Bamboo fiber material for towels

A bamboo fiber and towel technology, applied in fiber treatment, plant fiber, chemical post-treatment of fibers, etc., can solve the problems of cumbersome production steps, bamboo fiber products do not have flame retardant effect, long processing time, etc., and achieve anti-loss Strong, prevent loss, high penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

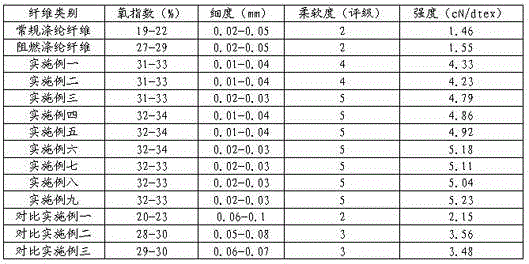

Examples

Embodiment 1

[0037] Choose annual moso bamboo. Use a perforator or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow cylinder or a semi-cylindrical tube, soak the flattened bamboo in the softening liquid, and the bamboo and the softening liquid The weight ratio is 100:8, and the softening solution is mixed with 100 parts by weight of water, 15 parts of milk mother soap, 8 parts of mineral oil and 5 parts of emulsifier OP;

[0038] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.02MPa, and then perform microwave softening treatment, the microwave frequency is 300MHz, and the microwave treatment time is 1min;

[0039] After the softened bamboo is rinsed with water, it is combed, and then the bamboo is made into a fiber bundle by a fiber separator; then steamed,

[0040] The cooking method is to place the bamboo filament-like fiber impregnate...

Embodiment 2

[0045] Choose biennial green bamboo.

[0046] Use a perforator or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow cylinder or a semi-cylindrical tube, soak the flattened bamboo in a softening solution, and the bamboo and the softened The weight ratio of the liquid is 100:2, and the softening liquid is mixed with 100 parts by weight of water, 20 parts of milk soap, 10 parts of mineral oil and 8 parts of Pingping plus O emulsifier;

[0047] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.001MPa, and then perform microwave softening treatment, the microwave frequency is 950MHz, and the microwave treatment time is 3min;

[0048] After the softened bamboo is rinsed with water, it is combed, and then the bamboo is made into a fiber bundle by a fiber separator; then steamed,

[0049] The cooking method is to place the impregnated and...

Embodiment 3

[0053] Choose three-year-old green bamboo. Use a puncher or other methods to perforate, or use a machine to cut the cylindrical bamboo into two halves, so that the bamboo becomes a hollow conical or semi-conical shape, soak the flattened bamboo in the softening solution, and the bamboo and the softened The weight ratio of the liquid is 100:5, and the softening liquid is a mixture of 100 parts by weight of water, 18 parts of milk soap, 9 parts of mineral oil and 6 parts of emulsifier OP.

[0054] Then put the bamboo soaked in the softening solution into a microwave vacuum tank, evacuate until the vacuum degree is -0.01MPa, and then perform microwave softening treatment, the microwave frequency is 600MHz, and the microwave treatment time is 2min;

[0055] After the softened bamboo is rinsed with water, it is combed, and then the bamboo is made into a fiber bundle by a fiber separator; then steamed,

[0056] The cooking method is to place the impregnated and flame-retardant bamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com