Rotating plasma spraying equipment

A spraying equipment and plasma technology, applied in the thermal spraying field of surface engineering technology, can solve problems such as the inability to guarantee the spraying distance, affect the coating quality, and cracking of the coating, achieve good social and economic benefits, ensure the coating quality, and reduce internal The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

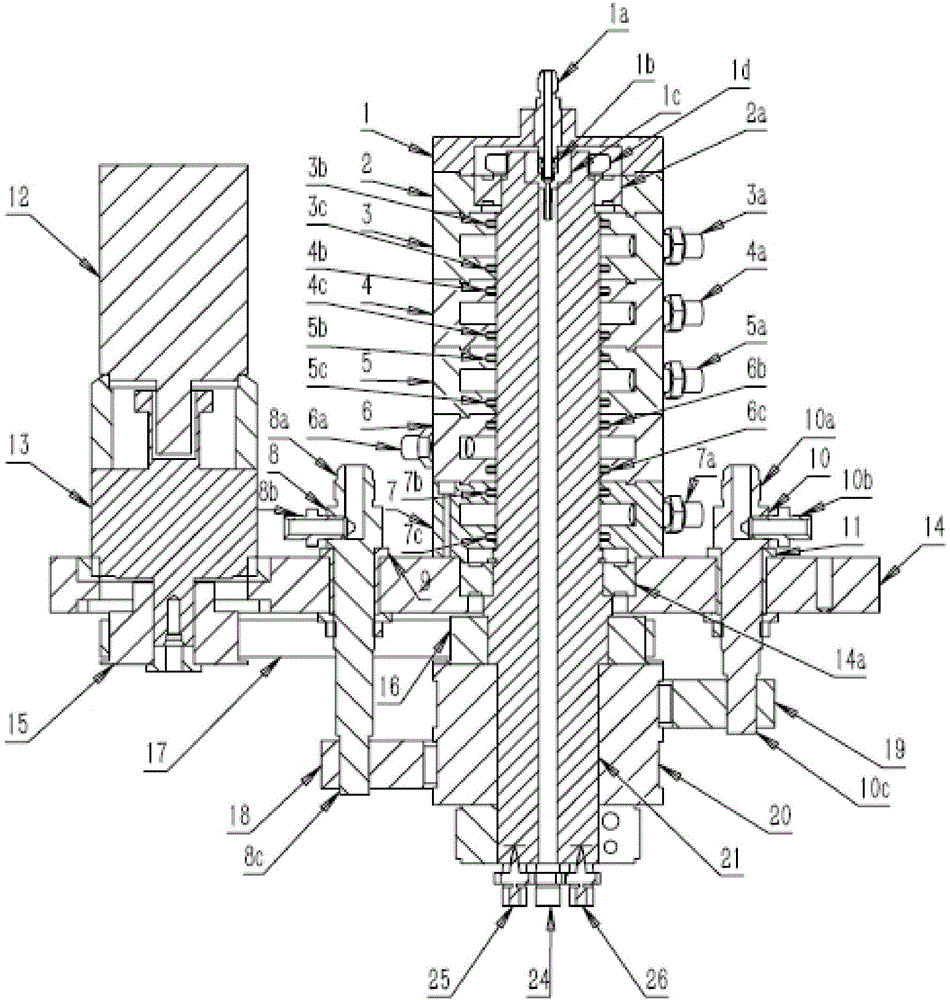

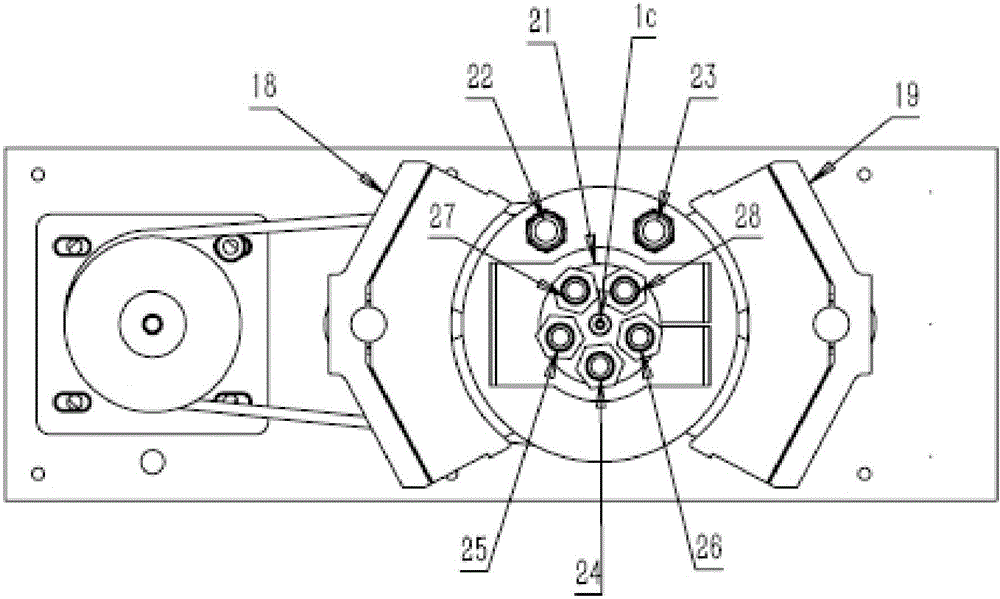

[0019] 1. Equipment structure and composition: the bearing (14a) is installed into the fixed plate (14); the water inlet ring (7) is installed into the water inlet ring sealing ring (7b) and the water inlet ring sealing ring (7c), and the bearing (14a ) is fixed on the fixed plate (14); the water outlet ring (6) is put into the water outlet ring sealing ring (6b) and the water outlet ring sealing ring (6c), and fixed on the water inlet ring (7); the cooling gas ring (5) is installed Insert the cooling gas sealing ring (5b) and the cooling gas sealing ring (5c), and fix it on the water outlet ring (6); the protective gas ring (4) is installed into the protective gas sealing ring (4b) and the protective gas sealing ring (4c), It is fixed on the cooling gas ring (5); the plasma gas ring (3) is put into the plasma gas sealing ring (3b) and the plasma gas sealing ring (3c), and fixed on the protective gas ring (4); the bearing ring (2) is installed into the bearing (2a), fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com