Plastic shoe board recycling and softening device

A softening device and shoe board technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of low softening efficiency, time-consuming, incomplete softening, etc., to save time, improve work efficiency, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

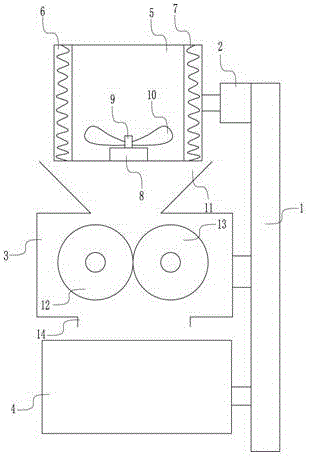

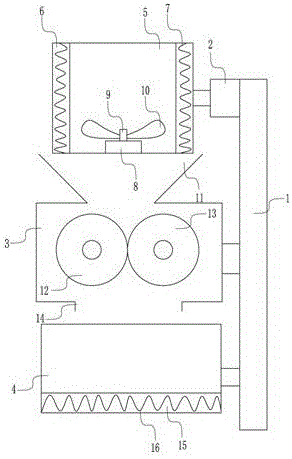

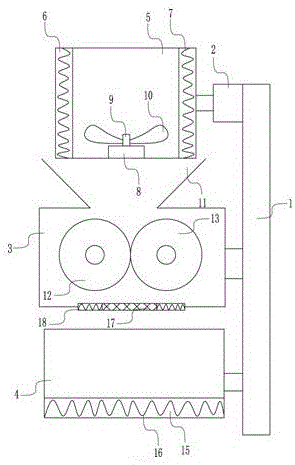

[0030] A plastic shoe board recovery and softening device, such as Figure 1-3 As shown, it includes a support frame 1, a first motor 2, a softening box 3, a collection box 4, a crushing box 5, a first electric heating box 6, a first heating wire 7, a second motor 8, a rotating shaft 9, and crushing blades 10. Feeding hopper 11, first electric grinding wheel 12 and second electric grinding wheel 13, the left part of support frame 1 is provided with first motor 2, softening box 3 and collection box 4 in sequence from top to bottom, first motor 2 The left part of the output shaft is connected with a crushing box 5, and the left and right interiors of the crushing box 5 are symmetrically provided with a first electric heating box 6, and the first electric heating wire 7 is installed in the first electric heating box 6, and the inner bottom of the crushing box 5 is arranged There is a second motor 8, the upper part of the second motor 8 is connected with a rotating shaft 9, the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com