Patents

Literature

134 results about "Plastic shoes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

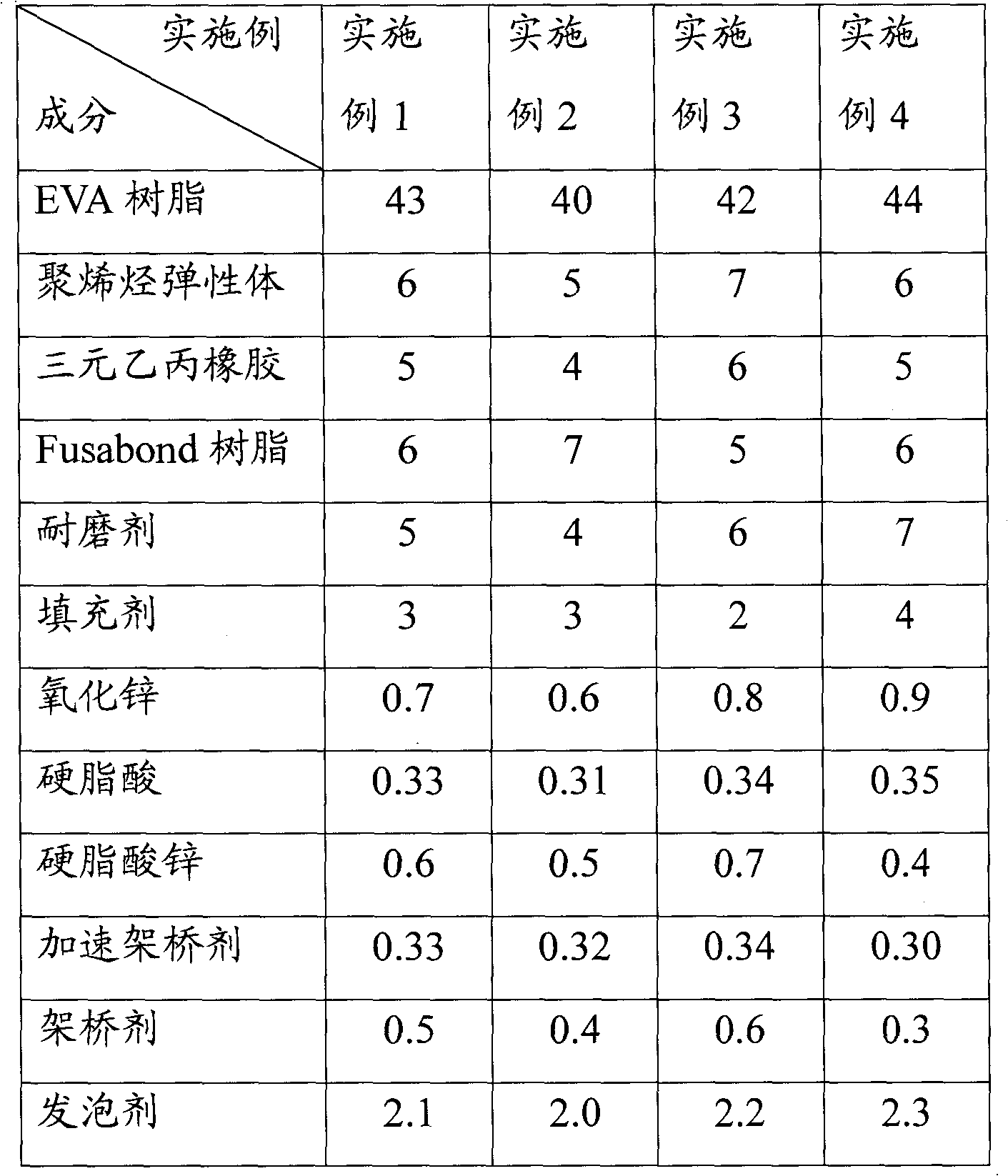

Plastic foam for sport shoe sole

The invention discloses a plastic foam for a sport shoe sole, which comprises the following components in part by weight: 70-74 parts of ethylene-vinyl acetate copolymer, 8-12 parts of ethylene-octylene copolymer, 6-10 parts of ethylene propylene ethylene-propylene-diene monomer, 8-12 parts of ethylene-acrylic acid copolymer, 8-9 parts of wear-resisting agent, 4-6 parts of filler, 1.0 -1.2 parts of zinc oxide, 0.5-0.6 part of stearic acid, 0.8-1.0 part of zinc stearate, 0.5-0.7 part of accelerate bridging agent, 0.8-0.9 part of bridging agent and 3.2-3.8 parts of foaming agent, wherein the ethylene propylene ethylene-propylene-diene monomeris a terpolymer of ethylene-propylene and non-conjugate diolefin. The plastic shoe sole of the sport shoe has the light weight performance, wear resistant performance and comfortable performance which are superior to those of a foam plastic formula injected by common IP, greatly reduces the physical consumption of athletes and has a plurality of performances such as durable comfort, durable buffer resistant performance and the like.

Owner:ANTA CHINA

Hepatitis C virus antibody quick diagnosis test paper and its preparation method

This invention discloses a kind of immunity chromatography test paper and its preparation method which can diagnose the type-C hepatitis virus fast, the said test paper includes the sampling tray, the gold size tray has labeled HCV mix antigen which links one end of the sampling tray closely, the pyroxylin film which links the other end of the gold size tray closely, and the suction sampling tray which links the other end of the pyroxylin film closely, the film encrusts the test (T) line and the quality control (C) line which are separate with each other, the sampling tray, the gold size tray, the film and the suction sampling tray are affixed in the plastic shoe plate to form the test paper, the said T line is the HCV mix antigen which is entrusted in the NC film, the said gold size tray has HCV recombination mix antigen, the said C line is the antibody of the HCV mix antigen entrusted in the film, it is used to test or clinical diagnosis of the HVC antigen, has the merits that the sensitive is high, the specificity is good, the operation is simple, the reaction is fast, it is fit to test in local and it is economical and useful.

Owner:天津中新科炬生物制药股份有限公司

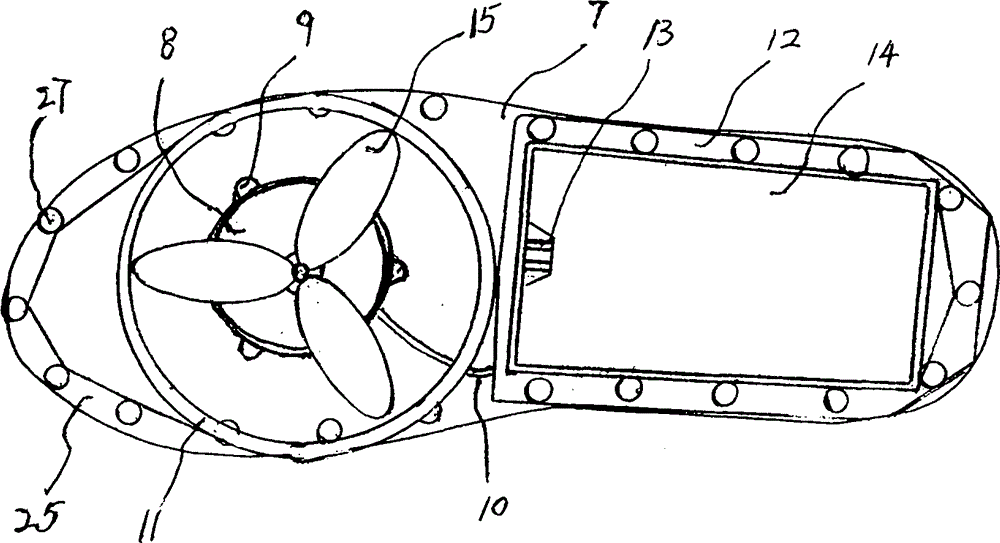

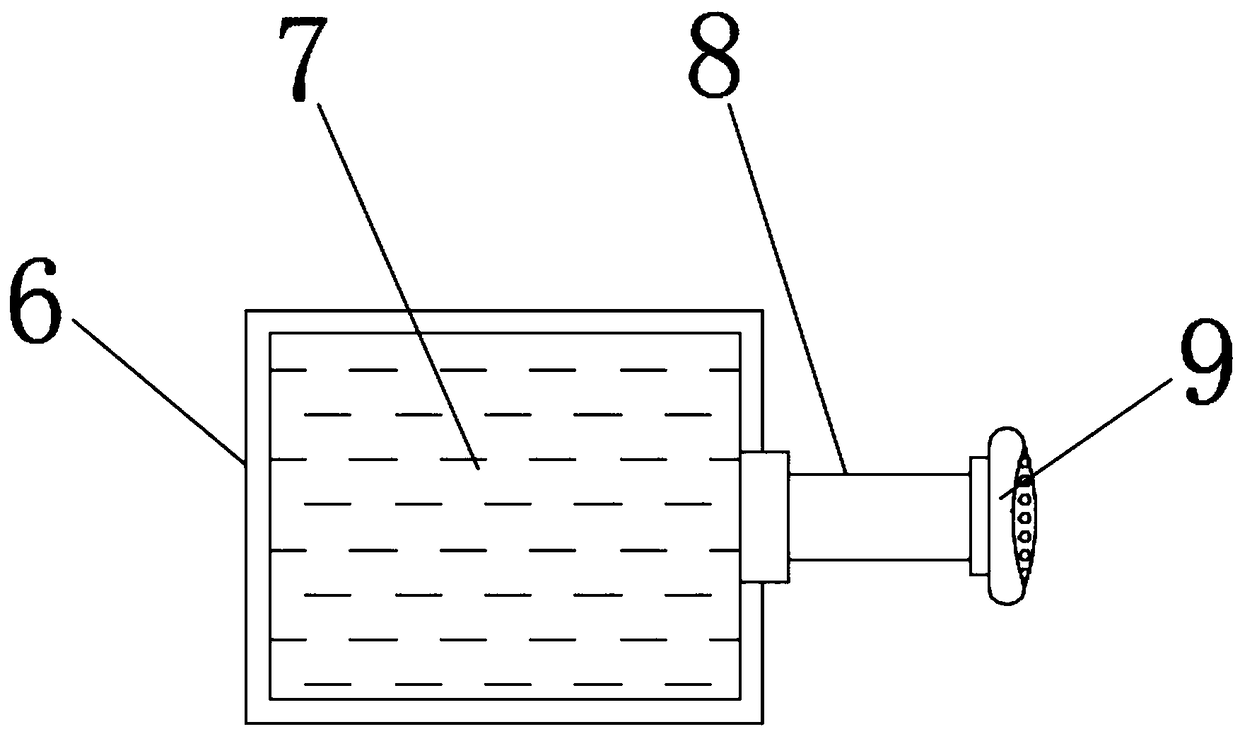

Underwater electric swim-assisting shoe

ActiveCN104432944AEasy to wearSimple structureWaterborne vesselsSwimming frameworkUnderwaterPropeller

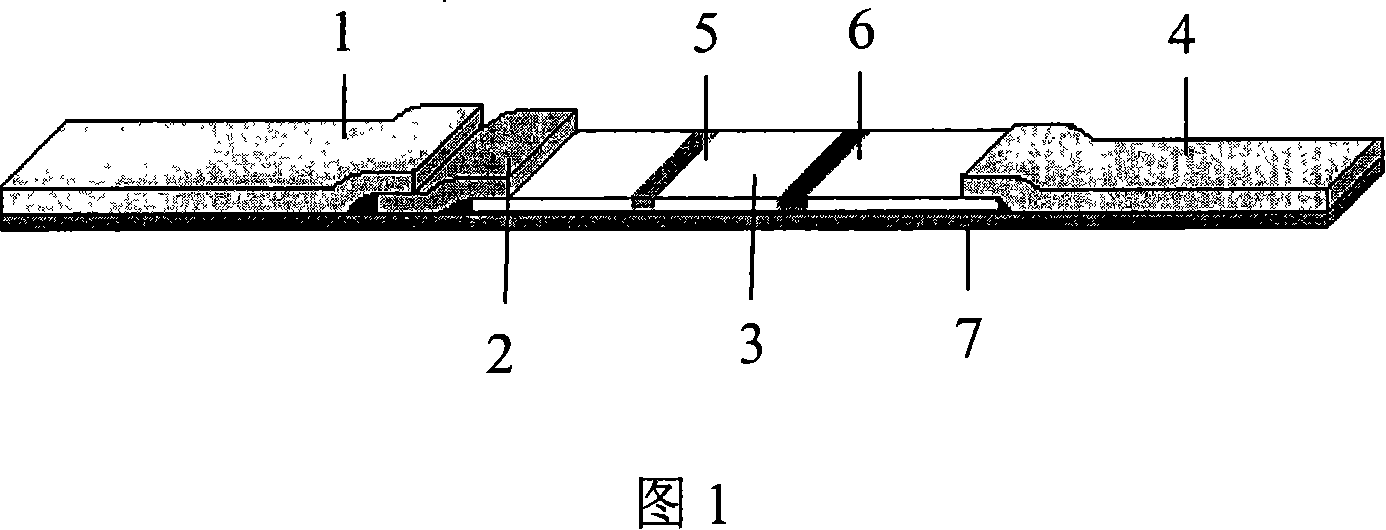

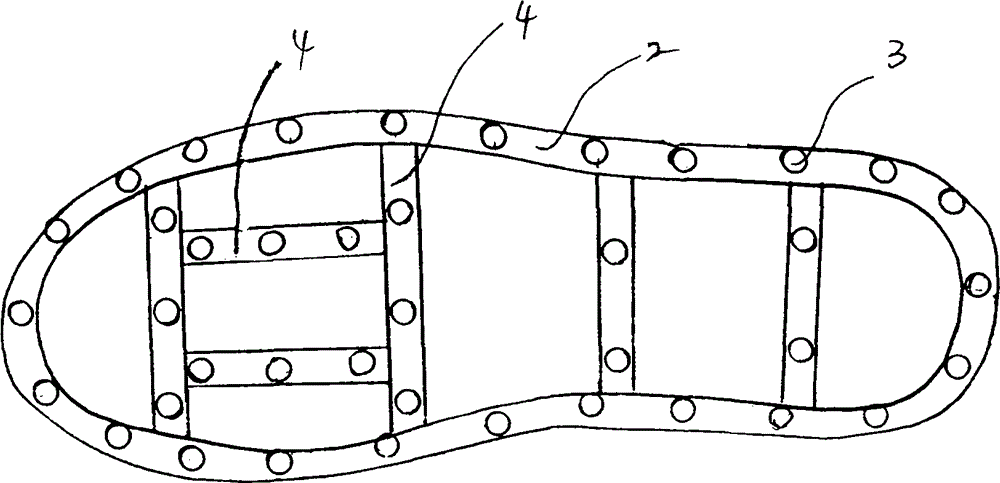

An underwater electric swim-assisting shoe comprises a plastic shoe outsole, a metal show sole from, a sole metal plate, a propulsion motor, a waterproof storage battery, a motor frame net cover and a battery protecting cover. A plurality of sole frame bolts and nuts are fixed on the metal shoe sole frame, the plastic shoe outsole after being positioned by injection and an electric swim-assisting vamp are assembled to form a shoe boot, the sole metal plate is fixed on the metal shoe sole frame by using the nuts, and the propulsion motor and the waterproof storage battery are fixed on the sole metal plate; after the motor frame net cover and the battery protecting cover are fixed on the metal shoe sole frame, underwater sundries can be prevented from tripping and winding propulsion propellers, and the underwater electric swim-assisting shoe can be worn to walk on shoals; when the underwater electric swim-assisting shoe is worn to move underwater, two feet are vigorously merged to push a sole triggering switch to act or press an electric shoe waterproof manual switch, in this way, the propulsion propellers on the propulsion motor can be controlled to rotate to push a human body to advance underwater. The underwater electric swim-assisting shoe is especially suitable for underwater sports, underwater exploration and navy special forces to use.

Owner:曹伟

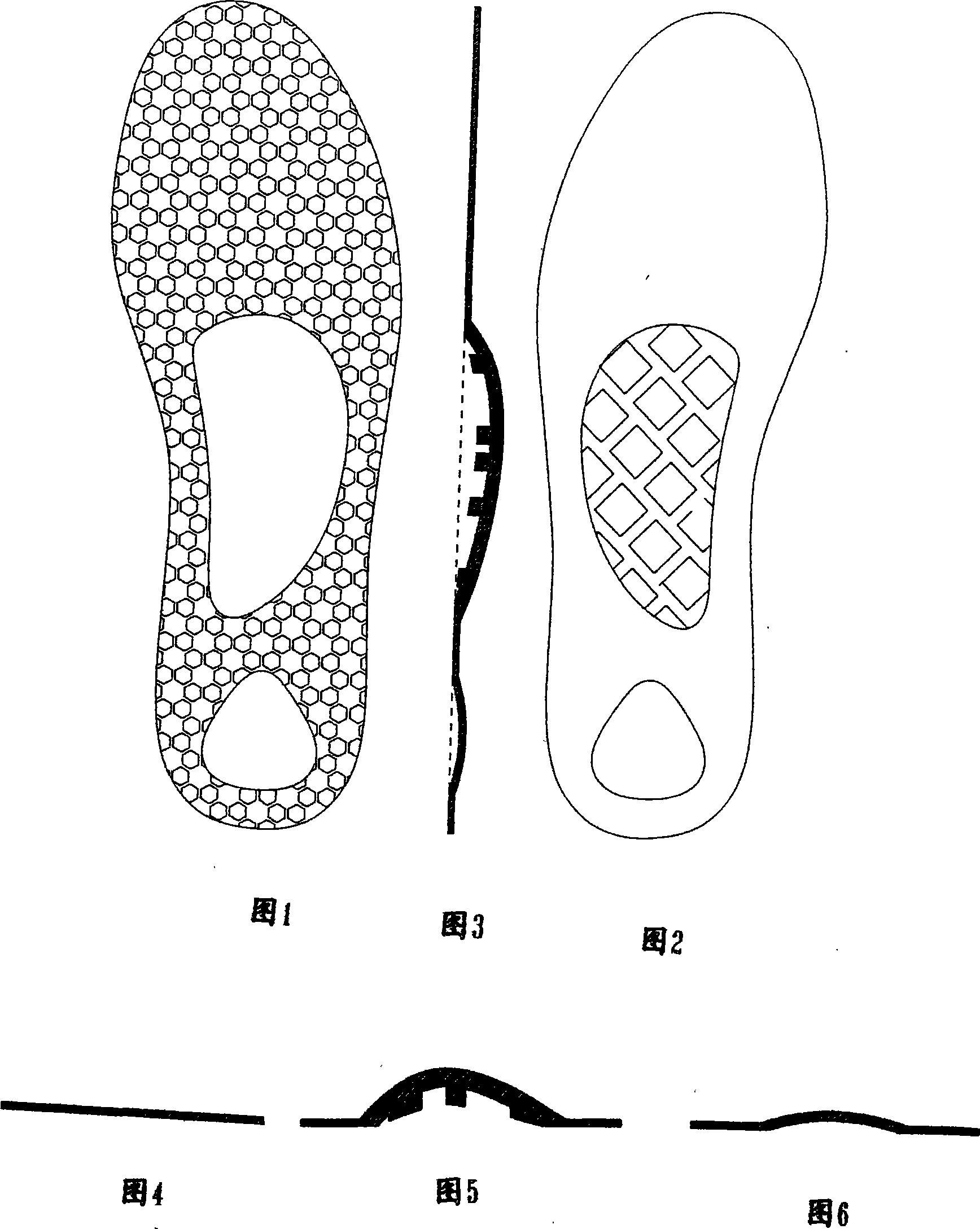

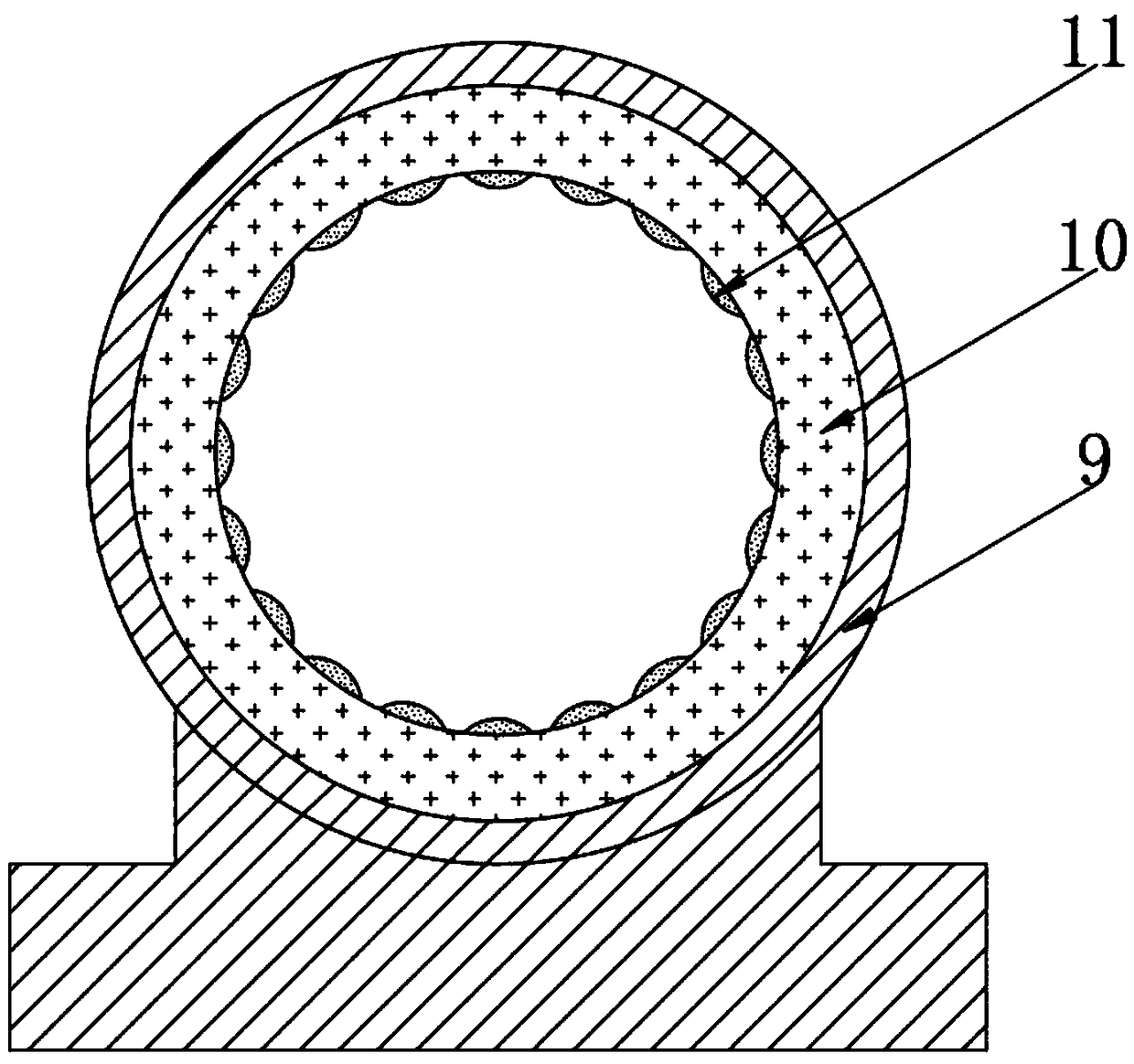

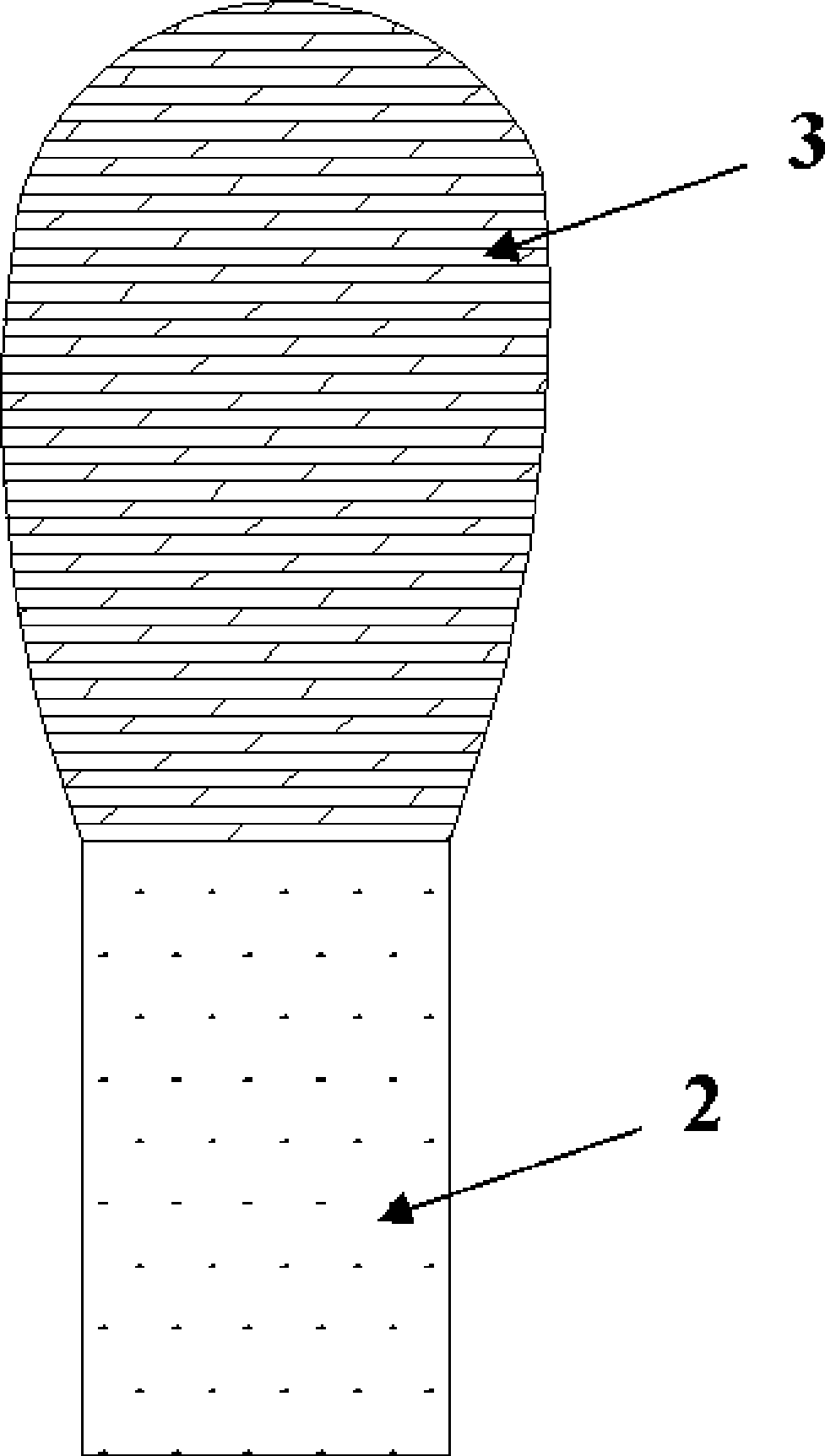

Wave energy resonance massage magnetic gas curative effect instant barycenter stabilising rubber and/or plastics mid-sole shoe material

ActiveCN101156720AAdjustable and blood runningIt has the function of stabilizing the center of gravity instantlyElectrotherapyInsolesInfraredHuman body

The invention relates to a wave energy resonant massage magnetic curative effect instant gravity center stabilization rubber and / or plastic shoe pad. The invention is characterized in that the shoe pad is a surface layer shoe pad formed by processing the admixing of far-infrared powder and anoin powder with rubber and / or plastic or film forming and applying or through printing, compression molding, or spraying, a similar bow shape matched with the foot sole shape of the human body is raised, the outer side outside a foot metacarpus center part gradually inclines to the inner side part, the foot heel and a foot toe part present an irregular inclined arc shape, a plurality of bulges arranged regularly and irregularly are arranged on the bottom, a heart arc shape salience is arranged at the foot root part, all parts respectively have a certain distance to the bottom surface, and a spot or a decorative pattern are arranged on the other parts. The invention has excellent effect of wave energy resonant massage, and magnetic curative effect as well as instant gravity center stabilization, the invention is comfortable for being wore, belongs to a new generation wave energy resonant massage magnetic curative effect instant gravity center stabilization rubber and / or plastic shoe pad with good foot sense, and thereby is widely used for various shoes.

Owner:陈威利 +1

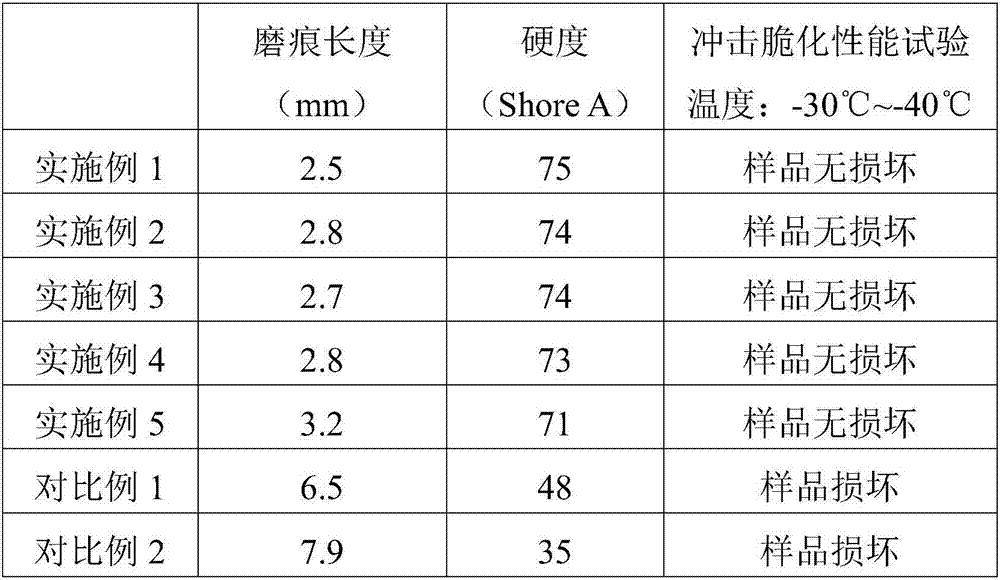

Wear-resisting and highly-hard plastic sole product

The invention relates to plastic shoes, in particular to a wear-resisting and highly-hard plastic sole product. The wear-resisting and highly-hard plastic sole product comprises, by weight, 50-68 parts of a plastic material, 3-8 parts of a plastic modifier, 15-24 parts of a rubber material, 5-10 parts of a blending modification additive, 10-25 parts of a plasticizer, 1-5 parts of a stabilizer, 0.1-2 parts of a lubricant, 0.5-3 parts of a foaming agent, 2-7 parts of inorganic filling particles and 2-10 parts of glass fiber; the plastic modifier is formed by blending of styrene-butadiene-styrene ternary block copolymer, ethylene-vinyl acetate copolymer and ethylene-octene elastomer. Through blending modification of plastic and rubber, advantages of toughness and hardness are achieved, and good wear-resisting and highly-hard characteristics of the plastic sole product are guaranteed; the plastic is modified, so that the shortcoming of low-temperature brittleness is overcome, and use temperature range of plastic soles is expanded.

Owner:界首市旭升塑胶制品有限公司

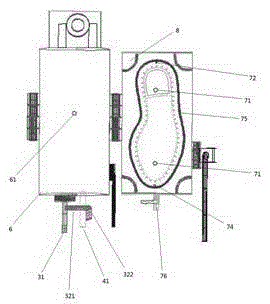

Multicolour die for forming lace surface and sole surrounding edge

ActiveCN106182589AFully functional and beautifulIncrease productivityDomestic articlesEngineeringPlastic shoes

The invention discloses a multicolour die for integrally forming a lace surface and a sole surrounding edge, for achieving the purpose of integral forming for the sole surrounding edge. The die for integrally forming the sole surrounding edge comprises a shoe tree, a fixed die, a first movable die and a second movable die, wherein the shoe tree is movably connected with the fixed die and forms an upper cavity; the first movable die is provided with a first concave die and a first runner; a sole non-surrounding-edge cavity is formed when the first concave die and the fixed die are assembled; the first runner communicates with the sole non-surrounding-edge cavity; the second movable die is provided with a first convex die, second runners and third runners; and a sole surrounding-edge cavity is formed when the first convex die and the fixed die are assembled, the second runners communicate with the upper cavity, and the third runners penetrate through the convex die and communicate with the sole surrounding-edge cavity. The die disclosed by the invention is used for producing plastic shoes, and is capable of integrally forming the sole surrounding edge, an upper and a sole non-surrounding-edge part, thus increasing the production efficiency.

Owner:东莞市鸿泰鑫机械设备有限公司

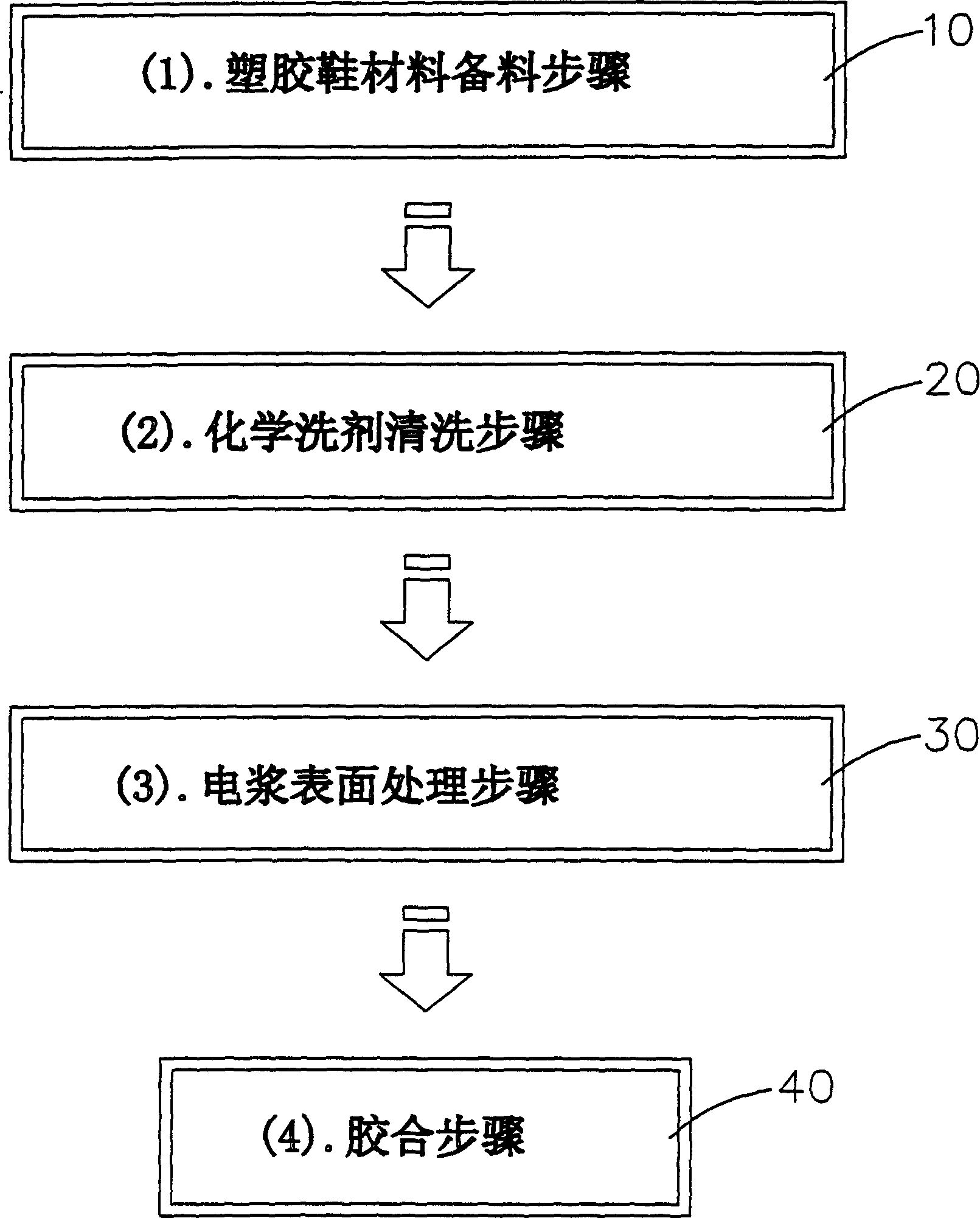

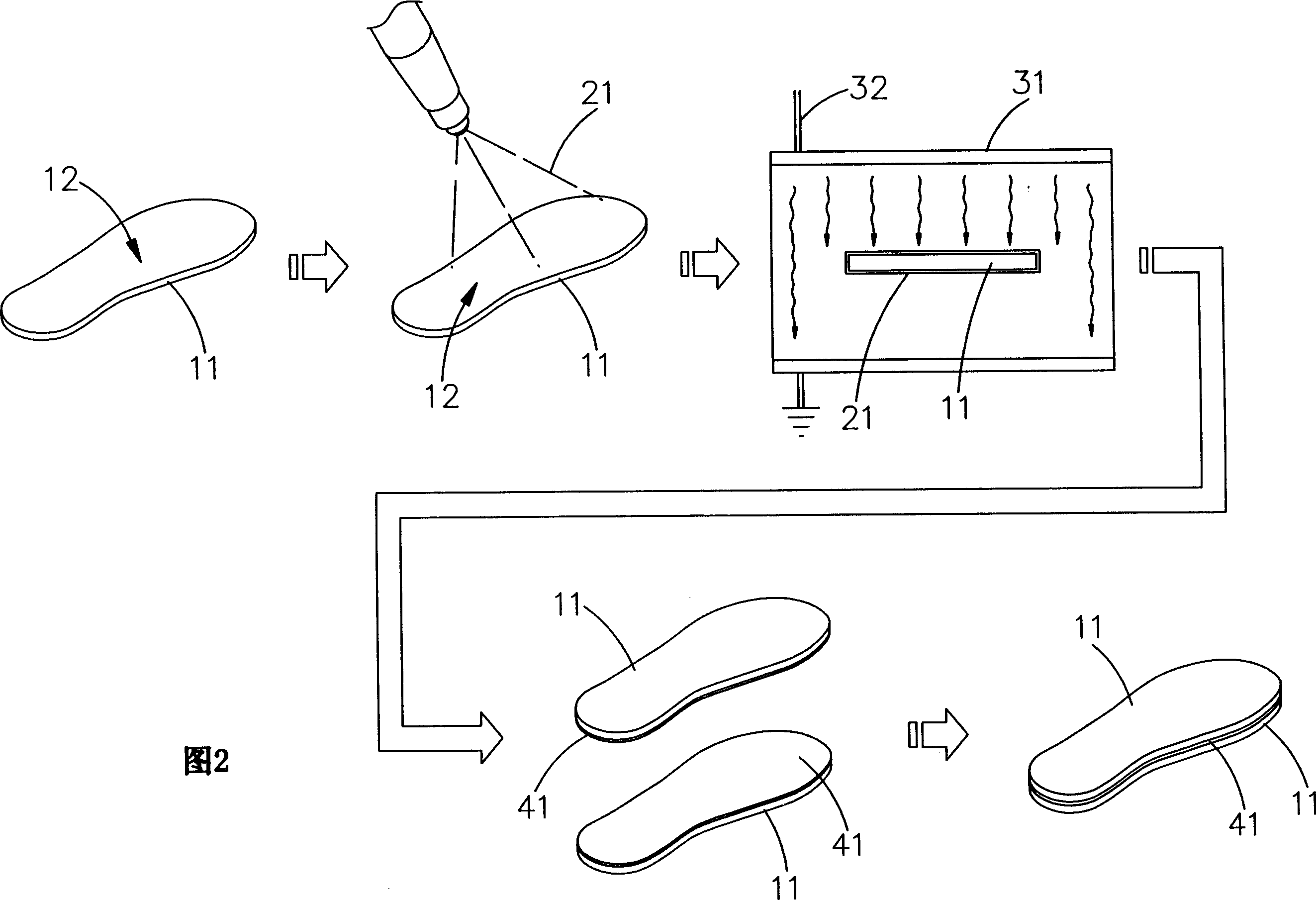

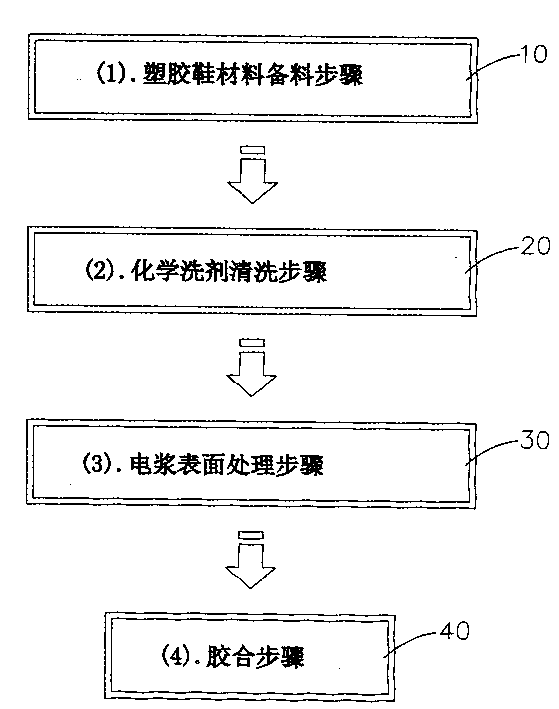

Electric plasm glue processing method for shoes material

InactiveCN1520995ASolve the problem of poor activation rateMeet environmental protection requirementsDomestic footwearAdhesiveSurface cleaning

The present invention proposes one plasma adhering treating method for shoe material and aims at raising the adhering effect of shoe material. The treating process of the present invention includes the following steps: preparing plastic shoe material, cleaning with chemical detergent, plasma surface treatment, and adhering. After surface cleaning with chemical detergent, the shoe material is surface treated with plasma to active physically and chemically. The present invention can raise the activating rate of shoe material adhering surface, and can reach the effects of protecting environment, saving adhesive, lowering cost and raising work efficiency. The present invention is one practical kind of shoe material treating method.

Owner:张秋墩

Shoemaking mold

The invention discloses a shoemaking mold. The shoemaking mold comprises a bottom plate, a mold core in a shoe tree shape, a left mold, a right mold, a front mold and a bottom cover mold. A cylinder perpendicular to the bottom plate is arranged at the tail end of the upper surface of the bottom plate, a base is arranged at the middle end of the upper surface of the bottom plate, and the mold core is fixed to the upper end of the base; the front mold is arranged at the head end of the upper surface of the bottom plate, the left mold is arranged on the left side of the mold core, and the right mold is arranged on the right side of the mold core; the tail end of the left mold and the tail end of the right mold are hinged to the cylinder, and the bottom cover mold is arranged at the right end of the right mold and is rotatably connected with the right mold through a rotating shaft; an inwards-concave shoe sole mold cavity is formed in the front face of the bottom cover mold, and the shoe sold mold cavity, the mold core, the left mold, the right mold and the front mold are closed to form an upper and shoe sole mold cavity; and an injection hole penetrating into the front face from the back face is formed in the bottom cover mold. According to the shoemaking mold, a molded plastic shoe can be easily separated from the mold, and a joint affecting attractiveness cannot appear in the upper.

Owner:JIEYANG HUIFENG DIE CO LTD

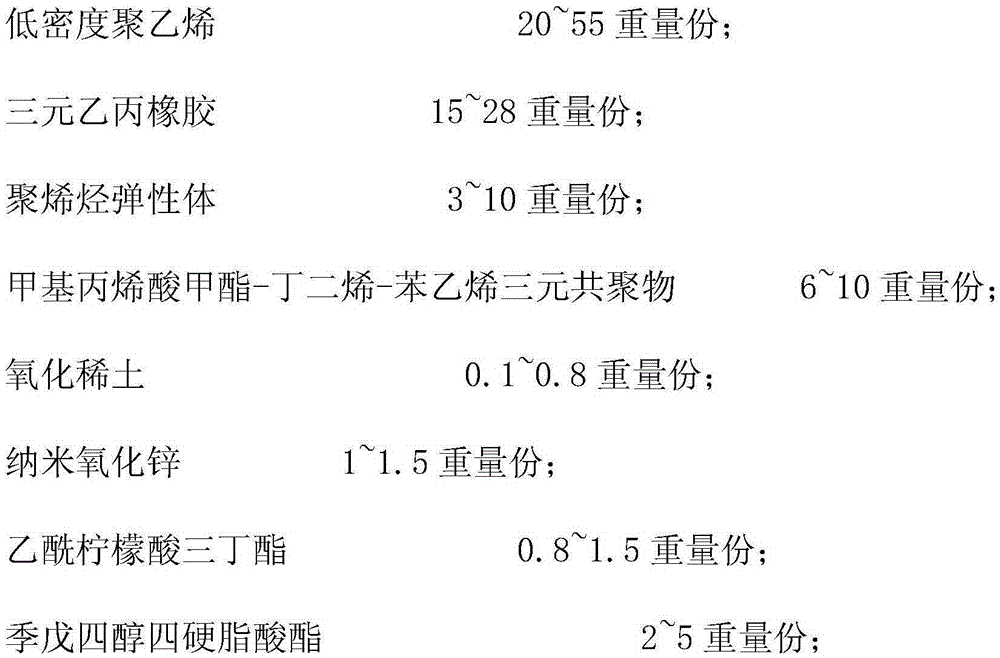

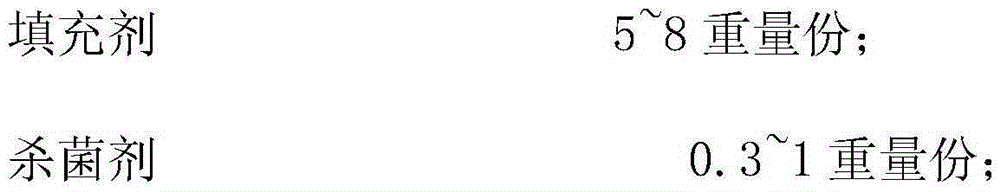

Antibacterial and mildewproof rubber-plastic shoe material and preparation method thereof

InactiveCN105400039AGuaranteed mechanical strengthGuaranteed heat resistanceInsolesLow-density polyethyleneElastomer

The invention discloses an antibacterial and mildewproof rubber-plastic shoe material. The antibacterial and mildewproof rubber-plastic shoe material comprises the following components: low density polyethylene, an ethylene-propylene-diene monomer, a polyolefin elastomer, a methyl methacrylate-butadiene-phenethylene terpolymer, rare earth oxide, nanometer zinc oxide, acetyl tributyl citrate, pentaerythrityl tetrastearate, calcium carbonate and a fungicide adopting a microcapsulate structure, wherein the particle size range of the microcapsulate structure is 10-100 microns, the ratio of a wall material to a sandwich layer is 1: (15-22), the sandwich layer is composite powder, and the wall material is polyester film. A shoe material prepared from the material provided by the invention is excellent in antibacterial and mildewproof effect, lasting in antibacterial effect, and long in effect time.

Owner:吴江市风尚鞋厂

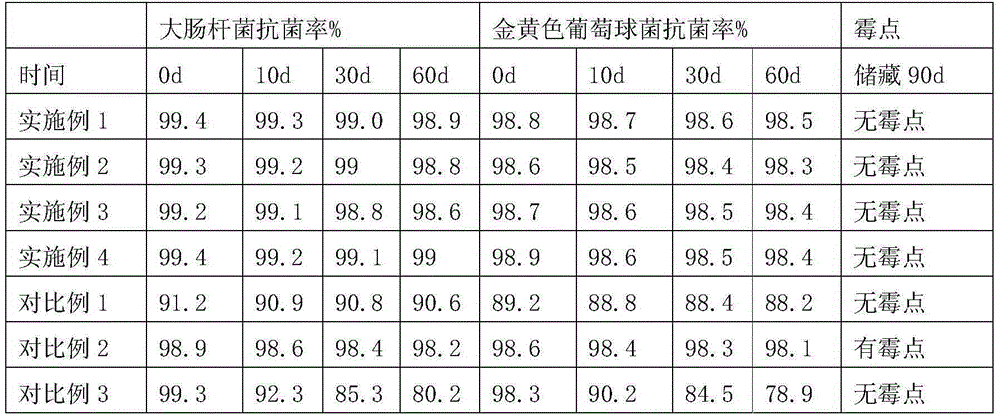

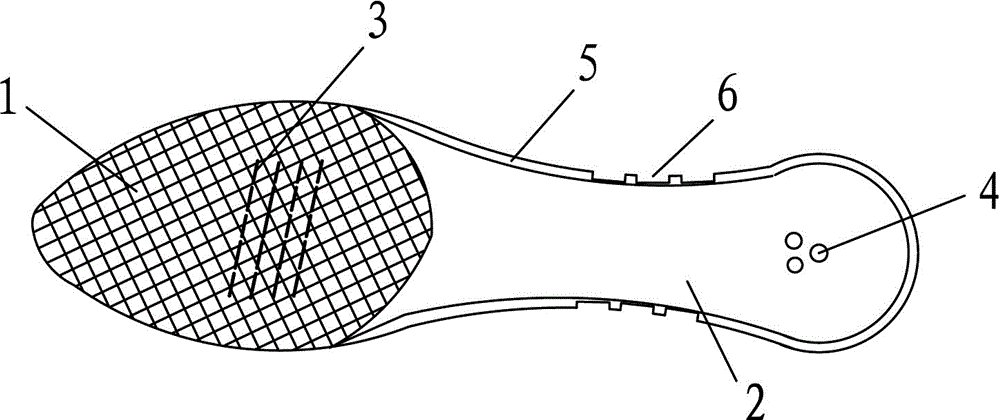

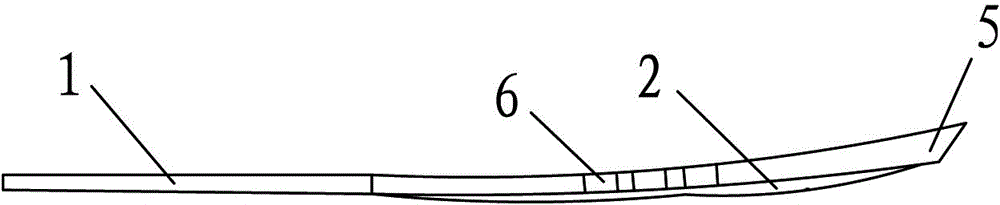

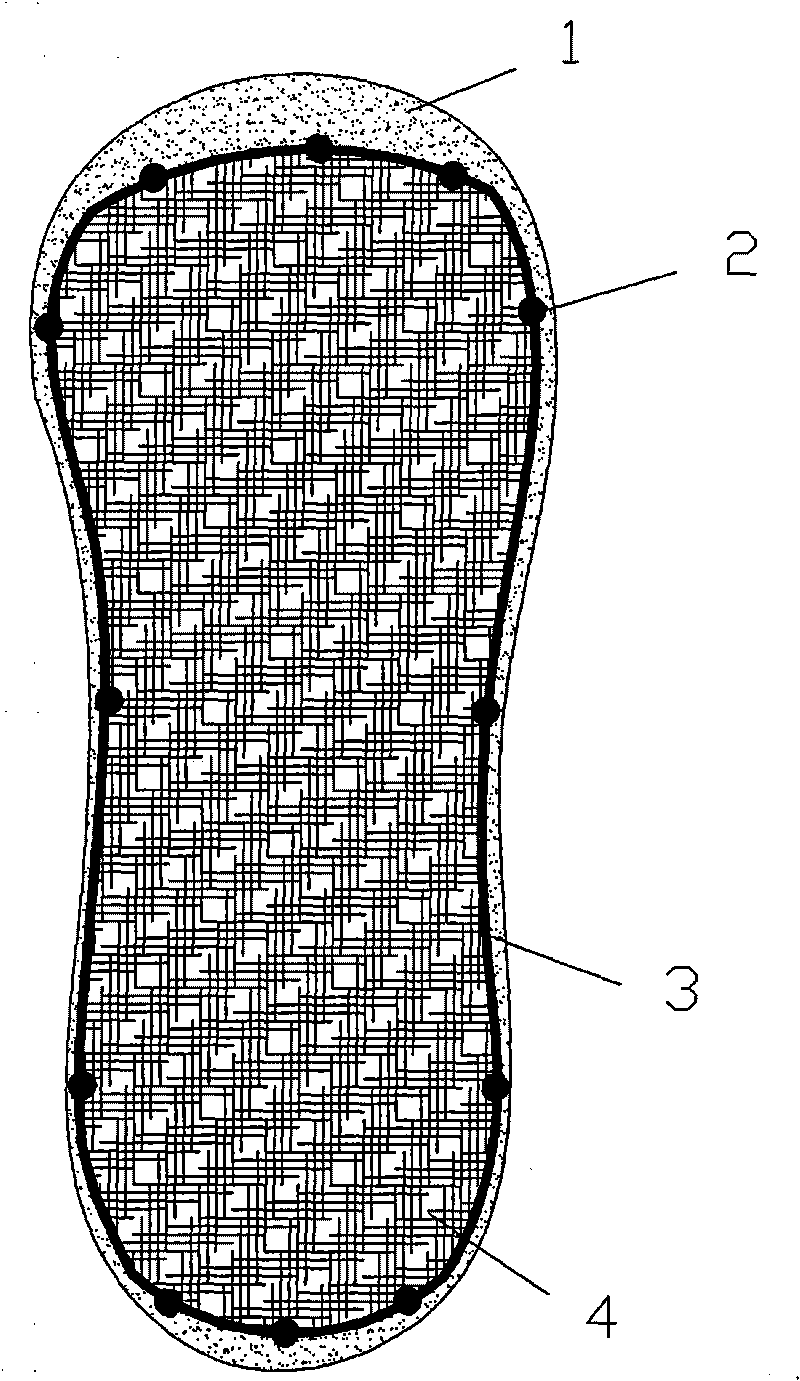

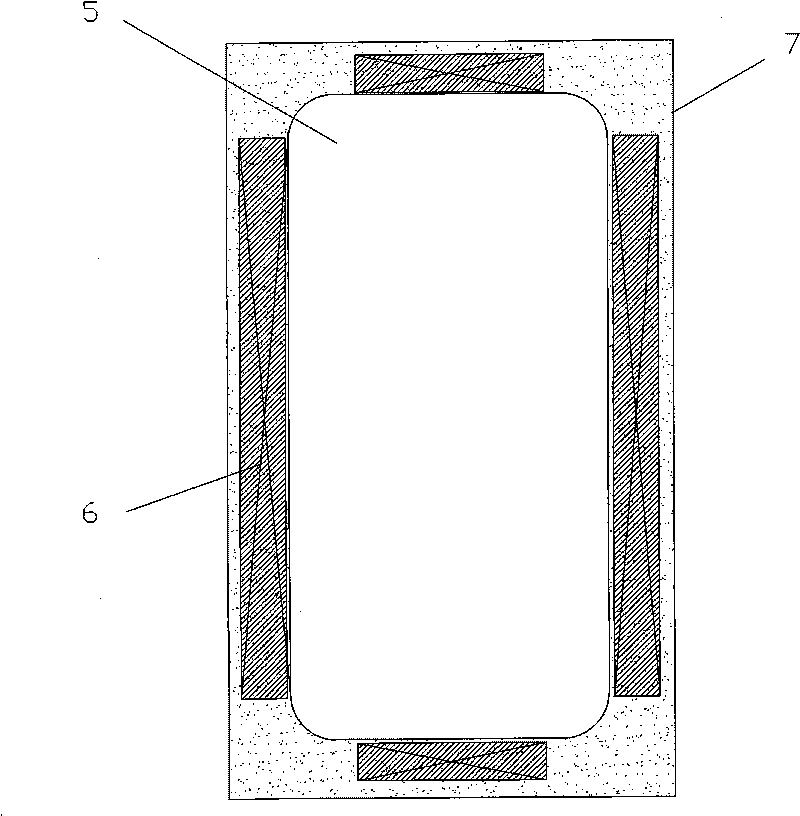

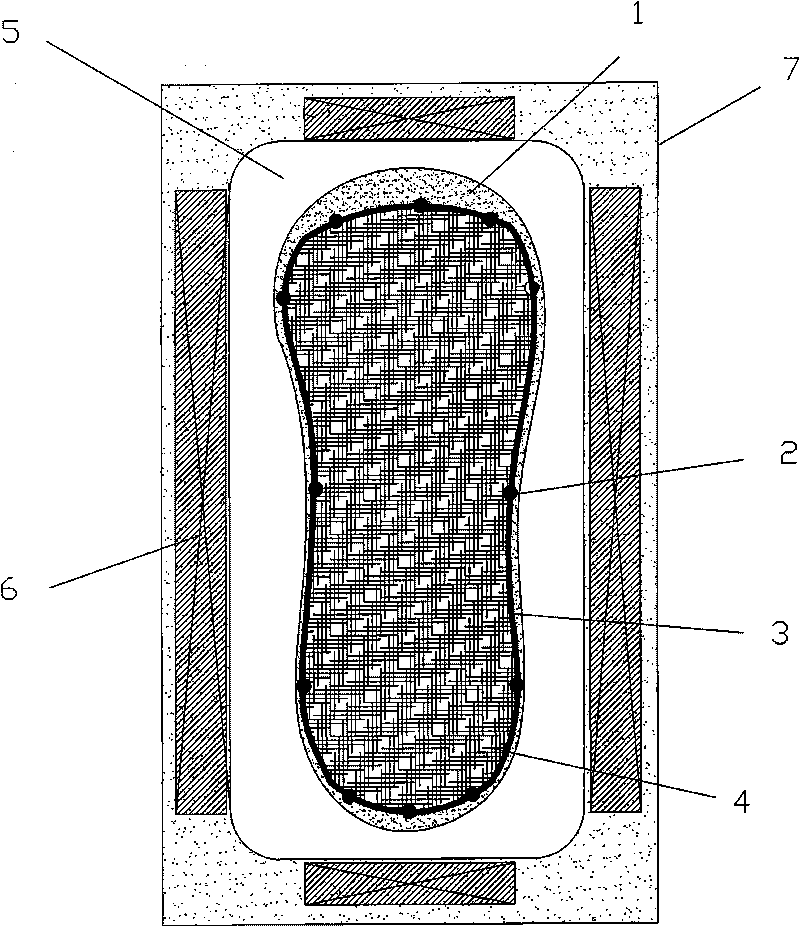

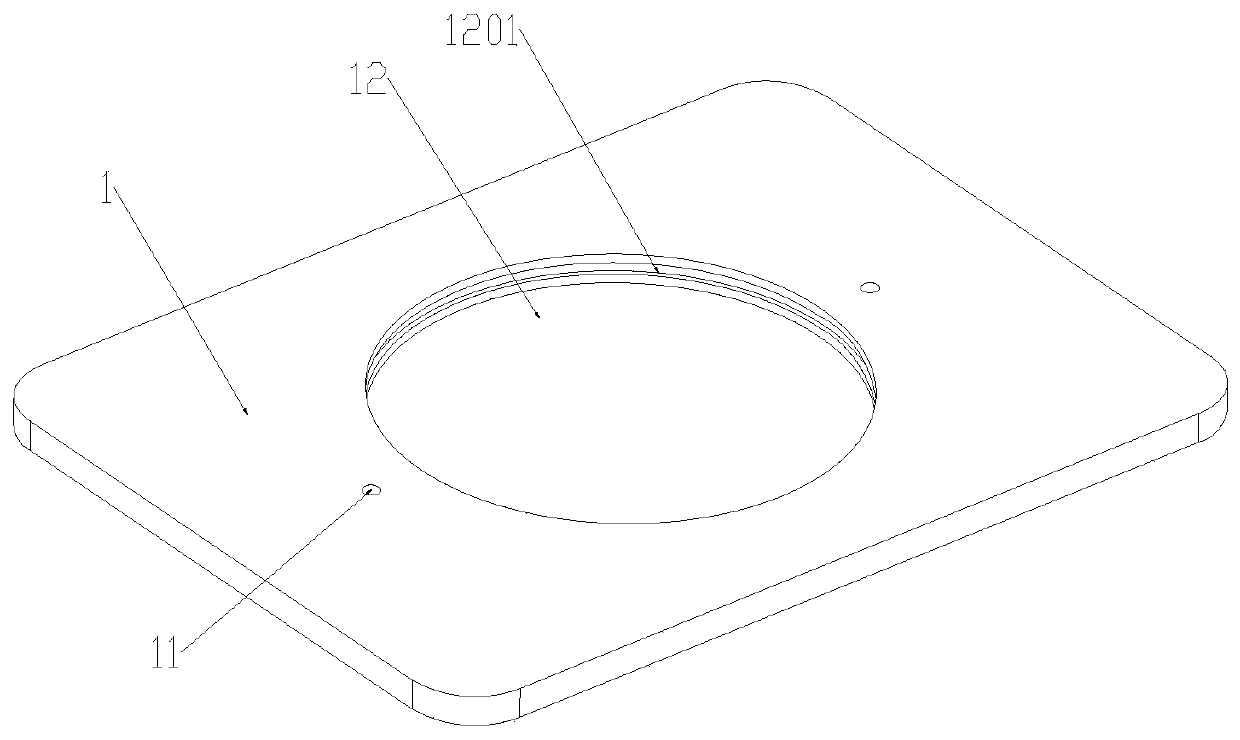

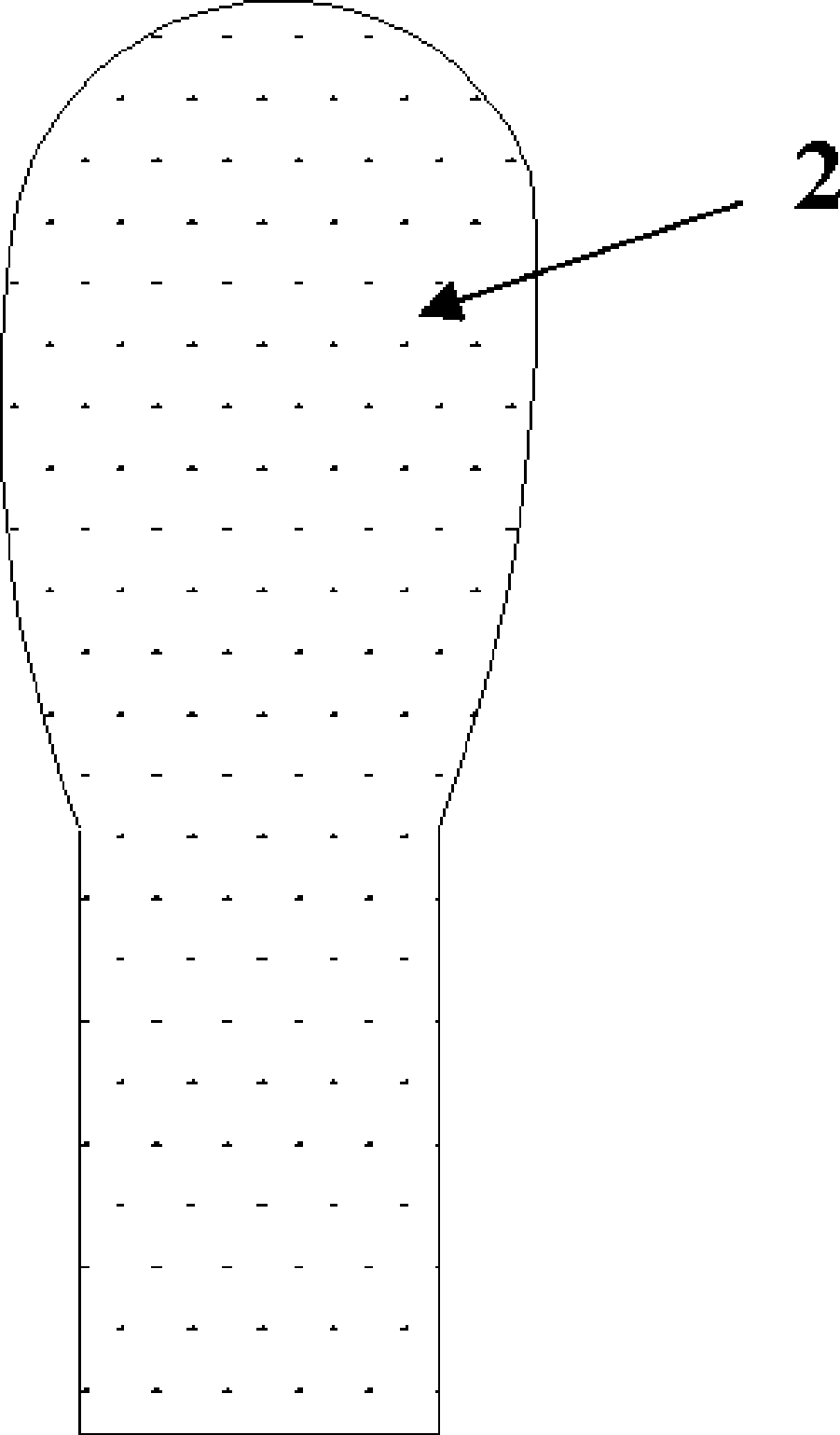

Plastic midsole for shoes for women and processing method for plastic midsole

The invention discloses a plastic midsole for shoes for women and a processing method for the plastic midsole. The midsole consists of a forefoot part and a heel part, wherein the forefoot part and the heel part are integrated into the midsole of which the shape is similar to that of a foot; the forefoot part is formed by laminating multiple layers of paperboards, and a cotton web formed by staggering cotton threads is attached to the lower surface of the forefoot part. The plastic midsole for shoes for women is strong in structural strength, and compared with the conventional midsole for shoes for women, the plastic midsole has the advantages that the lateral surface of the injection-molded midsole is smooth, and during injection molding, required preformed shoe lace openings can be synchronously processed without performing grinding polishing and causing the appearance problem of damage to the lateral surface of the midsole; moreover, the positions of the preformed openings can be corrected at any time by regulating the positions of plastic square blocks, so that modification requirements in a designing and manufacturing process of modern shoes for women can be well met.

Owner:威海高新园区运营管理有限公司

Sole drilling device for production of plastic shoes

ActiveCN109093749AScientific and reasonable structureEasy to useEdge grinding machinesShoemaking devicesWater storage tankEngineering

The invention discloses a sole drilling device for production of plastic shoes. The sole drilling device comprises a water storage tank, a spraying head, a horizontal rotating device, fixed end corners, a waste collecting tank and a filtering template. The inner side of the water storage tank is connected with the spraying head, and the fixed end corners are mounted on the upper portions of the two sides of the horizontal rotating device correspondingly. The filtering template is mounted in the waste collecting tank. The sole drilling device is scientific and reasonable in structure and safe and convenient to use, the spraying head sprays water in the water storage tank to the drilling positions of the drilled plastic shoes through a water conveying pipe, heat generated by drilling of theplastic shoes is eliminated through water cooling, and the phenomenon that the drilling positions of the plastic shoes are carbonized and deform due to the over-high heat is avoided; and a servo motordrives the horizontal rotating device to rotate, thus the drilling positions of the plastic shoes are convenient to adjust, the trouble of manual adjusting is lowered, the drilling efficiency of thedevice is improved, the plastic shoes and the drilling device are more fixedly connected through the fixed end corners, and thus deflecting of the drilling positions during drilling is avoided.

Owner:浙江杭泉家纺科技有限公司

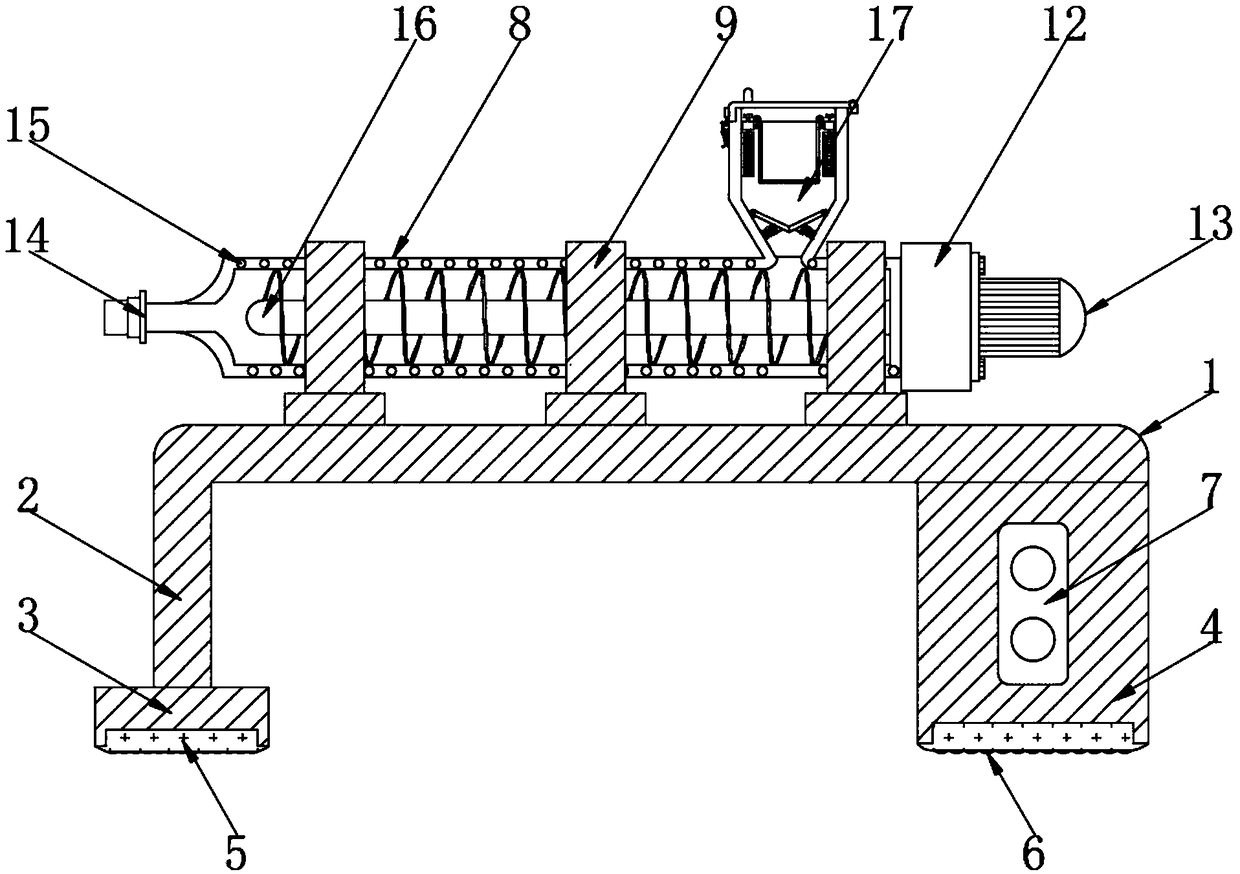

Plastic rubber gas-blowing foaming injection machine for footwear

InactiveCN101077604AShorten barrel screwSuitable for needsDomestic articlesEngineeringInjection molding machine

The present invention relates to plastic shoe sole producing apparatus, and is especially one kind of air blowing and plastic foaming injection machine for producing shoe sole. The machine includes one injecting mechanism, one mold clamping mechanism, one turntable and one turning disc mechanism. The mold clamping mechanism includes one mold clamping pressure cylinder and one jaw type mold rack; and the injecting mechanism has injecting nozzle aligned to the jaw of the mold rack. The machine of the present invention has the advantages of high product quality, convenient maintenance, capacity of producing different products, etc.

Owner:SHANGHAI DRB & TAFU IND

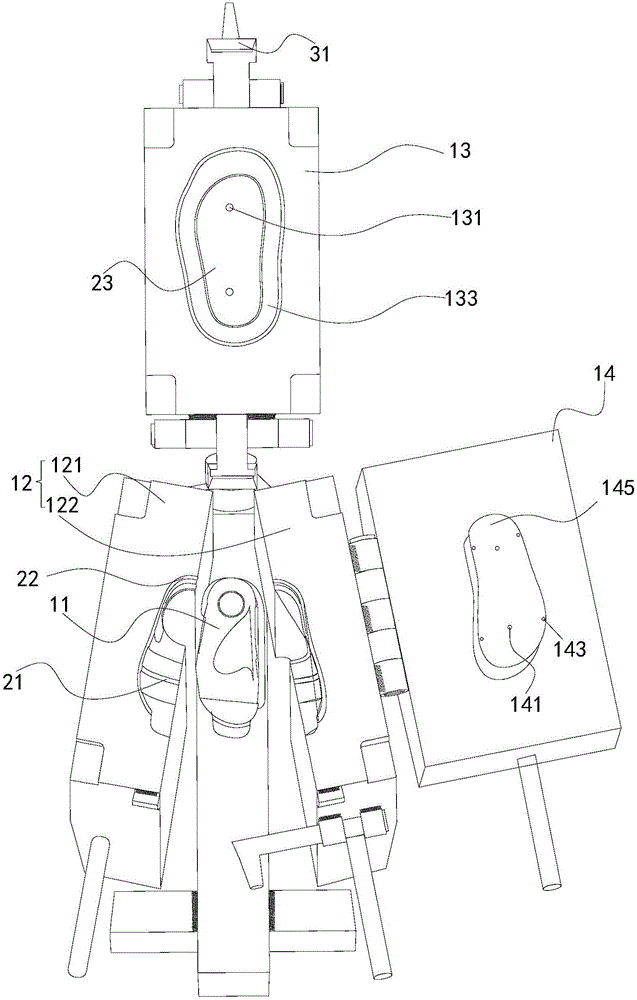

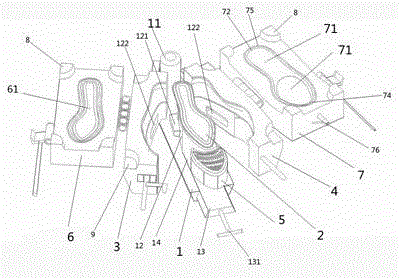

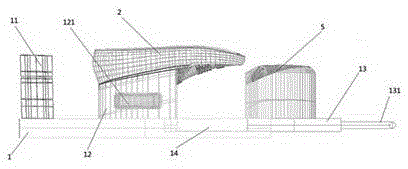

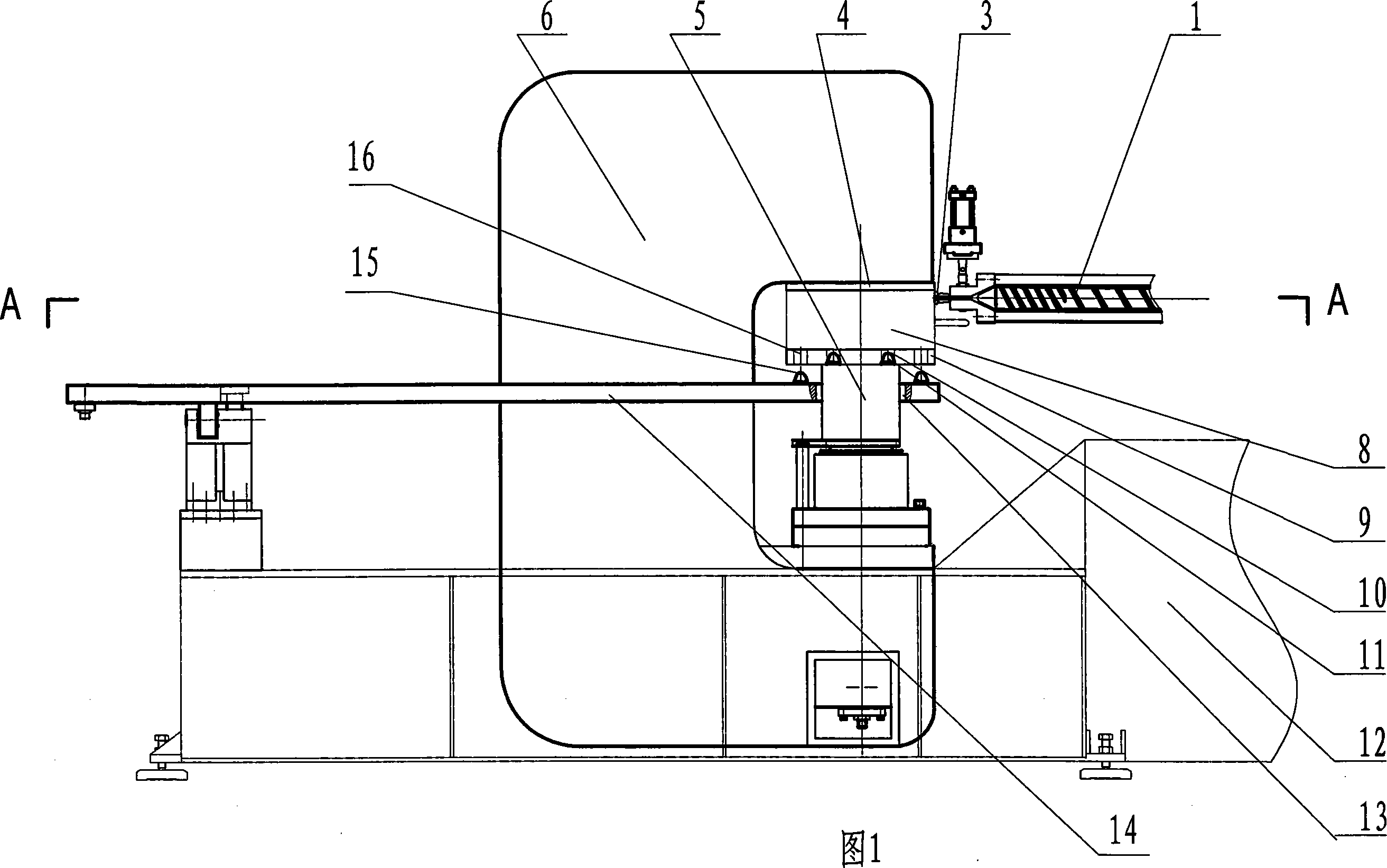

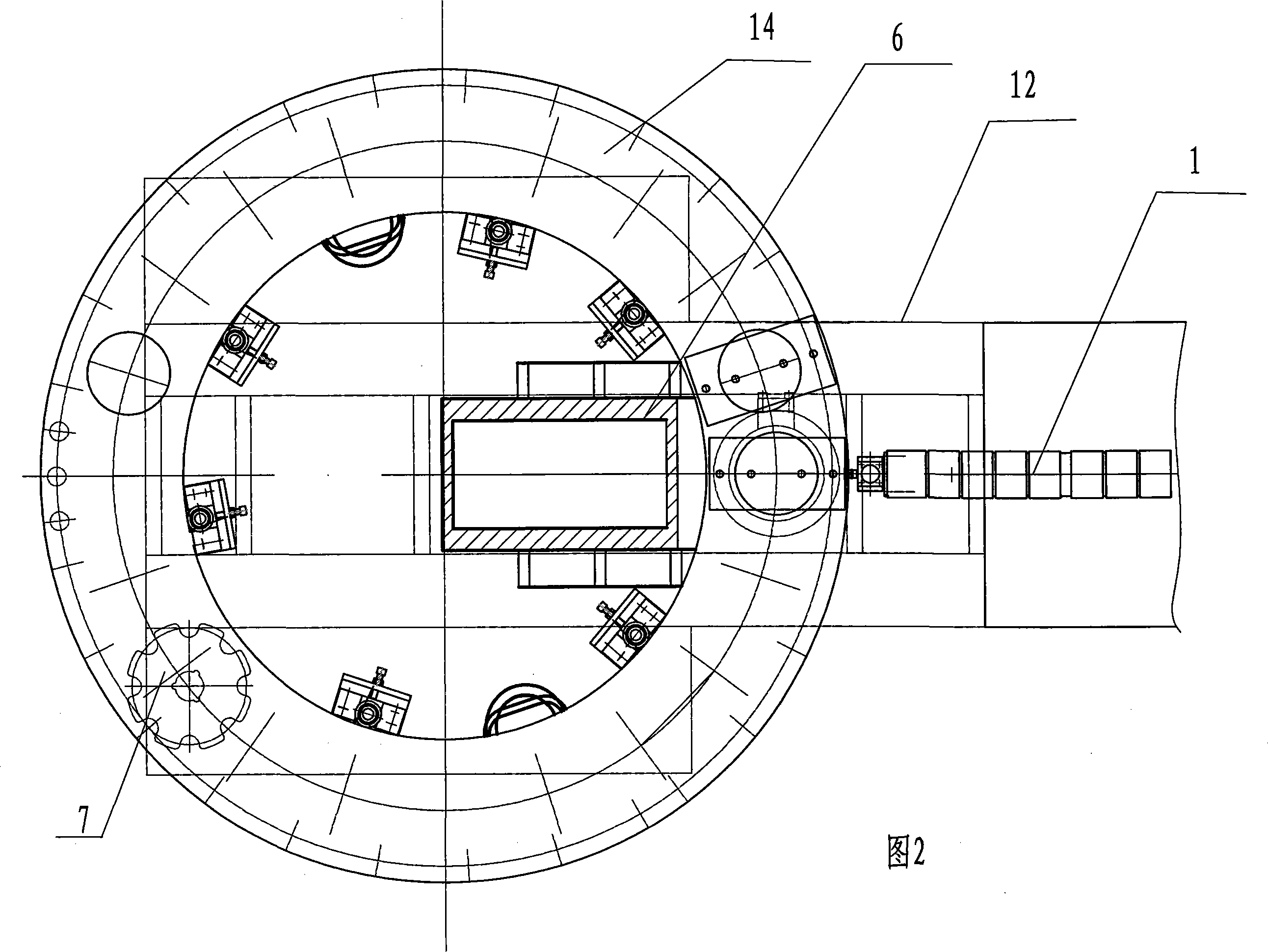

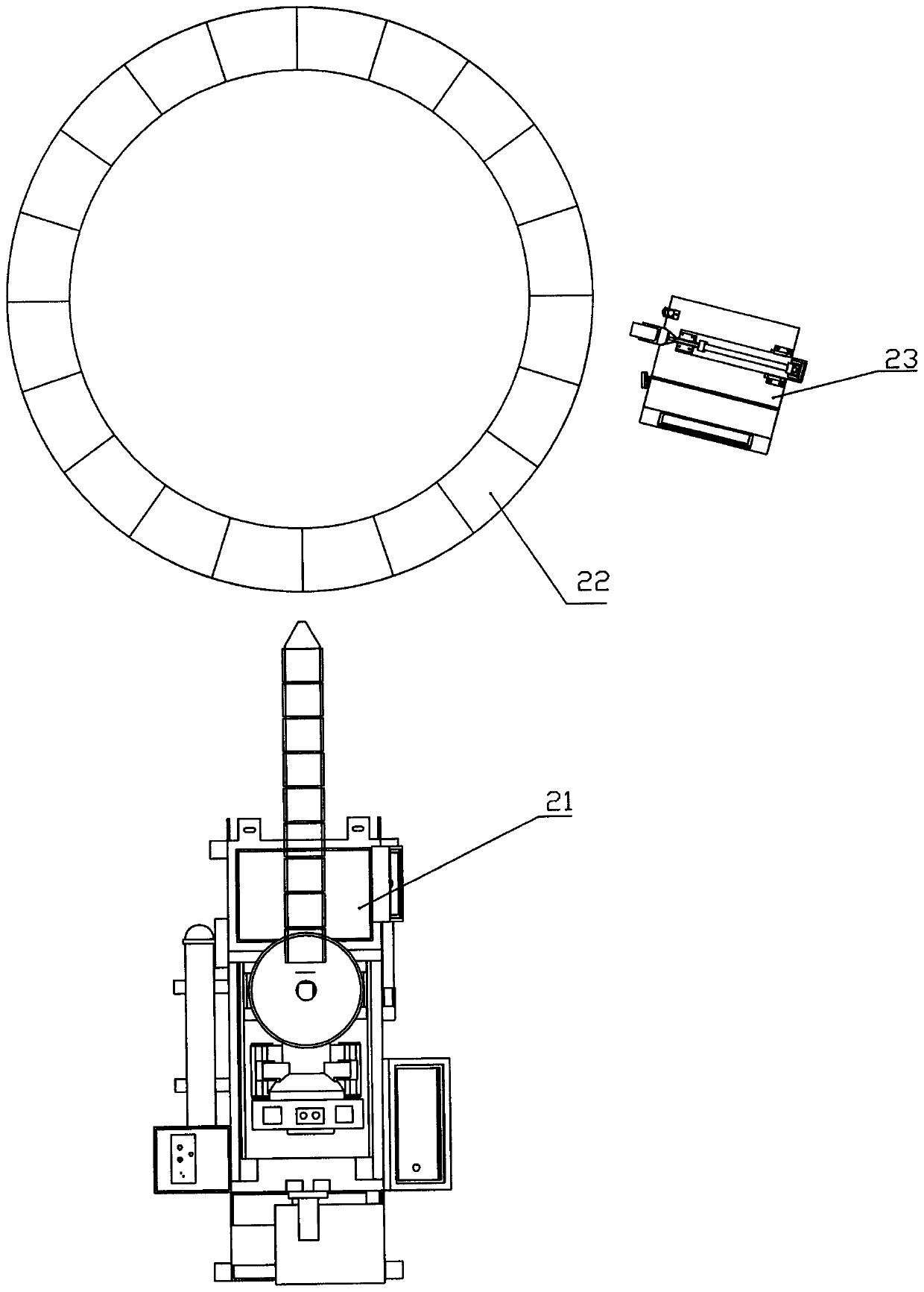

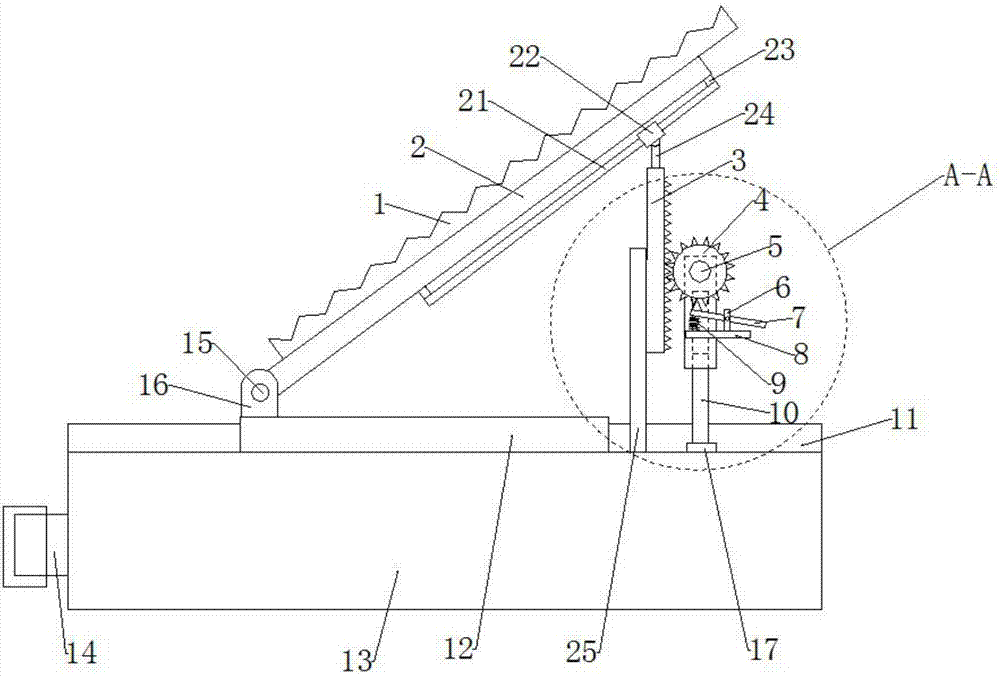

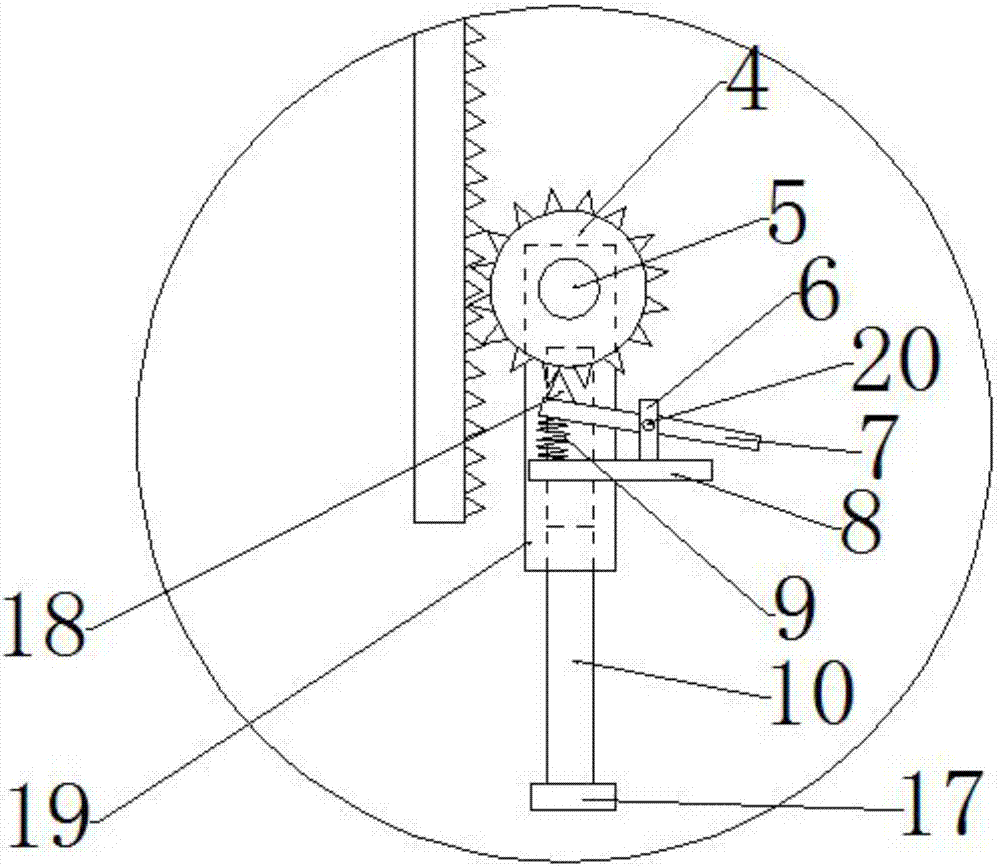

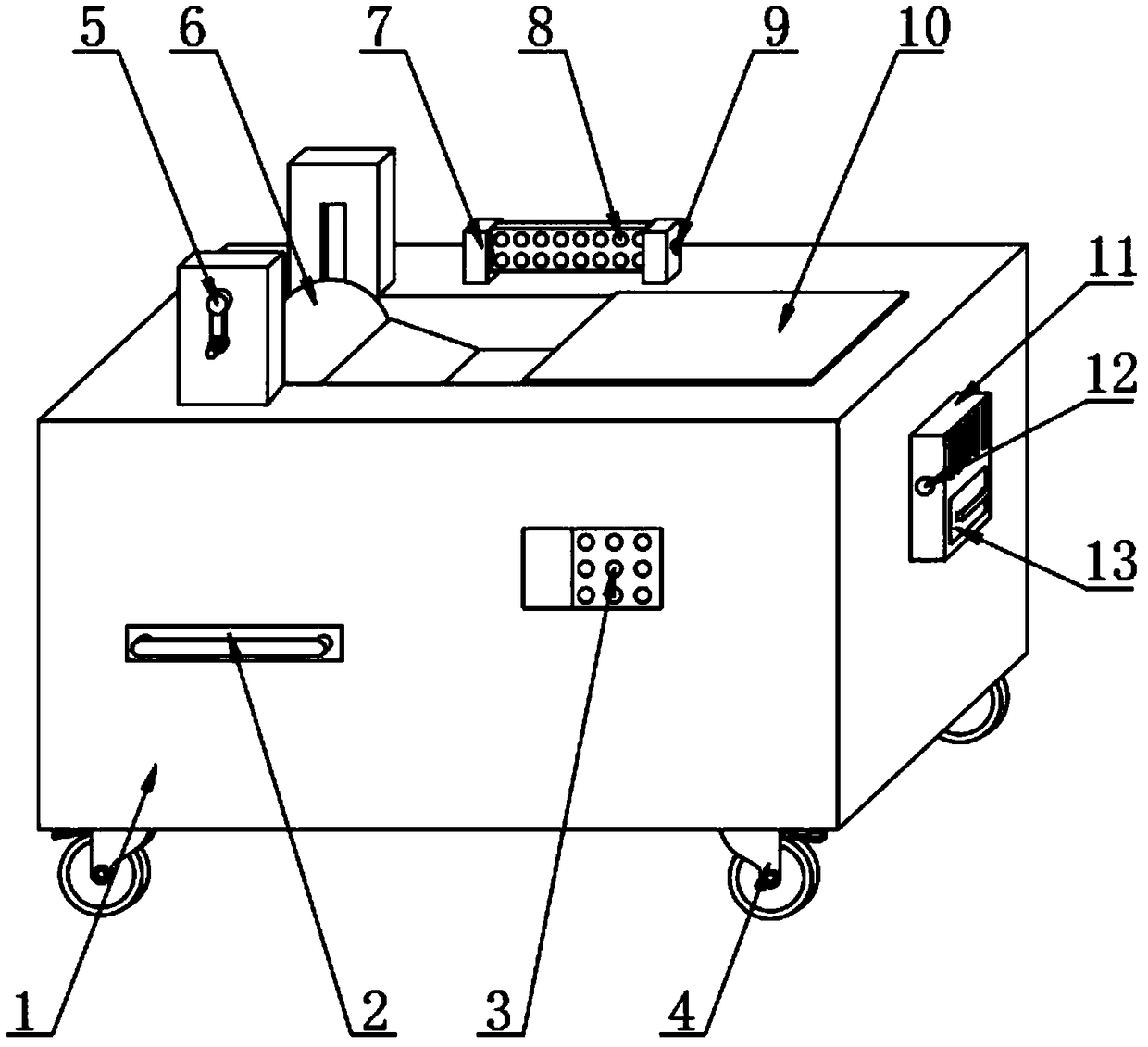

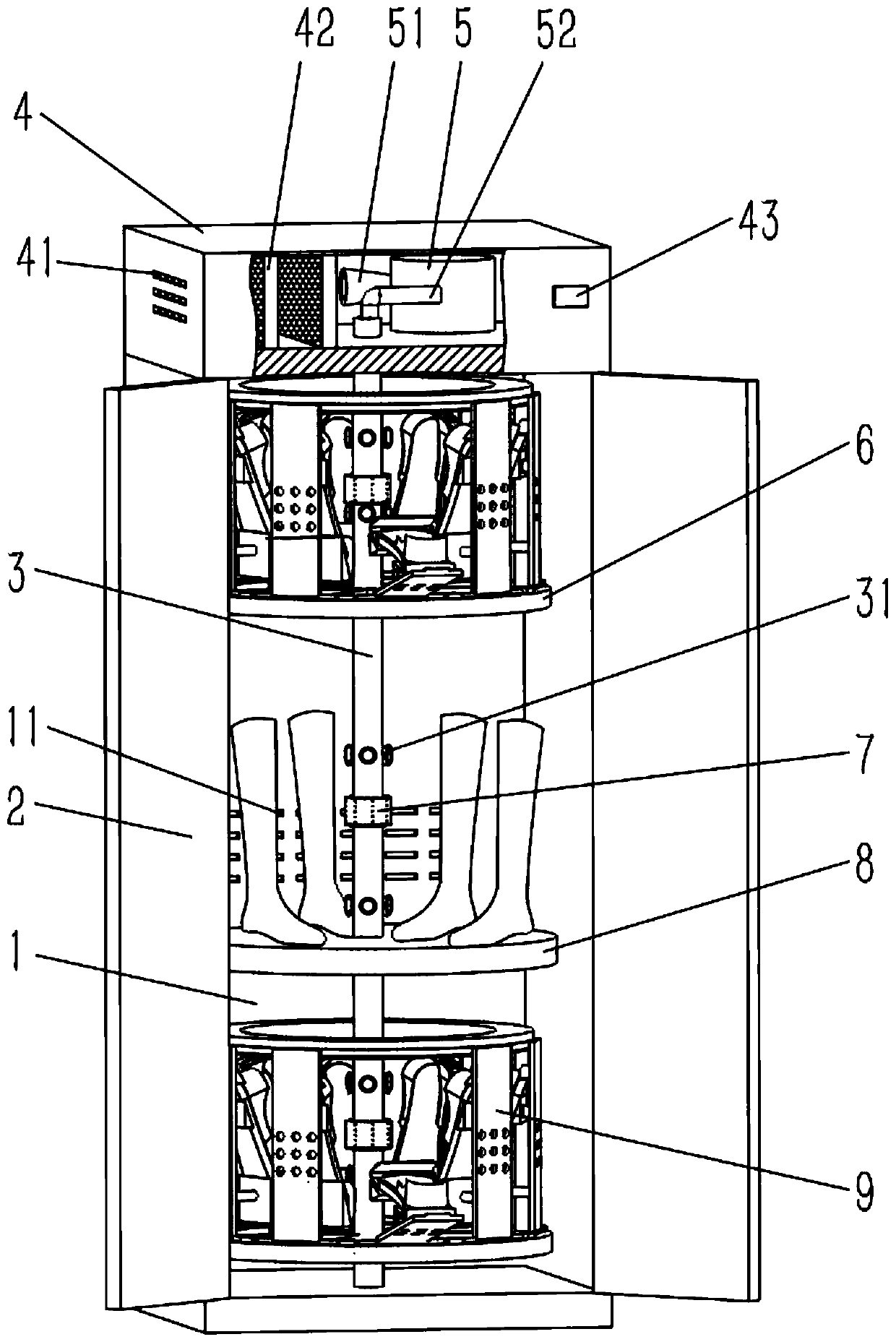

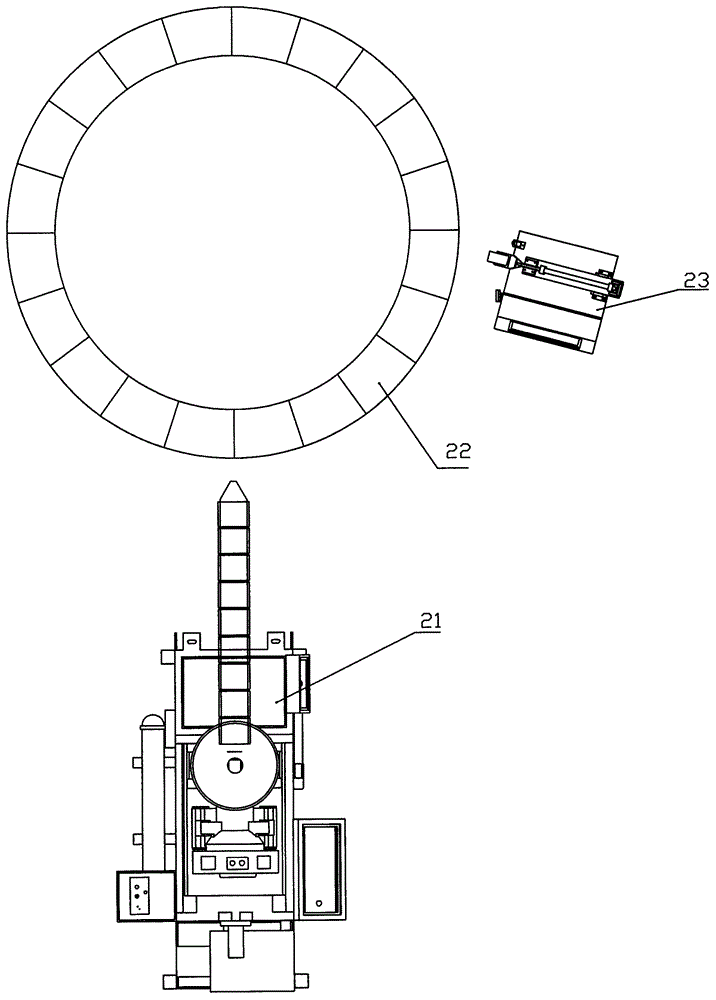

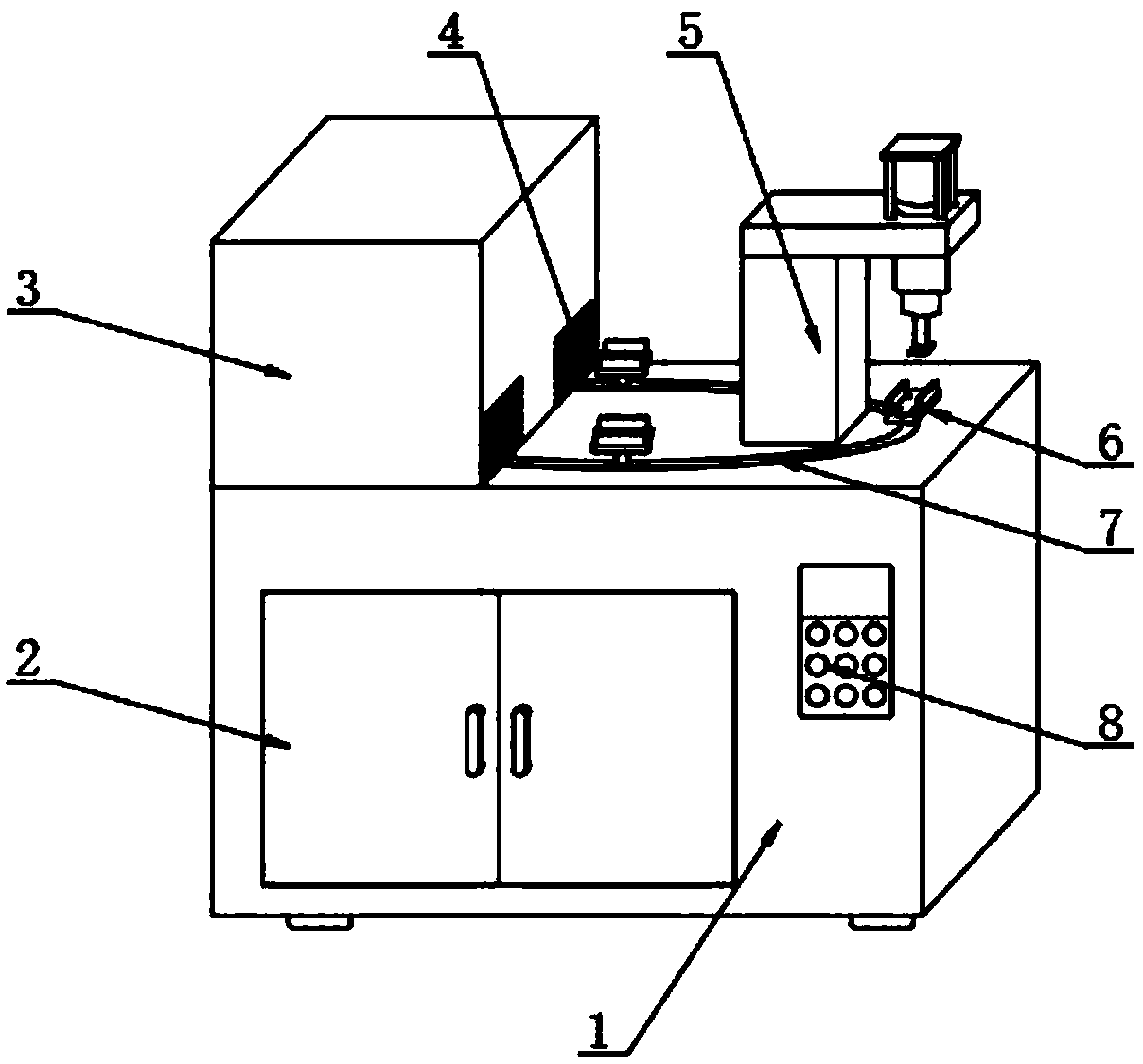

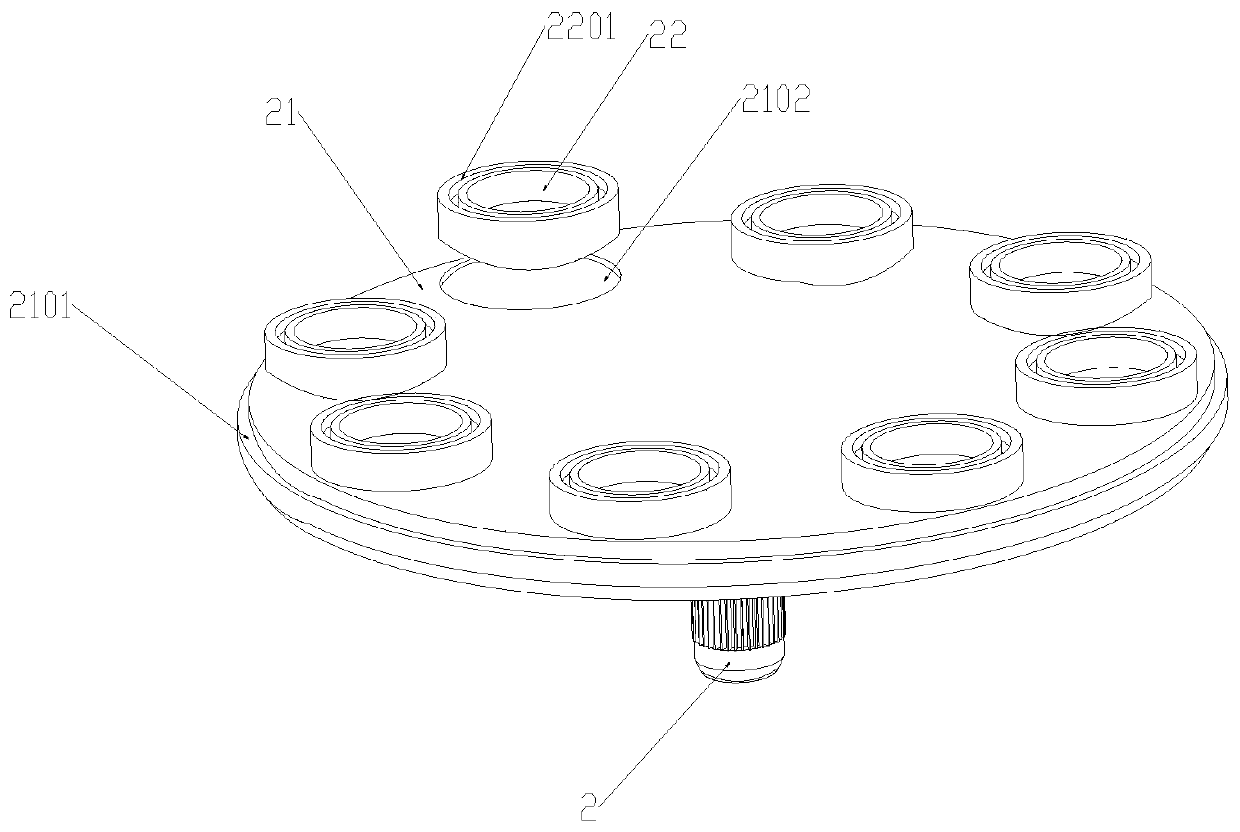

Rotary type full-automatic shoe molding machine

ActiveCN104175587AReduce labor intensityImprove work efficiencyDomestic footwearMolding machineManipulator

The invention discloses a rotary type full-automatic shoe molding machine which comprises a plastic injection mechanism (21) and a rotating disc type plastic shoe sole molding mechanism (22). A full-automatic shoe mold manipulator device (23) is arranged at the side of the rotating disc type plastic shoe sole molding mechanism and comprises a stand (9); mould opening cylinders (4) are arranged in the middle of the stand and are connected with mould opening heads (20); a material head boosting cylinder (6) is also arranged in the middle of the stand and is connected with a material head loosening and tightening piece (7); a material head lifting cylinder (8) is arranged under the material head boosting cylinder; a lifting cylinder (1) is arranged at the upper part of the stand; a mould lifting boosting cylinder (2) is arranged above the lifting cylinder and is connected with a support wheel (3). The rotary type full-automatic shoe molding machine can be operated by only one operator, the labor intensity is low, the working efficiency is increased, the production cost is lowered, and the potential safety hazard of operation is eliminated.

Owner:瑞安市兴中实业有限公司

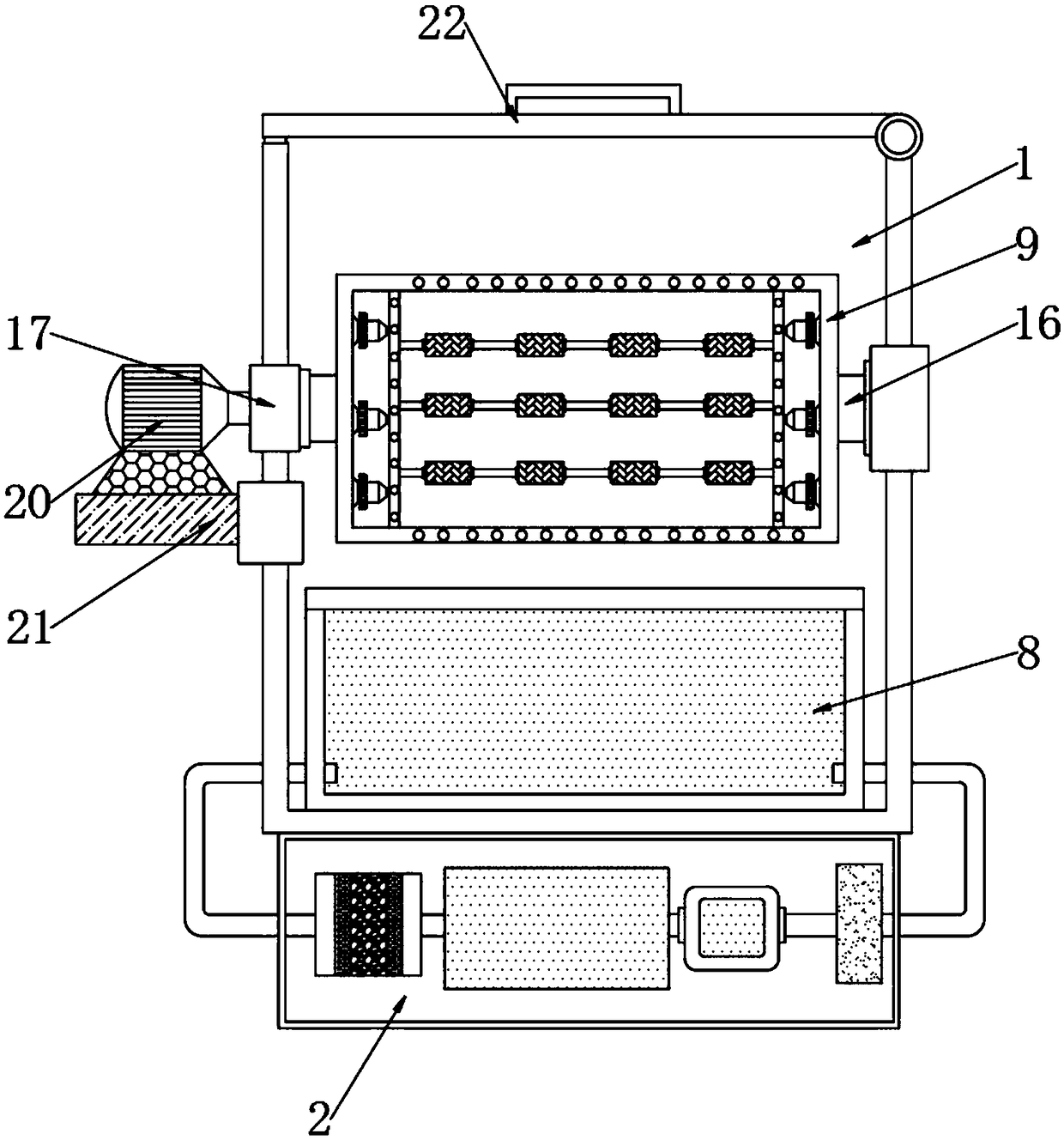

Pre-delivery cleaning device for producing plastic shoes

InactiveCN109176999AScientific and reasonable structureEasy to useCleaning using toolsCleaning using liquidsWater sourceWater resources

The invention discloses pre-delivery cleaning device for producing plastic shoes. The pre-delivery cleaning device comprises a cleaning device body, a water circulating tank, a rotating cleaning basket and sliding blocks, wherein the water circulating tank is mounted at the lower end of the cleaning device body, the rotating cleaning basket is mounted at the upper end of the water circulating tank, and the sliding blocks are mounted on two sides of the rotating cleaning basket. The pre-delivery cleaning device is scientific and reasonable in structure and safe and convenient to use; the pre-delivery cleaning device is connected with a soaking tank through a circulating connecting water pipe, so that a water source can be conveniently supplied to the soaking tank, the sewage in the soakingtank is conveniently collected, the water flow circulation is realized, and the water resource is saved; by arranging the rotating cleaning basket, soaked plastic shoes can be further conveniently cleaned by virtue of the effect of spray heads on two sides can be conveniently rubbed and cleaned through the effect of a sponge column, so that the cleaning effect is improved; and by arranging the sliding blocks, the vibration pressure caused the sliding blocks in the rotation process of a rotating shaft can be absorbed by virtue of the effects of an inner buffer plate and a damping spring, so that the stability of the device is improved.

Owner:合肥五凡工程设计有限公司

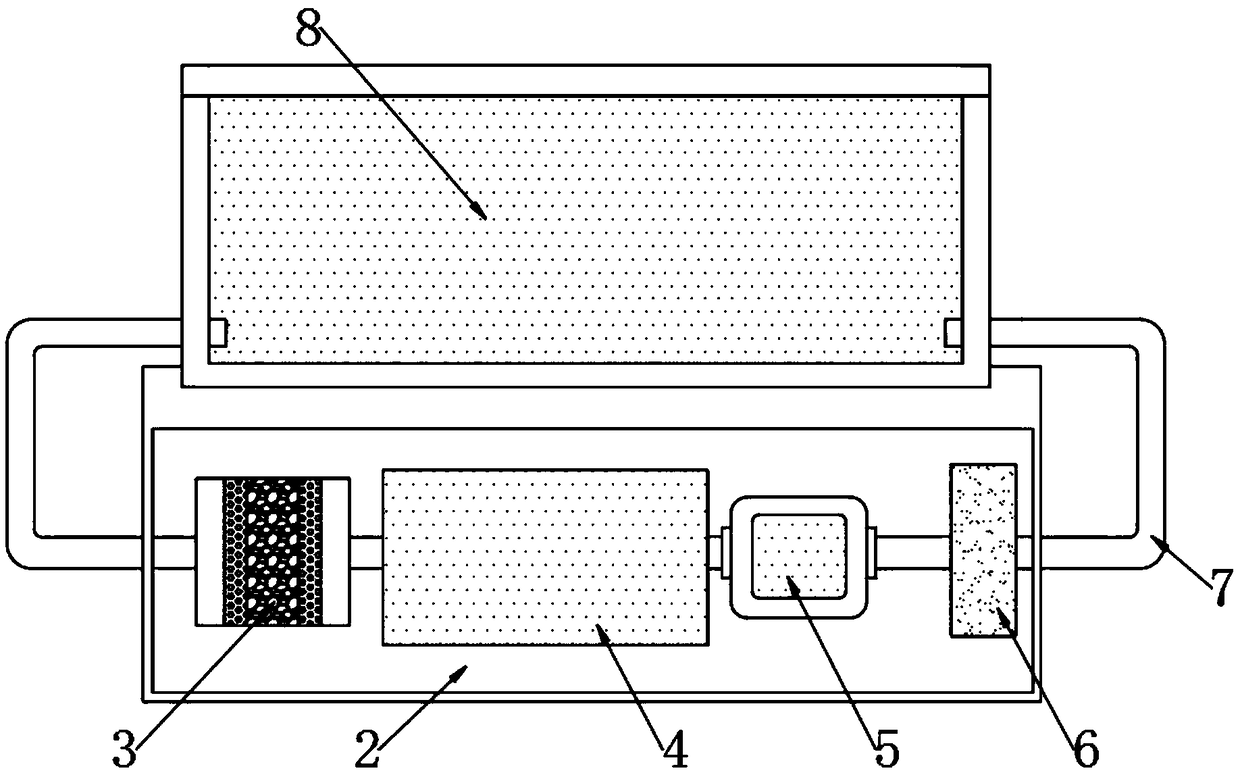

Plastic shoe drying rack with adjustable angle

InactiveCN106901582ARealize the angle adjustment functionAvoid breedingApparel holdersFootwear cleanersWater storage tankWater flow

The invention belongs to the technical field of plastic shoe racks, and in particular relates to an angle-adjustable plastic shoe drying rack. The top of the water storage tank is provided with a groove, and the bottom of the base is fixedly arranged on the bottom wall of the groove. The bottom wall in the groove is provided with a plurality of water leakage holes communicating with the interior of the water storage tank, and a slide bar is provided below the shoe drying pallet frame, and the two ends of the slide bar pass through the support block and the shoe drying support respectively. The bottom wall of the plate frame is fixedly connected, a slide block is slidably sleeved on the slide bar, and a fixed bar is hinged at the bottom of the slide block. The angle adjustment mechanism includes a rack, a fixed plate, and a limit rod. The rack The top of the shoe is connected with the bottom of the fixed rod. The angle-adjustable plastic shoe rack can not only adjust the angle of the shoes according to the angle of the sun, so that the sun can shine directly into the toe position of the shoes, which can dry quickly, but also can Store the water that flows out of the shoes, preventing the water from flowing out randomly, making the floor and interior damp and breeding bacteria.

Owner:天津市金广众包装制品有限公司

Automatic shoe over machine

The invention discloses an automatic shoe cover machine, which comprises a shoe cover and an actuating device arranged for controlling the open and close of the shoe cover. The shoe cover is provided with a circle of skirt edge on the rim of the sole; an elastic cord is penetrated through the edge of the skirt edge so as to form a shape of bag; a plurality of magnets are inlayed at an interval along the edge of the skirt edge; the actuating device arranged for controlling the open and close of the shoe cover is provided with a box having an opening; electromagnets which are used for absorbing the magnets on the shoe cover are arranged on the periphery of box; a control circuit which is used for controlling the switch-on / off of the electromagnet is arranged on the actuating device; and the electromagnet is electrically connected with the control circuit. The shoe cover is arranged in the actuating device in order to open the shoe cover by absorbing the magnets on the periphery of the shoe cover with the electromagnet so as to take off or take on the shoe cover without manual operation. The machine of the invention has the advantage of sanitation and convenience. The shoe cover is made of cloth, is washable and reusable and is more environment-friendly than the past plastic shoe cover.

Owner:吴善勇

Shoe sole grinding device for plastic shoe production

InactiveCN108936967AScientific and reasonable structureEasy to useShoemaking devicesGrinding machinesSlagEngineering

The invention discloses a shoe sole grinding device for plastic shoe production. The device comprises a box, a slag storage bin, a lamp panel, a dust collection box, a groove and a draft fan; the groove is formed in the top of the box, the draft fan is embedded into one side of the groove, the slag storage bin is embedded in one side of the box, the dust collection box is connected to the other side of the box, and the lamp panel is installed on one side of the groove. The device is scientific and reasonable in structure and safe and convenient to use; by means of running of the draft fan, dust in air can be sucked into an air duct; by means of a filter screen in the dust collection box, the dust in the air can be filtered; by rotating an adjusting knob, dust accumulated on the filter screen can be scraped, and residual dust in the air is cleaned away conveniently; by shaking the crank handle, before the device is used, the height of a grinding wheel can be adjusted; after the device is finished using, the grinding wheel can be lowered into the box; by means of a cover plate, the grinding wheel is stored and protected.

Owner:巩春艳

Plastic shoe cabinet

InactiveCN111012067AImprove ventilationKeep dryWardrobesDispersed particle filtrationStructural engineeringPlastic shoes

The invention discloses a plastic shoe cabinet that comprises a cabinet body and a cabinet door; a box body is fixed at the top of the cabinet body; a hollow fixed rod with the top end penetrating through the bottom wall of the box body is fixedly connected between the inner walls of the upper side and the lower side of the cabinet body; two first supporting plates are rotatably connected to the fixed rod; the outer wall of the fixed rod between the two first supporting plates is sleeved with second supporting plates; placing assemblies used for placing shoes are arranged on the two second supporting plates. An exhaust fan is mounted on the bottom wall of the box body; the air outlet end of the exhaust fan is connected with an exhaust guide pipe communicating with the interior of the fixedrod; the air inlet end of the exhaust fan is connected with an air inlet guide pipe, a plurality of nozzles are fixed to the outer wall of the fixed rod, a power switch electrically connected with the exhaust fan is arranged on the outer wall of the front side of the box body, the exhaust fan is electrically connected with an external power source, and the shoe cabinet has the beneficial effectsthat shoes can be conveniently stored and taken out, and drying and ventilating of the shoes are facilitated.

Owner:特固(江苏)塑料制品有限公司

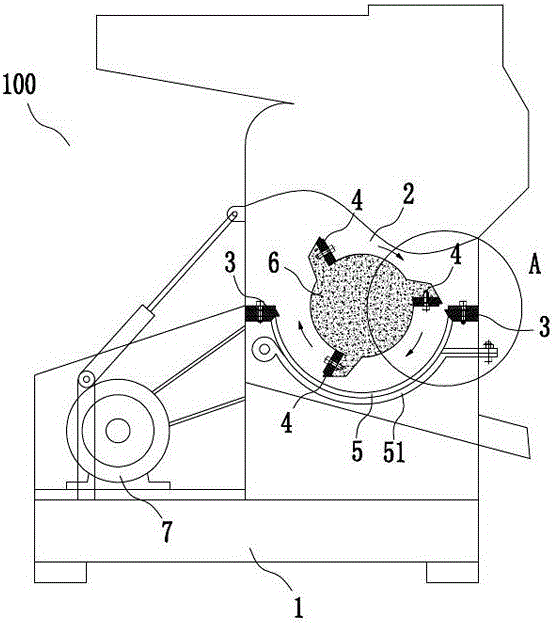

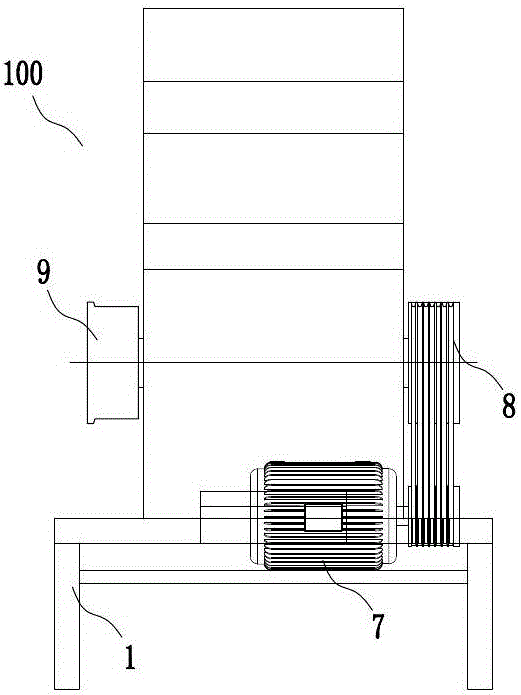

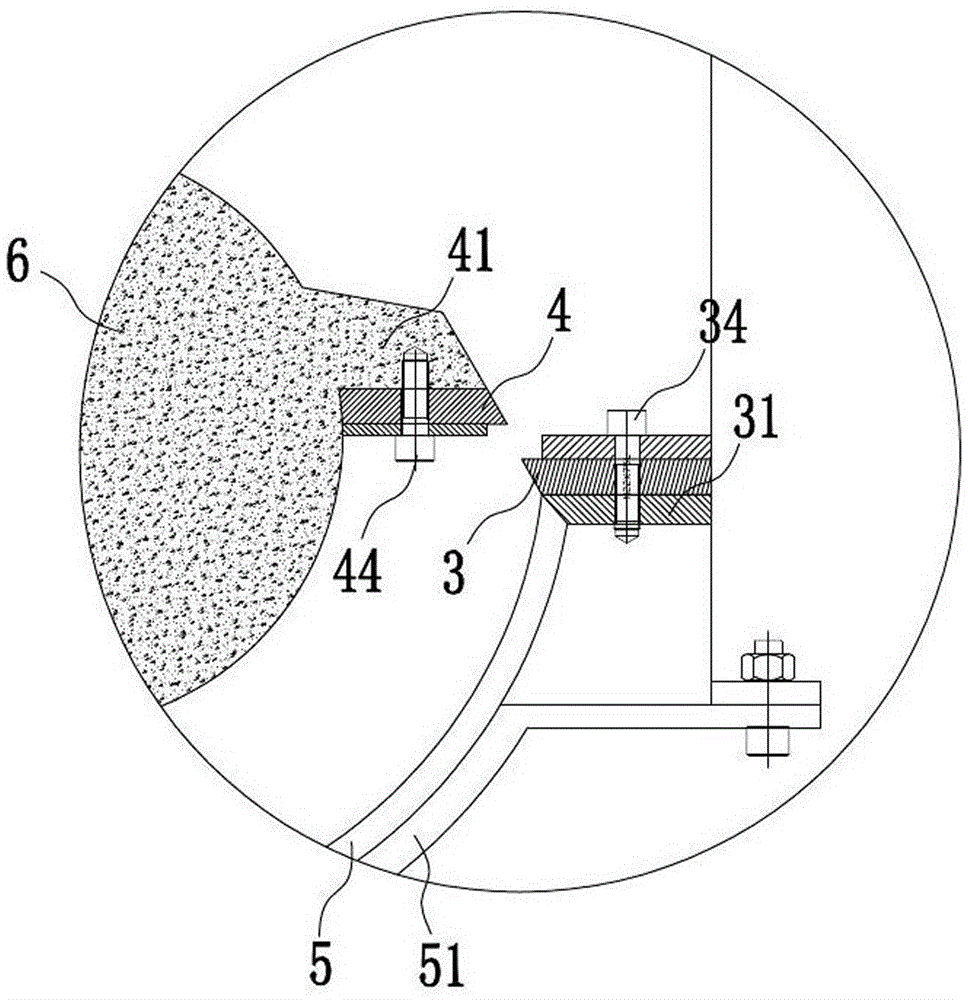

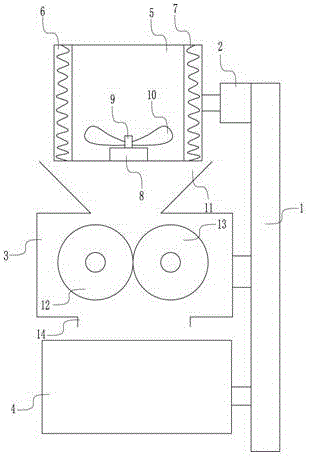

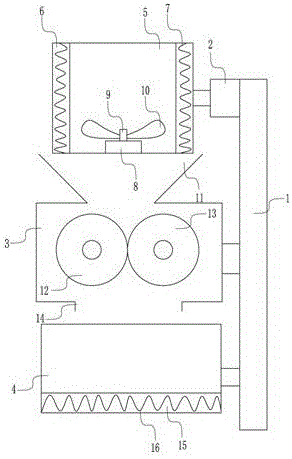

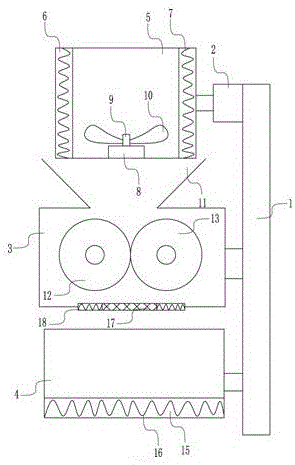

Plastic shoe tree crusher, shoe tree crushing production line and crushing method

ActiveCN105690601AIncrease crushing outputReduce laborPlastic recyclingGrain treatmentsProduction lineEngineering

The invention discloses a plastic shoe tree crusher, a shoe tree crushing production line and a crushing method. The plastic shoe tree crusher comprises a rack, a crushing cavity, fixed cutters, movable cutters, a discharging screen, a movable cutter rolling disc and a motor. The movable cutter rolling disc is arranged in the crushing cavity. A plurality of rows of movable cutter grooves are formed in the movable cutter rolling disc in the radial direction. Each row of movable cutter grooves are provided with a plurality of movable cutter bases distributed in a staggered manner. The movable cutters are fixedly arranged in the movable cutter bases, and the cutting edges of the movable cutters are higher than the outer surface of the movable cutter rolling disc. One fixed cutter base is arranged at the front end of the crushing cavity, one fixed cutter base is arranged at the rear end of the crushing cavity, the fixed cutters are fixedly arranged in the fixed cutter bases, and the cutting edges of the fixed cutters are higher than the inner surface of the crushing cavity. The motor is used for driving the movable cutter rolling disc to rotate, and the discharging screen is arranged at the lower end of the crushing cavity. In the movable cutter rolling disc rotating process, shoe tree crushing is caused due to gaps between the cutting edges of the movable cutters and the cutting edges of the fixed cutters, and crushed shoe tree materials pass through the discharging screen and then are output. According to the plastic shoe tree crusher, the shoe tree crushing production line and the crushing method, the crushing yield is high, the manual work is little, the crushing cost is low, and plastic shoe trees with metal can be directly crushed.

Owner:DONGGUAN JIANFA SHOE MATERIAL CO LTD

High-performance plastic shoe sole and preparation method thereof

The invention discloses a high-performance plastic shoe sole and belongs to the technical field of clothes materials. The high-performance plastic shoe sole is prepared from the following raw materials in parts by weight: 60 to 80 parts of PVC, 12 to 15 parts of calcium carbonate, 1 to 2 parts of epoxidized soybean oil, 0.5 to 1 part of citrate, 1 to 3 parts of tribasic lead sulfate, 1 to 2 parts of dibasic lead phosphite, 1.2 to 1.5 parts of barium stearate, 0.3 to 0.5 part of paraffin, 2 to 4 parts of foaming agent, 1.2 to 1.5 parts of pearl concentrate, 13 to 15 parts of chloroprene rubber, 1 to 2 parts of talcum powder, 0.4 to 0.8 part of ultraviolet light absorber, 3 to 4 parts of fire retardant and 5 to 10 parts of compatilizer. The invention further discloses a preparation method of the high-performance plastic shoe sole, and the high-performance plastic shoe sole disclosed by the invention has long service life, wear resistance and difficulty in swelling and broken phenomena.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

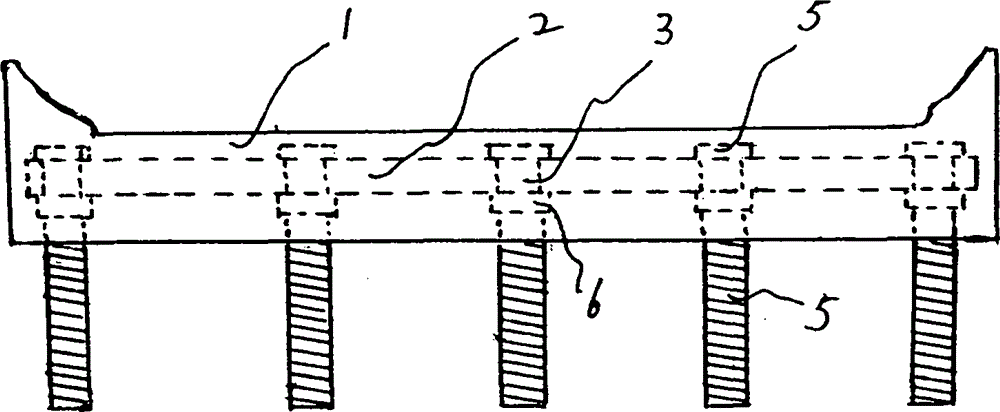

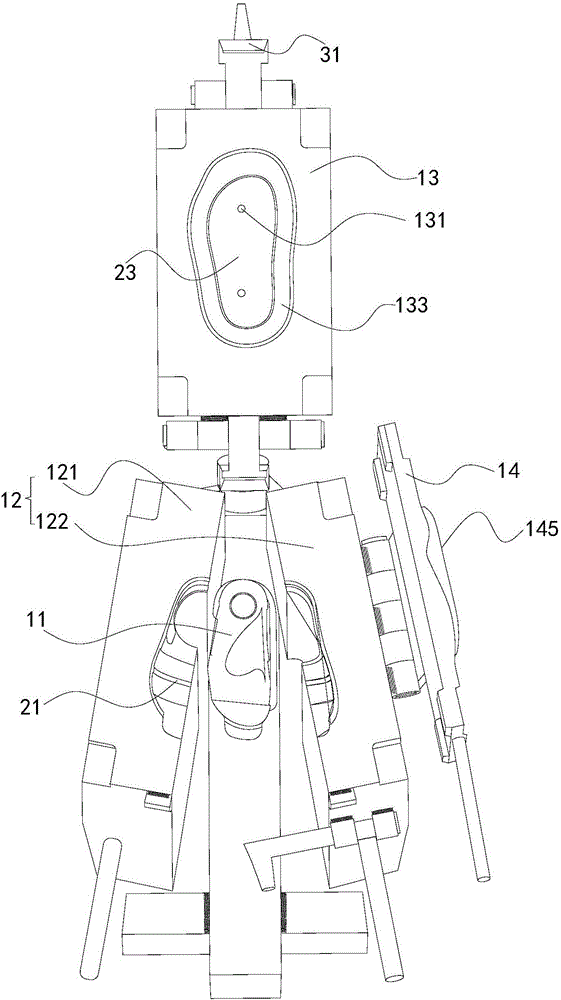

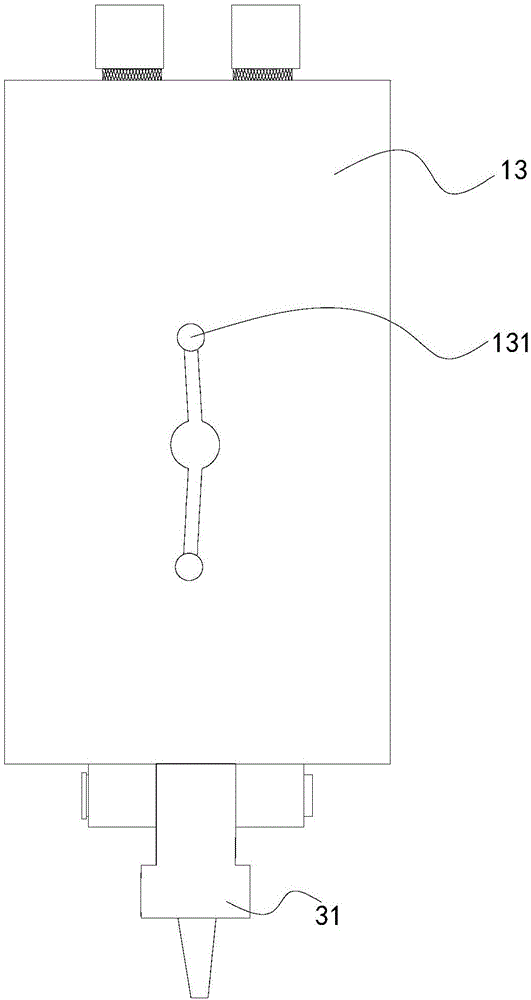

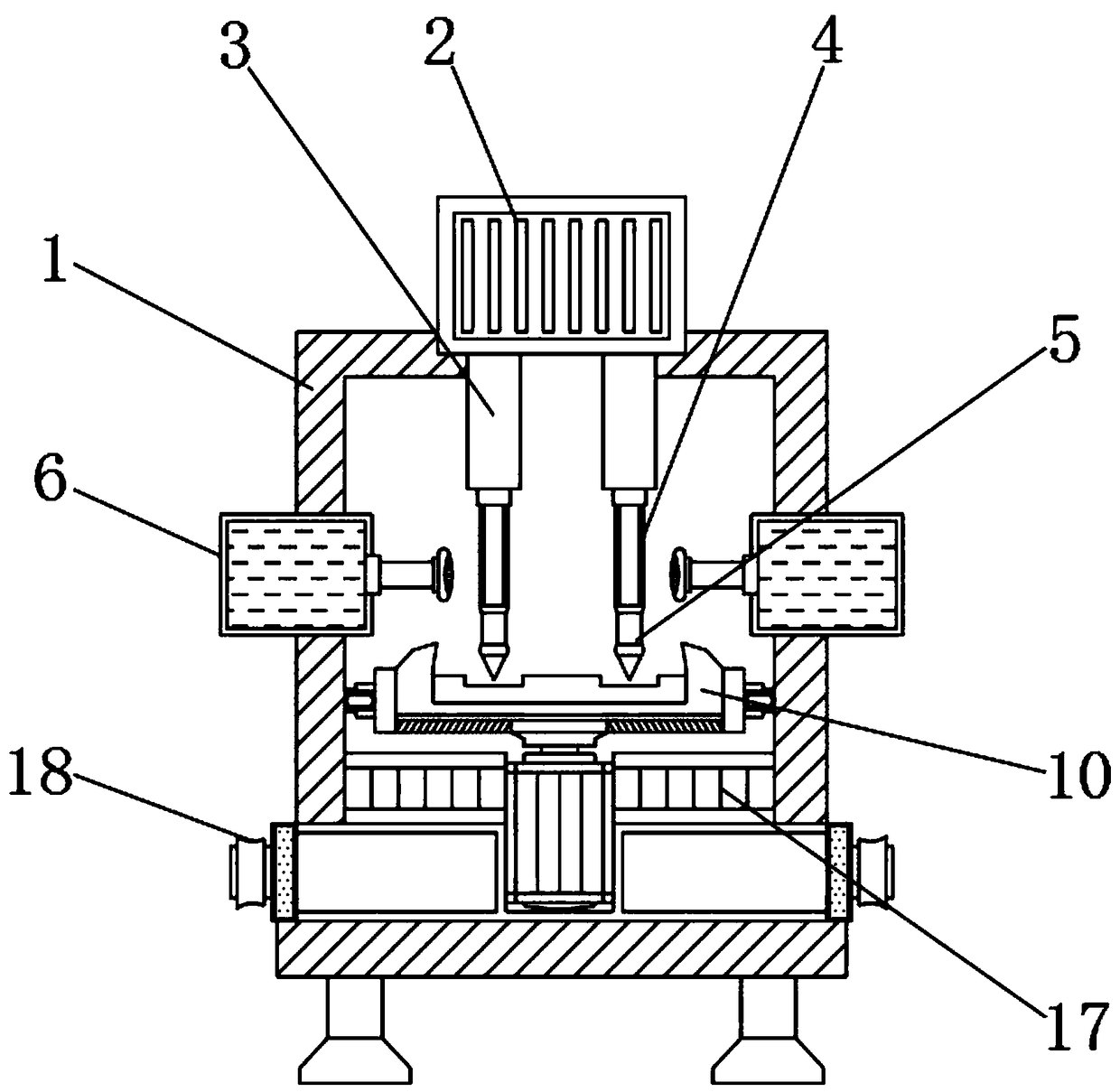

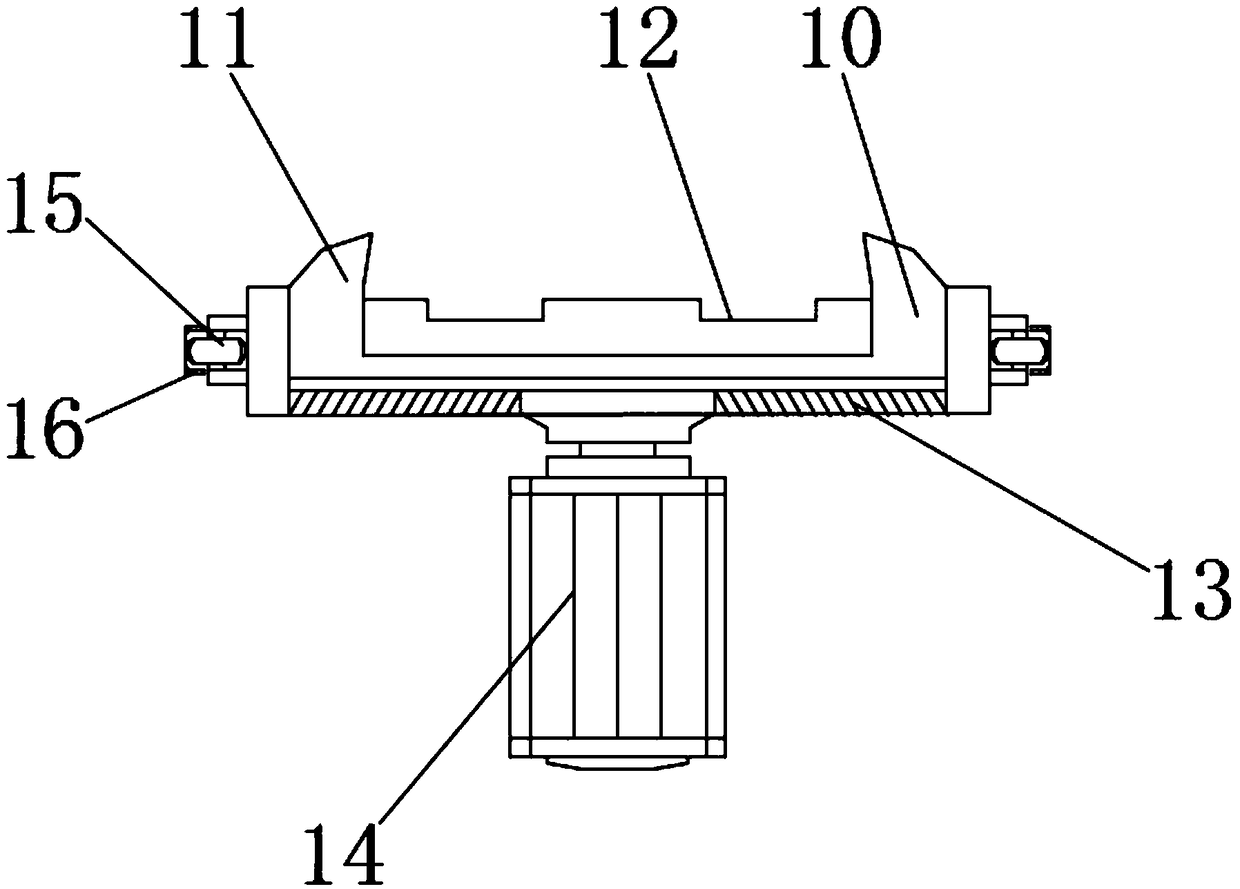

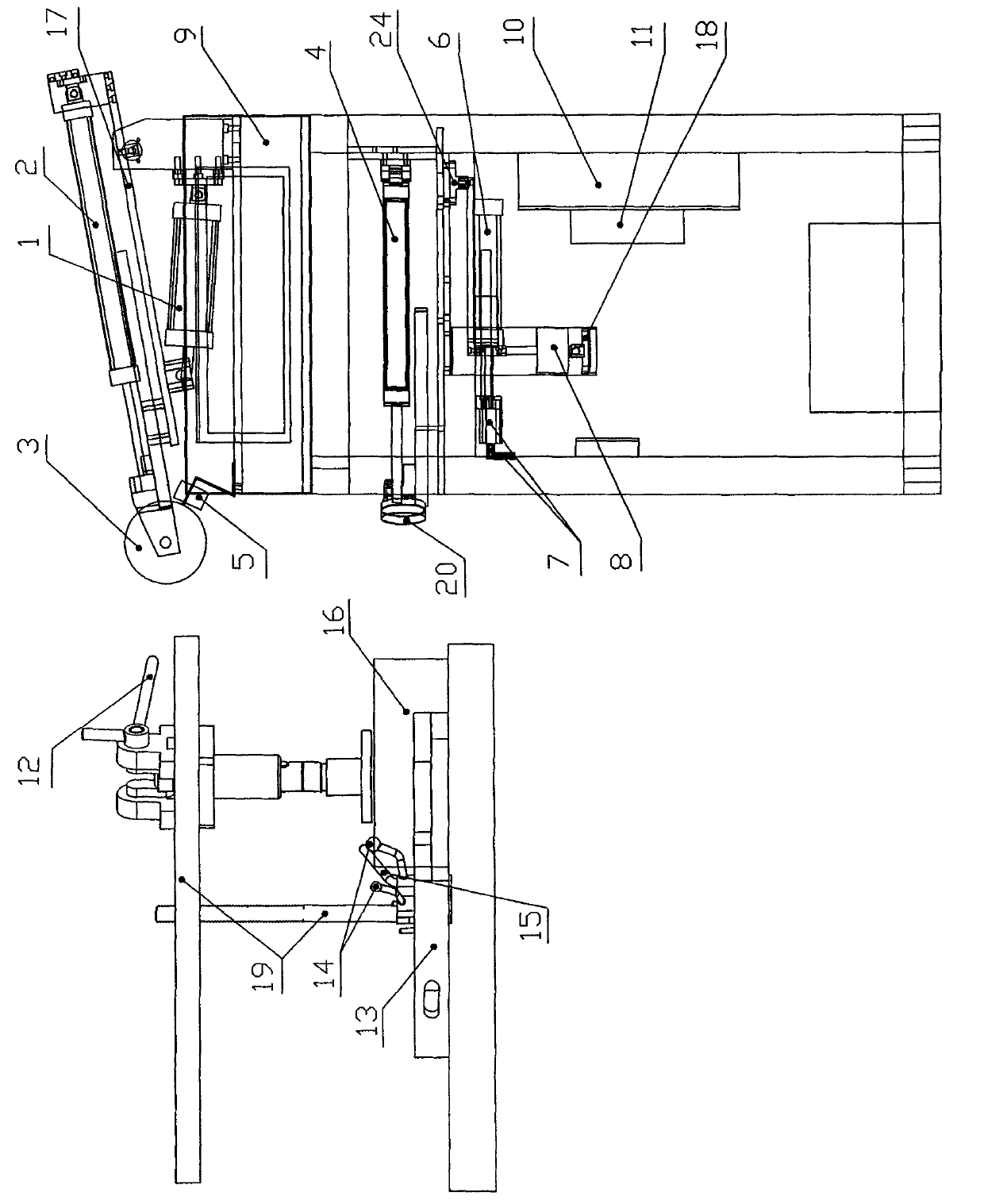

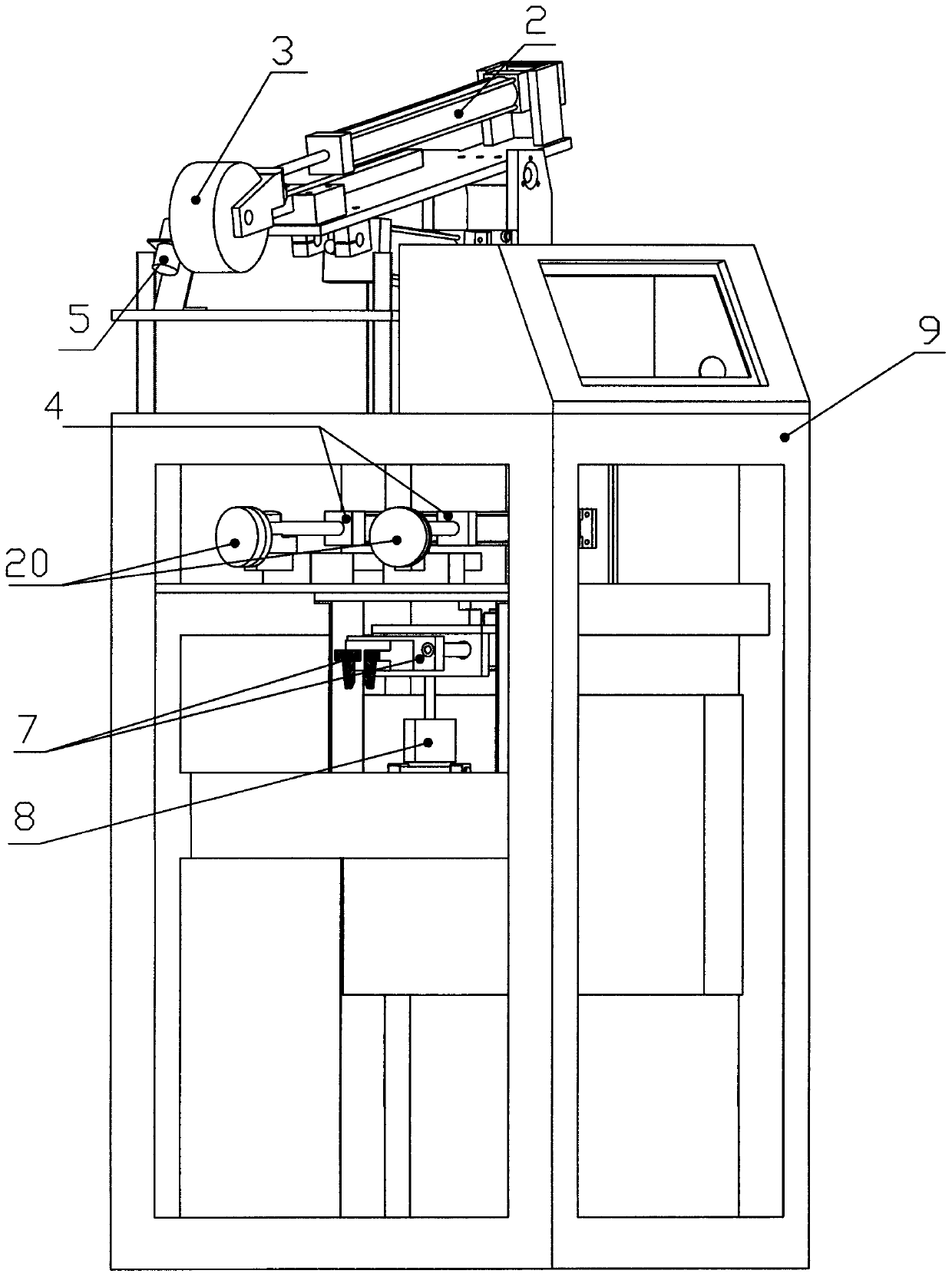

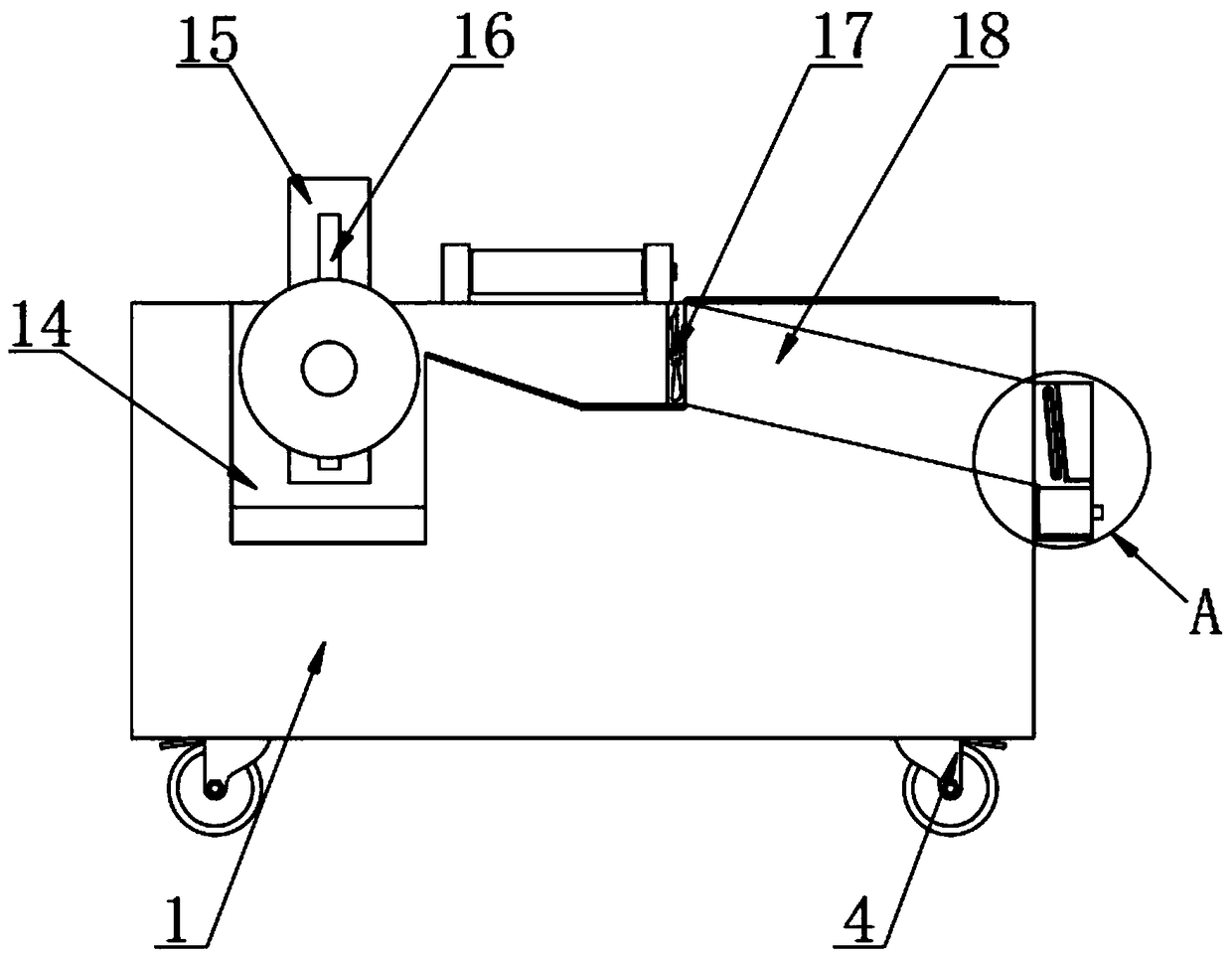

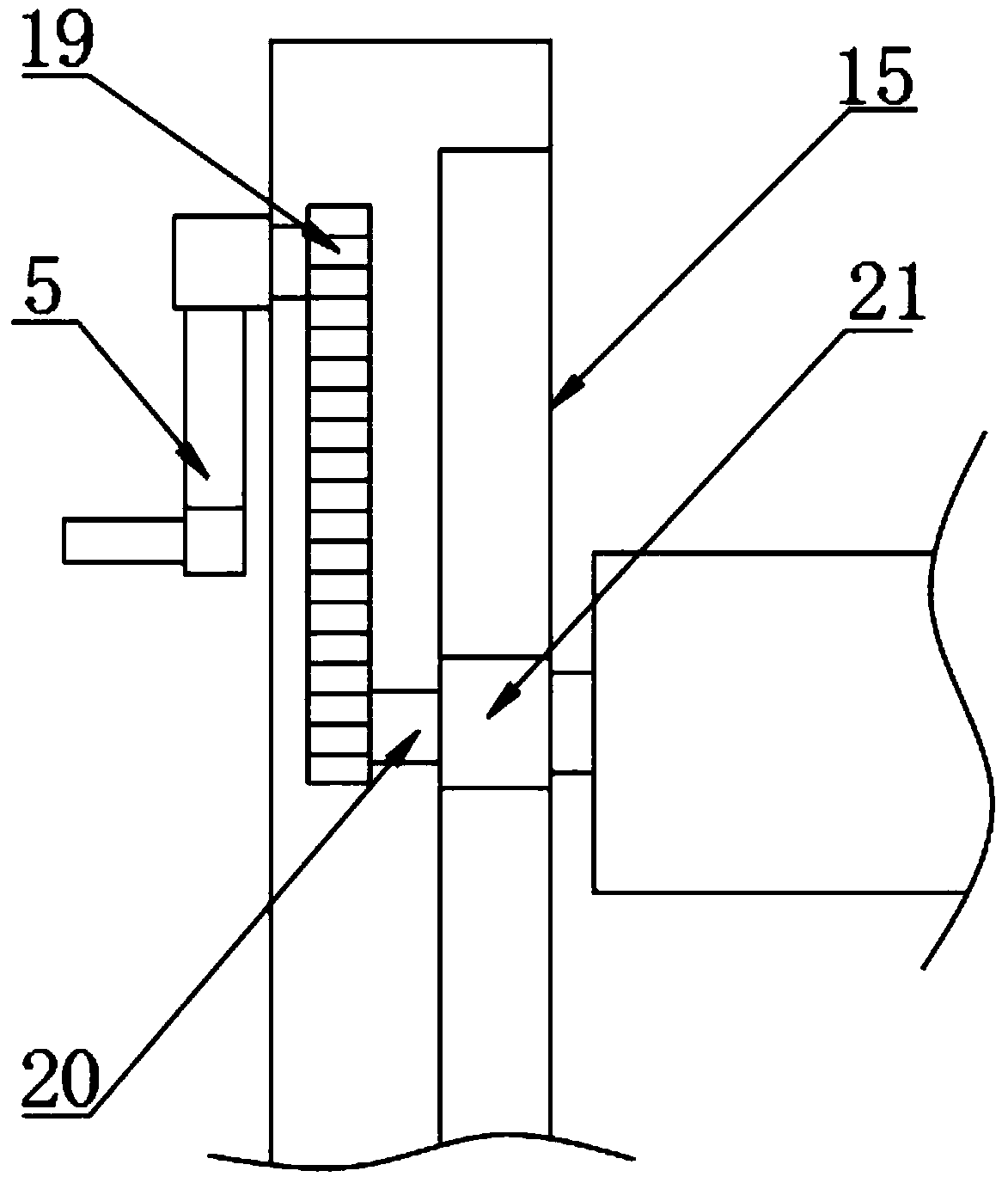

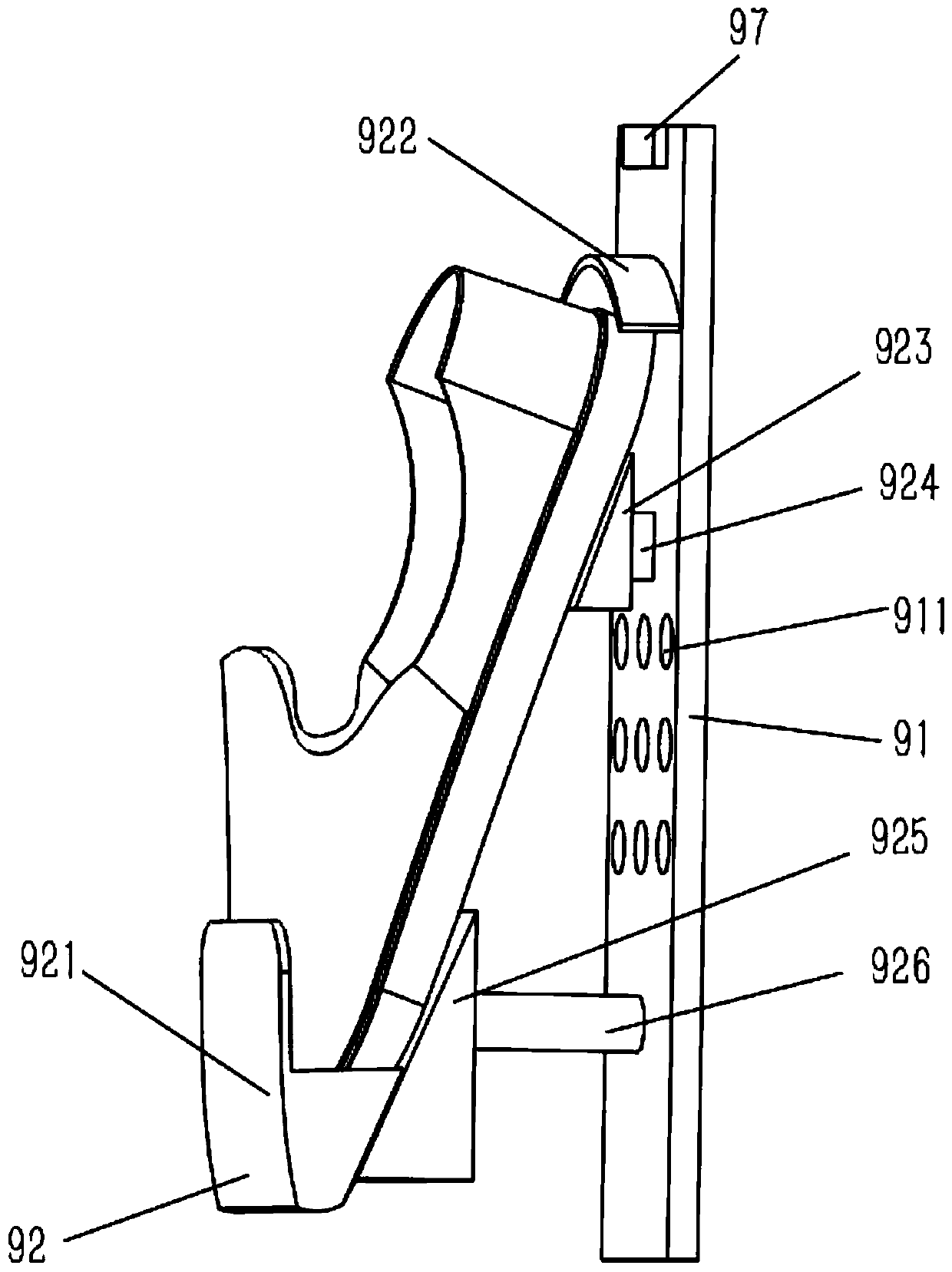

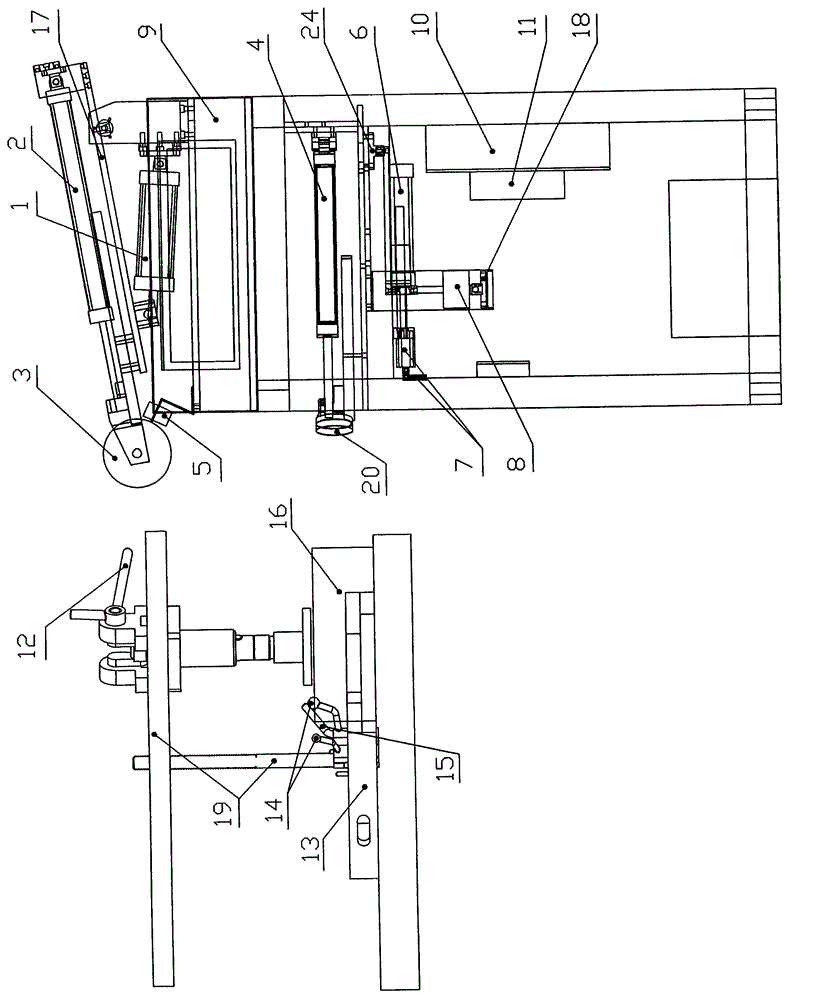

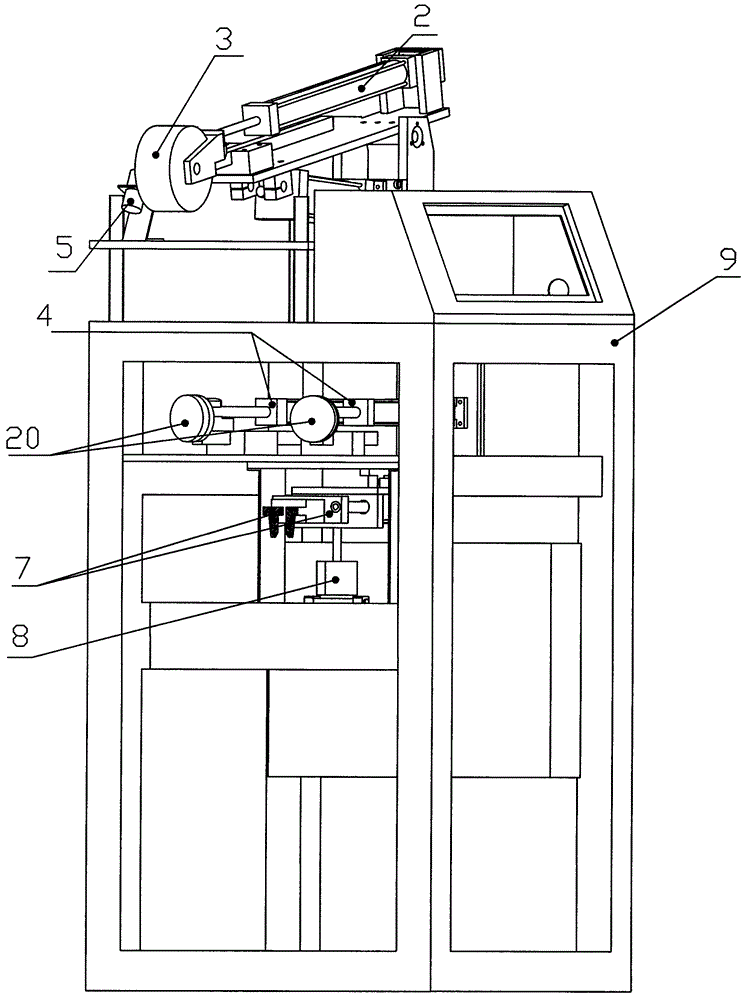

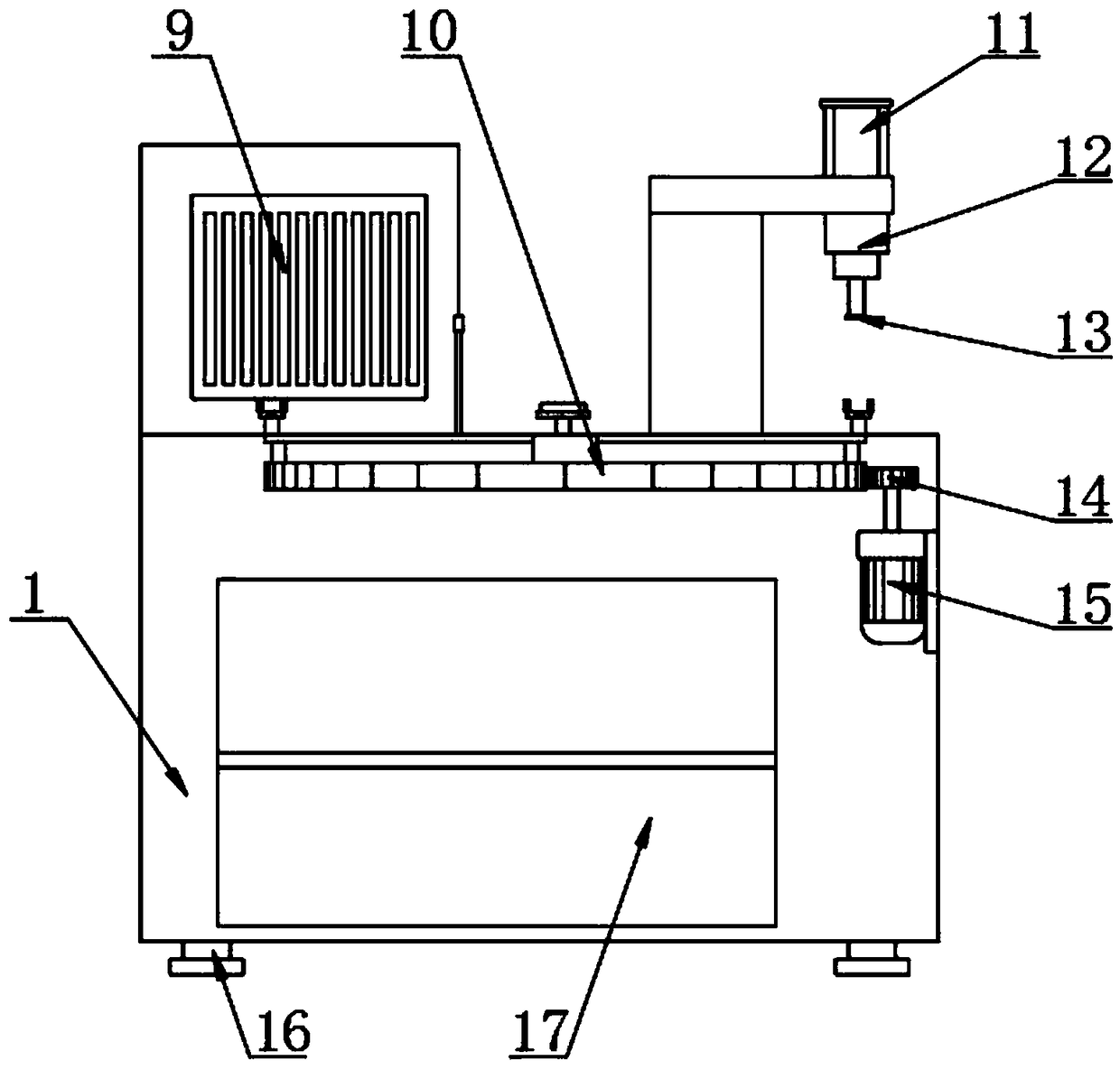

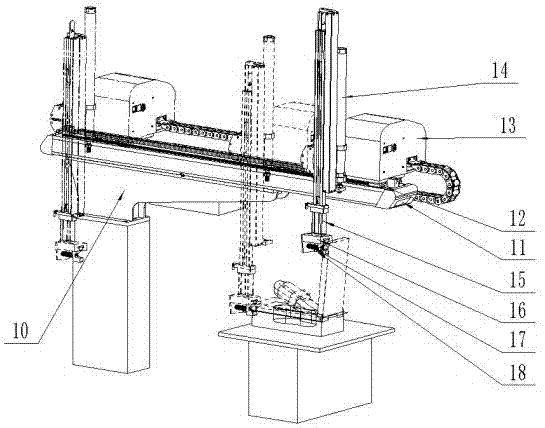

Full automatic shoe mold mechanical arm mechanism

The invention discloses a full automatic shoe mold mechanical arm mechanism which comprises a rack (9). A lifting air cylinder (1) is mounted on the upper portion of the rack, the lifting air cylinder is provided with a mold lifting propelling air cylinder (2) through a mold lifting propelling air cylinder seat (17), and the mold lifting propelling air cylinder is connected with a supporting roller (3). A mold opening air cylinder (4) is mounted in the middle of the rack and is connected with a mold opening head (20), a material head propelling air cylinder (6) is further mounted in the middle of the rack, the material head propelling air cylinder is connected with a material head loosening and tightening piece (7), and a material head lifting air cylinder (8) is arranged below the material head propelling air cylinder through a material head lifting air cylinder seat (18). The full automatic shoe mold mechanical arm mechanism is applied to plastic shoe forming machines, only one operator is needed, the labor intensity of the operator is small, the working efficiency is improved, production cost is lowered, and the potential safety hazard of operation is eliminated.

Owner:瑞安市兴中实业有限公司

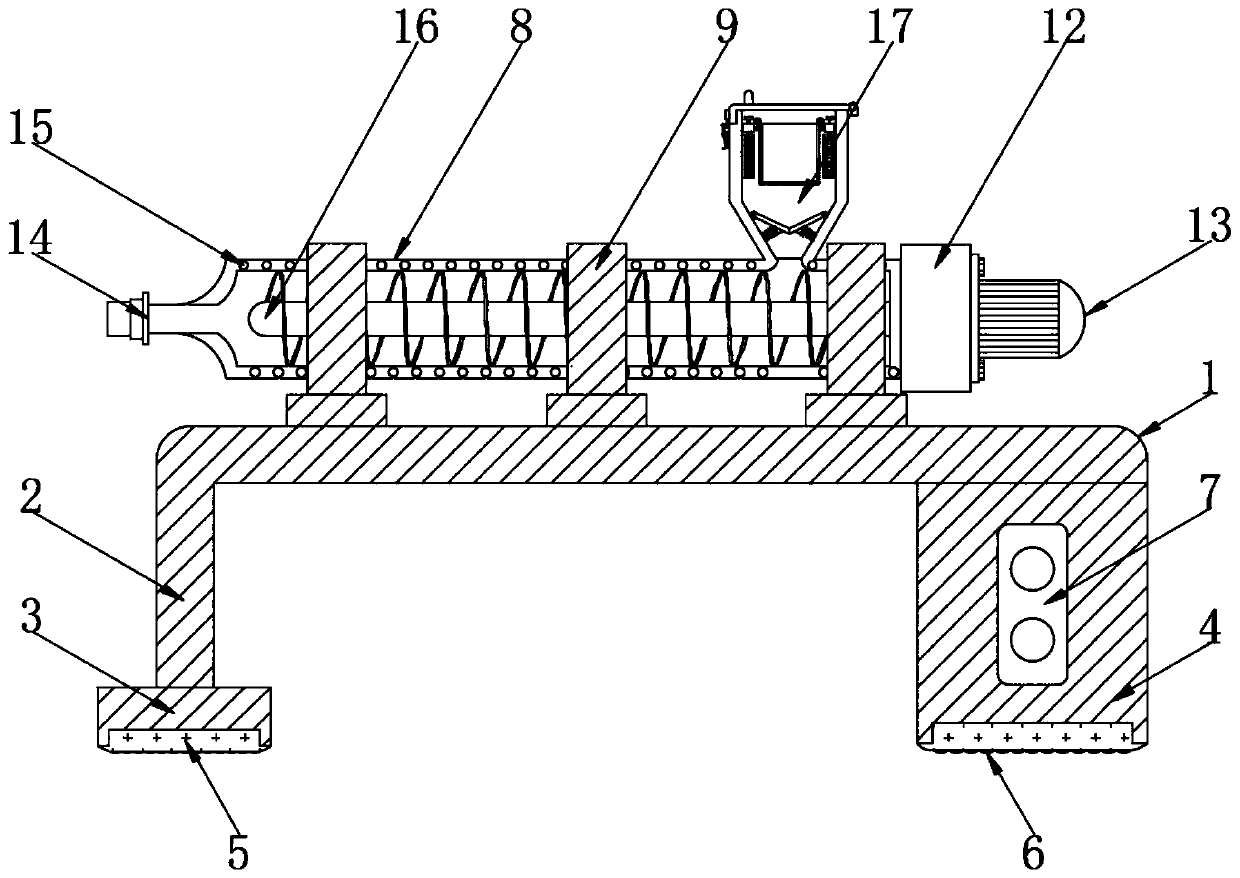

High-stability injection molding machine for plastic shoes

ActiveCN109177029AScientific and reasonable structureEasy to useDomestic articlesPower flowEngineering

The invention discloses a high-stability injection molding machine for plastic shoes. The injection molding machine comprises a feeding hole, electromagnets, sliding rods, magnets, a screening basketand screening holes, wherein the electromagnets are mounted on the inner wall in the feeding hole, the sliding rods are mounted at the top ends of the electromagnets and are externally sleeved with the magnets, a screening screen is fixedly mounted on one sides of the magnets through buckles, and the screening holes are formed in the bottom end and bottom of the screening screen. The injection molding machine is scientific and reasonable in structure and safe and convenient to use; by arranging the electromagnets, the sliding rods, the magnets, the screening basket and the screening holes, alternating current in the electromagnets is continuously changed so as to change the magnetism of the electromagnets constantly, the to-and-fro shaking of the screening basket is effectively realized through the cooperation with the magnets, and the automatic screening of the raw materials in the feeding process can be realized through the cooperation with the screening holes, so that the raw material screening time is saved, the working efficiency of the injection molding machine is improved, and the injection molding quality of the injection molding machine is improved.

Owner:揭阳市新华龙机械设备有限公司

Sweat-absorbing-and-deodorizing slippers and preparing technology thereof

InactiveCN107048573AImprove toughnessImprove breathabilityInsolesDomestic footwearFiberPlastic materials

The present invention proposes a sweat-absorbing and deodorant slippers and a preparation process thereof, comprising a plastic shoe body and a fiber lining, the plastic shoe body including a sole and a vamp, the upper surface of the sole and the lower surface of the vamp are fitted by Velcro. There is the fiber lining, the plastic shoe body is made of modified polyurethane material, and the fiber lining is modified blended fiber cloth. The slipper of the present invention adopts a two-layer structure, and the plastic shoe body and the fiber lining can be connected by Velcro. Tear and fit, easy to clean and replace. Compared with disposable slippers, it is safe and environmentally friendly, and can effectively reduce costs. In addition, the plastic shoe body made through a reasonable formula combination is comfortable, soft, strong and tough, antibacterial and wear-resistant, and with fiber The lining absorbs sweat, deodorizes, sterilizes, and has good air permeability, which improves the overall quality.

Owner:安徽爱舍家居制品有限公司

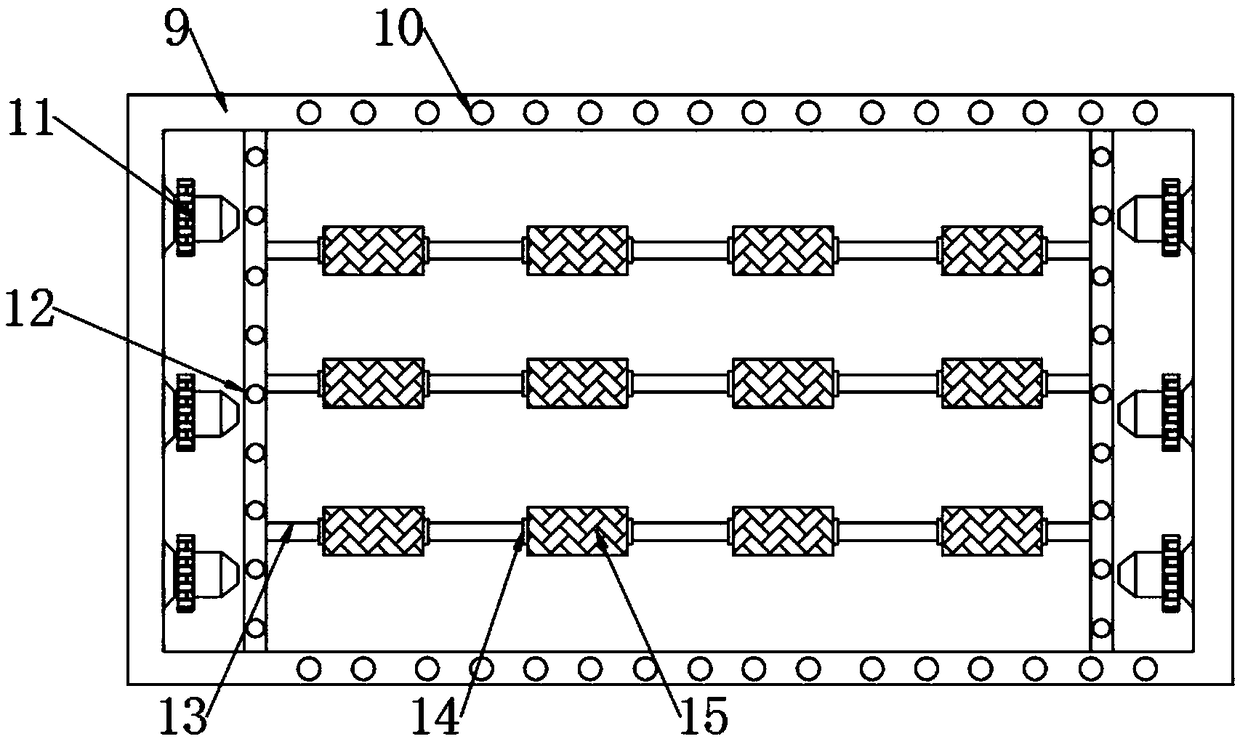

Softening and adhering device for production of plastic shoe boards

InactiveCN109008081AScientific and reasonable structureEasy to useShoe gluingElectric machineryProcess efficiency

The invention discloses a softening and adhering device for production of plastic shoe boards. The device comprises a box body, a heating bin, heating plates, a pneumatic pump, a pressing plate and aclamping plate. The heating bin is installed on one side of the top of the box body. The heating plate is installed on the inner wall of the heating bin. The pneumatic pump is installed on the box body. The pressing plate is installed under the pneumatic pump. The top of the box body is uniformly connected with the clamping plate. According to the invention, the device is proper in structure, andsafe and convenient to use; by screwing an adjusting knob, plastic shoe boards can be clamped and fixed, so the plastic shoe boards are prevented from moving during softening and adhering to cause deviation of the adhesion positions; through operation of a motor, rotational processing can be performed on the plastic shoe boards on a rotation ring and softened shoe plates can be smeared with glue,so idle time of workers during softening of the plastic shoe boards is saved; processing efficiency of the plastic shoe boards is improved; and through operation of the pneumatic pump, a telescopic column can be driven to stretch, so adhesion between the to-be-adhered parts and the plastic shoe boards is quite firm.

Owner:合肥五凡工程设计有限公司

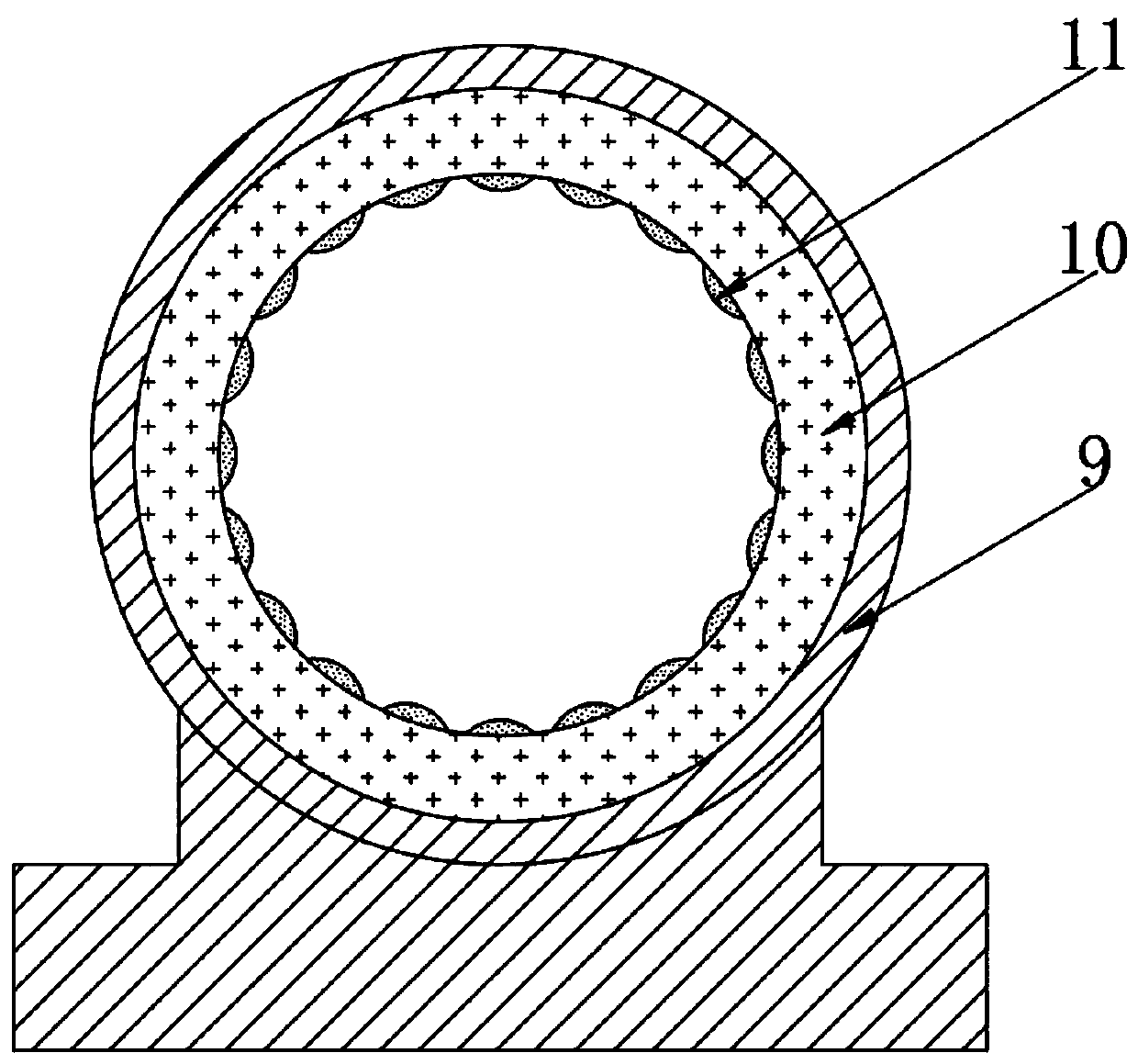

Plastic shoe board recycling and softening device

ActiveCN106476172ASoften thoroughlyImprove work efficiencyPlastic recyclingMechanical material recoveryEngineeringSoftening

The invention relates to a plastic shoe board softening device, in particular to a plastic shoe board recycling and softening device, and aims at solving the technical problem of providing a plastic shoe board recycling and softening device which is thorough in softening, high in softening efficiency and capable of saving time. In order to solve the above-mentioned technical problem, the plastic shoe board recycling and softening device is provided and comprises a support frame, a first motor, a softening box, a collecting box, a mincing box, first electric heating cases, first electric heating wires, a second motor, a rotating shaft, mincing blades, a feeding hopper and the like, wherein the first motor, the softening box and the collecting box are sequentially arranged on the left portion of the support frame from top to bottom, and the mincing box is connected to the left portion of an output shaft of the first motor. According to the plastic shoe board recycling and softening device, by adopting a mode of combining mincing and softening, not only can plastic shoe boards be thoroughly softened, but also the working efficiency can be improved in the softening process.

Owner:安庆市安鑫体育用品有限公司

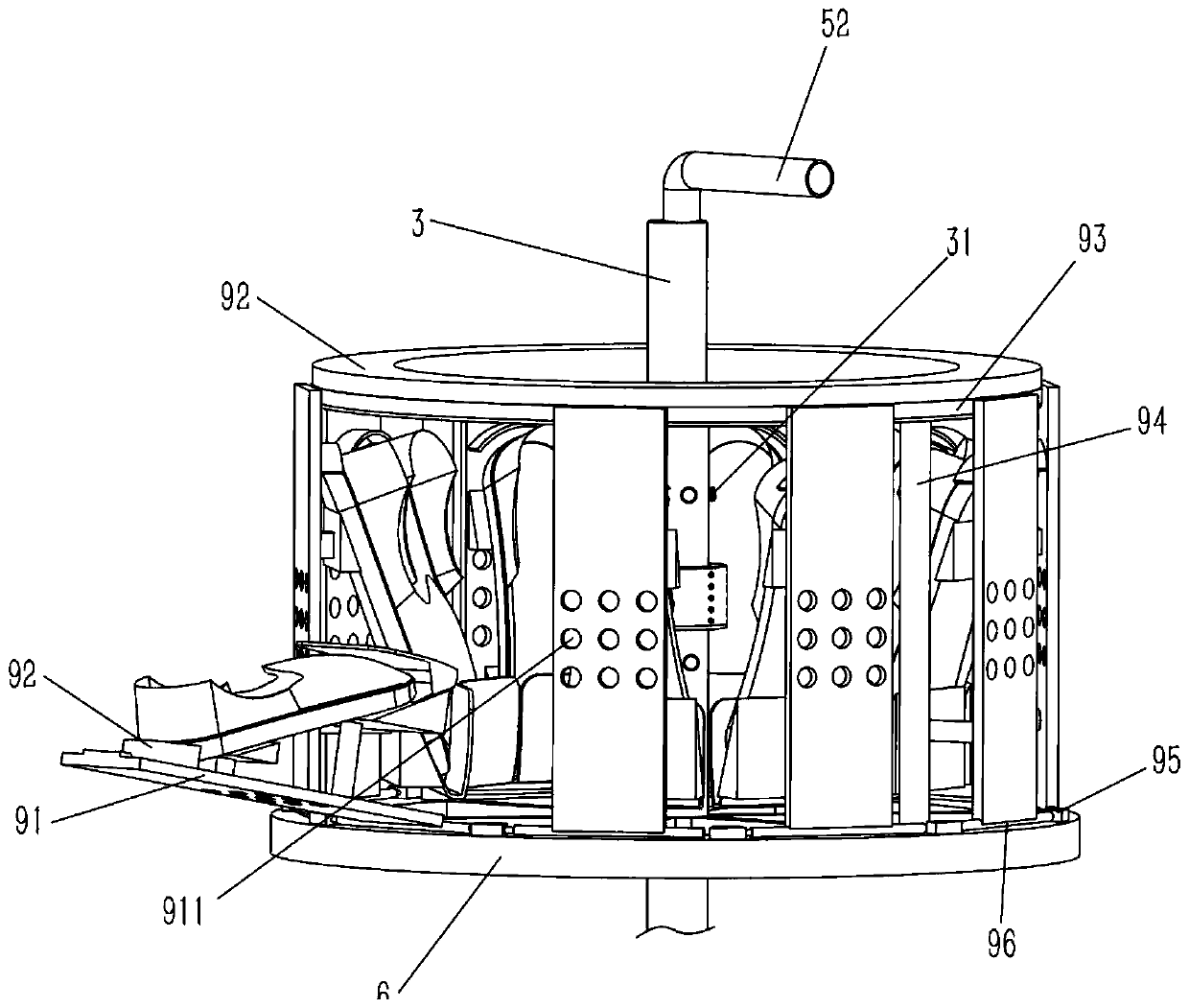

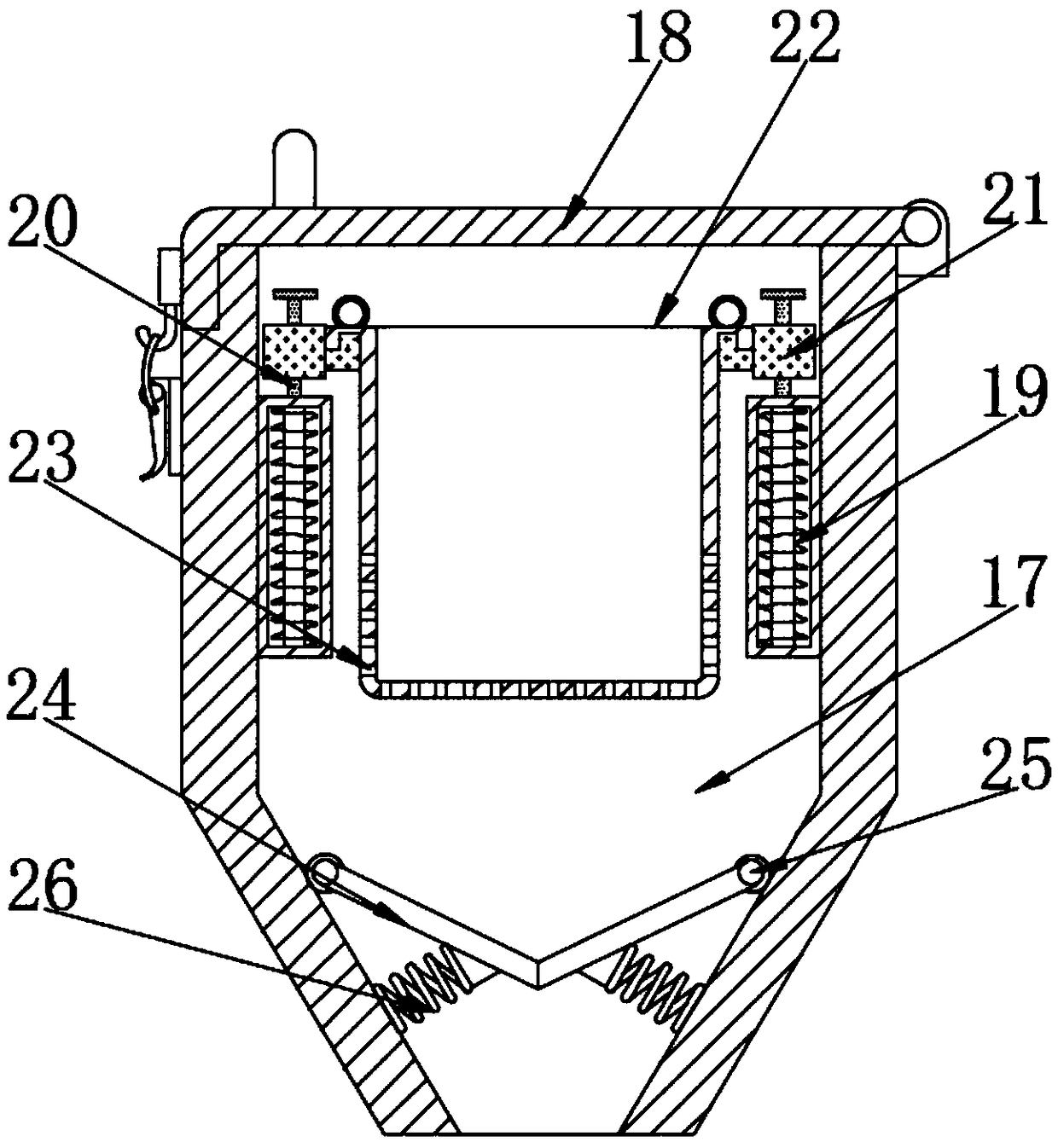

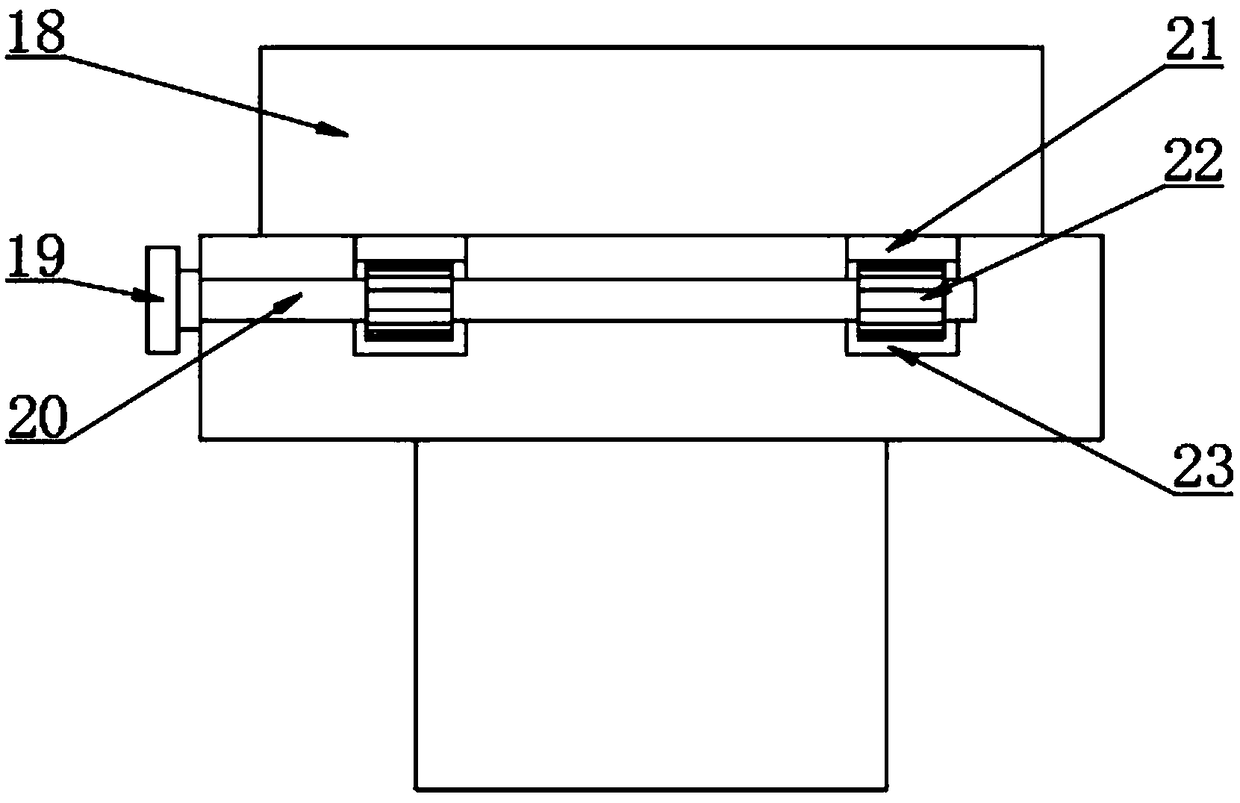

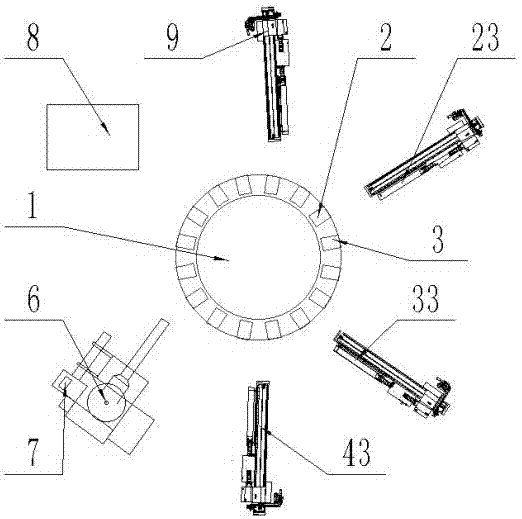

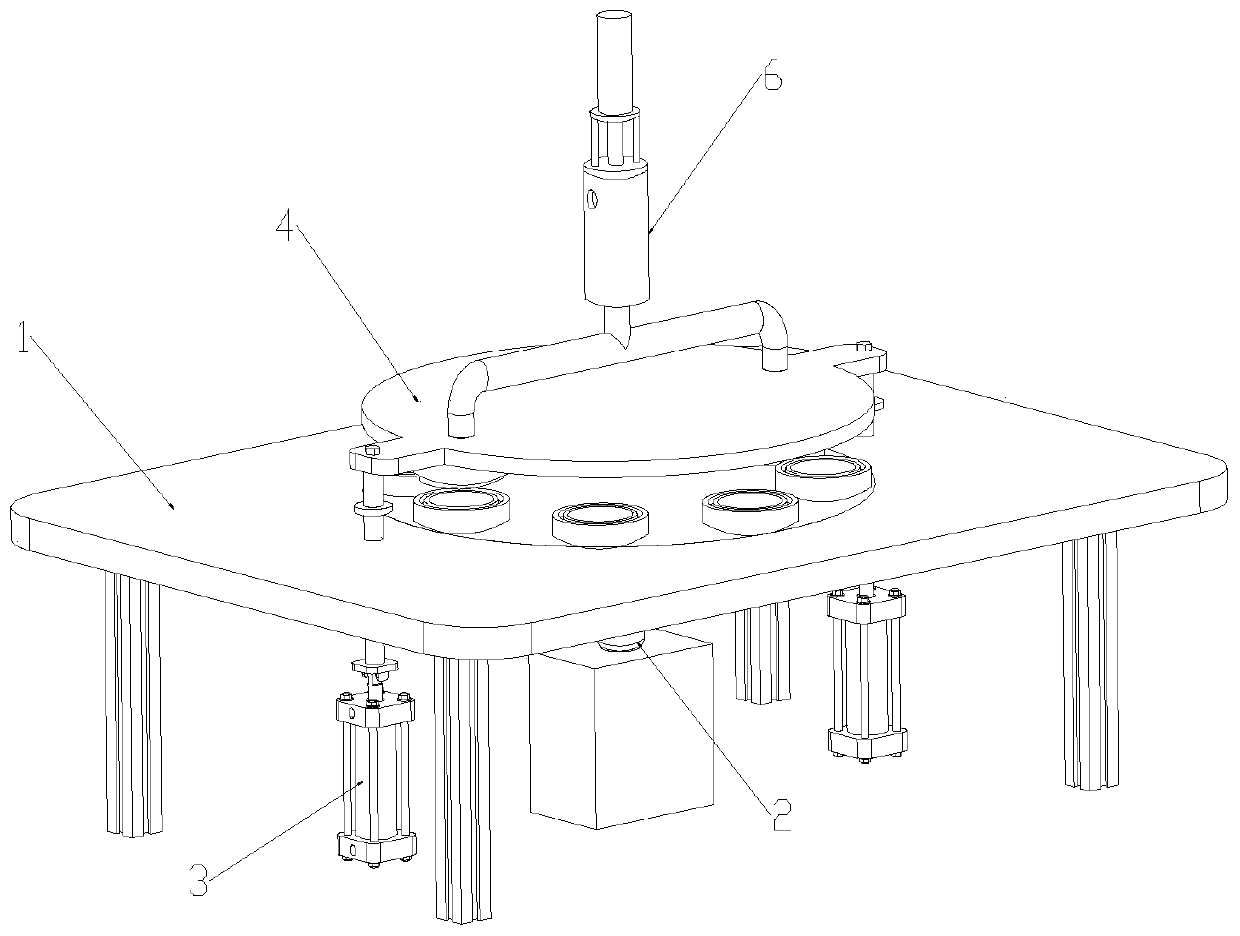

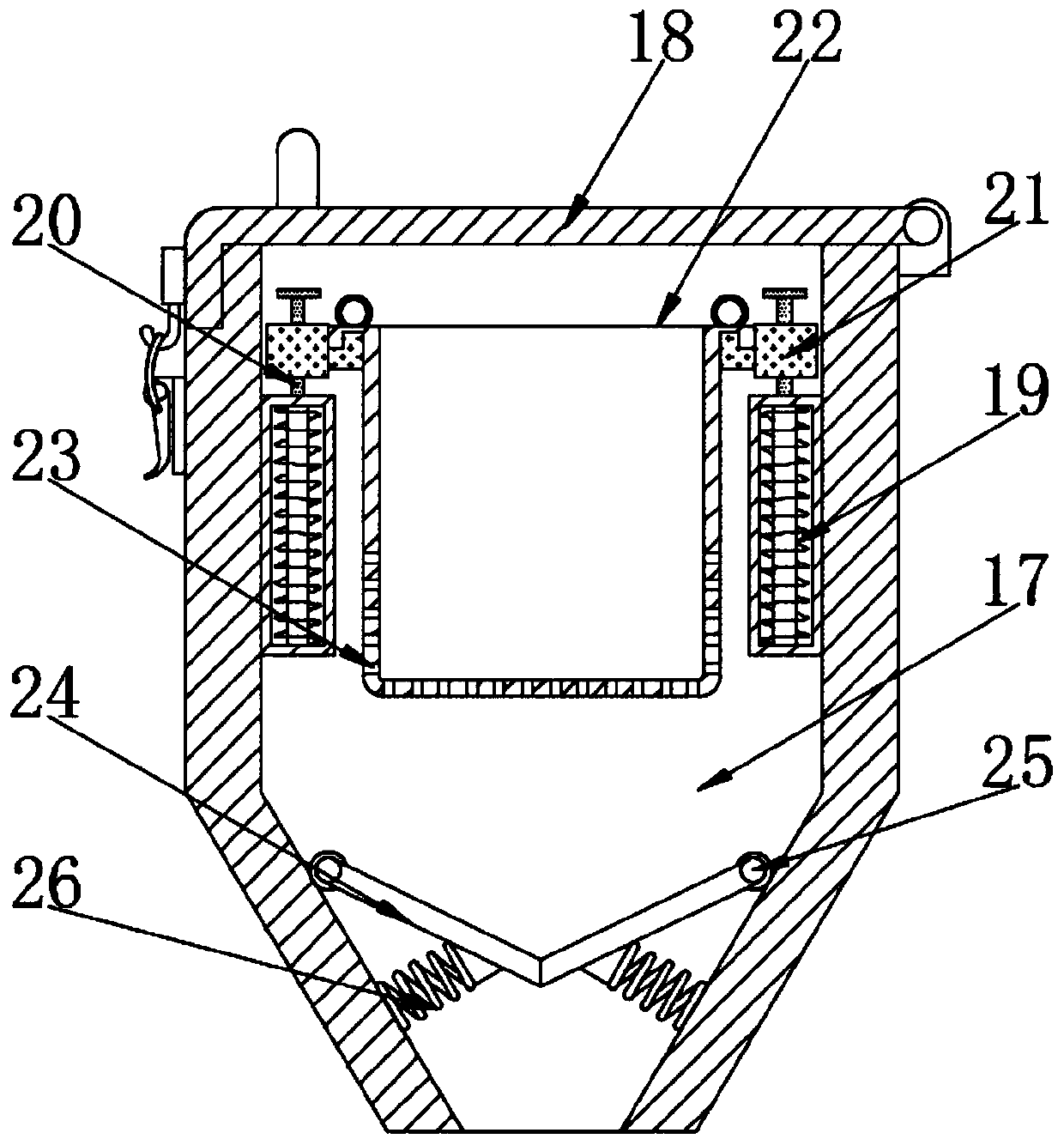

Full-automatic shoe fetching manipulator device applied to plastic shoe forming machine

InactiveCN107487007ARealize automated productionEasy to produceDomestic footwearCircular discInjection molding machine

The invention discloses a full-automatic shoe fetching manipulator device applied to a plastic shoe forming machine. The full-automatic shoe fetching manipulator device applied to the plastic shoe forming machine comprises a disc mechanism; shoe molds are evenly distributed on the upper surface of the disc mechanism; upper mold pillars are arranged on the shoe molds; a rotary motor with the rotary end being vertically upward is arranged below the disc mechanism; an injection molding machine, a shoe mold cooling mechanism, a mold opening manipulator, a shoe fetching manipulator, a mold closing manipulator and a shoe offcut fetching manipulator are arranged around the disc mechanism, each provided with a shoe mold sensor, an air cylinder, a manipulator controller and the like, and electrically connected with a PLC; and as all the mechanical devices are matched with one another during operation of the full-automatic shoe fetching manipulator device, the full-automatic shoe fetching manipulator device can automatically open the shoe molds, fetch shoes, close the shoe molds and remove plastic offcut of the shoe molds. The full-automatic shoe fetching manipulator device has the beneficial effects of being simple in structure and high in practicability.

Owner:深圳市怡善自动化科技有限公司

Injection molding mechanism for wear-resistant plastic shoes

InactiveCN110253820AMold stabilityAutomate operationDomestic articlesHydraulic cylinderWear resistant

The invention discloses an injection molding mechanism for wear-resistant plastic shoes. The injection molding mechanism for the wear-resistant plastic shoes comprises a workbench, wherein a servo motor is arranged at the bottom end of the workbench, a rotating plate is fixed at the output end of the servo motor, hydraulic cylinders are arranged at the bottom end of the workbench, a bottom plate is arranged at the upper end of a piston rod of each hydraulic cylinder, a sliding rod is fixed at the upper end of each bottom plate, and a mounting plate is arranged between the top ends of the sliding rods. A feeding pipe is arranged above the mounting plate, and the bottom end of the feeding pipe communicates with a circulating pipe. The injection molding mechanism for the wear-resistant plastic shoes is provided with the hydraulic cylinders, the hydraulic cylinders drive an upper mold and a lower mold on the mounting plate to be attached to each other, then molten plastic is injected into the upper mold, and after the molten plastic is cooled, a mold is formed, and thus, automatic operation is realized; meanwhile, a plurality of plastic shoes can be formed at a time, and the processing efficiency is improved; after the plastic liquid heated and melted by an electric heating wire moves downwards through a piston to extrude the plastic downwards, the plastic flows into a cavity of the upper mold from a circulation pipe, the extruded plastic liquid is compact, the mold is firm, and thus, the formed plastic shoes are wear-resistant.

Owner:界首市旭升塑胶制品有限公司

Coated leather-like sole and manufacture method thereof

The invention belongs to the technical field of a shoe sole and a manufacturing method thereof, in particular to a film-covered and leather-imitating shoe sole and the manufacturing method thereof. The first technical problem to be solved by the invention is to provide a film-covered and leather-imitating shoe sole with a level surface. The film-covered and leather-imitating shoe sole comprises a rubber plastic shoe sole and a compound transferring film, wherein, the compound transferring film is printed on the ground-contacted side of the shoe sole. The ground-contacted side refers to the side of the shoe sole that is contacted with the ground when in walking. The film-covered and leather-imitating shoe sole of the invention has level surfaces and beautiful flower colors, and ensures the processing procedures of the manufacturing method, costs, the amounts of organic solvent and pollution on workers and environment to be greatly reduced.

Owner:都江堰海耀橡塑有限公司

Crack-resistant plastic shoe and preparation method thereof

InactiveCN108577049AImprove diffusivityImprove bindingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer scienceAdhesive

The invention relates to a rubber adhesive, and discloses a crack-resistant plastic shoe and a preparation method thereof. The preparation process of the invention improves the dispersion of raw materials in the adhesive. Moreover, epoxy groups are introduced into a chloroprene rubber and styrene-butadiene-styrene block copolymer, thereby improving the adhesion of the adhesive with the bonded rubber or plastic. On the other hand, an adhesive with higher stickiness and durability is obtained in conjunction with a composition B containing nitroso-fluororubber raw rubber, butyl acrylate, a crosslinking agent, magnesium oxide and zinc oxide. The adhesive has the advantages of simple preparation method, adoption of readily-available raw materials and higher popularization and application value.By applying the adhesive with high and persistent stickiness, the defects of weak and insufficient stickiness of the adhesive in the prior art are overcome. The anti-cracking plastic shoe is simple in preparation method.

Owner:WUHU FENGXUE RUBBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com