Composite coating method for the surface of heat-dissipating tooth parts

A technology for heat dissipation gears and parts, which is applied to the device and coating of the surface coating liquid, which can solve the problems of paint film accumulation in the top area, easy peeling off of the paint film, and high rework rate, so as to improve environmental adaptability and improve resistance. Corrosion ability, effect of enhancing coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

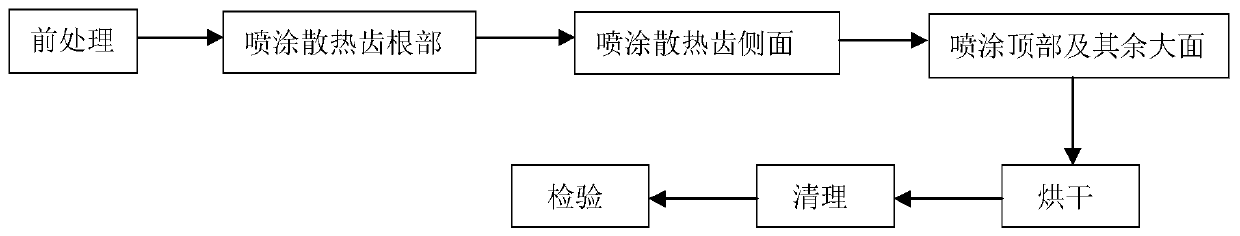

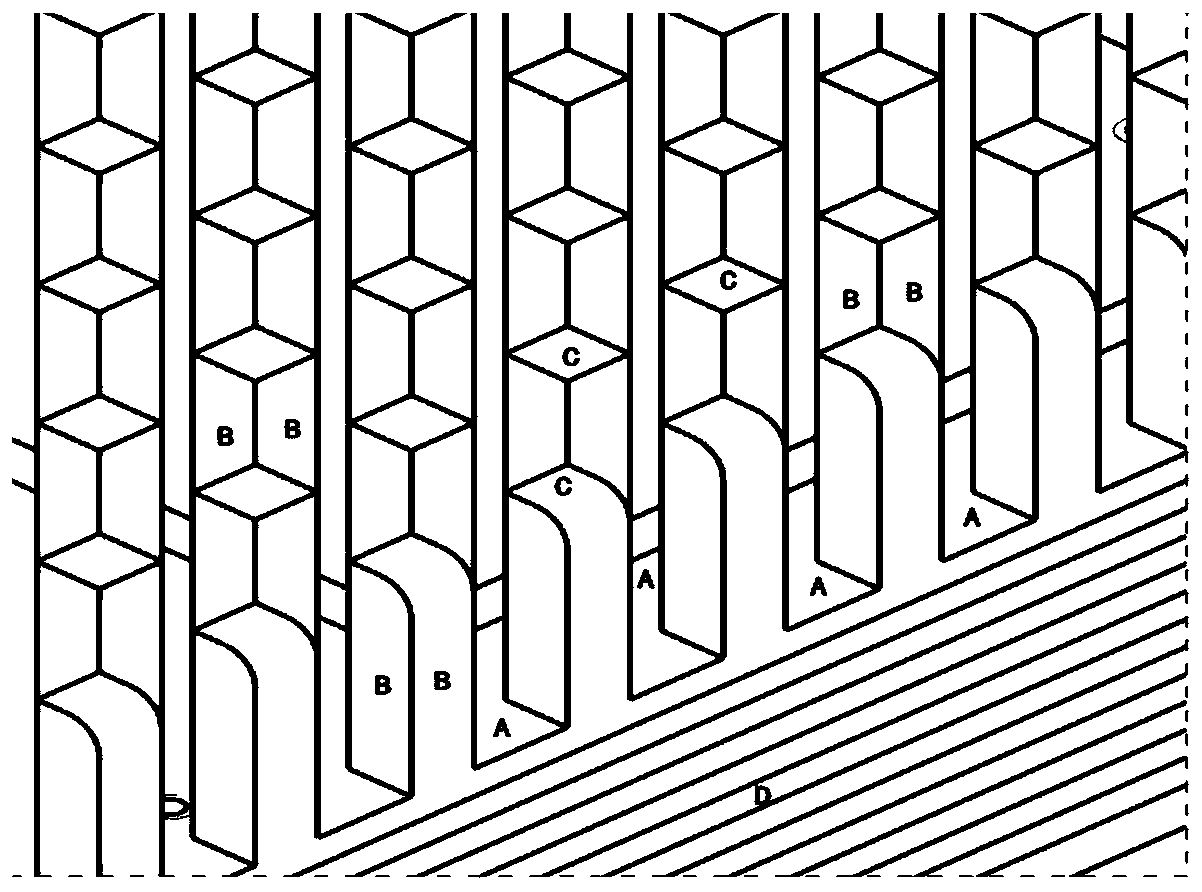

[0012] refer to figure 1 . According to the present invention, firstly, pretreatment work such as surface cleaning and non-coating position protection is performed on each painted part on the surface of the heat-dissipating tooth parts; a matching narrow-tube long-necked spray gun is selected according to the length of the heat-dissipating teeth of the parts, and the spraying parameters are adjusted. The narrow tube length of the thin tube long neck spray gun is selected from 90mm to 150mm, the nozzle diameter is from 6mm to 9mm, and the spray width is from 35mm to 55mm. First, use a thin tube long-neck spray gun to spray the bottom of the heat dissipation teeth and the deep cavity of the side wall in a stepwise spraying process; avoid other areas, and spray the bottom area of the heat dissipation teeth at a vertical angle in jump intervals, and then spray at 70° Spray the side wall area of the heat dissipation tooth at an angle of ~80° from bottom to top; let it stand fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com