Sole drilling device for production of plastic shoes

A drilling device, plastic technology, applied in the application, footwear, shoe-making machinery and other directions, can solve the problems of deformation, sole carbonization, surface pollution of the drilling device, etc., achieve scientific and reasonable structure, reduce labor intensity, and use safety. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

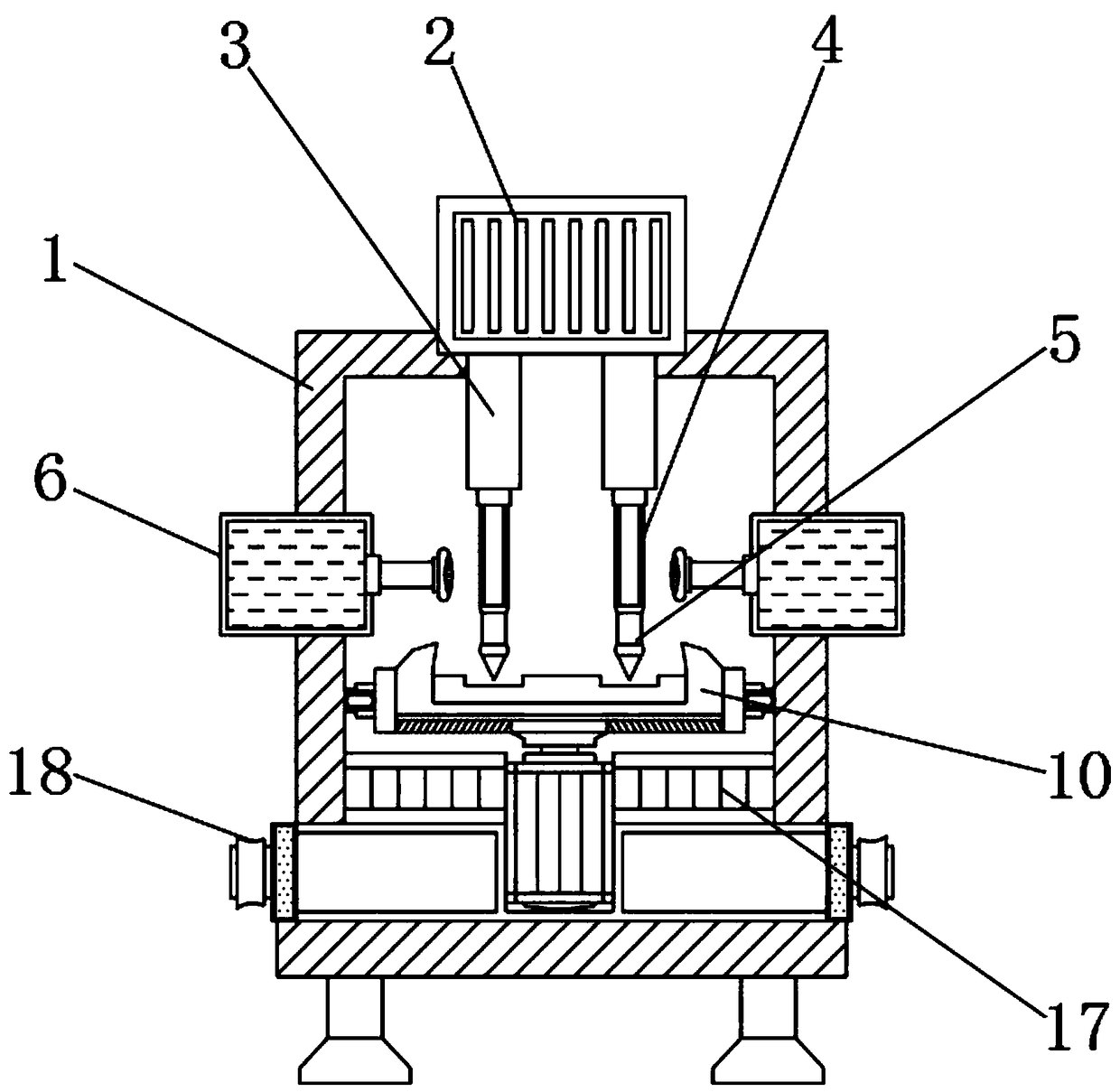

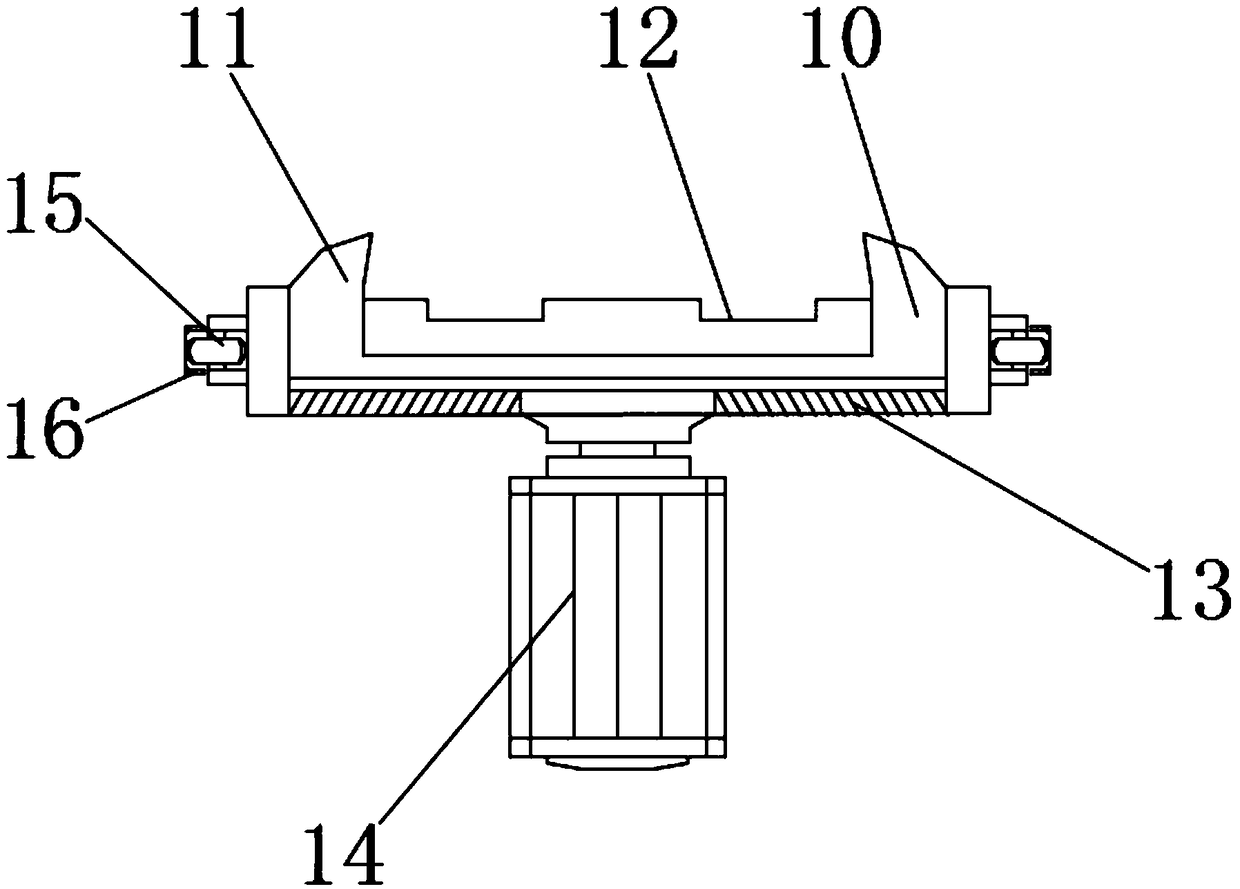

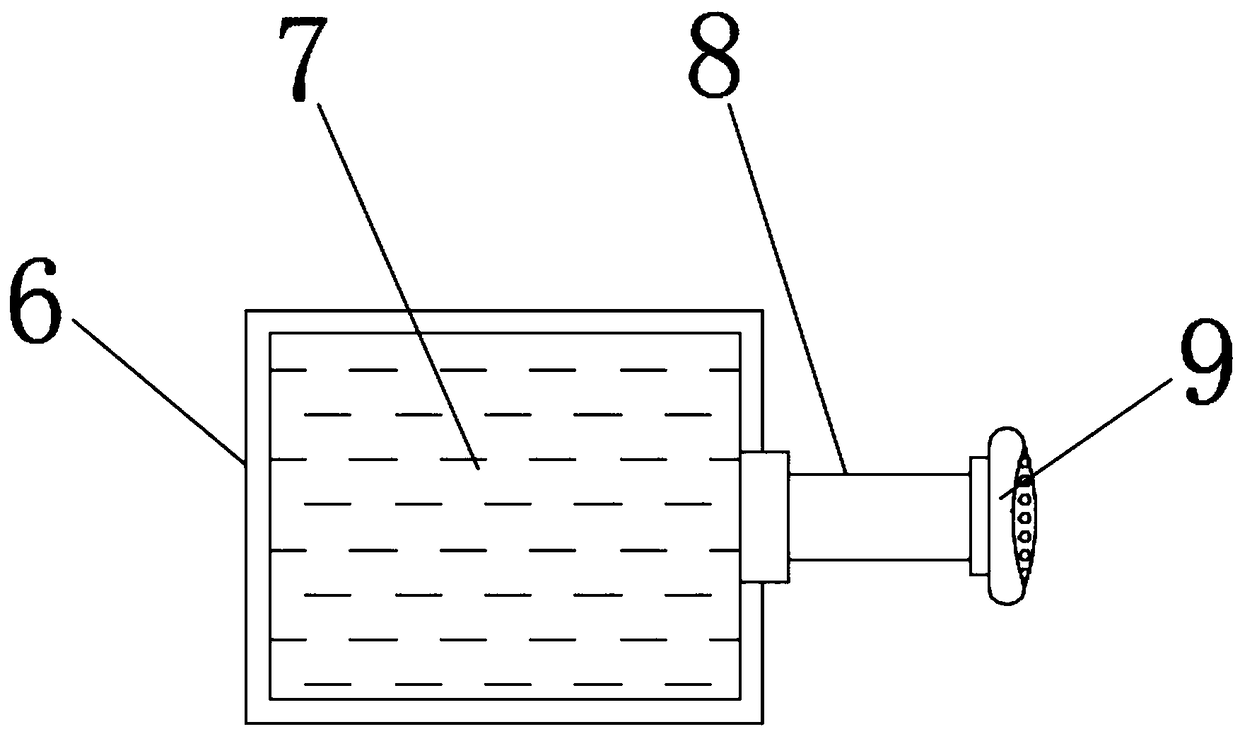

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a sole drilling device for plastic shoe production, including a drilling frame 1, a drilling power box 2, a drill arm 3, a grinding roller 4, a drill bit 5, and a water sprayer 6. , Water storage tank 7, water delivery pipe 8, sprinkler head 9, horizontal rotator 10, fixed end angle 11, fitting slot 12, guide groove plate 13, servo motor 14, rotating roller 15, limit plate 16, Leakage chute 17, decontamination device 18, waste collection box 19, filter template 20 and sewage outlet 21. Drilling power box 2 is fixedly installed above the middle of drilling frame 1, in order to make drilling frame 1 in operation The bottom has a higher supporting capacity. The bottom of the drilling frame 1 is fixedly supported with a shock-absorbing base, in order to facilitate the fixed installation between the drilling power box 2 and the drilling frame 1 and to facilitate the drilling of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com