Preparation method of bamboo fiber materials for towels

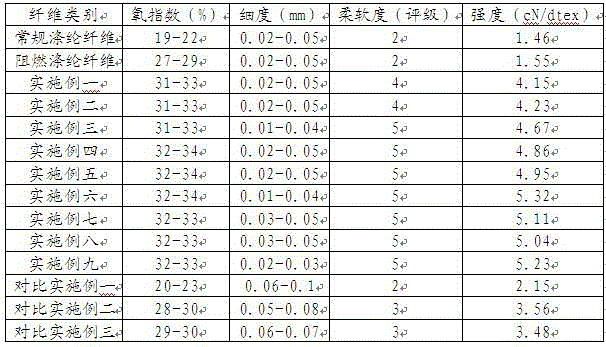

A bamboo fiber and towel technology, which is applied in the chemical post-treatment of fibers, fiber treatment, plant fibers, etc., can solve the problems of cumbersome production steps, long processing time, and bamboo fiber products do not have flame retardant effect, so as to achieve anti-loss Enhanced strength, fineness and softness, preventing runoff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Choose annual bamboo. Use a punching machine or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves to make the bamboo into a hollow cylindrical or semi-cylindrical shape,

[0034] The flattened bamboo is impregnated with flame retardant treatment,

[0035] Impregnation flame retardant treatment adopts vacuum pressure flame retardant treatment: during the treatment process, the bamboo material is first put into a vacuum pressure tank and evacuated to make the vacuum degree -0.015MPa, and then the flame retardant is added into the tank and the inner pressure of the tank is increased to 0.1MPa, the flame retardant used is composed of the following components in parts by weight: 20 parts of ammonium oligophosphate, 10 parts of ammonium phosphate, 6 parts of ammonium pyrophosphate, 5 parts of ammonium sulfate, 5 parts of boric acid, and 10 parts of water; Next, soften the bamboo,

[0036] Immerse the bamboo material after the impregn...

Embodiment 2

[0043] Choose two-year-old green bamboo.

[0044] Perforate with a punching machine or other methods, or cut the cylindrical bamboo into two halves with a machine to make the bamboo into a hollow cylindrical or semi-cylindrical shape, and impregnate the flattened bamboo with flame retardant treatment.

[0045]Impregnation flame retardant treatment adopts vacuum pressure flame retardant treatment: in the treatment process, the bamboo filamentous fibers obtained after fiber opening are first put into a vacuum pressure tank and evacuated to make the vacuum degree -0.025Mpa, and then the flame retardant is added to the tank The internal pressure of the tank is increased to 0.8Mpa, and the flame retardant used is composed of the following components in parts by weight: 50 parts of ammonium oligophosphate, 25 parts of ammonium phosphate, 12 parts of ammonium pyrophosphate, 20 parts of ammonium sulfate, 10 parts of boric acid, 25 parts of water; then soften the bamboo,

[0046] The ...

Embodiment 3

[0053] Choose three-year-old green bamboo. Use a punching machine or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves to make the bamboo into a hollow conical or semi-conical shape, and impregnate the flattened bamboo for flame retardant treatment.

[0054] Impregnation flame retardant treatment adopts vacuum pressure flame retardant treatment: in the treatment process, the bamboo filamentous fibers obtained after fiber opening are first put into a vacuum pressure tank and vacuumed to make the vacuum degree -0.02Mpa, and then the flame retardant is added to the tank The pressure inside the tank is increased to 0.6Mpa, and the flame retardant used is composed of the following components in parts by weight: 30 parts of ammonium oligophosphate, 15 parts of ammonium phosphate, 8 parts of ammonium pyrophosphate, 15 parts of ammonium sulfate, 8 parts of boric acid, 15 parts of water; then soften the bamboo,

[0055] The bamboo wood after th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com