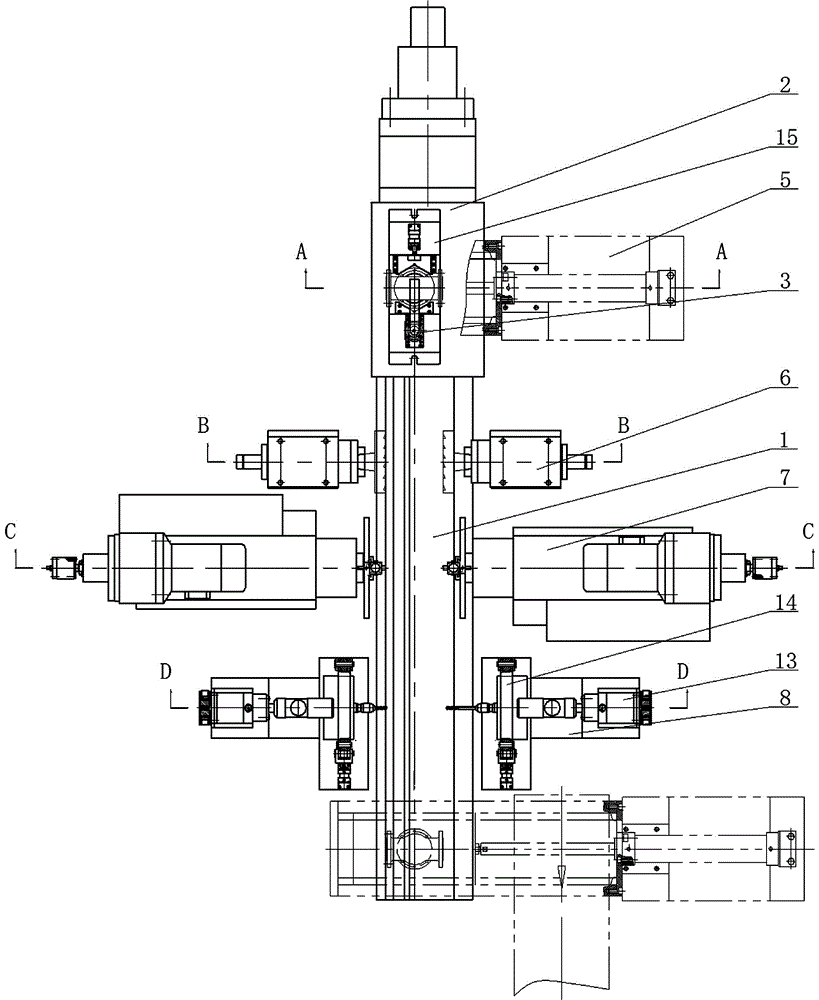

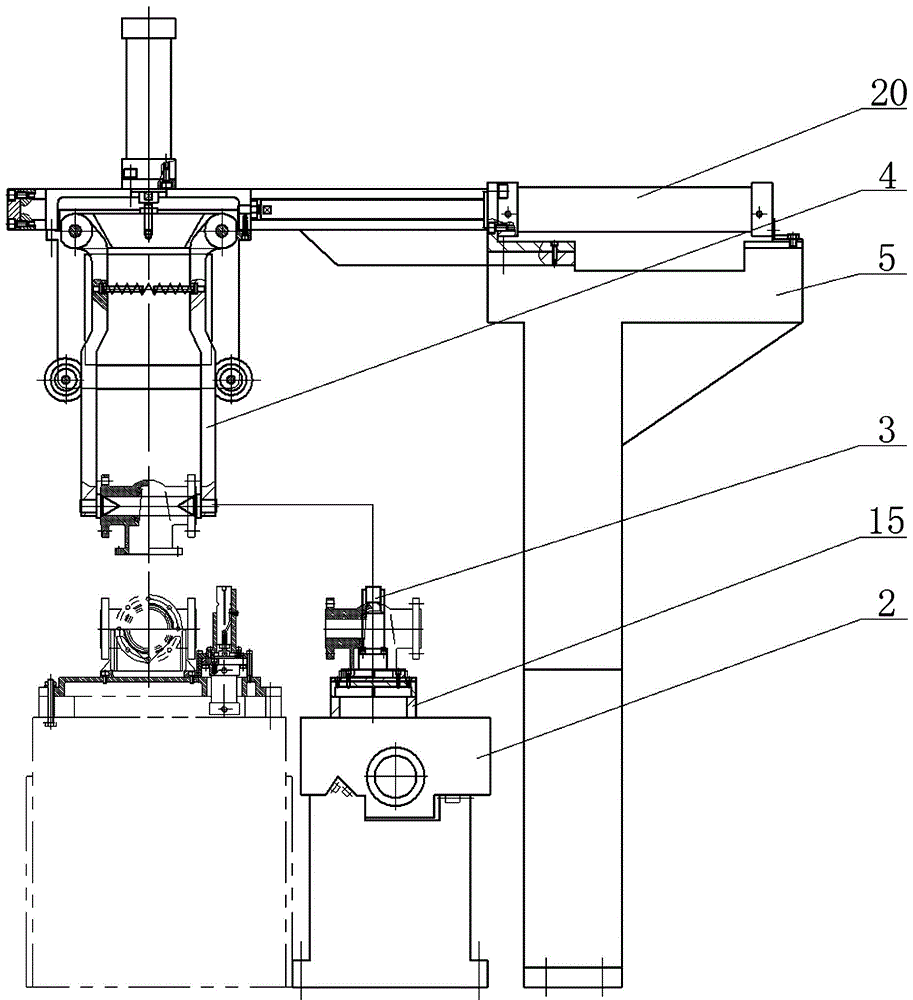

Automated assembly line for machining of valves

ActiveCN106425511AQuality controllableAvoid vibrationPrecision positioning equipmentWork clamping meansNumerical controlGeneral purpose

The invention relates to an automated assembly line for machining of valves, and mainly solves the problems that when a connecting seat on a valve is machined by an existing general-purpose machine tool, repeated clamping is required, form and location tolerance is difficult to guarantee, quality of the valve is not easy to control, and machining efficiency is low. The automated assembly line for machining of valves is characterized in that an end surface milling power head (6), a boring power head (7), a groove milling power head (8) and drilling power heads (9) which are respectively mounted on a longitudinal sliding table (28) are successively arranged on the other side of a transverse numerical-control sliding table (2) from left to right, three V-shaped positioning plates (18) are fixed above a supporting seat (17), and a pneumatic lifting deflection clamp (19) is arranged on the supporting seat (17). The automated assembly line for machining of the valves is controlled by a PLC, can automatically convey and clamp the valves and machine various machining parts of connecting seats of the valves in order; and because machining is implemented by a disposable clamping assembly line, machining precision is guaranteed, the quality of the valves is easy to control, and machining efficiency is improved.

Owner:江苏迎华精密机械科技有限公司

Method for processing thin stephanoporate steel plate

The invention relates to a method for processing a thin perforated steel plate, which is characterized in that the method comprises the following steps: four to six thin steel plates are overlapped first; then the positions to be drilled originally, on the overlapped thin steel plates are drilled with at least two holes first which are taken as positioning holes; bolts are arranged on the positioning holes for fixation; and finally peripheral holes are drilled first on the fixedly overlapped thin steel plates, and then holes inside the periphery are drilled. The method has the advantages that the method has simple and convenient operation, and effectively reduces the deformation of the thin steel plates and tube plates caused by poor rigidity and the stress of drilling operation.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Drilling deviation rectification method for 60-meter-long hole drilling of tunnel large pipe shed

InactiveCN104373041AReduce the number of cyclesShorten the construction periodDirectional drillingEconomic benefitsDrill bit

The invention discloses a drilling deviation rectification method for 60-meter-long hole drilling of a tunnel large pipe shed. The method comprises the steps that a guide probe arranged on the rear portion of a drill bit monitors the orientation of a facing angle and the deviation direction of the drill bit; a signal line penetrating through a drill pipe is connected to a display screen located at a drill machine operation table; the display screen displays the inclination angle, namely, the horizontal angle, of the drill bit and the facing angle, namely, the direction of a guide plate; and the drilling direction is adjusted according to the inclination angle and the facing angle displayed by the display screen. The wedge face of the drill bit is adjusted to be in the deviated direction; and after a drill machine is stopped from rotating, stress application jacking is carried out, the drill bit deviates in the opposite direction due to the action of a slope, and therefore the drilling direction is adjusted. The drilling deviation rectification method has the advantages that a 60-meter-long drilling hole is formed in a single drilling process; the construction period is greatly shortened; great economic benefit is obtained; the drilling quality is ensured; and safety guarantee is provided for construction in the next step.

Owner:CHINA RAILWAY 16TH BUREAU GRP 5TH ENG

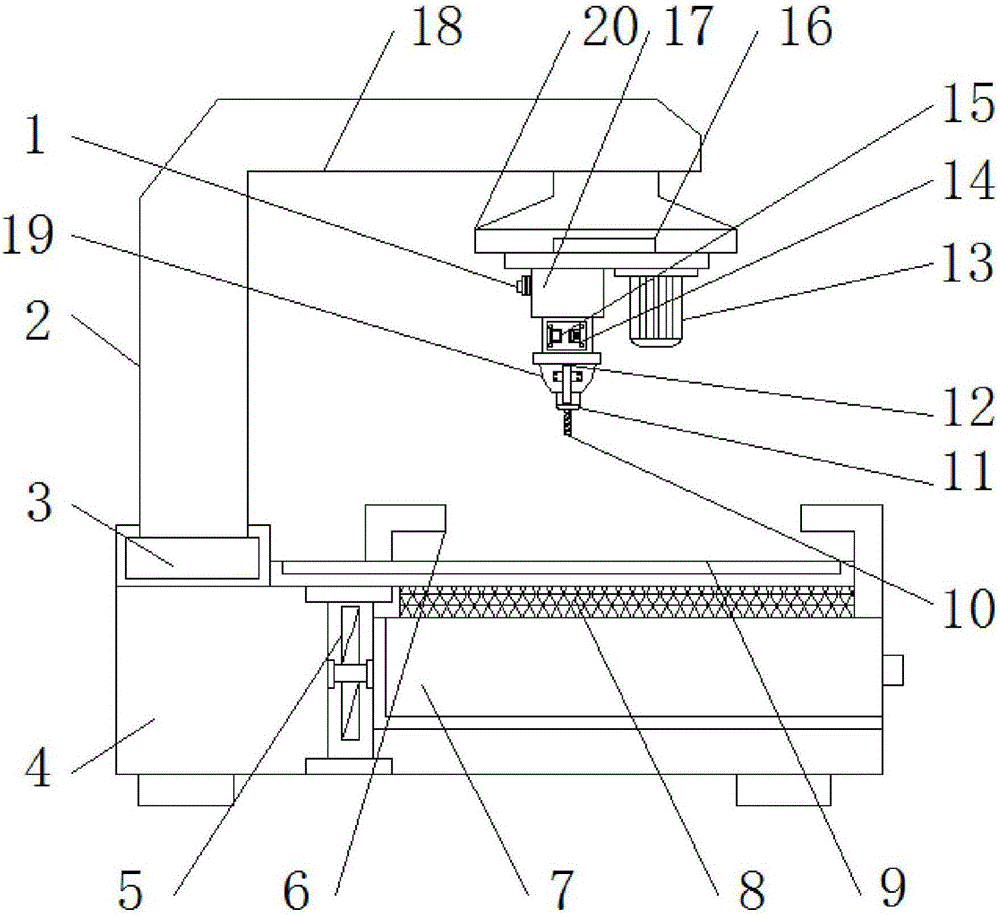

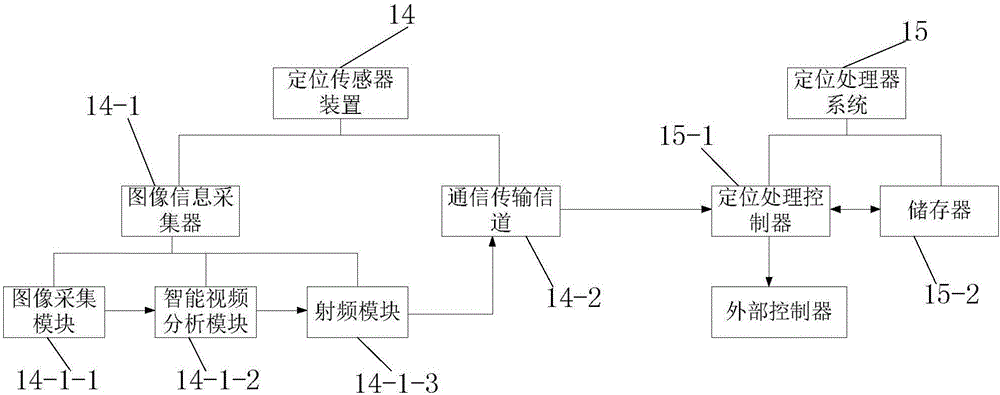

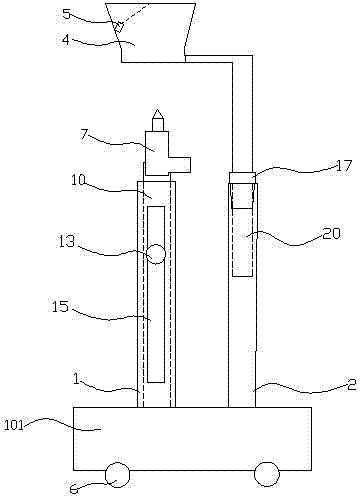

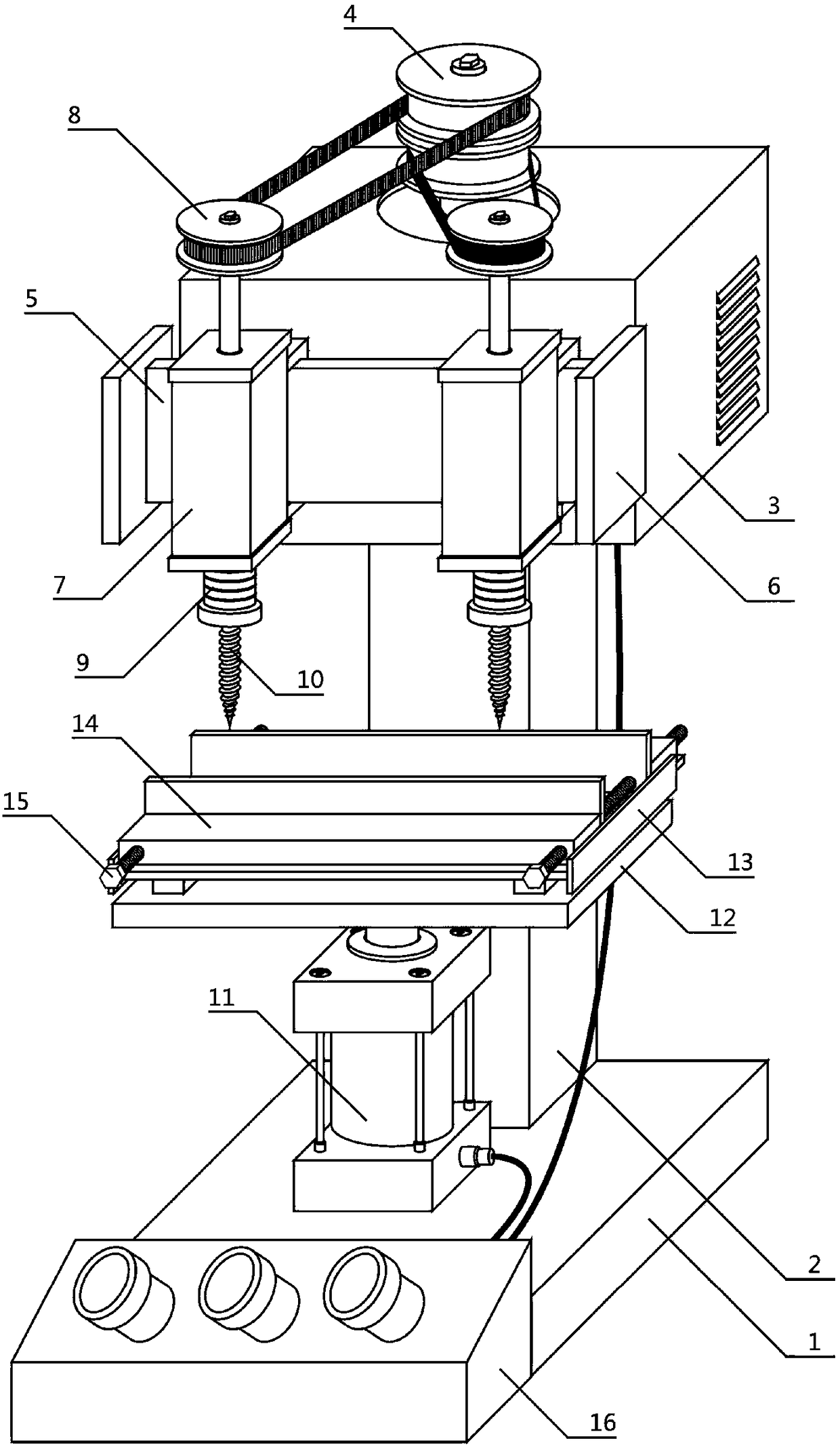

Fully-automatic drilling machine

ActiveCN106670526AImprove the security environmentHigh positioning accuracyImage enhancementImage analysisPsychological healthFully automatic

The invention discloses a fully-automatic drilling machine. The fully-automatic drilling machine is provided with a drilling machine supporting platform and a drilling machine main supporting column; a dust-collecting drawer is arranged in the drilling machine supporting platform and a negative-pressure fan is arranged on one side of the dust-collecting drawer; a dust-collecting net is arranged above the dust-collecting drawer; an objective table is arranged above the drilling machine supporting platform; a longitudinal sliding groove is formed in the drilling machine supporting platform; and the drilling machine main supporting column is arranged above the longitudinal sliding groove. The fully-automatic drilling machine can synchronously collect harmful substances such as dust particles generated by drilling in the drilling process, improve the workshop environment, protect physical and psychological health of workers and be beneficial to environmental protection; a laser receiving and transmitting device can accurately position the drilling position by utilizing laser; and a positioning sensor device is arranged in a drilling device, so the drilling positioning precision is improved, the drilling quality is guaranteed, drilling operation can be conducted effectively by the device instead of manual power, and the drilling efficiency is improved.

Owner:SICHUAN UNIV

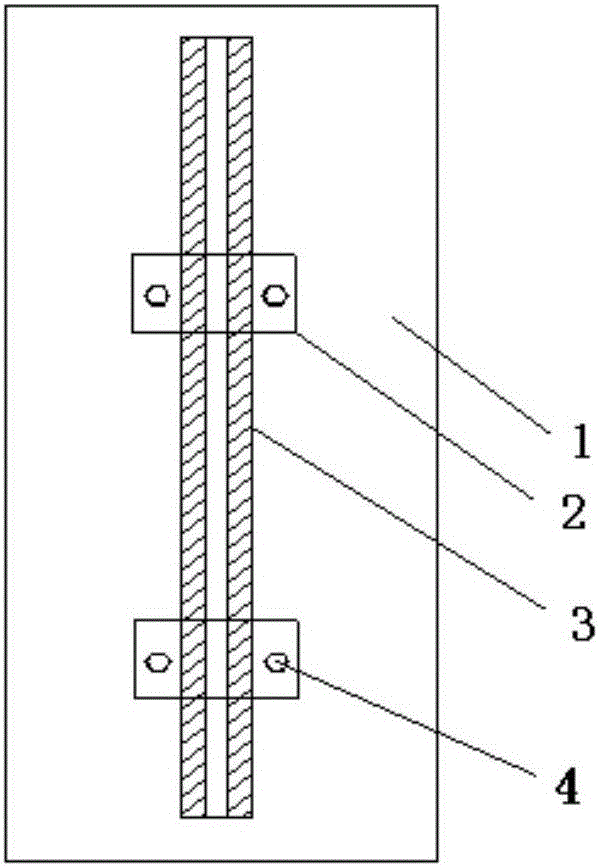

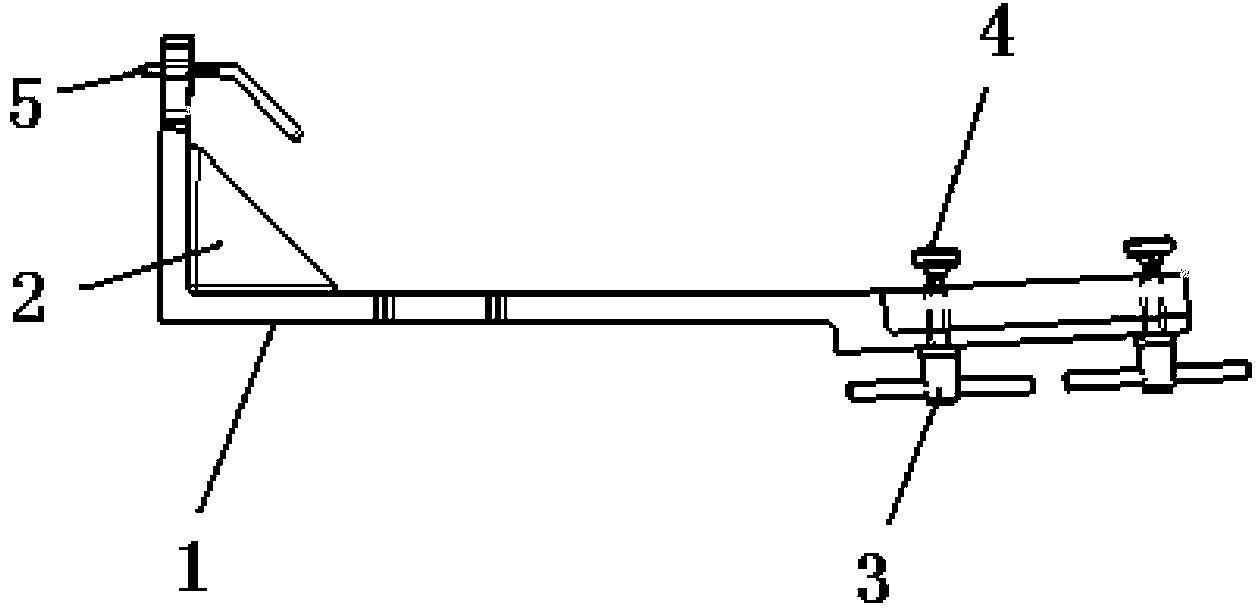

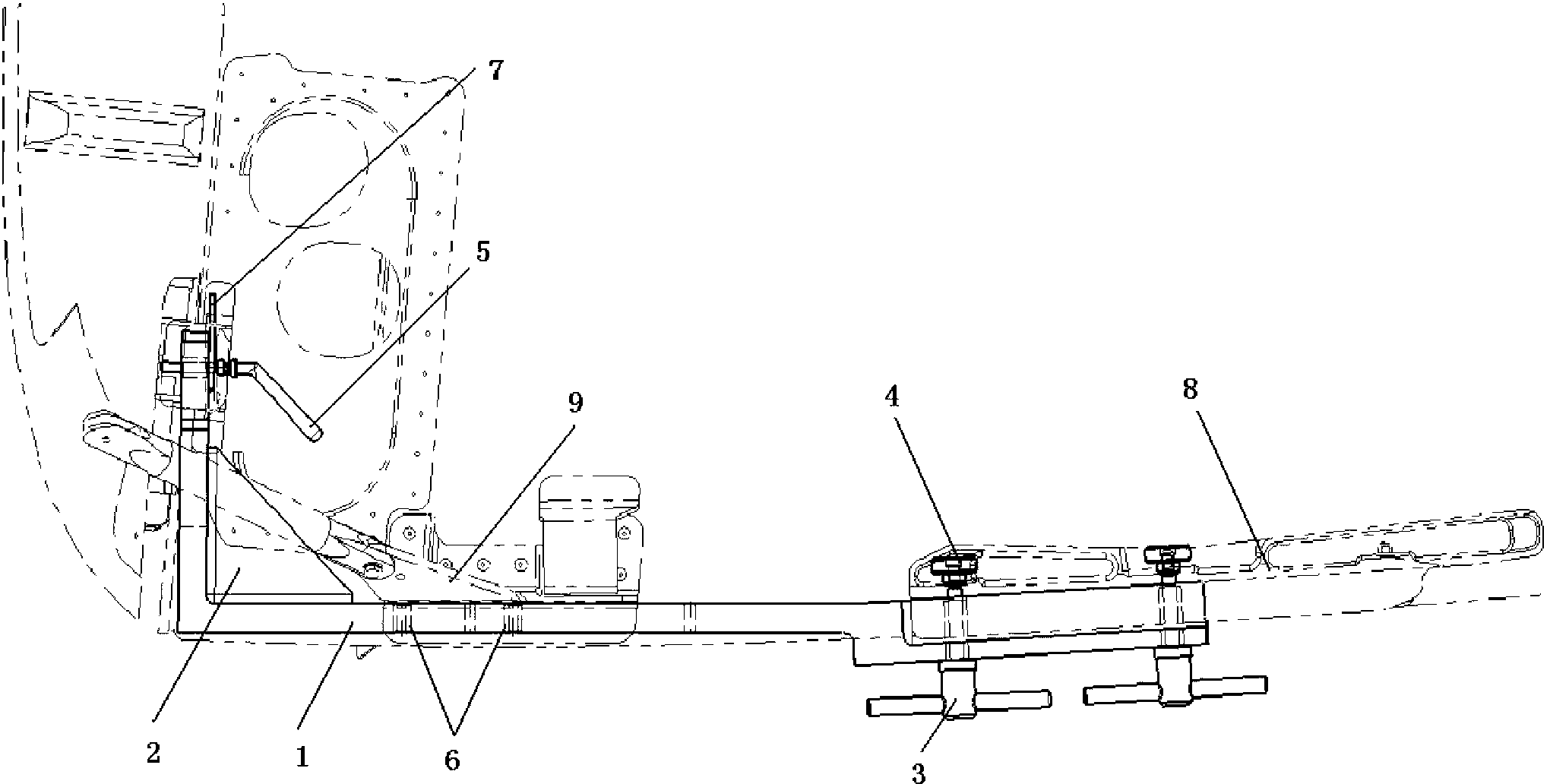

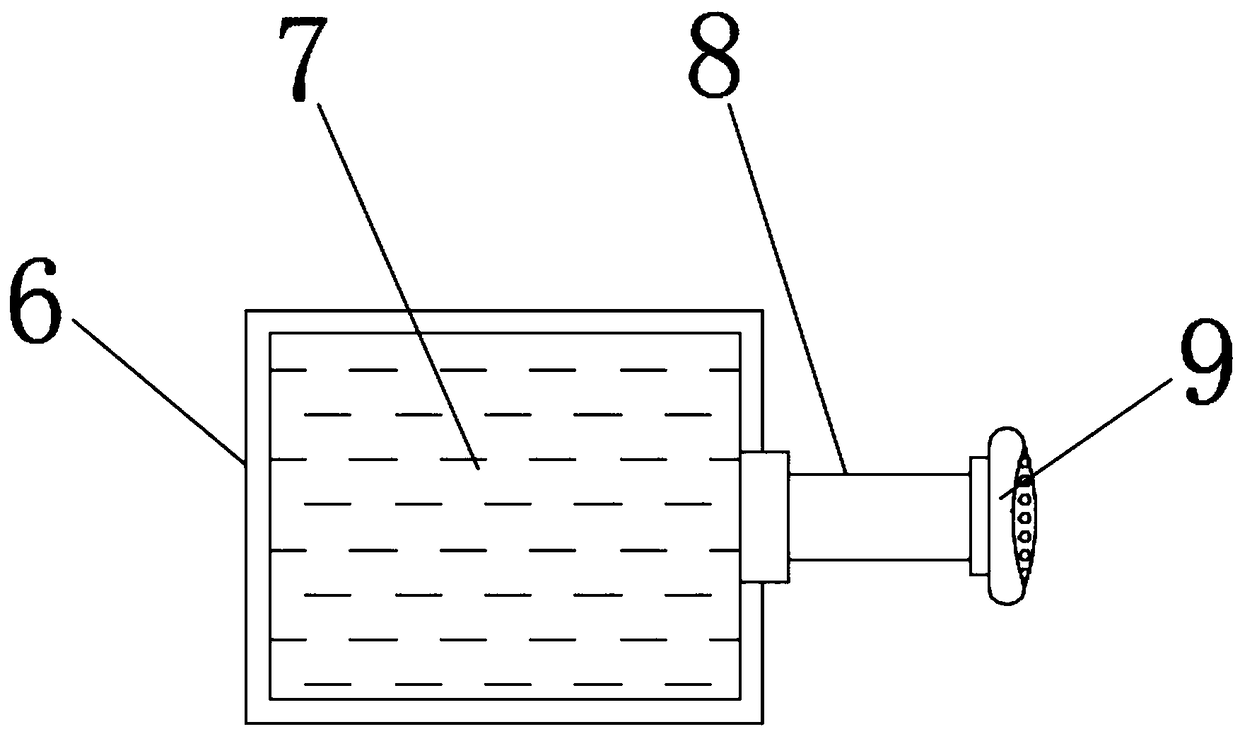

Drilling tool for airplane sliding rail

InactiveCN103192118AEasy to install holesAvoid drillingDrill jigsStructural engineeringDrill bushing

The invention relates to a drilling tool for an airplane sliding rail. The drilling tool comprises an L-shaped drill template (1), wherein a bending part of the L-shaped drill template (1) is fixed and reinforced by using a reinforcing angle plate (2), the inner surface of the drill template (1) is clung to the exterior of the side surfaces of a sliding rail front bracket (7) and a sliding rail rear bracket (8), a bent handle pin (5) is installed at the front end of the drill template (1) and connected with a precast positioning hole in the sliding rail front bracket (7) for positioning, two positioning bolts (3) and knurled nuts (4) are installed at the rear end of the drill template (1) and connected with two precast positioning holes in the sliding rail rear bracket (8) for positioning, two drill bushing holes (6) are formed in the middle of the drill template (1), the positions of the two drill bushing holes (6) correspond to those of two holes to be machined in a sliding rail middle bracket (9), and the diameter of the two drill bushing holes (6) is 5 plus or minus 0.2mm. The drilling tool facilitates drilling in the installation of the airplane sliding rail, avoids deviation occurring in pre-installation of a finished product of the sliding rail, ensures the drilling quality, satisfies the requirement on the interchangeability of the sliding rail, and improves the percent of pass of the product.

Owner:HARBIN

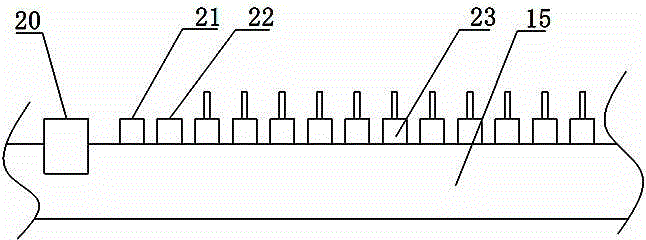

Full-automatic circuit board perforating machine

ActiveCN104858931AEnsure drilling qualityQuality improvementMetal working apparatusDrive motorEngineering

The invention discloses a full-automatic circuit board perforating machine. The full-automatic circuit board perforating machine comprises a stand, a working cavity is opened in the stand, a substrate plate is arranged in the working cavity, the substrate plate is connected with a support plate in a sliding fit mode, a settlement step is arranged in the support plate, the settlement step is provided with a plurality of slide rails B, the slide rails B are connected with a sliding plate in a sliding fit mode, a drive motor B for driving the sliding plate to move is arranged on the front head face of the support plate, a drive motor A for driving the support plate is arranged on the rear head face of the support plate, a plurality of drilling machines are arranged on the sliding plate, a workbench is arranged in the working cavity, the workbench is driven by a drive motor C arranged at the rear end of the working cavity, and the workbench is provided with a tool changer. The full-automatic circuit board perforating machine has beneficial effects of high automatic degree, high drilling efficiency and high tool changing precision.

Owner:SICHUAN SHENGDA XINXING ELECTRONICS

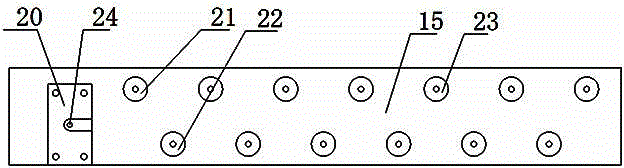

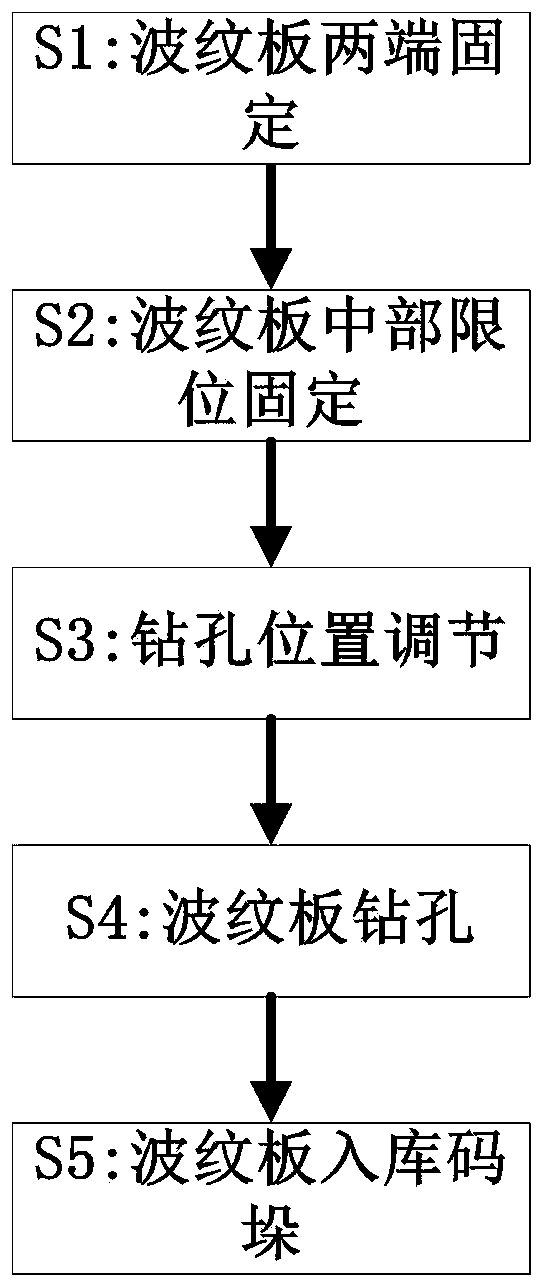

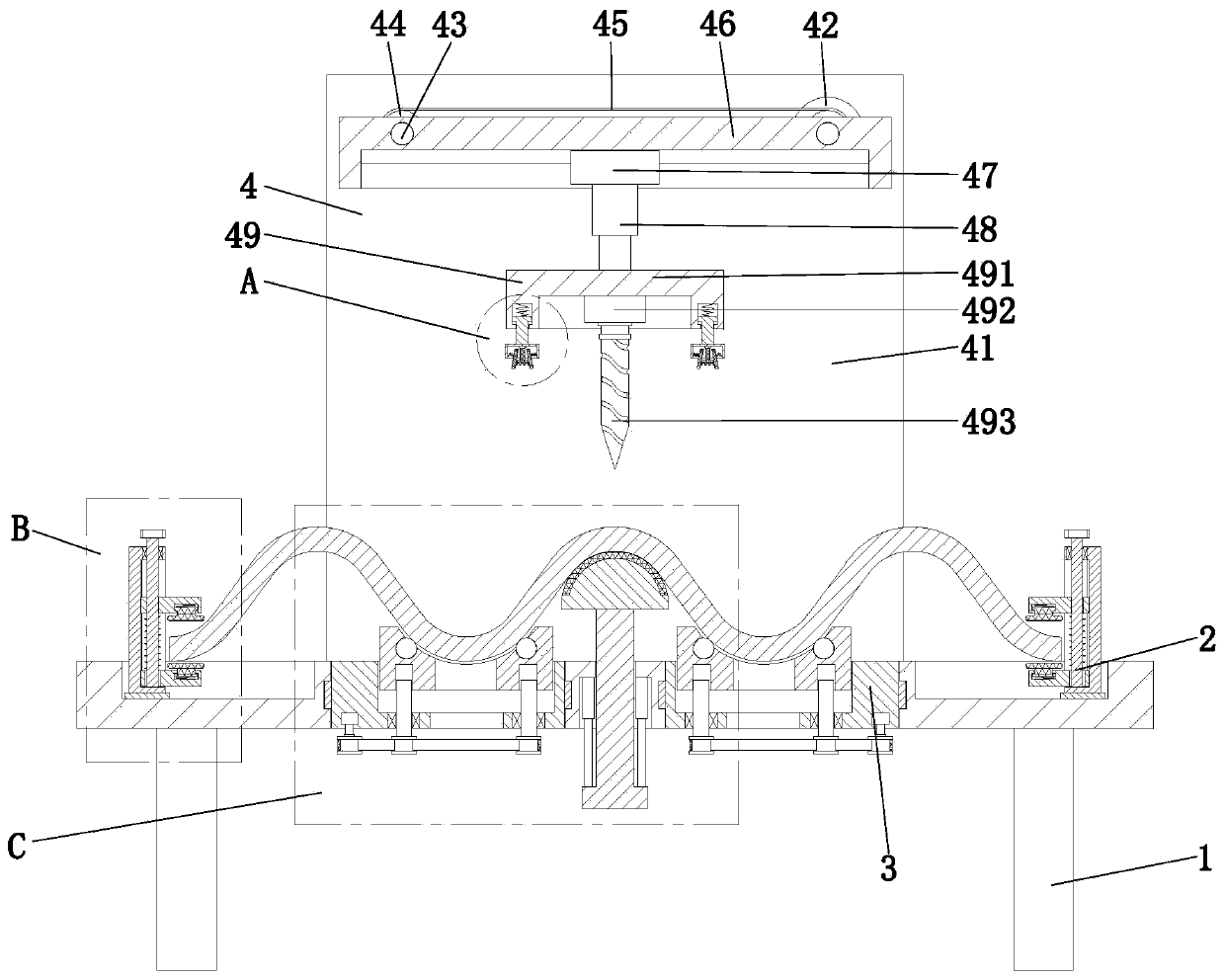

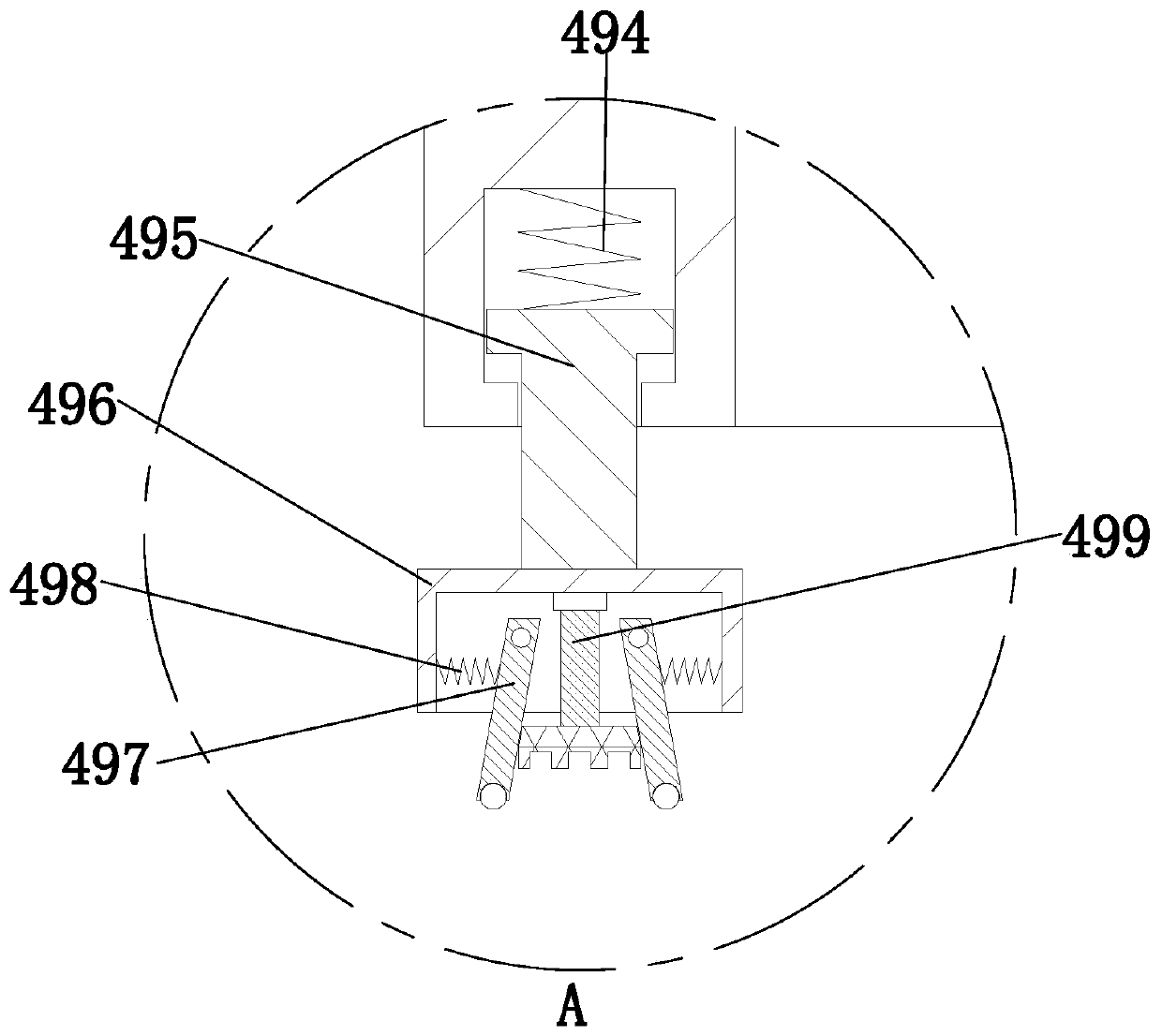

Drilling method for interlayer board of steel-structured building

InactiveCN111545792AAvoid shakingQuality assuranceFeeding apparatusPositioning apparatusArchitectural engineeringStructure building

Owner:吴传江

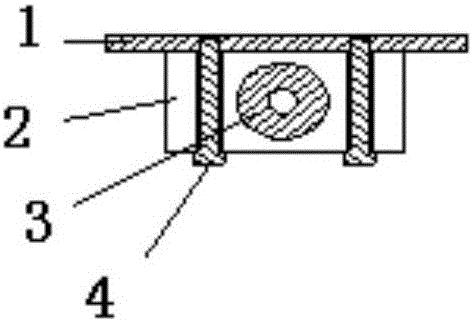

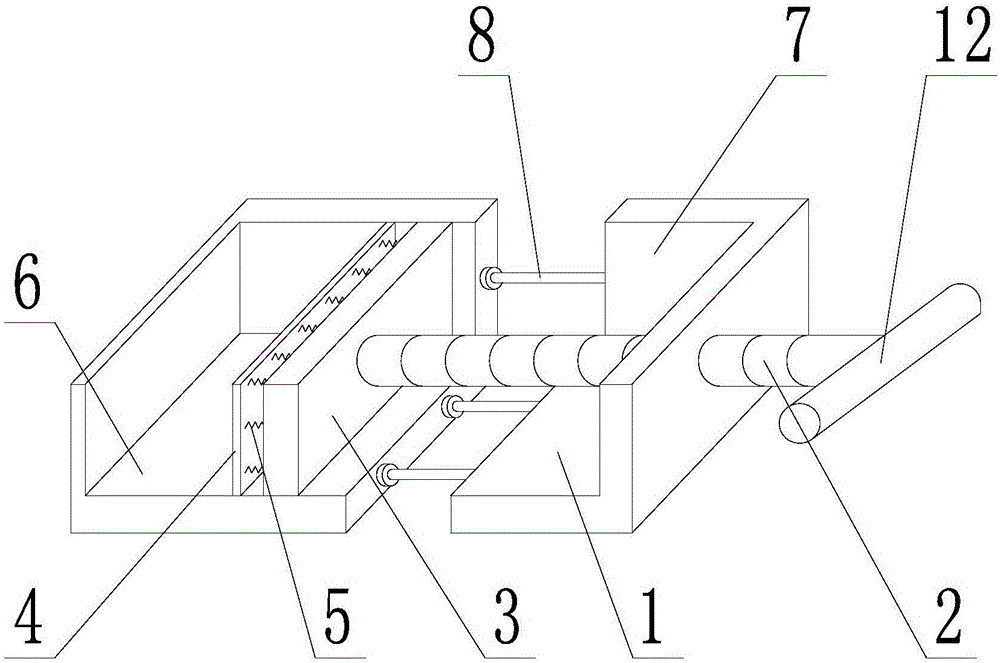

Clamping mechanism for drilling of round seat plate of round seat

ActiveCN110640182AEasy to drillImprove efficiencyPositioning apparatusMetal-working holdersEngineeringMachining time

The invention discloses a clamping mechanism for drilling of a round seat plate of a round seat, and relates to the field of plate machining. According to the problems that an existing plate machiningdevice is long in drilling time and low in efficiency, the following scheme is provided, wherein the clamping mechanism comprises a workbench fixed to a base; vertical rectangular supporting rods arranged left and right are arranged on the workbench; the upper end of the rectangular supporting rod located on the right side penetrates through the workbench and extends to the upper portion of the workbench; a clamping assembly, a drilling assembly and an adjusting assembly are mounted on the workbench; the drilling assembly is mounted on the adjusting assembly; and the adjusting assembly is intransmission connection with the clamping assembly. Clamping and fixing of the round plate and lifting of a drilled hole are linked, and therefore the round plate can be automatically clamped in the process of moving the drilled hole downwards; and in the process that the drilled hole continues to move downwards after clamping, the round plate is clamped firmly and cannot be loosened, and drillingis convenient.

Owner:HUZHOU TEACHERS COLLEGE

Application method for clamping device of electric cabinet

InactiveCN106826300APrevent slidingReduce vibrationPositioning apparatusMetal-working holdersMechanical engineering

Owner:CHENGDU ZHENZHONG ELECTRIC

Borehole charging method for underwater silt seam disturbance blasting

A borehole charging method for underwater silt seam disturbance blasting includes the steps of 1, setting up and fixing a drilling platform; 2, mounting a positioning guide pipe; 3, tripping a steel casing into the positioning guide pipe; 4, drilling a silt seam; 5, drilling to base rock; 6, clearing a borehole and charging a charge casing into the borehole; 7, performing trial charging; 8, charging and marking; 9, fixing cartridges to a charge half pipe segment by segment in sequence; 10, placing the cartridges to the bottom of the borehole segment by segment; 11, checking the number of the cartridges and determining a charge position; 12, making a detonating fuse, a detonator mark and fixing; 13, sealing. The method has the advantages that drilling quality and precision of the silt borehole can be ensured, precise in-place charging can be ensured, quality check and control can be facilitated during the process, disturbance blasting effect of the silt borehole is guaranteed, water around the underground silt borehole is directly used as sealing material to seal space of the underwater silt borehole remaining above the cartridges, manufacturing is not required, cost is low, sealing tightness is good, and sealing quality is guaranteed.

Owner:中国水利水电第六工程局有限公司

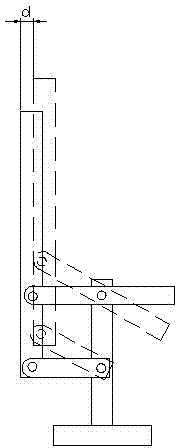

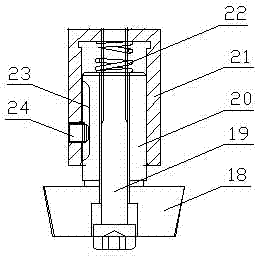

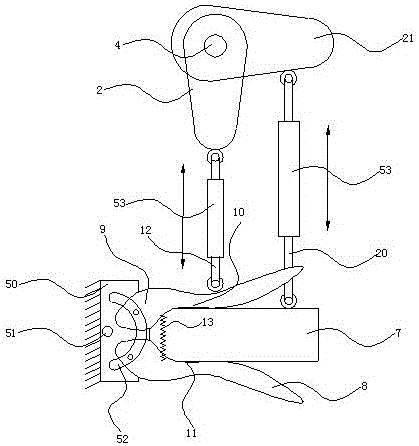

Vertical drilling assisting electric drill frame for handheld electric drill

ActiveCN103042251AEnsure drilling qualityPrecise positioningPortable drilling machinesEngineeringDrill bit

The invention relates to a vertical drilling assisting electric drill frame for a handheld electric drill. The vertical drilling assisting electric drill frame comprises a base, a first guide sleeve and a second guide sleeve are abreast arranged on the base, a first guide column is slidably arranged in the first guide sleeve, an electric drill holder used for fixing the electric drill is arranged at the end of the first guide column, and a push rod is arranged on the side wall of the first guide column. The side wall of the first guide sleeve starts from a push rod groove matched with the push rod, a second guide column is sleeved in the second guide sleeve, a transparent cover is fixedly arranged at the upper end of the second guide column, and a screw nut used for fixing the second guide column is arranged at the joint of the second guide column with the second guide sleeve. During drilling, the electric drill passes through the cover which is provided with a light source on the side wall, and light emitted by the light source passes through the point of intersection of the centre of the electric drill and the plane of the cover end. Horizontal movement of a drill bit of the electric drill is prevented when the drill bit of the electric drill moves vertically, and accuracy in positioning is achieved.

Owner:NINGBO XINSHENG TOOLS

Adjustable drill hole positioning device and drill hole positioning method for air inlet flange of exhaust manifold

The invention discloses an adjustable drill hole positioning device and a drill hole positioning method for an air inlet flange of an exhaust manifold. The drill hole positioning device is provided with a clamp body; a positioning plane for the positioning of the reference plane of an exhaust manifold is arranged at the bottom of a top plate of the clamp body; a double-hole positioning mold, a single-hole positioning mold and a plurality of through holes matched with the double-hole positioning mold and the single-hole positioning mold are arranged on the top plate; a drill jig hole for guiding a drill is also formed on the top plate; and at least two sets of workpiece clamping mechanisms are arranged below the top plate. As for the drill hole positioning method, two air inlets of the exhaust manifold are used as positioning reference, and the air inlets are positioned in a way of three points. The drill hole positioning device and the drill hole positioning method disclosed by the invention can precisely position the air inlet flange of the exhaust manifold, can reliably ensure the quality of drill holes, and can achieve large-scale production of drill hole machining of air inlet flanges of various exhaust manifolds. The drill hole positioning device has a simple structure, and is low in cost and convenient to operate.

Owner:FEILONG AUTO COMPONENTS CO LTD

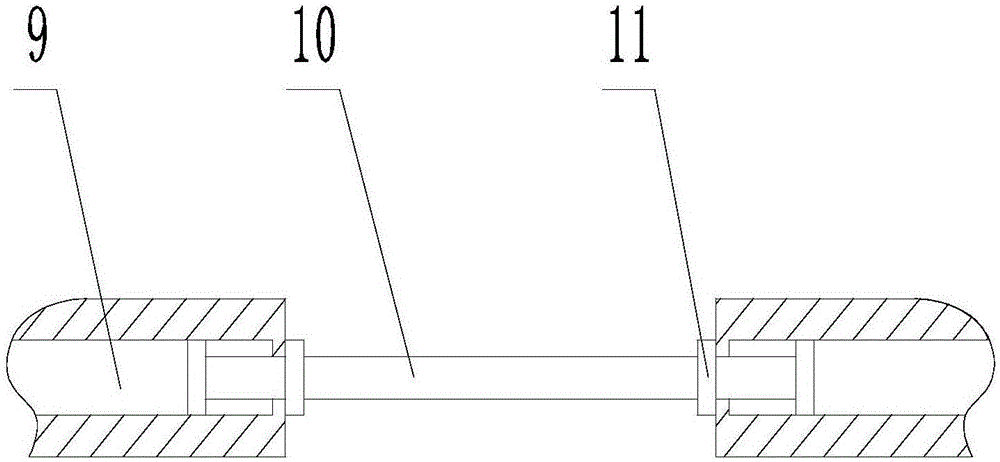

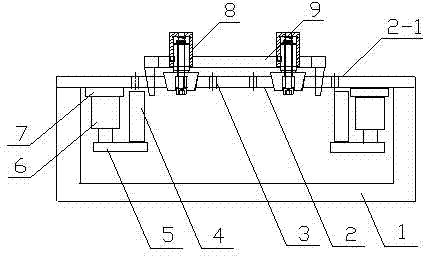

Dual-drill-head locating and drilling mechanism

The invention provides a dual-drill-head locating and drilling mechanism. According to the technical scheme, the dual drill head locating and drilling mechanism comprises a base, a support frame, a drilling driving motor, an adjusting slide rail, two stamping devices, a lifting-driving device, a lifting platform, a drilling platform and a control platform, and each stamping device is provided withan auxiliary transmission shaft, a damping spring and a drill head; the drilling platform is provided with two adjusting plates and two adjusting screws, operating personnel only needs to adjust thescrews clamp all parts, and the practical requirements of drilling parts are met; the two stamping devices can move freely and horizontally, and the drilling distance of different parts is met; and the lifting-driving device is matched with the damping spring to achieve buffering during the drilling process. The dual drill head locating and drilling mechanism is simple in structure, the dual-drill-head drilling way capable of adjusting the distance can complete the drilling process for parts of different specifications and sizes, the process accuracy is high, the quality is better, drilling work of bulk parts can be completed, and the time cost is saved.

Owner:天津修瑕建筑工程有限公司

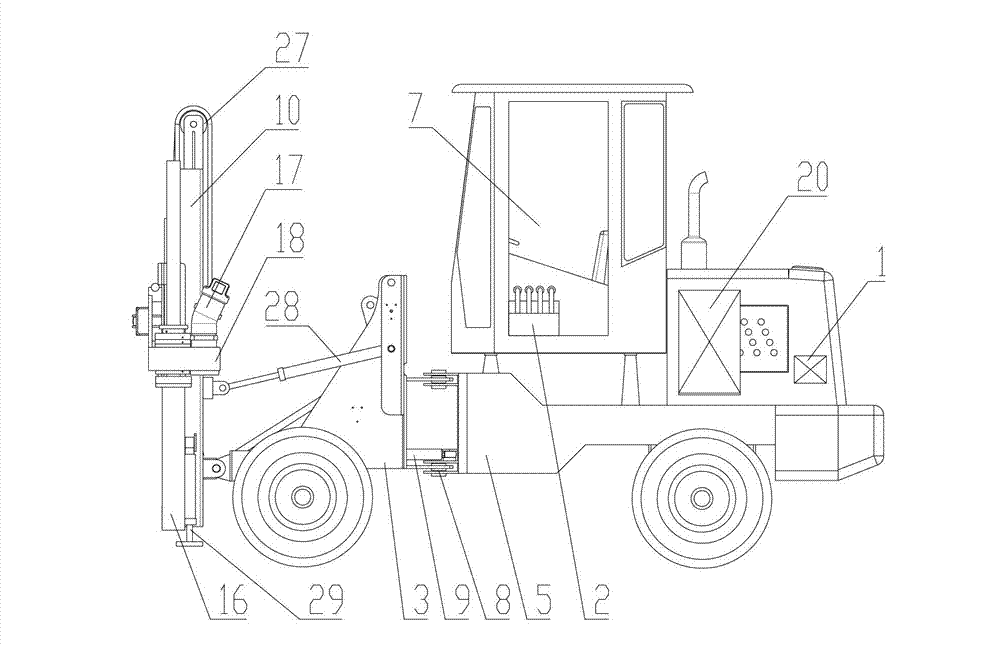

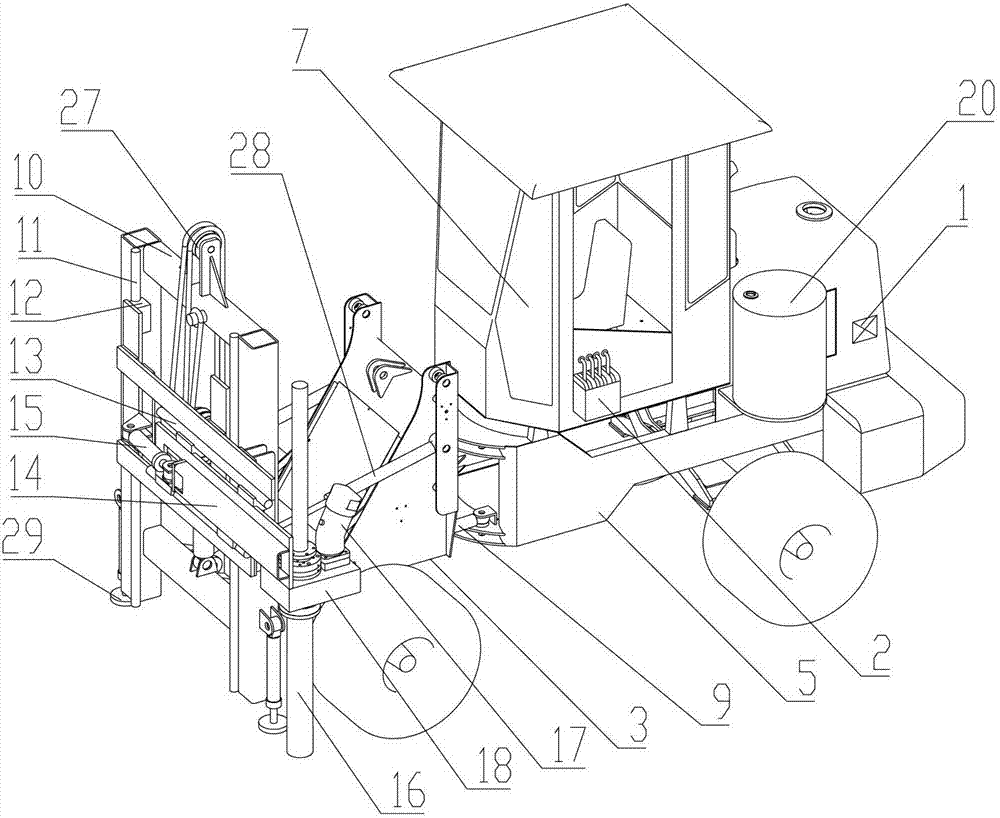

Wheel drilling machine

ActiveCN102926658APrecise positioningEasy to operateDrilling rodsDerricks/mastsEngineeringMechanical engineering

The invention discloses a wheel drilling machine which comprises a wheel traveling mechanism, a drilling rod assembly, a drilling machine loading mechanism and a hydraulic control mechanism. The hydraulic control mechanism comprises an oil pump and a multi-path control valve. The wheel traveling mechanism is arranged in hinged mode, and accordingly a drilling rod can perform positioning and drilling fast and accurately. A diesel engine supplies power to the wheel drilling machine, and the wheel drilling machine is self-propelled. Hydraulic oil reaches the multi-path control valve through a gear pump, and the multi-path control valve can carry out six groups of movements, namely vertical lifting, supporting legs, back-and-forth inclining, left-and-right moving, drilling and core pushing. The wheel drilling machine solves the problems that the existing drilling machine is inflexible in angle adjusting, inaccurate in positioning and much in manpower consumption.

Owner:CHONGQING HONGGONG INSTRUCTIONAL MACHINE

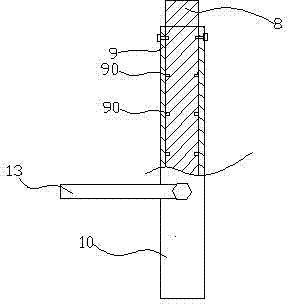

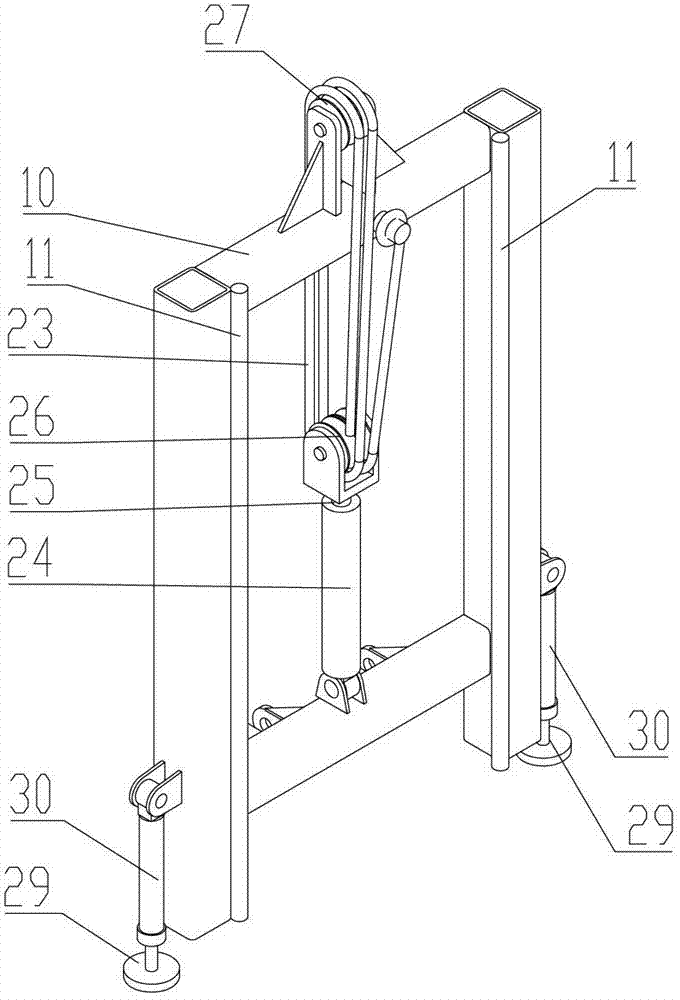

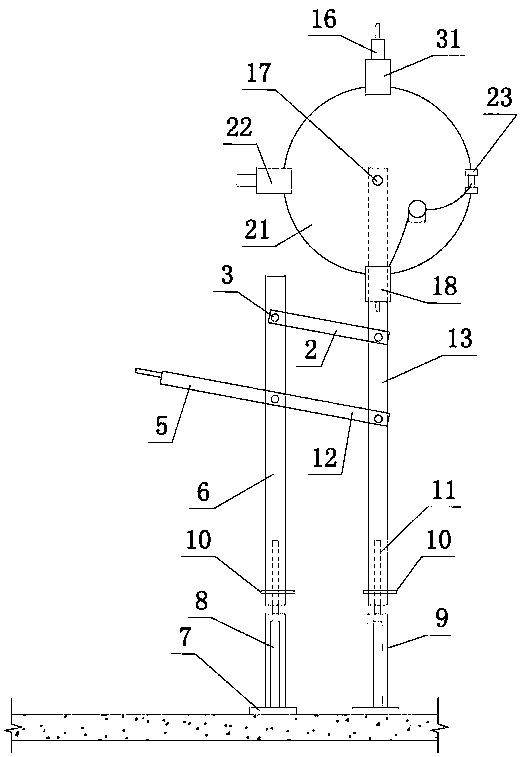

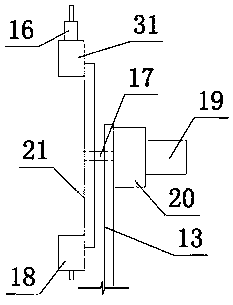

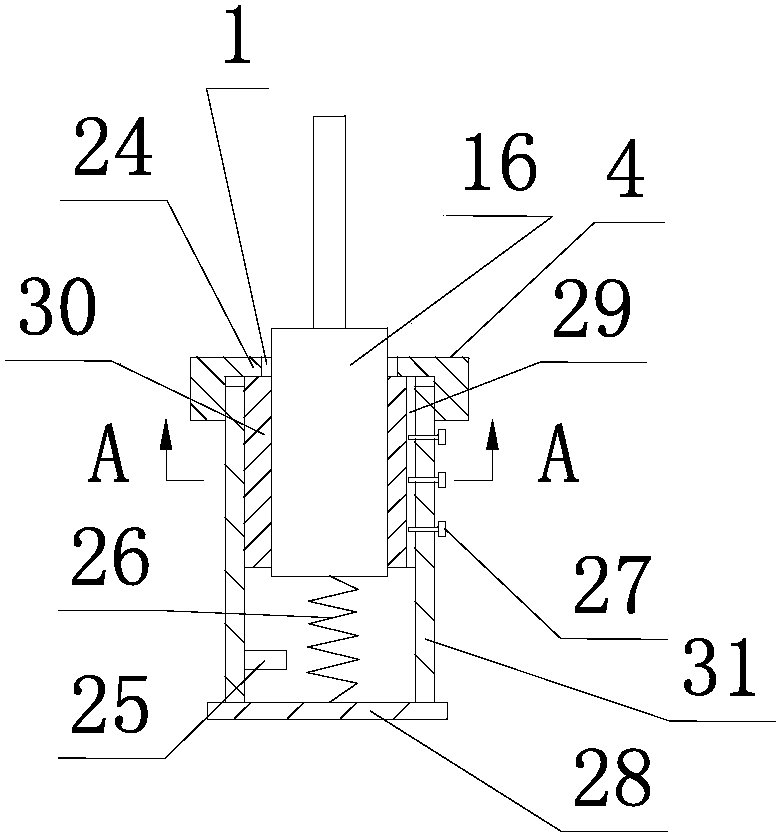

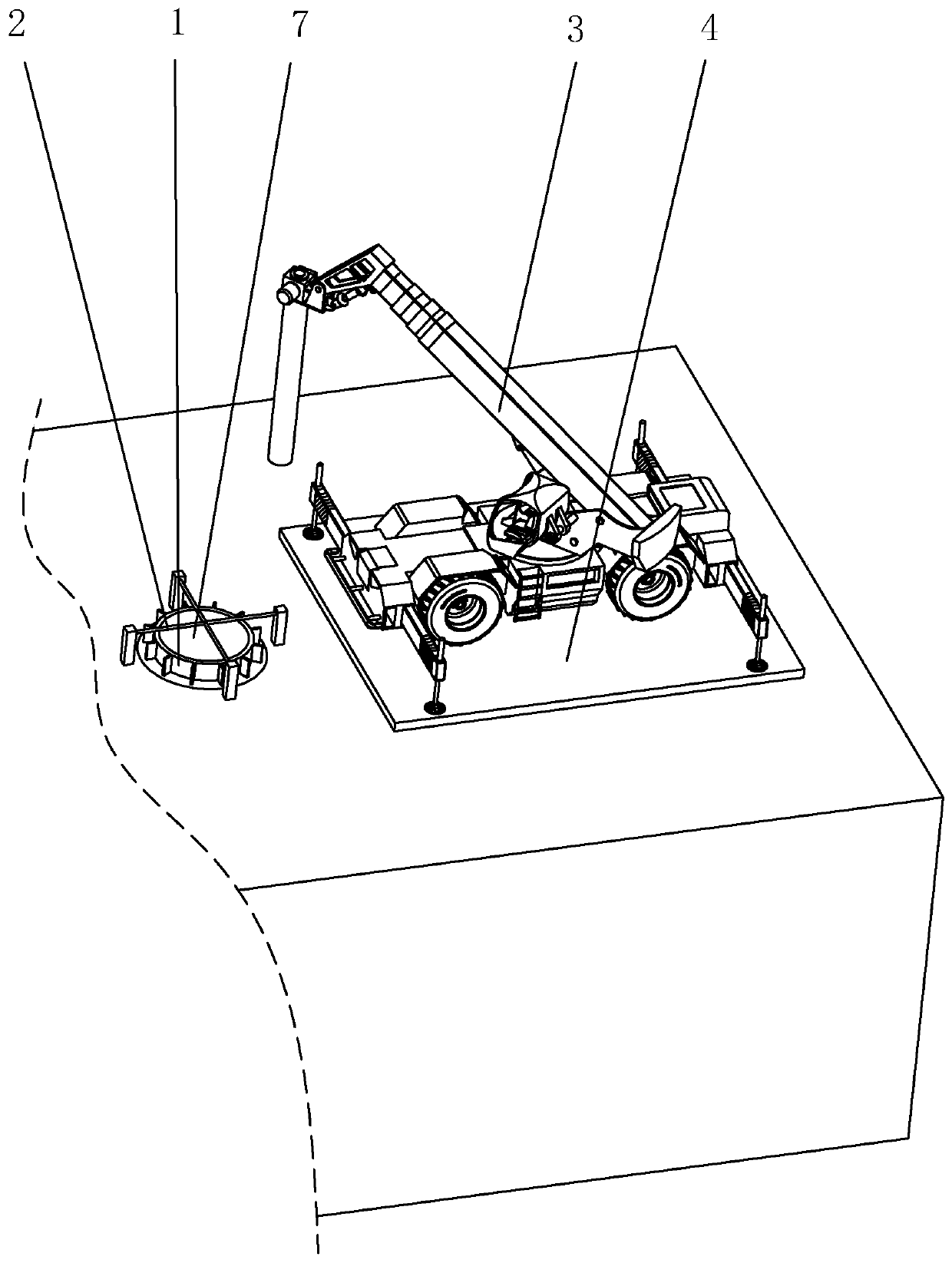

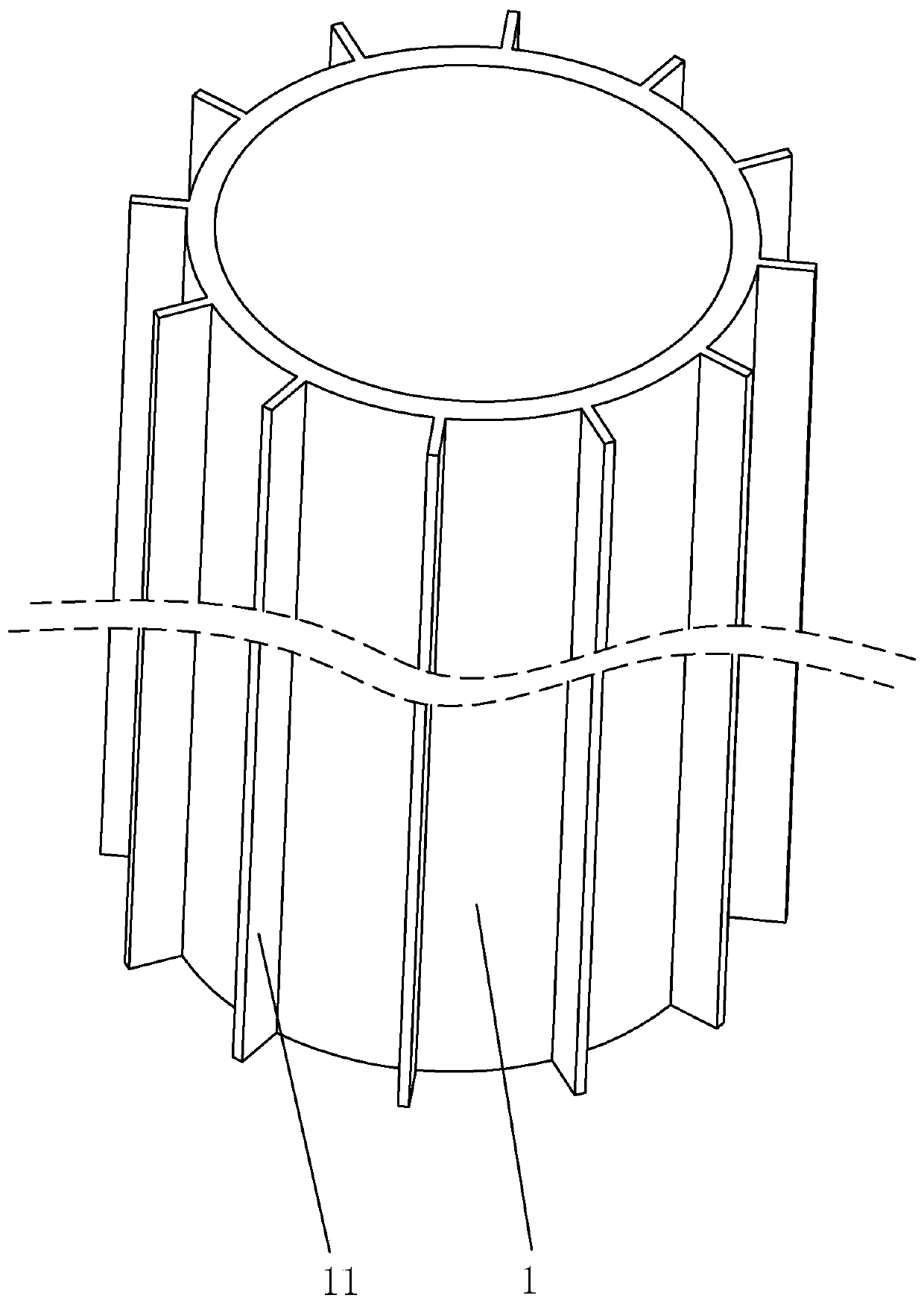

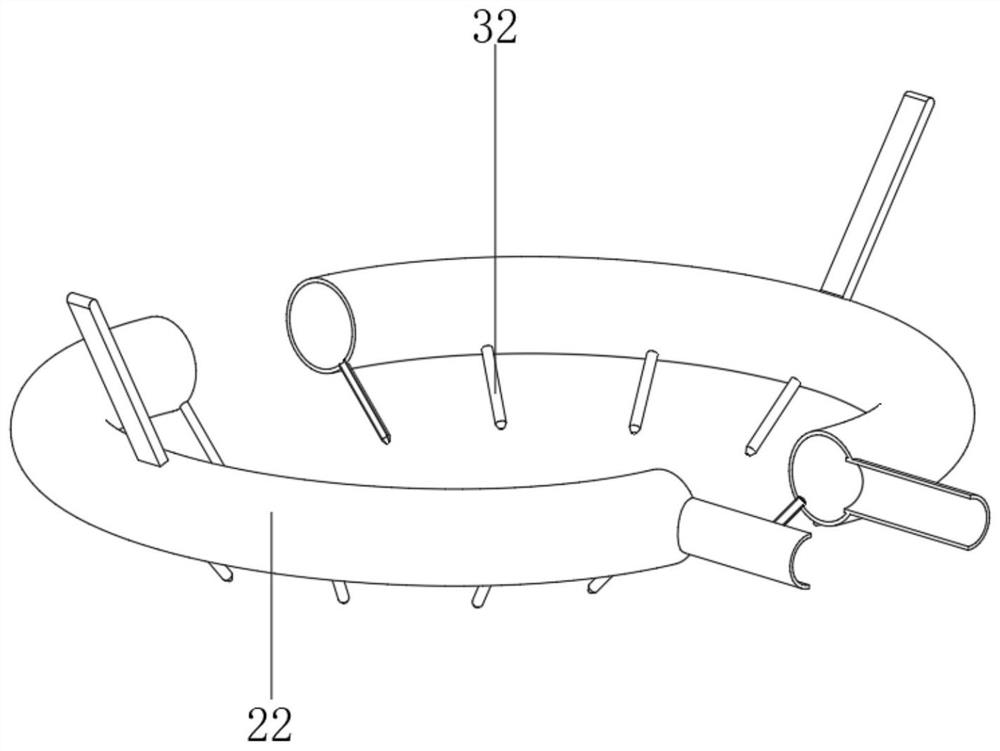

Support for hole drilling and rebar planting of indoor building top and wall column side face and construction method thereof

ActiveCN108086663AShorten the timeSave energyAgriculture gas emission reductionBuilding scaffoldsAir blowerRebar

The invention discloses a support for hole drilling and rebar planting of indoor building top and wall column side face and a hole drilling and rebar planting construction method thereof. The supportcomprises a first upright, a second upright and a four-connection-rod mechanism, and a tool mounting device is arranged at the end, close to the building top and the wall column side face, of a secondforce transmission rod; a turnplate a structure driving the turnplate to rotate and a structure enabling the turnplate to be located at a preset position are arranged at the end, close to the building top and the wall column side face, of the second force transmission rod, and a drilling tool mounting device, an electric air blower mounting device, a glue injector mounting device and a pneumaticfinger for mounting and rebar planting are sequentially and equally fixed at the edge of the turnplate along the circumference. The support is convenient to operate and high in construction efficiencyand safety. By adopting the support and the construction method, hole drilling, cleaning of dust in holes, glue injecting and rebar planting can be performed on the ground, so that time and physicalpower of operating personnel for getting on and off an operation frame or a herringbone ladder are saved in the whole process, and potential safety hazards and accidents caused by hole drilling operation on the frame or the ladder are avoided; the support is convenient to operate and high in construction efficiency and safety.

Owner:DARONG CONSTR GROUP

Constructing process of cast-in-situ bored piles

InactiveCN111206576AGuaranteed construction accuracyAvoid affecting drillingBulkheads/pilesArchitectural engineeringSlurry

The invention relates to a constructing process of cast-in-situ bored piles, and belongs to the technical field of building construction. According to the technical scheme, the constructing process ischaracterized by including the following steps of S1, making a preparation for construction, wherein a construction site is leveled and firmly compacted, and a road bed plate is laid at an operationposition of a drilling machine; S2, burying pile casings, wherein the soil within the burying depth range of the pile casings at pore positions are dug out through a rotary excavating drill bit, the pile casings are directly pressed into soil after being hung in place, the outer wall of each pile casing is axially and fixedly provided with a plurality of reinforcing pieces, the reinforcing piecesare evenly distributed in the circumferential direction of the pile casings, loam is firmly compacted outside the pile casings, and the height of water heads in the pile casings is 1.0-1.5 m; S3, putting the drilling machine in position, wherein the drilling machine is fixed to the road bed plate; S4, performing drilling, wherein a drill stem slowly and continuously operates during bore forming construction, and static slurry is adopted for protecting the walls in the drilling process; S5, putting down a reinforcement cage, wherein the bores are cleaned first, and then the reinforcement cage is slowly put down section by section at a constant speed; and S6, pouring cement, wherein the cement is poured continuously through a guide pipe method, and the effect of improving the burying stability of the pile casings is realized.

Owner:重庆渝能建筑安装工程有限公司

Self-service safety perforator

InactiveCN104308214ASimple structureEasy to operateMaintainance and safety accessoriesBoring/drilling machinesSelf-serviceDrill bit

The invention relates to the technical field of mechanical perforating equipment, in particular to a self-service safety perforator comprising a base, a positioning die block, a pillar, a sliding rod, an ejector rod and a drill bit. The positioning die block is disposed on the base. The pillar is arranged at the upper end of one side of the positioning die block. One side of the pillar is connected with the ejector rod through the sliding rod. The drill bit is disposed at the lower end of the ejector rod. A bench is arranged at the lower end of one side of the positioning die block. The drill bit corresponds to the bench in position. A motor is arranged inside the base and connected with the drill bit to drive the same in motion. The self-service safety perforator is simple in structure and easy to operate and allows drilling quality to be ensured.

Owner:陈灿金

Foundation pile hole drilling construction process

InactiveCN104141300AEasy to moveIncrease drilling speedExcavationsBulkheads/pilesEngineeringFoundation engineering

The invention discloses a foundation pile hole drilling construction process, which comprises the following technical flow processes of construction preparation, field flattening, pile position lofting, protection tube burying, drilling machine place taking, drilling, hole cleaning, hole forming quality checking, steel bar cage and catheter mounting, catheter mounting, secondary hole cleaning, underwater concrete filling, protection tube pulling and removing and pile forming quality checking. The foundation pile hole drilling construction process has the advantages that the construction time of the foundation engineering is shortened, the construction period pressure of a lower part structure is reduced, and in addition, a part of labor, machine and material investment is reduced, so the total construction cost of the project is reduced.

Owner:LUOYANG GUANGXIN CONSTR GRP

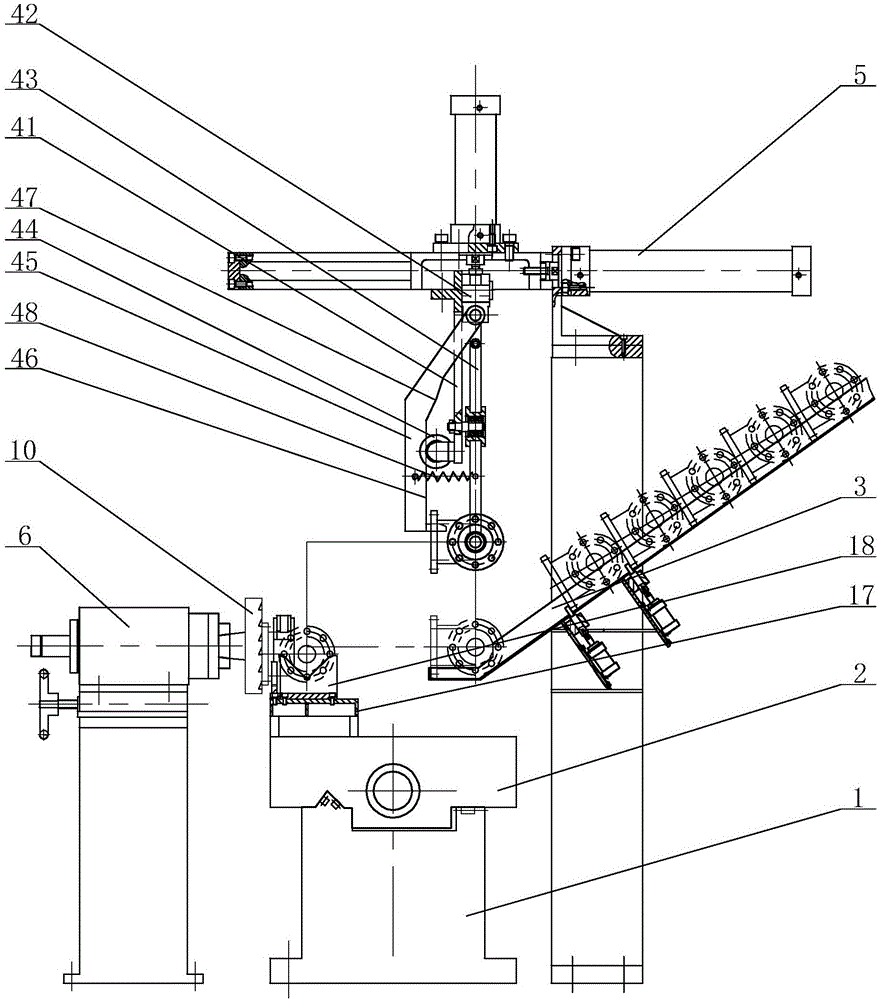

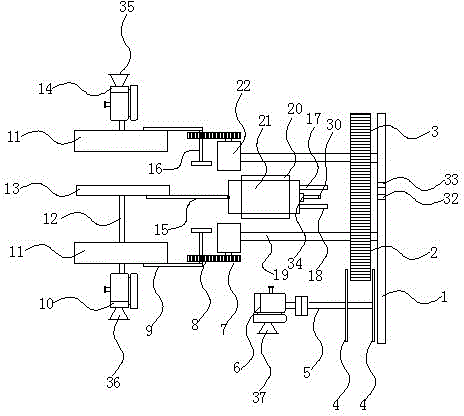

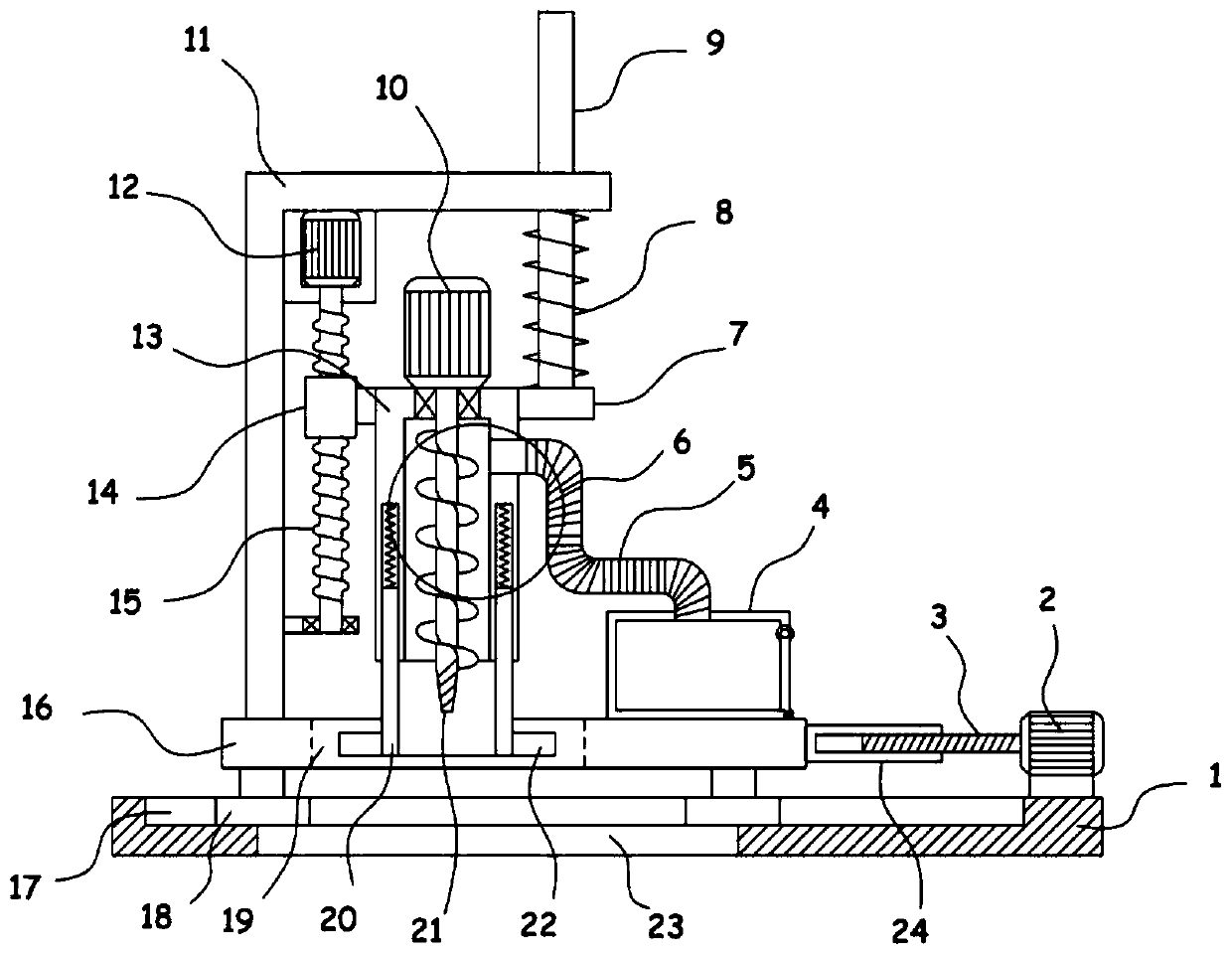

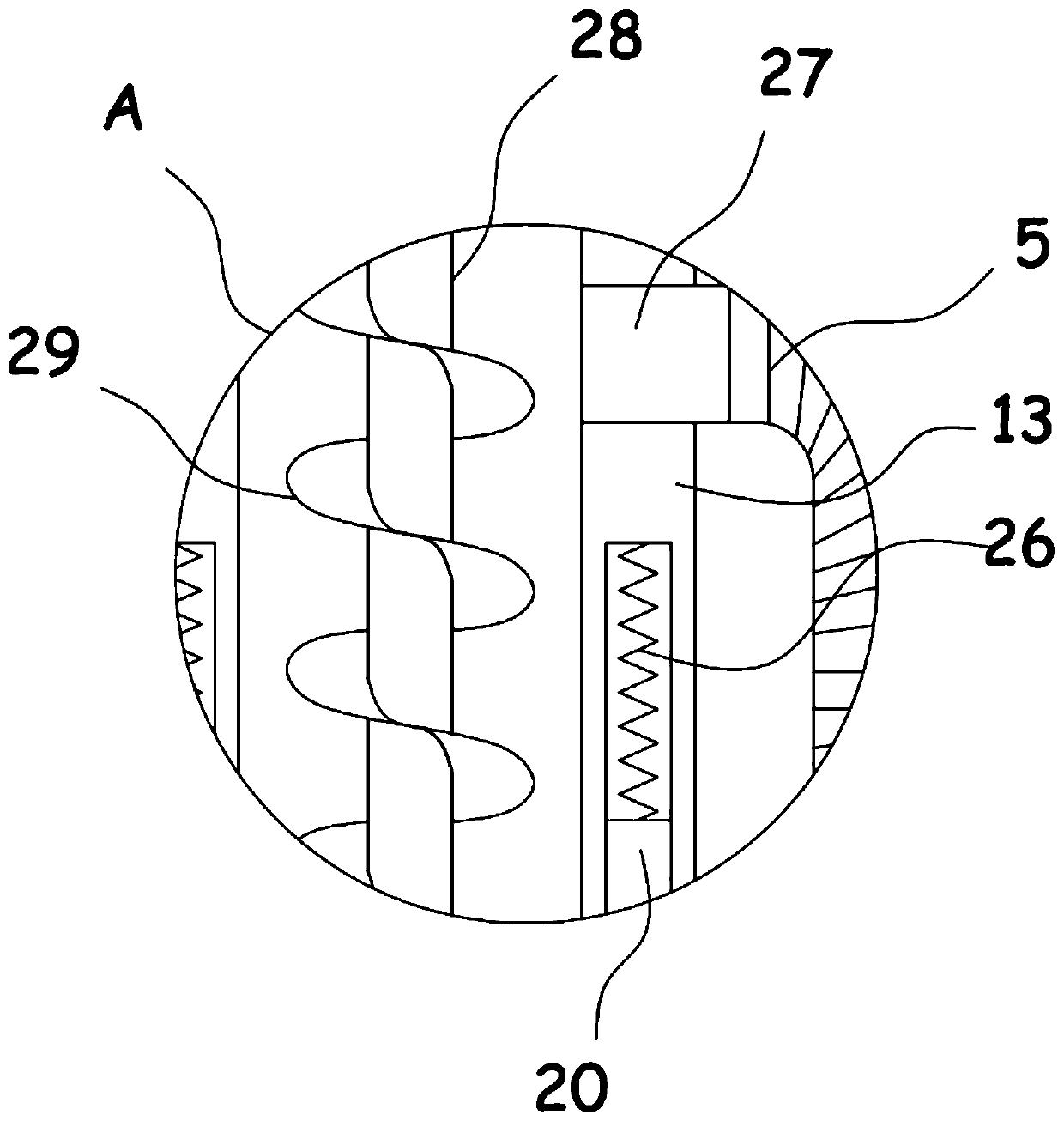

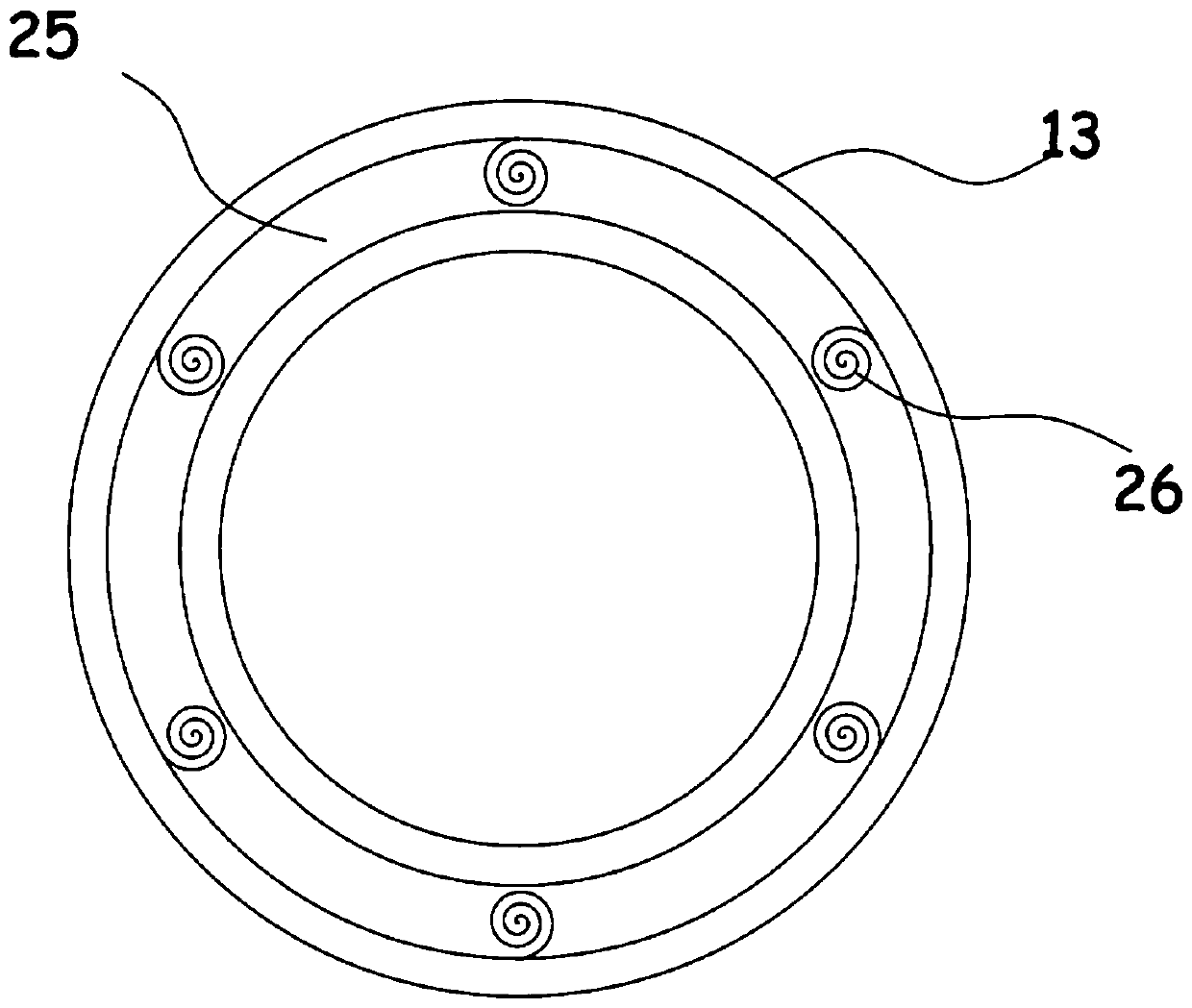

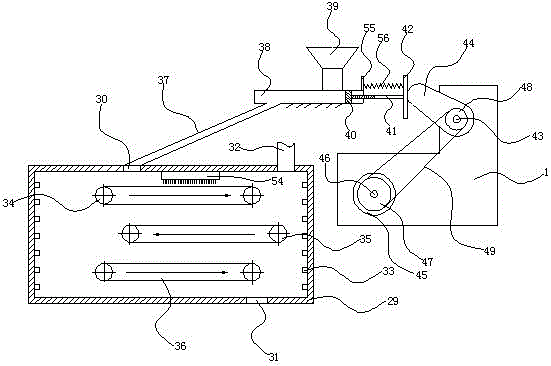

Drilling device of spherical jade

InactiveCN104802324AEnsure drilling qualityGuaranteed drilling effectWorking accessoriesFine working devicesEngineeringCrankshaft

The invention discloses a drilling device of spherical jade. The drilling device comprises a machine frame, a main turntable, a sub turntable, a main transmission device, a sub transmission device, a main motor and a sub motor, wherein the main transmission device is connected with the main turntable, the sub transmission device is connected with the sub turntable, the main motor is used for driving the main transmission device to work, the sub motor is used for driving the sub transmission device to work, the main turntable and the sub turntable are in parallel arrangement and are rotationally arranged on the machine frame, the rotating directions of the main turntable and the sub turntable are opposite, a plurality of main round grooves are formed in the main turntable, a plurality of sub round grooves are formed in the sub turntable, the main round grooves and the sub round grooves are matched in the tangent positions of the main turntable and the sub turntable for forming a clamping part used for clamping the jade, the main transmission device is in transmission connection with a crankshaft through a first rotating shaft, a first connecting rod is connected onto the crankshaft, and a drilling assembly used for jade hole drilling work is hinged to the first connecting rod. The drilling device has the advantages that the drilling quality of the jade can be effectively ensured, and the processing efficiency is greatly improved.

Owner:河南嘉豪珠宝股份有限公司

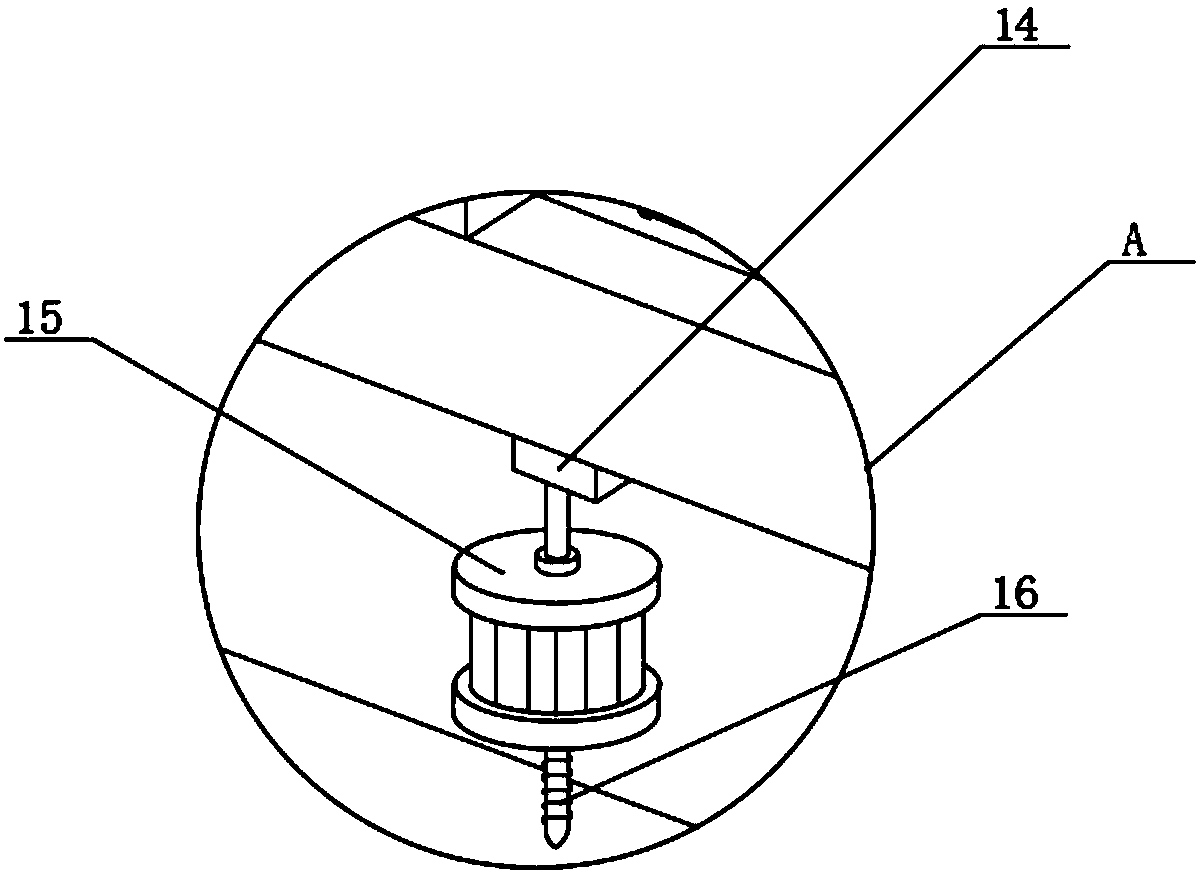

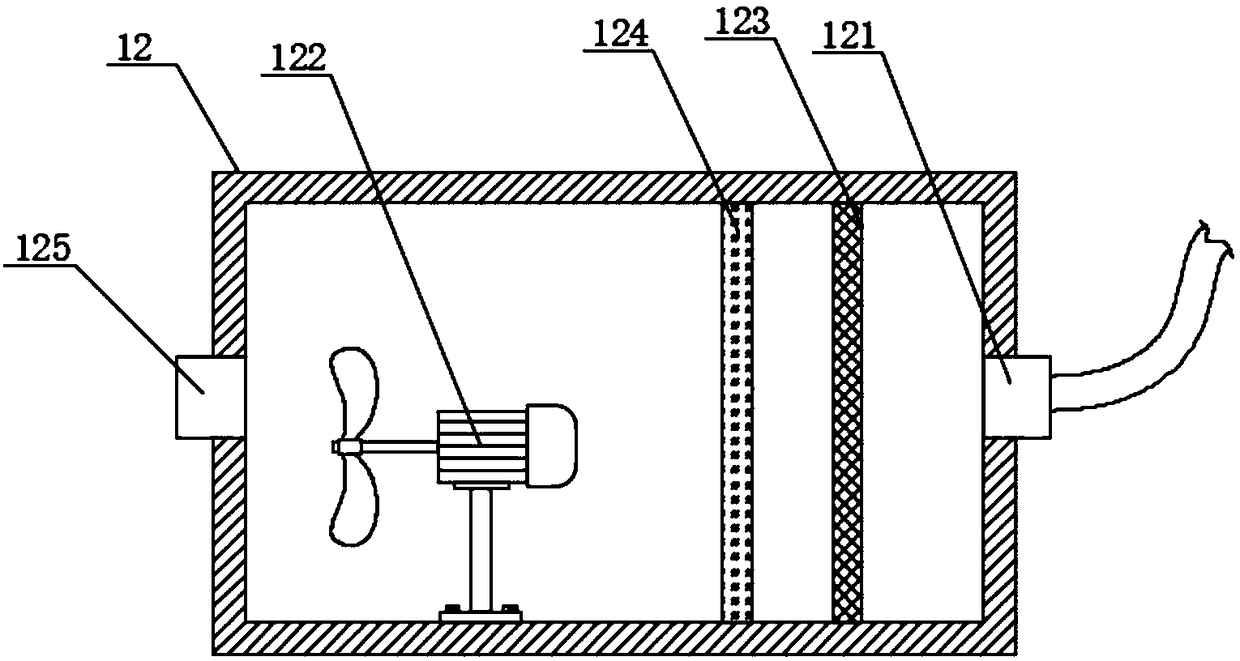

Multi-station drilling device for steel plate machining

InactiveCN109454255AGuaranteed stabilityEnsure drilling qualityDispersed particle filtrationLarge fixed membersSheet steelControl switch

The invention discloses a multi-station drilling device for steel plate machining. The multi-station drilling device comprises a workbench; supporting legs are installed at the positions, close to theedges, of the bottom end of the workbench, and a control switch is embedded in the front surface of the workbench; a mounting frame is arranged on the upper surface of the workbench, and a baffle plate is arranged on the position of each side, close to the mounting frame, of the upper surface of the workbench; and drilling stations are arranged at the positions, close to the middle position, of the upper surface of the workbench. According to the multi-station drilling device, long screw rods are arranged so that a steel plate placed into the drilling stations can be fixed, the stability of the steel plate during drilling is guaranteed, the drilling precision is improved, and the drilling quality of the steel plate is guaranteed; the drilling stations are arranged, and a moving assembly is used cooperatively so that the steel plate on the drilling stations can be drilled, and the multi-station drilling process of the steel plate is realized; and a connecting pipe and a purification chamber are arranged, so that peculiar smell generated during drilling of the steel plate can be adsorbed and purified.

Owner:仲池

Device for opening holes in pavement for urban road construction

ActiveCN110295853AImprove drilling qualityPlay a guiding effectDrilling rodsDrilling with mechanical conveyingCause blockageSpiral blade

The invention discloses a device for opening holes in a pavement for urban road construction, relating to the technical field of road construction. The device comprises a supporting plate which is connected with a sliding frame in a transmission manner through a lateral adjusting mechanism, and a supporting frame is fixed on the sliding frame; a drilling assembly comprising a drill bit, which extends to the inside of a collecting cylinder, is connected to a driving motor in a driving manner; a supporting assembly is connected to the lower part of the collecting cylinder, a through hole vertically corresponding to the supporting assembly is formed in the sliding frame, and the supporting plate is provided with a strip hole vertically corresponding to the through hole. When the holes are drilled by the drill bit, the surrounding area of the hole can be pressed and stabilized by a pressure plate on the supporting assembly, and also a guiding effect for the drill bit during rotation is achieved, thus fully guaranteeing the drilling quality; scraps generated when the holes are opened can be raised by a spiral blade, and collected through a collecting box, thus being prevented from falling into the holes and causing blockage, and improving the drilling quality.

Owner:江苏格利尔光电科技有限公司

Horizontal directional drilling machine for clamping and turning and using method thereof

InactiveCN109630017AReduce consumptionEnsure drilling qualityDerricks/mastsDirectional drillingHydraulic cylinderPhotoelectric conversion

The invention discloses a horizontal directional drilling machine for clamping and turning and a using method thereof. The horizontal directional drilling machine for clamping and turning comprises abacking plate, a cross bar and a clamping seat, wherein the upper side of a bottom plate is provided with the cross bar, the upper side of the cross bar is provided with the clamping seat, the lower side of the backing plate is provided with fixing teeth, and a fixing hole is formed in one side wall of the clamping seat. The horizontal directional drilling machine has the advantages that the machine can execute photoelectric conversion and thus convert solar energy into electric energy and provide electric energy through an arranged solar panel, the consumption of external power resources is reduced; by means of the arranged fixing teeth, the placement stability of the backing plate is greatly improved, and thus the drilling quality of a drill rod is ensured; by means of a second rotary hydraulic cylinder, a rotating rod, a clamping rod seat, a rod groove, a sliding block and a third hydraulic rod which are arranged, installation of the drill rod is mechanically and automatically executed, and the installation efficiency of the drill rod is improved.

Owner:湖南润成机械有限公司

Sole drilling device for production of plastic shoes

ActiveCN109093749AScientific and reasonable structureEasy to useEdge grinding machinesShoemaking devicesWater storage tankEngineering

The invention discloses a sole drilling device for production of plastic shoes. The sole drilling device comprises a water storage tank, a spraying head, a horizontal rotating device, fixed end corners, a waste collecting tank and a filtering template. The inner side of the water storage tank is connected with the spraying head, and the fixed end corners are mounted on the upper portions of the two sides of the horizontal rotating device correspondingly. The filtering template is mounted in the waste collecting tank. The sole drilling device is scientific and reasonable in structure and safe and convenient to use, the spraying head sprays water in the water storage tank to the drilling positions of the drilled plastic shoes through a water conveying pipe, heat generated by drilling of theplastic shoes is eliminated through water cooling, and the phenomenon that the drilling positions of the plastic shoes are carbonized and deform due to the over-high heat is avoided; and a servo motordrives the horizontal rotating device to rotate, thus the drilling positions of the plastic shoes are convenient to adjust, the trouble of manual adjusting is lowered, the drilling efficiency of thedevice is improved, the plastic shoes and the drilling device are more fixedly connected through the fixed end corners, and thus deflecting of the drilling positions during drilling is avoided.

Owner:浙江杭泉家纺科技有限公司

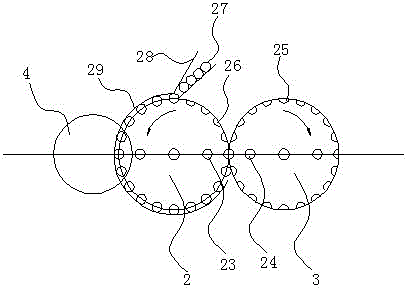

High-efficiency spherical jade drilling device

InactiveCN106346621AReduce labor intensityEnsure drilling qualityWorking accessoriesFine working devicesCamEngineering

The invention discloses a high-efficiency spherical jade drilling device which comprises a machine frame, a first cam, a first motor, a first rotation rod, a first feed hopper, a first pipeline, a support part, a fixed clamp and a movable clamp, wherein the movable clamp can move far away or close to the fixed clamp, a first arc portion is arranged on the fixed clamp, a second arc portion is arranged on the movable clamp, a first push column is further arranged on the machine frame, the tail end of the first push column abuts against the lateral end of the movable clamp, the first cam is arranged on the first rotation rod, a first spring is arranged between the fixed clamp and the movable clamp, a drilling cutter is inserted on the support part, an air cylinder is arranged at the bottom of the support part, a second motor is arranged at the bottom of the support through a motor base and above the air cylinder, the output shaft of the second motor is connected with the drilling cutter, and the air cylinder can push the motor base to slide up and down. The high-efficiency spherical jade drilling device can obviously reduce the labor intensity of workers, effectively guarantee the jade drilling quality and remarkably improve the processing efficiency.

Owner:郭文英

Bolt drilling mechanical equipment for hardware processing

InactiveCN111842968AHigh torqueReduce loadPositioning apparatusBoring/drilling componentsComputer hardwareHeat conducting

The invention belongs to the technical field of hardware processing, in particular to bolt drilling mechanical equipment for hardware processing. In order to solve the problem that most conventional drilling machines for hardware processing are relatively simple in structure and are relatively common in cooling effect of a drilled part, the invention provides a scheme as follows: the equipment comprises an operating table, wherein side vertical plates are vertically welded to two sides of the operating table and a hydraulic rod is fixed to the outer walls of the bottoms of the side vertical plates through bolts, a driving box is fixed to the end part of an extension rod of the hydraulic rod through a bolt, a transmission column is rotatably connected to the inner wall of the driving box through a bearing, and worm wheels are in key connection to two ends of the transmission column. The equipment can cool a cooling liquid well by means of good heat exchange action among a heat conducting plate, a heat exchange partition plate and a heat exchange cylinder plate. By means of a corrugated pipe, an annular water pipe and water dividing oblique pipes which are annularly distributed in anequally spaced manner, the equipment can spray the cooling liquid uniformly around a drill pipe so as to achieve a quick water-cooling and cooling effect.

Owner:俞玲燕

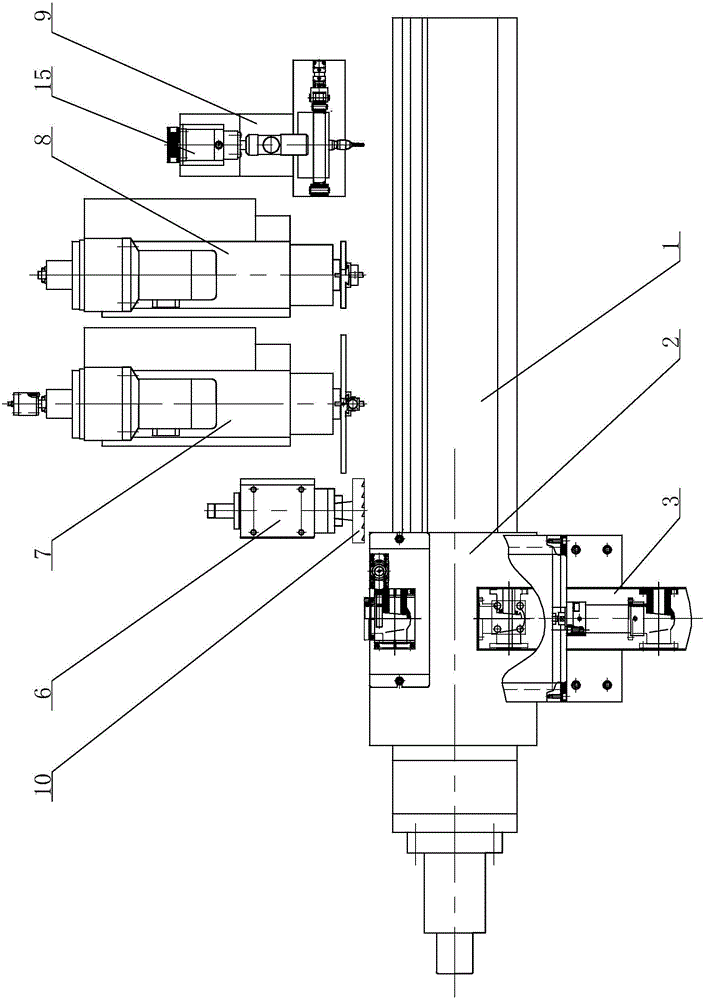

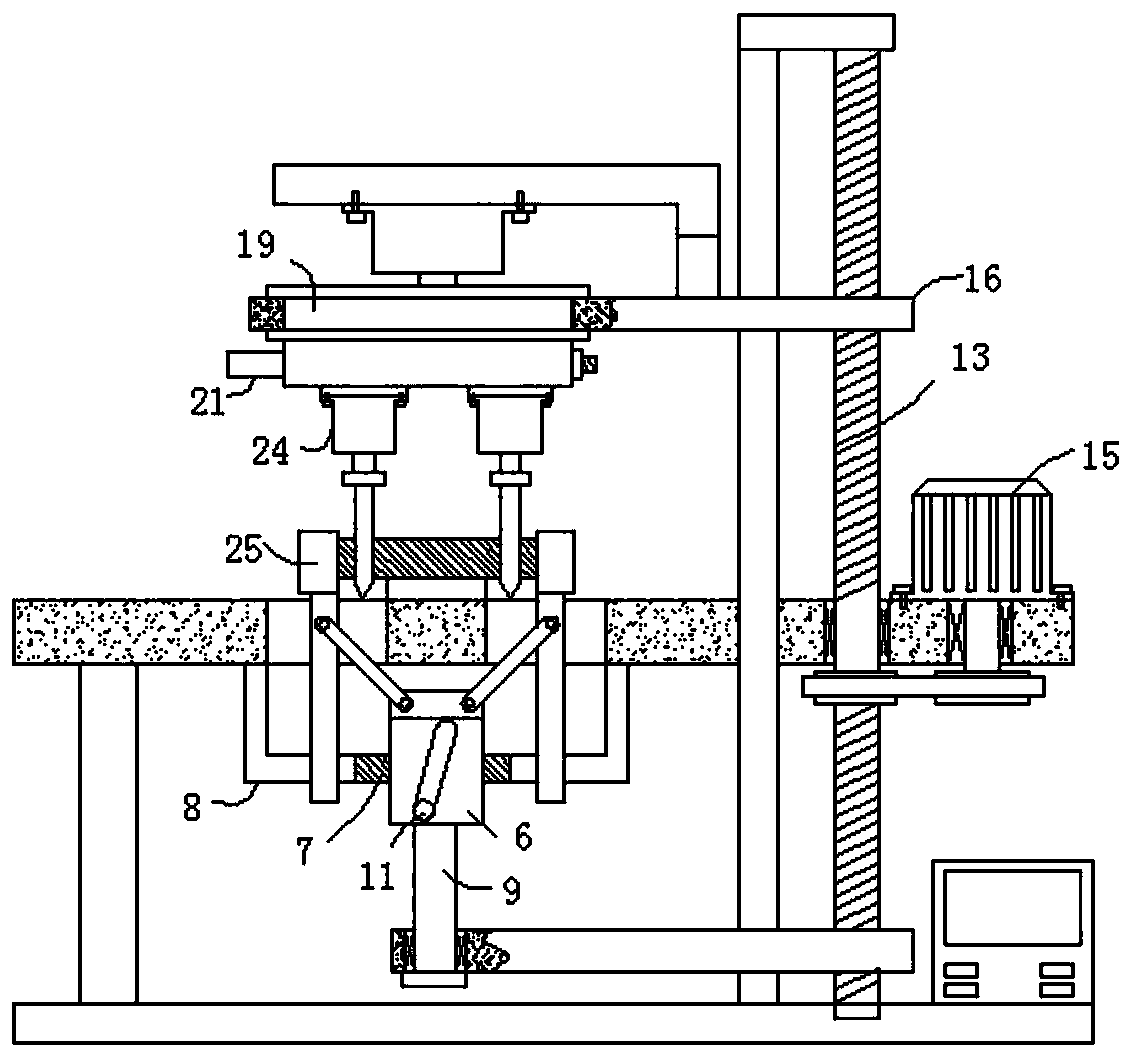

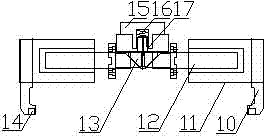

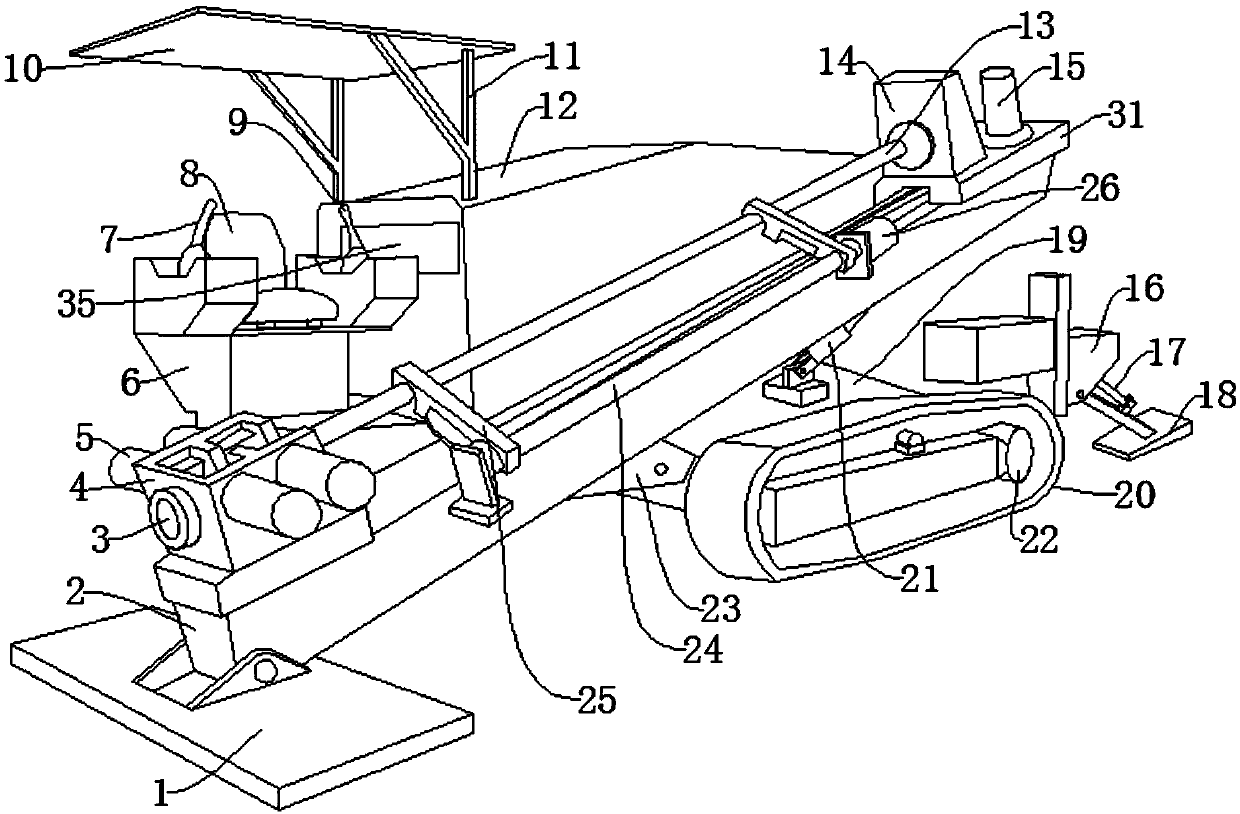

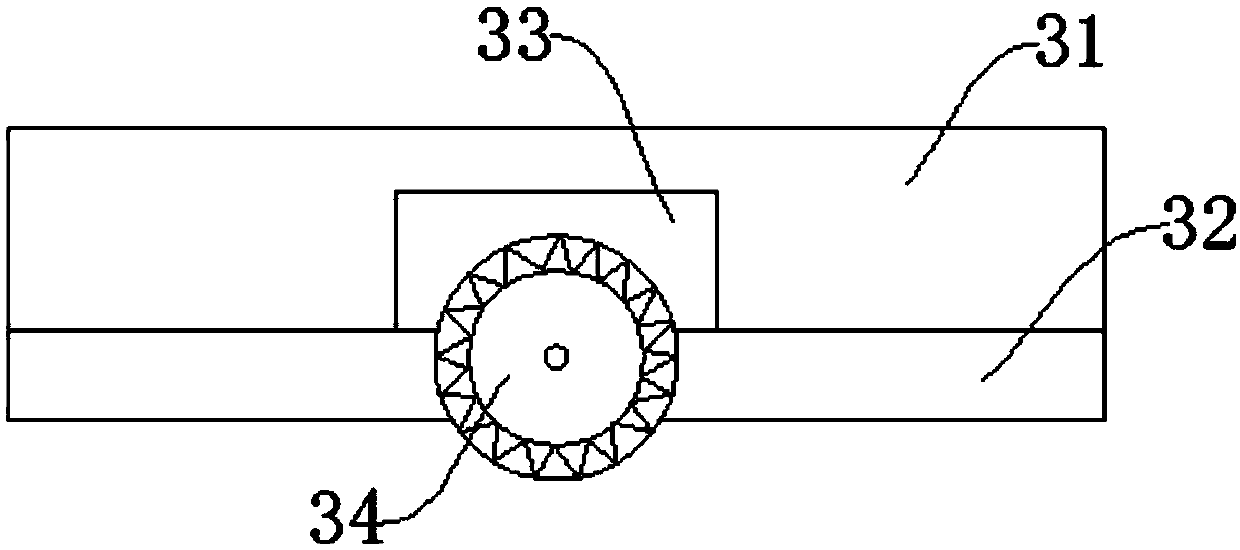

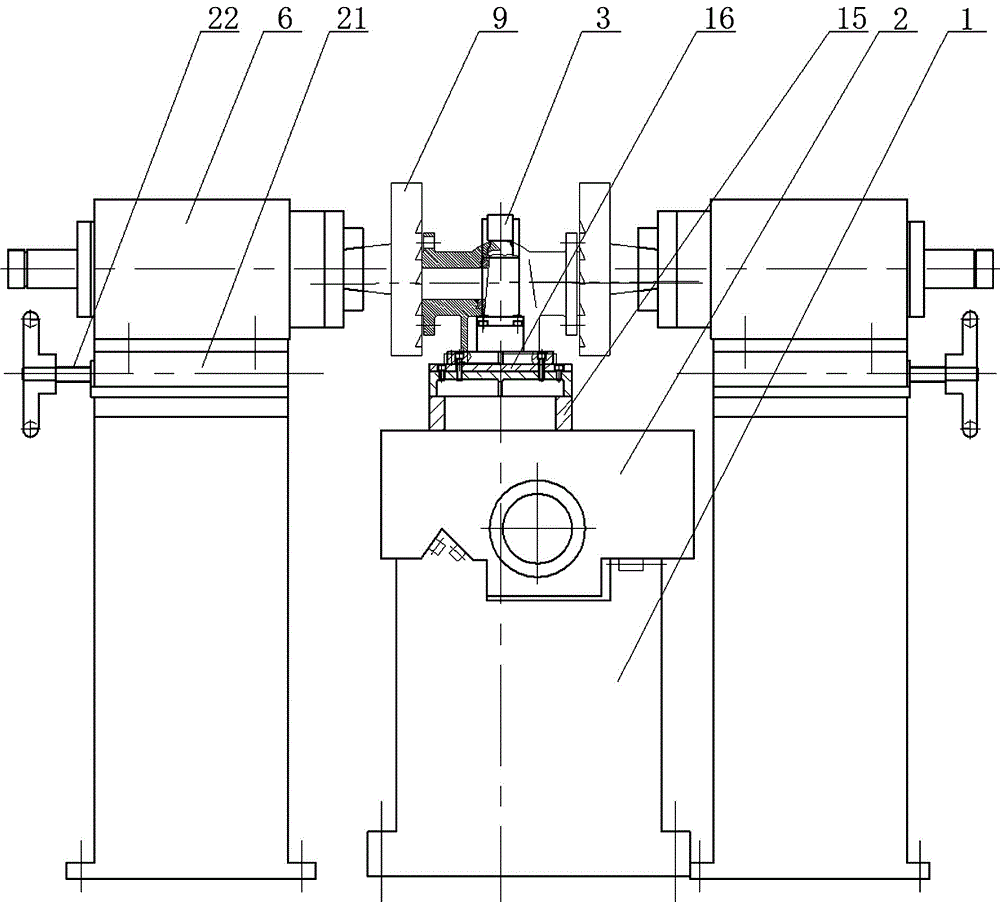

Machining automatic assembly line for inlet and outlet connecting flange on valve body

InactiveCN106736598AQuality controllableAvoid vibrationOther manufacturing equipments/toolsMachine partsEngineering

The invention relates to a machining automatic assembly line for an inlet and outlet connecting flange on a valve body. The problems that an import and export connecting flange on an existing common machine tool machining valve body needs to be mounted and clamped for multiple times, form and location tolerance is difficult to guarantee, the valve body quality is not easy to control, and the machining efficiency is low are mainly solved. The automatic assembly line is characterized in that symmetrical end face milling power heads (6), symmetrical boring end face power heads (7) and symmetrical drilling power heads (8) are sequentially arranged on the two sides of a tool body (1); and a fixed V-shaped clamping plate (17) and a sliding V-shaped clamping plate (18) are oppositely arranged on a positioning flat plate (16). The machining automatic assembly line can automatically convey and mount and clamp the valve body and machine all the machining parts of the inlet and outlet connection flange on the valve body in sequence, the machining accuracy is guaranteed, the valve body quality is easy to control, the machining efficiency is increased, and all machining parts on the valve body can be completed at one time by the matching use of the automatic assembly line and a valve body machining automatic assembly line for machining a connecting seat on the valve body.

Owner:XUZHOU SHUNFENG VALVE

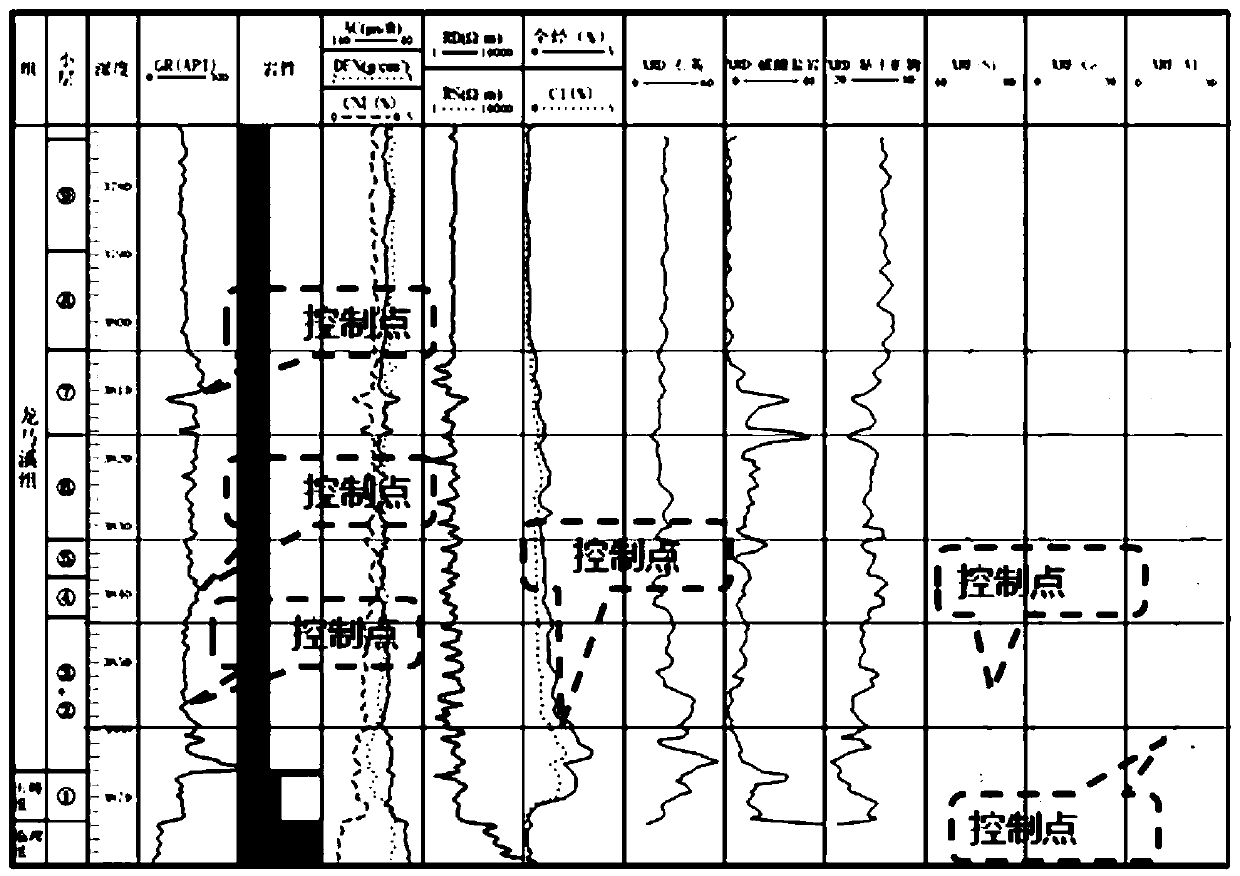

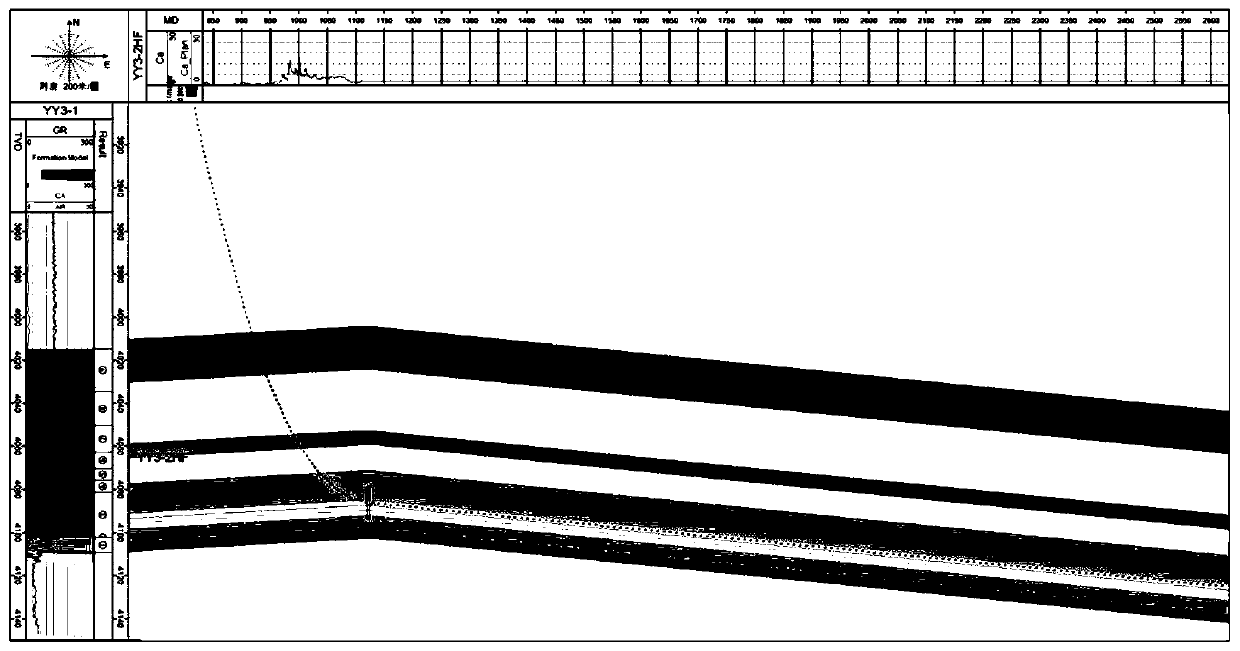

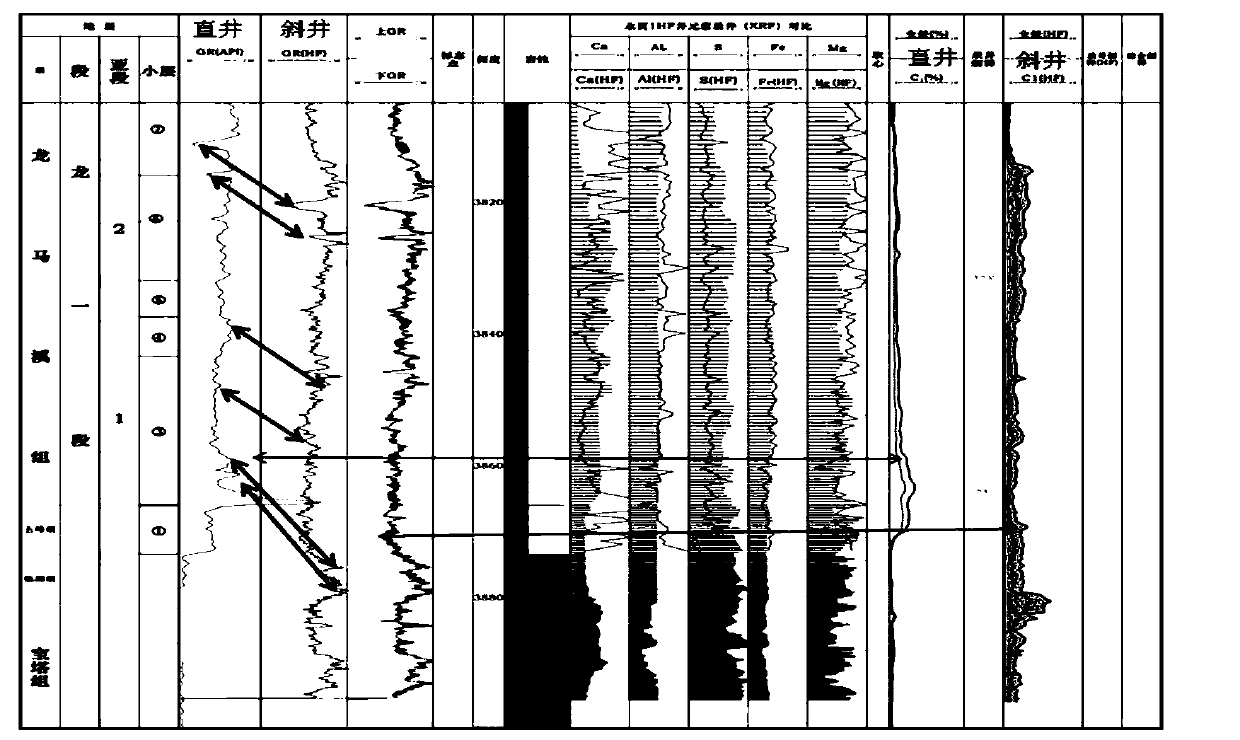

Horizontal well geosteering method based on element logging

ActiveCN110965938AAccurately determine the locationAdjust in timeSurveyDirectional drillingHorizontal wellsGeophysics

The invention discloses a horizontal well geosteering method based on element logging. The horizontal well geosteering method comprises the following specific steps: 1, acquiring geological element data of a target horizontal well; 2, establishing ratio data of longitudinal characteristic elements and related elements of the target horizontal well; 3, obtaining geological element difference data of a target layer and a non-target layer of the target horizontal well; 4, establishing a geological element initial model of the target horizontal well along the design trajectory of the target horizontal well, and predicting geological element change data along the design trajectory of the target horizontal well; 5, carrying out actual drilling on the target horizontal well, obtaining geologicalelement data actually measured while drilling, and carrying out comparative analysis on the geological element data actually measured while drilling and the predicted geological element data, so the geological element data actually measured while drilling and the predicted geological element data tend to be consistent. The position of the drill bit at the bottom of the well can be accurately judged, and the concealed fault is successfully identified, so the drilling trajectory is reliably guided to be timely and reliably adjusted, and the drilling quality is guaranteed.

Owner:CHINA PETROCHEMICAL CORP +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com