Patents

Literature

54results about How to "Uniform surface coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

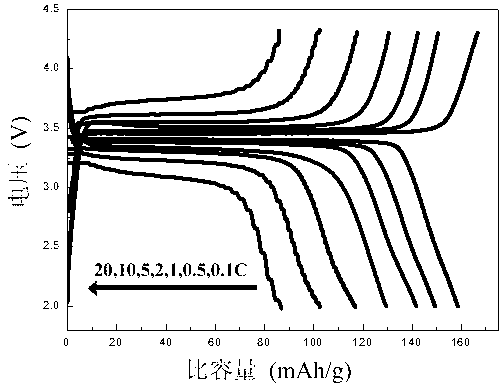

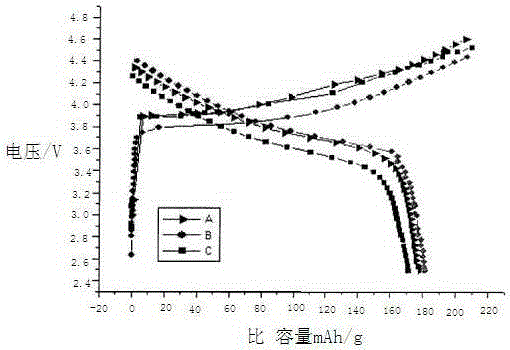

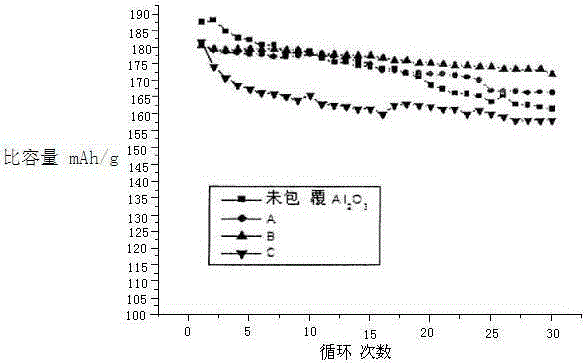

Preparation method of alumina composite nickel-cobalt lithium manganate ternary material

ActiveCN103618064AImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseAlumina composite

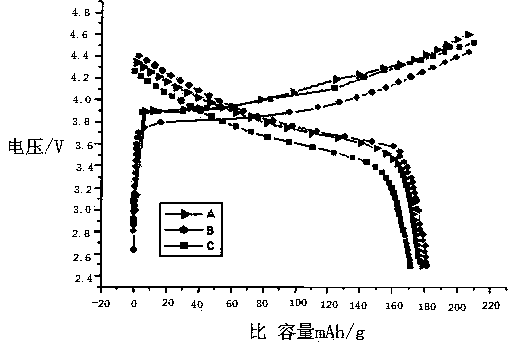

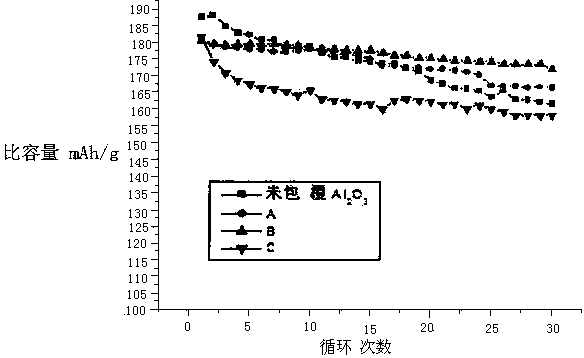

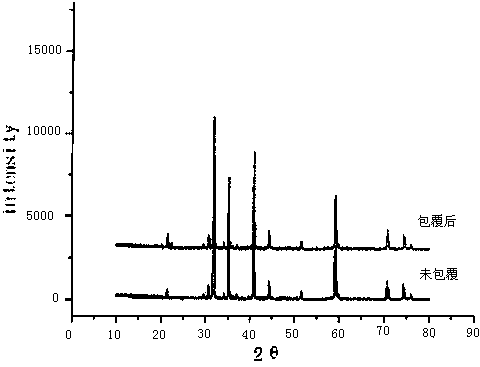

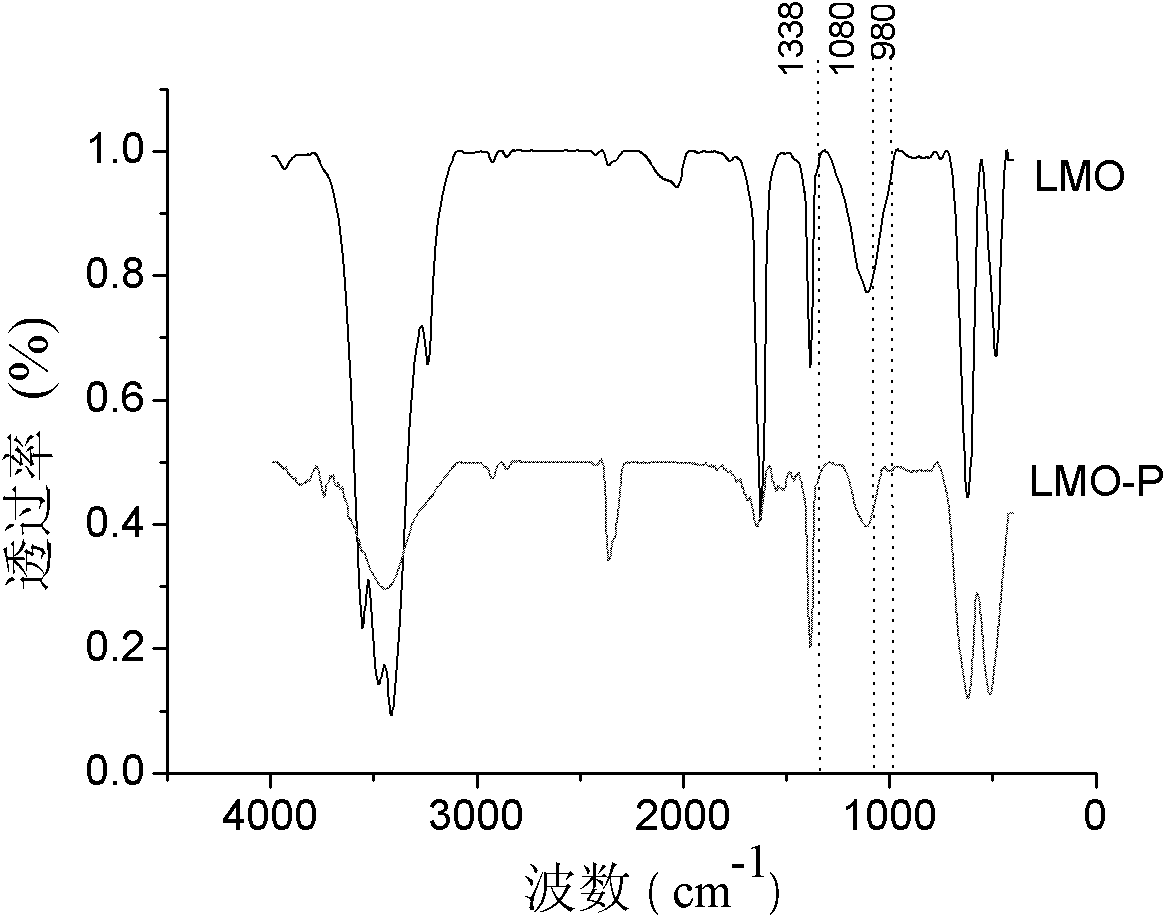

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

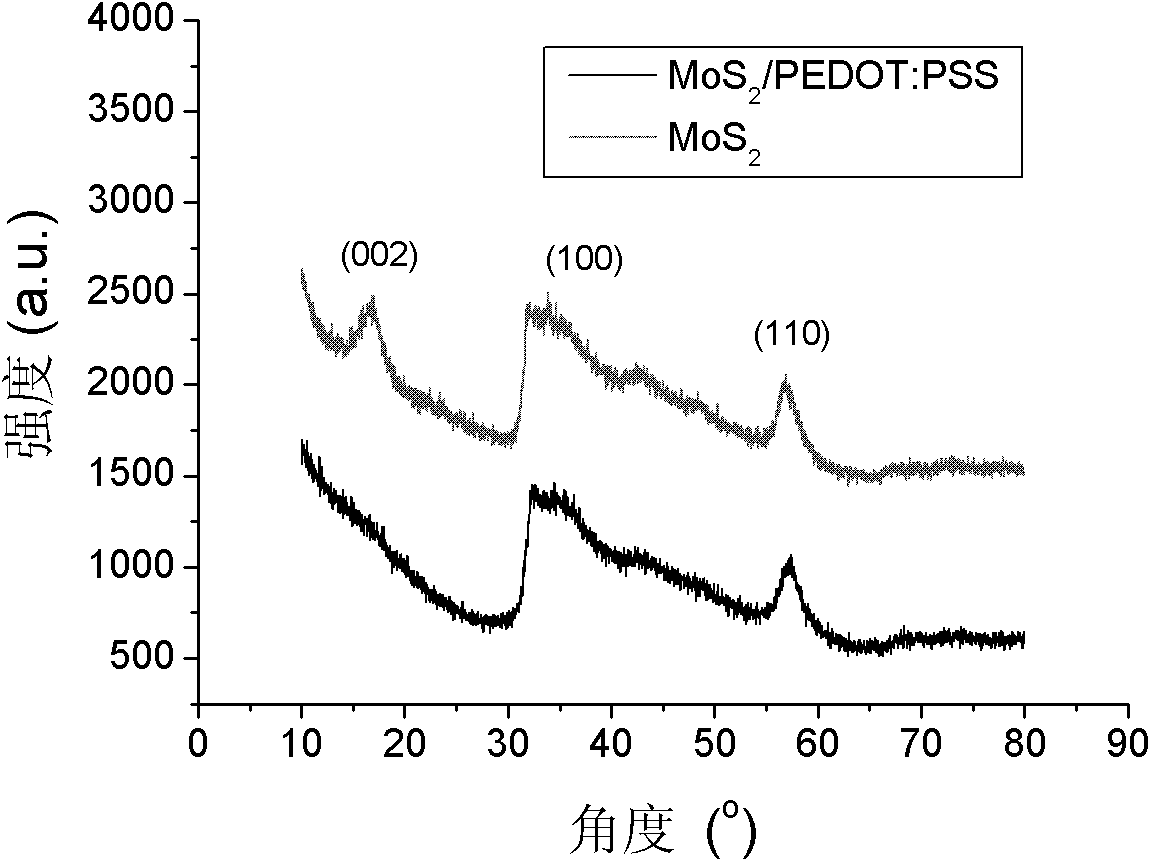

Conducting-polymer dipped and coated lithium-ion battery composite-electrode material and preparation method thereof

InactiveCN102522563ADon't need protectionReduce energy consumptionHybrid capacitor electrodesLi-accumulatorsDischarge efficiencyConductive polymer

The invention provides a conducting-polymer dipped and coated lithium-ion battery composite-electrode material and a preparation method thereof. A high-polymer conducting polymer is coated on the lithium-ion battery electrode material of the composite electrode material, the conducting polymer is the conducting polymer which is easily dispersed into an aqueous solution, and the aqueous solution of dispersants, such as polystyrolsulfon acid and the like is used as a dispersing medium. The composite electrode material is prepared through the following steps of: dipping a lithium-ion anode material or cathode material into the aqueous solution of the high-polymer conducting polymer, and obtaining the surface-coated lithium-ion battery composite-electrode material through dipping and coating processing. The composite electrode material has cheap preparation raw materials, the surface of the novel composite electrode material is uniformly coated, and the composite electrode material has the advantages of high specific capacity, high charging and discharging efficiency and long cycling life. Compared with the prior art, the preparation method of the composite electrode material has the advantages of simple process, low cost, good effect and green and environment-friendly production process, is easy for industrial popularization and is convenient for large-scale industrialized production.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Positive electrode material for lithium ion battery and preparation method of positive electrode material

The invention discloses a positive electrode material for a lithium ion battery as well as a preparation method and application of the positive electrode material. Slurry prepared from the positive electrode material for the lithium ion battery is still stable after being arranged for a period of time and cannot be gelled, and therefore, a positive electrode piece can be prepared easily; meanwhile, the positive electrode material has excellent cycle performance at high temperature and under high voltage. According to the method for preparing the positive electrode material for the lithium ion battery, a microwave absorbent is added so that raw materials can be synthesized and subjected to coating reaction under a relatively high microwave power without secondary high-temperature annealing, and the added microwave absorbent which is taken as the raw material of the coating does not need to be removed, preparation operation is simple and industrial practicability is achieved.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

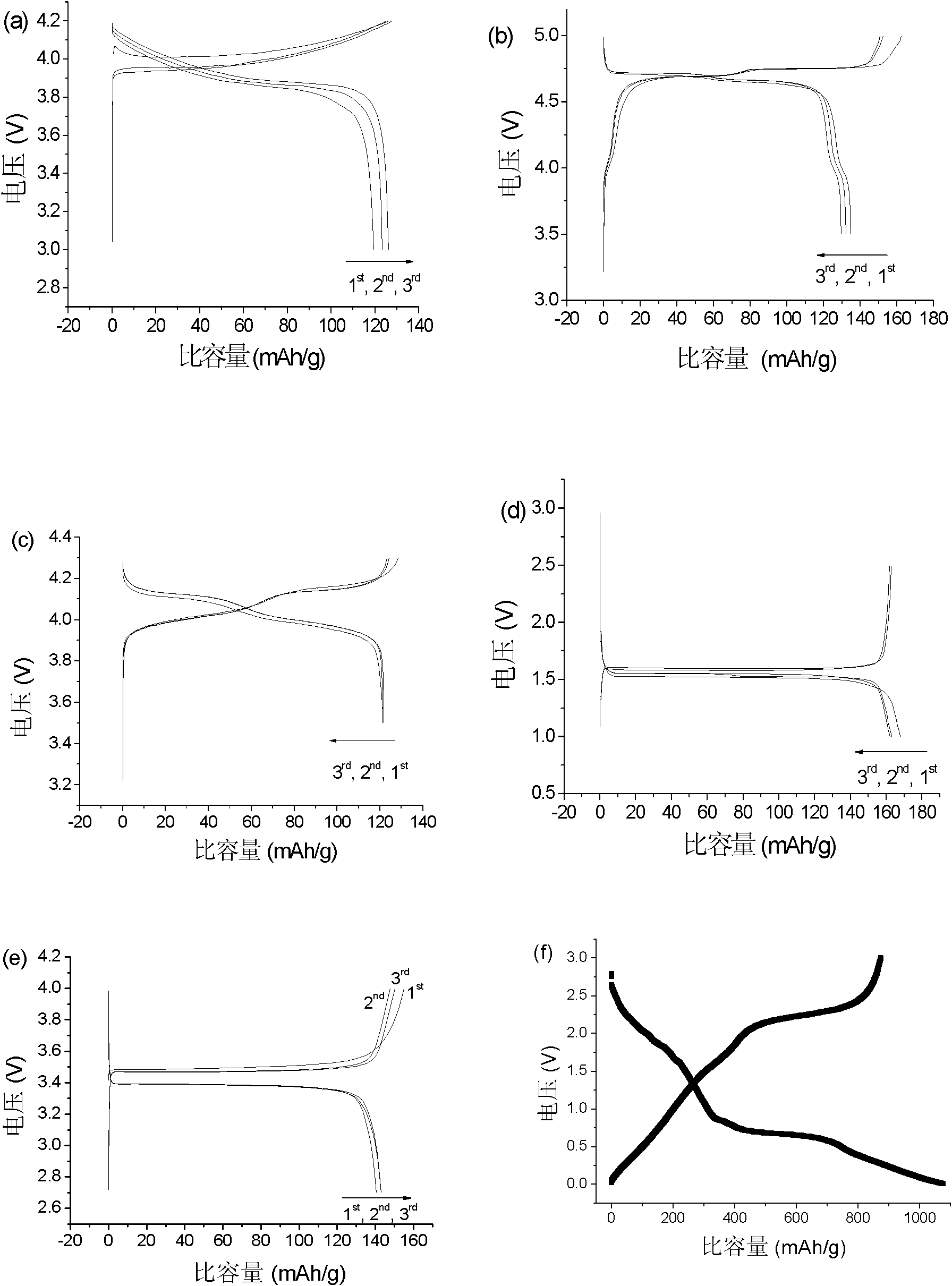

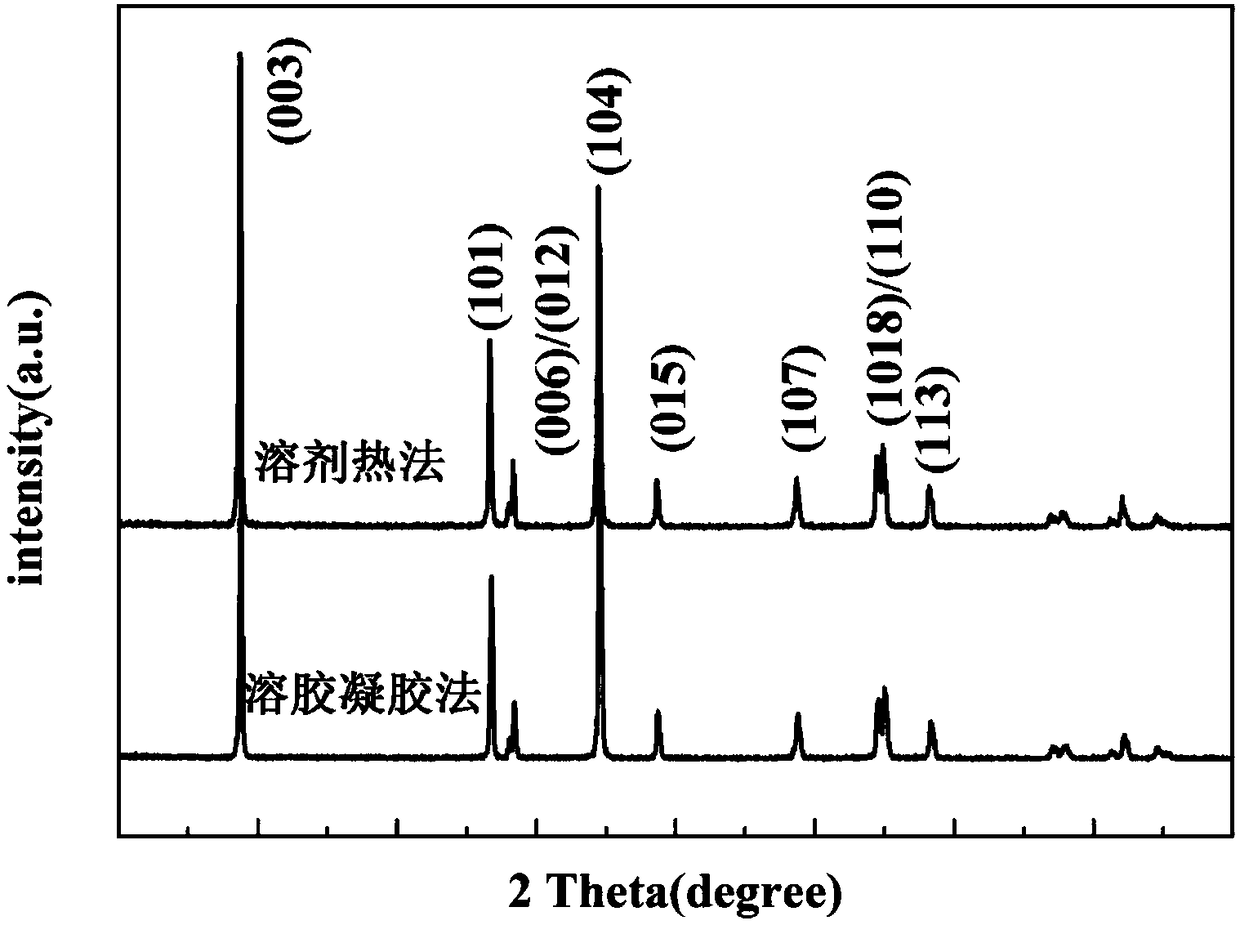

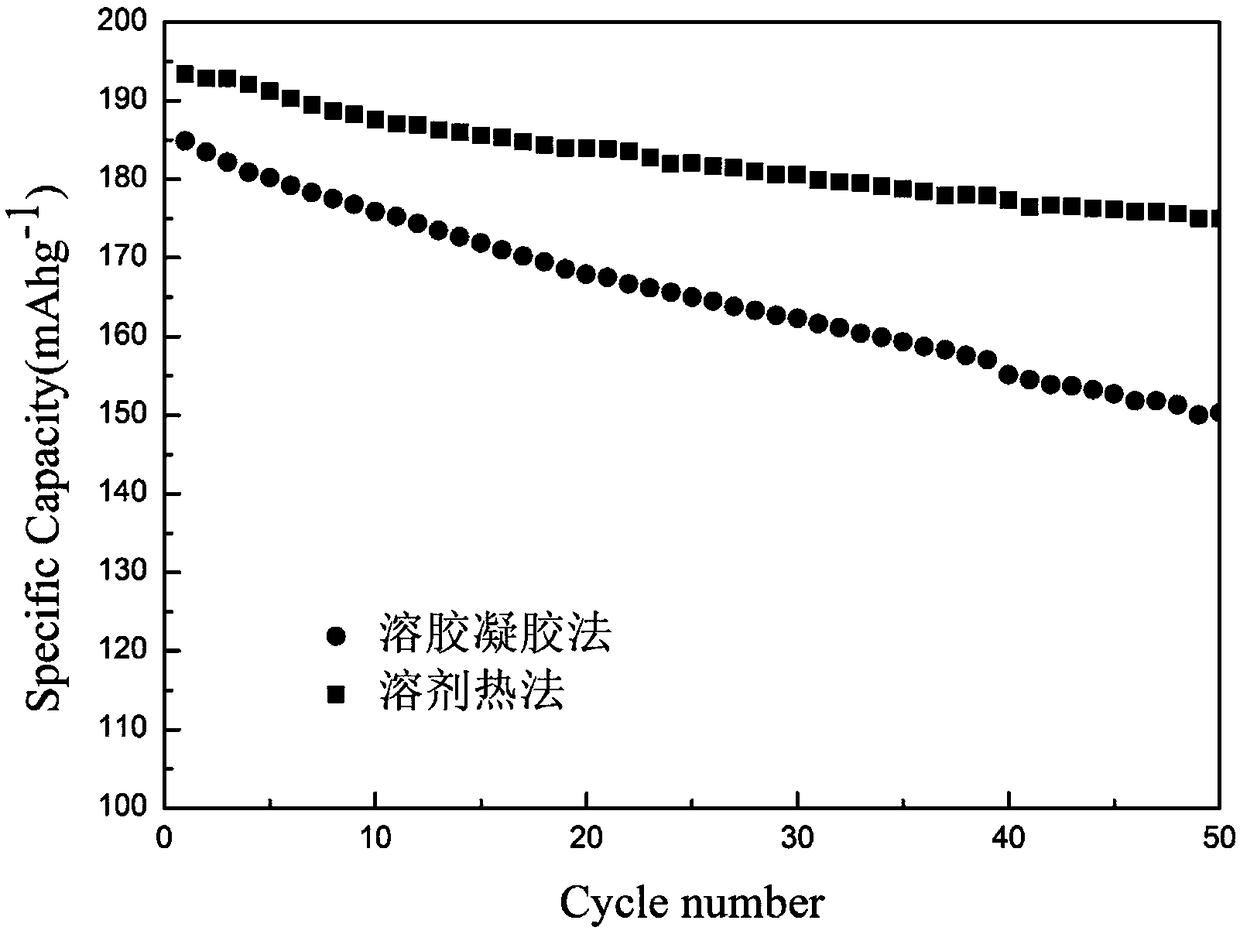

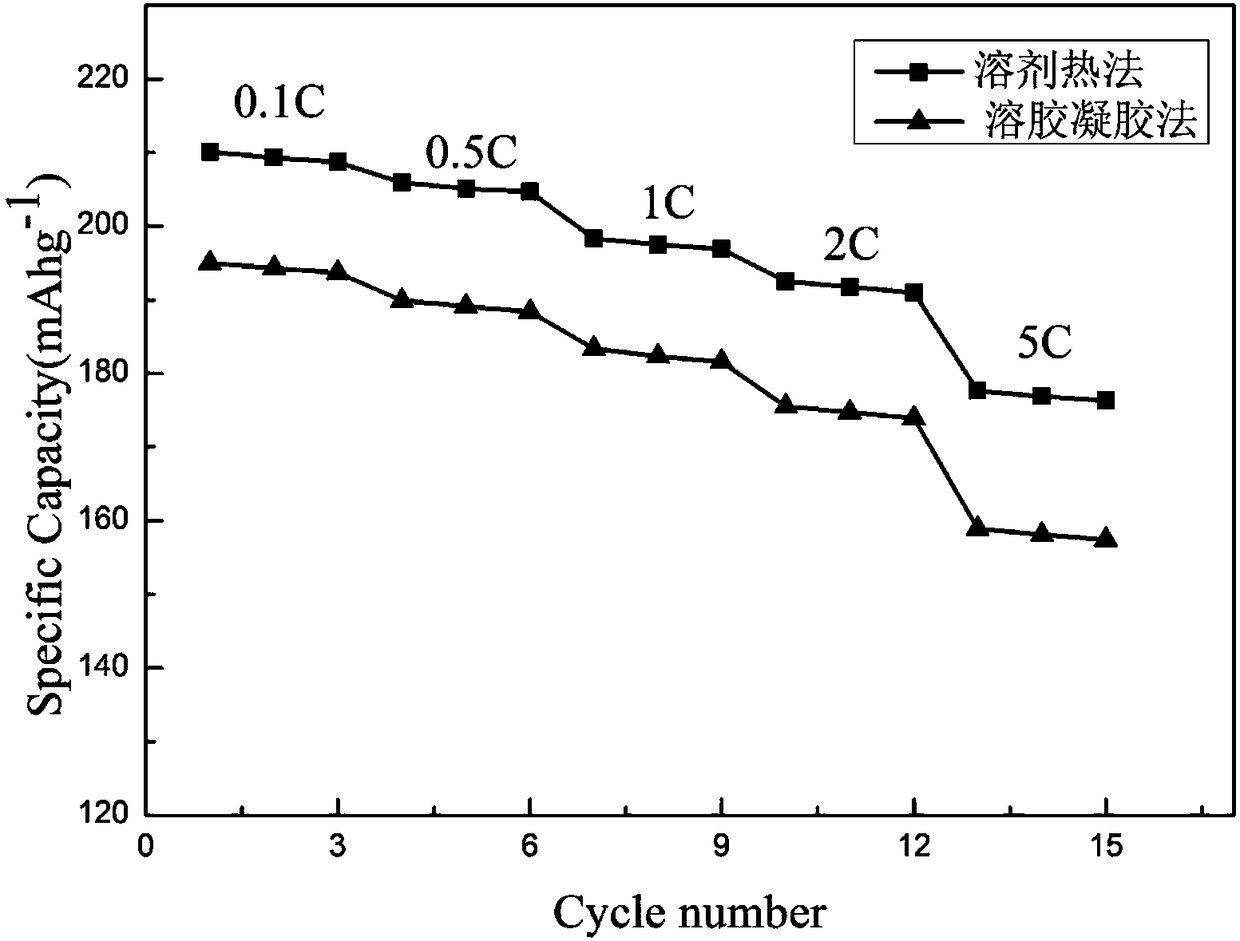

Coating method for improving electrochemical property of high-nickel ternary nickel cobalt manganese anode material

ActiveCN108321366AImprove electrochemical performanceAvoid direct contactCell electrodesSecondary cellsManganeseElectrochemistry

The invention discloses a coating method for improving electrochemical properties of a high-nickel ternary nickel cobalt manganese anode material. The coating method comprises the following steps: dissolving a titanium source into a solvent so as to obtain a solution, dissolving a lithium source, and further adding citric acid so as to obtain a mixed solution; uniformly dispersing a high-nickel ternary nickel cobalt manganese anode material into a solvent, adding the mixed solution, uniformly mixing, and performing a hydrothermal reaction or a solvent thermal reaction so as to obtain a reaction solution; evaporating the reaction solution to a gel state, and drying so as to obtain an anode material mixture; calcining the anode material mixture, thereby obtaining the high-nickel ternary nickel cobalt manganese anode material with a lithium titanate coating layer. The coating method for improving the electrochemical properties of the high-nickel ternary nickel cobalt manganese anode material, which is disclosed by the invention, is simple in process, low in cost and good in repeatability, the obtained coating layer is high in crystallization degree, small in particle size and good inuniformity, and the charge and discharge specific capacity, the circulation property and the multiplying power of the high-nickel ternary nickel cobalt manganese anode material can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

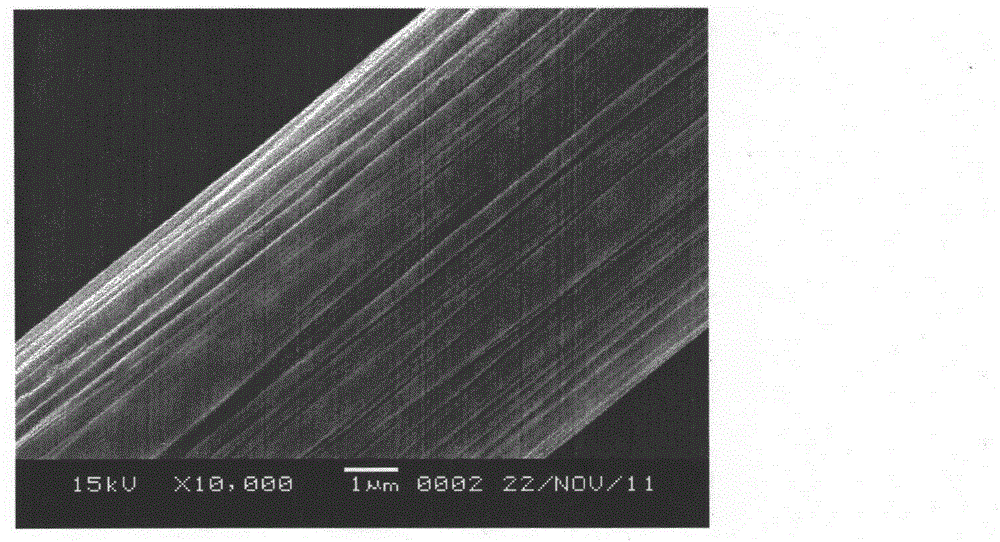

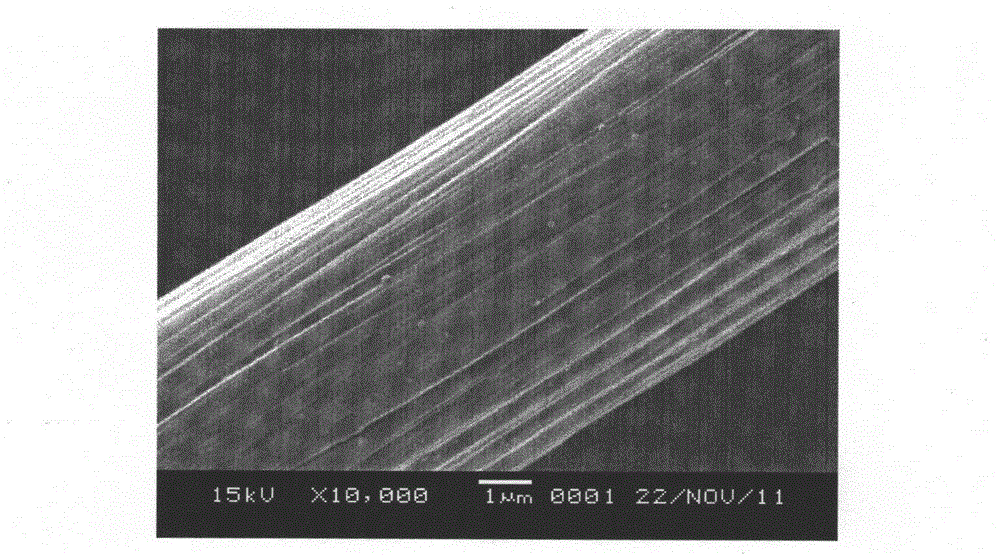

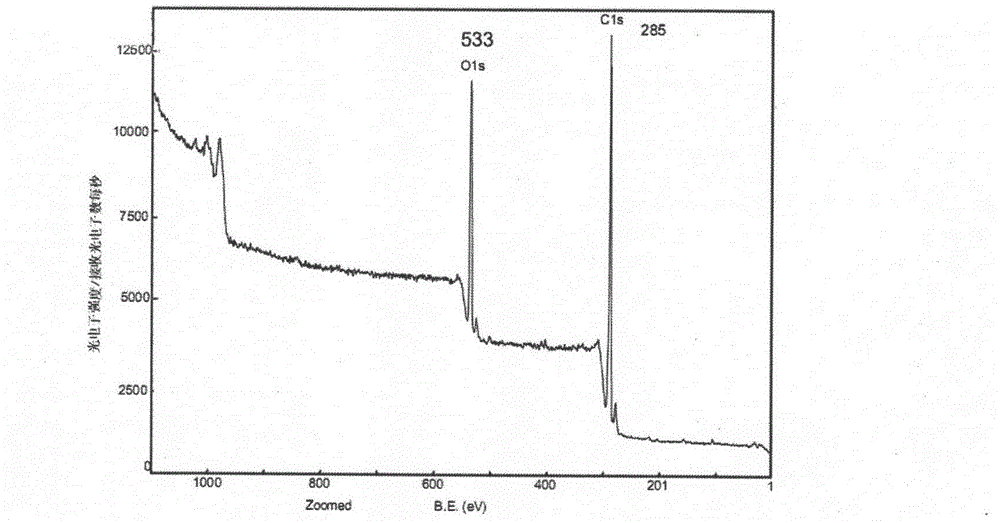

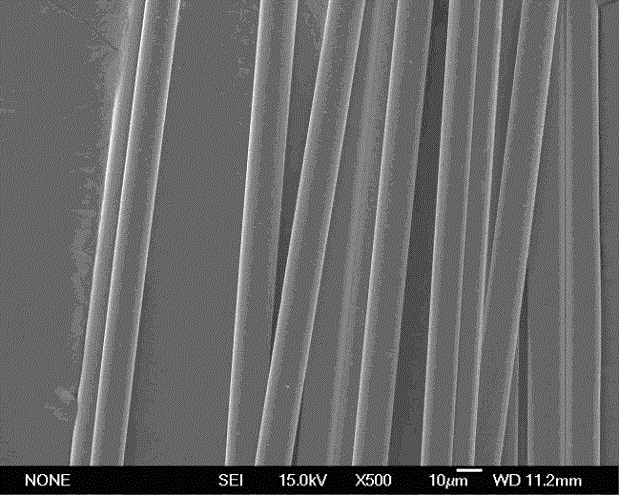

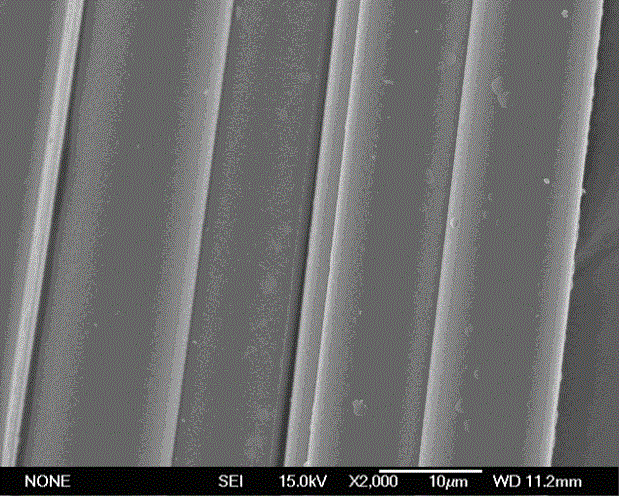

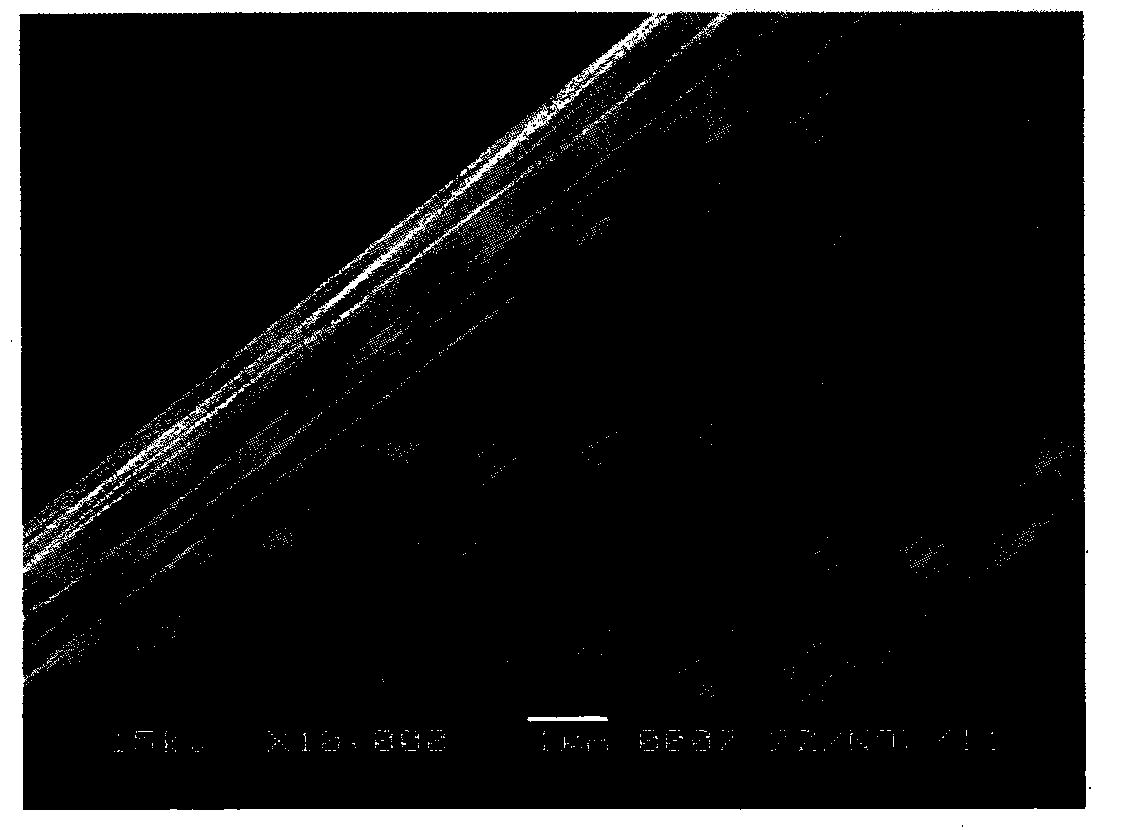

Preparation method for improving interfacial properties of carbon fiber composite material

InactiveCN102720061AImprove interface performanceThe polymerization reaction is fastFibre treatmentFiberOxygen

The invention provides a preparation method for improving interfacial properties of a carbon fiber composite material. The method is characterized by comprising the steps of firstly, preparing plasma activated carbon fiber; secondly, preparing a maleic anhydride dimethylbenzene solution; thirdly, subjecting the activated carbon fiber to ultrasonic infiltration; fourthly, performing grafting of maleic anhydride; and fifthly, purifying a crude product of the plasma activated carbon fiber which the maleic anhydride is grafted to. The method has the advantages that the free radicals formed on the surface of carbon fiber are processed through plasmas of argon-oxygen mixed gas, so that the polymerization reaction speed of the free radicals and the maleic anhydride is accelerated and the degree us improved; the reaction speed is accelerated through a high temperature, and the grafting reaction time is only 3 min to 7 min, so that grafting carbon fiber which is uniform in surface coating and high in grafting rate and has certain quantities of anhydride groups is obtained, the grafting carbon fiber and epoxy resin are subjected to reaction well, and the interfacial properties of the composite material is improved; and the method is energy-saving, environment-friendly and convenient to process.

Owner:DONGHUA UNIV

Porous lithium iron phosphate/carbon composite microspheres and preparation method thereof

InactiveCN103078114ALarge specific surface areaHigh tap densityCell electrodesPhosphorus compoundsCarbon compositesIron salts

The invention provides porous lithium iron phosphate / carbon composite microspheres and a preparation method thereof. The porous lithium iron phosphate / carbon composite microspheres and the preparation method thereof are characterized in that iron phosphate oxalate is used as a precursor and the preparation method comprises the following steps: (1) dispersing solution of iron salt and phosphate solution into a precipitating agent ethanol, adding lithium salt, carrying out ultrasonic stirring to enable the solution of iron salt, the phosphate solution and the lithium salt to be totally dissolved, and adding a certain quantity of oxalic ethanol solution into the obtained solution; (2) placing the obtained mixture into an oven to dry at a certain temperature so as to obtain a yellow jelly iron phosphate oxalate precursor; and (3) after mixing a carbon source and the iron phosphate oxalate precursor, calcining to obtain the porous lithium iron phosphate / carbon composite microspheres. The preparation method provided by the invention is low in cost and is simple and easy to operate; the pH does not need to be regulated; the products have high purity, high tap density and good repeatability; the products are spherical particles formed by self-assembling disk nano-scale particles, and thus, the specific surface area is large; and moreover, the diffusion path of lithium ions is greatly shortened, so that the porous lithium iron phosphate / carbon composite microspheres have excellent electrochemical property and are suitable for large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

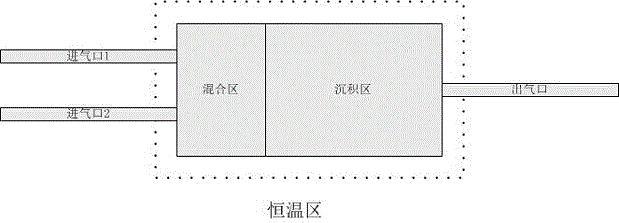

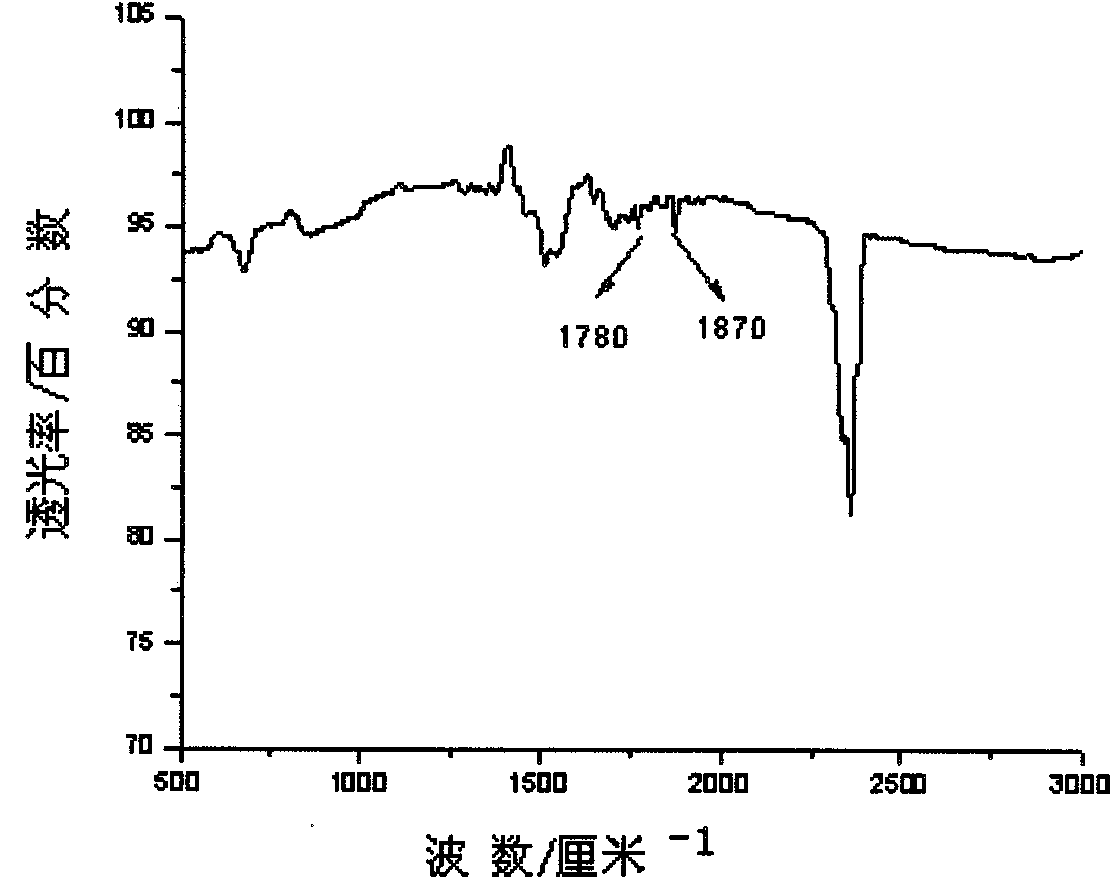

Preparation method of homogenized boron nitride coating

InactiveCN105296960AUniform thicknessThickness is easy to controlChemical vapor deposition coatingBoron trichlorideScanning tunneling microscope

The invention relates to a preparation method of a homogenized boron nitride coating. According to the method, boron trichloride (BCl<3>) and ammonia gas (NH<3>) serve as reaction gases and are fed into a reactor, firstly the reaction gases are evenly mixed in a mixing region and then generate surface deposition in a deposition reaction region, finally an obtained sample is subjected to high-temperature heat treatment, and through a scanning tunneling microscope (SEM), Fourier transform infraRed (FT-IR) and X-ray diffraction (XRD) detection, the boron nitride coating which is even in thickness, singular in ingredient and high in degree of crystallinity is obtained. The method can be used for preparing a boron nitride interface in composite and for preparing boron nitride coatings on the surfaces of other samples and can be further used for researching the boron nitride vapor deposition process and mechanism. The method mainly solves the problem that gases are not evenly mixed in the two-component chemical gas phase sedimentary boron nitride process, so that the uniformity of the boron nitride coating is improved, and the coating thickness is better controlled.

Owner:SHANGHAI UNIV

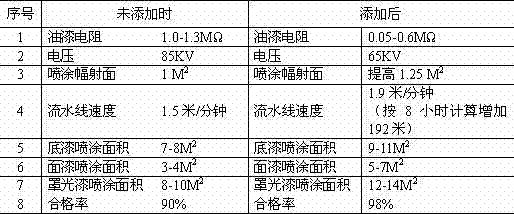

Powder electrostatic spraying process for metal parts

InactiveCN107398413AStrong adhesionUniform surface coatingPretreated surfacesCoatingsElectrostatic coatingMetal

The invention discloses a powder electrostatic spraying process for metal parts. The powder electrostatic spraying process for the metal parts comprises the steps of pretreatment, electrostatic spraying and high-temperature curing. According to the process, the coating prepared by the process is uniform in surface, free of bubbling, free of pits, high in adhesion, not prone to fall off and uniform in color and luster.

Owner:苏州盈腾五金制品有限公司

A kind of preparation method of aluminum oxide composite nickel cobalt lithium manganese oxide ternary material

ActiveCN103618064BImproved magnification performanceImprove high temperature performanceCell electrodesSecondary cellsElectrochemical responseManganese

The invention provides a preparation method of an alumina composite nickel-cobalt lithium manganate ternary material. The preparation method comprises the following steps: (1), preparing liquor A; (2), preparing liquor B; (3), installing and configuring a reaction flask; (4), adding the liquor A and the liquor B into the reaction flask to participate in hybrid reaction; (5), preparing liquor C, and adding into the flask for reaction; (6), obtaining a precursor by suction-filtering, washing and drying; and (7), mixing and roasting the precursor with a lithium source to prepare the alumina composite nickel-cobalt lithium manganate ternary material. The preparation method disclosed by the invention has the beneficial effects that firstly, liquid-phase coating is adopted, production preparation period is short, efficiency is high, and coating and dispersing are uniform; secondly, the coating layer alumina on the surface of the ternary material is a film with an amorphous structure, so that charging and discharging voltage difference is reduced, multiplying power performance and high-performance performance of the material are improved; and thirdly, characteristics of a solid-liquid phase interface among an anode material, electrolyte and a diaphragm are improved by alumina film-coating, so that velocity and efficiency of electrochemical reaction are improved.

Owner:博尔特新材料(银川)有限公司

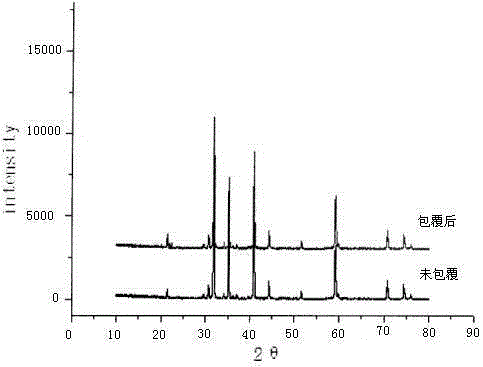

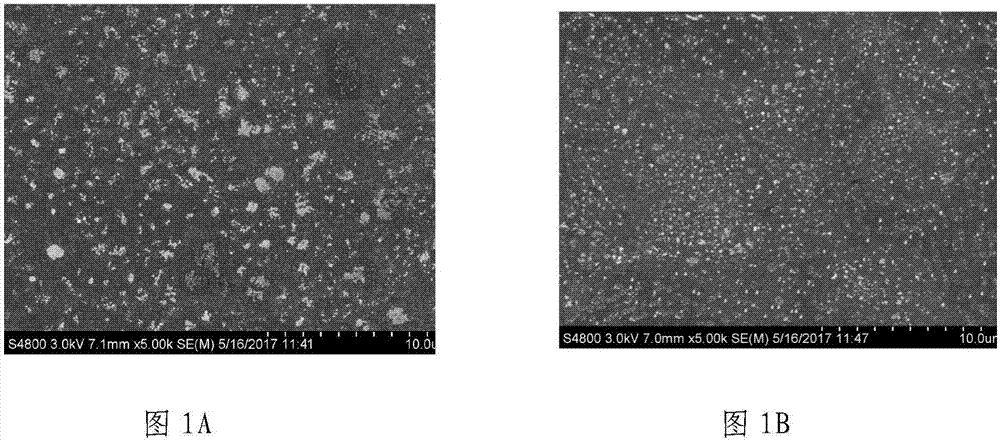

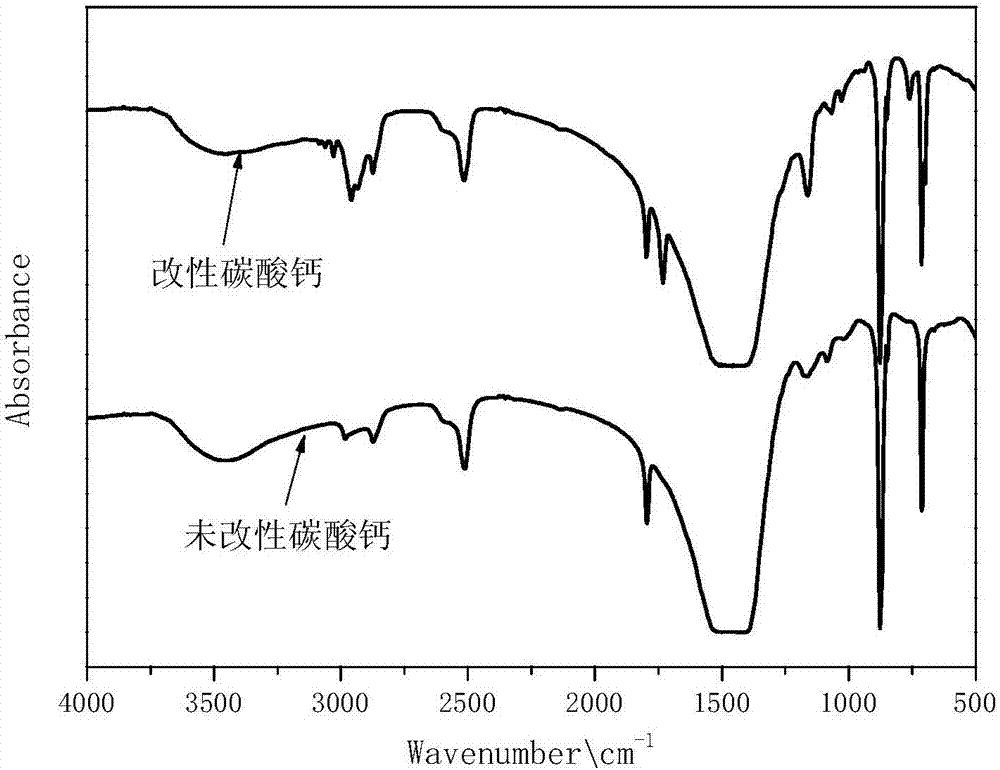

Preparation method of modified nano calcium carbonate powder for high-end waterborne coatings

ActiveCN107254211AThe process steps are simpleReduce process costCoatingsPigment treatment with macromolecular organic compoundsFilling materialsEmulsion

The invention belongs to preparation of filling materials for high-end waterborne coatings and particularly relates to a method of modifying nano calcium carbonate powder for high-end waterborne coatings; the method comprises the steps such as preparing polymer emulsion, preparing nano calcium carbonate slurry, modifying the calcium carbonate; the problems of traditional drying process and wet process, such as high modifier usage, coating non-uniformity, high proneness of a modifier to loss with water, are solved, and the technical bottlenecks of in-situ polymerization process, such as complexity, high production cost and industrialization difficulty are broken through. The method has the advantages that the process steps are simple, the process cost is low, the period is short, the prepared product has good dispersity and coating effect and has good compatibility with base emulsion for waterborne coatings, and the main performance indexes of the product meet the corresponding international requirements.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

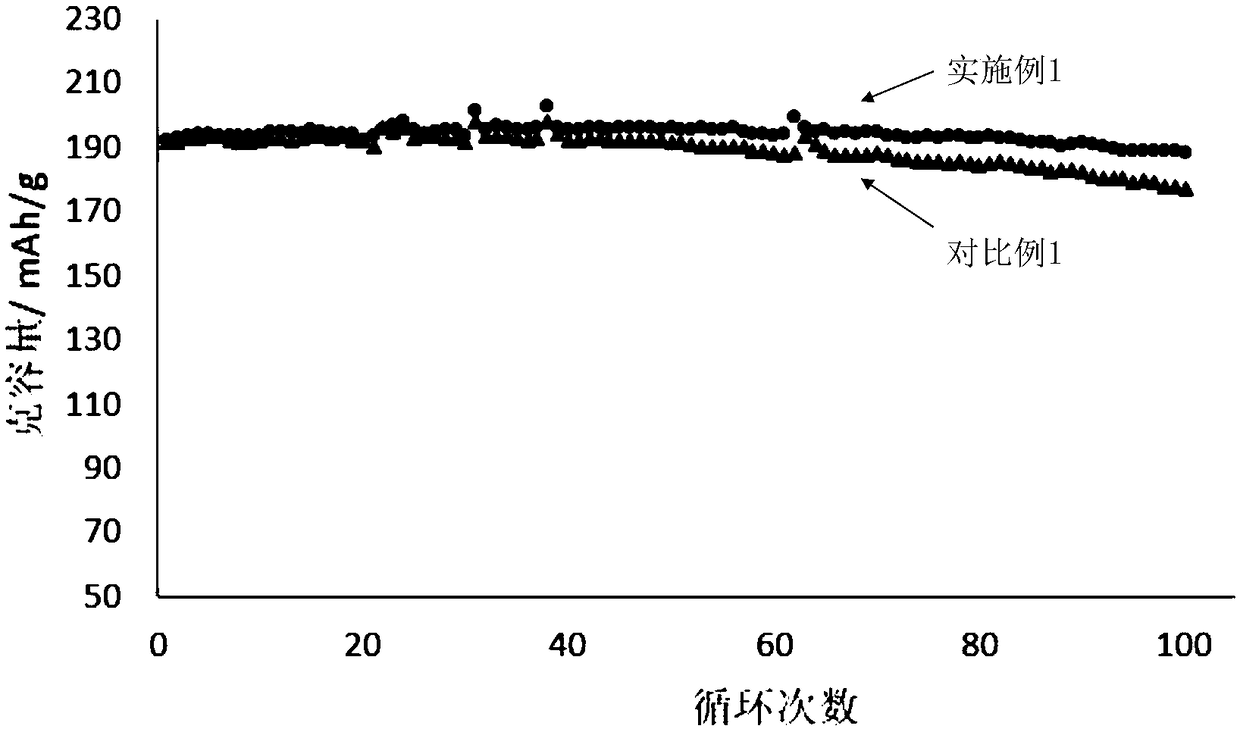

Positive electrode material and preparation method thereof, lithium ion battery

InactiveCN109192971ALow costUniform surface coatingSecondary cellsPositive electrodesHigh energyLithium-ion battery

The invention discloses a positive electrode material and a preparation method thereof, a lithium ion battery. The preparation method of the bismuth phosphate coated 811NCM material is as follows: sintering the coated precursor to obtain the bismuth phosphate coated 811NCM material. The coated precursor is obtained by mixing 811 NCM solution, Bi (NO3) 3 *5 H 2 O aqueous solution and (NH4) H2PO4 aqueous solution. The molar ratio of 811NCM to Bi (NO3) 3 *5 H2O is 300: 1 - 100: 1. The molar ratio of 811NCM to Bi (NO3) 3 * 5 H2O is 300: 1 - 100: 1. The molar ratio of 811NCM to Bi (NO3) 3*5 H2Ois 100: 1. The raw material of the invention is cheap and easy to obtain, and the cost is low. The preparation method is simple and convenient for large-scale production. The coating can reduce the surface alkalinity of 811NCM, reduce the contact between electrolyte and active material, and inhibit the erosion of HF in electrolyte. The obtained BiPO_4 coated 811NCM material has excellent cycle stability and can be used as positive electrode material for high energy density batteries.

Owner:SHANGHAI ELECTRICAL GUOXUAN NEW ENERGY TECH CO LTD

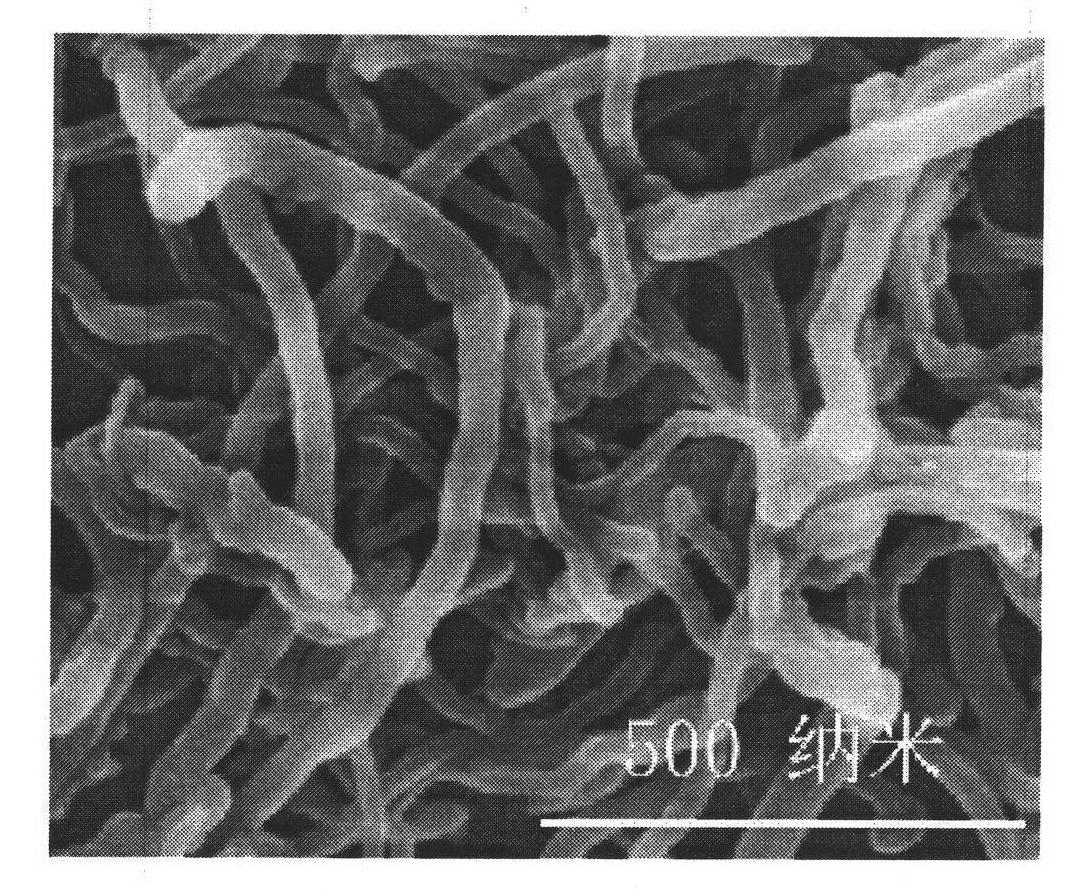

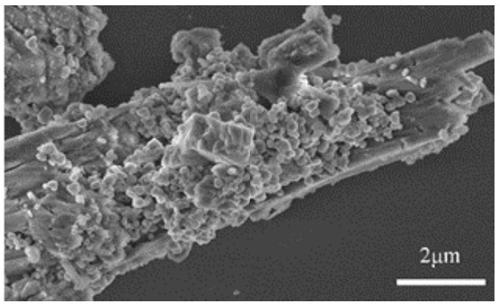

Preparation method for grafting maleic anhydride onto plasma activated carbon nano tube

The invention discloses a preparation method for grafting maleic anhydride onto a plasma activated carbon nano tube. The method comprises the following steps: preparing the plasma activated carbon nano tube, preparing maleic anhydride dimethylbenzene solution, carrying out ultrasonic treatment on the plasma activated carbon nano tube, and utilizing microwaves to initiate the purification of the plasma activated carbon nano tube on which the maleic anhydride is grafted. The invention utilizes the plasma activated microwave induced grafting technology to improve the compatibility of a carbon nano tube with the maleic anhydride, and obtains the modified carbon nano tube with the highest grafting ratio of 15%. The invention has the advantages of easy obtainment of raw materials, simple operation, simple and convenient apparatuses, short grafting reaction time of 20-60 min, easy control of product performance and structure.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

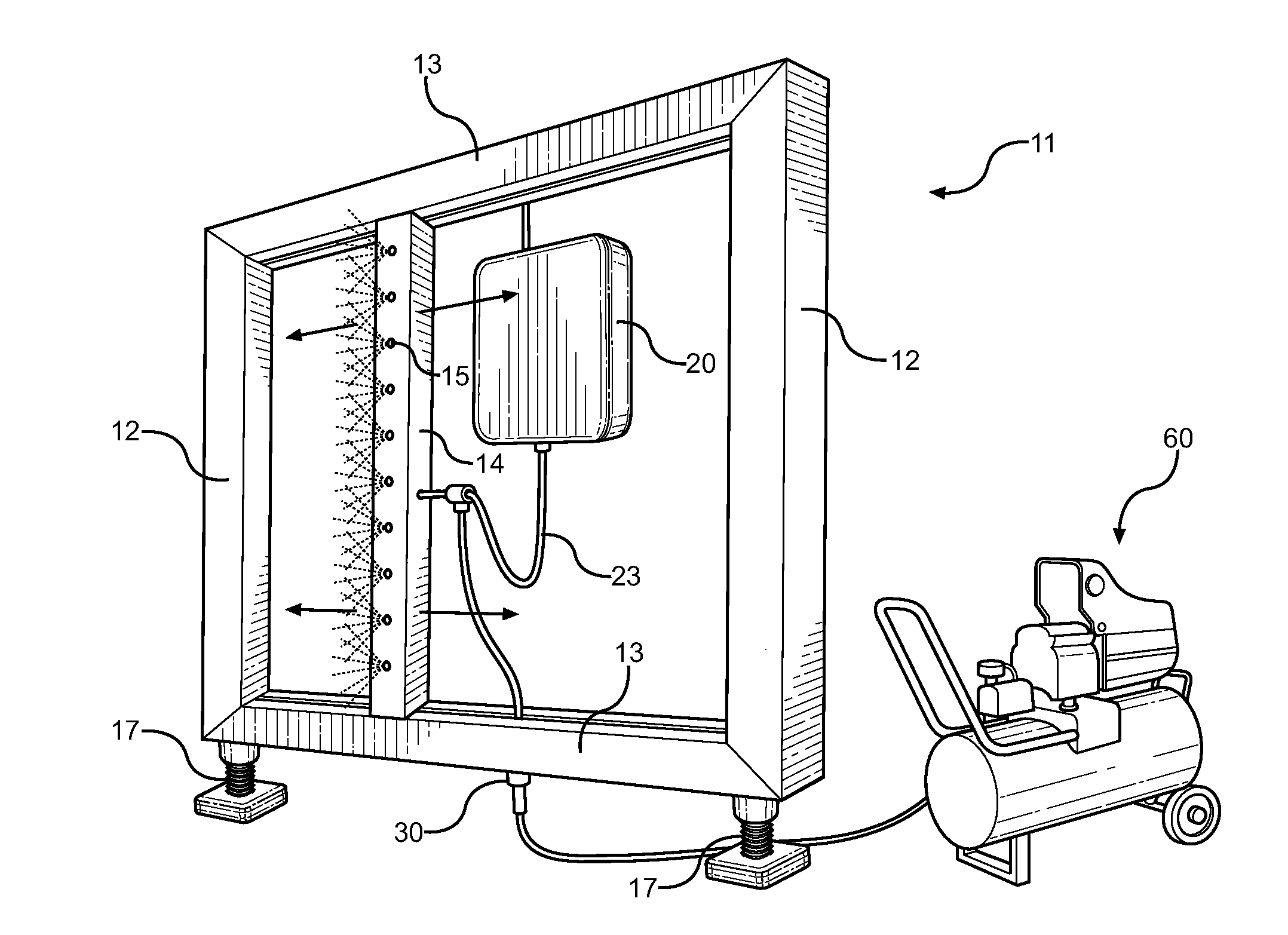

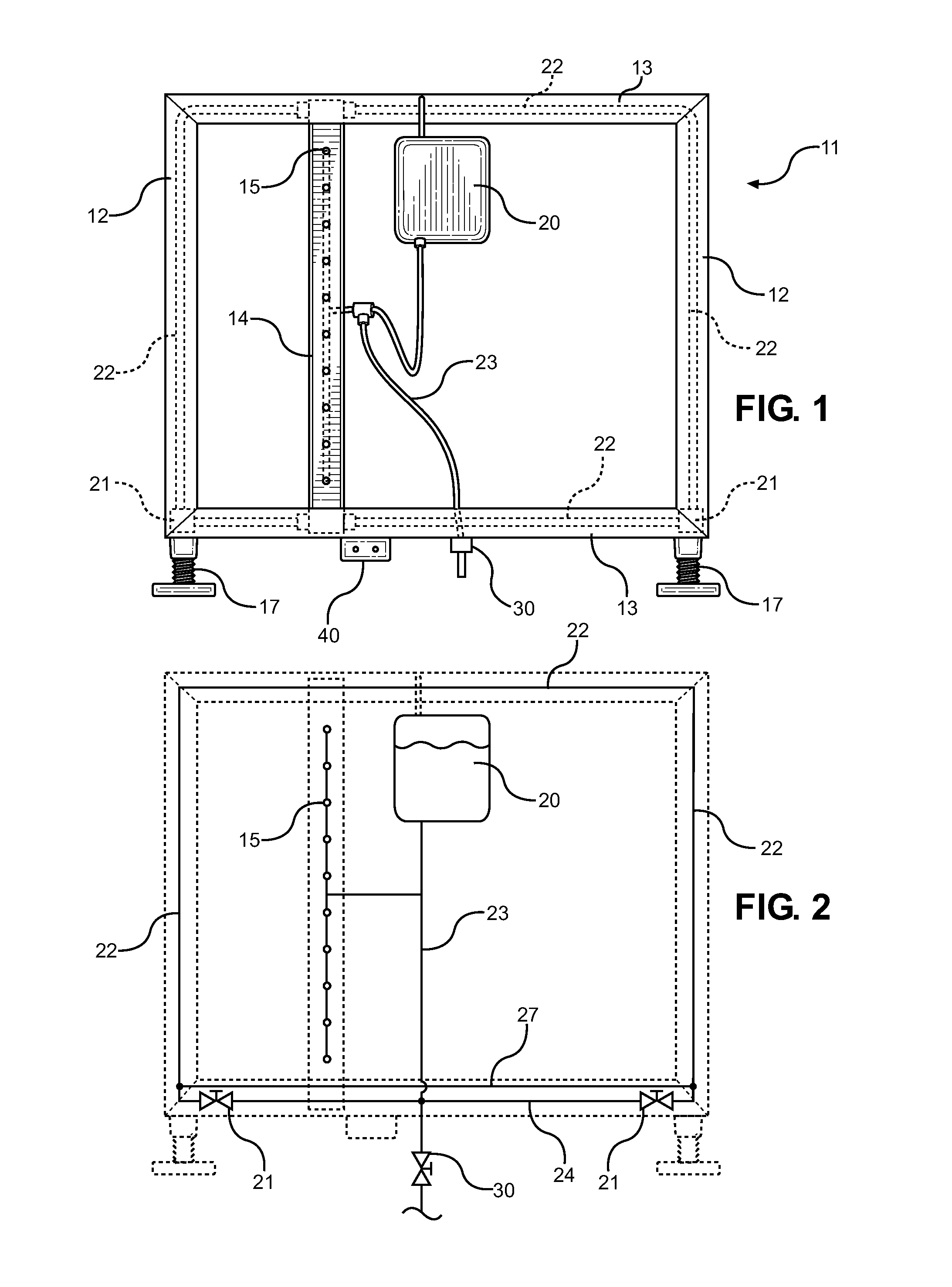

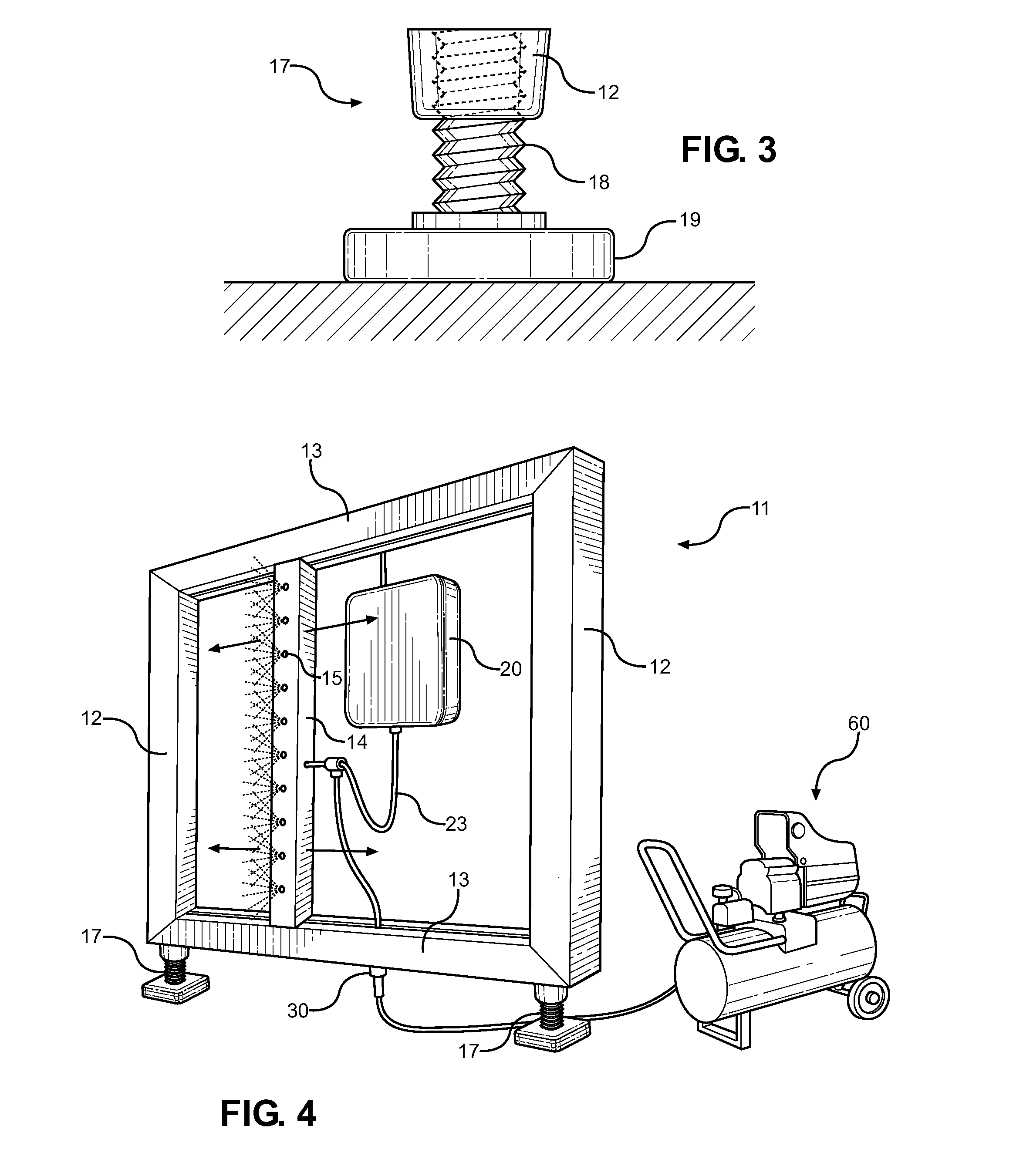

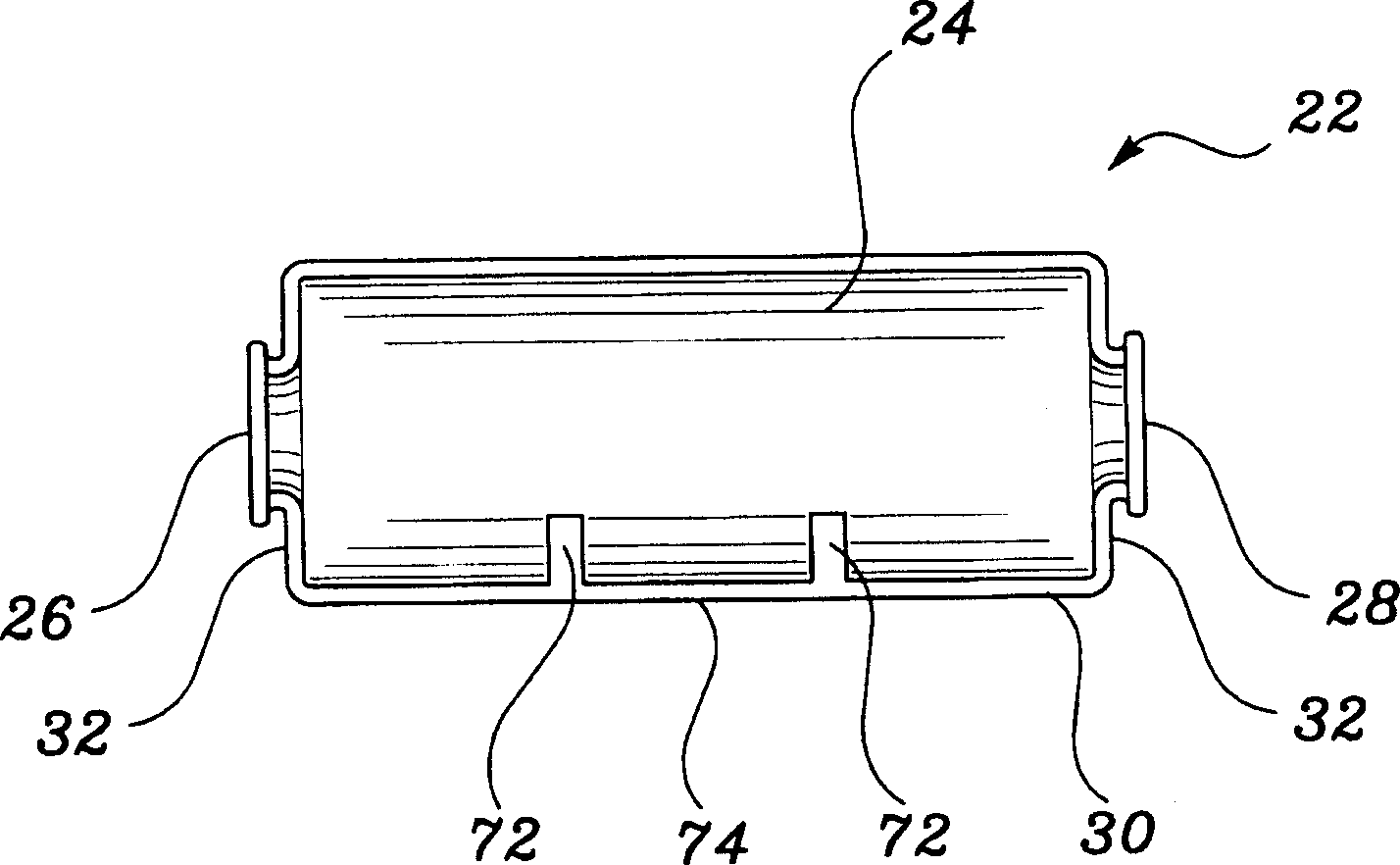

Pneumatic Surface Painting Frame

InactiveUS20150136019A1Reduce errorsUniform surface coatingLiquid surface applicatorsMovable spraying apparatusRemote controlSpray nozzle

A pneumatically controlled painting frame is provided for painting large, open surfaces with a uniform coating of paint, primer, or other surface coating that is spray-applied. The device comprises a rectangular frame having a slidable paint spray rail within the frame. The paint spray rail is slidably controlled using compressed air, which forces the rail along the frame in a singular direction, while the compressed air draws the coating from a container for communication through a plurality of spray nozzles along one surface of the rail. The device is positioned against a surface, adjusted using jack screw base supports, connected to a compressor, and operated using a remote control, which activates the release of the compressed air through the system to allow one pass of the rail across the adjacent surface for coating the same.

Owner:BELLAMY JOSEPH

Method for preparing ceramic-magnetofluid composite stent

ActiveCN112773945AShorten the production cycleMagnetic controllableAdditive manufacturing apparatusTissue regenerationUltrasonic emulsificationActive agent

The invention provides a method for preparing a ceramic-magnetofluid composite stent, and belongs to the field of composite material preparation. The preparation method comprises the following steps: firstly, printing a biological ceramic stent by adopting 3D gel, then preparing Fe3O4 magnetic nanoparticles by adopting an ultrasonic emulsification composite chemical coprecipitation method, then preparing Fe3O4 magnetic fluids with different volume fractions by adding different amounts of deionized water and a surfactant, dipping the ceramic stent which is subjected to 3D printing and sintering into the magnetic fluids, and then centrifuging and drying to obtain uniform Fe3O4 magnetic fluid coatings with different magnetisms on the surface of the stent. The method for preparing the magnetic nano coating is simple and stable to operate, the cost can be saved, and the production efficiency can be improved.

Owner:UNIV OF SCI & TECH BEIJING

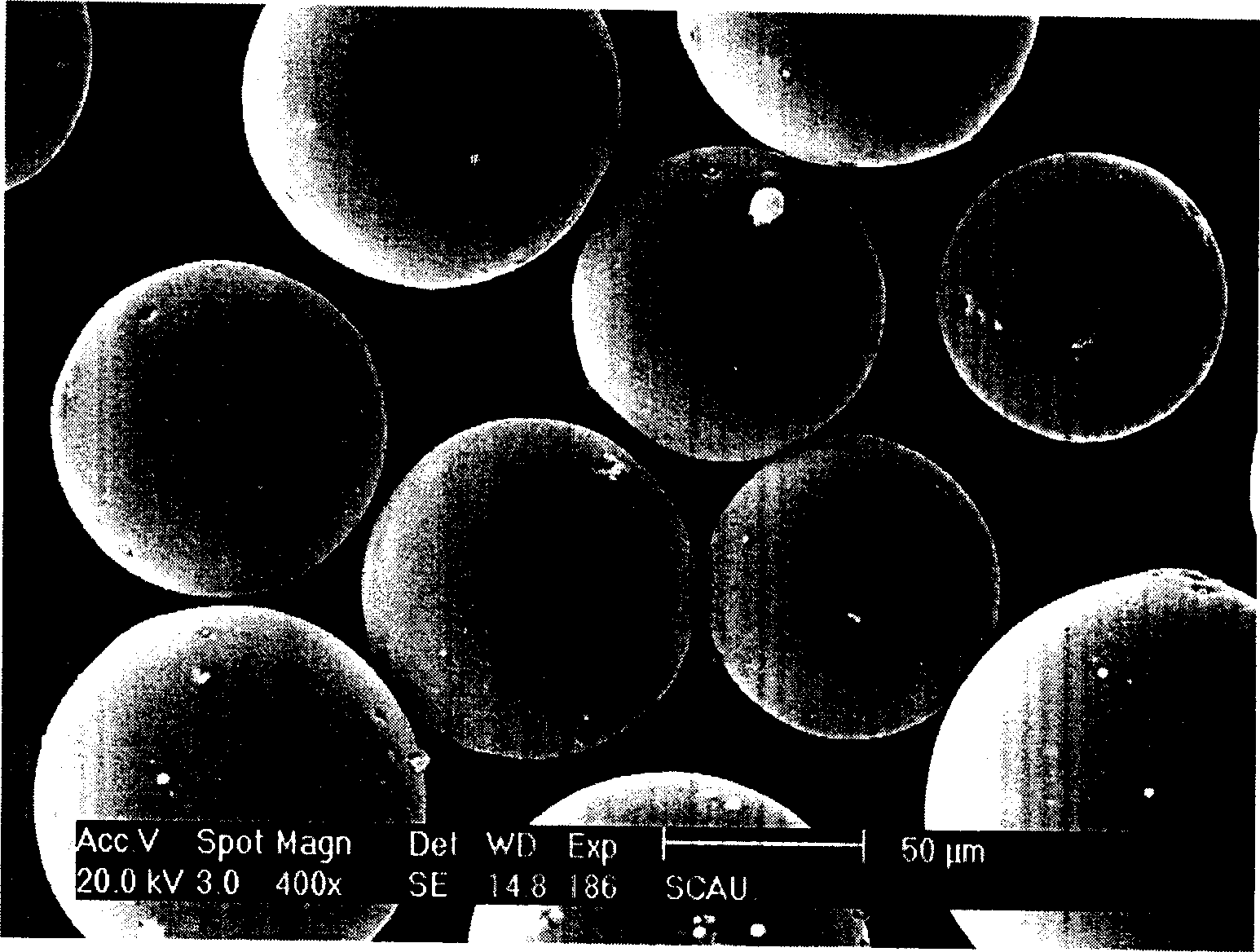

Process for preparing magnetic polymethyl methacrylate microsphere by two-step method

The invention relates to a method for manufacturing magnetic polymethyl methacryate microsphere, which comprises two steps: first, preparing polymethyl methacryate microsphere; second, preparing magnetic polymethyl methacryate microsphere. Compared with existing technology of one step, the invention divides process into two steps. The first step controls particle size and purity of microsphere, while the second step embeds ferrous powder into polymethyl methacryate microsphere. The invention can get magnetic polymethyl methacryate microsphere with adaptive particle size, good monodisperse, mechanic stability and so on.

Owner:SOUTH CHINA UNIV OF TECH

Technological method for performing static fluorocarbon spraying on surface of stainless steel

ActiveCN102407218AUniform coatingExpand the scope of applicationPretreated surfacesCoatingsNanometreFluorocarbon

The invention relates to a technological method for performing static fluorocarbon spraying on a surface of stainless steel, and the method comprises the following steps of: (1) putting the stainless steel into an acid degreaser so as to remove greasy dirt on the surface of the stainless steel after soaking; (2) washing the greasy-dirt-removed stainless steel with water, dewatering and drying; (3) spraying a metal nanometer finishing agent on the processed surface of the stainless steel; (4) by using a wet-on-wet coating operation, performing general static fluorocarbon spraying on the processed surface of the stainless steel; and (5) obtaining a finished product after curing at a high temperature. By utilizing the technological method, decorative stainless steel materials with different colors can be manufactured; and furthermore, the adhesive force of a coating film is improved to 0 level so that actual use requirements are met.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Wet surface treatment process for calcium carbonate

InactiveCN108047765AUniform surface coatingEasy to makePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsCalciteCrystal structure

The invention discloses a wet surface treatment process for calcium carbonate, which relates to the technical field of surface treatment for calcium carbonate. The wet surface treatment process for calcium carbonate comprises choice of material, agitation, addition of modifier and washing and drying. The steps are as follows: choice of material: the average grain size of chosen calcium carbonate is about 30nm to 70nm, and the crystal form structure is the form of calcite; agitation: the calcium carbonate powder is put into a reaction kettle, so that a calcium carbonate suspension is prepared,the temperature of the calcium carbonate suspension is kept within a range from 70 to 80 DEG C, and the agitation speed of agitating blades is controlled; addition of modifier: the temperature of thecalcium carbonate suspension and the agitation speed in step 2 are kept unchanged, the ratio of the dosage of added modifier to the dosage of the calcium carbonate is 1-4 / 100g, and reaction time is within a range from 20 to 30 minutes; and washing and drying: the hot slurry is filtered, the filter cake is washed to remove the unreacted modifier, and after drying, active calcium carbonate powder isobtained. The operation process of the wet surface treatment method disclosed by invention is simple, and in the process of treatment, an activator can more uniformly wrap the surface of calcium carbonate.

Owner:XUANCHENG XINTAO CALCIUM CARBONATE

Method for preparing copper cladded iron composite powder

A preparation method of copper-clad iron composite powder which includes procedures as follow: the alcaline etching waste liquor containing copper is added into the acid etching waste liquor, thus feed solution with pH between 2 and 4.5 is obtained and the concentration of copper between 50 and 100g / L. The reduced iron powder is washed by acid, delivered to a reaction kettle with turbine type stirring, added with water with stirring, added orderly with dispersant agent and inhibitor and evenly with feed solution containing copper with continuous stirring, making the copper completely claddingthe surface of the iron powder grain, thus copper-clad iron composite powder is obtained. Then the copper-clad iron composite powder is subject to pumping filtration, washing, centrifugal dehydration,antioxidation treatment, vacuum drying and screen separation, thus termination production is obtained. The method of the invention can make the copper evenly, tightly, firmly and completely claddingthe iron powder grain, and not be oxidized for six months of storage, thus increasing the oxidation resistance. The prepared copper-clad iron powder by the invention has bright surface colour and lustre, high cladding rate, even and compact surface cladding, futhermore, the cost is lower compared with prior preparation methods because of avoiding using copper sulfate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Liquid friction-increasing rubber for shoe plate of rear-drum brake and preparation method thereof

ActiveCN104327607AImprove the bonding rateImprove comfortConjugated diene hydrocarbon coatingsVulcanizationBenzoyl peroxide

The invention relates to liquid friction-increasing rubber for a shoe plate of a rear-drum brake and a preparation method thereof. The preparation method comprises the following steps: 1, dissolving silicon carbide, antimony sulfide, benzoyl peroxide, sulphur, quartz powder and Buna-N rubber in ethyl acetate and fully stirring; 2, smearing the above mixture onto the surface of a processed shoe plate by a brushing method or an infiltration method; 3, standing and air-drying; 4, placing the shoe plate in a constant-temperature vulcanization box to fully vulcanize rubber; and 5, cooling the vulcanized shoe plate and directly applying the shoe plate in assembling of the brake. The invention has the following beneficial effects: as the friction-increasing formula is blended into a liquid state, the liquid friction-increasing rubber is convenient to smear, can produce productivity and is suitable for mass production; the surface coating is uniform so as to effectively cancel influence of processing precision and raise conjoint ratio; as NRB (Buna-N rubber) is used as a base material, elasticity and buffer performance are enhanced and noise is reduced effectively; and as quartz powder is used to replace emery, the friction-increasing material is easier to distribute uniformly, hard lumps and hard spots are eliminated, and comfortability of drivers is improved.

Owner:ZHEJIANG WANXIANG SYST +1

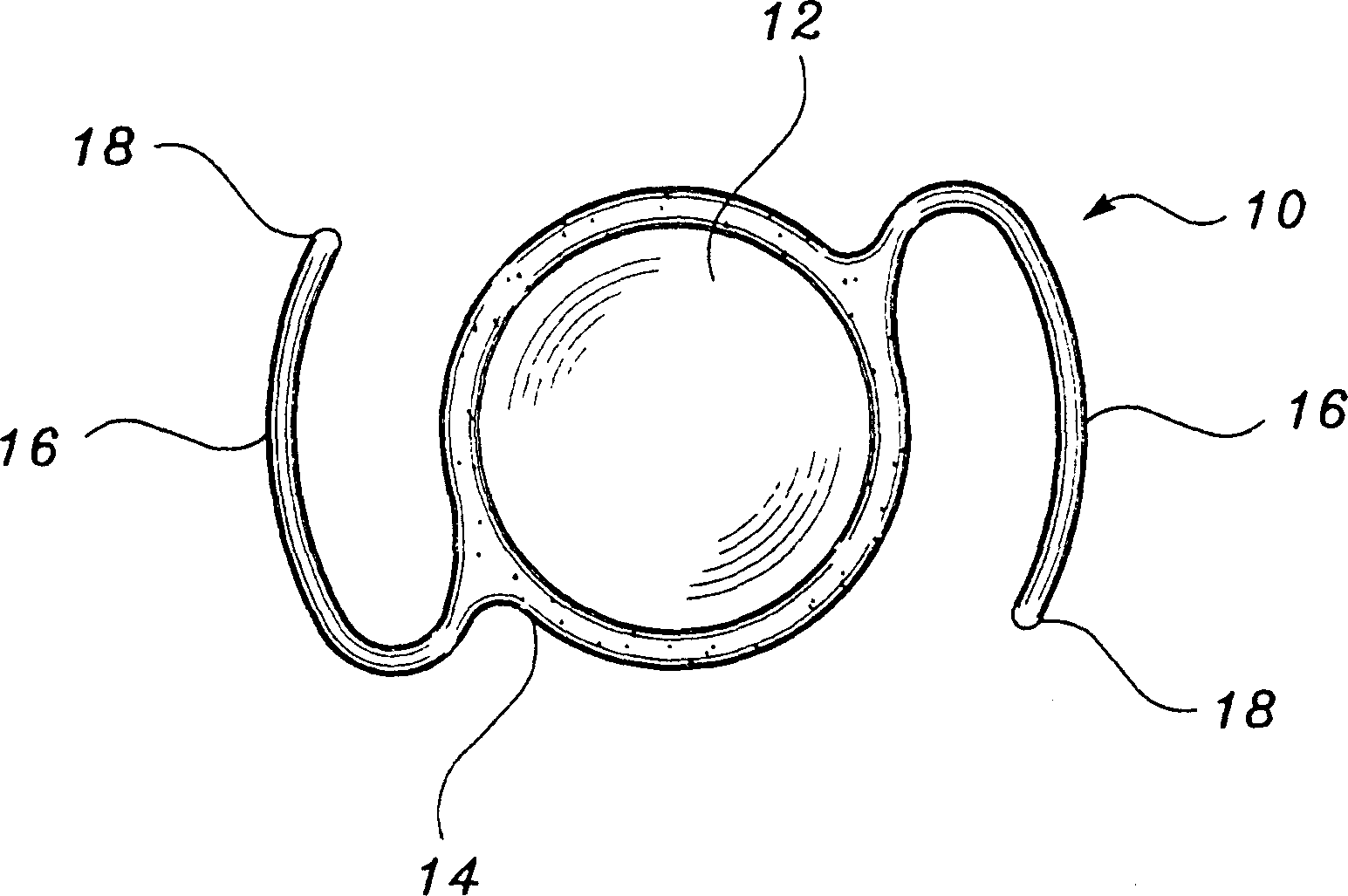

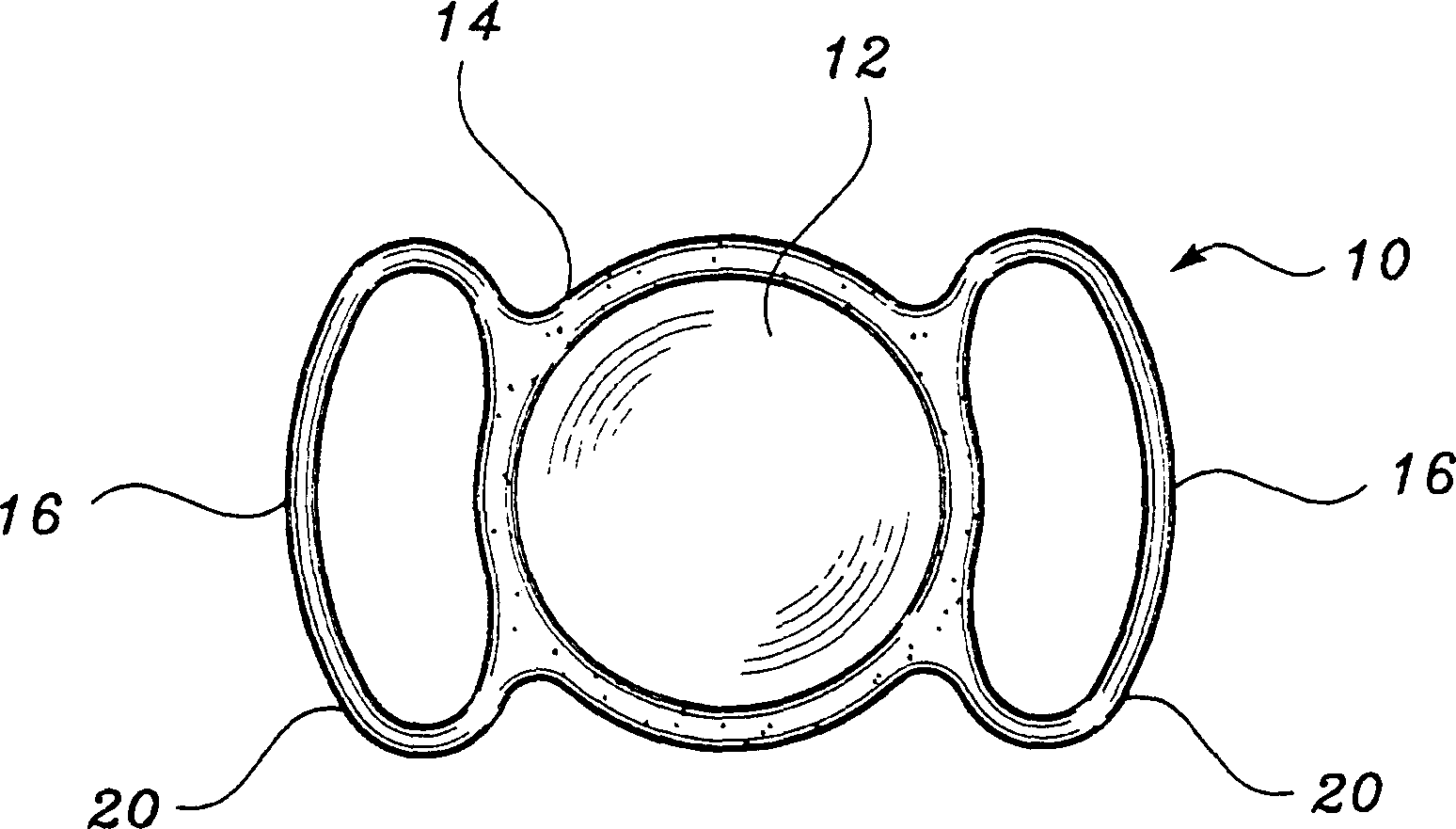

Dry polishing of intraocular lenses

InactiveCN1479664AUniform surface coatingEdge grinding machinesPolishing machinesMedicineIntraocular lenses

A process of dry polishing molded or lathe cut intraocular lenses to removing flash, sharp edges and / or surface irregularities therefrom. The process includes rotational tumbling of partially protected intraocular lenses in a dry polishing media. The process is suitable for single piece and multipiece intraocular lenses of varying composition.

Owner:BAUSCH & LOMB INC

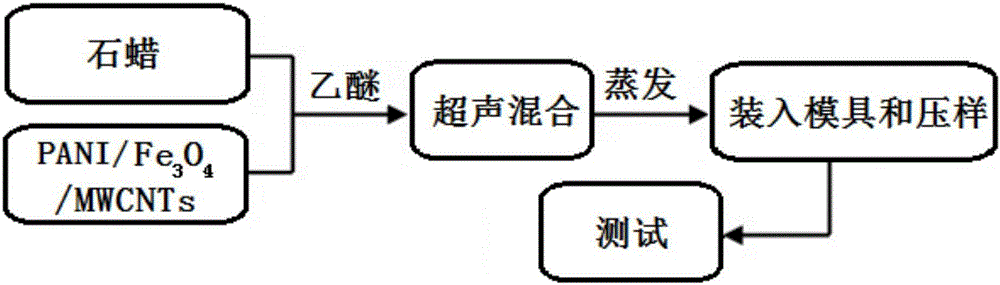

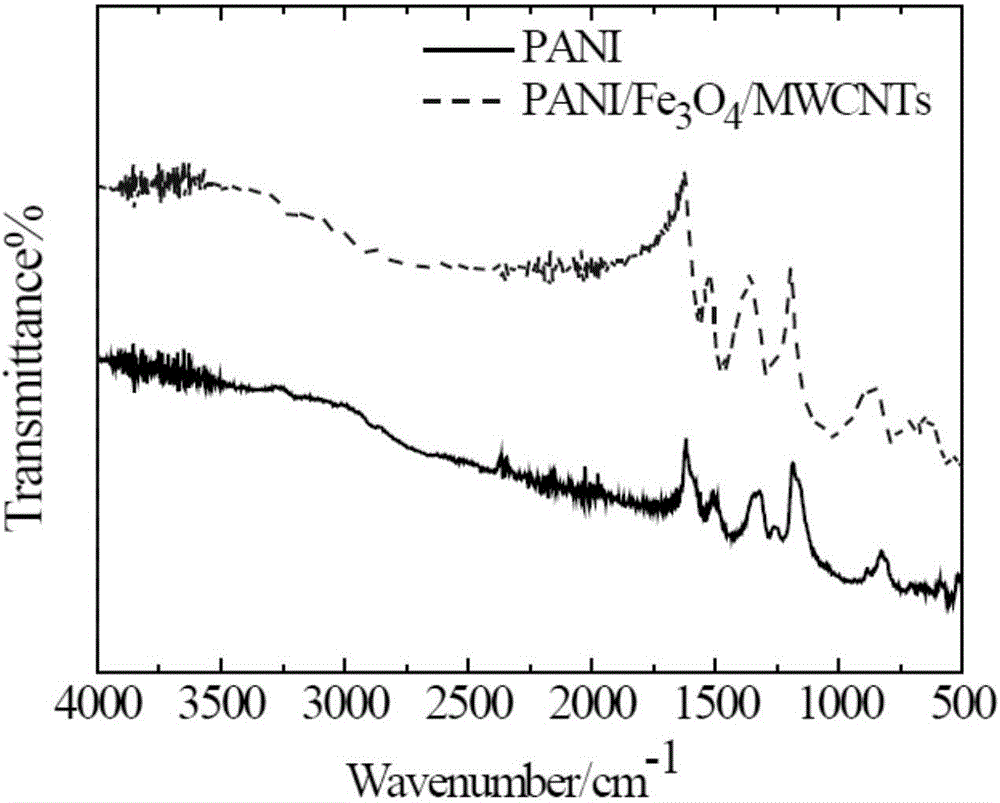

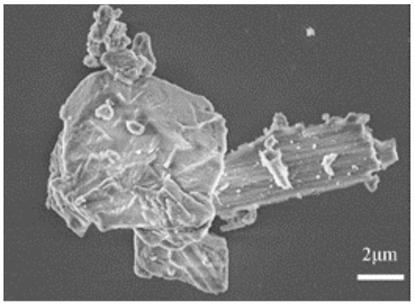

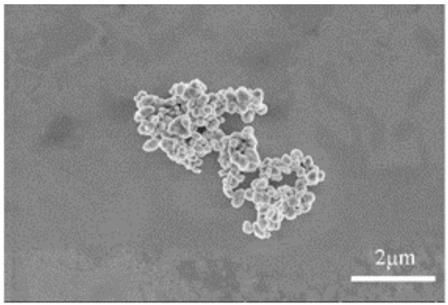

Preparation method of PANI/FE3O4/MWCNTs-paraffin composite material

The invention provides a preparation method of a PANI / FE3O4 / MWCNTs-paraffin composite material. The method comprises the steps that CNT and an acid solution is placed into a three-month flask, the three-month flask is placed into an oil bath pan to be mechanically stirred for several hours, suction filtration is performed, a sample obtained after filtering is performed is put into a drying oven, and an acidified MWCNTs suspension is obtained; a functionalized carbon nano tubes are added into a beaker to perform ultrasonic treatment, a stable carbon nano tube suspension is obtained, 20 ml of 157 mg (0.4 mmol) (NH4)2FeSO4-6H2O and 386 mg (0.8 mmol) of NH4Fe(SO4)2-12H2O are added to continue to perform ultrasonic treatment, and a Fe3O4 / MWCNTs heterostructure is obtained; 0.02 g of Fe3O4 / MWCNTs and 0.8 g of paraffin are added into the 100 ml beaker, 20 ml of diethyl ether is added for performing ultrasonic dispersion, after diethyl ether is evaporated completely, cooling is performed to the room temperature, the sample is put into a mold, and a cylinder is obtained through pressing. Compared with the prior art, the obtained PANI / FE3O4 / MWCNTs-paraffin composite is uniform in surface coating, the structure is orderly, and meanwhile the dielectric property is good.

Owner:SHENZHEN PEICHENG TECH CO LTD

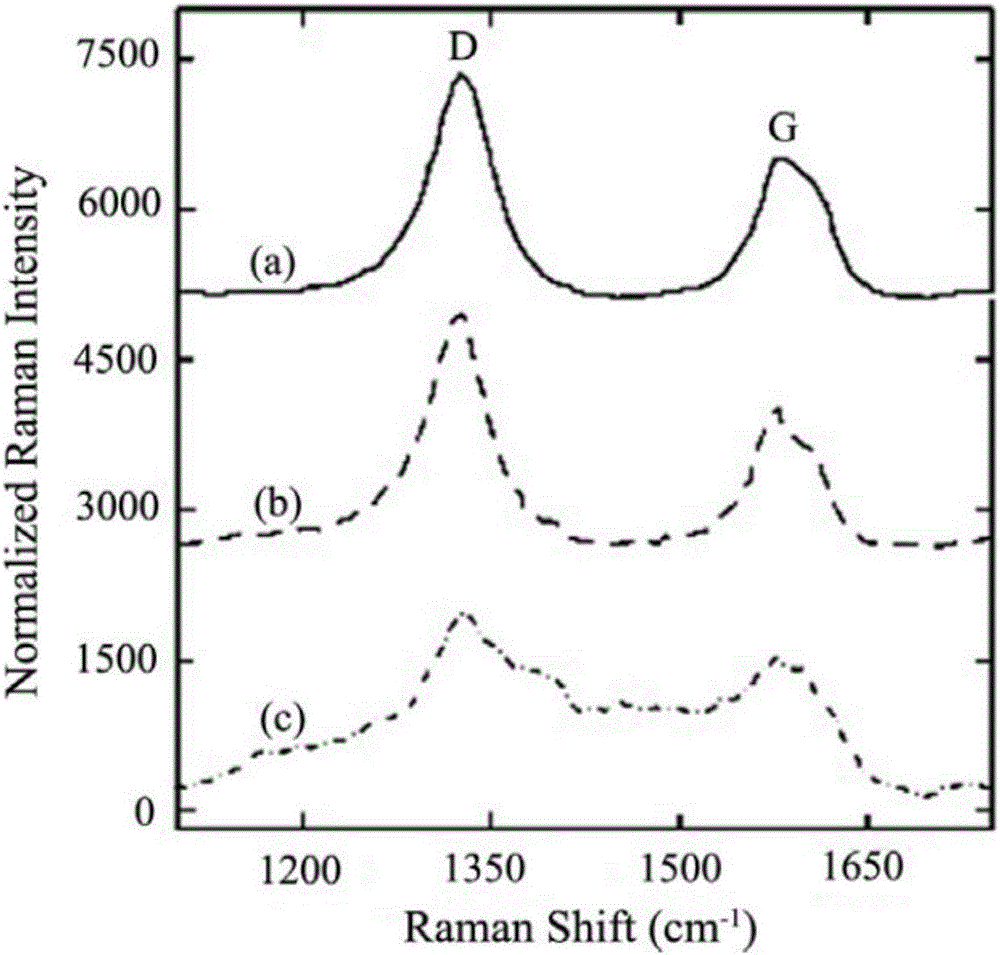

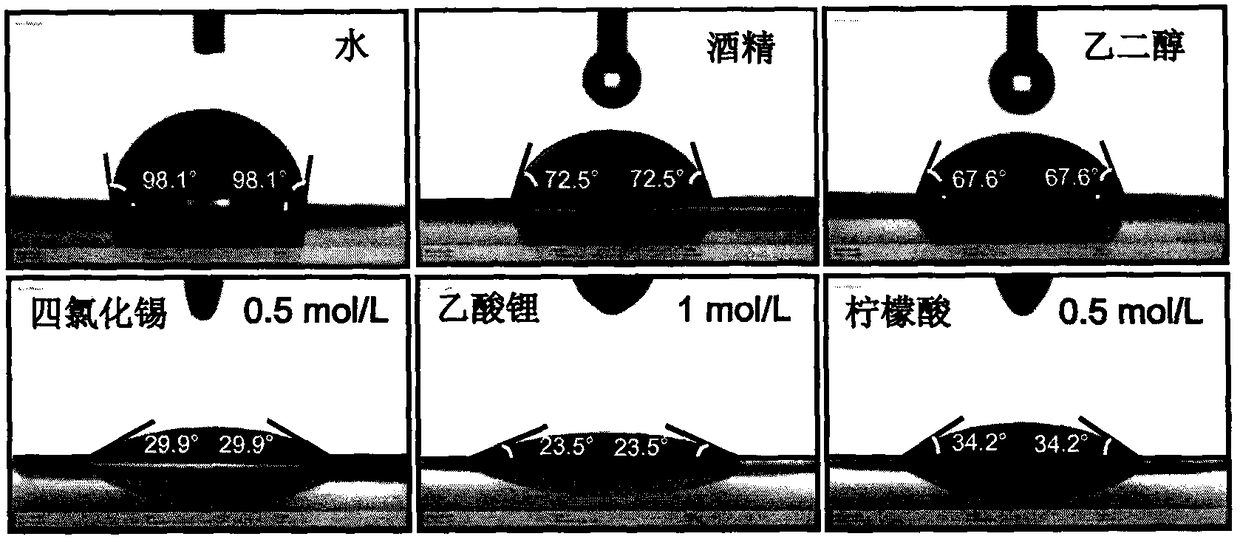

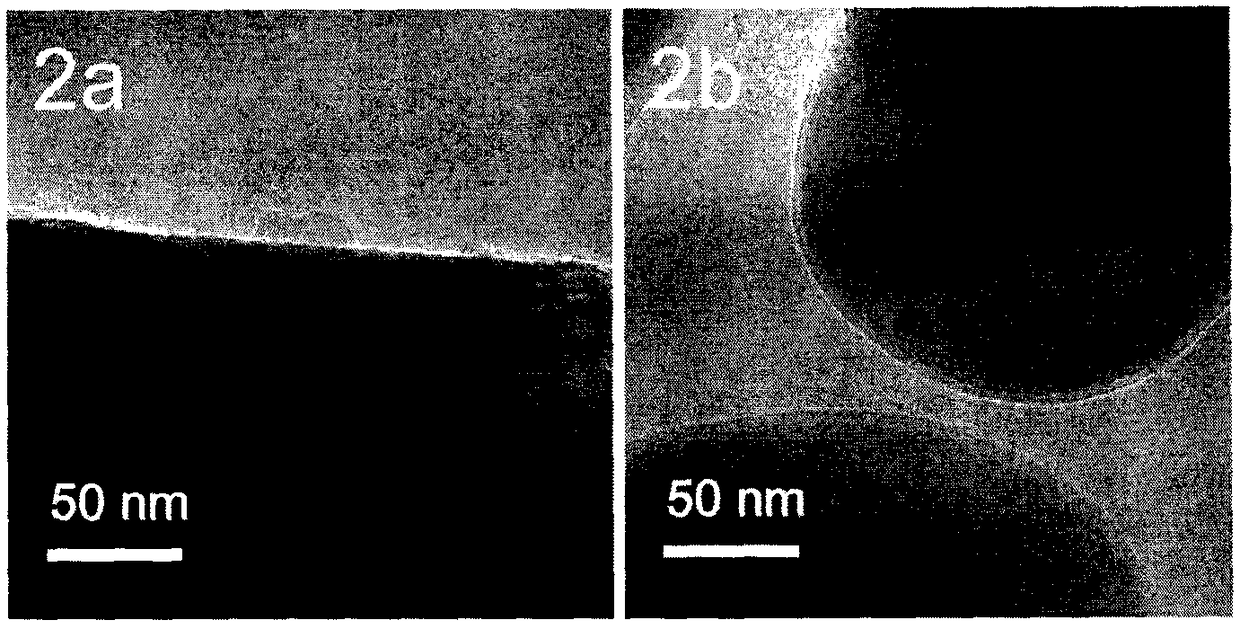

Method for preparing electrode material surface uniform modified layer based on contact angle test

ActiveCN108649192AImprove structural stabilityImprove cycle stabilityCell electrodesSurface/boundary effectSolventThermal safety

The invention provides a method for preparing an electrode material surface uniform modified layer based on a contact angle test, belongs to the technical field of surface modification, and relates tothe wetting property of a coating precursor liquid on an electrode material surface. The method employs the contact angle test, a suitable solvent and concentration required for surface modificationare determined by the size of the contact angle, thereby obtaining the coating precursor liquid having better wettability. The method provided by the invention can achieve uniform surface coating, thereby effectively improving the structural stability, thermal safety and cycling stability of the material. The invention has a simple operation flow, low cost and good application value.

Owner:HENAN UNIVERSITY

Waterborne surface treating agent for PVC and PU artificial leather and preparation method and product thereof

InactiveCN107141989AHealth effectsMeet the protection requirementsFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPhenyl Ethers

The invention discloses a waterborne surface treating agent for PVC and PU artificial leather, and the surface treating agent is prepared from the following components: 25-60 parts of waterborne aliphatic polyurethane resin, 5-25 parts of waterborne acrylic resin, 10-35 parts of water, 5-15 parts of isopropanol, 0.1-3 parts of a poly-2-methyl-4-isothiazolin-3-one compound, 1-5 parts of a dispersant, 0.1-5 parts of a paracresol and dicyclopentadiene butyl compound, 0.1-5 parts of polyether modified polydimethyl siloxane, 0.1-5 parts of a silane coupling agent, 0.1-8 parts of propylene glycol phenyl ether, 0.1-8 parts of matting powder and 0.1-5 parts of an acrylate polymer. Correspondingly, the invention also provides a preparation method of the waterborne surface treating agent for PVC and PU artificial leather. The waterborne surface treating agent for PVC and PU artificial leather has multiple functions, integrates multiple properties of scratch resistance, wear resistance, high temperature resistance and yellow stain resistance, can achieve the operating requirements by only one-step treatment, and is simultaneously suitable for PVC and PU artificial leather.

Owner:MINGHAI CHEM ENTERPRISE

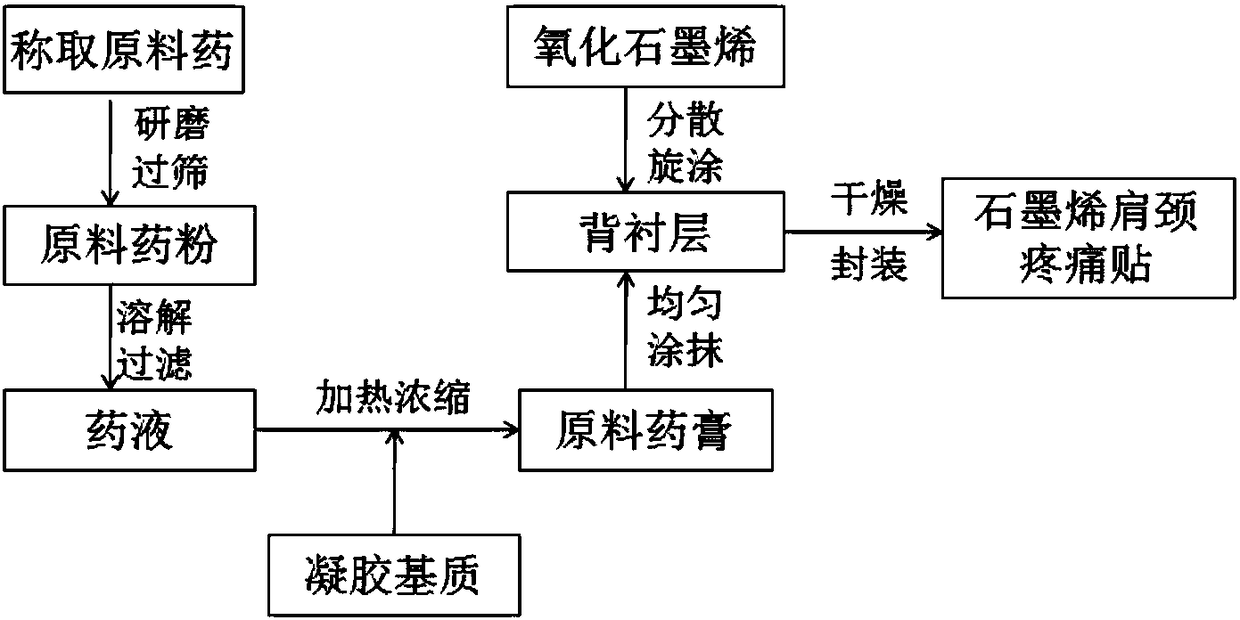

Graphene shoulder and neck pain patch and preparation method thereof

InactiveCN108404102AGood healing effectImprove numbnessAntipyreticAnalgesicsAngelica Sinensis RootNeck pain

The invention discloses a graphene shoulder and neck pain patch comprising a backing layer, a graphene film layer, a raw material medicine layer and an anti-sticking release paper layer. The raw material medicine layer is placed between the anti-sticking release paper and the backing layer; a raw material medicine is in the middle position of the raw material medicine layer and comprises the following substances: radix angelica sinensis, rhizoma gastrodiae, pilose antler, radix saposhnikoviae, notopterygium root, radix angelicae tuhuo, baked ginger, asarum sieboldii, fructus evodiae, safflower, radix dipsaci and garden balsam stem; the raw material medicine is also mixed with sodium hydroxymethylcellulose, sodium alginate and glycerol, so the raw material medicine is uniform in coating, has good adhesion and does not produce greater fluidity; the outer side of the raw material medicine is laid with the graphene film layer which can effectively activate the vitality of damaged cells andrestore normal function. The graphene shoulder and neck pain patch has the advantages of low price and convenient and quick use, and has the functions of relaxing tendons and dredging collaterals, activating blood circulation and promoting qi. The graphene film layer at the bottom layer can effectively promote the transmission of drugs, accelerates the absorption of the raw material medicine, andhas a good healing effect on shoulder and neck pain and other symptoms.

Owner:GUANGXI UNIV OF CHINESE MEDICINE

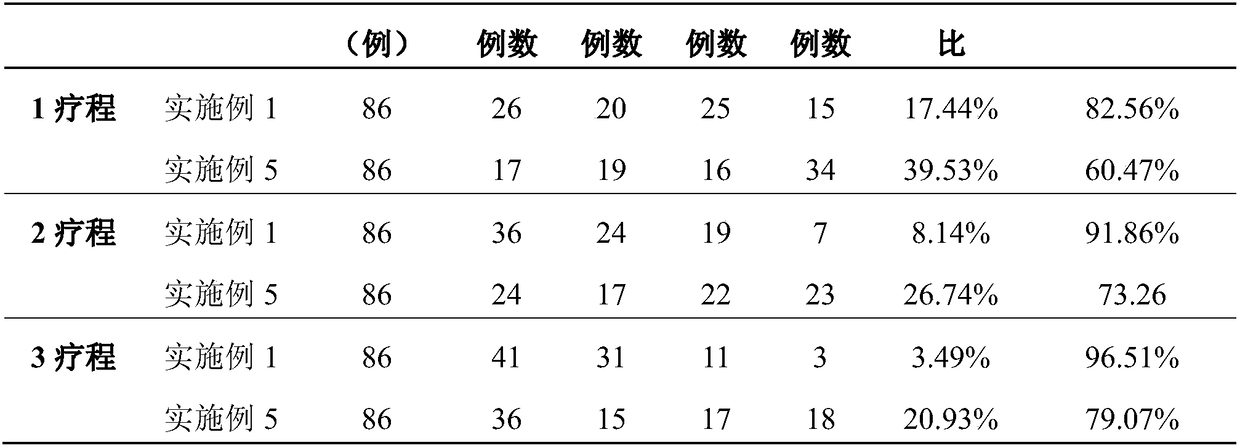

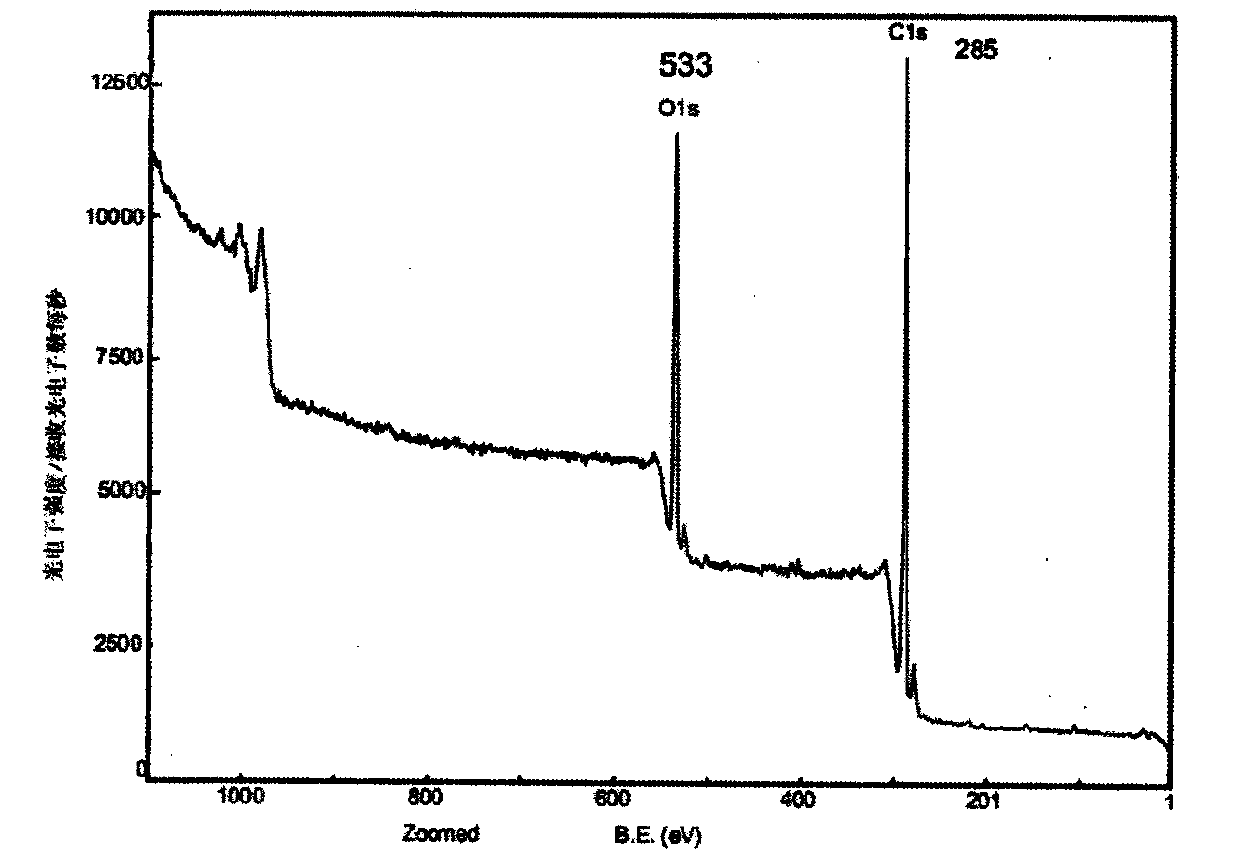

Additive capable of improving electrostatic effect for spraying fluorocarbon paint

ActiveCN102268210BLower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

Preparation method for improving interfacial properties of carbon fiber composite material

InactiveCN102720061BImprove interface performanceThe polymerization reaction is fastFibre treatmentFiberOxygen

The invention provides a preparation method for improving interfacial properties of a carbon fiber composite material. The method is characterized by comprising the steps of firstly, preparing plasma activated carbon fiber; secondly, preparing a maleic anhydride dimethylbenzene solution; thirdly, subjecting the activated carbon fiber to ultrasonic infiltration; fourthly, performing grafting of maleic anhydride; and fifthly, purifying a crude product of the plasma activated carbon fiber which the maleic anhydride is grafted to. The method has the advantages that the free radicals formed on the surface of carbon fiber are processed through plasmas of argon-oxygen mixed gas, so that the polymerization reaction speed of the free radicals and the maleic anhydride is accelerated and the degree us improved; the reaction speed is accelerated through a high temperature, and the grafting reaction time is only 3 min to 7 min, so that grafting carbon fiber which is uniform in surface coating and high in grafting rate and has certain quantities of anhydride groups is obtained, the grafting carbon fiber and epoxy resin are subjected to reaction well, and the interfacial properties of the composite material is improved; and the method is energy-saving, environment-friendly and convenient to process.

Owner:DONGHUA UNIV

Additive for fluorocarbon paint spraying that can increase electrostatic effect

ActiveCN102268210ALower resistanceImprove conductivityElectrically-conductive paintsDiethylene glycol monobutyl etherButyl acetate

The invention belongs to the technical field of fluorocarbon paints, and particularly relates to an additive capable of improving the electrostatic effect for spraying fluorocarbon paint. The additive consists of the following components in percentage by weight: 15-25 percent of methyl ethyl ketone, 10-20 percent of diethylene glycol monobutyl ether, 2-4 percent of methyl isobuthyl ketone, 3-6 percent of butyl acetate and 45-70 percent of alkane main solution. The additive can be used for overcoming the defects of low atomizing efficiency of a spray gun, low adsorption force, low painting efficiency and non-uniform distribution of metal fine particles and the like caused by weak electrostatic effect and poor electric conductivity in the spraying process of the fluorocarbon paint at present.

Owner:上海新大余氟碳喷涂材料有限公司

Technological method for electrostatic powder coating on stainless steel surface

InactiveCN102423754AMeet the use requirementsUniform surface coatingPretreated surfacesSpecial surfacesNanometrePowder coating

A technological method for electrostatic powder coating on a stainless steel surface comprises the steps that: stainless steel is placed into an acid degreasing fluid to remove the surface grease; the stainless steel which is removed with the grease is flushed by clean water, is dehydrated and aired; a metal nanometer finishing agent is painted onto the stainless steel surface; the primary high temperature solidification is carried out; the stainless steel surface after the primary solidification is undergone the conventional electrostatic powder coating; and the secondary high temperature solidification is carried out, so a finished product is produced. The technological method can produce stainless steel decorative materials of various colors, the adhesive forces of the coating and the stainless steel are improved to the zero level, and the practical use requirement is satisfied.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Method for preparing nano TiO2/wollastonite compound used for papermaking

ActiveCN109183497AHigh whitenessCoated evenlyInorganic pigment treatmentInorganic compound additionWeather resistancePapermaking

The invention relates to a method for preparing nano TiO2 / wollastonite compound used for papermaking, which belongs to the technical field of inorganic synthesis. The invention discloses a new methodwhich is not reported yet, and the method successfully synthesizes a novel nano TiO2 / wollastonite compound product with uniform coating, and the properties of the compound product can reach the standard. The compound product obtained by the preparation method is in a plate-like structure, and has the characteristics of high whiteness, uniform coating and good weather resistance. When the obtainedcompound product is used as a papermaking filler, the properties of the paper are similar to those of titanium dioxide as a filler. The production process of the invention is simple, and the rate forintroducing gas and the addition amount of titanium dioxide can be controlled, so that the size of the titanium dioxide particles and the coating rate of wollastonite can be adjusted, the wollastonitesurface is uniformly coated, the yield is high, the reaction condition is mild, and industrial production is easy to be realized.

Owner:JILIN UNIV

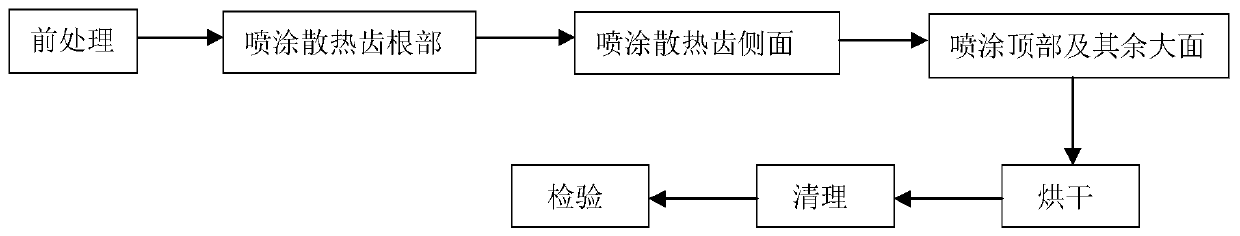

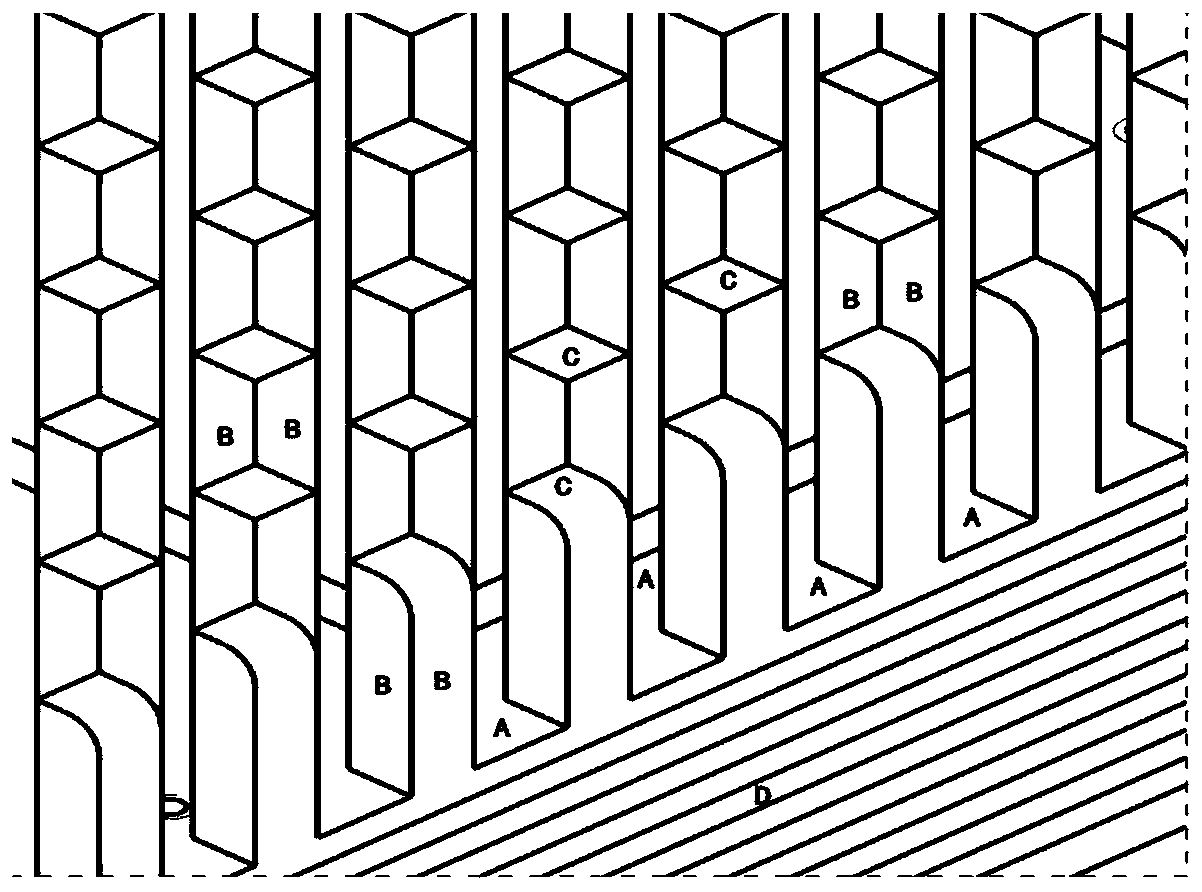

Composite coating method for the surface of heat-dissipating tooth parts

ActiveCN106238285BGuarantee coating qualityImprove corrosion resistanceLiquid surface applicatorsCoatingsThree stageMaterials science

The invention discloses a compound painting method for surfaces of heat radiating teeth class parts. By utilizing the method, the root regions of heat radiating teeth can be reached, and the coating quality of deep regions is enhanced. The compound painting method is realized through the technical scheme: dividing the surfaces of the heat radiating teeth class parts into A, B, C and D painting regions according to the teeth width and teeth depth parameters of the heat radiating teeth, and carrying out three-stage stepped spraying treatment on the roots, side surfaces and tops of the heat radiating teeth class parts; first, using a thin-pipe long-neck spraying gun to carry out stepped spraying treatment on the bottom and side wall deep-cavity coating regions of the heat radiating teeth; avoiding other regions, carrying out skip spaced spraying on the bottom regions of the heat radiating teeth at a perpendicular angle, and then, spraying the side wall regions of the heat radiating teeth from bottom to top at an angle of 70-80 degrees; and after standing for 5-10 minutes, changing a common spraying gun after coated films are leveled, and carrying out large-area spraying on the top and other outer coating regions of the heat radiating teeth by using the common spraying gun.

Owner:10TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com