Method for preparing electrode material surface uniform modified layer based on contact angle test

An electrode material and surface modification technology, which is applied in the field of preparing a uniform modification layer on the surface of electrode materials based on a contact angle test, can solve problems such as expensive coating costs, achieve industrial application, be easy to repeat, and improve the stability of electrode structure and cycle stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: In lithium-rich layered material Li[Li 0.2 Ni 0.17 co 0.07 mn 0.56 ]O 2 The surface is coated with lithium stannate (Li 2 SnO 3 ) suitable solvent and concentration

[0018] 1. Weigh 0.08g of lithium-rich material Li[Li 0.2 Ni 0.17 co 0.07 mn 0.56 ]O 2 After grinding for 30 minutes in a mortar, add an appropriate amount of NMP (N-methylpyrrolidone), grind evenly and apply it on a flat and clean aluminum foil, then fully dry it in a vacuum drying oven, take it out and slice the electrode piece;

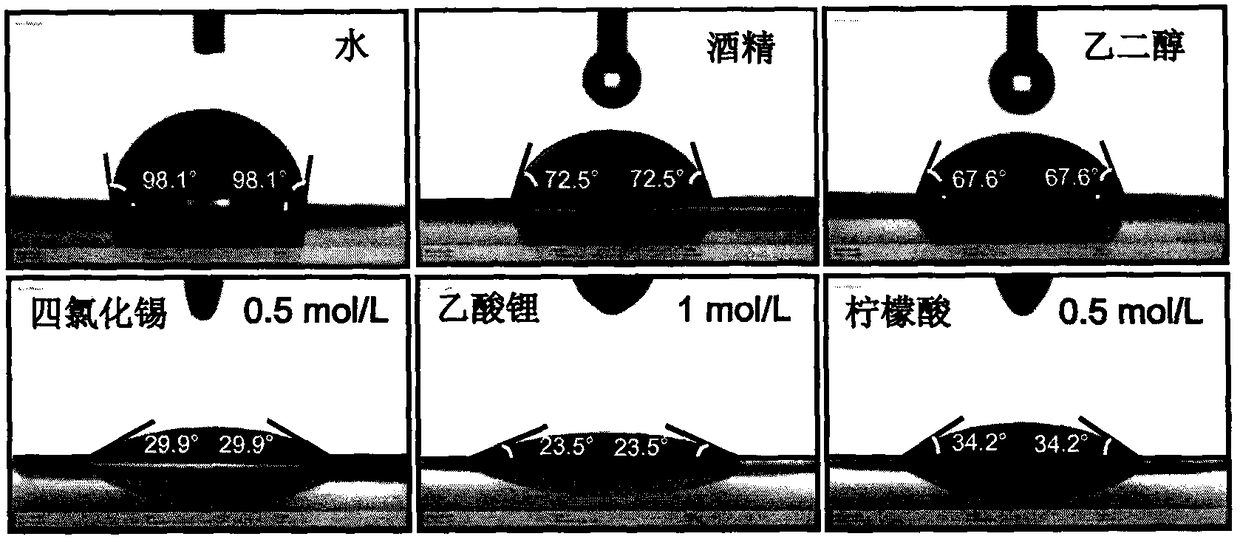

[0019] 2. The three solvents of water, absolute ethanol and ethylene glycol were used to test the contact angle of the electrode sheet cut in the above 1, and the ethylene glycol solvent with the smallest contact angle was selected (the contact angle was 67.7°);

[0020] 3. Dissolve the ethylene glycol solvents selected in the above 2 to prepare Li 2 SnO 3 The precursor material (anhydrous tin tetrachloride (SnCl 4 ·5H 2 O), lithium acetate (CH 3 CO...

Embodiment 2

[0023] Embodiment 2: in spinel material (LiNi 0.5 mn 1.5 o 4 ) coated with yttrium phosphate (YPO 4 ) suitable solvent and concentration

[0024] 1. Weigh 0.08g of spinel material LiNi 0.5 mn 1.5 o 4After grinding for 30 minutes in a mortar, add an appropriate amount of NMP (N-methylpyrrolidone), grind evenly and apply it on a flat and clean aluminum foil, then fully dry it in a vacuum drying oven, take it out and slice the electrode sheet;

[0025] 2. Test the contact angle of the above-mentioned 1-cut electrode sheet with water, absolute ethanol, and ethylene glycol, and select the alcohol solvent with the smallest contact angle (the contact angle is 64.3°);

[0026] 3. Dissolve the alcohol solvents selected above to prepare YPO 4 The precursor material (yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O), ammonium dihydrogen phosphate (NH 4 h 2 PO 4 )) and make a series of concentration gradients (0.1, 0.2, 0.5, 1, 2, 5, 10mol / L), and then conduct a contact angle ...

Embodiment 3

[0029] Embodiment 3: in lithium-rich layered material Li[Li 0.2 Ni 0.17 co 0.07 mn 0.56 ]O 2 The surface is coated with zirconium fluoride (ZrF 4 ) suitable solvent and concentration

[0030] 1. Weigh 0.08g of lithium-rich material Li[Li 0.2 Ni 0.17 co 0.07 mn 0.56 ]O 2 After grinding for 30 minutes in a mortar, add an appropriate amount of NMP (N-methylpyrrolidone), grind evenly and apply it on a flat and clean aluminum foil, then fully dry it in a vacuum drying oven, take it out and slice the electrode sheet;

[0031] 2. The three solvents of water, absolute ethanol and ethylene glycol were used to test the contact angle of the electrode sheet cut in the above 1, and the ethylene glycol solvent with the smallest contact angle was selected (the contact angle was 67.7°);

[0032] 3. Dissolve the above selected ethylene glycol solvents to prepare ZrF 4 The precursor material (anhydrous zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O) and ammonium fluoride (NH 4 F)), and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com