Patents

Literature

333results about How to "Improve penetration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

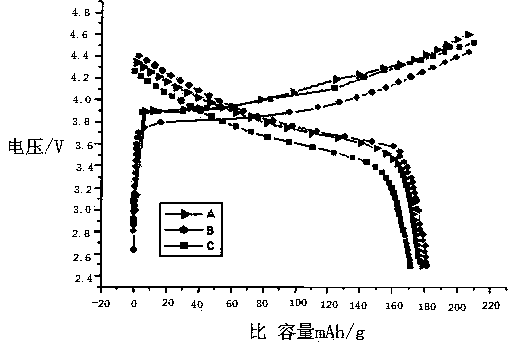

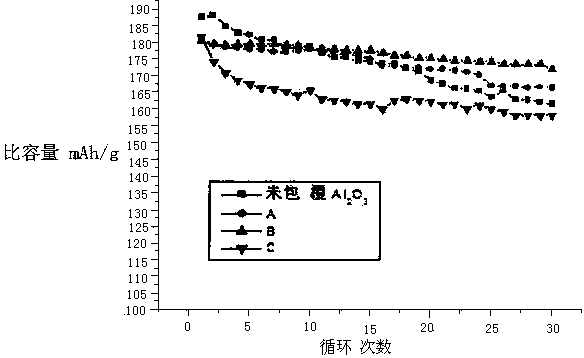

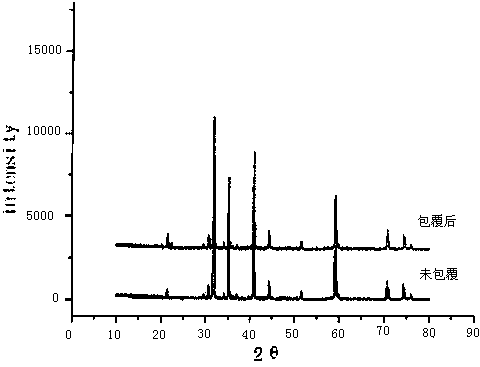

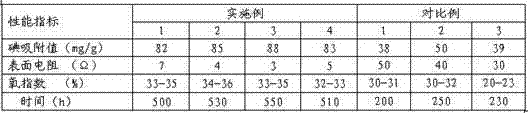

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

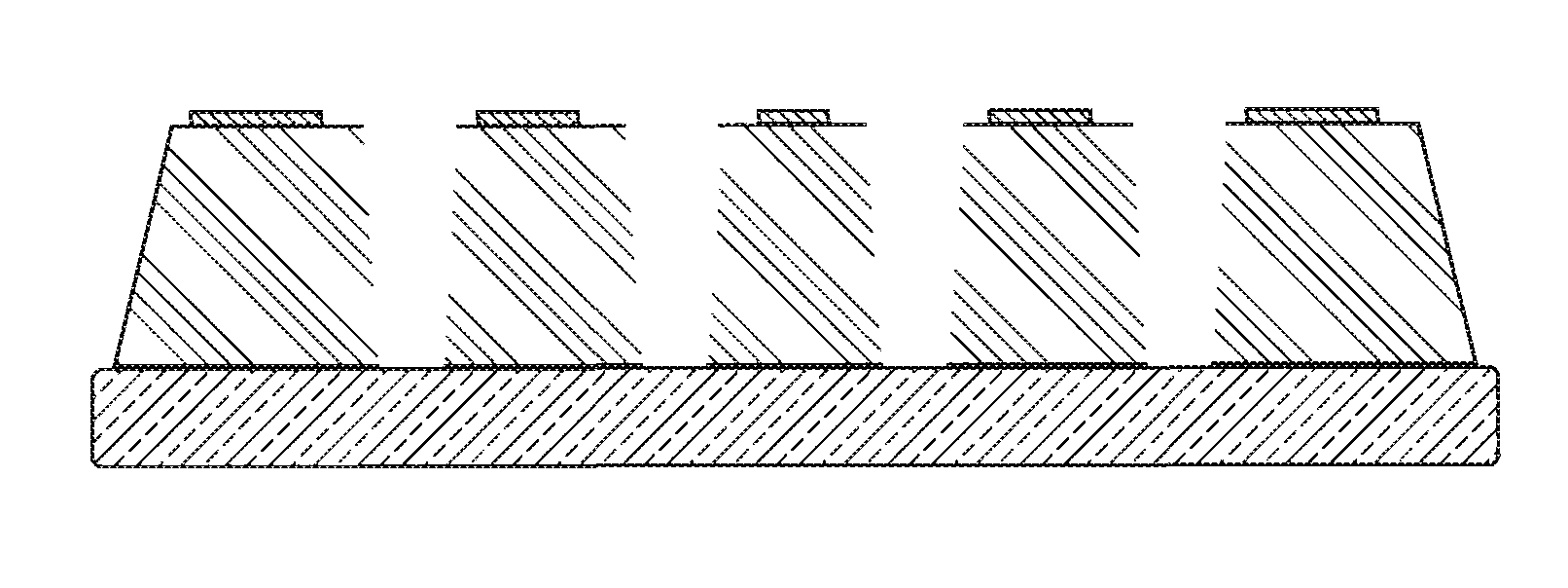

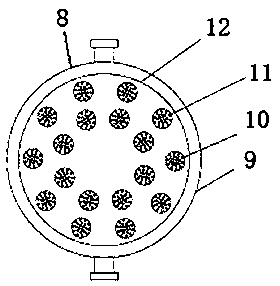

Porous ceramic membrane support with flat structure and preparation method thereof

ActiveCN102688700AReduce frictionAvoid accumulationSemi-permeable membranesPolyvinyl alcoholAdhesive

The invention relates to a porous ceramic membrane support with a flat structure and a preparation method thereof, and belongs to the technical field of ceramic membrane supports. The ceramic membrane support is flat and consists of two flat membrane supports; a certain space is reserved between the two flat membrane supports; at least one supporting column is distributed in the space; and at least one water outlet passage is formed in each flat membrane support, so that flowing resistance of filtrate in the support with the flat structure is reduced. The ceramic aggregate of the support is one or more of alumina, zirconia, silicon dioxide, silicon carbide, titanium oxide, mullite and cordierite; the pore-forming agent is starch, graphite, phenolic resin spheres and the like; and the adhesive is methylcellulose, polyvinyl alcohol and the like. The porosity of the prepared porous ceramic membrane support with the flat structure can reach 30 to 50 percent, the aperture is 20 to 200 nanometers, and the compressive strength can reach 20 to 40MPa; and the support can be used for substituting an organic hollow fiber membrane bioreactor, and has great potential application in the fields of sewage treatment, fine chemical industry and the like.

Owner:TSINGHUA UNIV +1

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

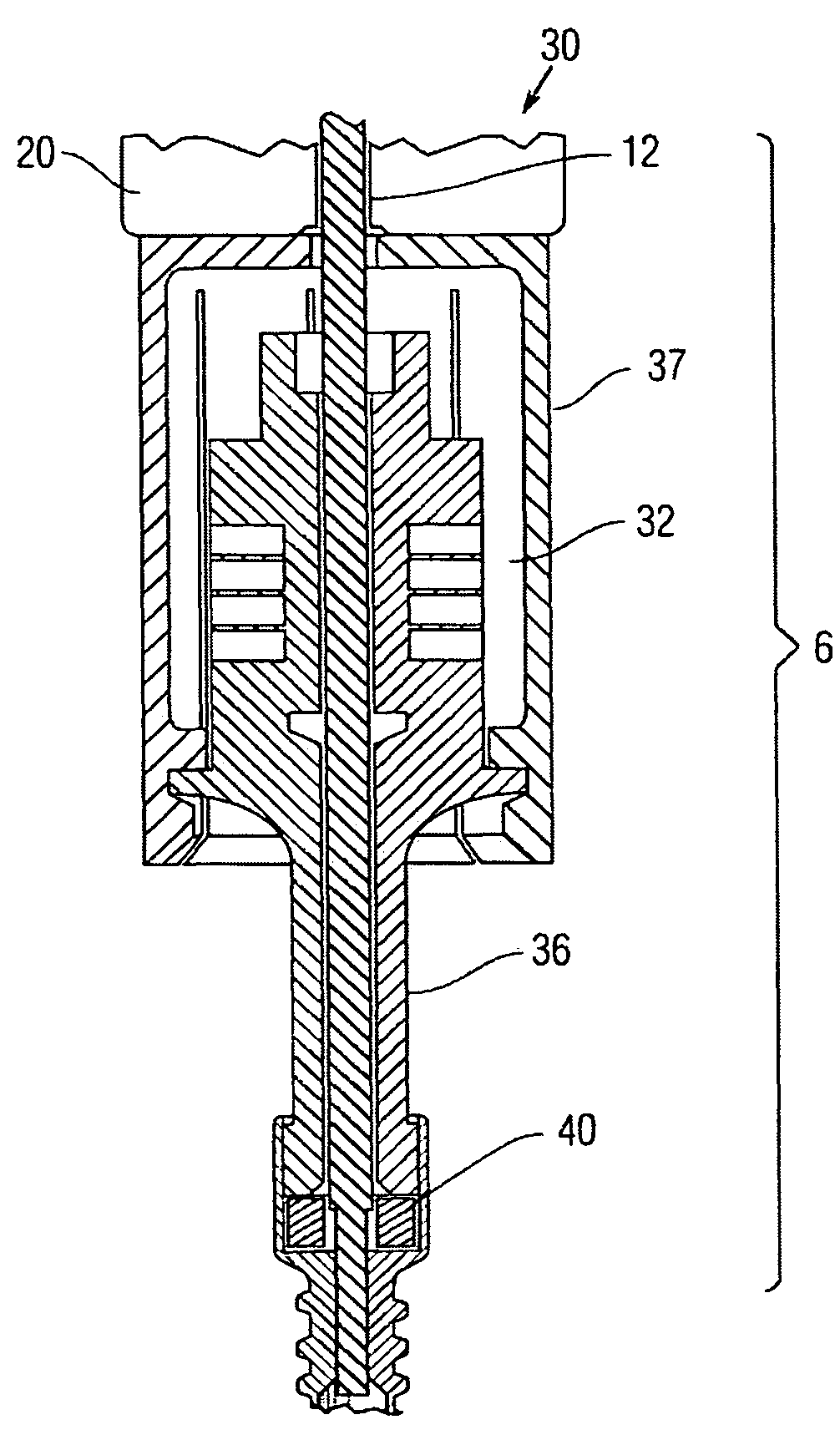

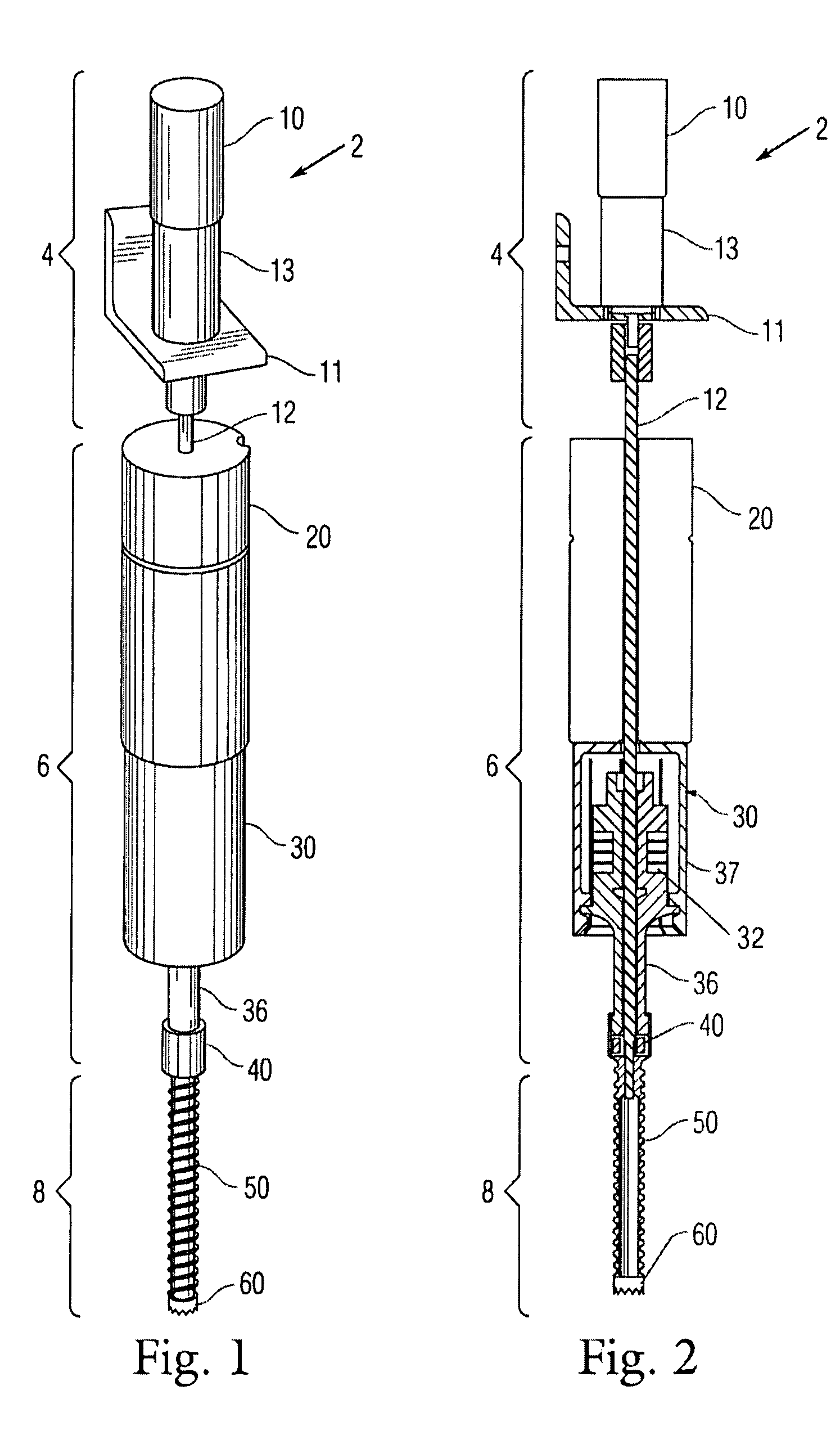

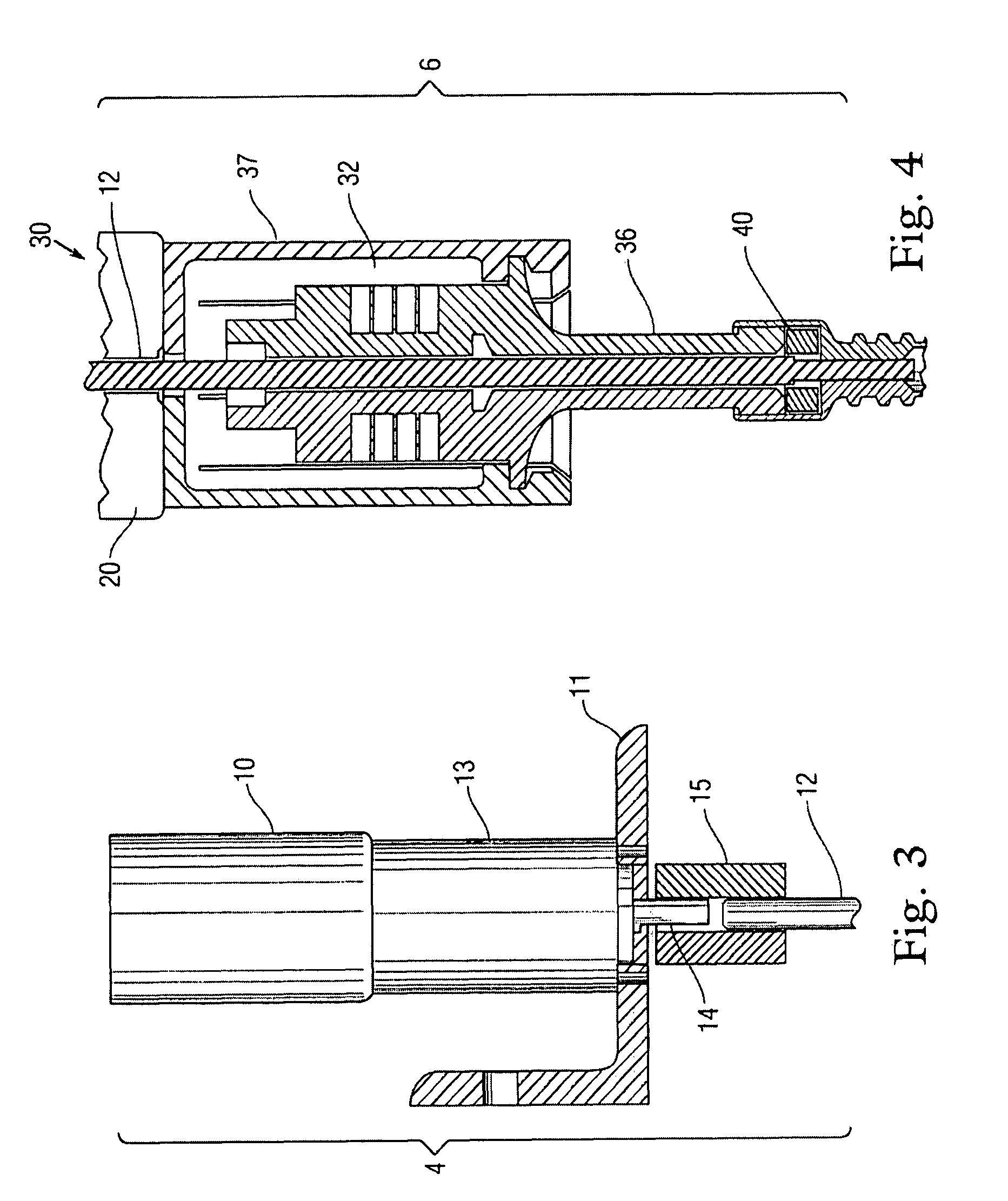

Ultrasonic rotary-hammer drill

InactiveUS7740088B1Light weightConsume low amountDrill bitsPiezoelectric/electrostriction/magnetostriction machinesDrive shaftAcoustic wave

A mechanism for drilling or coring by a combination of sonic hammering and rotation. The drill includes a hammering section with a set of preload weights mounted atop a hammering actuator and an axial passage through the hammering section. In addition, a rotary section includes a motor coupled to a drive shaft that traverses the axial passage through the hammering section. A drill bit is coupled to the drive shaft for drilling by a combination of sonic hammering and rotation. The drill bit includes a fluted shaft leading to a distal crown cutter with teeth. The bit penetrates sampled media by repeated hammering action. In addition, the bit is rotated. As it rotates the fluted bit carries powdered cuttings helically upward along the side of the bit to the surface.

Owner:NAT AERONAUTICS & SPACE ADMINISTATION U S GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE

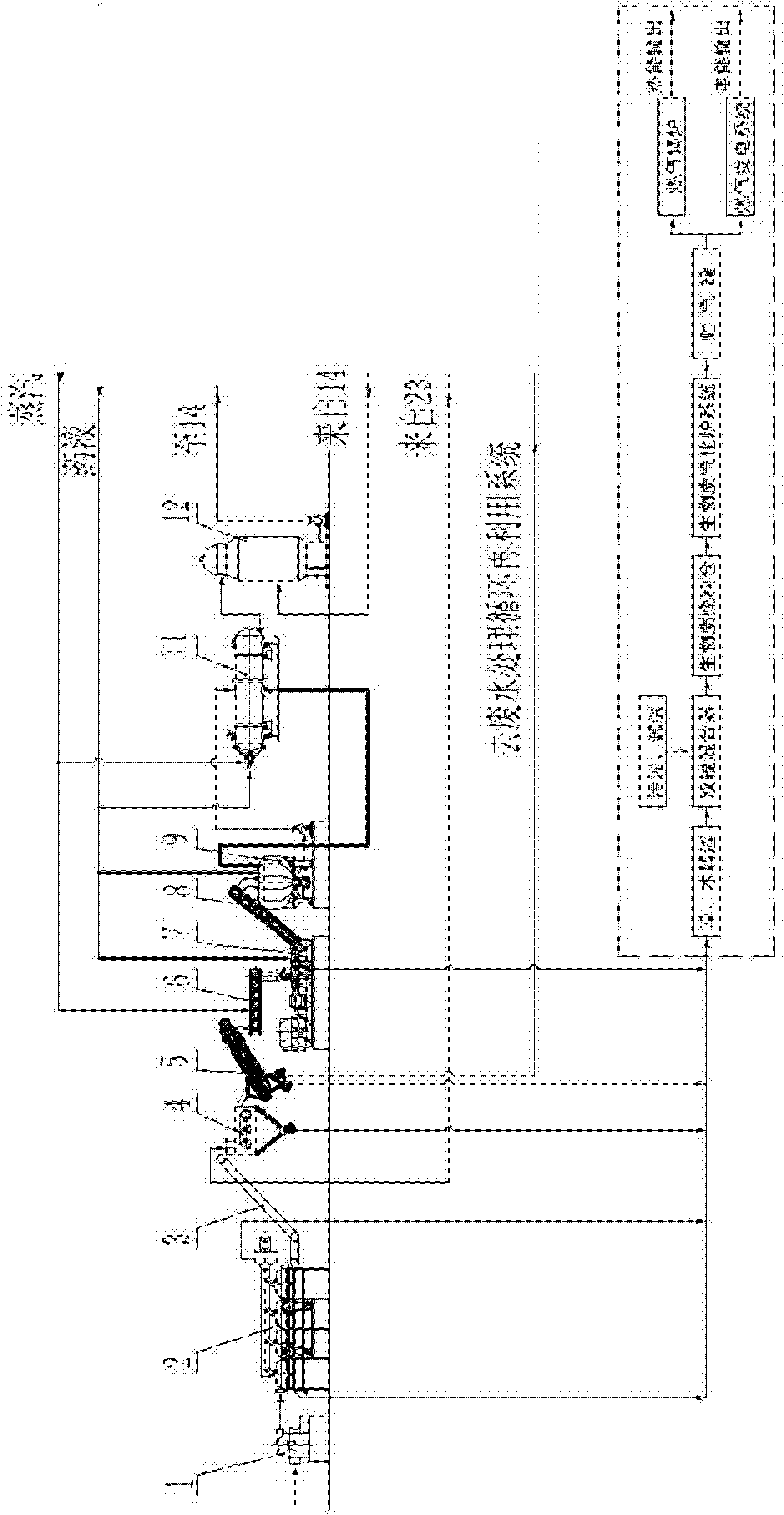

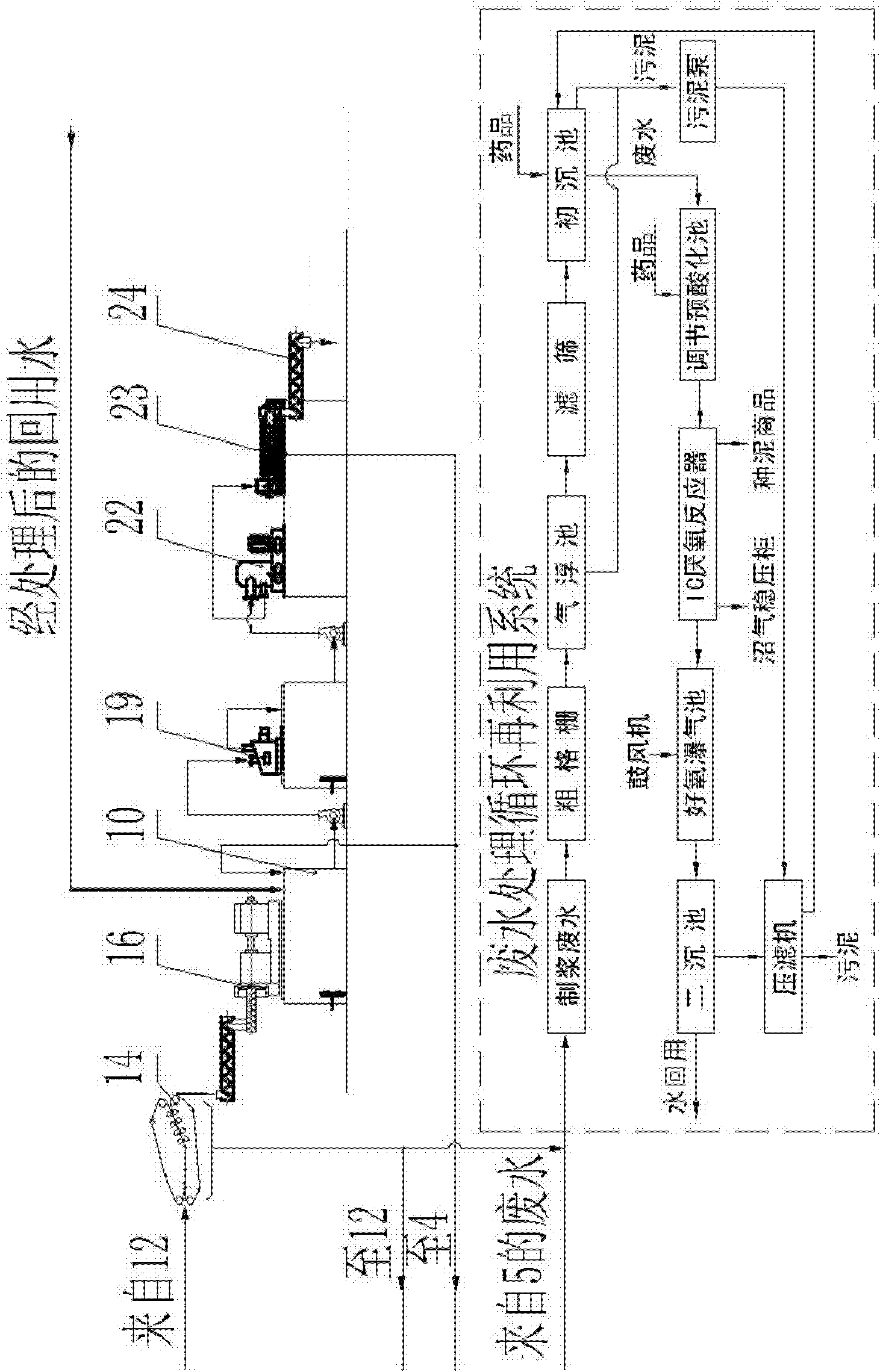

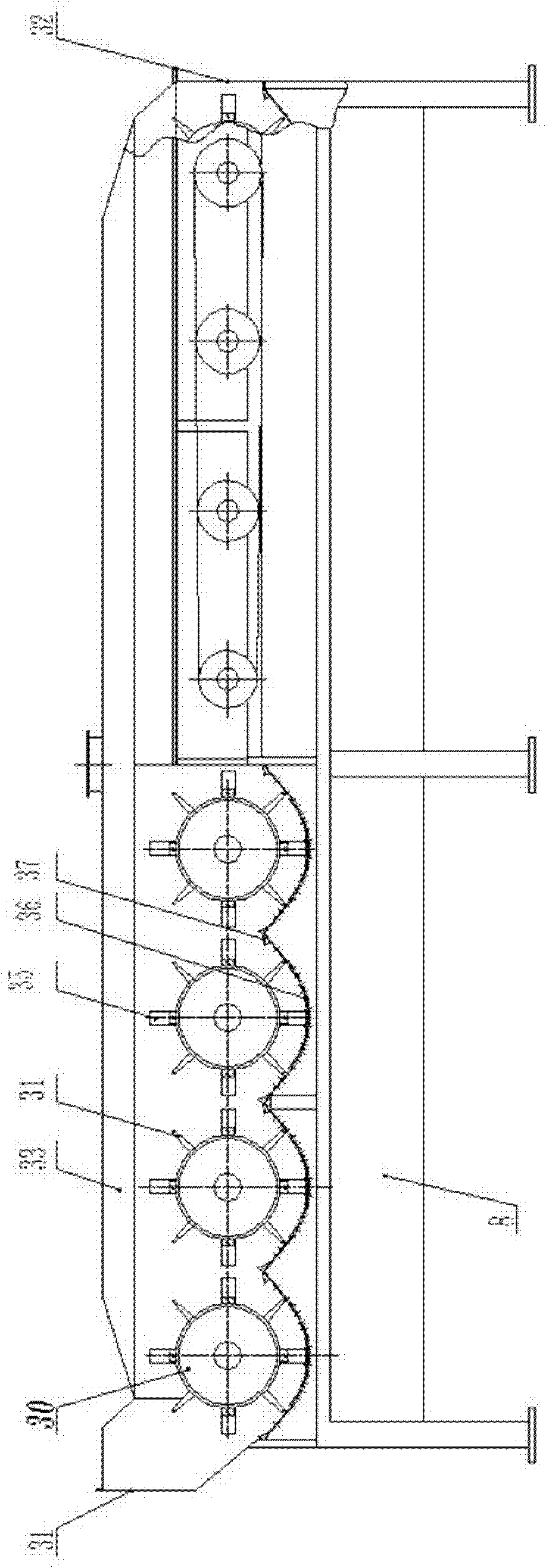

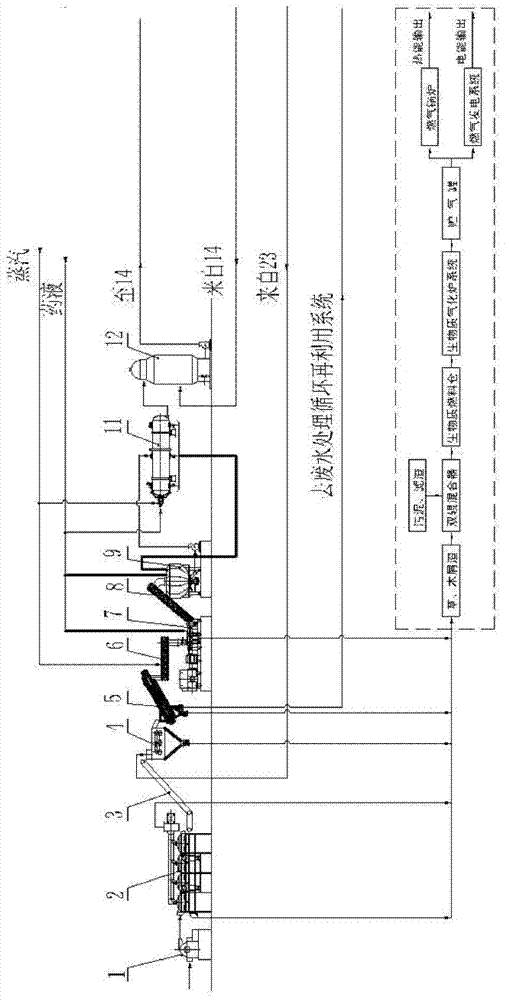

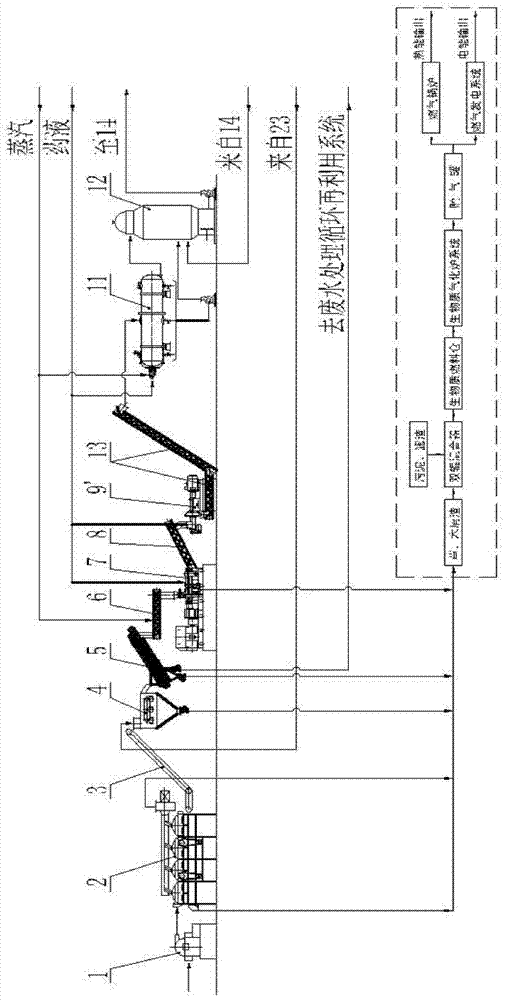

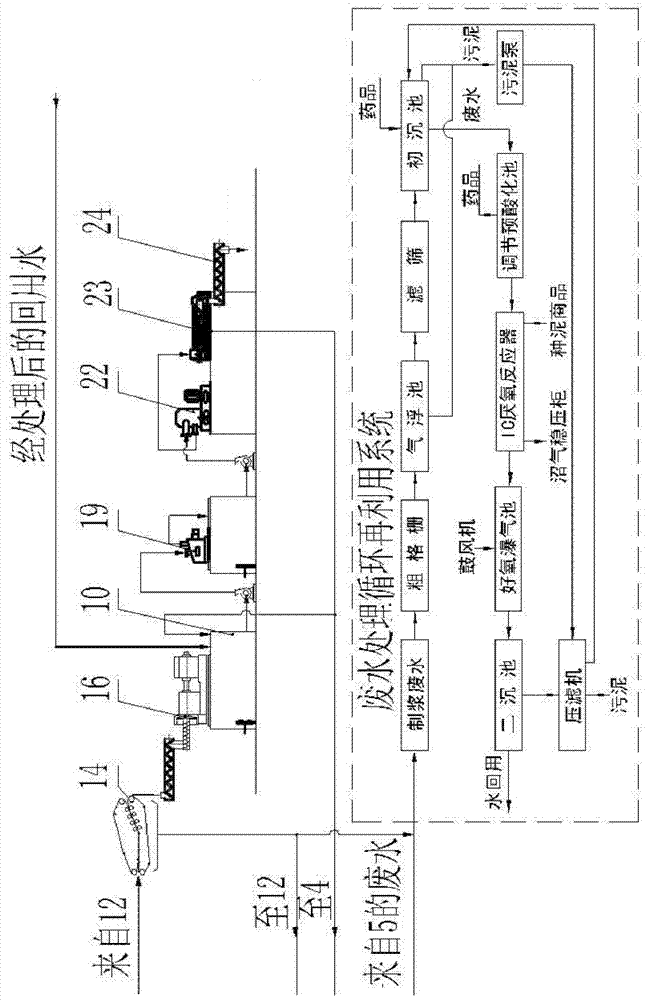

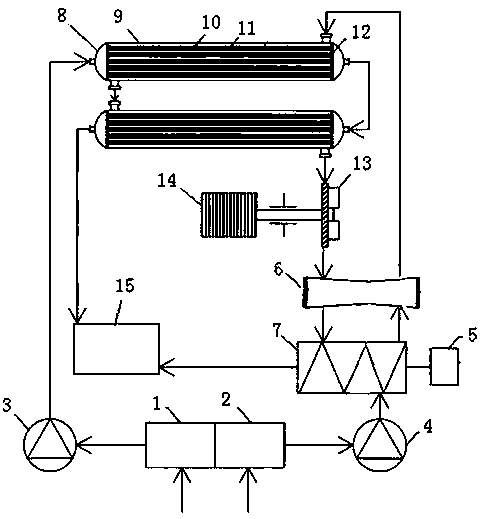

Environmentally-friendly paper making and pulping technique and system with high yield

InactiveCN102242512AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsFiberBlack liquor

The application of the invention provides an environmentally-friendly paper making and pulping technique with high yield, which comprises a raw material preprocessing stage, a physical fibrillation impregnating processing stage, an impregnating, steaming and bleaching three-section integrated pulping stage and a thickening and dewatering processing stage. An environmentally-friendly paper making and pulping system with high yield realizing the pulping technique comprises a stock cutter, a hammering and fibrillation screening dust remover, a washing dust remover, dewatering conveying equipment, a spiral steaming conveyor, a crashing, extruding and impregnating machine, a stirring and impregnating cabin, a pump pipe and a discharge pipe of a high-enriched steaming, bleaching and pulping all-in-one machine, wherein the pump pipe is connected to the high-enriched steaming bleaching pulping all-in-one machine; the discharge pipe of the high-enriched steaming, bleaching and pulping all-in-one machine is connected to a pulp cabin; the pump pipe of the pulp cabin is connected with a thickening and dewatering machine; the thickening and dewatering machine is output to the high-enriched pulping machine; the output of the high-enriched pulping machine is connected with a screening purifier and a thickening and squeezing machine in sequence. In the invention, the problems of high pollution, high energy consumption, serious shortage of paper making raw material and the like in present pulping and paper making industry can be solved fundamentally; rich plant fiber in the nature can be used, and the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption can be realized.

Owner:李刚荣 +1

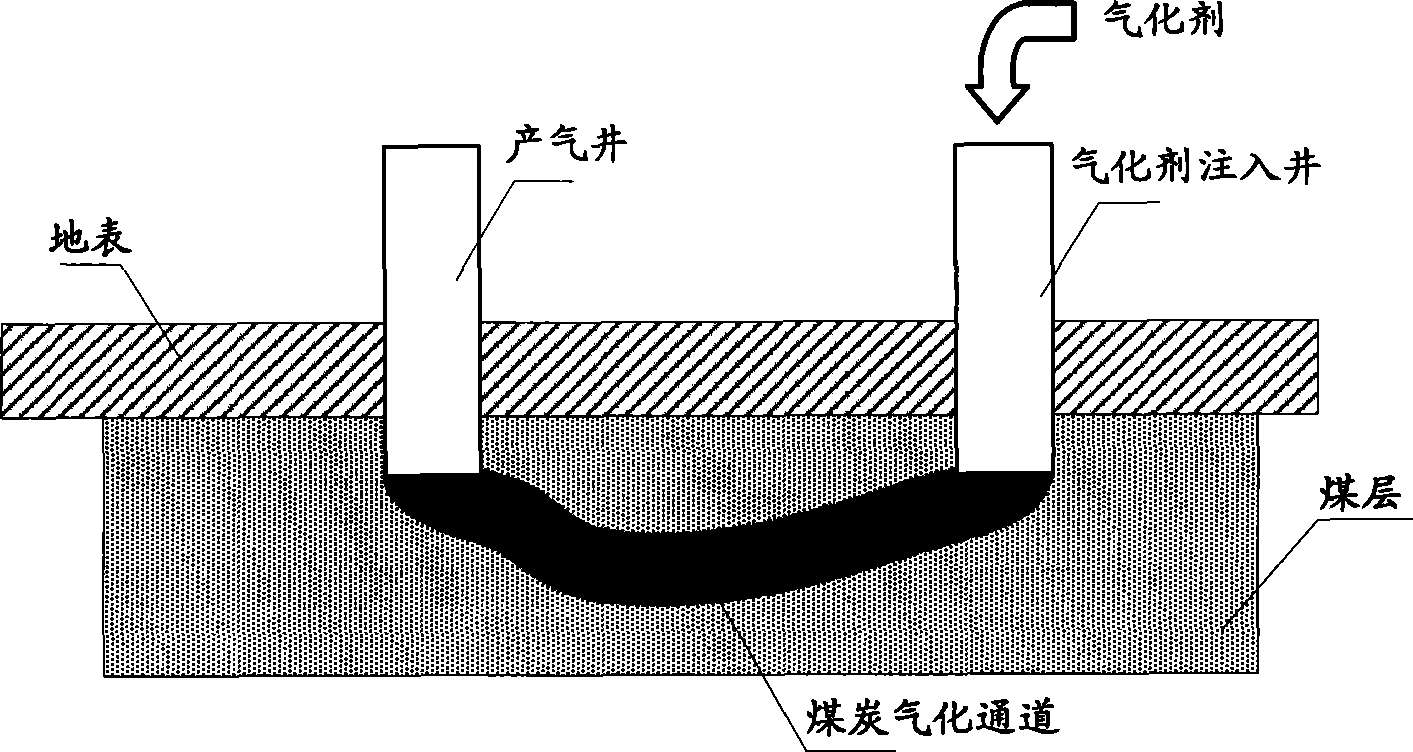

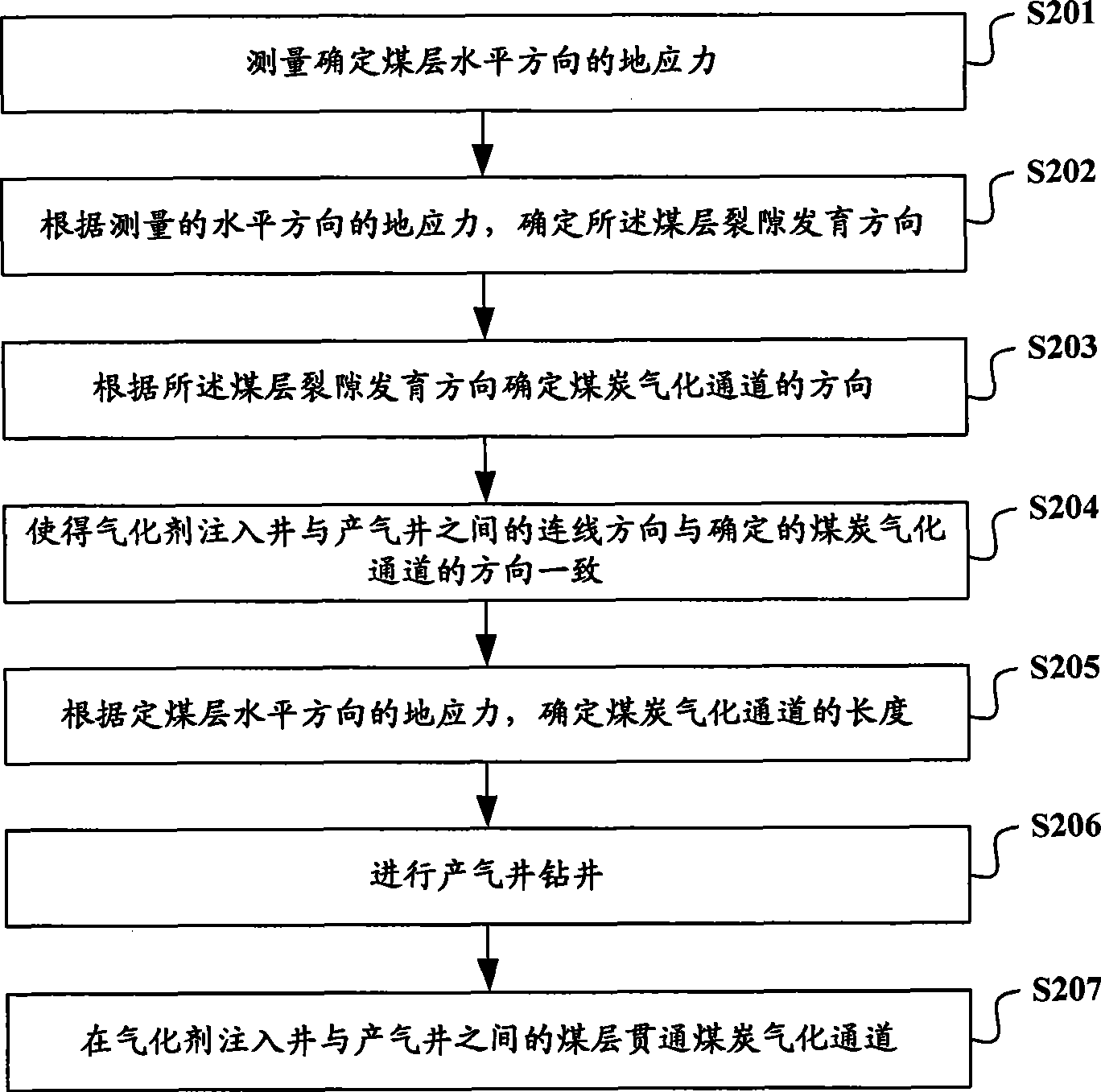

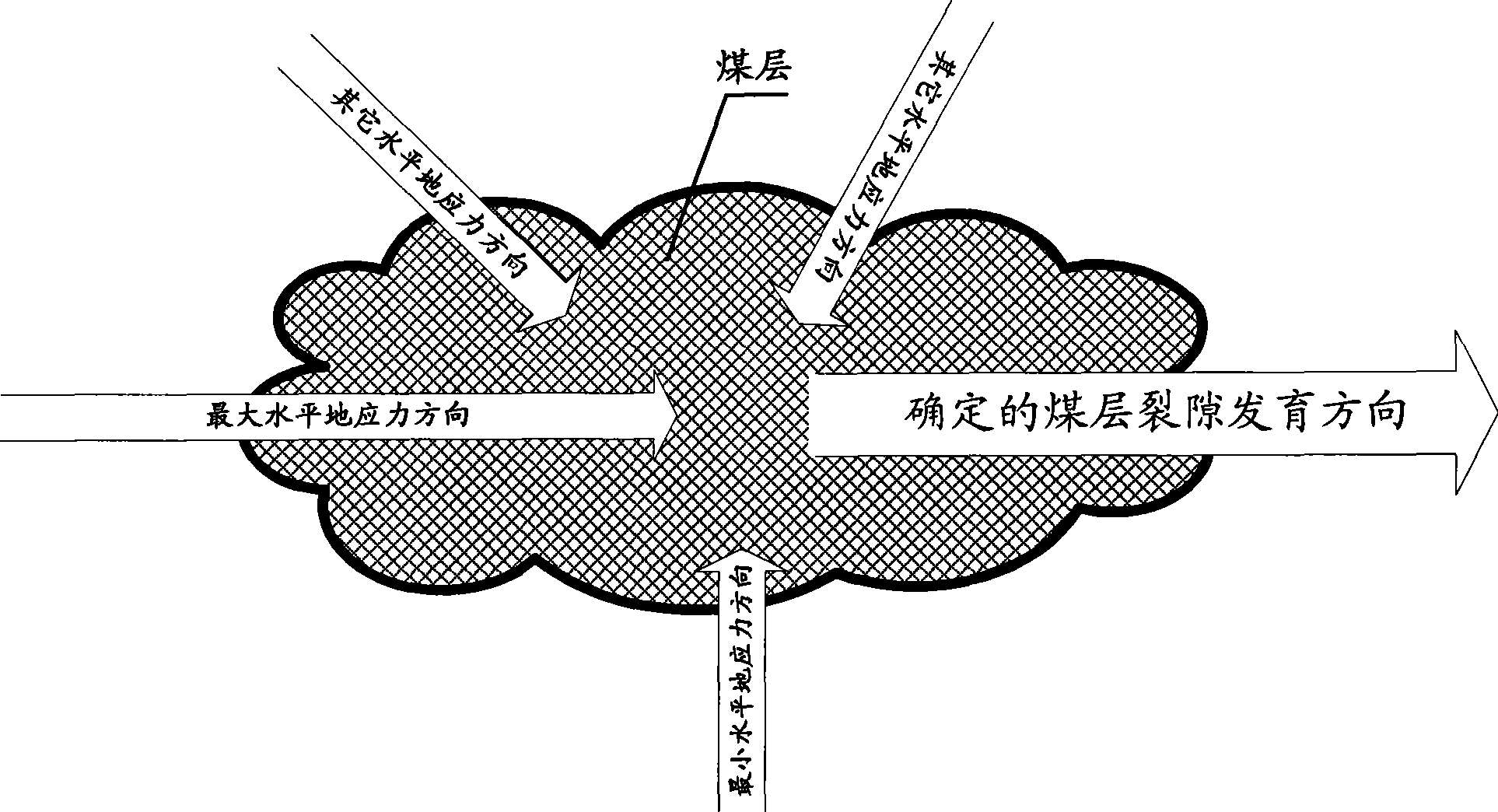

Method and system for determining and penetrating underground coal gasification passage

ActiveCN101424181AImprove penetration efficiencyIncrease the lengthConstructionsCoal gasificationEnvironmental geologyCrustal stress

The invention relates to the field of underground coal gasification, in particular to a technology for ensuring and channeling a coal gasification tunnel. The invention provides a method and a system for ensuring and channeling the coal gasification tunnel, wherein the method comprises the following steps: measuring the crustal stress in the horizontal direction of a coal bed; ensuring the cranny developing direction of the coal bed according to the measured crustal stress in the horizontal direction; and ensuring the direction of the coal gasification tunnel according to the cranny developing direction of the coal bed. Because the cranny developing direction in the coal bed is ensured according to the crustal stress in the horizontal direction of the coal bed and the direction of the coal gasification tunnel is decided according to the cranny developing direction of the coal bed, when the coal gasification tunnel exploited along the cranny developing direction of the coal bed reaches the same permeability, the required external force is smaller so that the channeling efficiency of the gasification tunnel is improved.

Owner:ENN SCI & TECH DEV

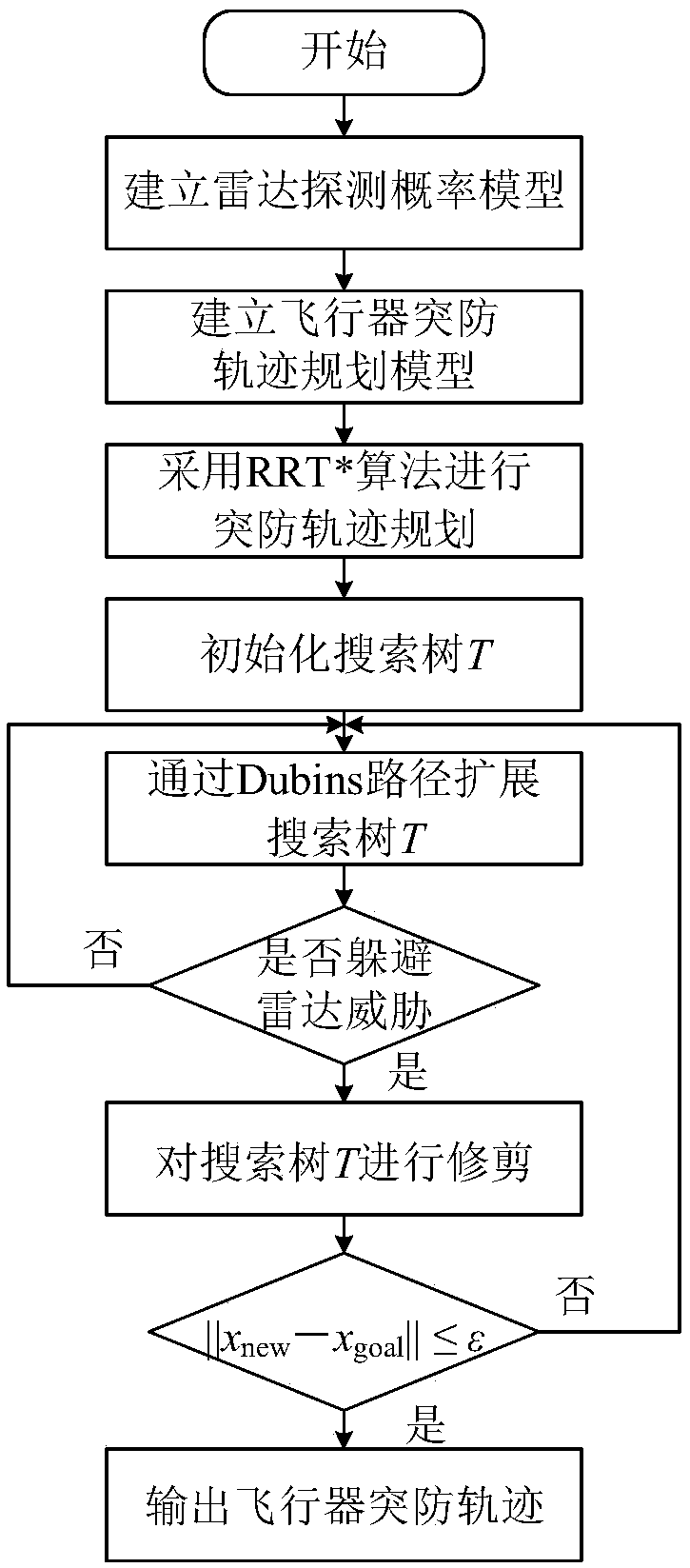

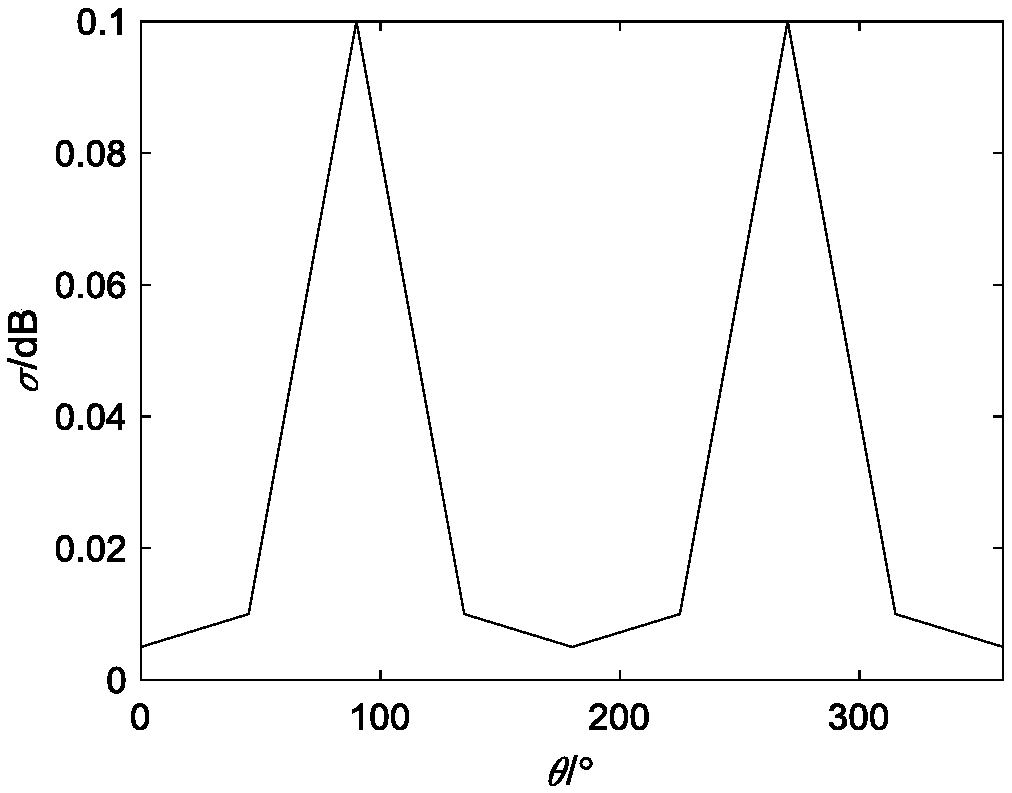

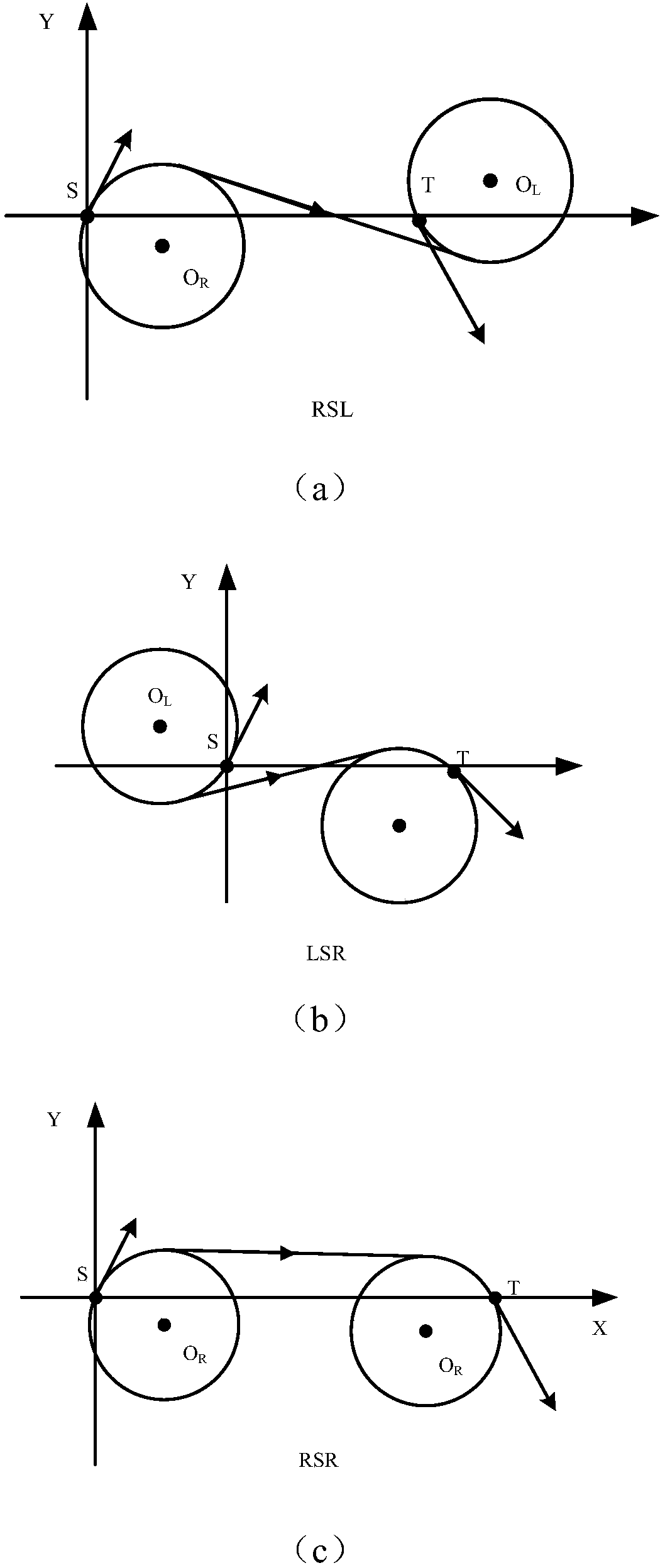

Aircraft penetration trajectory planning method based on RRT* algorithm

ActiveCN108958292AAchieving threat avoidanceReduce the cost of trajectory planningPosition/course control in three dimensionsAirplaneEnvironmental geology

The invention discloses an aircraft penetration trajectory planning method based on an RRT* algorithm and belongs to the field of aircraft trajectory planning. The implementation method disclosed in the present invention comprises the following steps: based on RCS data of an aircraft under different attitudes in a circumferential direction, a radar detection probability model is established to determine the probability that the aircraft is detected by radar during penetration processes; an aircraft penetration trajectory planning model is established based on a Dubins path; based on the RRT* algorithm and the aircraft penetration trajectory planning model, penetration trajectory planning is conducted, that is, the penetration trajectory planning is conducted based on combination of asymptotic optimality of the RRT* algorithm and a feature of a shortest Dubins path, the cost of aircraft penetration trajectory planning can be effectively reduced, an aircraft penetration trajectory can beobtained, and effective penetration of the aircraft can be achieved. Since no numerical integration method is needed for the Dubins path to solve a dynamic model, a principle to solve based on a geometric method, and therefore efficiency of the trajectory planning can be improved. The aircraft penetration trajectory planning method disclosed in the invention can be applied to stealth penetrationtrajectory planning of the aircraft, and is especially suitable for the stealth penetration trajectory planning of an airplane.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of light calcium-alginate-base sponge body functional material

The invention discloses a preparation method of a light calcium-alginate-base sponge body functional material. The preparation method comprises the following steps: in room temperature, evenly mixing sodium alginate powder with soluble calcium salt, magnesium salt or aluminum salt, a reinforcing agent, peroxide and a catalyst to obtain a mixture; moistening with an alcohol-water solution to form paste; rolling by molding equipment to form a film material or a plate material; and then sequentially performing infiltration, complexation for pore formation, and expansion for pore formation. The preparation method has the characteristics of simple technology, low control difficulty, low equipment investment, energy-saving effect, low production cost and the like and is applicable to large-scaled industrial production; the prepared light calcium-alginate-base sponge body functional material is the same in structure and composition regardless of interior or exterior, good in quality, light in weight, high in mechanical strength, and excellent in imbibition performance and air permeability, and can be widely applicable to the fields of antibacterial materials, flame-resistant materials, adsorbing materials, acoustic materials, vibration-absorptive materials and the like; the market prospect is extensive.

Owner:QINGDAO UNIV

Method for preparing calcium alginate based cavernous body functional material

The invention discloses a method for preparing a calcium alginate based cavernous body functional material. The method comprises the following steps of: uniformly mixing sodium alginate powder with a soluble calcium salt, magnesium salt or aluminum salt and an enhancer; sequentially forming into membranes and pieces by virtue of equipment; performing infiltration reaction and pore formation reaction to obtain the material, wherein the sodium alginate powder, the soluble calcium salt, magnesium salt or aluminum salt and the enhancer are 10-65 to 7-30 to 15-35 to 10-30 in percentage by weight. The method is simple in process control and has less equipment investment, and sewage discharge is basically avoided; the prepared functional material is a cavernous body having a nanometer structure, has the characteristics of high consistency of internal structure and external structure and composition, high imbibition air permeability, powerful mechanical strength, high flexibility and elasticity and the like, and can be used as medical auxiliaries, antibacterial materials, flame-resistant materials, absorption materials and sound-absorbent materials, vibration-absorptive materials and the like.

Owner:QINGDAO UNIV

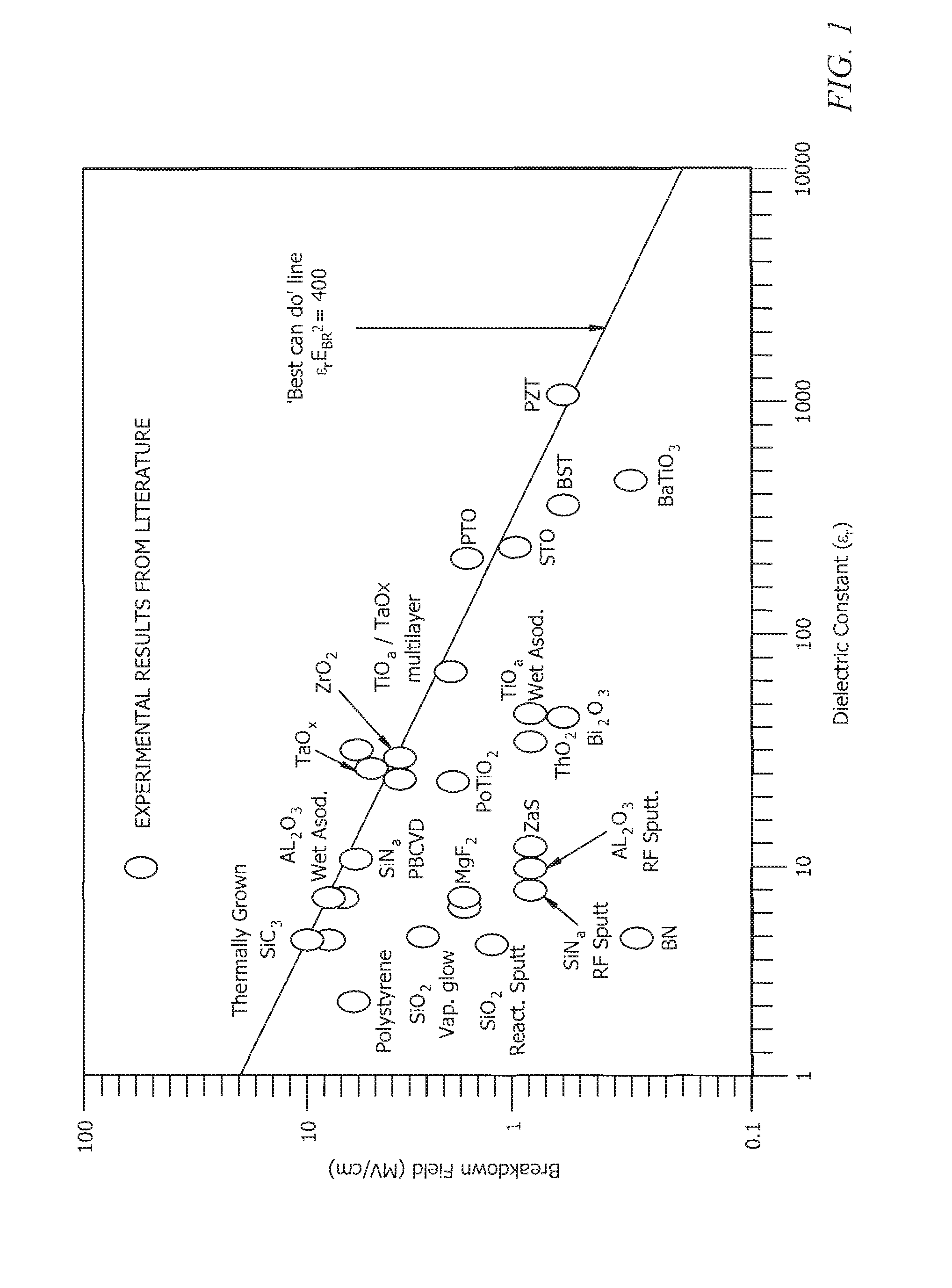

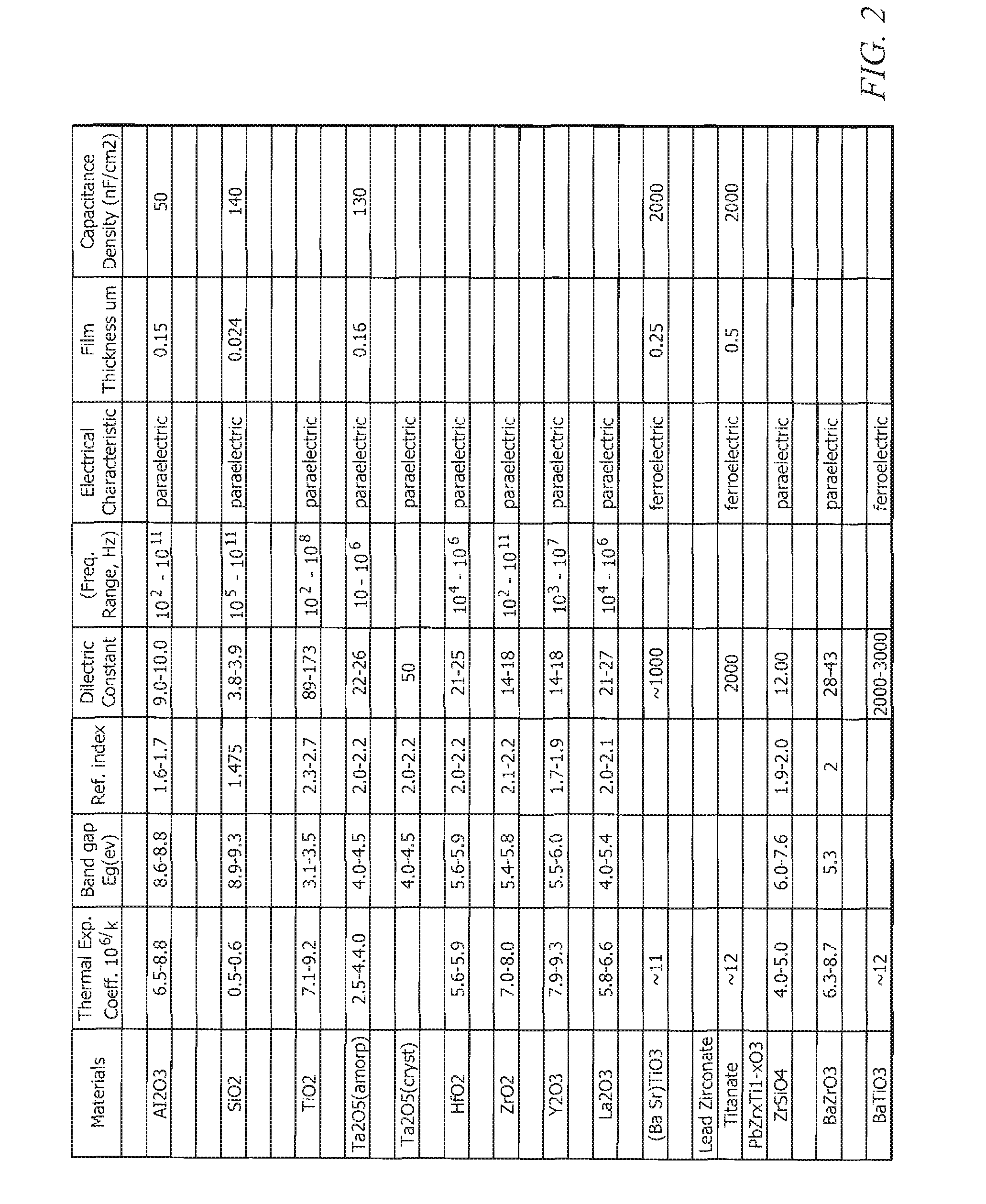

High-dielectric constant thin film metal oxides on silicon wafers for capacitor applications and methods of manufacture

InactiveUS20080220153A1Low costHigh bulk densityRadiation applicationsVacuum evaporation coatingDielectricCapacitor

A method of fabrication of high-k paraelectric metal oxide films at low temperatures utilizing ordered mesoporous metal oxide thin films synthesized by organic templating methodology. The process consisting of (a) chemical solution deposition of periodic ordered mesoporous structures containing high-k metal oxide films, (b) removal of organic template additives, (c) infiltration of the pores with an appropriate second phase, and (d) low temperature thermal and / or annealing of infiltrated films.

Owner:SBA MATERIALS

High-yield environment-friendly papermaking and pulping process method and system

ActiveCN102817262AReduce adverse effectsImprove wettabilityPretreatment with water/steamPretreatment with alkaline reacting compoundsBlack liquorPlant fibre

The invention provides a high-yield environment-friendly papermaking and pulping process method which includes a raw material pre-processing section, a physical threading immersion processing section, an immersing, steaming and bleaching integrated pulping section and a thickening and dewatering processing section. A high-yield environment-friendly papermaking and pulping system for achieving the pulping process method sequentially comprises a stock cutter, a hammer thread screening deduster, a washing deduster, a dewatering conveying device, a steaming spiral conveyor, a squeezing cracking and thread squeezing impregnator, a disperse impregnating device, a high-concentration cooking and bleaching pulping all-in-one machine, a pulp bin, a concentration dewaterer, a high-concentration stuff grinder, a screening purifier and a concentration presser according to the process route, wherein a pump pipe is connected onto the high-concentration cooking and bleaching pulping all-in-one machine, a discharging pipe of the high-concentration cooking and bleaching pulping all-in-one machine is connected to the pulp bin, a pulp bin pump pipe is connected with the concentration dewaterer, the output end of the concentration dewaterer is connected onto the high-concentration stuff grinder, and the output end of the high-concentration stuff grinder is sequentially connected with the screening purifier and the concentration presser. The high-yield environment-friendly papermaking and pulping process method and system fundamentally solve problems of high pollution and energy consumption, shortage of papermaking raw materials and the like existing in the papermaking industry, and achieve the technical purposes of efficient bleaching, high yield, no black liquor and low energy consumption by using abundant plant fibers in the nature.

Owner:丹东东方轻工机械有限公司

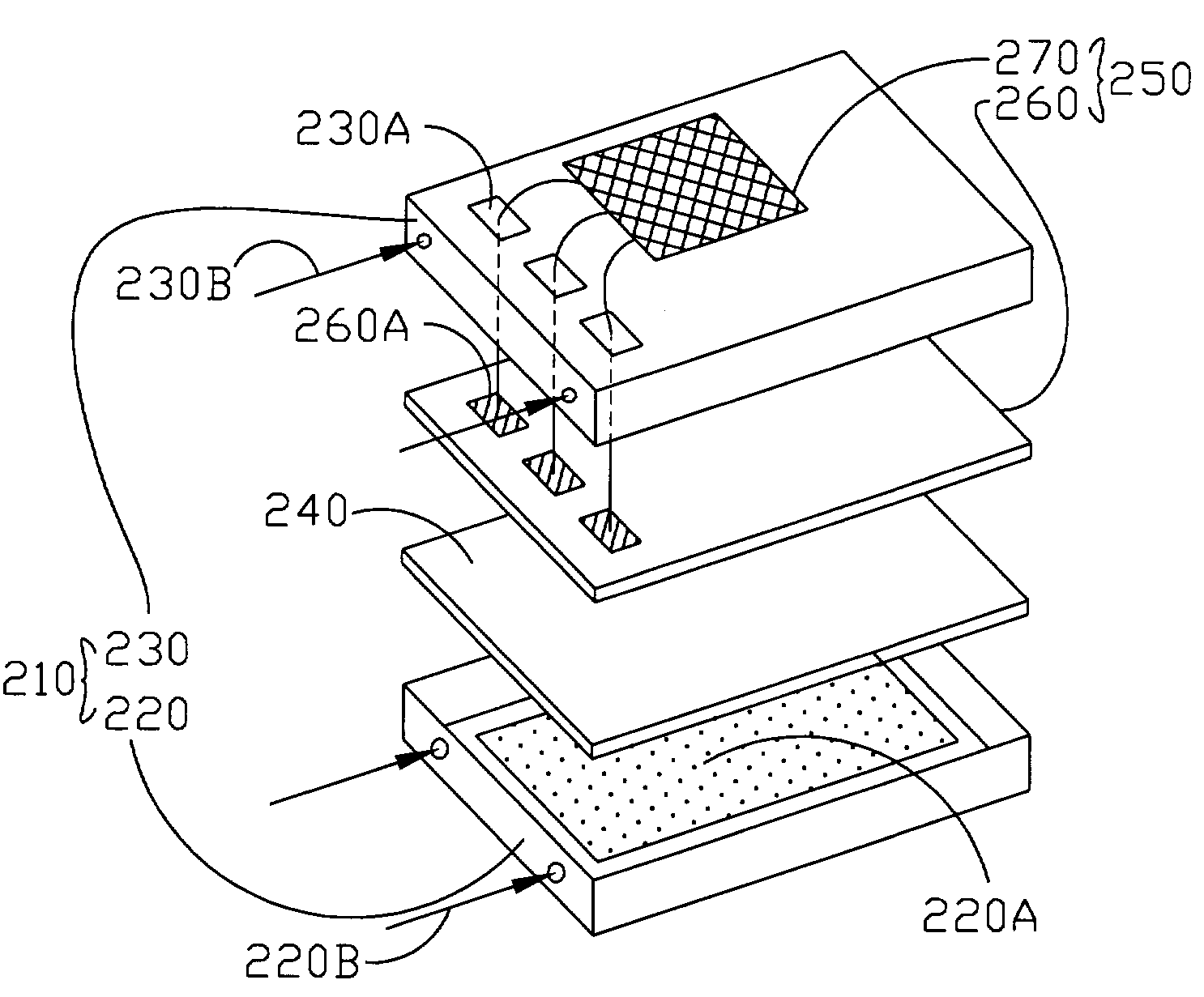

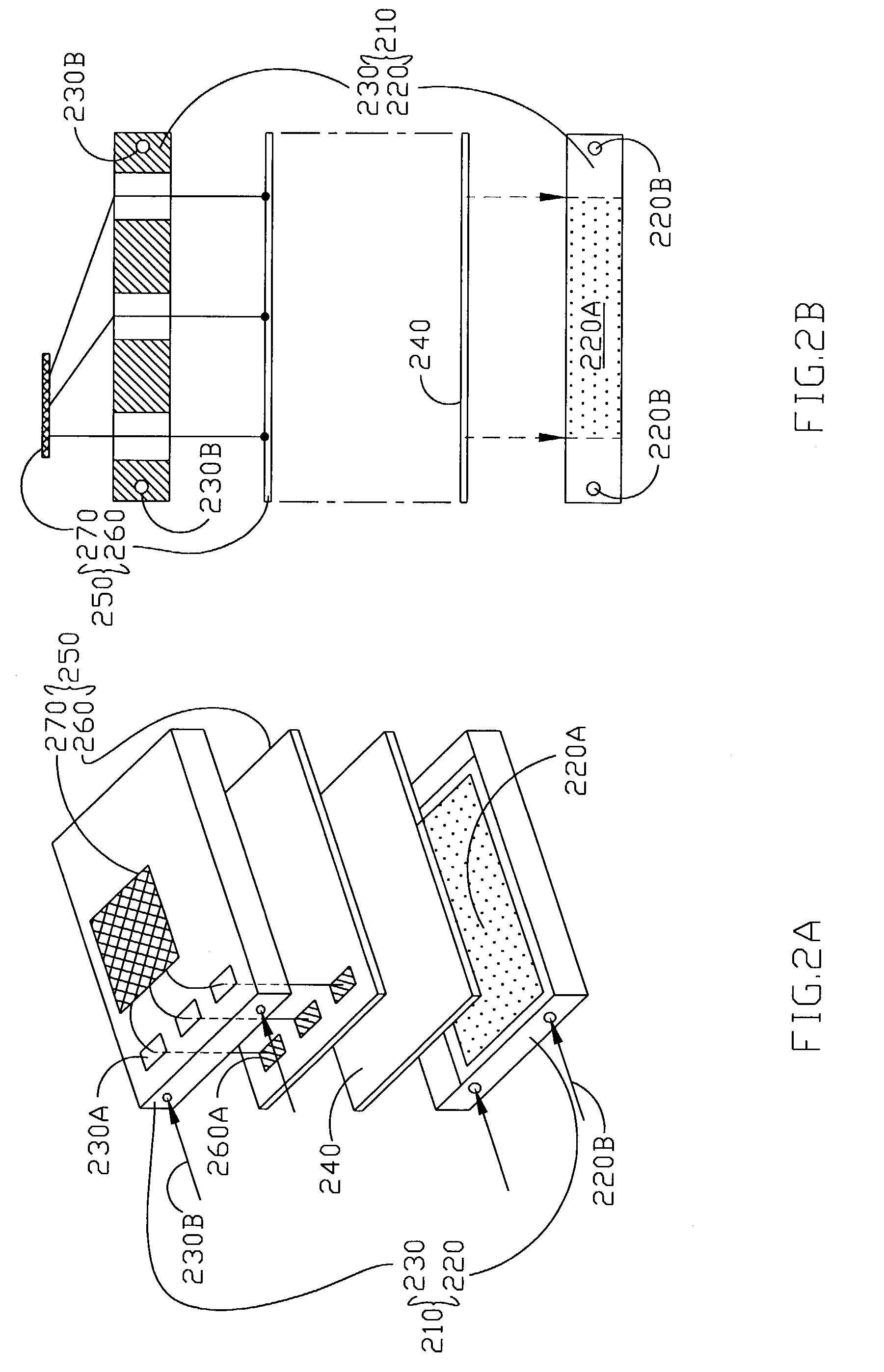

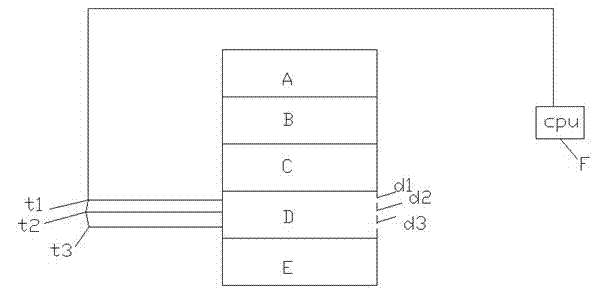

Package for the display module with the electromagnetic module

InactiveUS7153016B2Reduced dimensionReduce processing costsShow cabinetsMechanical apparatusLiquid-crystal displayComputer module

This invention discloses a package for a liquid crystal display with the electromagnetic module. This invention provides a package for the liquid crystal display with the electromagnetic module, the package for the liquid crystal display with the electromagnetic module comprises: a lightguide sub-module, an electromagnetic sub-module and a package sub-module; the electromagnetic sub-module further comprises an antenna circuit board with the connectors, a control device; and further the package sub-module comprises a first package-cover and a second package-cover, wherein the first package-cover comprises an opening of an about equivalent lightguide area of the lightguide sub-module, the surface of the second package-cover comprises the second openings. Furthermore, the backlight module with the electromagnetic module in the present invention utilizes a sidewall-fixed method to fix the inside devices.

Owner:WACOM CO LTD

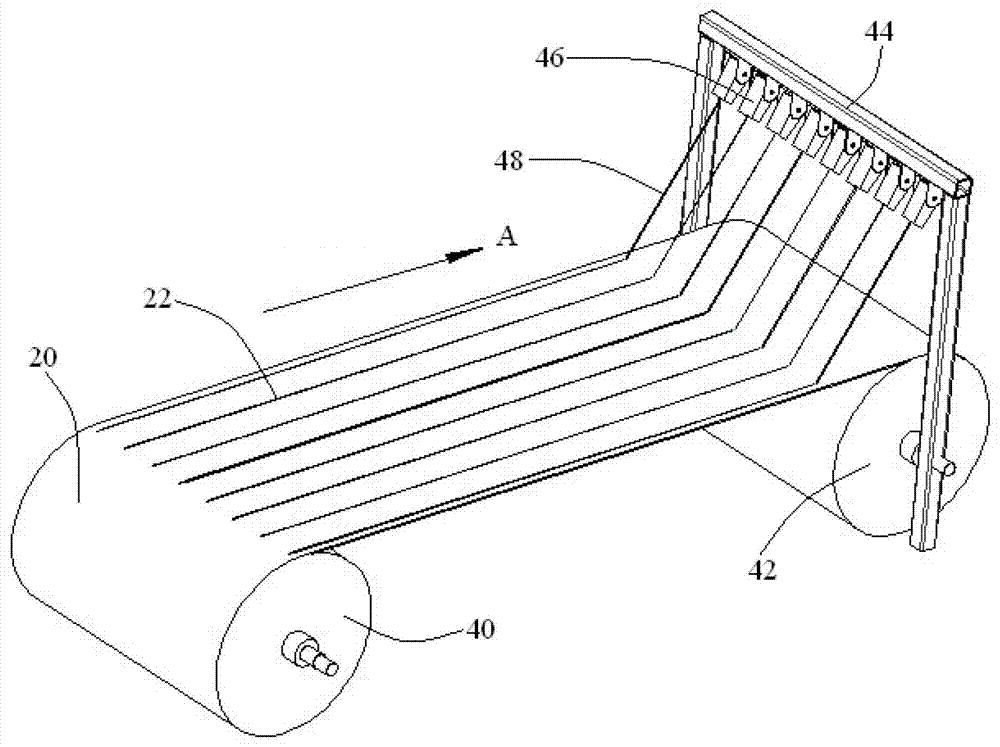

Positive plate of lithium ion power battery as well as manufacturing method and laser etching device of positive plate

InactiveCN103094521AIncrease productivityImprove wettabilityNon-aqueous electrolyte accumulator electrodesPower batteryLaser etching

The invention discloses a positive plate of a lithium ion power battery as well as a manufacturing method and a laser etching device of the positive plate. The positive plate comprises a positive current collection body and a positive membrane applied onto the positive current collection body, wherein a micro groove is etched on the positive membrane; and the depth of the micro groove is smaller than the thickness of a one-layer electrode membrane. The micro groove is etched on the positive membrane after the cold-pressing operation, so that the wetting performance of the surface of the lithium iron phosphate positive plate to an electrolyte solution is improved to a great extent, the permeation efficiency of the electrolyte solution of the high-capacity lithium ion power battery is improved, the distribution uniformity of the electrolyte solution in the positive plate is improved, the capacity of the lithium ion power battery is increased, the cycle life of the lithium ion power battery is prolonged, and the production efficiency of the lithium ion power battery is improved at the same time.

Owner:CONTEMPORARY AMPEREX TECH CO

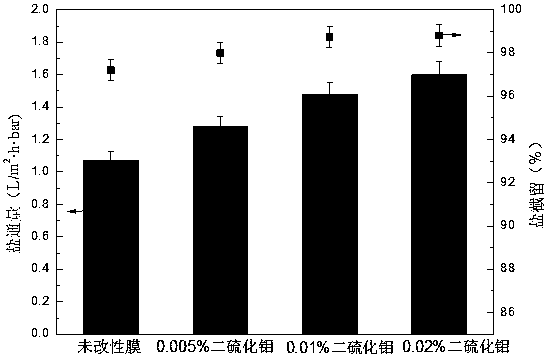

Modification method for establishing water channel by utilizing molybdenum disulfide to enhance water flux of polyamide reverse osmosis membrane

InactiveCN108097059AImprove water permeabilityImprove penetration efficiencySemi-permeable membranesMembranesCvd grapheneLayered structure

The invention relates to a modification method for establishing a water channel by utilizing molybdenum disulfide to enhance the water flux of a polyamide reverse osmosis membrane, and belongs to thefield of material modification. The method comprises the following steps: preparing a molybdenum disulfide and m-phenylenediamine mixed solution; pouring the mixed solution on the surface of a polyether sulfone-based membrane and maintaining for 10 minutes; taking out the polyether sulfone-based membrane and blow-drying by nitrogen; pouring a 1,3,5-toluenyl chloride n-hexane solution on the surface of the polyether sulfone-based membrane to enable the 1,3,5-toluenyl chloride n-hexane solution and the polyether sulfone-based membrane to completely react for 1 minute; taking out the polyether sulfone-based membrane, blow-drying with nitrogen and removing the redundant solution; and placing the prepared membrane in a drying oven with the temperature of 60 DEG C and reacting for 15 minutes. The method has the following advantages: single-layer nanometer molybdenum disulfide has a two-dimensional layered structure similar to graphene, only has the thickness of 1 nanometer, is filled with nanometer pores, and can leak a large amount of sea water and remain salt and other components during sea water desalination and salt interception to fulfill the aims of sea water desalination and saltinterception. The method is simple in process and convenient in preparation.

Owner:HARBIN INST OF TECH

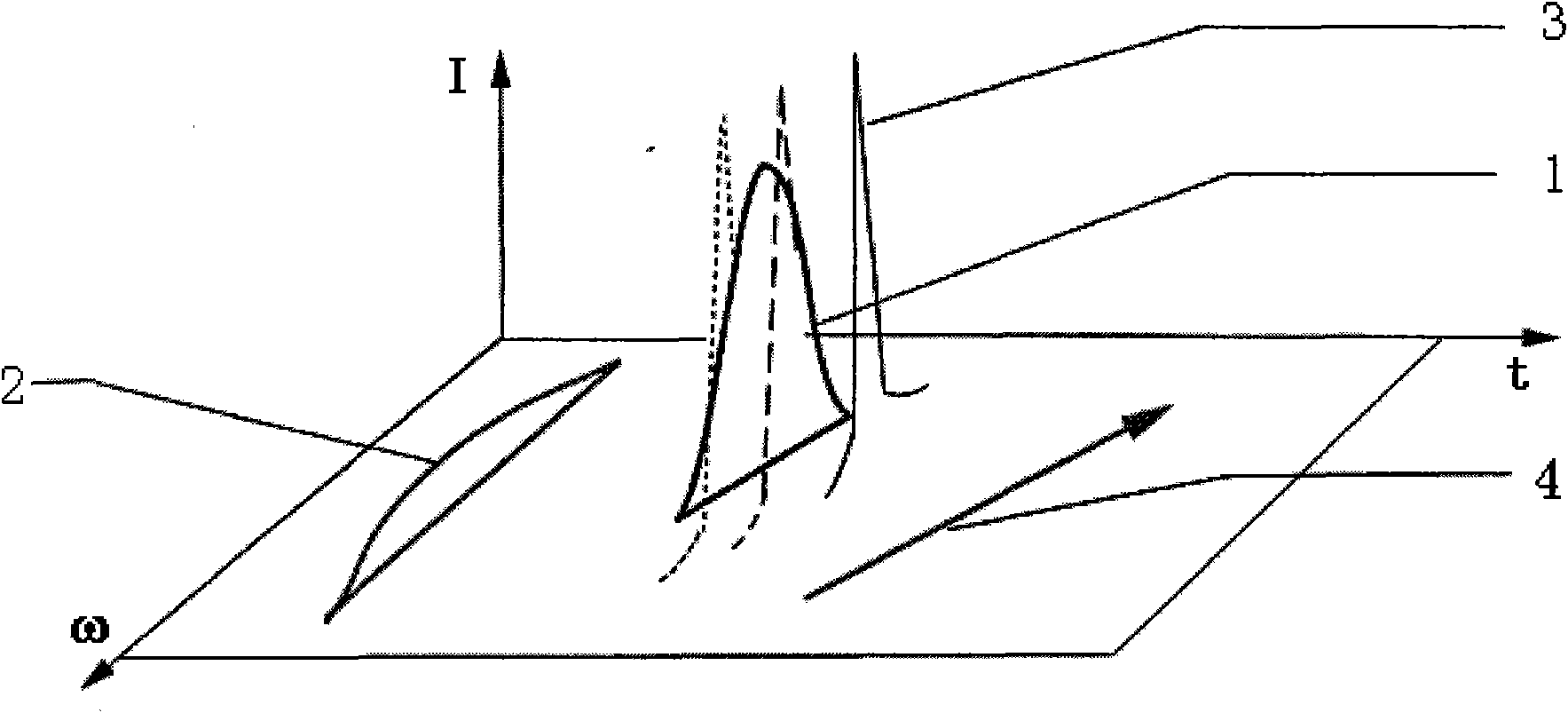

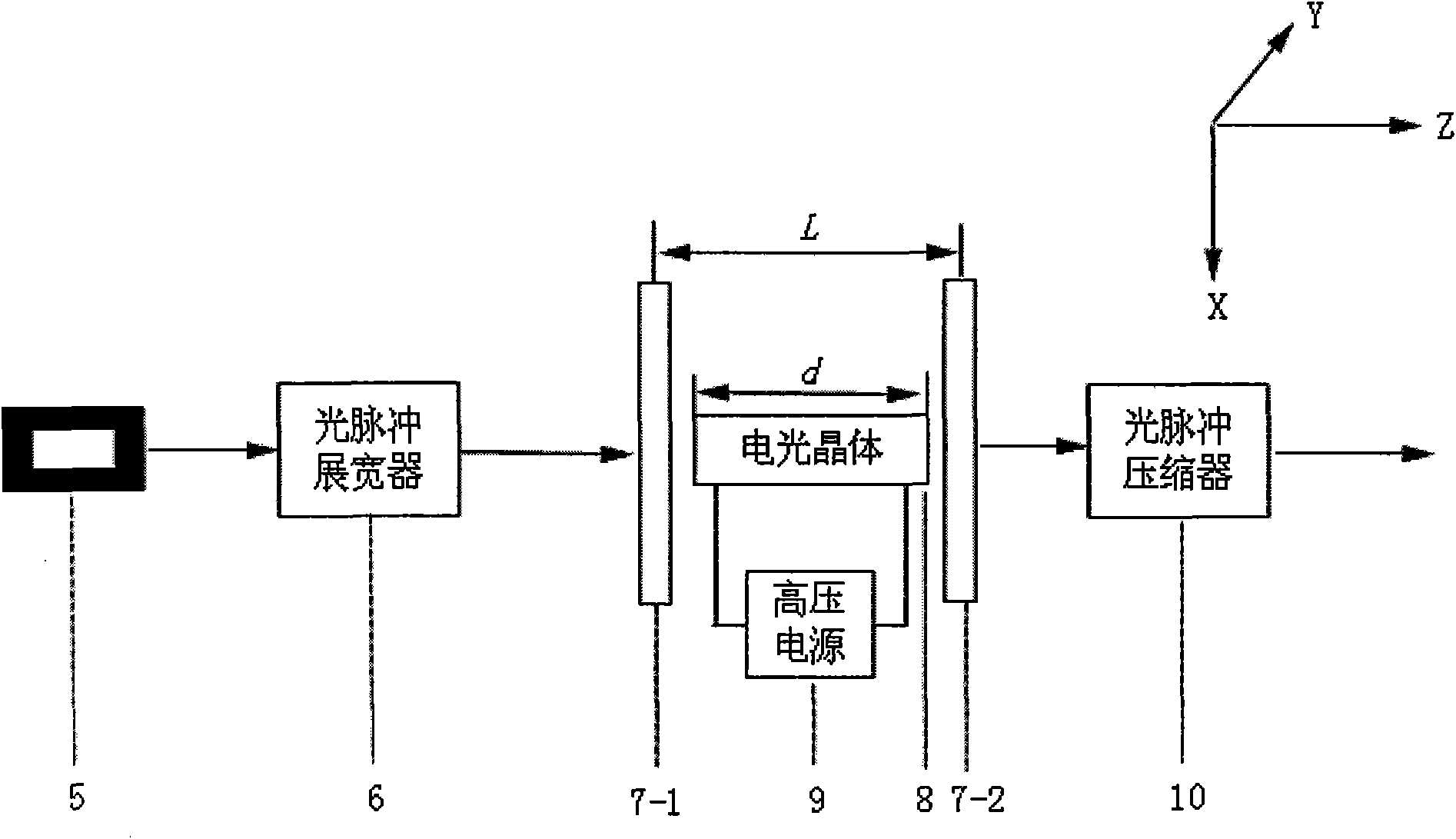

Method for increasing signal to noise ratio of femtosecond laser through F-P (Fabry-Perol) etalon internally installed with electro-optic crystal

InactiveCN101867145AGreat filtrationImprove signal-to-noise ratioLaser detailsSignal lightLaser light

The invention relates to a method for increasing the signal to noise ratio of a femtosecond laser through an F-P (Fabry-Perol) etalon internally installed with an electro-optic crystal and a device thereof, which belong to the technical field of ultrashort pulses. The method comprises the following steps: firstly, stretching a femtosecond laser pulse to be increased in the signal to noise ratio, which is output from a femtosecond laser light source, into chirp signal light; enabling an instaneous spectral filtering function output by the F-P etalon to be consistent with the chirp size of the chirp signal light by modulating the voltages of both ends of the electro-optic crystal internally installed in the F-P etalon, and thereby, a chirp signal pulse efficiently pass, whereas noise is filtered off to achieve the goal of increasing the signal to noise ratio of the chirp pulse; finally, compressing the chirp signal light into the femtosecond laser with higher signal to noise ratio. The device for realizing the method comprises the femtosecond laser light source, a laser pulse stretcher, the F-P etalon, the electro-optic crystal, a high-voltage pulse power supply, a laser pulse compressor and the like. The signal to noise ratio of the femtosecond laser can be effectively increased by adopting the method and the device. Moreover, the device has simple structure and convenient adjustment.

Owner:SICHUAN UNIV

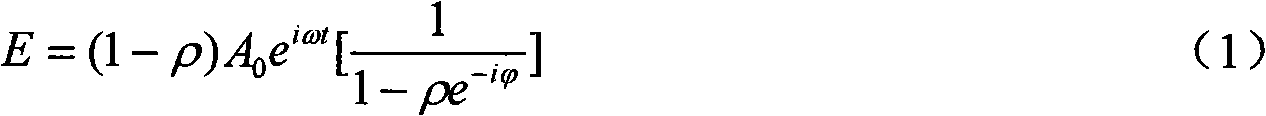

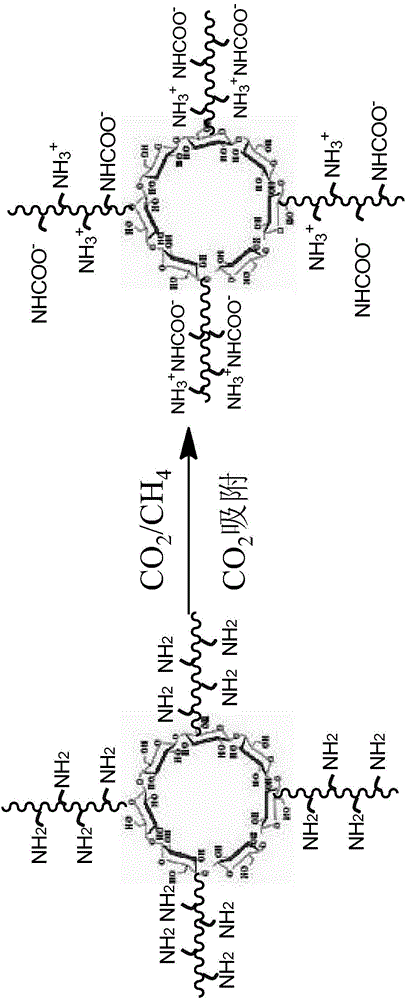

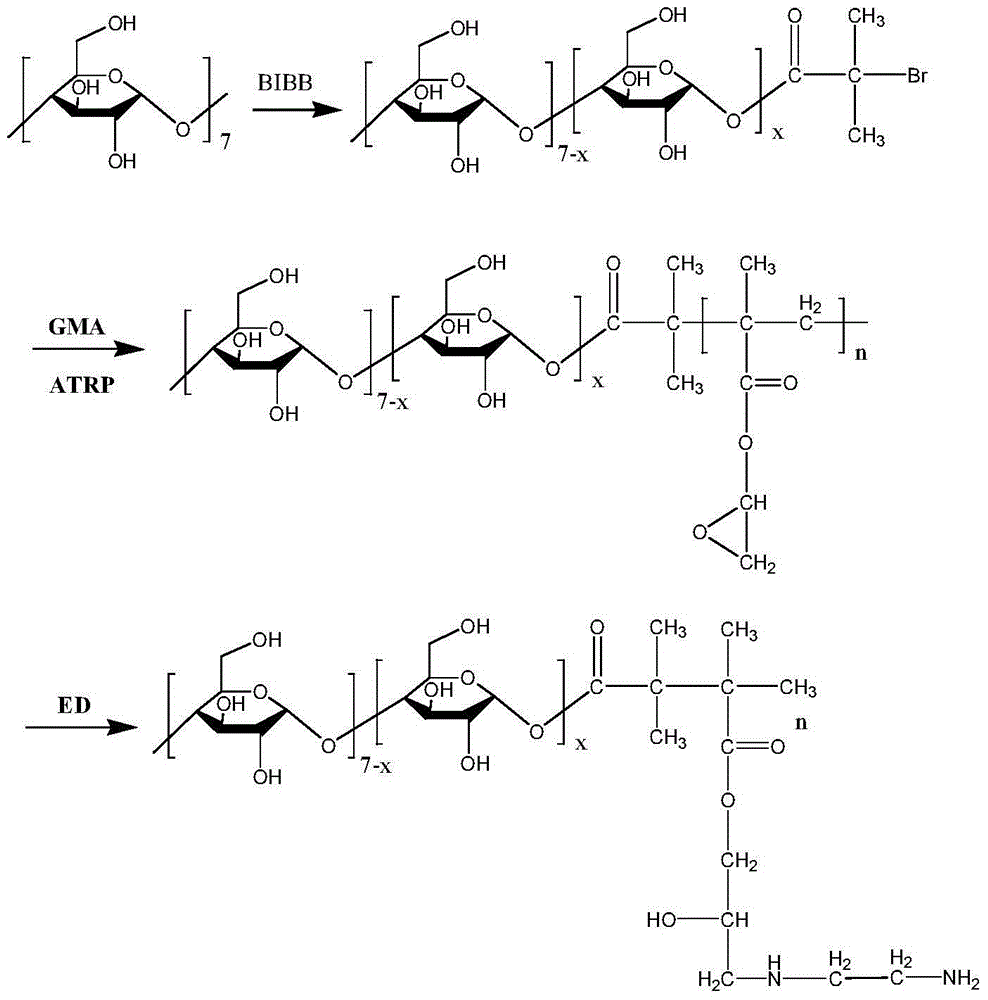

Star carbon dioxide fixed carrier and preparation method thereof as well as preparation method of separating membrane material

ActiveCN104548964AImprove penetration efficiencyGood storage stabilitySemi-permeable membranesCarbon compoundsArm lengthsWeight distribution

The invention discloses a star carbon dioxide fixed carrier which is characterized in that the fixed carrier is a polymer taking CD as a core and PGED as an arm. The fixed carrier is established by an atom transfer radical polymerization method, the method has a smooth polymerization reaction and is easy to control, and the star CO2 fixed carrier with different arm numbers, different arm lengths, different molecular weights and narrow molecular weight distribution can be prepared according to the needs. The prepared CO2 fixed carrier has good storage stability, the amino on the arm is a CO2 promoting transfer carrier, and therefore, the fixed carrier can be used as a separating membrane material, and has CO2 selective permeability, high permeation selectivity on a CO2 / CH4 system, and has the application potential in a methane purification technology.

Owner:CHONGQING ACAD OF AGRI SCI +1

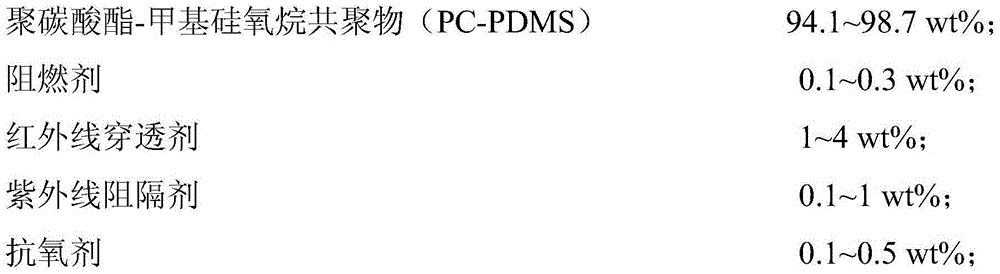

Polycarbonate-organosiloxane copolymer material capable of selectively transmitting near-infrared rays

ActiveCN104017347AImprove penetration efficiencyImprove mechanical propertiesPolymer scienceAntioxidant

The invention belongs to the technical field of near-infrared ray transmission materials, and discloses a polycarbonate-organosiloxane copolymer material capable of selectively transmitting near-infrared rays. The product prepared from the material has higher low-temperature impact resistance and near-infrared ray transmission selectivity. The material comprises 94.1-98.7wt% of polycarbonate-methylsiloxane copolymer, 0.1-0.3 wt% of flame retardant, 1-4 wt% of infrared penetrant, 0.1-1 wt% of ultraviolet blocking agent, 0.1-0.5 wt% of antioxidant and 0-0.1 wt% of lubricant. The polycarbonate-organosiloxane copolymer selected as the substrate has better mechanical properties than the existing material, and has higher low-temperature impact resistance and high near-infrared transmittance. By selecting the perylene organic pigment as the near-infrared penetrant, the material can implement very high visible light covering performance, near-infrared region transmittance and selectivity for multiple colors.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

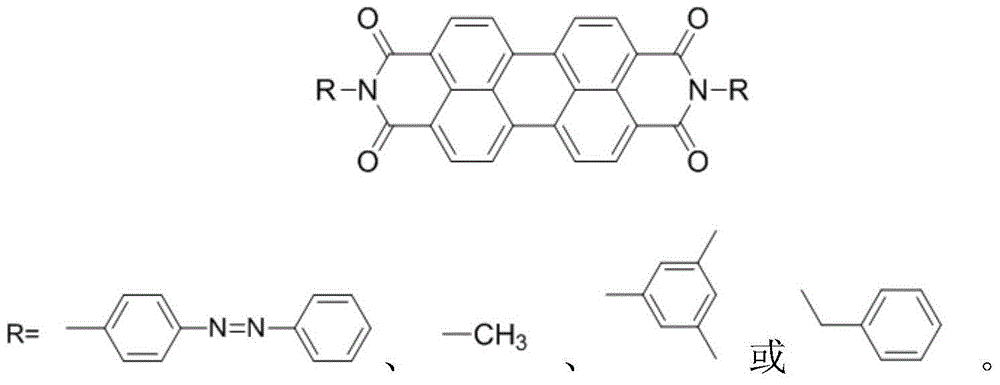

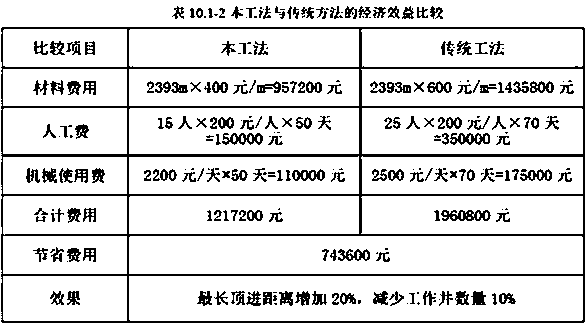

Manual jacking technology of long-distance heavy-caliber concrete pipe for complex stratums

InactiveCN109798396AImprove penetration efficiencyImprove construction accuracyPipe laying and repairRoad surfaceLubrication

The invention relates to the technical field of pipeline project construction, in particular to a manual jacking technology of a long-distance heavy-caliber concrete pipe for complex stratums. The manual jacking technology of the long-distance heavy-caliber concrete pipe for the complex stratums comprises the following steps of (1) construction preparation, (2) pipeline axis measurement and location, (3) pipe jacking work well construction, (4) guiding rail mounting, (5) tool pipe cap mounting, (6) mounting and debugging of pipe jacking equipment, (7) pipeline jacking construction, (8) inspection well construction, and (9) trench backfilling and pavement recovering. The manual jacking technology of the long-distance heavy-caliber concrete pipe for the complex stratums is applied to the manual jacking construction of the long-distance heavy-caliber concrete pipe in the complex stratums, the damage degree of pavements can be reduced, the construction process is simple, the construction cost is low, the construction period is short, lubrication and drag reduction are conducted on the pipeline, construction accuracy is high, the pushing force of pipeline jacking is small, the jacking distance is long, the progress of works is greatly improved, and working efficiency is improved.

Owner:青岛瑞源工程集团有限公司

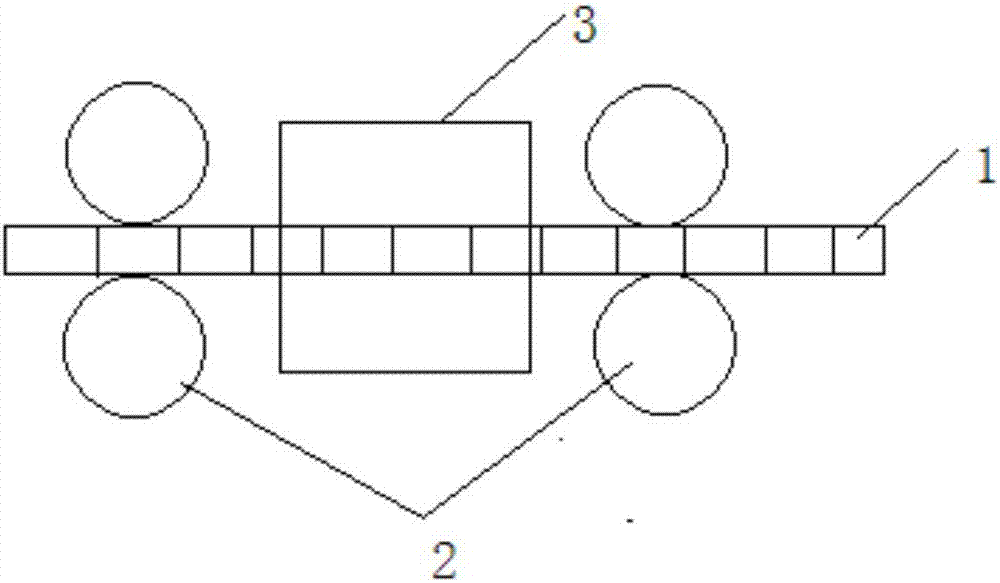

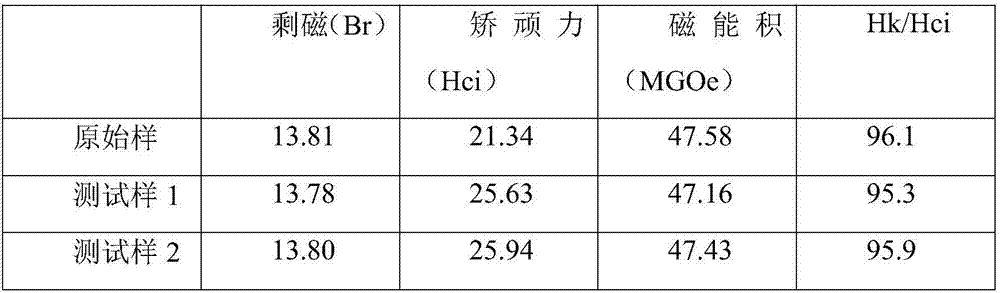

Preparation method of permanent magnet material

ActiveCN105185500AImprove coercive forceUniform penetrationMagnetic materialsRare-earth elementPressure - action

The invention provides a preparation method of a permanent magnet material. The preparation method provided by the invention comprises a coating process and a permeation process, wherein a material containing a rare-earth element coats the surfaces of sintered neodymium-iron-boron magnets; the thickness of each sintered neodymium-iron-boron magnet in one direction is at least less than 10mm; the sintered neodymium-iron-boron magnets are regularly arranged; with respective surfaces with the maximum area as contact surfaces, the sintered neodymium-iron-boron magnets tightly contact one another under the pressure action; and then the sintered neodymium-iron-boron magnets are subjected to heat treatment. By the preparation method provided by the invention, the rare-earth element can permeate evenly and the permeability is high. In addition, by the preparation method provided by the invention, the coercive force of the permanent magnet material can be greatly improved while the residual magnetism is reduced slightly.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

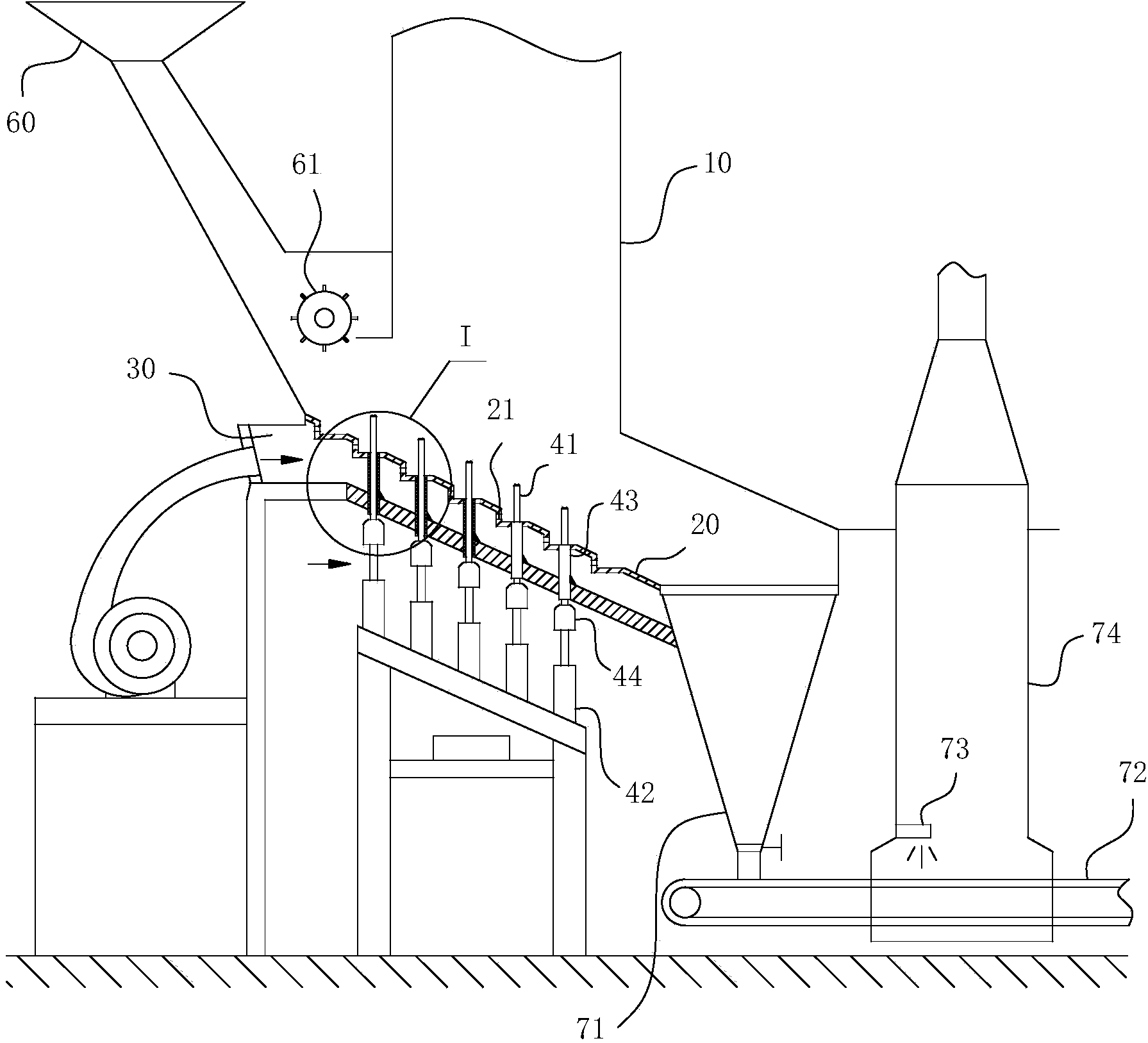

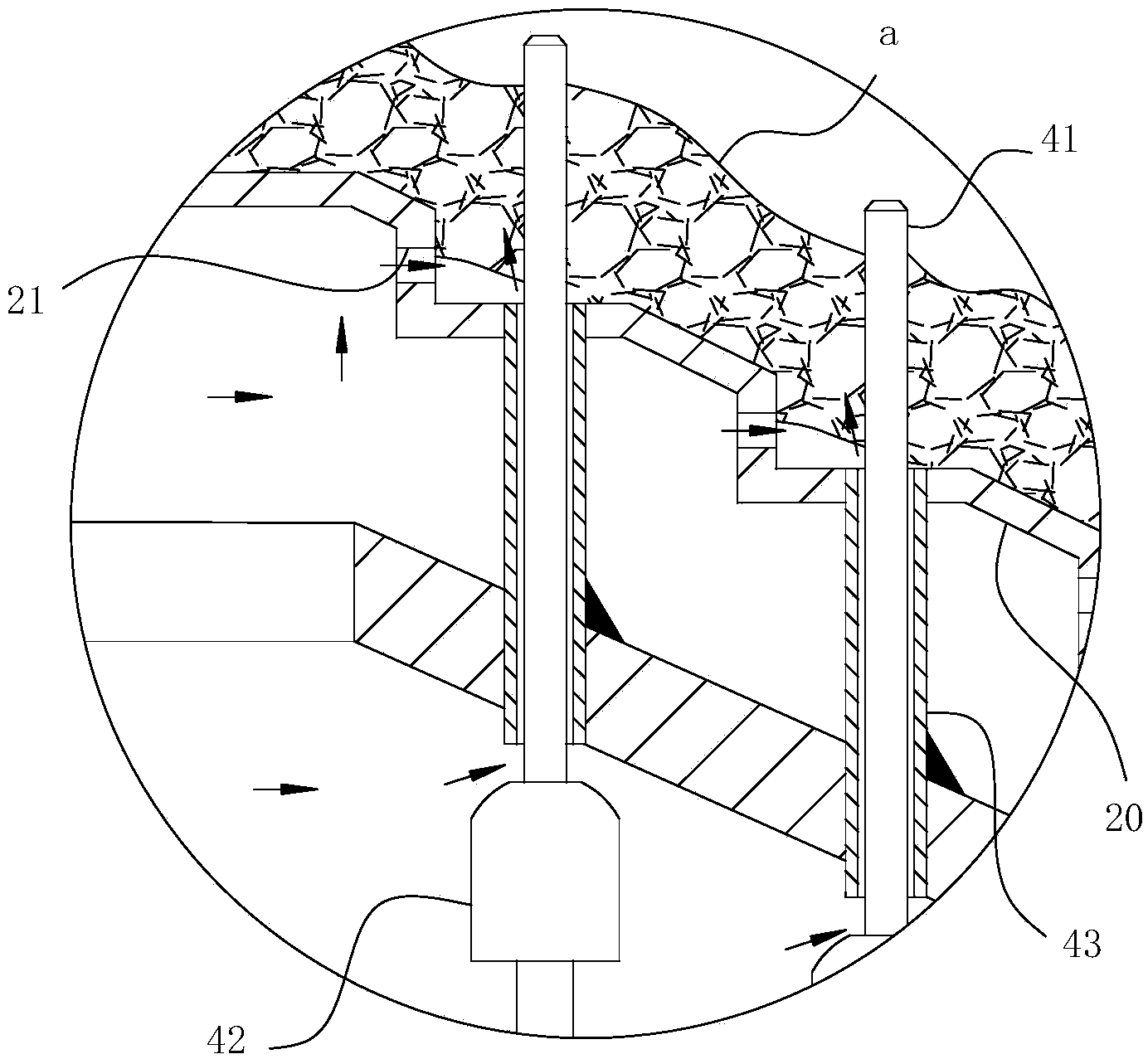

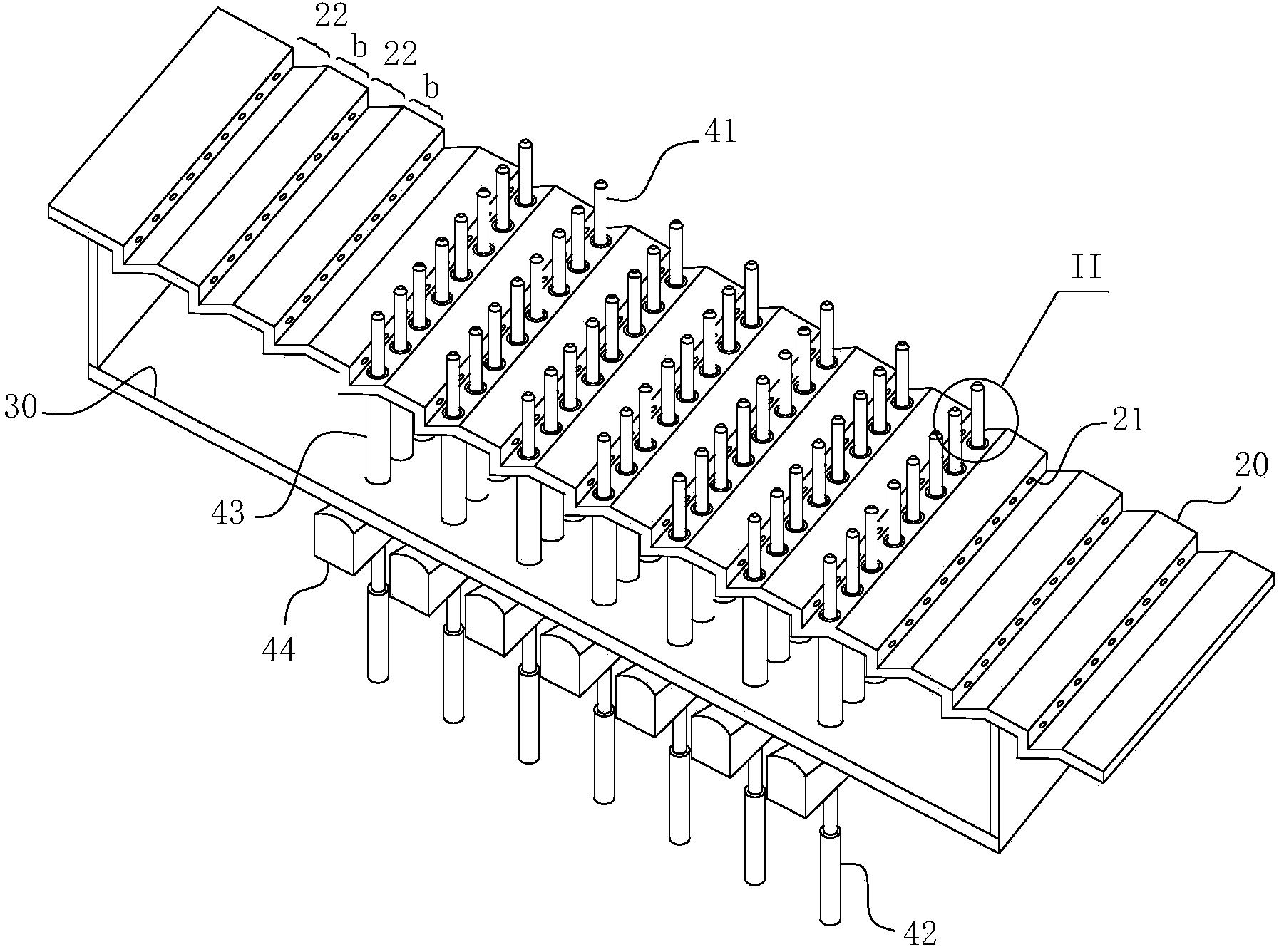

Fixed grate incinerator

InactiveCN104296148AAvoid subsequent continuous thermal expansion until it becomes soft and stuck.With self-cooling functionIncinerator apparatusCombustion chamberSlag

The invention belongs to the field of waste incineration equipment and particularly relates to a fixed grate incinerator comprising a main combustion chamber and a fixed fire grate. The fixed fire grate is arranged obliquely, the higher end is provide with a material input end, the lower end is provided a slag outlet for slags after material combustion, and the slag outlet is communicated with a slag discharging component; a hot air chamber is arranged below the main combustion chamber; a hot air supply path penetrates the fixed fire grate; the fixed grate incinerator further comprises an ejecting rod and a power portion; the maximum lift of the ejecting rod penetrates the material layer of the fixed fire grate; an ejecting rod component further comprises a shaft sleeve with the preset length, one end of the shaft sleeve penetrates and is fixedly connected to the fixed fire grate along the moving direction of the ejecting rod, a vent gap allowing the air to penetrate is formed between the shaft sleeve and the ejecting rod, and the other end of the shaft sleeve is communicated with the outside and / or an air cooling chamber. The fixed grate incinerator has the advantages that material burning efficiency is high, the component operation reliability is high, and the service life is prolonged effectively.

Owner:安徽盛燃焚烧炉科技有限公司

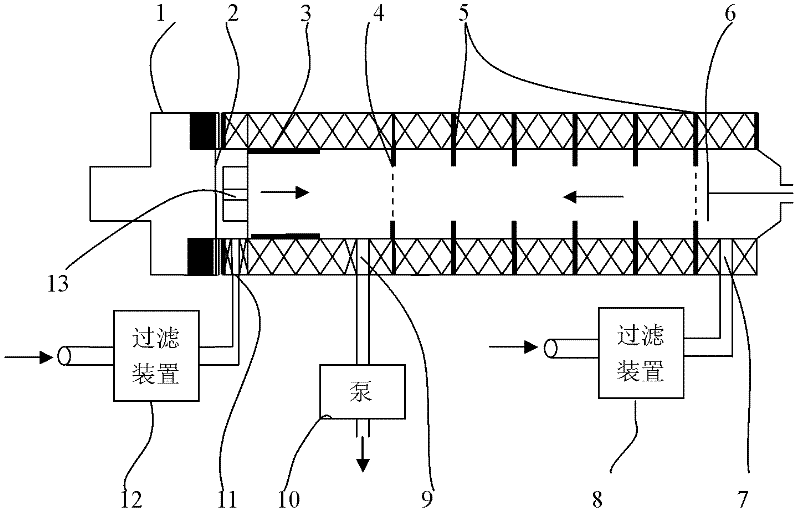

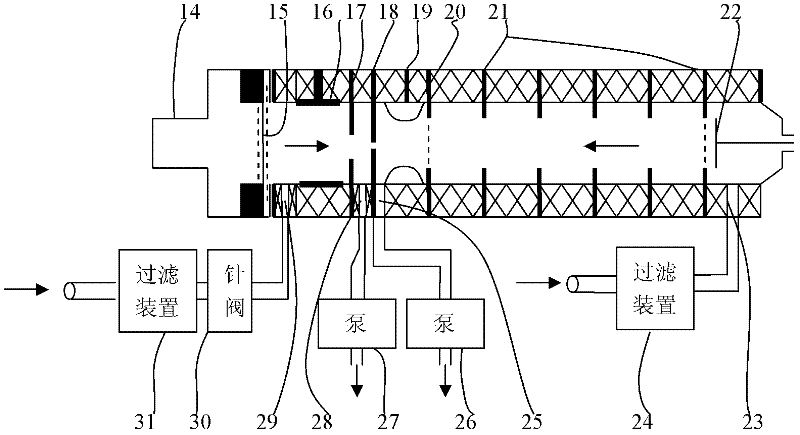

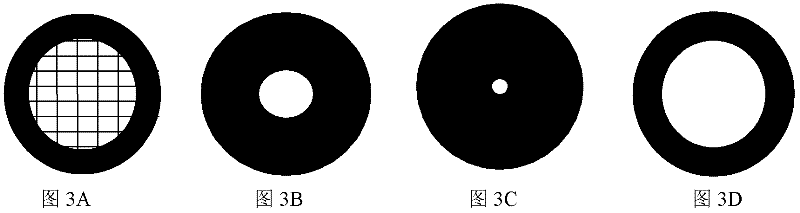

Ion mobility spectrometer

ActiveCN102539514AImprove penetration efficiencyLower requirementMaterial analysis by electric/magnetic meansIonizationPhysics

The invention discloses an ion mobility spectrometer which comprises a sample injector, a semipermeable membrane, an ionization area and an end electrode which are sequentially arranged along a transference tube, wherein one or a plurality of gas inlets are arranged at the side of the ionization area, which is close to the semipermeable membrane, and are connected with a needle valve and a first filtering device and are used for feeding gas; the end electrode is provided with at least one hole of which the diameter is less than that of each gas inlet; and a hole is arranged at the position of the ionization area, which is close to the end electrode, and is connected with a gas extracting pump for extracting gas. According to the invention, due to the adoption of the structure, the gas flow rate of a pump connected with the ionization area is controlled, a high gas resistance is formed due to a micropore structure and the application of the needle valve and a low gas pressure is formed in the ionization area and at the position of the semipermeable membrane, so that the permeating efficiency of the semipermeable membrane is greatly improved; and due to a double metal mesh clamping structure of the semipermeable membrane, the semipermeable membrane cannot be raised due to the low gas pressure.

Owner:NUCTECH CO LTD +1

Vanadium dioxide series sun heat reflection intelligent temp./control high molecular sheet (plate) material

InactiveCN1624041AImprove reflection efficiencyImprove penetration efficiencySolar heat devicesSolar thermal energy generationVanadium dioxideOptoelectronics

A high-molecular plate (or sheet) with intelligent temp controlling function by reflecting sun-heat or not is prepared from high-molecular material, composite pigment, organic glass, polycarbonate, modified terylene fibres and terylene fibres. Its features that full-band infrared light can be reflected when the temp is higher than its phase-change temp, or not when the temp is lower than its phase-change temp. It can be used for building, car, ship, etc.

Owner:SUN YAT SEN UNIV

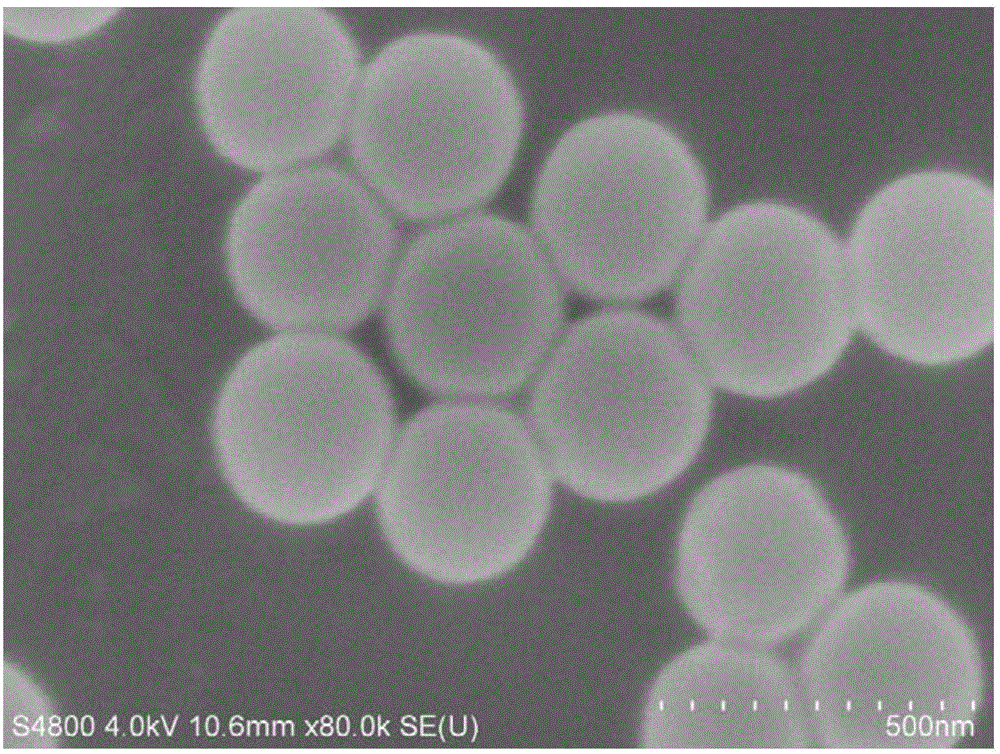

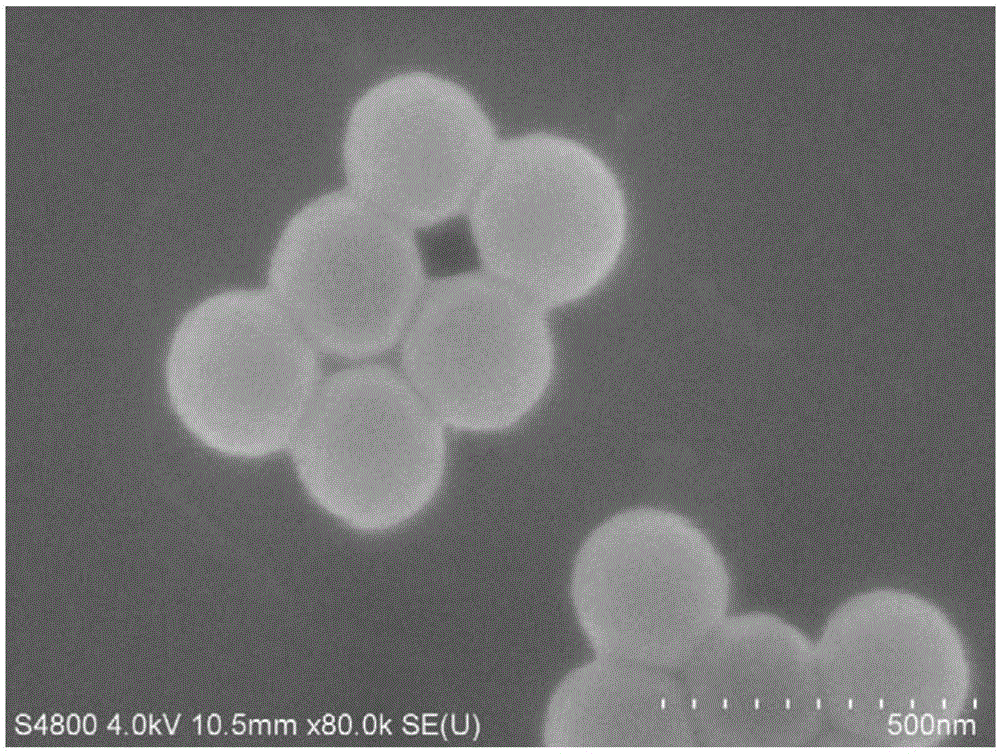

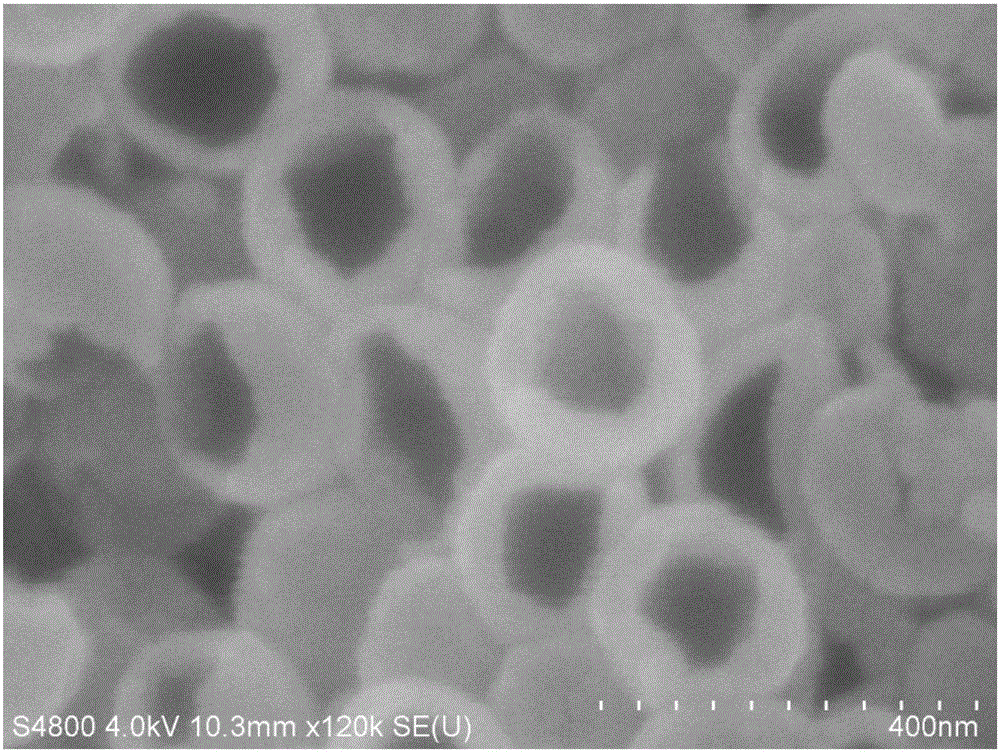

Hollow bowl-shaped silicon dioxide nanoparticles, preparation method and application thereof

ActiveCN106629747AMild preparation conditionsEasy to operateSilicaNanotechnologyOptical propertyFilm-coated tablet

The present invention relates to hollow bowl-shaped silicon dioxide nanoparticles, a preparation method and an application thereof. In particular, the present invention discloses the preparation method of the hollow bowl-shaped silicon dioxide nanoparticles. The method has the characteristics of being mild in preparation method, simple in operation, and meeting the demands of scale productions. The hollow bowl-shaped silicon dioxide nanoparticles have the novel hemispherical hollow recess structure, therefore have special physical properties (such as optical properties), and are expected to be used in the various application fields of film coating, gas sensing, catalysis, drugs, biology, etc.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of carbon granules used for air circulation of air conditioner

InactiveCN102963892AAids in preparationImprove conductivityCarbon compoundsMicrowaveRoom temperature

The invention relates to the field of macromolecules and particularly relates to a preparation method of carbon granules used for air circulation of an air conditioner. The carbon granules are prepared by the following steps of: pretreating raw materials: feeding plant materials into a microwave vacuum tank, vacuumizing, and then carrying out microwave treatment; then sequentially drying, pre-carbonizing, carbonizing, sintering and cooling, controlling combustion to heat up to 700-750 DEG C or 900-1000 DEG C at the rate of 5-15 DEG C / min, preserving heat for 40-80 minutes, then heating up to 1000-1500 DEG C or 1600-1800 DEG C at the rate of 5-15 DEG C / min, preserving heat for 2-8 hours, then cooling to 300-400 DEG C at the rate of 18-25 DEG C / min, and then cooling to room temperature along with a furnace to obtain primary carbon; activating: mixing the obtained primary carbon with a 8-10% potassium oxalate solution according to the mass ratio of 1:(3-4), immersing for 3-5 hours, then cleaning with deionized water until the pH value is neutral, and then carrying out vacuum pressurized flame retardant treatment, primary bamboo vinegar treatment, secondary bamboo vinegar treatment and microwave treatment; and preparing carbon granules. The carbon granules prepared by the preparation method has good antistatic property and air purification effect, and has the flame retardant function.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

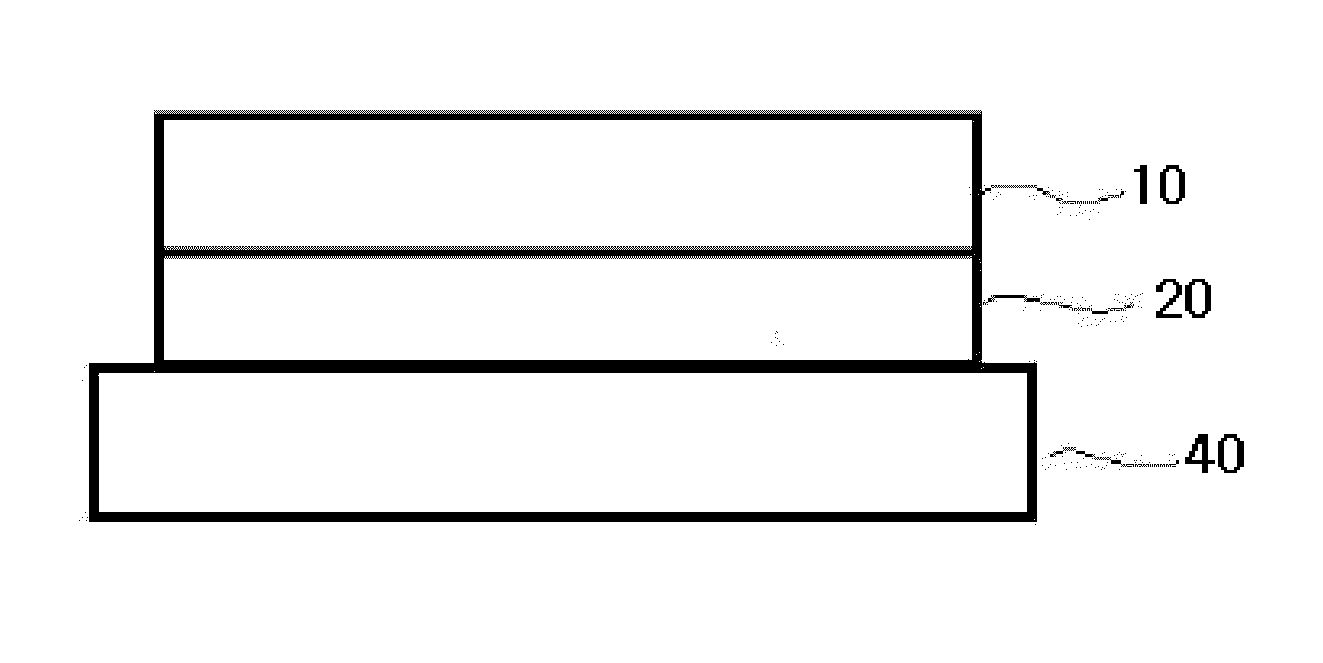

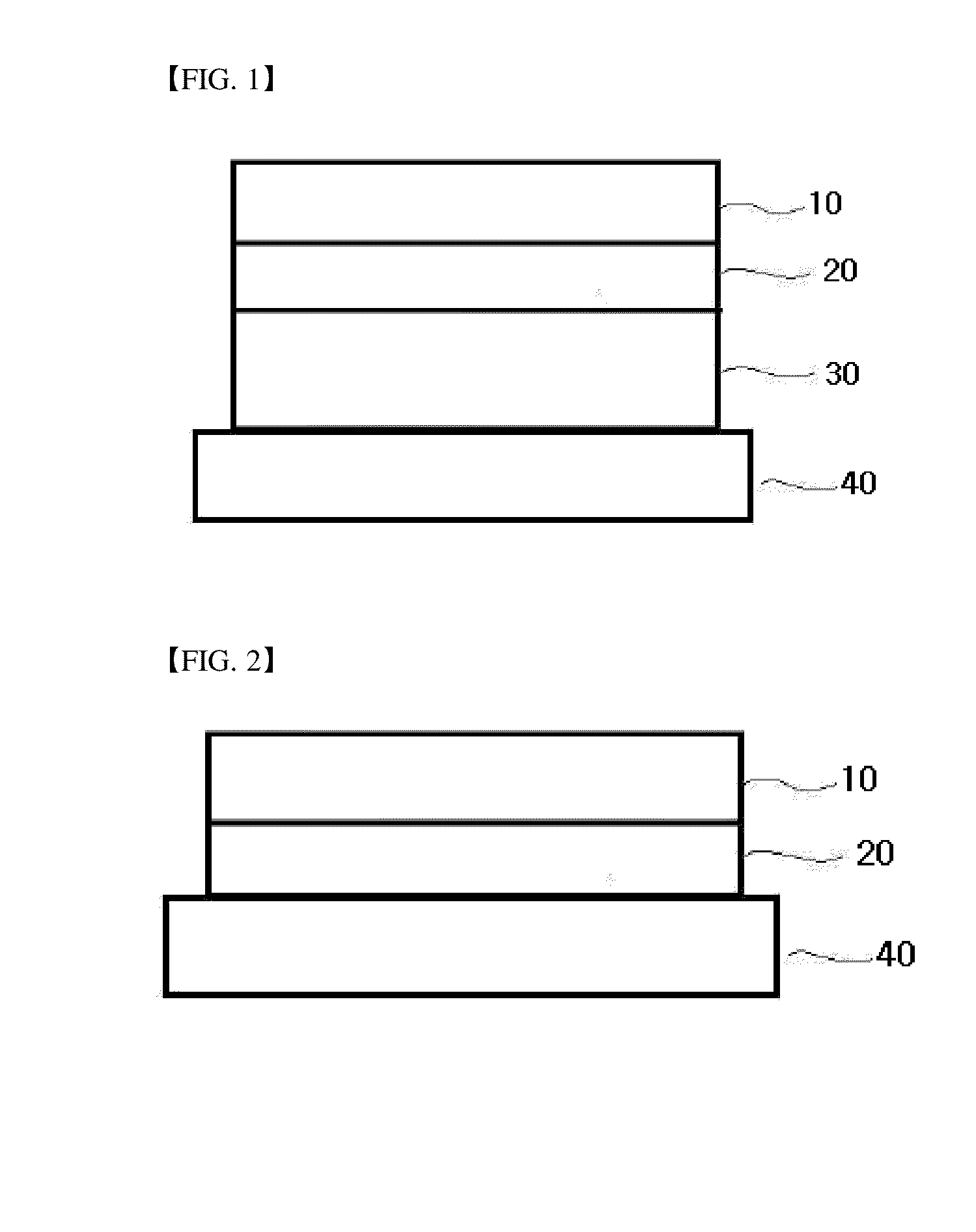

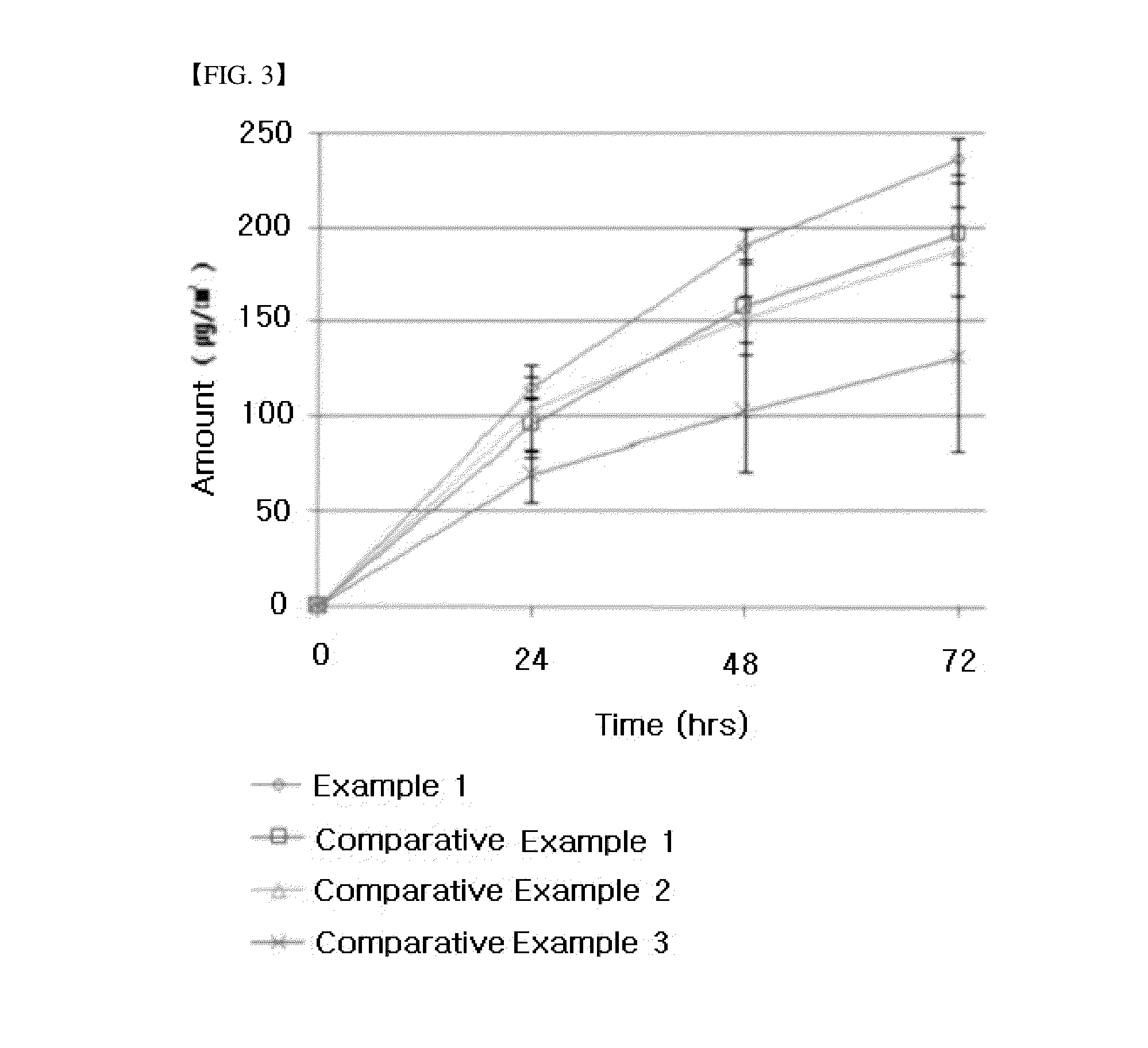

Percutaneously absorbable preparation containing fentanyl and homologue thereof

InactiveUS20140243765A1Improve penetration efficiencyReduce drug doseBiocideAdhesive dressingsAdhesiveFentanyl

Disclosed is a transdermal preparation, comprising sequentially-stacked layers of a backing layer, a barrier layer, a drug adhesive layer and a release layer, wherein the drug adhesive layer contains a drug selected from the group consisting of fentanyl, an analogue thereof and a pharmaceutically-acceptable salt thereof, a skin permeation enhancer of the drug, and a polyacrylate adhesive, which shows a high skin permeation with a low drug dosage, equivalent to one with high drug dosage, by increasing the skin permeation rate of drug.

Owner:SAMYANG BIOPHARMLS CORP

Treatment method capable of improving flexibility of osier

InactiveCN107471374AGood flexibilityEnhance aggregation abilityRadiation/waves wood treatmentWood treatment detailsCelluloseMicrowave

The invention belongs to the technical field of willow artwork, and particularly discloses a treatment method capable of improving the flexibility of osier. The treatment method specifically comprises the following steps: (1) ethanol solution soaking, constant-temperature fermentation and variable-temperature freezing treatment; and (2) microwave drying, vacuum soaking and variable-temperature drying treatment. According to the treatment method disclosed by the invention, pretreatment is carried out at first, and ethanol molecules are enabled to permeate into cellulose as protective mediums, so that the aggregation capacity among cellulose molecules is effectively improved, and the strength of the osier is effectively increased; and then the microwave drying and the vacuum soaking for a treatment liquid are carried out, the permeation time of the treatment liquid is effectively shortened, and the permeation efficiency is increased, so that the treatment liquid is capable of permeating into osier bark to soften and enable the bark to be closely bonded with an inner wood layer, bark peeling is avoided, high flexibility is achieved, the occurrence of a cracking phenomenon in a weaving process is effectively prevented, the weaving difficulty of the osier is lowered, the high-temperature-resistant and sun-screening capacity of the osier is improved, and the service life of the osier is effectively prolonged.

Owner:阜南县金威工艺品有限公司

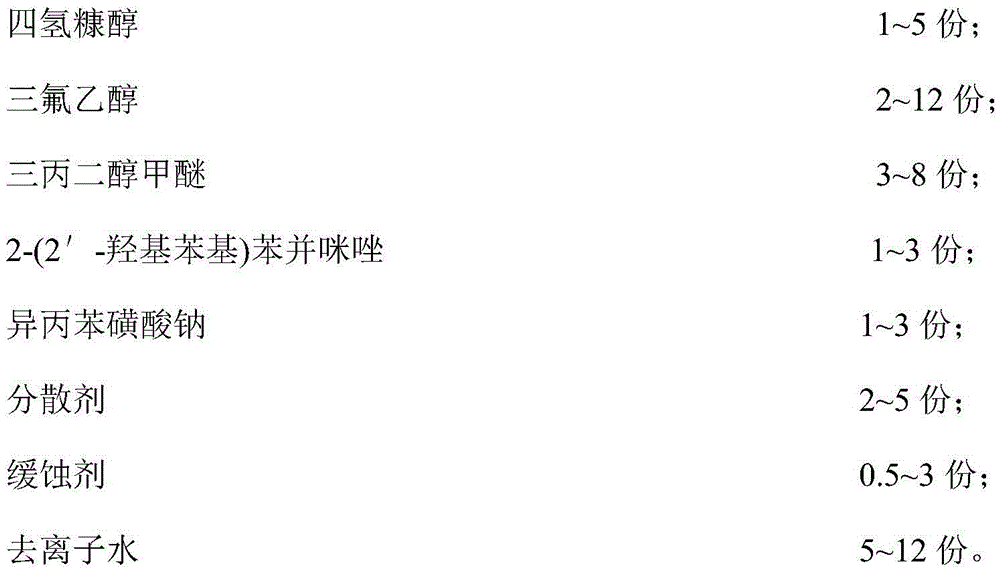

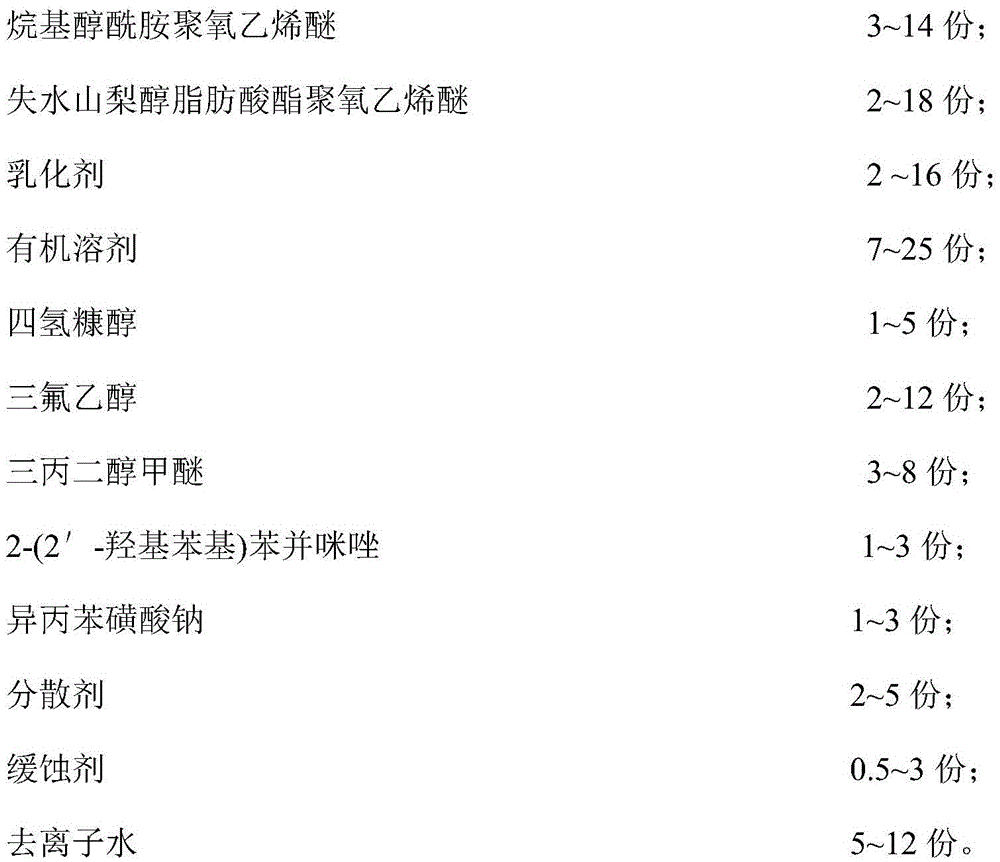

Water-based LED (light emitting diode) chip cleaning agent

InactiveCN105542990ANo generationReduce harmOrganic detergent compounding agentsSurface-active detergent compositionsWater basedCleansing Agents

The invention discloses a water-based LED (light emitting diode) chip cleaning agent, prepared from the following components of alkylolamide polyoxyethylene ether, polyoxyethylene sorbitan fatty acid ester, an emulsifier, an organic solvent, tetrahydrofurfuryl alcohol, trifluoroethanol, tripropylene glycol monomethyl ether, 2-(2'-hydroxylphenyl)benzoimidazole, sodium cumenesulfonate, a dispersant, a corrosion inhibitor and deionized water. The cleaning agent provided by the invention has the advantages that the effects of high cleaning efficiency, strong detergency, good safety performance, freeness from environmental pollution, energy saving and low washing cost are achieved; an LED is not damaged in a washing process; a protective film can be formed on the surface of a chip through the cleaning agent, so that air is isolated, and the chip is prevented from being corroded by moisture and other molecules in the air, therefore the effect of oxidation resistance is achieved, and a next production process is conveniently performed.

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

Device and method for generating electricity through strong brine

PendingCN109538430AIncrease temperatureIncrease osmotic pressure differenceMultistage water/sewage treatmentMachines/enginesElectricitySaline water

The invention relates to a device and method for generating electricity through strong brine and belongs to the technical field of salt difference power generation equipment and methods. According tothe technical scheme, a fresh water pretreatment assembly is connected with a fresh water side inlet of a permeable membrane assembly through a fresh water supply pump and a fresh water pipeline; a strong brine pretreatment assembly is connected with a heat exchanger through a strong brine supply pump and a strong brine pipeline; an external heating source is connected with the heat exchanger; theheated strong brine pipeline is connected with a strong brine inlet of the permeable membrane assembly; a strong brine outlet pipeline of the permeable membrane assembly is connected with a water turbine power generation device; a water outlet pipeline of the water turbine power generation device is connected with a pressure exchanger; the pressure exchanger is connected with the heat exchanger;and the heat exchanger is connected with a mixing treatment device. Strong brine can be utilized more effectively for electricity generation, a new solution is provided for comprehensive utilization of strong brine, meanwhile, waste of water resources is reduced, and environmental pollution caused by strong brine discharge is avoided.

Owner:HEBEI IRON AND STEEL

Method for processing marinated fruits and vegetables

ActiveCN103637134AImprove penetration efficiencyReduce salinityFood dryingFood ultrasonic treatmentBiotechnologyBiology

The invention discloses a method for processing marinated fruits and vegetables. The method comprises the following steps: selecting, cleaning, drying and cutting marinating raw materials, adding edible salt and pure water, and marinating the raw materials by virtue of three-frequency ultrasonic assistance to obtain marinated fruits and vegetables, wherein the three-frequency ultrasonic assistance is specifically as follows: the upper marinating layer is 20-30KHz, the middle marinating layer is 90-100KHz, and the lower marinating layer is 50-60KHz, namely the upper layer is 10-30cm deep, the middle layer is 30-80cm deep, and the lower layer is 80-100cm deep; taking out marinated fruit and vegetable embryos and centrifugally removing water; putting the marinated fruit and vegetable embryos into a cylinder to implement natural fermentation so as to obtain fermented marinated fruit and vegetable products; performing seasoning preparation, microwave drying and packaging. According to the method disclosed by the invention, the marinated fruits and vegetables are processed by a three-frequency ultrasonic assistance marinating technology and a microwave drying technology; compared with the prior art, the method has the advantages that the salinity of a product is reduced, the production efficiency is improved, the production period is shortened, and the product quality is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

Method for improving performance of rare-earth permanent magnetic material by high temperature compressive stress

ActiveCN106952721AImprove magnetismImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsDiffusionRare earth

The invention discloses a method for improving the performance of a rare-earth permanent magnetic material by high temperature compressive stress. The method for improving the performance of the rare-earth permanent magnetic material by high temperature compressive stress at least comprises the following steps: attaching heavy rare-earth compounds to the surface of the sintered magnet; and obtaining the magnet through heating and applying compressive stress at high temperature. According to the invention, the problems of the limitation of the magnet specification and dimension and the inconsistency of the heavy rare-earth diffusion in the traditional process can be overcome by improving the diffusion depth of magnet, therefore, the diffusion effect is enhanced, the magnet can obtain better magnetic performance, the equipment investment is simple, the cost is lower, and the invention is suitable for large-scale promotion.

Owner:宁波金鸡强磁股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com