Oil-removing, regenerating and recycling system for leather shoe waste

A recycling system and leather technology, which is applied in the field of leather shoe waste degreasing and recycling system, can solve the problems of low utilization rate of waste leather, short service life of leather, uneven coloring of regenerated leather, etc., and reach a wide range of society Value and economic value, reducing the use of raw materials, and improving the effect of conversion utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

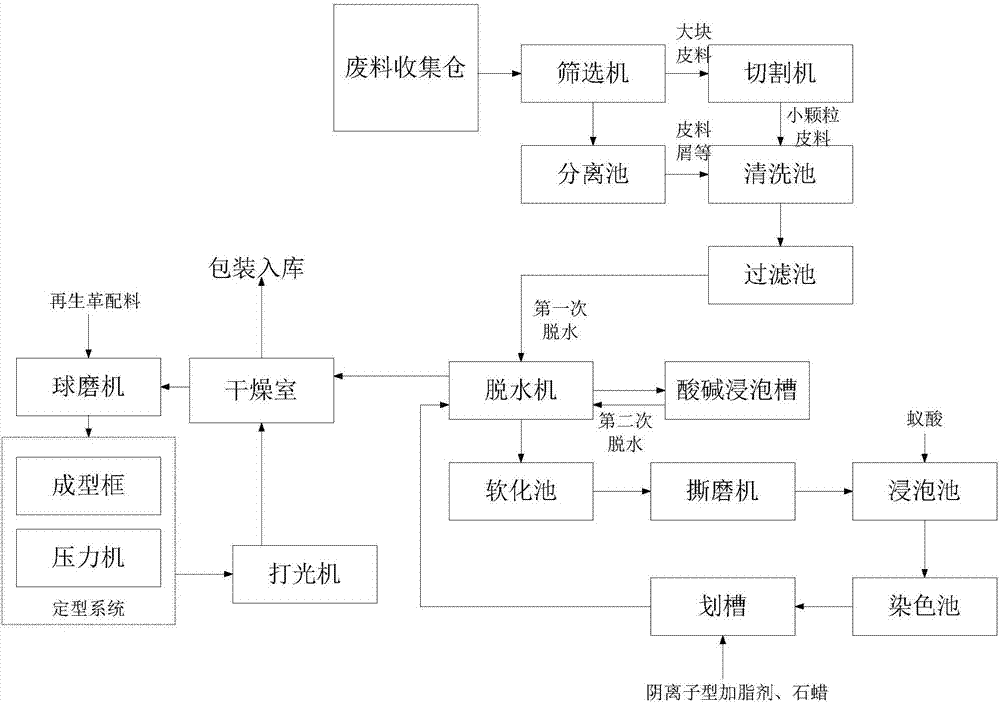

[0022] Such as figure 1 The degreasing and recycling system for leather shoe waste shown in the figure includes a waste leather collection bin connected by a conveyor belt, a screening machine, a separation tank, a cleaning tank, a filter tank, an acid-base soaking tank, a softening tank, a dehydrator, a tearing The mill, and the immersion tank connected with the tearing mill, also includes a cutting machine connected with the screening machine, wherein the leather waste in the waste leather collection bin is transported to the screening machine, and the large leather waste in the leather waste is transported to the screening machine by the screening machine Screened out, the screened large pieces of leather are transported to the cutting machine to cut into small particles of 1-2cm, and then transported to the cleaning pool for soaking for 2 hours and cleaning 3 times; after removing the large leather, other leather garbage is transported to the separation pool Add water and ...

Embodiment 2

[0025] Such as figure 1 Shown is a system for degreasing and regenerating leather shoe waste. On the basis of Example 1, the sizing system includes a molding frame and a press, wherein the leather fiber mixture is flattened in the molding frame for molding, and then the press is started. Apply pressure to the leather fiber mixture in the molding frame for 8 minutes to make the leather molded, then take it out and transport it to a drying room for drying for 24 hours, so that the water content in the regenerated leather is controlled at 12%.

Embodiment 3

[0027] Such as figure 1 A kind of degreasing regeneration recovery system of leather shoe waste shown, on the basis of embodiment 1, the pressure that described press machine is applied to the leather fiber mixture in the molding frame is gradually increased from 25Mpa to 150Mpa, so that the regenerated leather can Press down firmly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com