Wear-resisting and highly-hard plastic sole product

A technology of plastics and products, applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of poor wear resistance and short service life, and achieve the effects of improving compatibility, improving low-temperature brittleness, and increasing the use temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

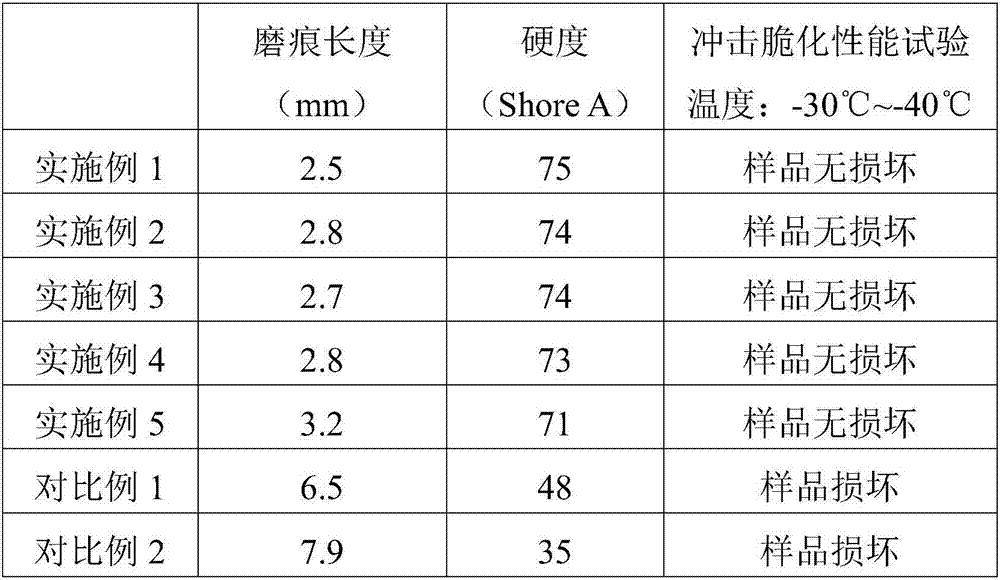

Examples

Embodiment 1

[0031] A wear-resistant and high-hardness plastic shoe sole product, comprising the following substances in parts by weight: 60 parts of polyvinyl chloride, 5 parts of plastic modifier, 20 parts of neoprene rubber, 8 parts of blending modifier, phthalic acid 18 parts of plasticizer, 4 parts of calcium-zinc composite stabilizer, 1 part of chlorinated paraffin, 1.5 parts of AD foaming agent, 5 parts of titanium dioxide, and 6 parts of glass fiber;

[0032] The plastic modifier is prepared by mixing styrene-butadiene-styrene ternary block copolymer, ethylene-vinyl acetate copolymer and ethylene-octene copolymer according to the weight ratio of 1:0.8:0.6;

[0033] The blending modification aid includes the following parts by weight: 15 parts of plasticizers such as phthalic acid, 20 parts of chlorinated polyolefin, 20 parts of ethylene-vinyl acetate copolymer, 5 parts of chlorinated paraffin , 5 parts of n-decyltriethoxysilane.

Embodiment 2

[0035] A wear-resistant and high-hardness plastic shoe sole product, comprising the following materials in parts by weight: 55 parts of polyethylene, 4 parts of plastic modifier, 18 parts of nitrile rubber, 6 parts of blending modifier, and phthalic acid 15 parts of plasticizer, 2 parts of calcium zinc composite stabilizer, 0.5 parts of stearate, 1 part of AD foaming agent, 3 parts of calcium carbonate, 5 parts of glass fiber;

[0036] The plastic modifier is prepared by mixing styrene-butadiene-styrene ternary block copolymer, ethylene-vinyl acetate copolymer and ethylene-octene copolymer according to the weight ratio of 1:0.8:0.6;

[0037] The blending modification aid includes the following parts by weight: 7 parts of plasticizers such as phthalic acid, 12 parts of chlorinated polyolefin, 15 parts of ethylene-vinyl acetate copolymer, 3 parts of stearate Parts, 2 parts of n-octyltriethoxysilane.

Embodiment 3

[0039] A wear-resistant and high-hardness plastic shoe sole product, comprising the following substances in parts by weight: 65 parts of polyurethane, 7 parts of plastic modifier, 22 parts of isoprene rubber, 9 parts of blending modifier, phthalic acid and the like 20 parts of plasticizer, 5 parts of calcium-zinc composite stabilizer, 1.5 parts of N,N'-ethylene bisstearamide, 2 parts of AD foaming agent, 6 parts of barium sulfate, and 8 parts of glass fiber;

[0040] The plastic modifier is prepared by mixing styrene-butadiene-styrene ternary block copolymer, ethylene-vinyl acetate copolymer and ethylene-octene copolymer according to the weight ratio of 1:0.8:0.6;

[0041] The blending modification aid includes the following parts by weight: 20 parts of plasticizers such as phthalic acid, 30 parts of anhydride grafted modified polyolefin, 30 parts of ethylene-vinyl acetate copolymer, N, 6 parts of N'-ethylenebisstearamide, 8 parts of dodecyltriethoxysilane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com