Full-automatic circuit board perforating machine

A circuit board and punching machine technology, which is applied in metal processing and other directions, can solve problems such as difficult detection of hole quality, circuit board quality problems, circuit board damage, etc., and achieve drilling quality assurance, quality improvement, and integrity assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

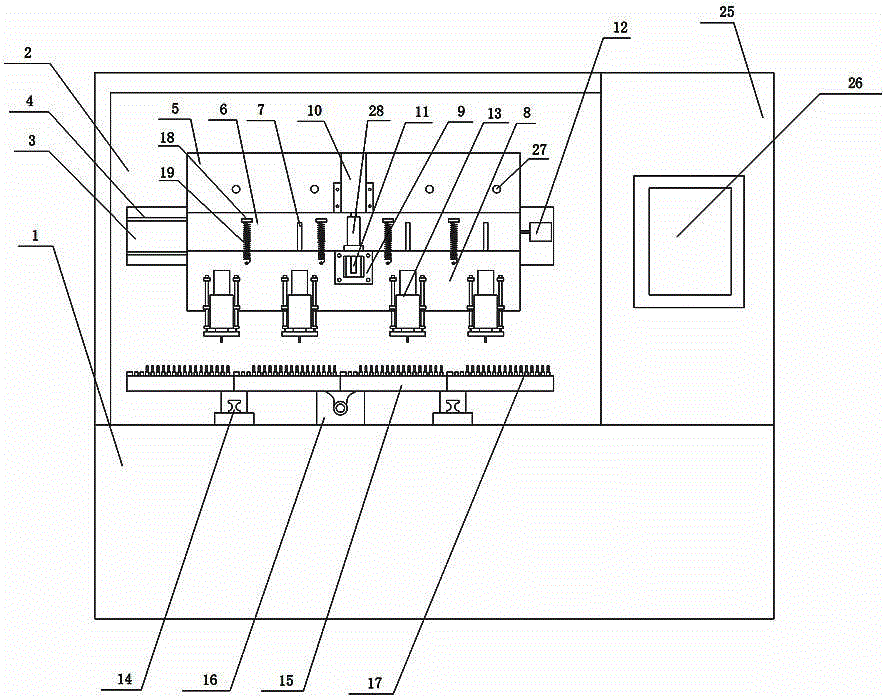

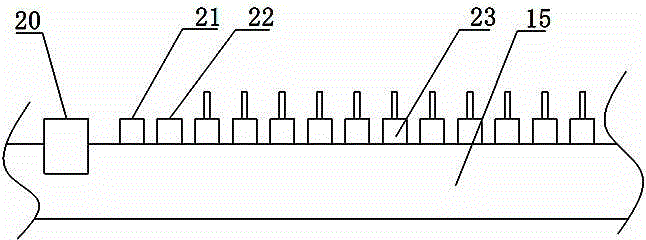

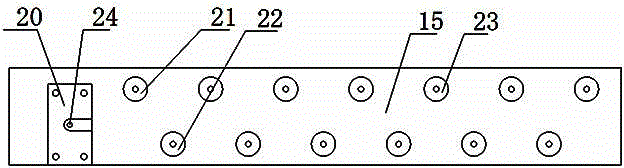

[0019] Such as figure 1 As shown, a fully automatic circuit board punching machine includes a frame 1, and a working cavity 2 is provided on the frame 1, and a base plate 3 is straddled in the working cavity 2, so that The base plate 3 is provided with a slide rail A4, and the base plate 3 is slidably connected to a support plate 5 through the slide rail A4. There are a plurality of slide rails B7, a slide plate 8 is slidably connected to the slide rail B7, a mount 9 is installed on the front end surface of the slide plate 8, and a sleeve 28 is installed on the upper surface of the mount 9, Threads are provided in the sleeve 28, and a drive motor B10 is installed on the front end surface of the support plate 5, and a lead screw 11 is installed on the main shaft of the drive motor B10, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com