Patents

Literature

328 results about "Plasma flame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flame plasma is formed when a flammable gas and atmospheric air are combined and combusted to form an intense blue flame.

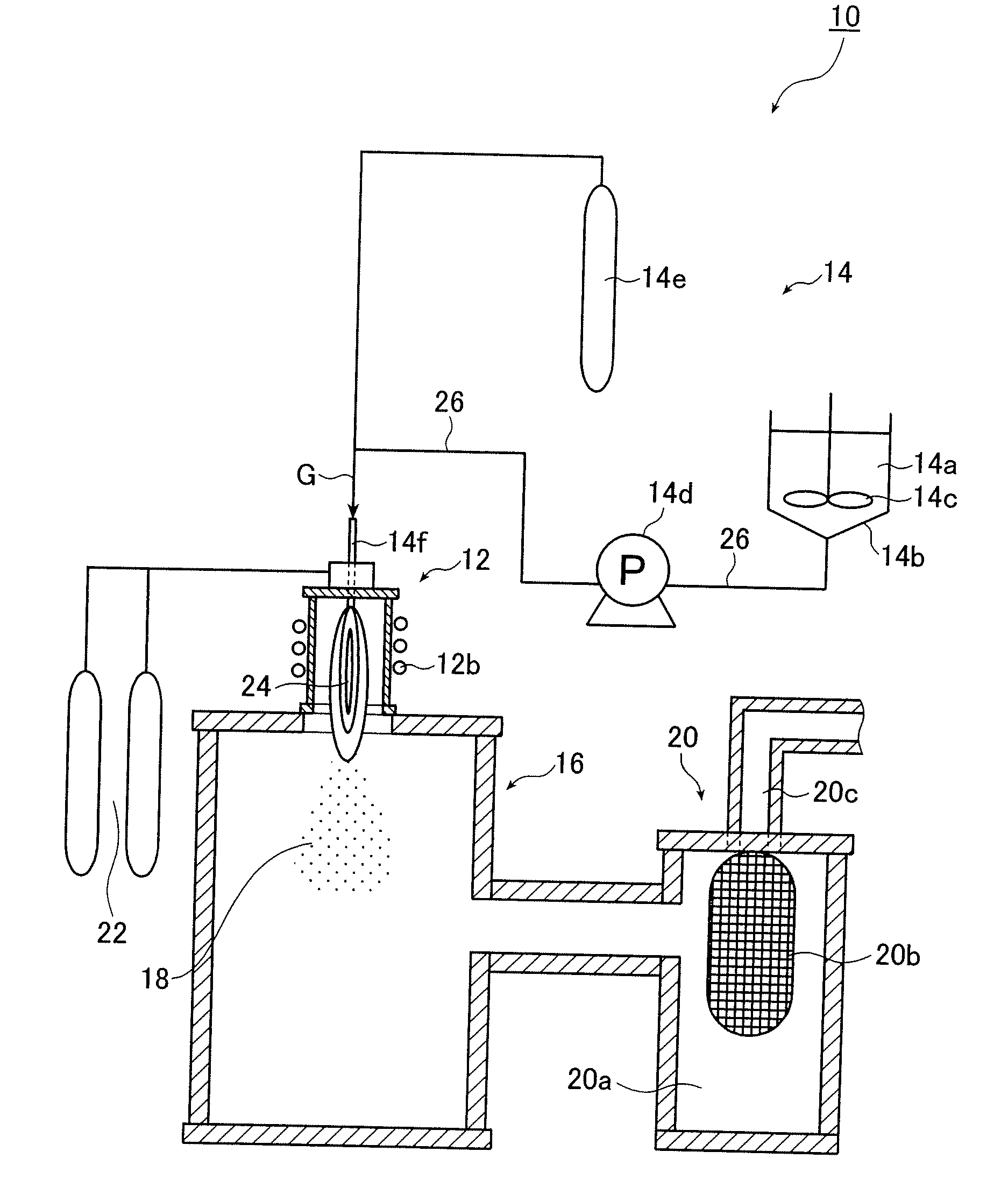

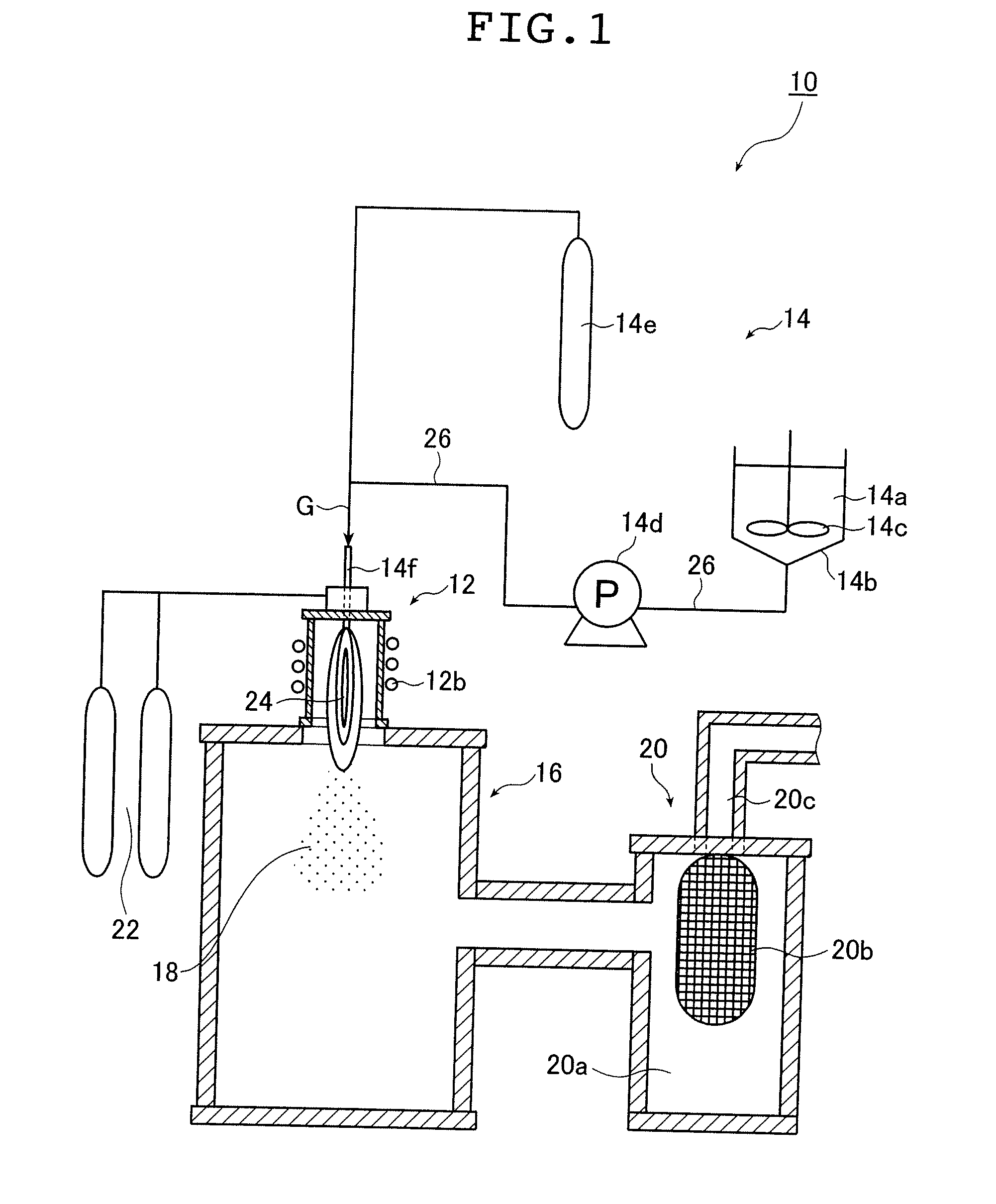

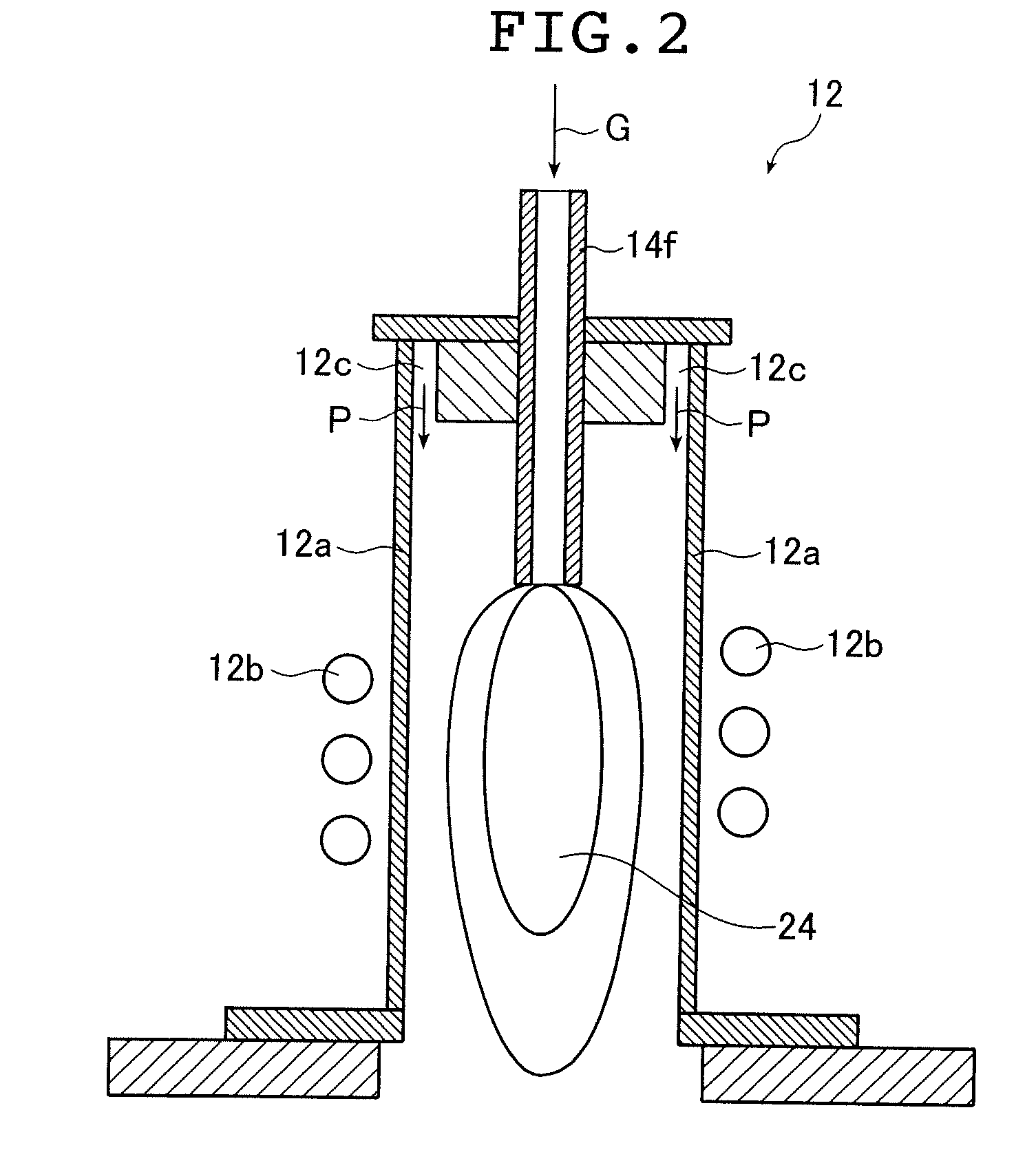

Process and Apparatus for Producing Fine Particles

ActiveUS20080006954A1Improve productivityFunction increaseAlkaline earth titanatesMaterial nanotechnologyGas phaseSlurry

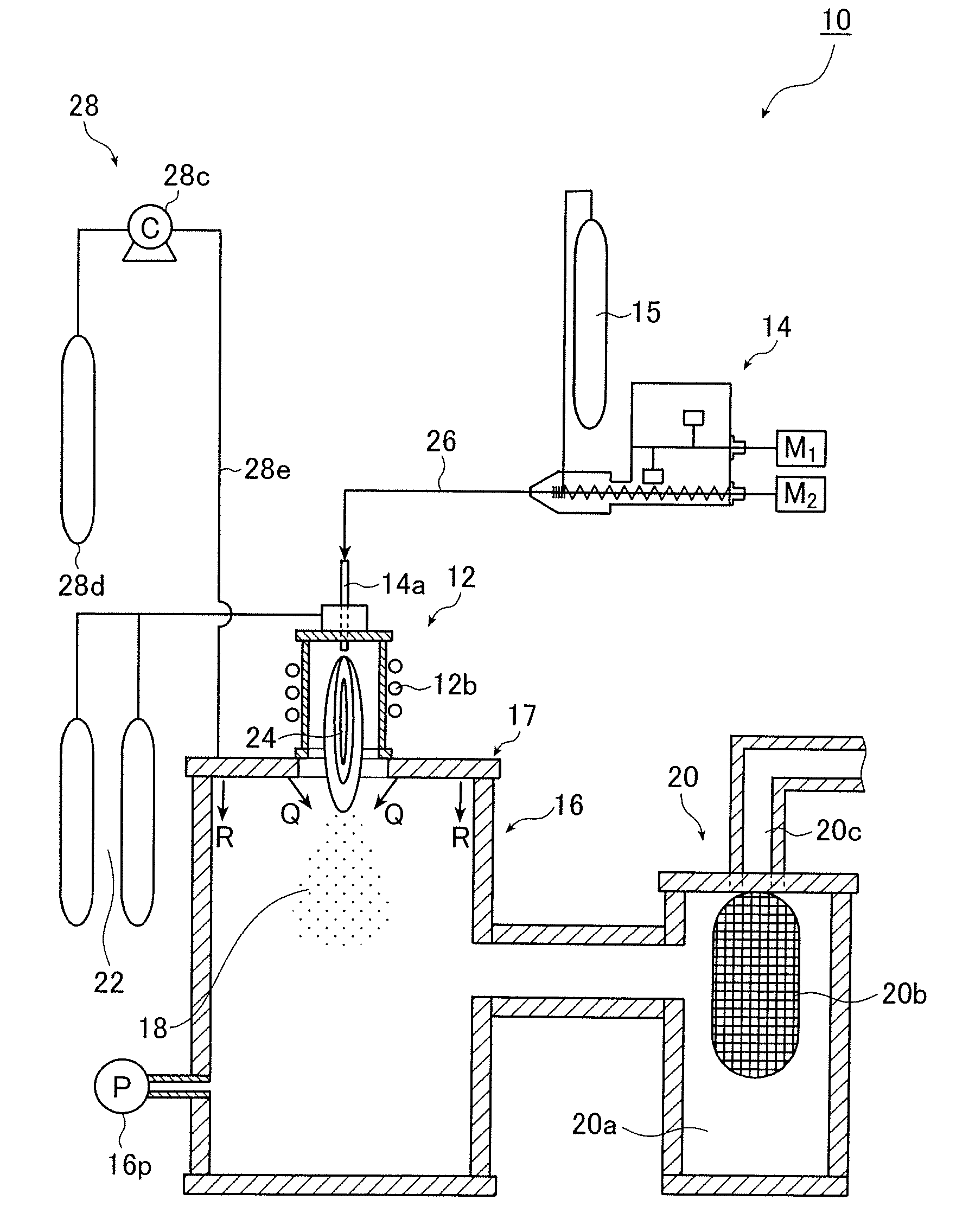

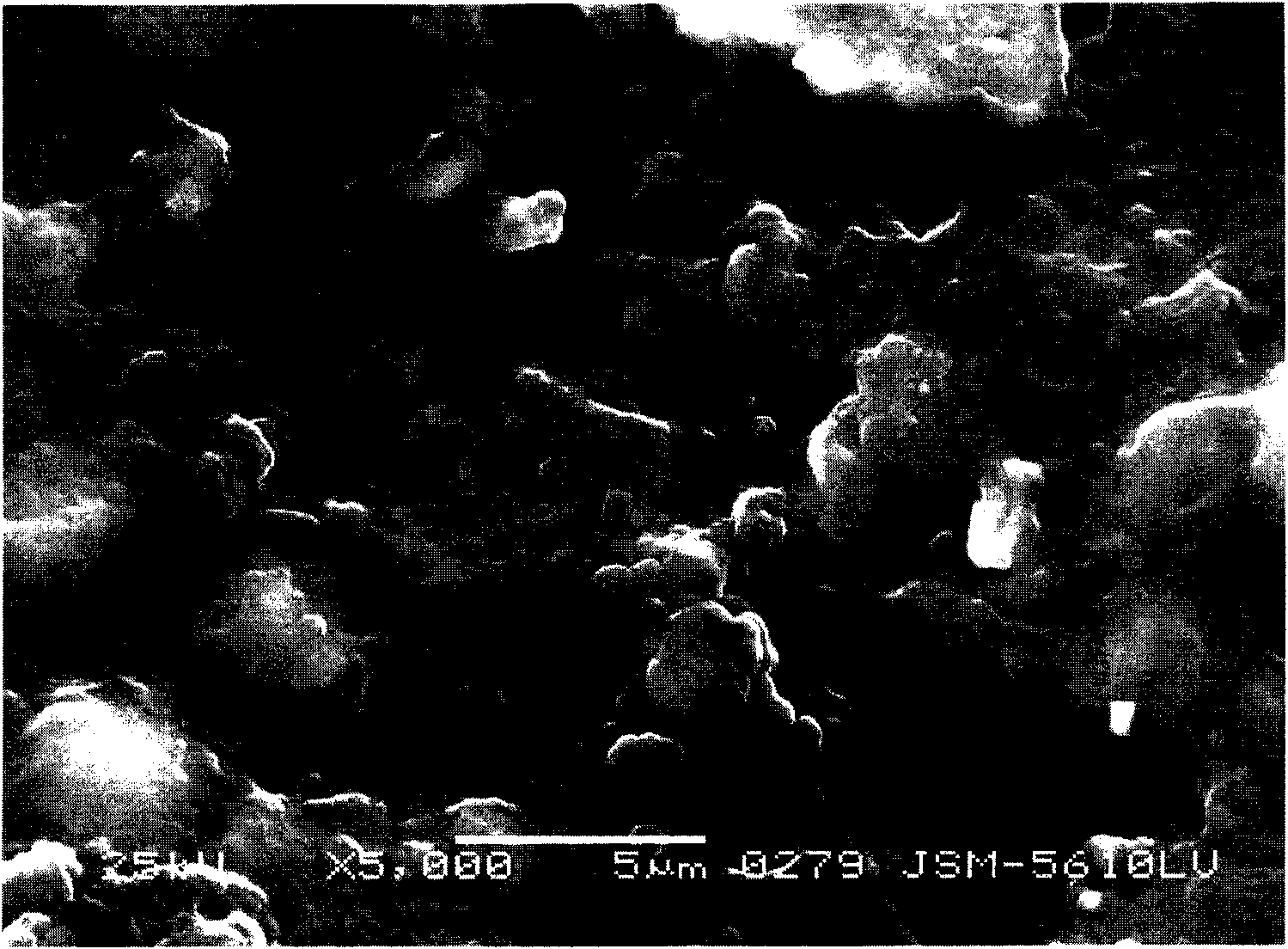

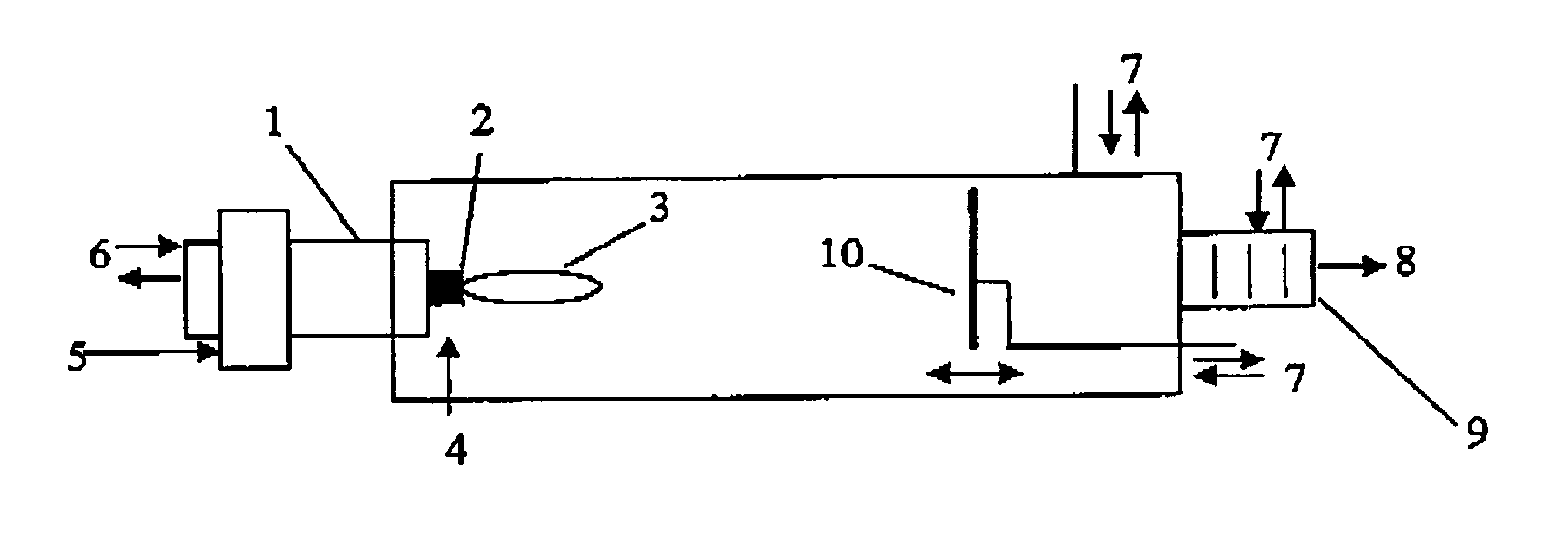

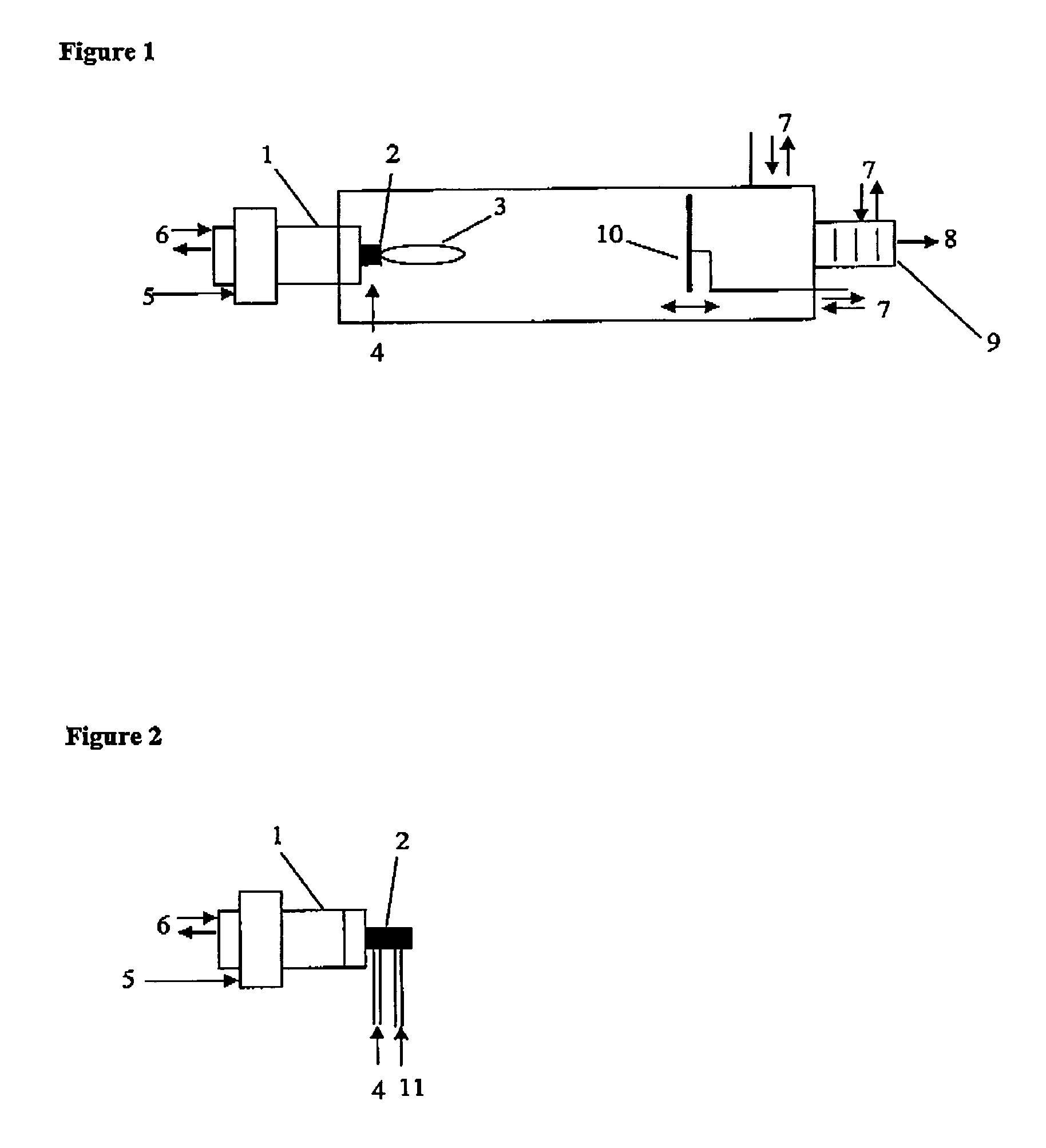

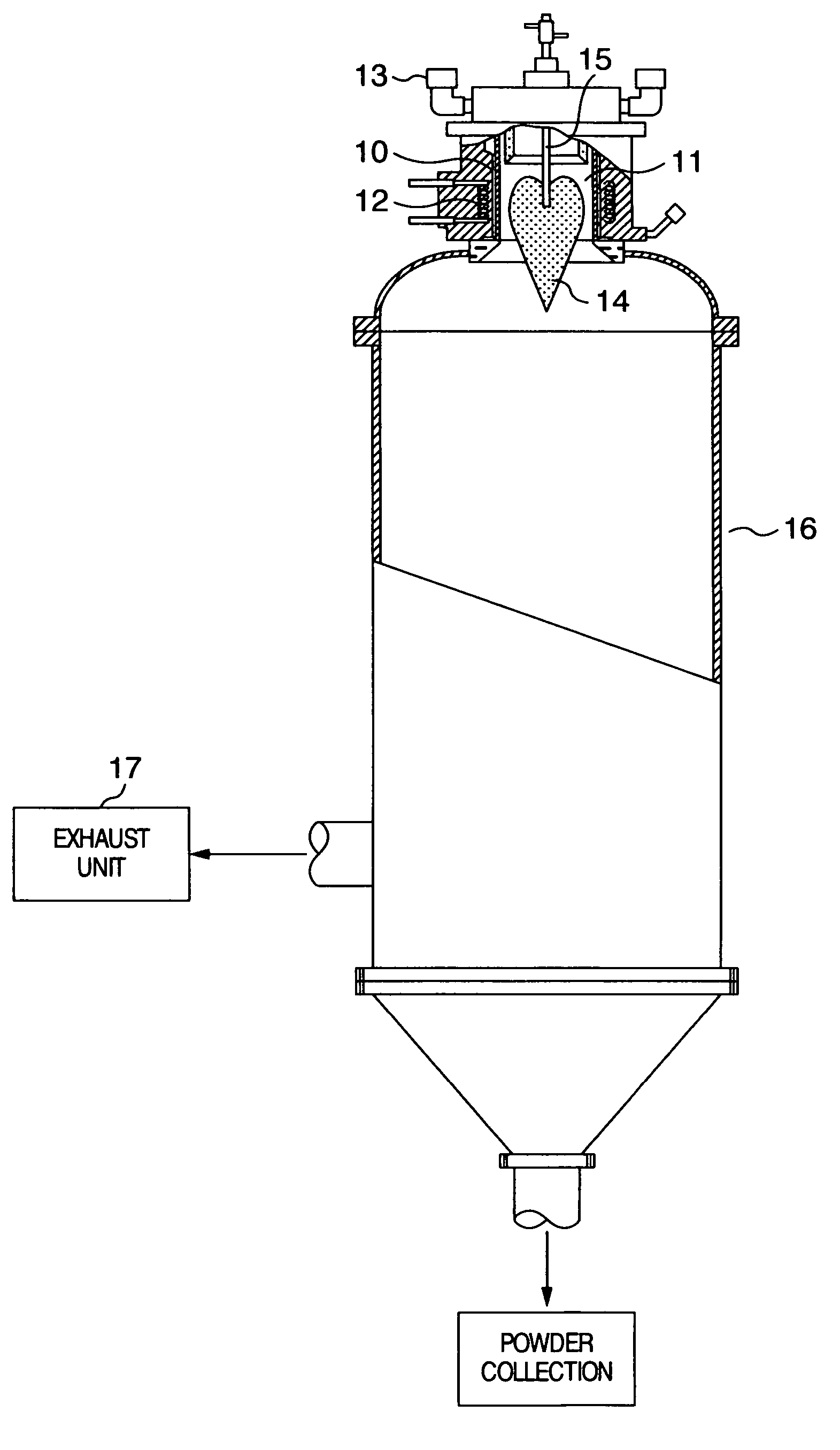

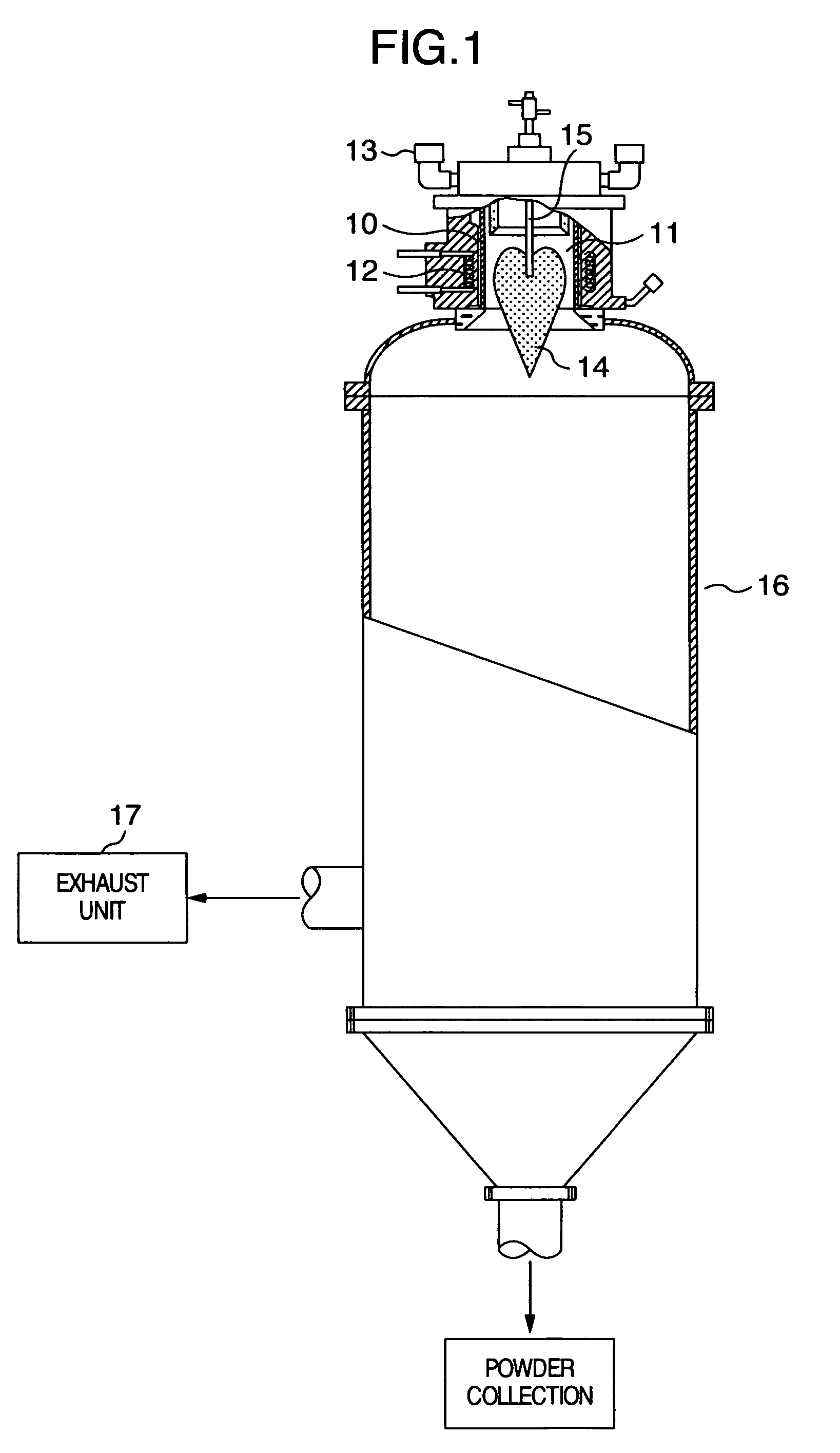

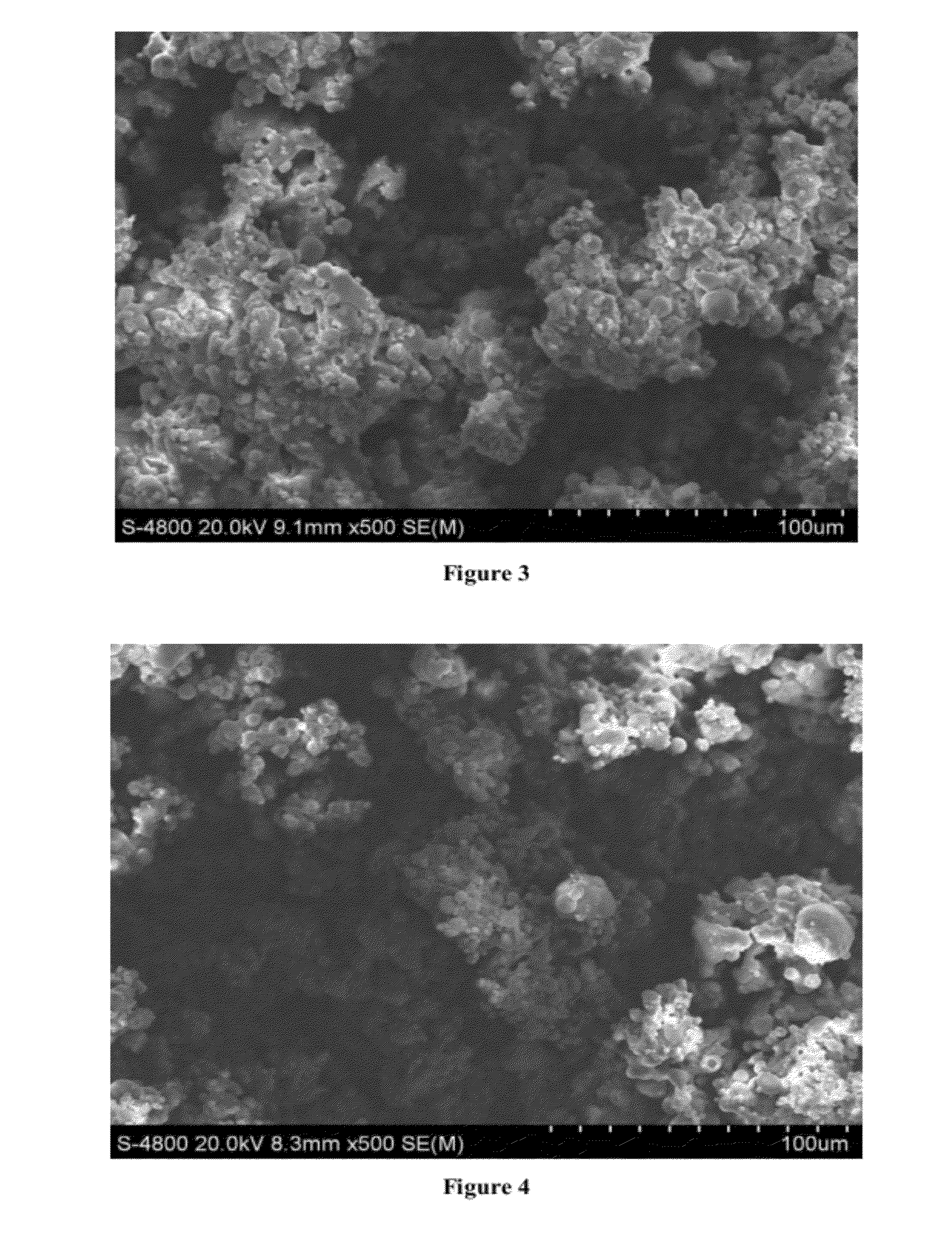

A fine particle producing process introduces a material for producing fine particles into a thermal plasma flame to make a vapor-phase mixture and quenches the vapor-phase mixture to form the fine particles. In the process, the material for producing the fine particles is dispersed or dissolved in a dispersion medium or solvent, preferably containing a combustible material to prepare a dispersion such as a slurry, a colloidal solution or a dissolution solution, the dispersion is made into a form of droplets, or the material for producing the fine particles is dispersed with a carrier gas and a combustible material and the dispersion in a droplet form or the dispersed material is introduced into the thermal plasma flame. In the fine particle producing process and apparatus, a gas of an amount sufficient to quench the vapor-phase mixture is supplied toward a tail of the thermal plasma flame. In the process and apparatus, primary fine particles are introduced into a cyclone to be subjected to cooling and classification and secondary fine particles having a particle size of 100 nm or less which are left upon removal of coarse particles are recovered.

Owner:NISSHIN SEIFUN GRP INC +1

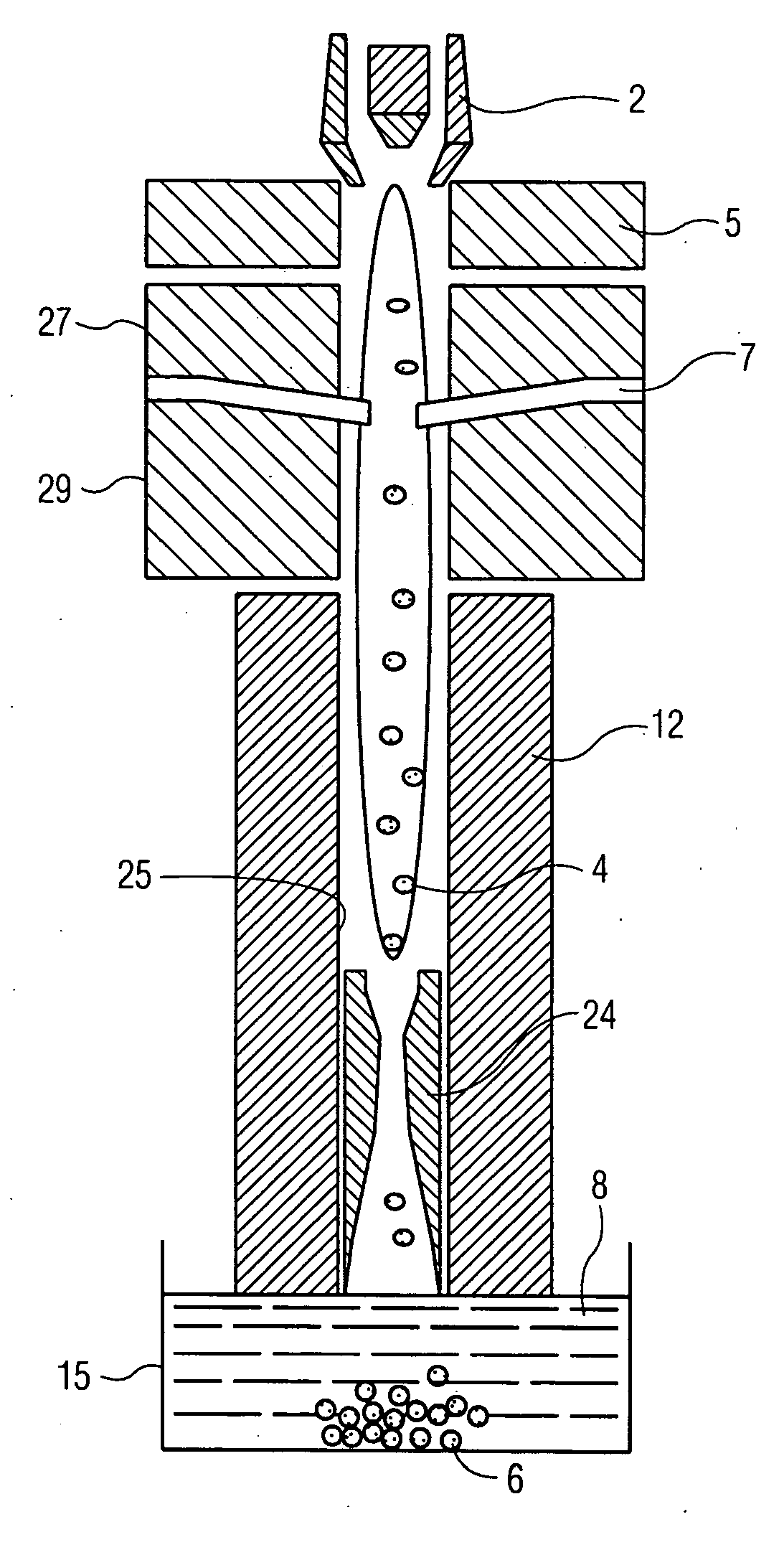

Process for producing ultrafine particles

ActiveUS20070084308A1Improve surface activityNovel functionNanotechTransportation and packagingGas phaseReactive gas

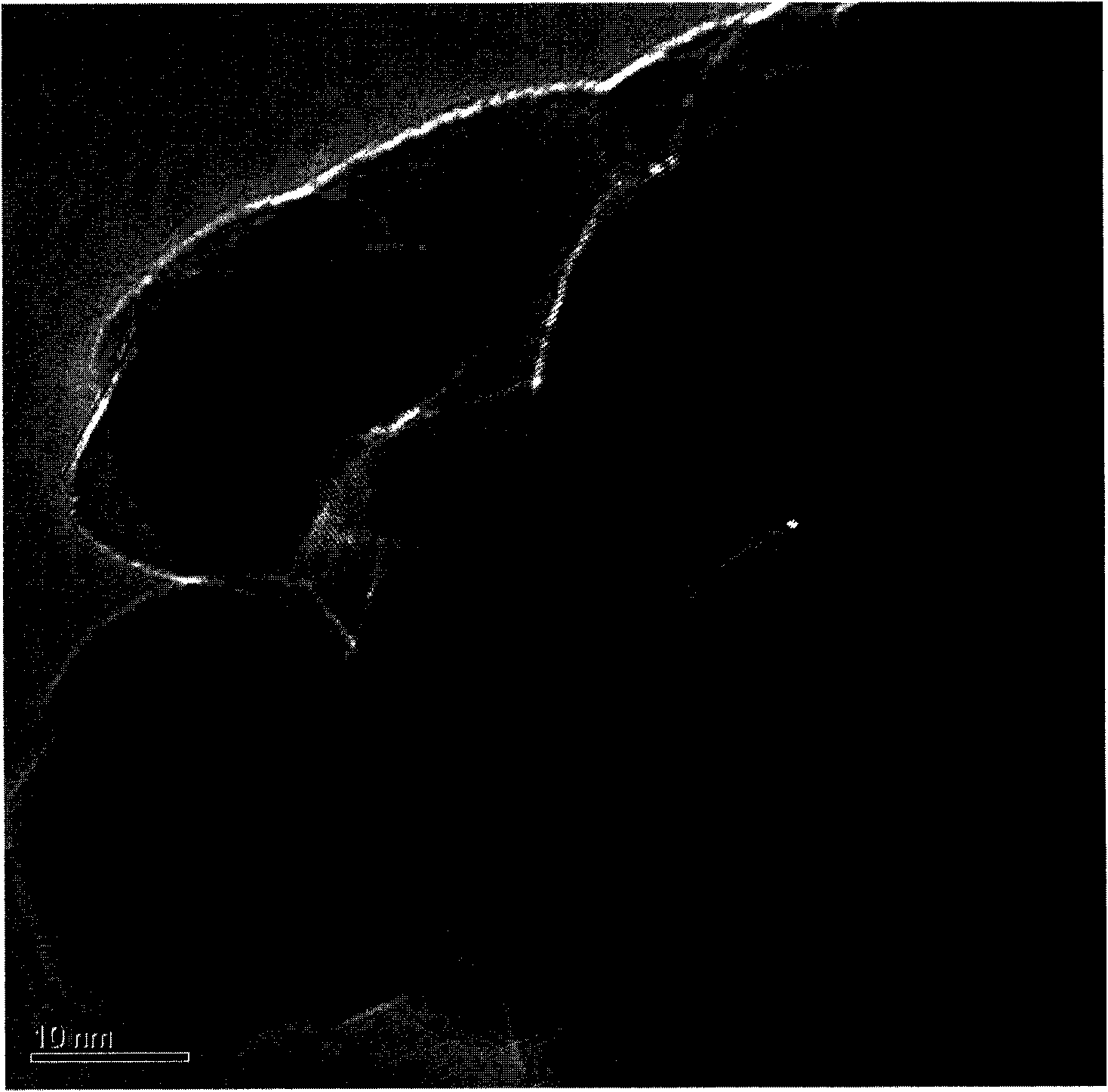

The ultrafine particle producing process introduces materials for producing ultrafine particles into a thermal plasma flame under reduced pressure to form a vapor-phase mixture, introduces a reactive gas and a cooling gas toward an end portion of the thermal plasma flame in supply amounts sufficient for quenching the vapor-phase mixture to generate the ultrafine particles and allows the resultant ultrafine particles to come into contact with the reactive gas so as to produce the ultrafine particles whose surfaces are coated with a thin film including one or more components compound derived from decomposition and / or reaction of the reactive gas, for example, an elementary carbon substance and / or a carbon. According to the process, thin film-coated ultrafine particles having high level uniformity in particle size and shape can be produced.

Owner:NISSHIN SEIFUN GRP INC

Nano powders, components and coatings by plasma technique

ActiveUS7615097B2Rapid quenching and generationHigh materialLiquid surface applicatorsMolten spray coatingRheniumChemical reaction

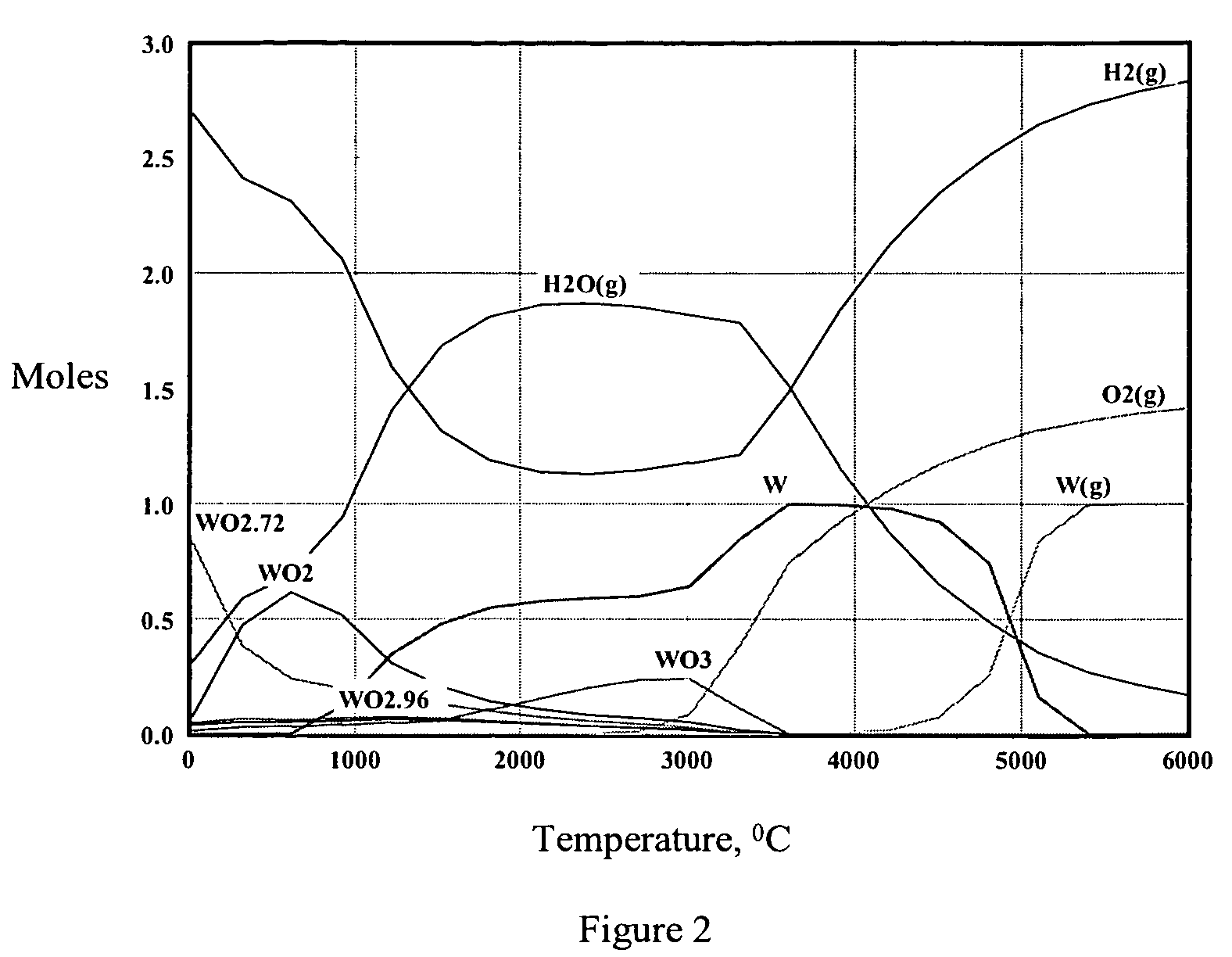

Ultra fine and nanometer powders and a method of producing same are provided, preferably refractory metal and ceramic nanopowders. When certain precursors are injected into the plasma flame in a reactor chamber, the materials are heated, melted and vaporized and the chemical reaction is induced in the vapor phase. The vapor phase is quenched rapidly to solid phase to yield the ultra pure, ultra fine and nano product. With this technique, powders have been made 20 nanometers in size in a system capable of a bulk production rate of more than 10 lbs / hr. The process is particularly applicable to tungsten, molybdenum, rhenium, tungsten carbide, molybdenum carbide and other related materials.

Owner:PLASMA PROCESSES

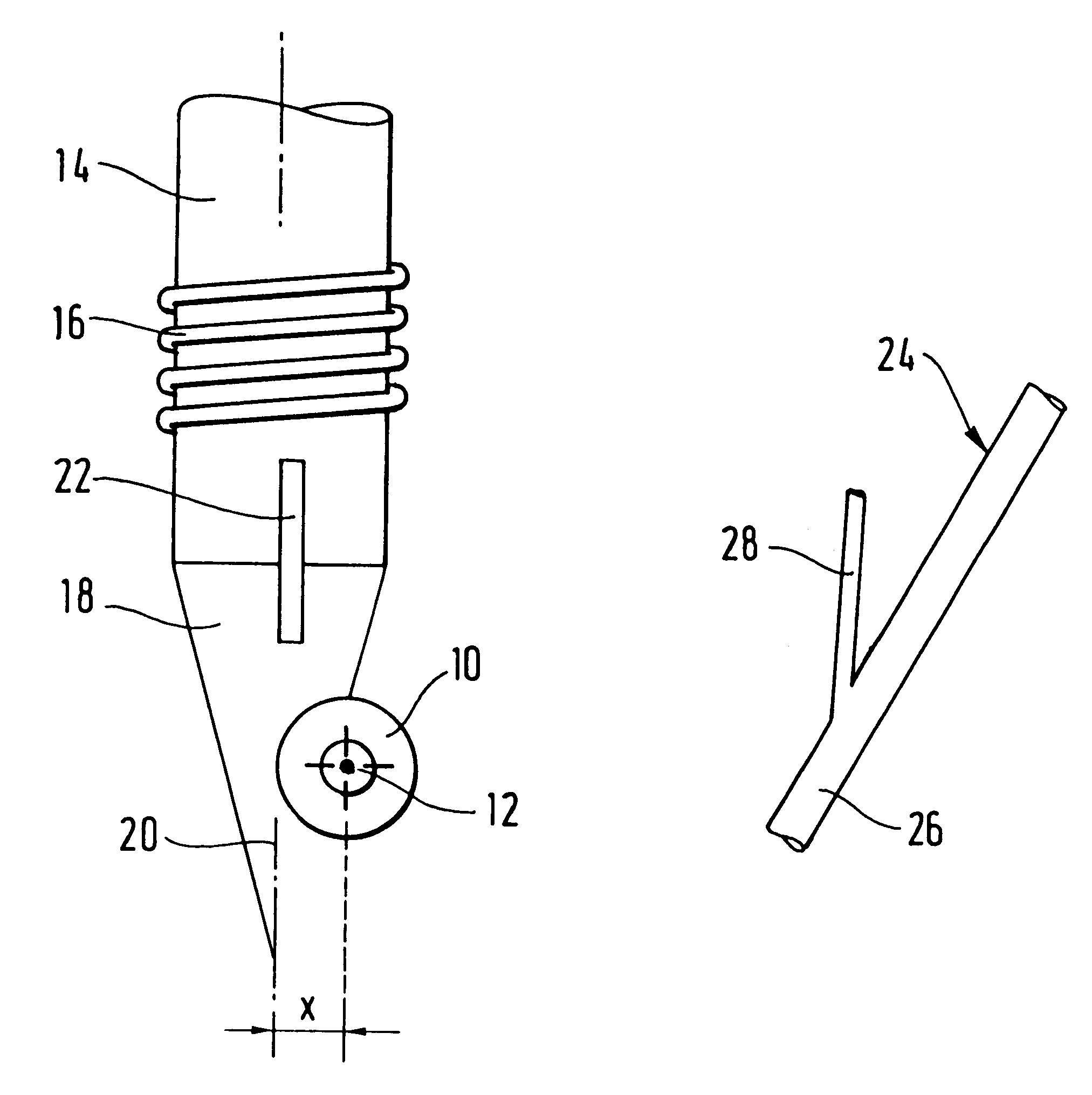

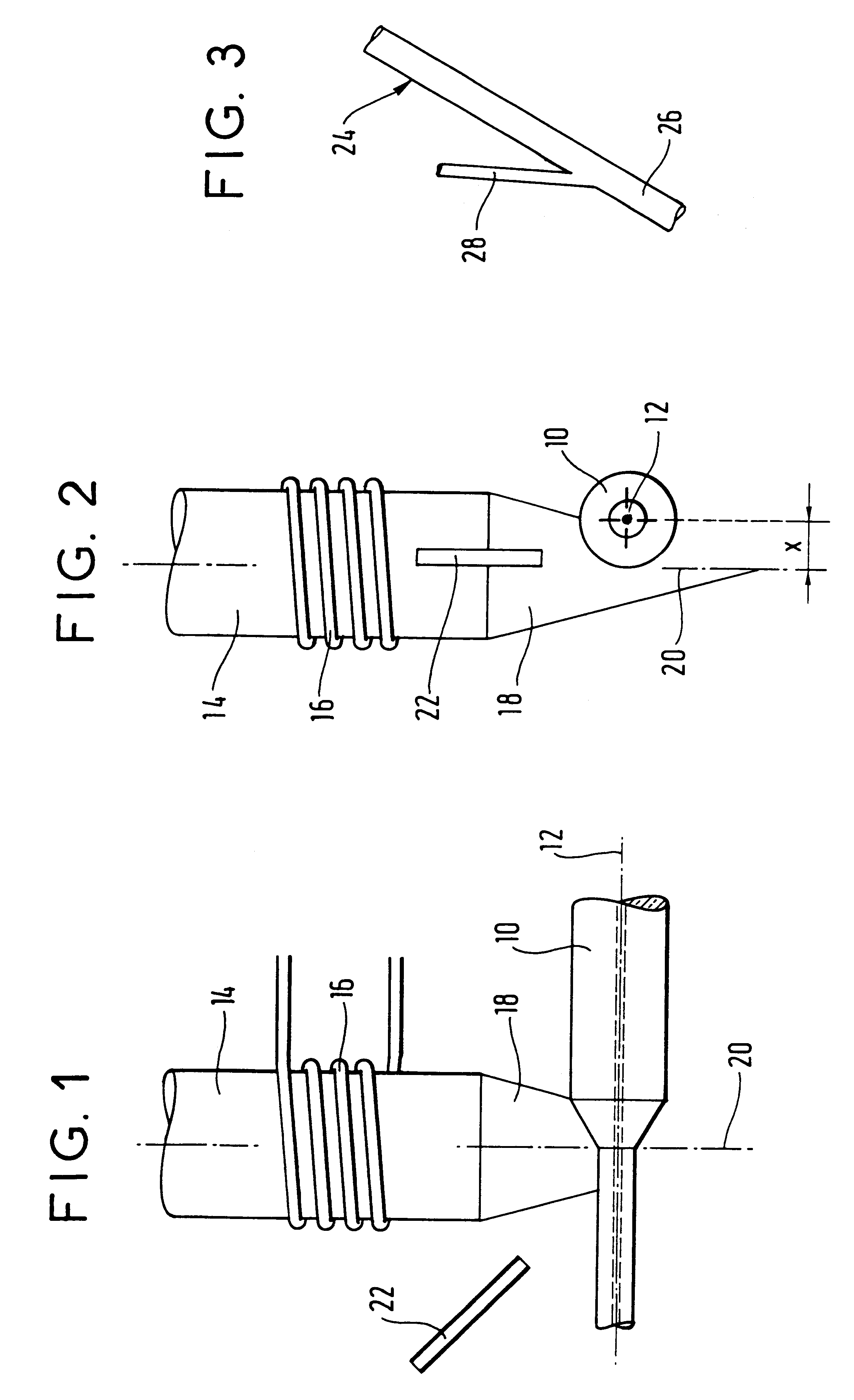

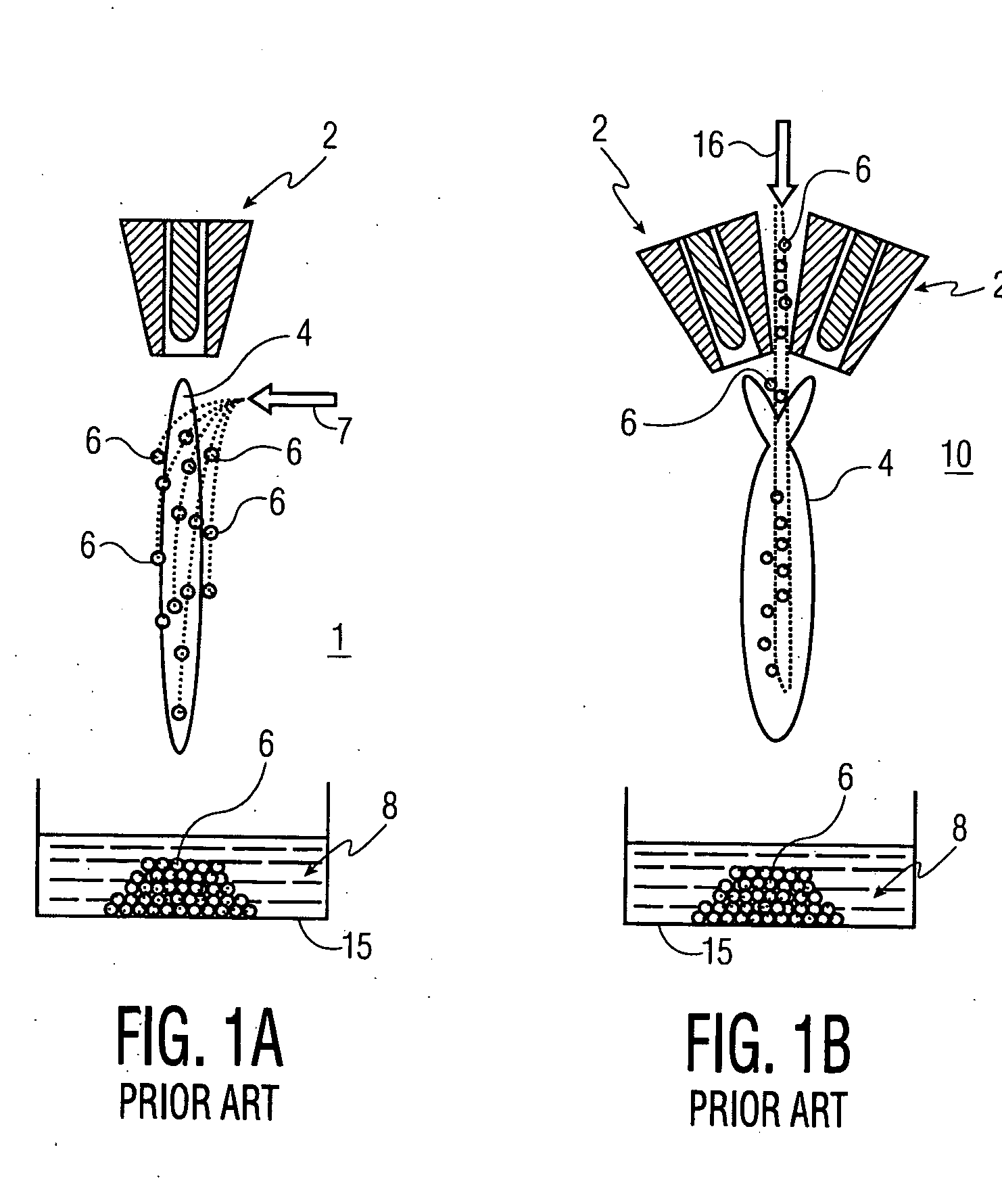

Method of making a glass fiber preform with adjusting a spacing while increasing acceleration of a starting glass powder

InactiveUS6202447B1Material analysis by optical meansGlass shaping apparatusGlass fiberOffset distance

The invention relates to manufacturing glass fiber preforms. It relates to a method comprising rotating preform about its own axis, and displacing a plasma torch in translation relative to the preform in a direction parallel to the axis of the preform, the axes of the flame and of the preform and being offset by a certain distance, and then inserting glass powder into the plasma flame under gravity. According to the invention, the glass powder is accelerated before penetrating into the plasma flame by means of an accelerator gas, and the offset distance between the axes is reduced with increasing acceleration of the powder. The invention is applicable to manufacturing glass fibers, and in particular optical fibers.

Owner:ALCATEL LUCENT SAS

Ultrafine alloy particles, and process for producing the same

The Ultrafine alloy particles of an alloy includes a primary metal and one or more subsidiary metals solid-soluble in said primary metal, a content of the one or more subsidiary metals is in a range of 1 wt % to 25 wt % and the one or more subsidiary metals solid-solved in the primary metal inhibit coalescence or oxidation of the ultrafine alloy particles including the primary metal, or both. The process introduces powder materials including the primary metal and the one or more subsidiary metals for producing the ultrafine alloy particles into a thermal plasma flame under reduced pressure to form a vapor-phase mixture and introduces a cooling gas toward an end portion of the thermal plasma flame in a supply amount sufficient for quenching the vapor-phase mixture so as to generate the ultrafine alloy particles.

Owner:NISSHIN ENG +1

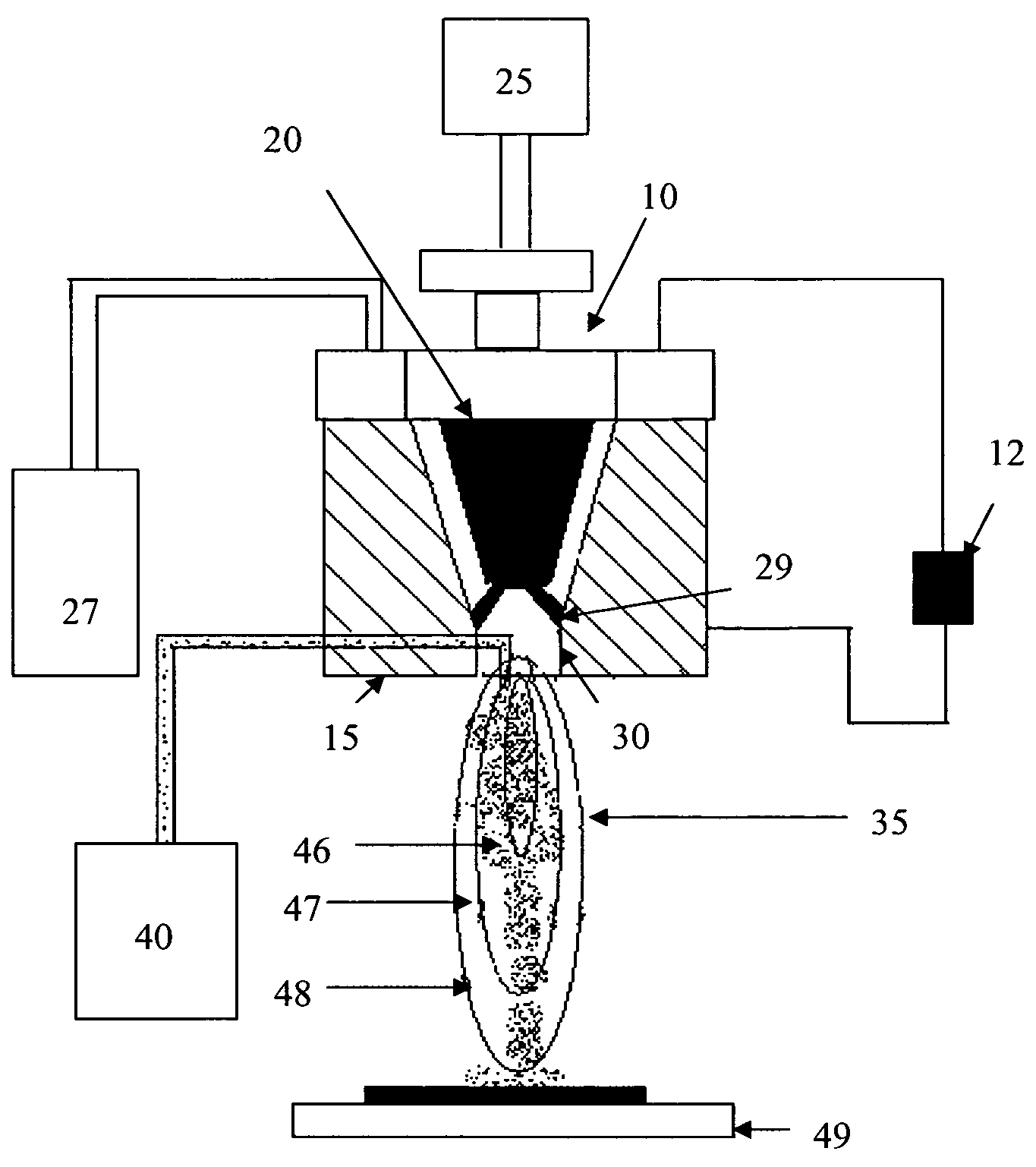

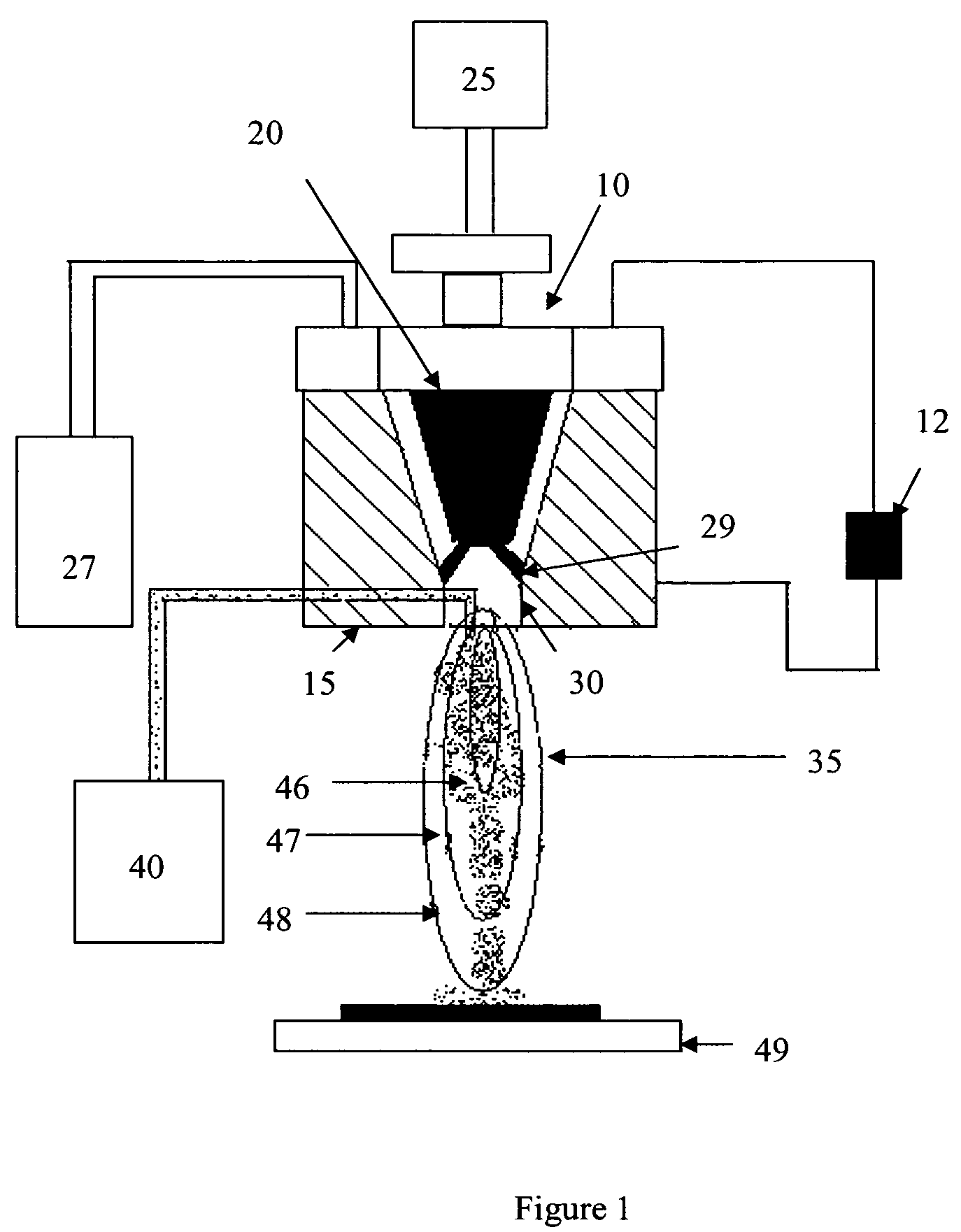

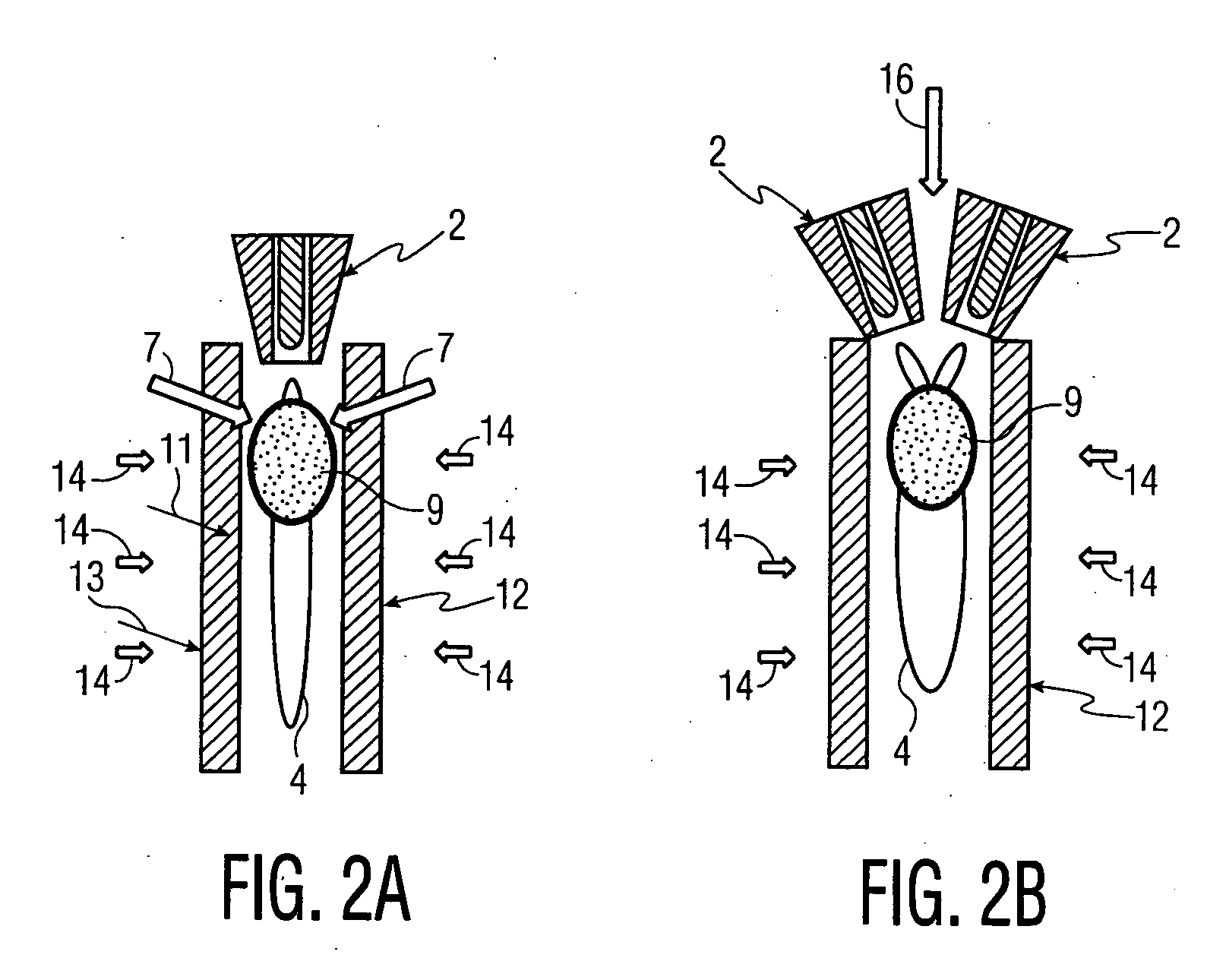

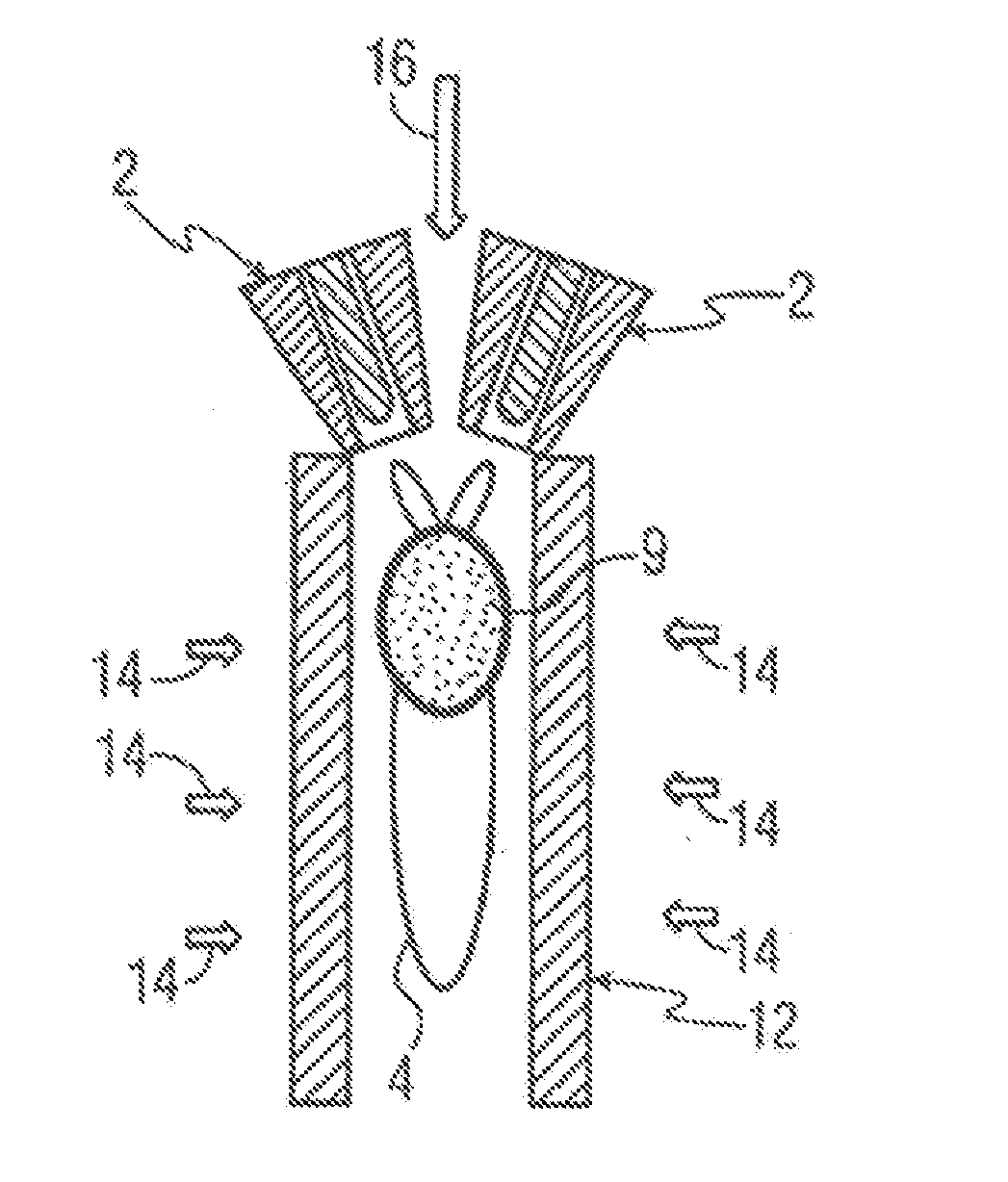

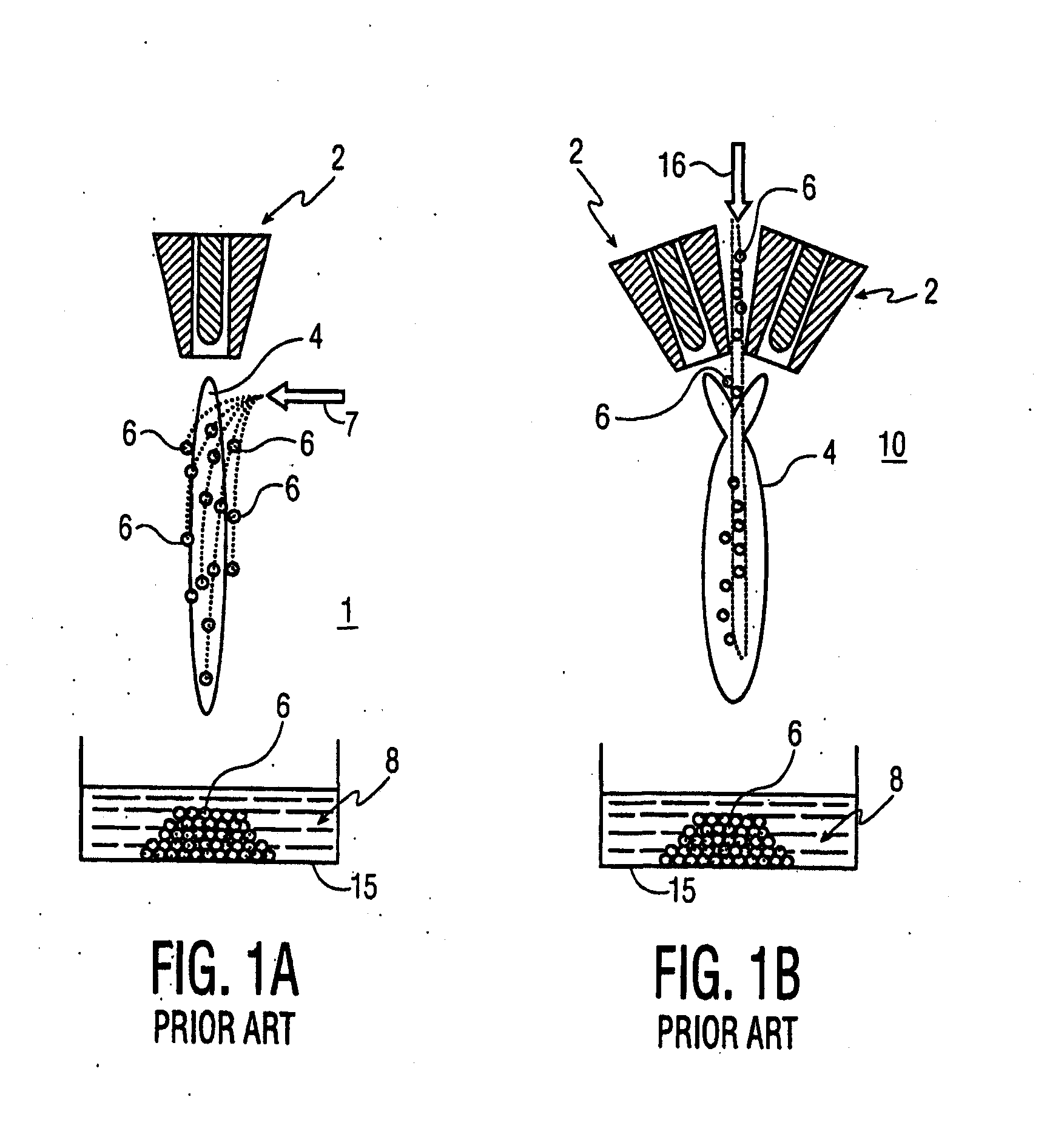

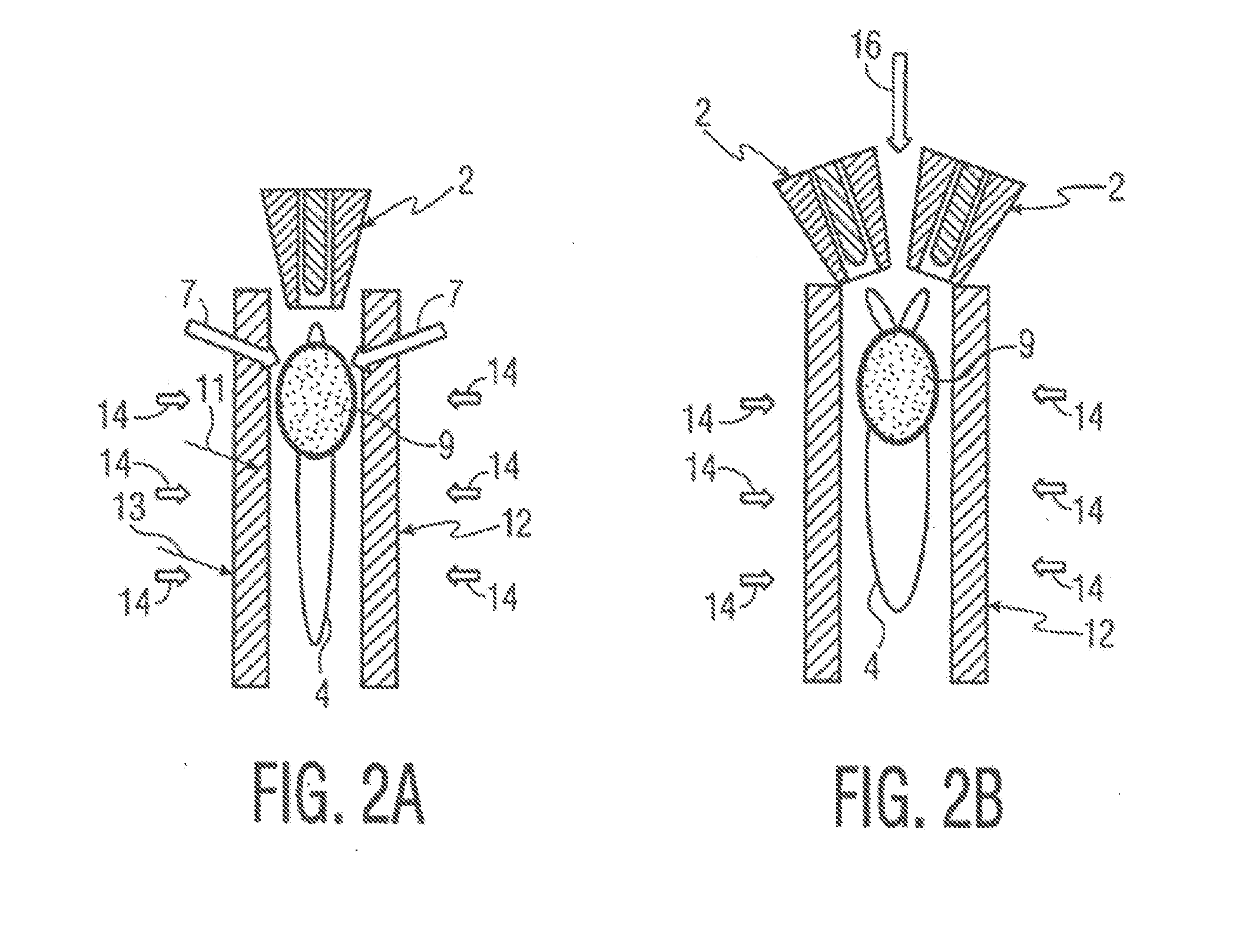

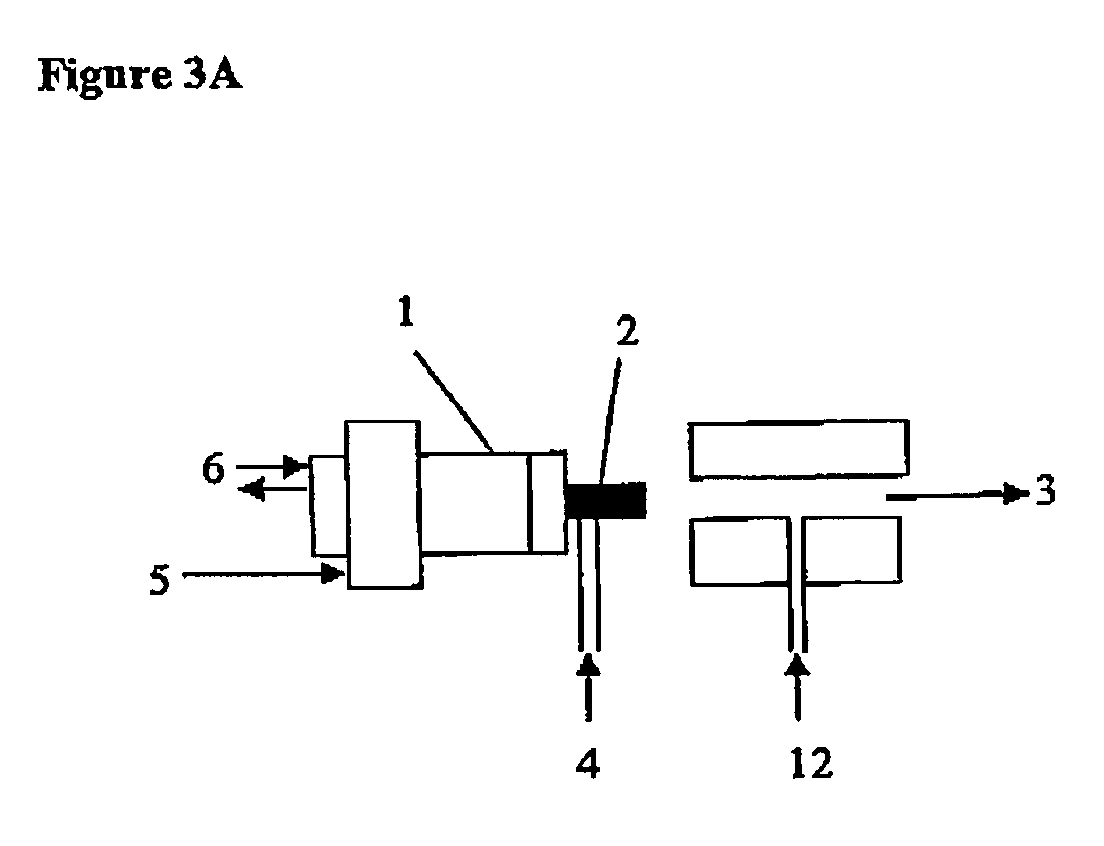

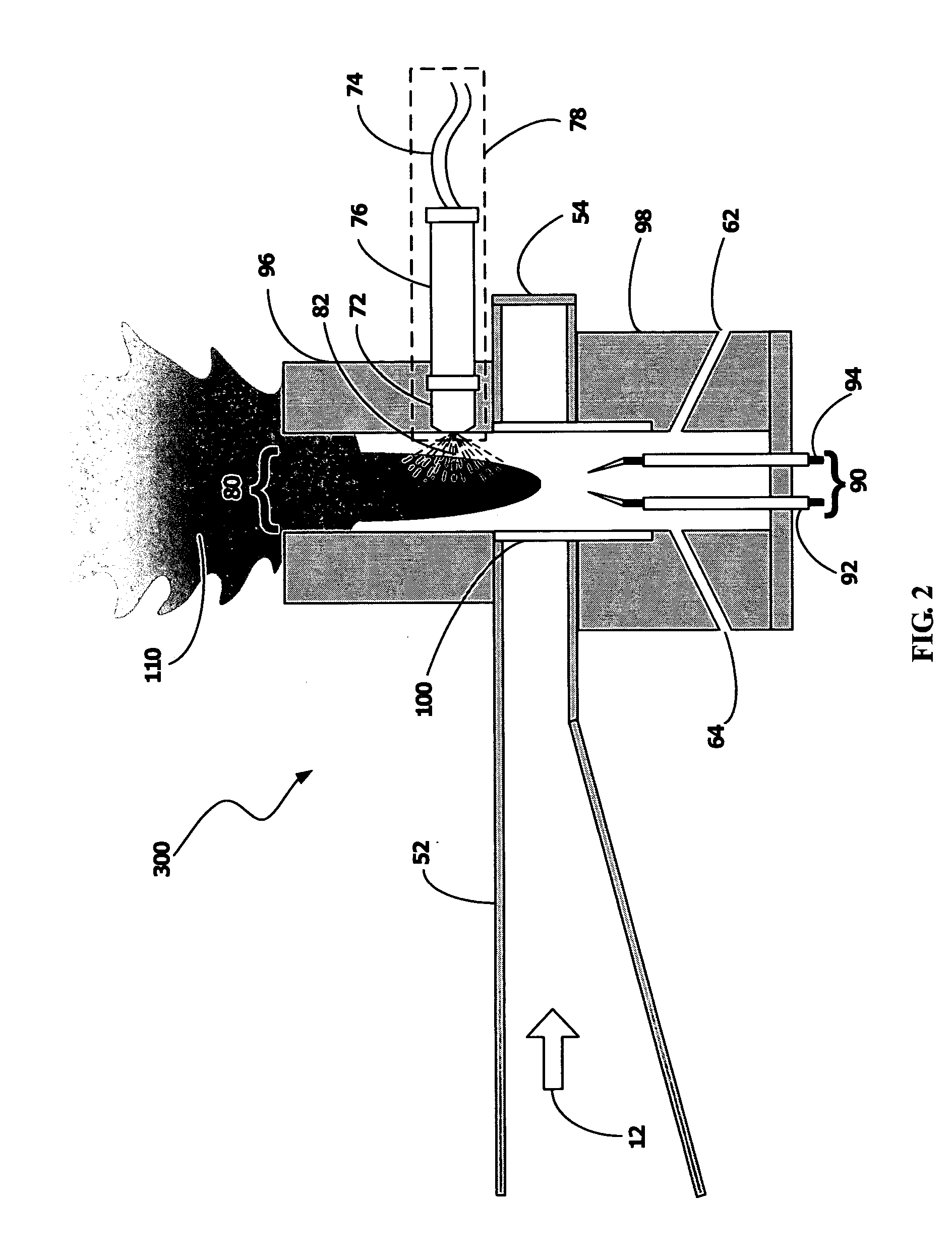

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

Shrouded-Plasma Process and Apparatus for the Production of Metastable Nanostructured Materials

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:KEAR BERNARD H +2

Preparation method of nanometer zirconia heat barrier coating

InactiveCN101660115AImprove applicabilityGood dispersionMolten spray coatingEfficient propulsion technologiesRare earthShock resistance

The invention relates to a preparation method of a nanometer zirconia heat barrier coating which is mixed with rare-earth oxide and used for liquid-phase plasma spraying. The method comprises that precursor sol is used as a spraying raw material, atomized into fine liquid drops under atomized gas pressure, sent into plasma flame flow and sprayed and deposited on a matrix to obtain the nanometer zirconia heat barrier coating. The precursor sol is hydroxid precursor sol. According to weight proportion, the raw material includes 63 to 73 percent of ZrOCl2.8H2O and 27 to 37 percent of crystalline-state stabilizer oxide which is rare earth oxide. The invention can overcome the problems of poor sol distribution, poor sol flowing performance, chlorid ion erosion, poor sol granule atomizing effect, uneven granule sizes, and the like in the the traditional liquid-phase plasma spraying process. In the invention, a composite coating is prepared, and has the advantages of high depositing efficiency, low cost, wide spraying material, strong adaptability of the liquid-phase precursor, low heat conductivity, good heat and shock resistance, and the like.

Owner:WUHAN UNIV OF TECH

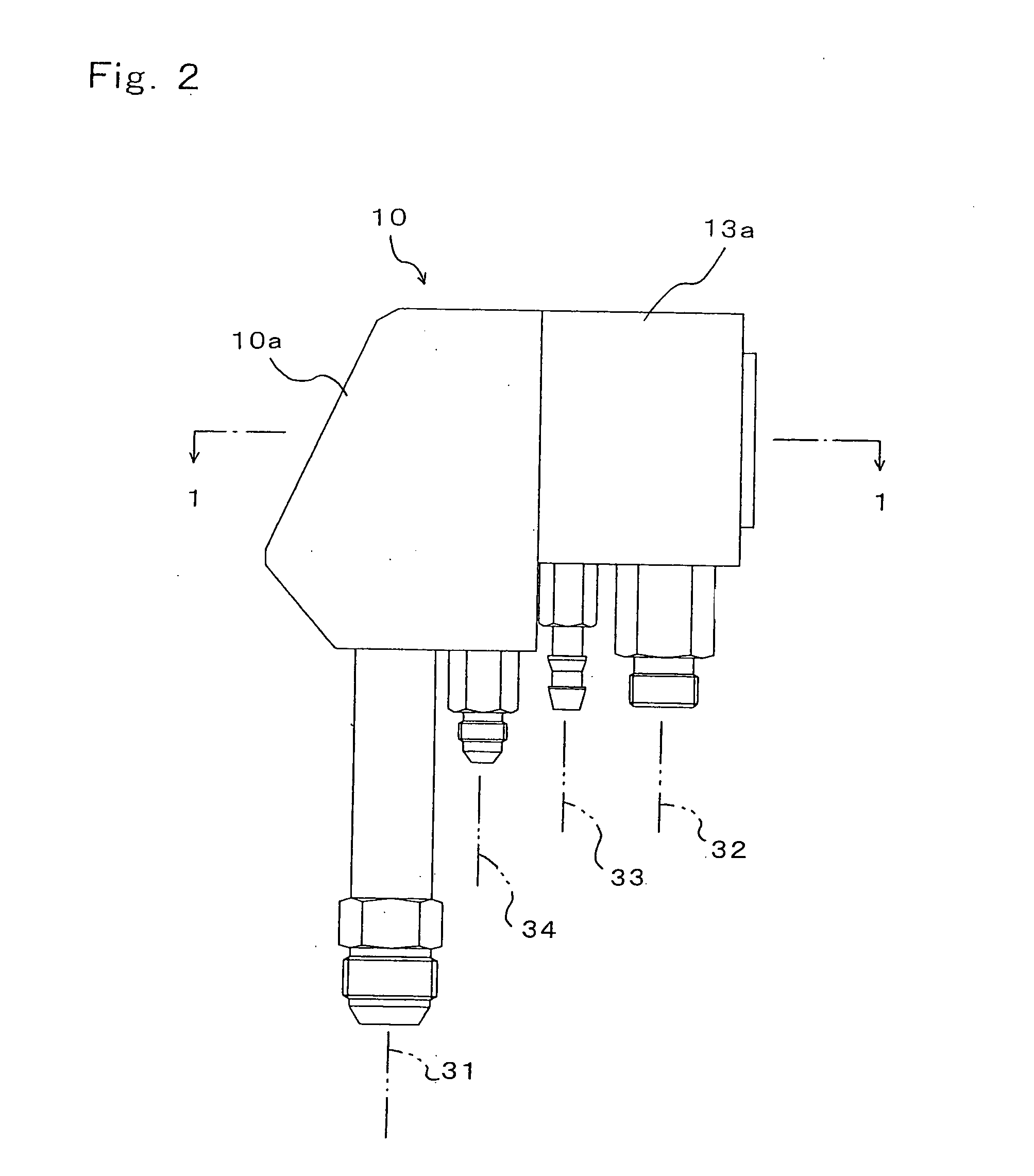

Plasma spray apparatus

To provide a plasma spray apparatus, having a reduced number of jet ports for the working medium transformed into plasma, resulting in a simplified structure thereof, and even when the trajectory of the working medium becomes misaligned, the apparatus remains capable of producing a plasma flame that can properly melt the spray material; thus, the spray material can be used effectively. Two jet paths in the plasma spray apparatus are formed at both sides of one supply port for spray material 17 and are arranged so that the axial directions cross each other at the outside of the nozzle anode 11; two cathodes 13 are disposed inside the two jet paths 12; and the openings of the jet paths 12 are formed into elongated holes so that the center lines thereof are parallel to each other and the areas thereof are the same.

Owner:SHIMAZU KOGYO YUGENKAISHA

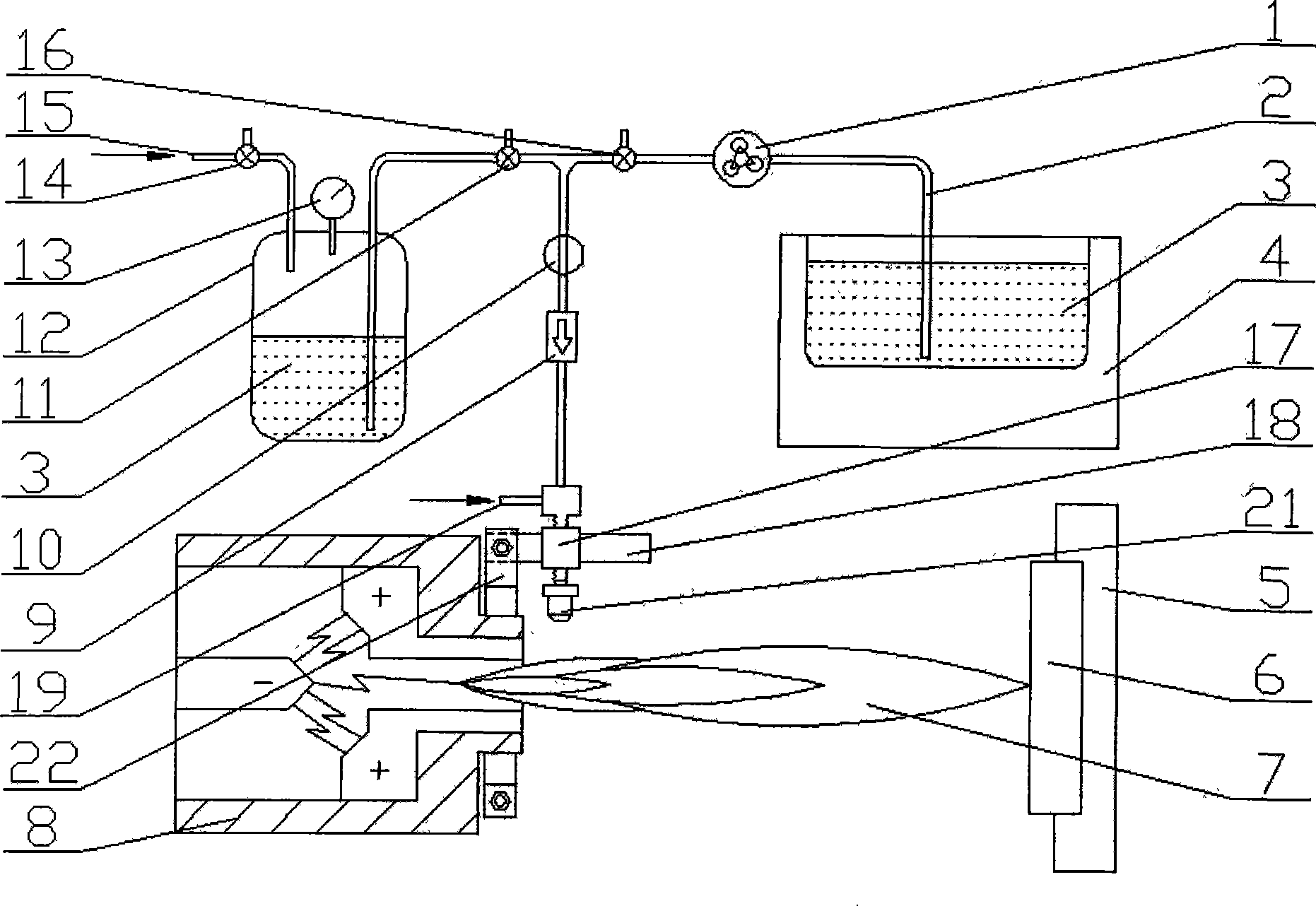

Burner using plasma

InactiveUS20120100497A1Good effectAvoid pollutionIncandescent ignitionIncinerator apparatusCombustion chamberOxygen

The present invention relates to a burner using plasma, which uses a mixture fuel in which water and industrial waste oil are mixed at an appropriate ratio. A combustion tank has a positive electrode (+), a rod installed at one side of the combustion tank has a negative electrode (−), and direct current electricity is supplied to the combustion tank and to the rod from a direct current electricity supply unit. A steam supply pipe of a steam generator is installed together with a plasma torch unit which is coupled to the combustion tank, such that high-temperature steam is discharged from the steam supply pipe together with the plasma torch generated by the plasma torch unit. Thus, the high-temperature plasma torch generates a high-temperature plasma flame of 800° C. or higher to heat a combustion chamber at the inner wall of the combustion tank. A mixture fuel supply pipe is wound into a coil on the outer surface of the combustion chamber, such that the mixture fuel supply pipe is preheated by high-temperature heat. The mixture fuel in the mixture fuel supply pipe is supplied at an air pressure of 50 through a high pressure pump, and water in the mixture fuel is decomposed into hydrogen and oxygen and waste oil in the mixture fuel is decomposed into carbons. The mixture fuel is injected or sprayed through a nozzle at a high temperature to effectively and completely burn the mixture fuel. The plasma torch unit operates by means of the direct current electricity supplied by the direct current electricity supply unit if needed, to adjust the temperature of the combustion chamber of the combustion tank, thereby enabling the smooth use of the burner.

Owner:JOO SUNG HO

Plasma spraying pyrolyzing process of preparing nanometer hollow oxide microsphere powder

The plasma spraying and pyrolyzing process of preparing nanometer hollow microsphere powder of nanometer crystalline oxide includes preparing precursor solution, atomizing, plasma spraying and pyrolyzing in plasma flame to form solid molten drop, and cooling in liquid to solidify form the hollow spherical nanometer crystal structure. The process is simple and suitable for industrial production.

Owner:WUHAN UNIV OF TECH

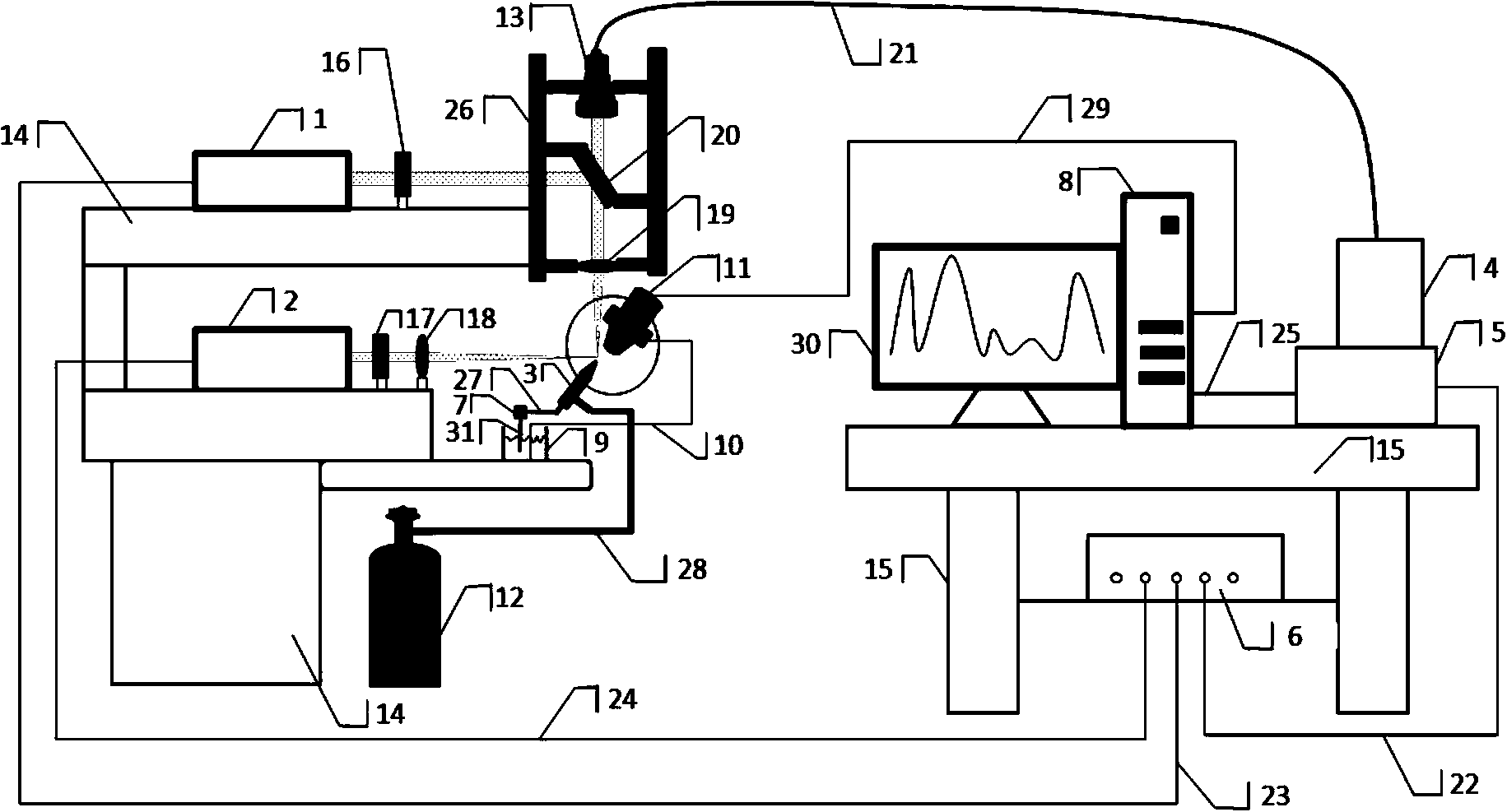

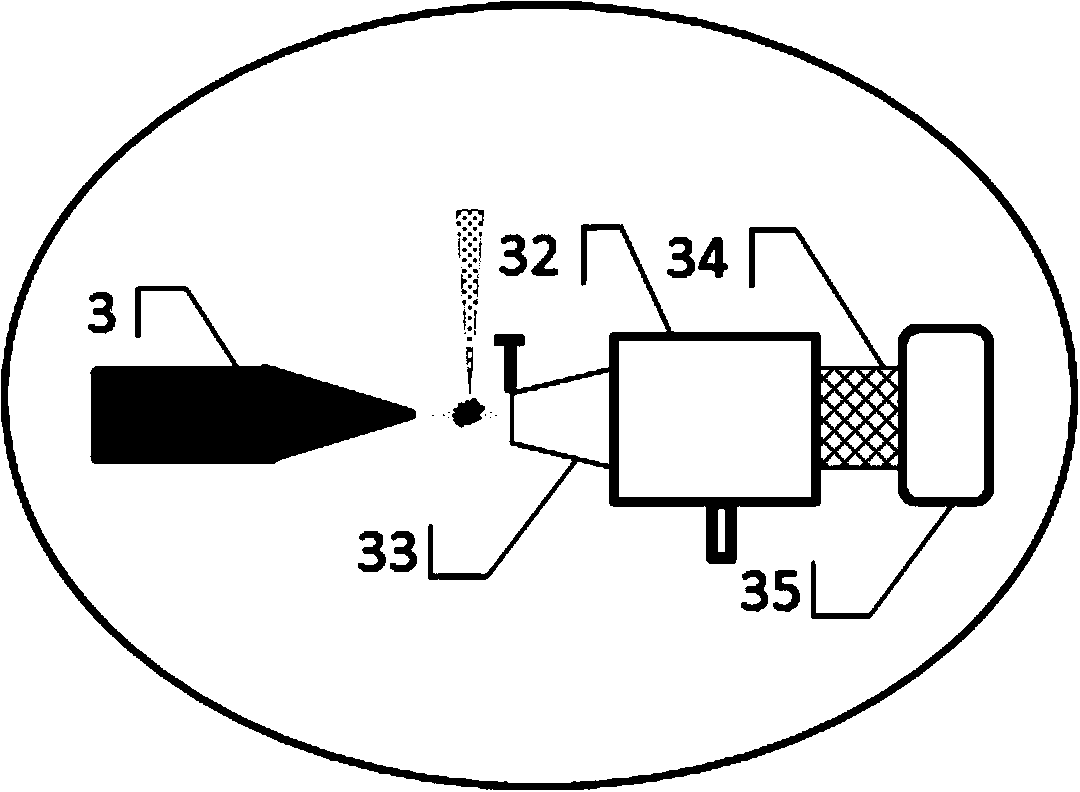

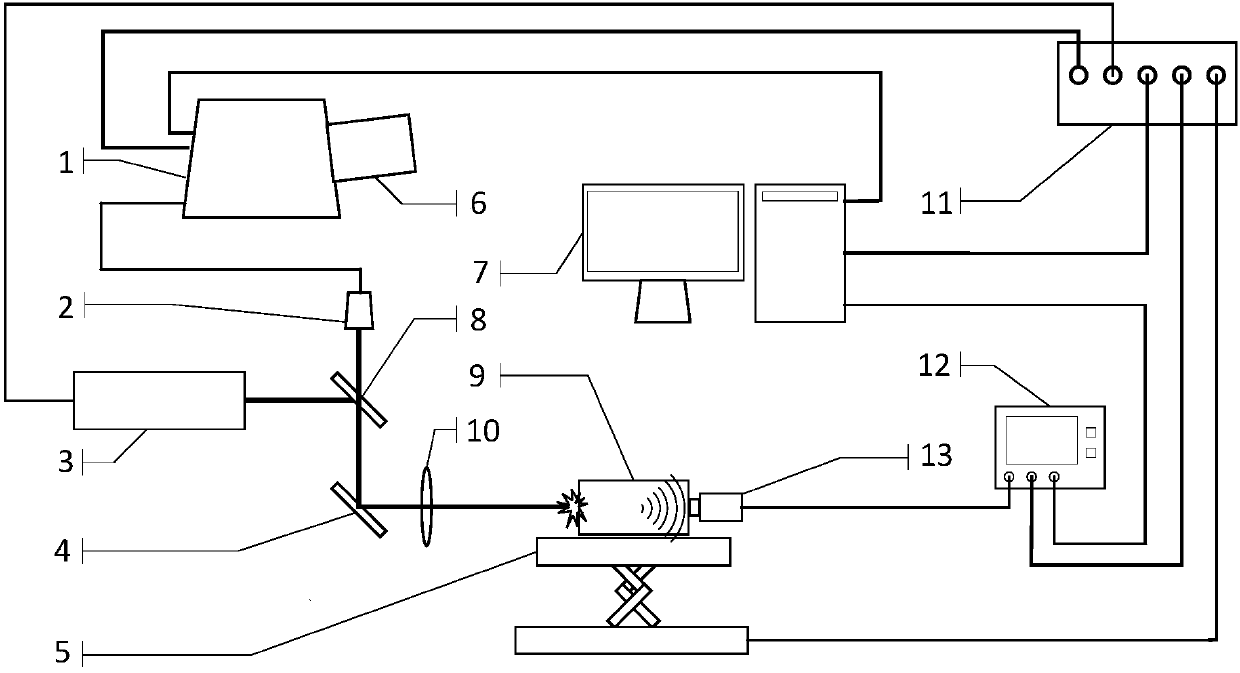

Laser probe analyzer based on aerosolization and resonance excitation

ActiveCN103712962AIncrease profitImprove compatibilityAnalysis by thermal excitationCollection systemLaser probe

The invention discloses a laser probe component analyzer. The laser probe component analyzer comprises a Nd. YAG (neodymium-doped yttrium aluminum garnet) laser system, a wavelength tunable laser system, an aerosolization system, a spectrum collection system and a computer, wherein the aerosolization system is used for producing an aerosol from a solution to be analyzed; the Nd. YAG laser is used for producing a high-energy laser beam and focusing the laser beam on the aerosol to excite plasma flame; the wavelength tunable laser system is used for producing a pumped laser beam with required resonance excitation wavelength and focusing the laser beam on the plasma flame to produce a resonance excitation effect; and the spectrum collection system is used for collecting characteristic spectral signals produced after resonance excitation, converting the spectral signals to electric signals and then transmitting the electric signals to the computer to analyze substance components in the solution. The system can overcome the shortcomings of the prior art, greatly improve the detection sensitivity of an LIBS (laser induced breakdown spectroscopy) technology in detection of trace elements in the solution, achieve the requirements of actual applications in the fields of environmental monitoring and the like and simultaneously perform online precise qualitative and quantitative analysis of substances in a liquid.

Owner:WUHAN XINRUIDA LASER ENG +1

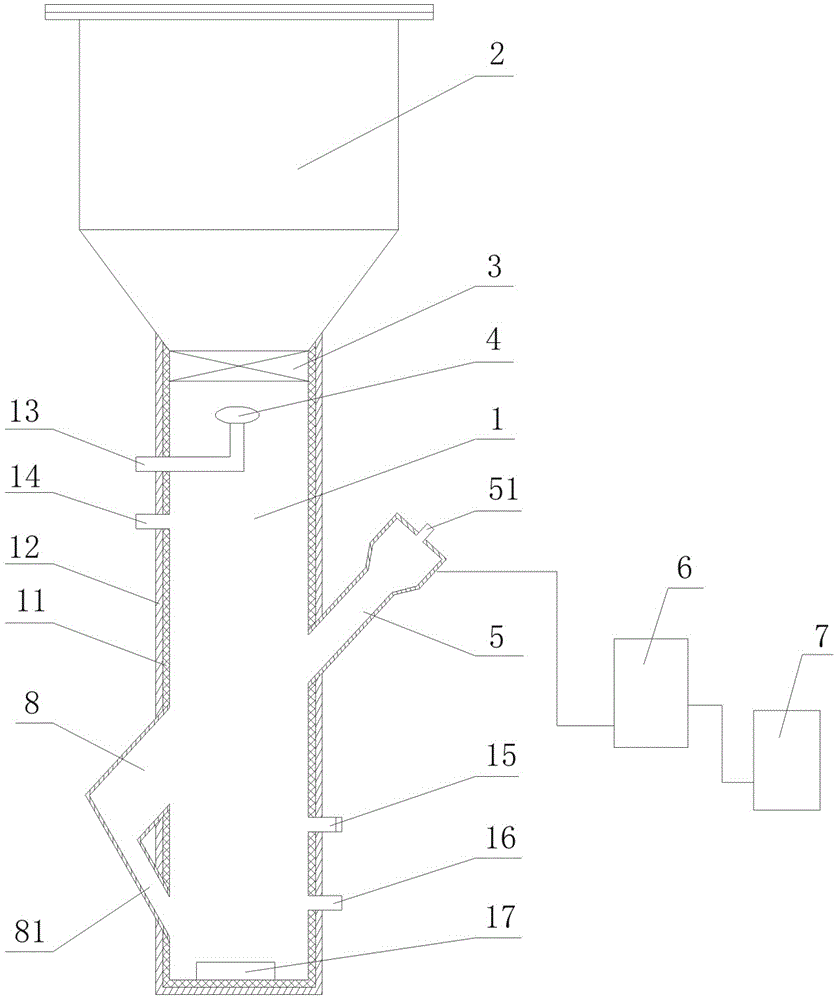

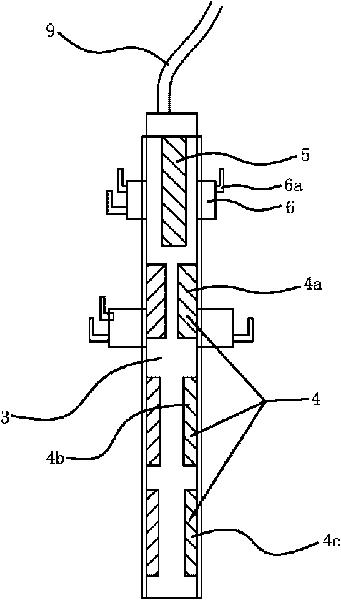

Method and device for purifying graphite

InactiveCN102745681APromote gasificationAchieve continuous purificationCarbon compoundsChemical industryInlet valveIonization

The invention belongs to the technical field of graphite purification, and particularly relates to a method and a device for high-purity purification of natural graphite. The method for purifying graphite is characterized by including the steps: 1) preparing a device for purifying graphite; 2) isolating the air; 3) generating high-temperature plasma flame flows, namely loading working gas to a working gas inlet of a plasma torch, and starting the plasma torch to enable the working gas to be connected by ionization puncture to eject high-temperature plasma flame flows from the plasma torch; and 4) using the high-temperature plasma flame flows to purify graphite, namely turning on a flash valve, feeding gas into a gas injection pipe, enabling graphite raw materials to fall into the bottom of a furnace via the high-temperature plasma flame flows to obtain purified graphite, and opening a taking port to take out the purified graphite after the furnace is cooled, wherein a gas inlet valve on the gas injection pipe is in linkage with the flash valve. The method is low in energy consumption, the graphite obtained by the method is high in purity, and the device is simple.

Owner:辽宁点石技术开发有限公司

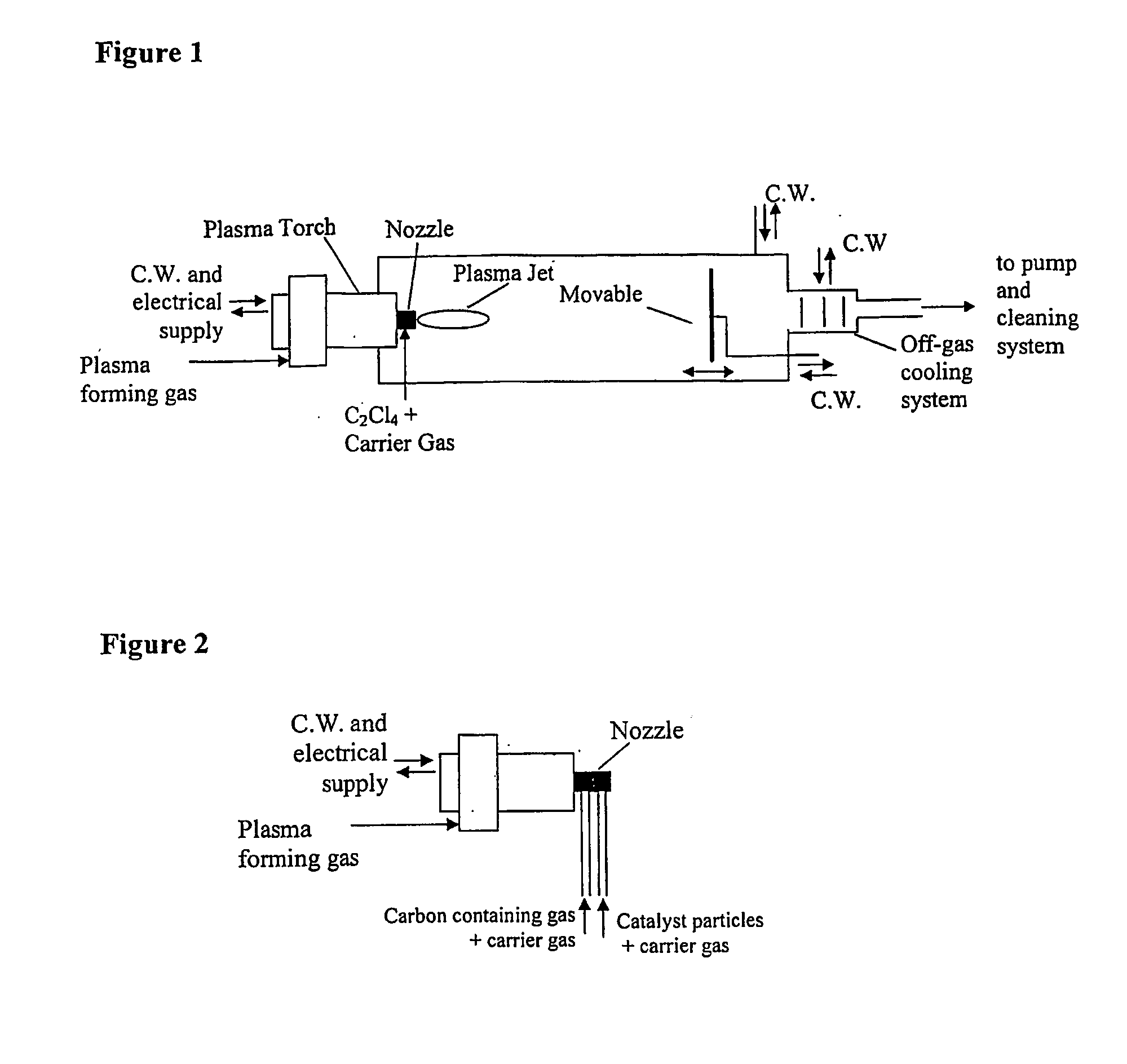

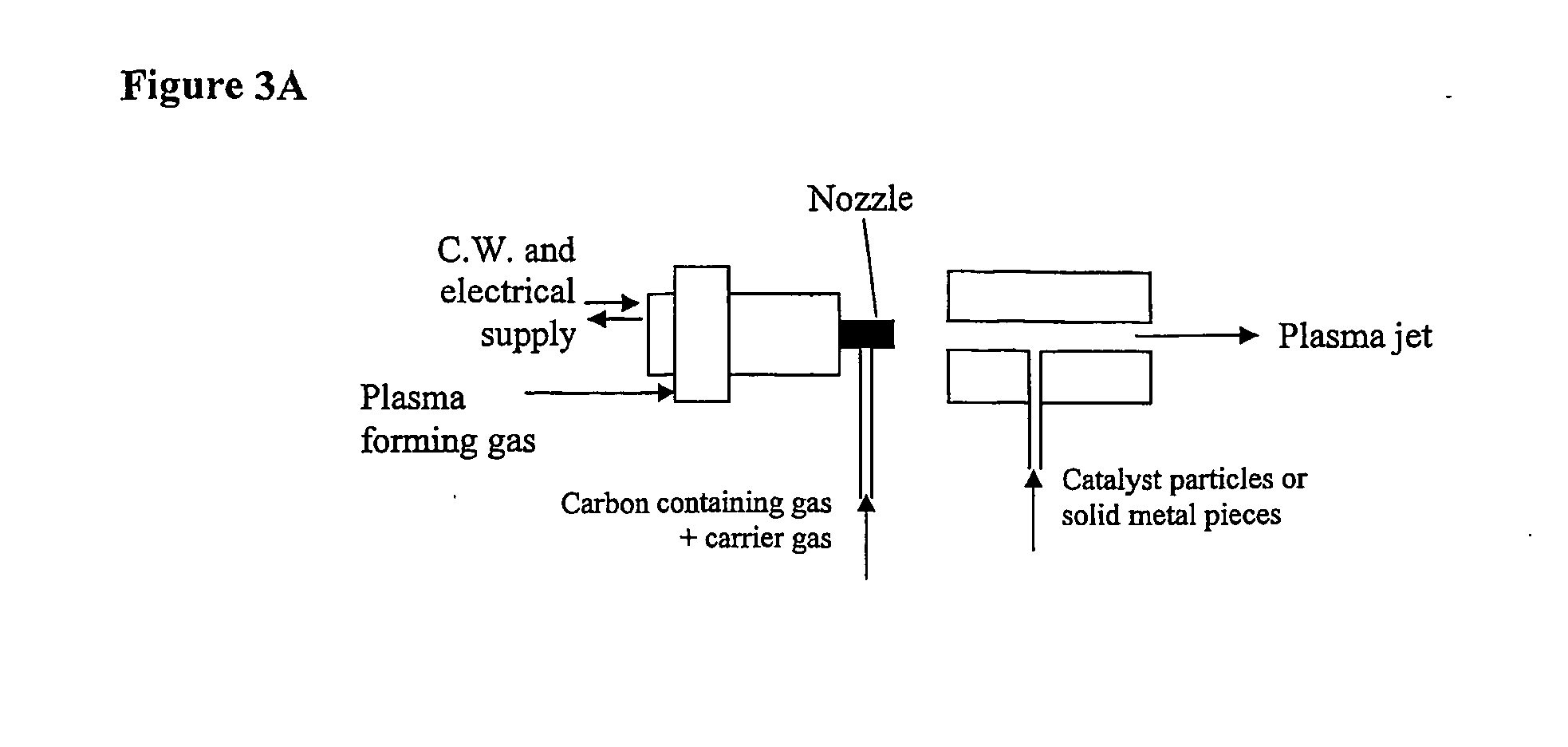

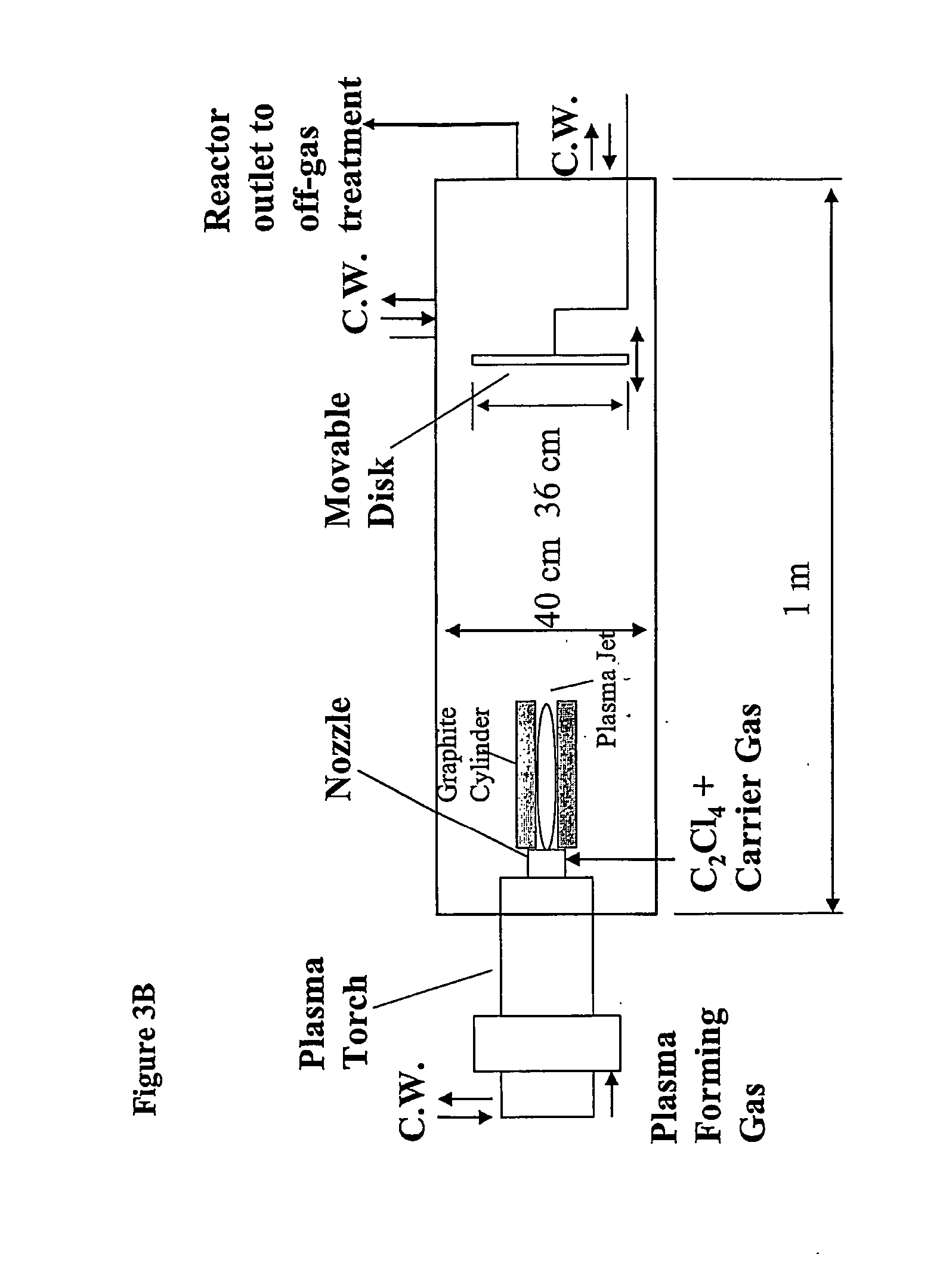

Method for producing carbon nanotubes using a DC non-transferred thermal plasma torch

InactiveUS7846414B2Easy to zoom inIncrease volumeMaterial nanotechnologyCarbon compoundsForming gasMetal catalyst

The present invention provides a process for the manufacture of carbon nanostructures, the carbon nanostructures being selected from carbon nanotubes and carbon nano-onions. The method comprises the steps of injecting a carbon-containing gas into a plasma flame generated from a plasma forming gas to provide atomic carbon, which in the presence of in situ generated nanometer sized metal catalyst particles that act as nucleation points for growth of carbon nanostructures, produce the carbon nanostructures, and collecting the carbon nanostructures.

Owner:MCGILL UNIV

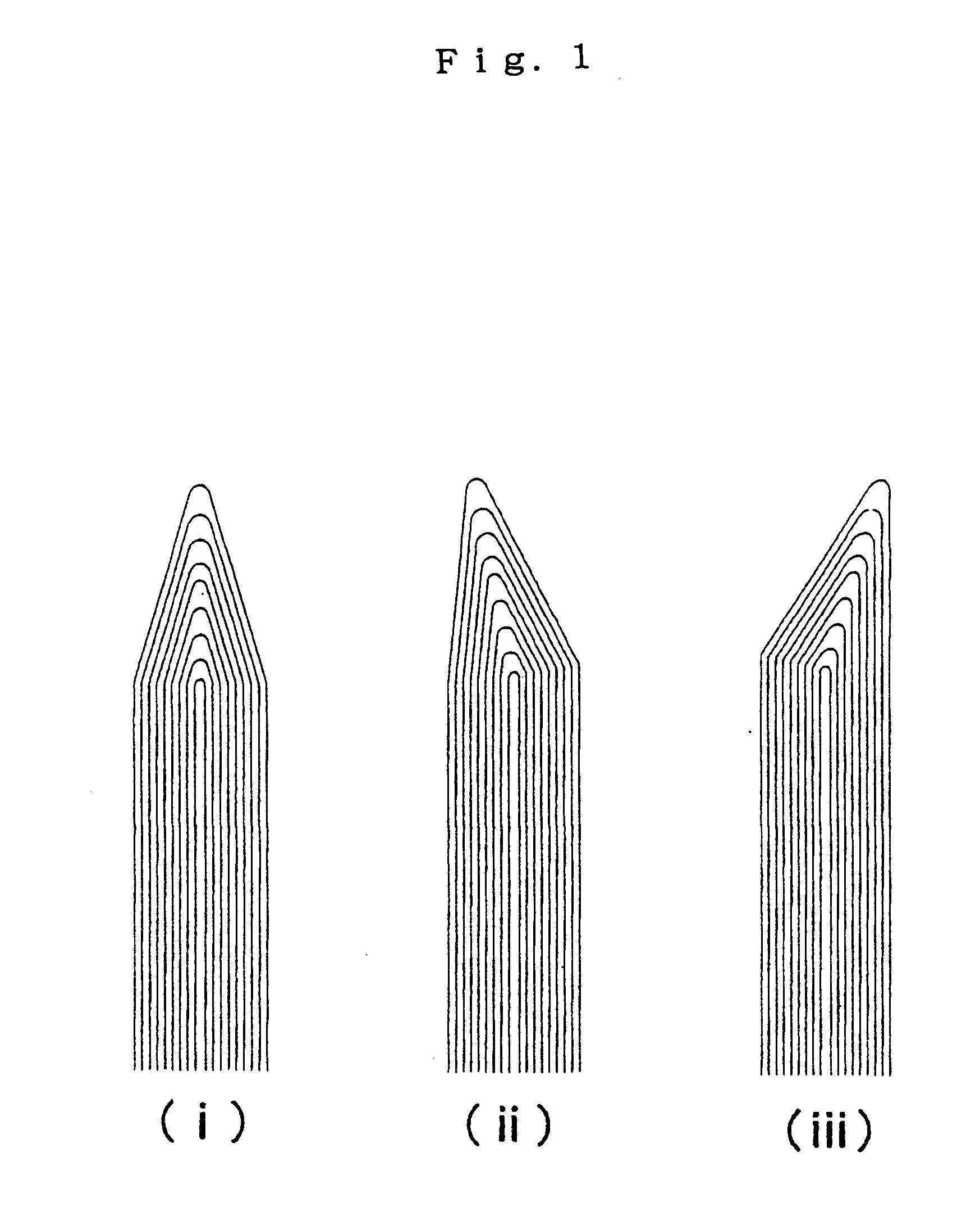

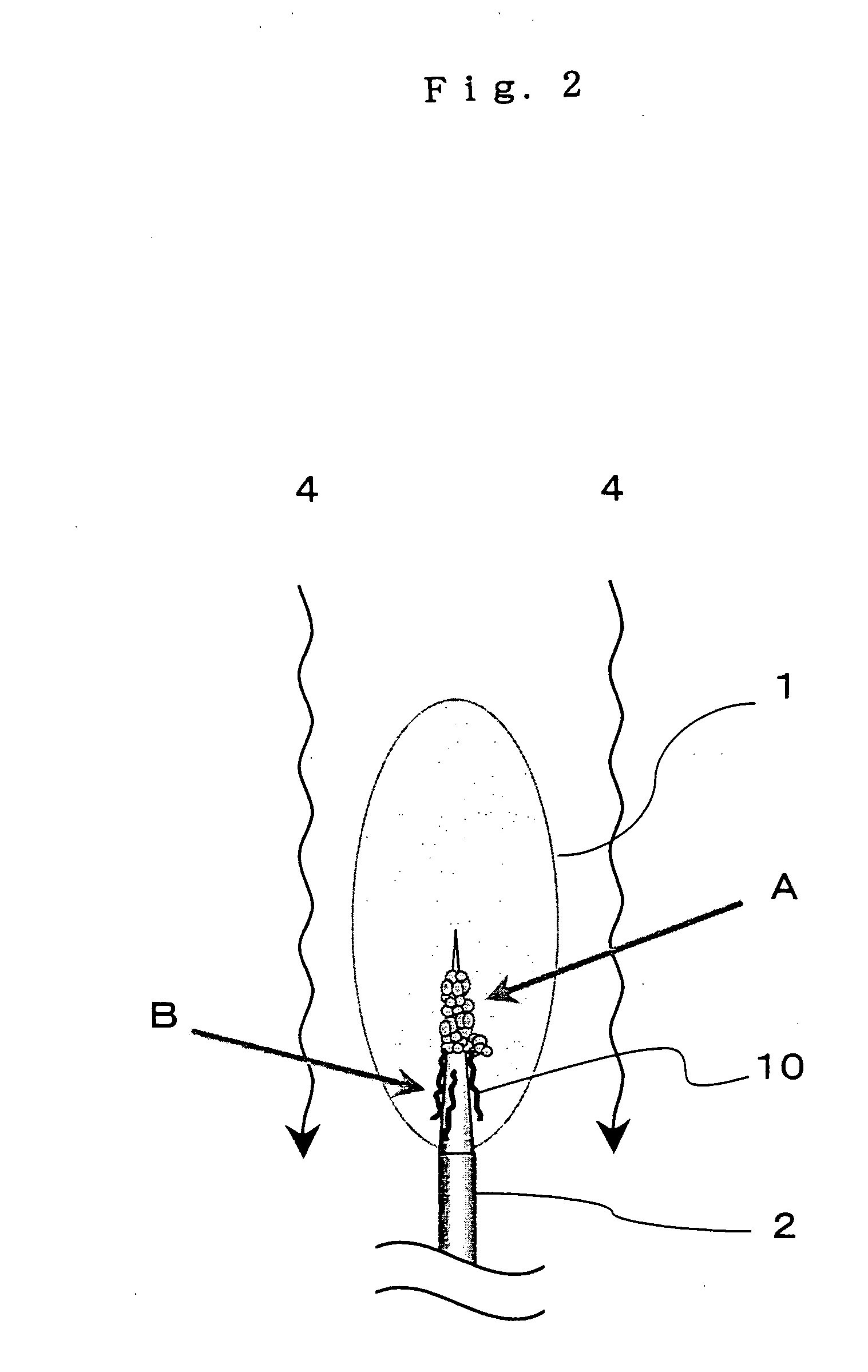

Sharp end, multi-layer carbon nano-tube radial aggregate and method of manufacturing the aggregate

A method of manufacturing a acute tip, multi-wall carbon nanotube radial aggregate, comprising the steps of leading a graphite rod into plasma flame generated in a hydrogen-added inert gas atmosphere to evaporate carbon from the graphite rod and stacking, on the surface of the graphite rod, the acute tip, multi-wall carbon nanotube radial aggregation of novel carbon nano-structure useful as field emission electron sources such as probes for STM and APM, display elements, and displays.

Owner:NEC CORP

Ring plasma jet method and apparatus for making an optical fiber preform

A plasma flame is generated in an interior volume of a tubular member to be a radially directed plasma flame, directed to an inside surface of the tubular member, and reagent chemicals are injected to form soot particles, and the soot particles are deposited on the inner surface by the plasma flame. The plasma flame is generated by establishing an electromagnetic field in a region in the tube interior and inserting a plasma gas feeder nozzle into the tube interior, with the nozzle structured to emit plasma gas in a manner forming the radially directed plasma flame.

Owner:GUSKOV MICHAEL I +4

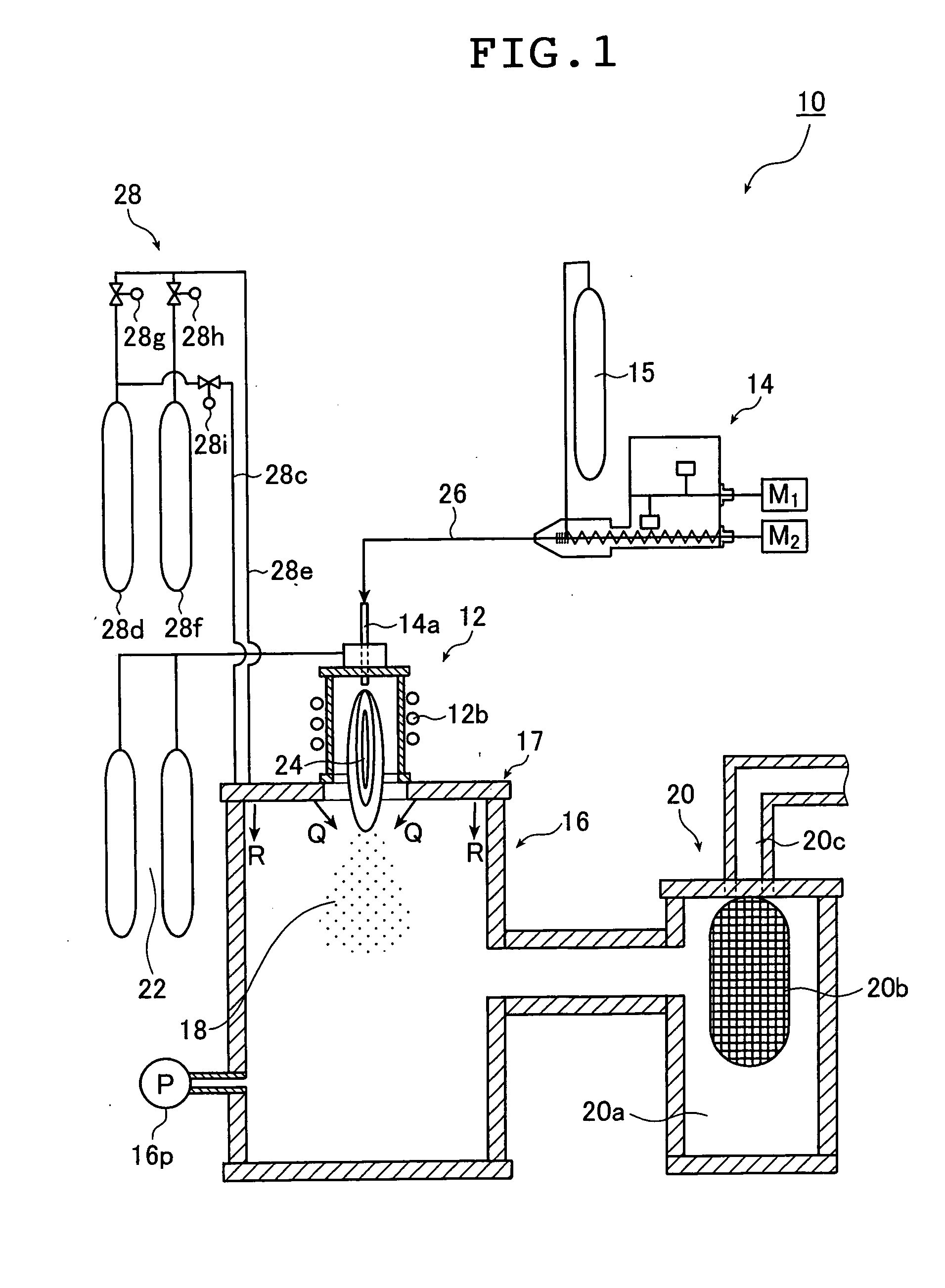

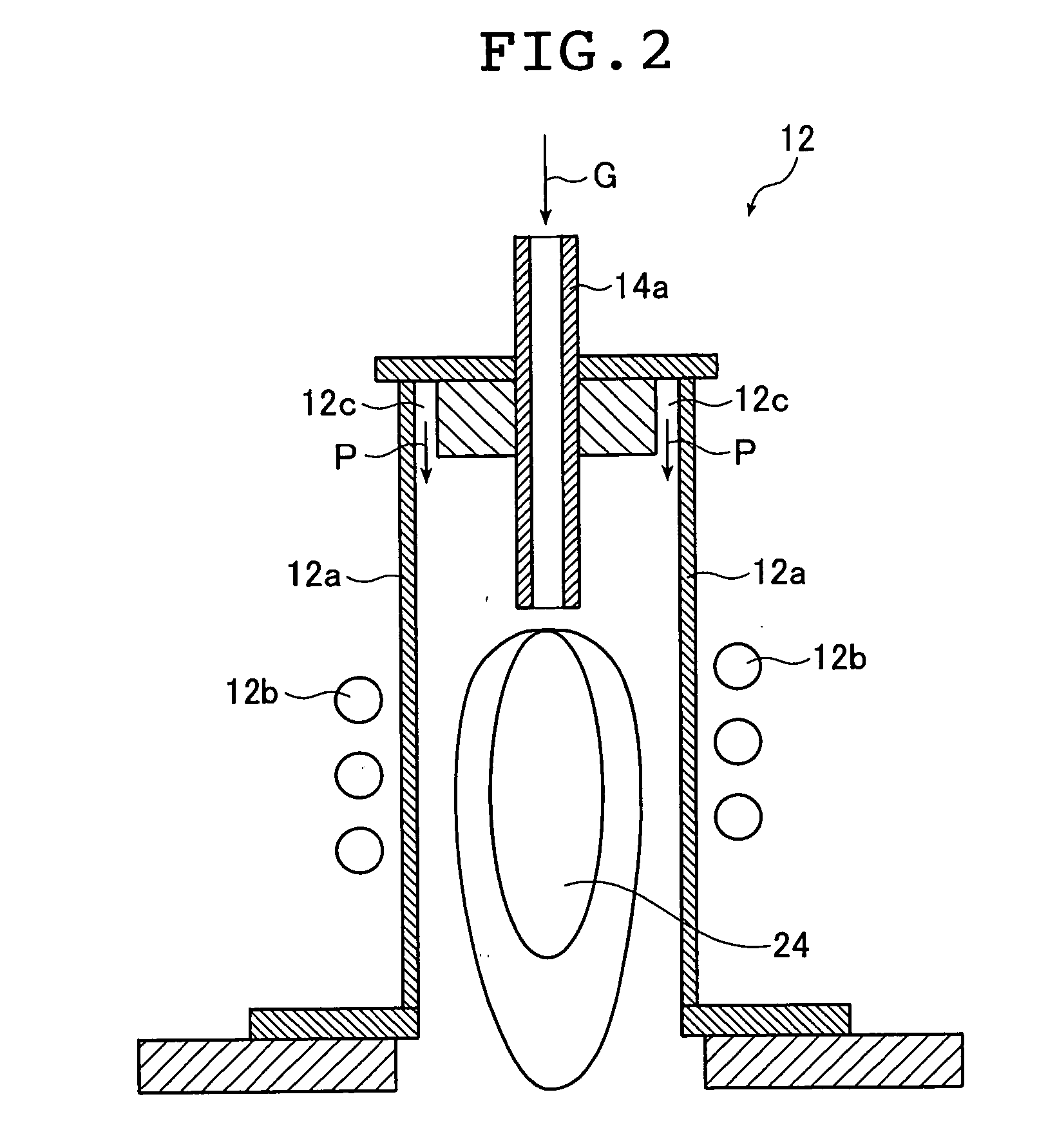

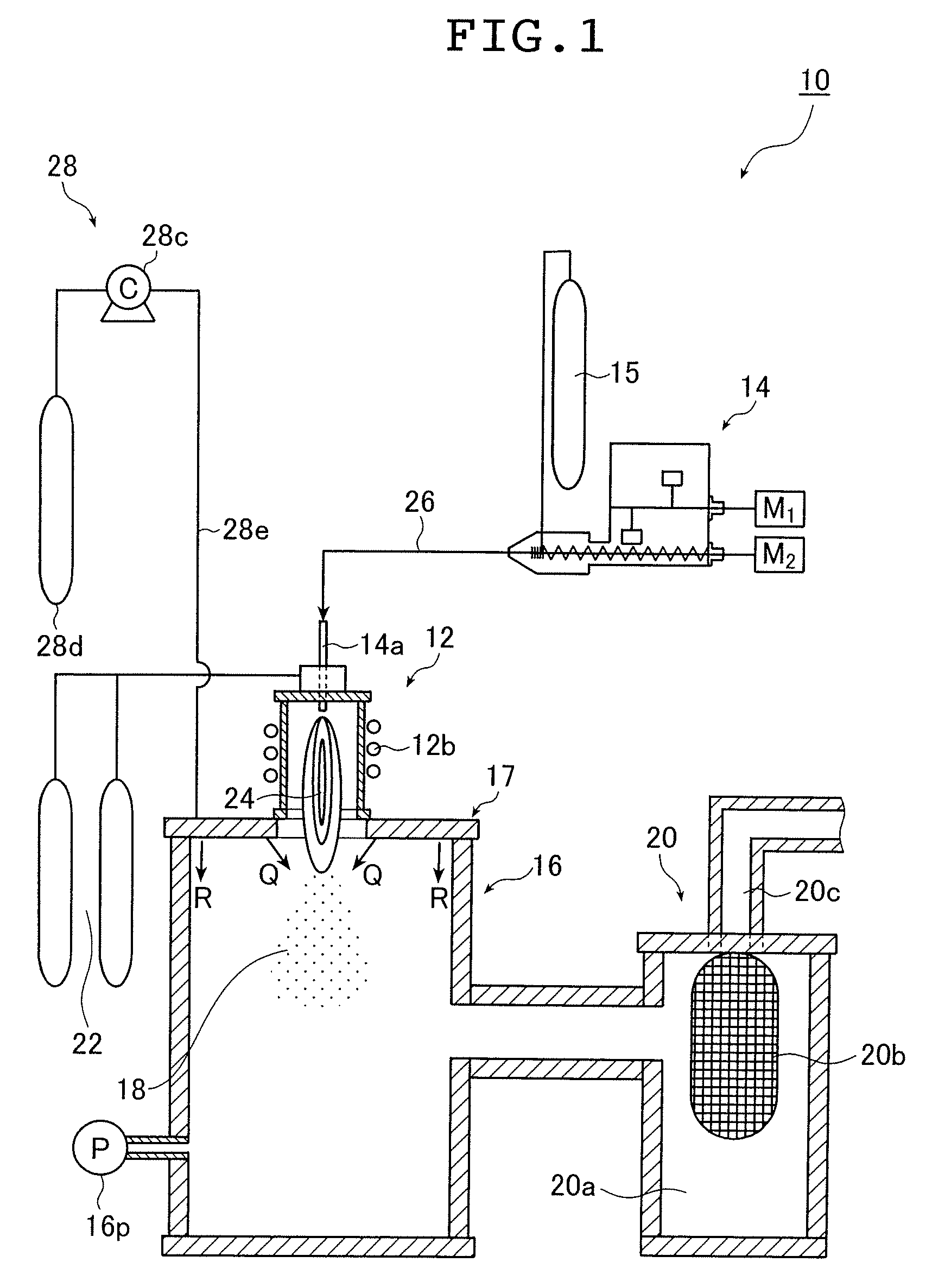

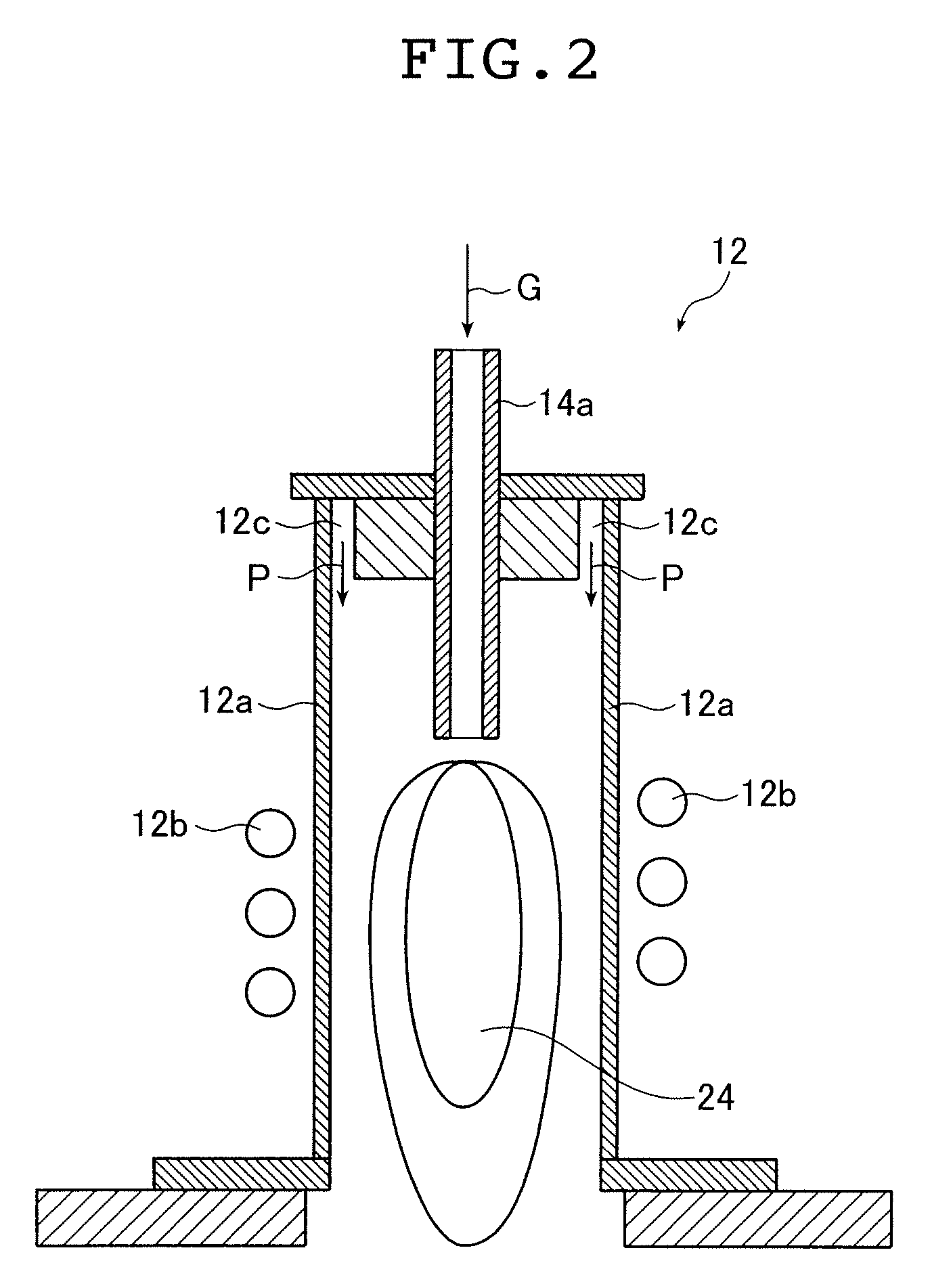

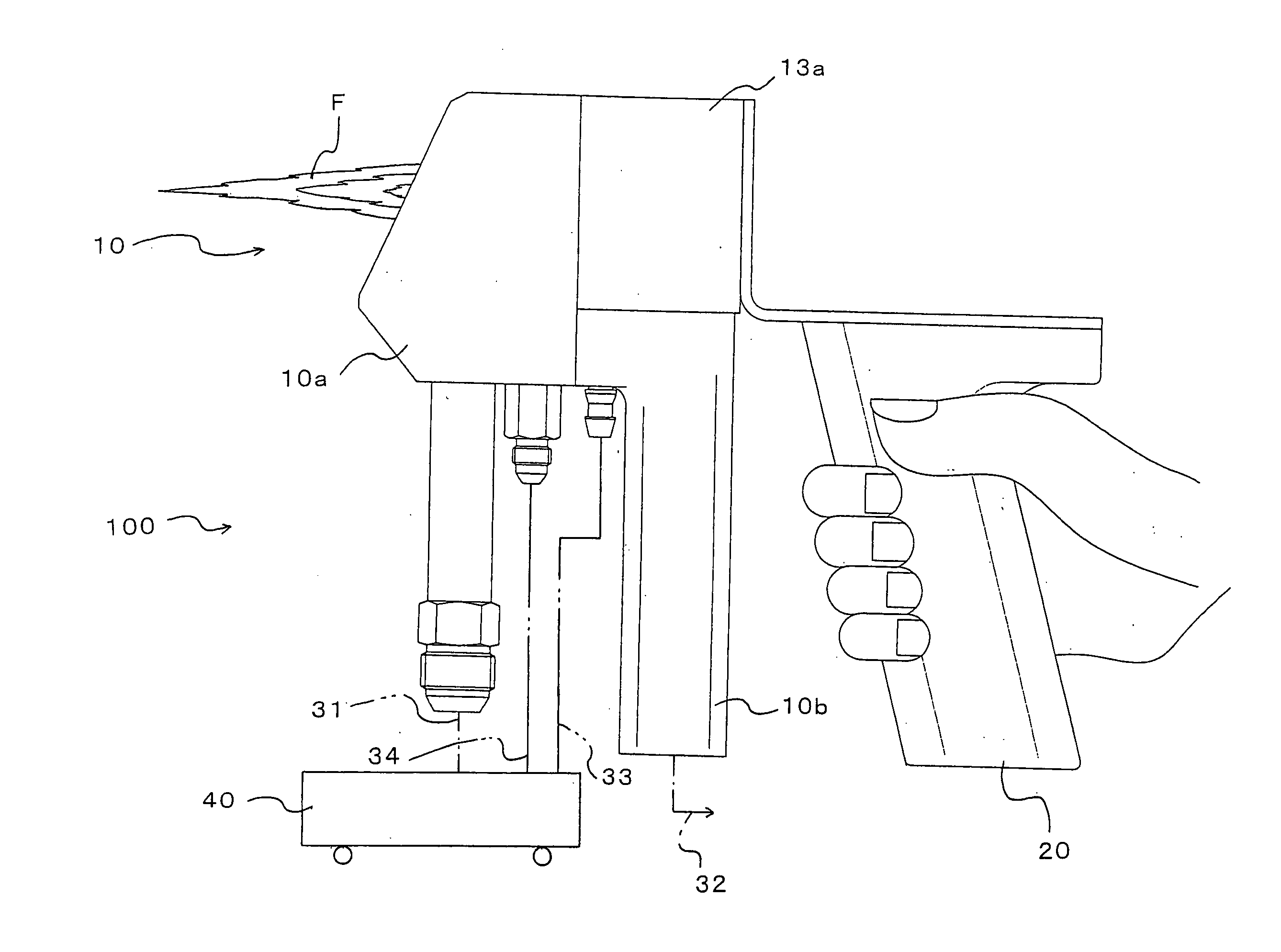

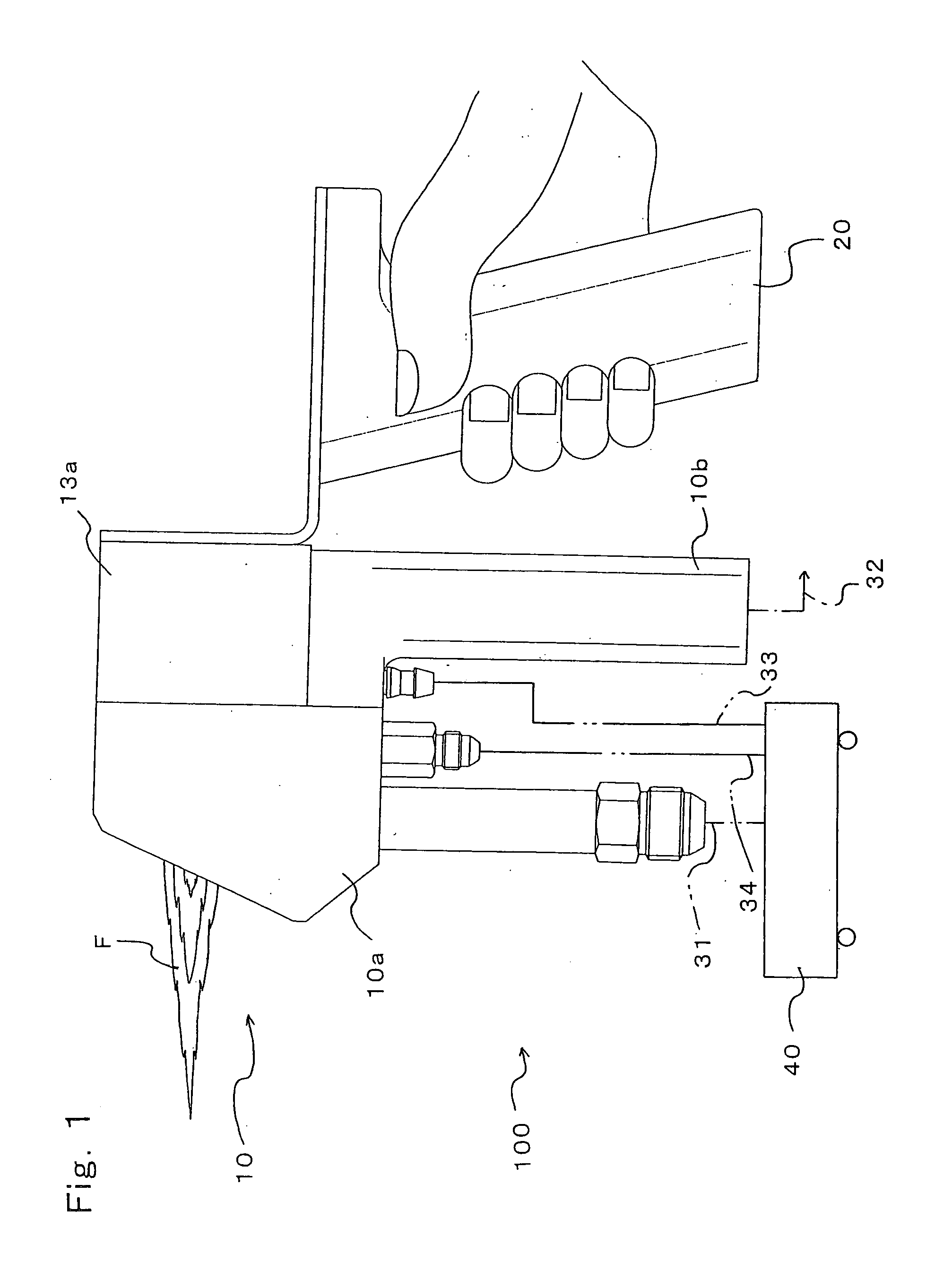

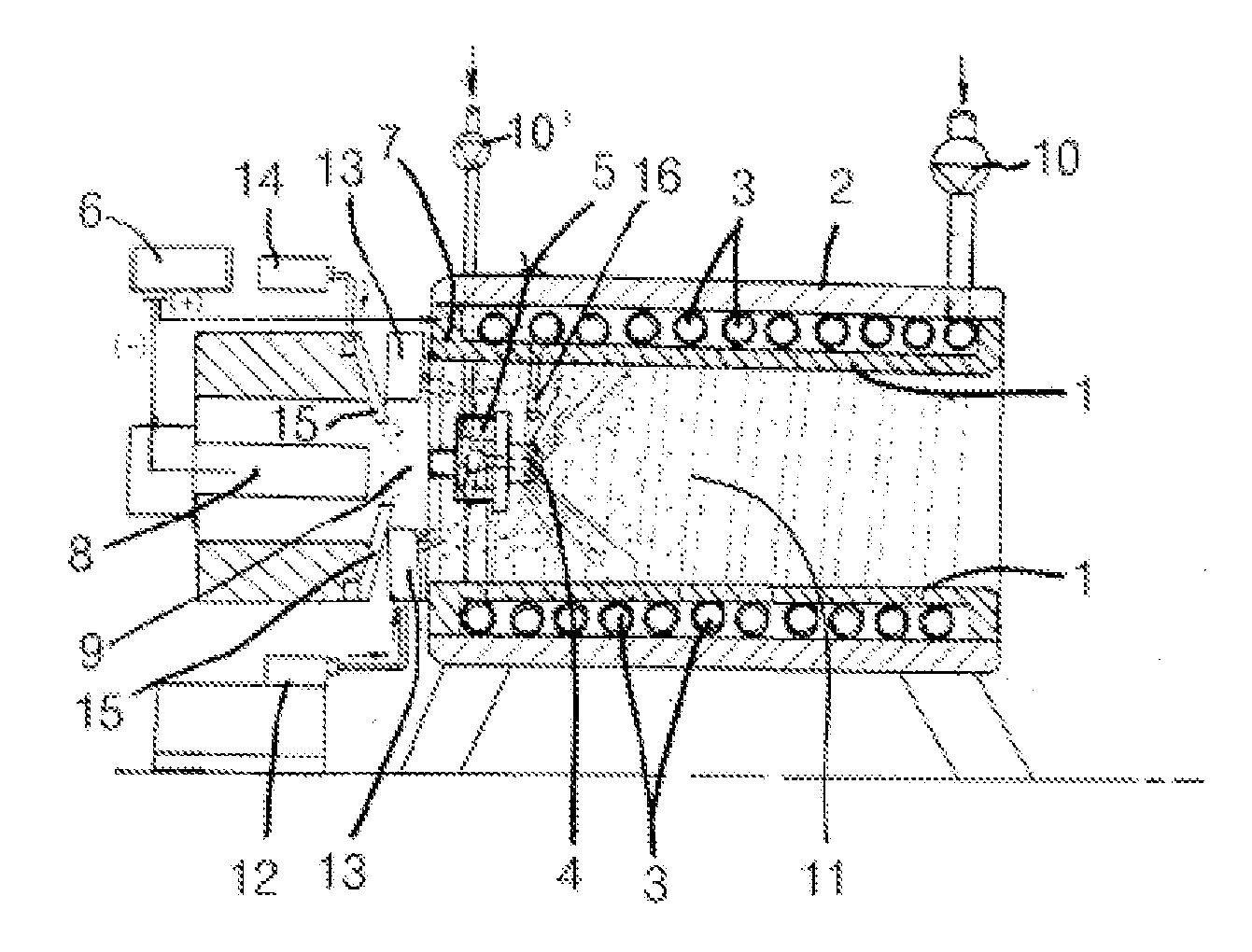

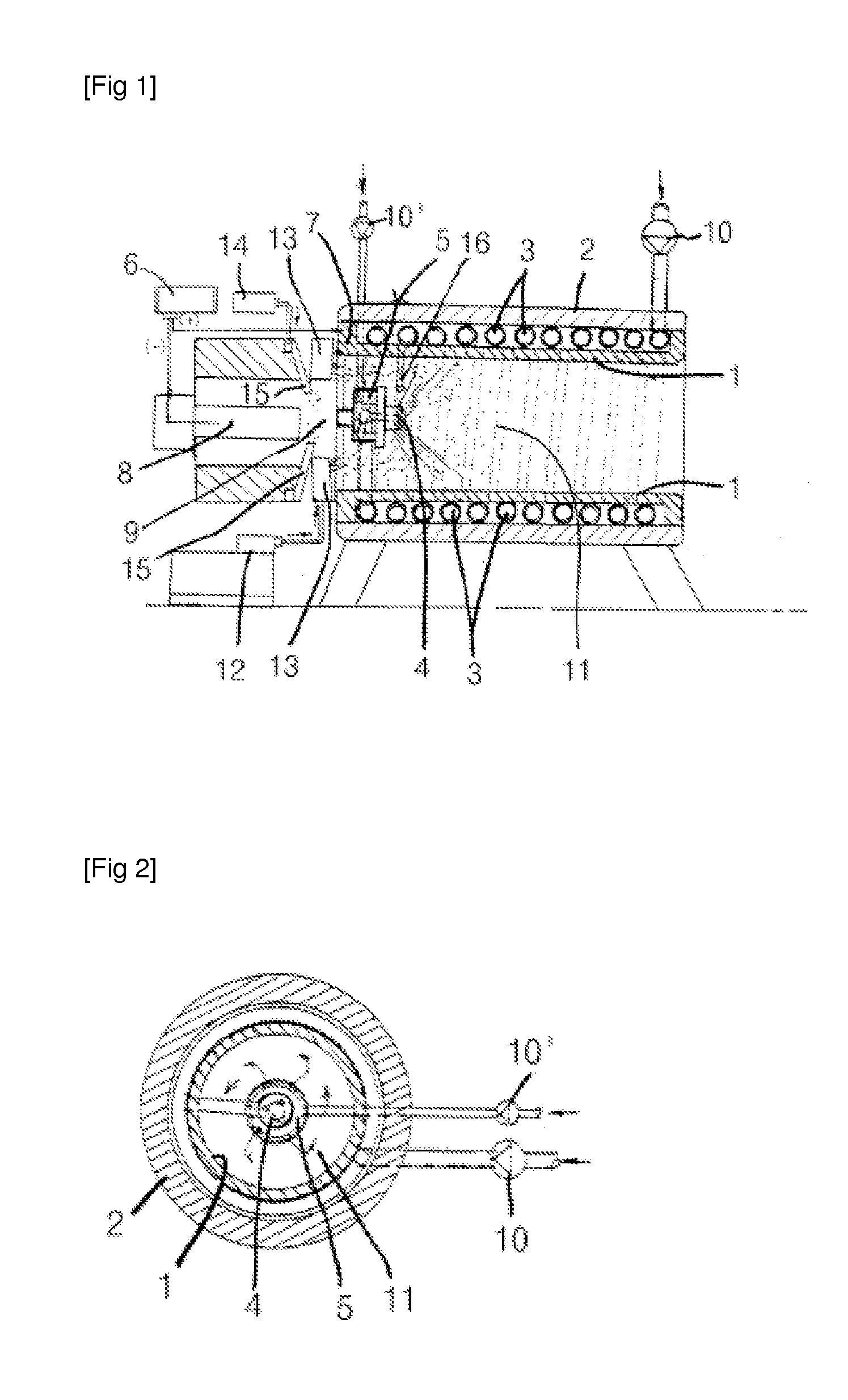

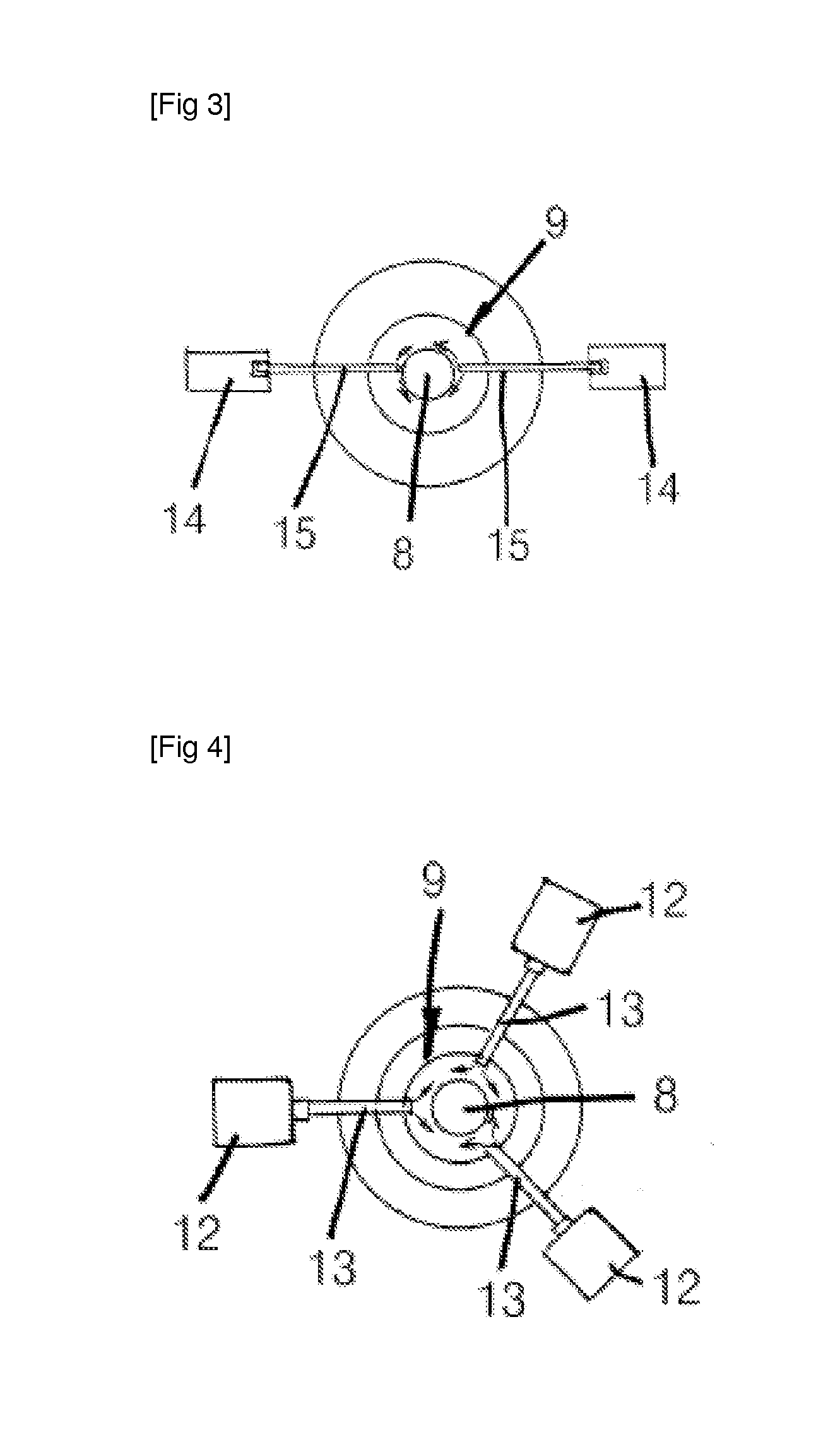

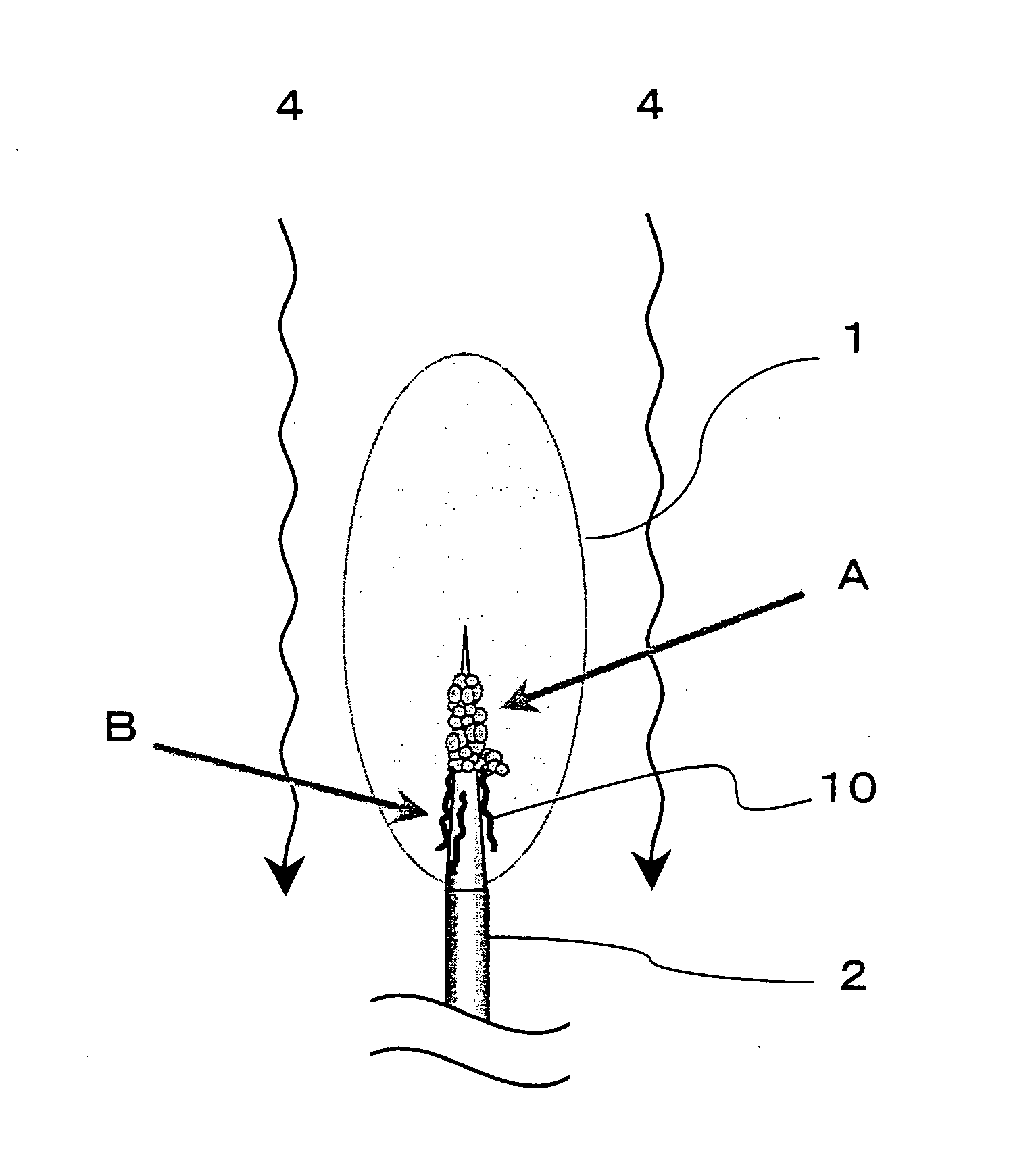

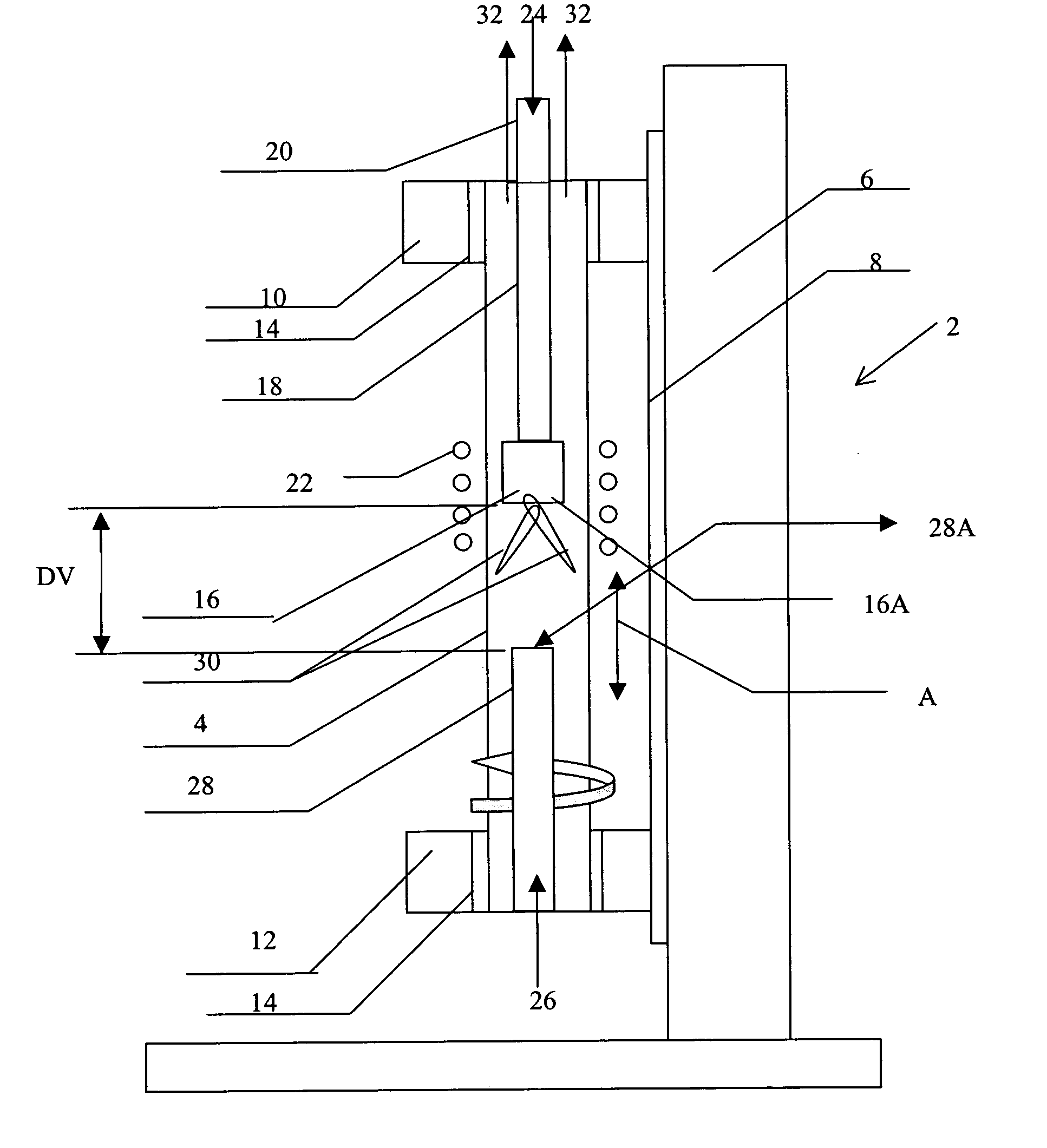

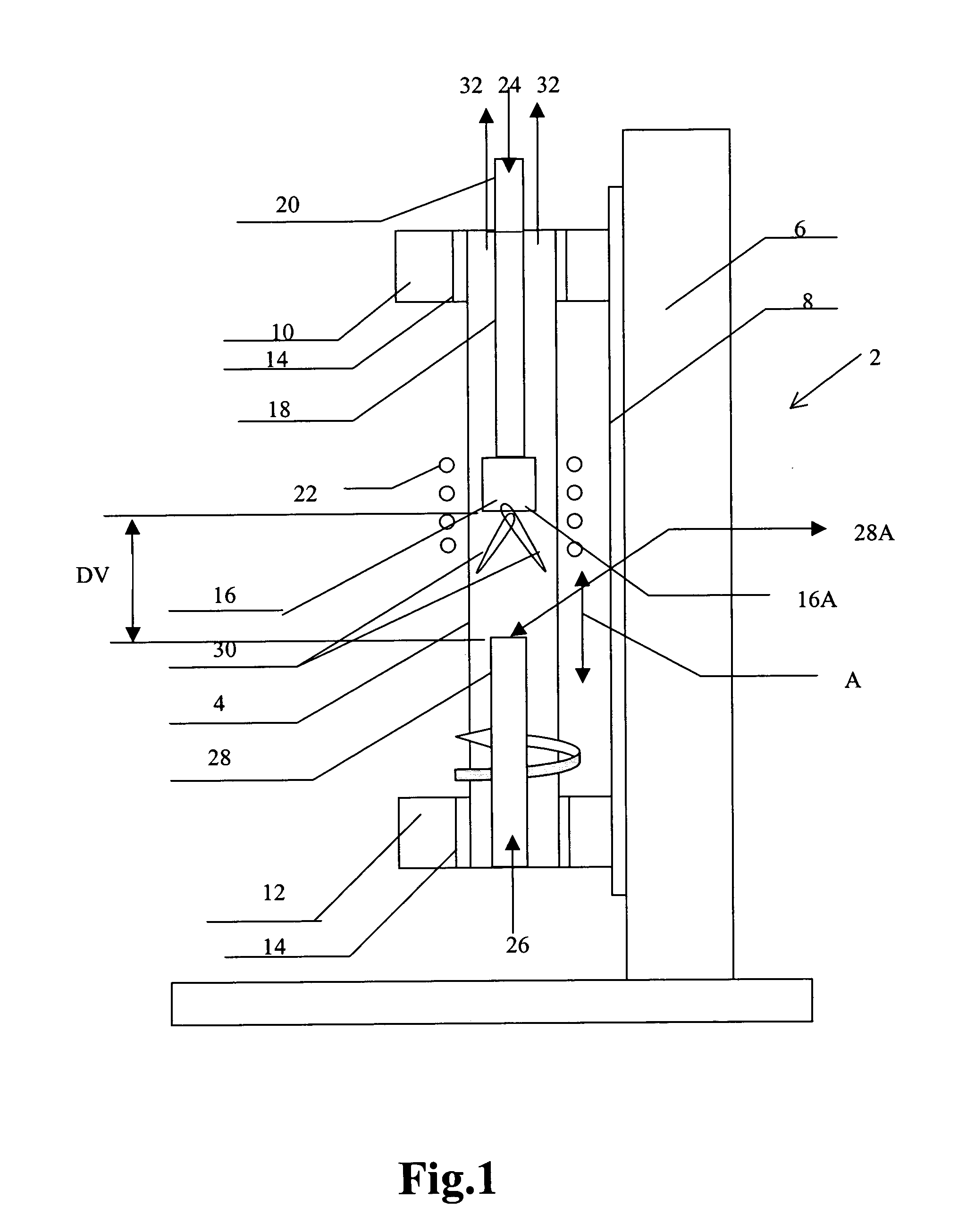

Plasma processing apparatus for powder and plasma processing method for powder

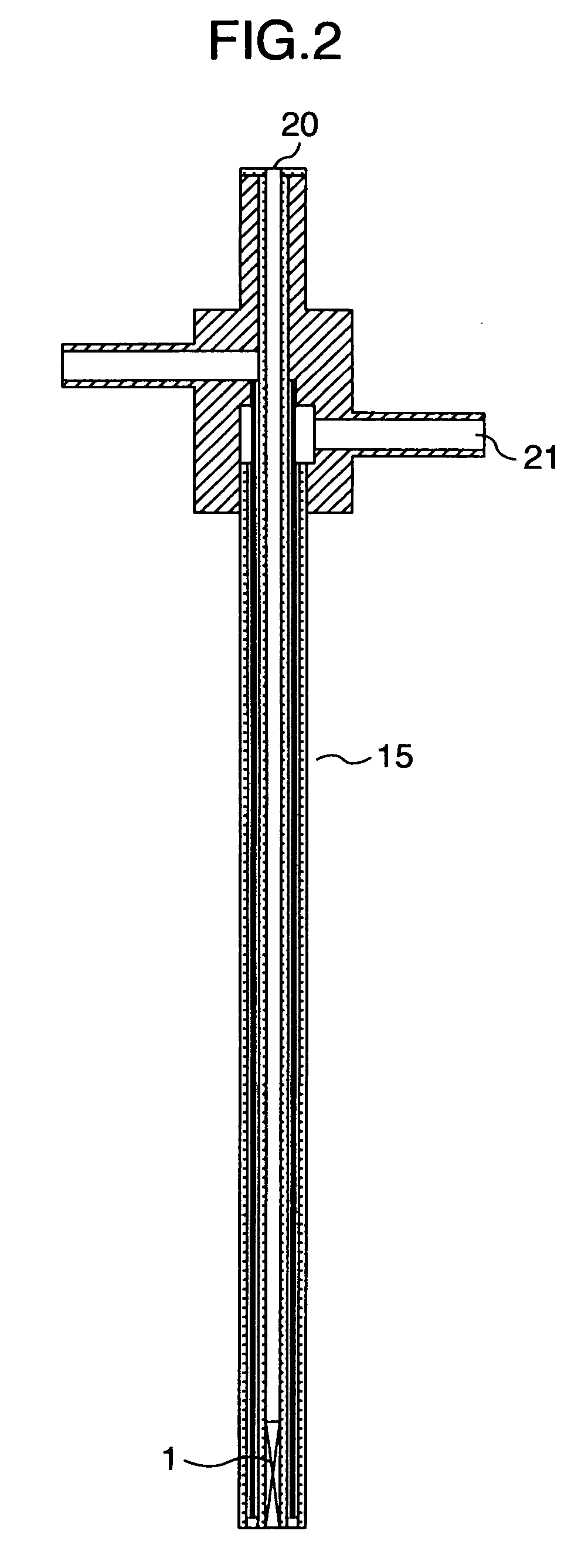

ActiveUS20050183542A1Improve processing efficiencySuppress generationMolten spray coatingTransportation and packagingMetallurgyPlasma flame

A plasma processing apparatus for powder, and a plasma processing method of powder, in which a powder supply nozzle is provided to supply a powder material into plasma flame generated inside a high-frequency coil, the powder supply nozzle arranged substantially radially centrally of the high-frequency coil comprises a revolving flow forming device, for example, a spiral-shaped plate, to cause a carrier gas and the powder material to form therein a revolving flow with an axis thereof directed axially of the high-frequency coil, and the revolving flow is discharged from an outlet at an end of the nozzle. More preferably, a transition space is provided between the outlet at the end of the nozzle and the revolving flow forming device, and the outlet at the end of the nozzle is made small in diameter.

Owner:HITACHI METALS LTD

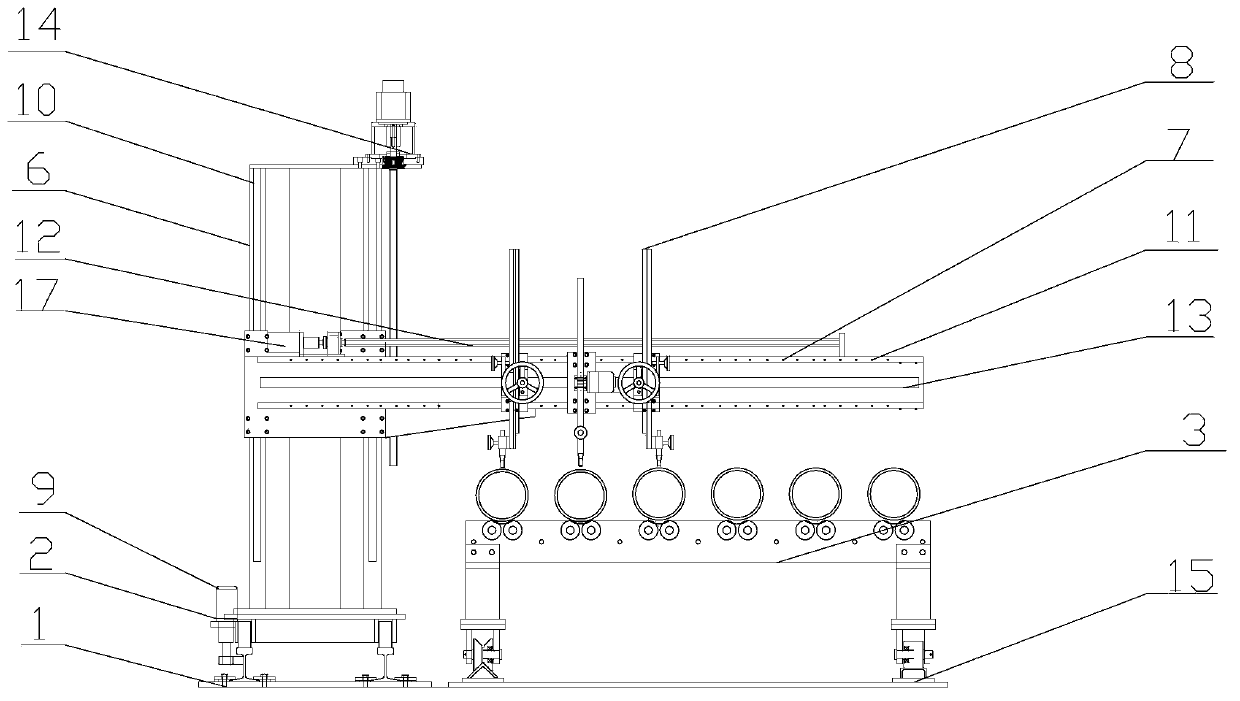

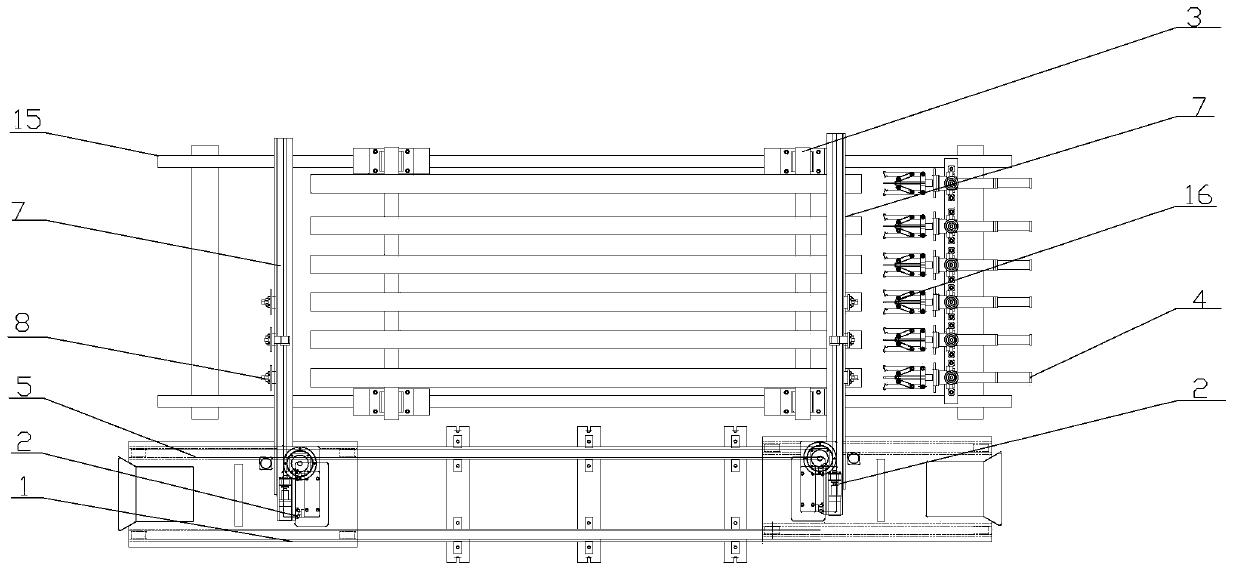

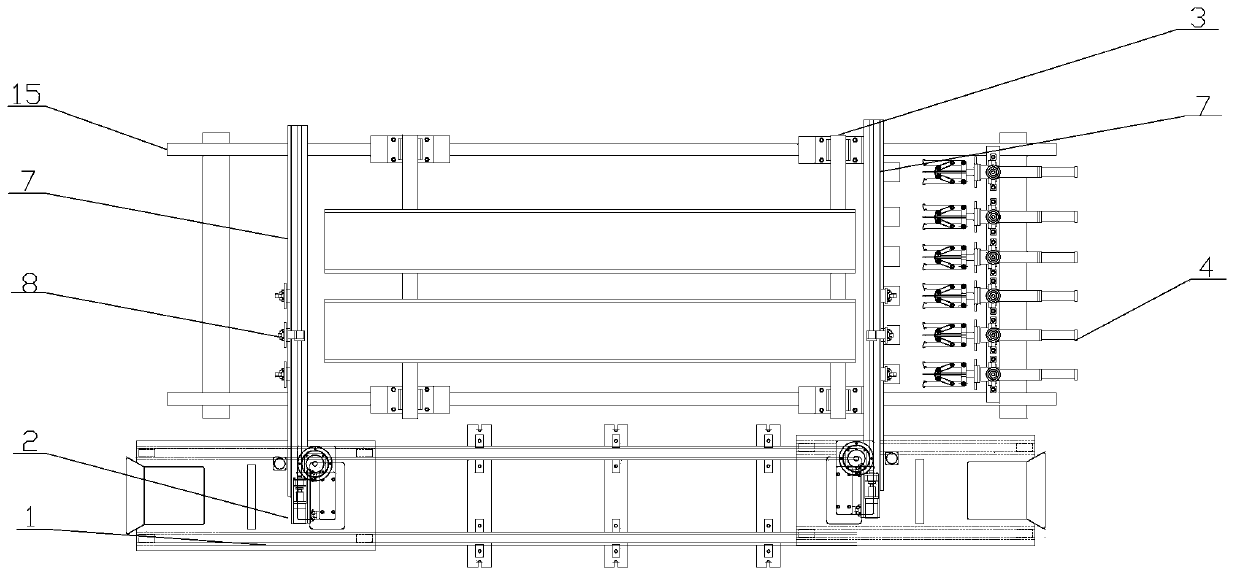

Cantilever type numerical control plasma flame structural steel three-dimensional cutting machine

ActiveCN103418881AImprove running stabilityImprove cutting accuracyWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlEngineering

The invention discloses a steel sheet cutting device, and particularly relates to a cantilever type numerical control plasma flame structural steel three-dimensional cutting machine used for cutting steel pipes. The cutting machine comprises two parallel Y-axis guide rails, two movable numerical control cutting main machines arranged on the Y-axis guide rails, a wheel overturning material frame used for storing steel pipes, and a pneumatic clamping dividing device arranged at one end of the wheel overturning material frame. Each numerical control cutting main machine comprises a walking cart, a stand column, a cantilever and a cutting gun, wherein the walking cart is driven by a Y-axis servo motor to move along the Y axis, and the stand column is provided with two parallel Z-axis guide rails. The cutting machine has the advantages that the grooving operation of the steel pipes and large-scale H-steel cutting operation can be achieved at the same time, one cutting machine can be used for multiple purposes, automatic cutting efficiency is high, operation is stable, and operation is simple and convenient.

Owner:QINGDAO EAST STEEL TOWER

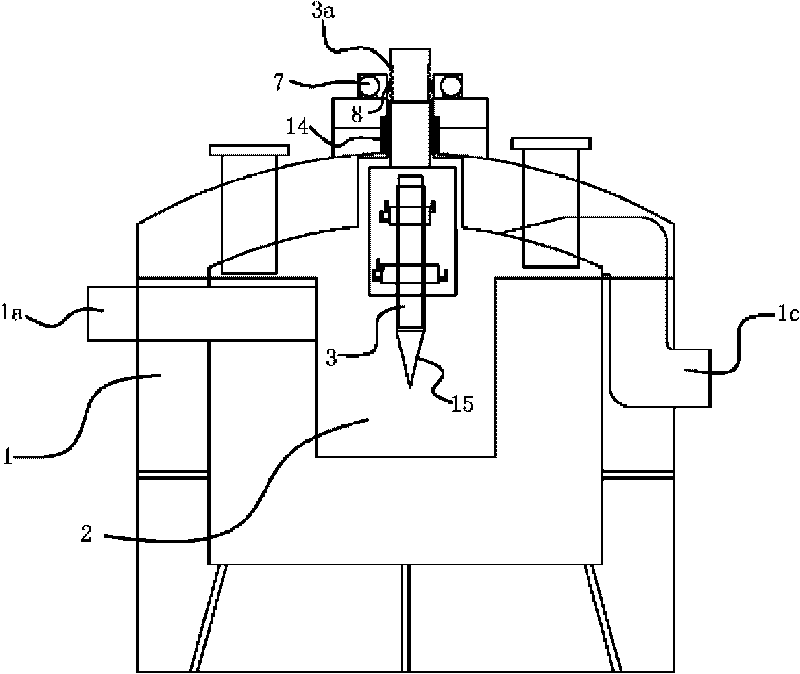

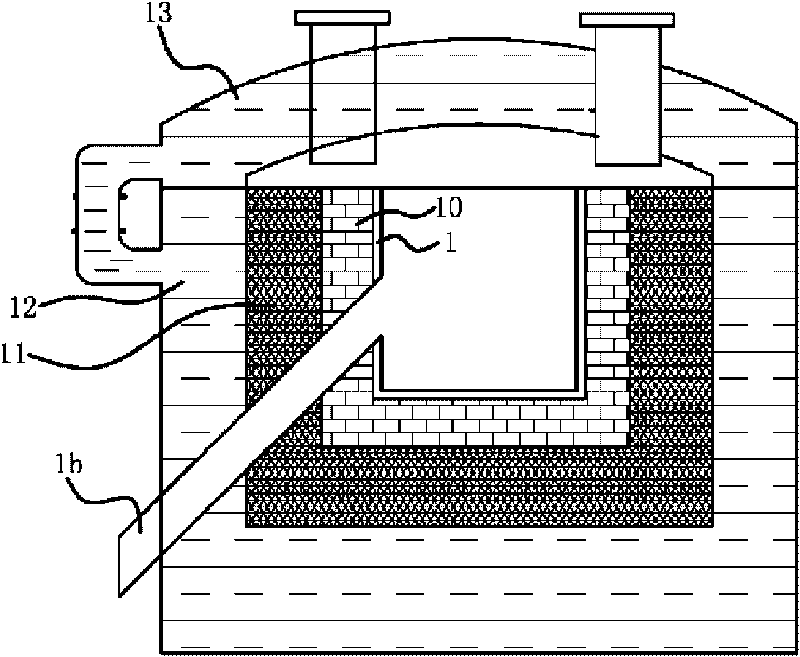

Plasma melting cracking treating equipment

ActiveCN101737786ABurn completelyImprove incineration effectIncinerator apparatusPlasma flameIncineration

The invention provides plasma melting cracking treating equipment belonging to the technical field of machines and solving the technical problems of low incineration temperature, poor incineration effect, insufficient incineration and the like of a traditional incineration furnace. The plasma melting cracking treating equipment comprises a furnace body with a charging port and a discharging port, wherein the furnace body is internally provided with an incineration cavity communicated with the charging port and the discharging port; the furnace body is also provided with a gas outlet communicated with the incineration cavity; the top of the furnace body is also provided with a plasma torch generator capable of generating plasma flames; one end of the plasma torch generator penetrates into the incineration cavity; and the other end penetrates out of the furnace body and is connected with a lifting mechanism capable of driving the plasma torch generator to lift upwards and downwards. The treating equipment has the advantages of higher flame temperature, more sufficient incineration, higher incineration efficiency and the like.

Owner:TAIZHOU WEIBO ENVIRONMENTAL PROTECTION EQUIP TECH

Method for producing carbon nanotubes using a dc non-transferred thermal plasma torch

InactiveUS20060127299A1Raise the potentialEnergy was cheapMaterial nanotechnologyFibre chemical featuresForming gasMetal catalyst

The present invention provides a process for the manufacture of carbon nanostructures, the carbon nanostructures being selected from carbon nanotubes and carbon nano-onions. The method comprises the steps of injecting a carbon-containing gas into a plasma flame generated from a plasma forming gas to provide atomic carbon, which in the presence of in situ generated nanometer sized metal catalyst particles that act as nucleation points for growth of carbon nanostructures, produce the carbon nanostructures, and collecting the carbon nanostructures.

Owner:MCGILL UNIV

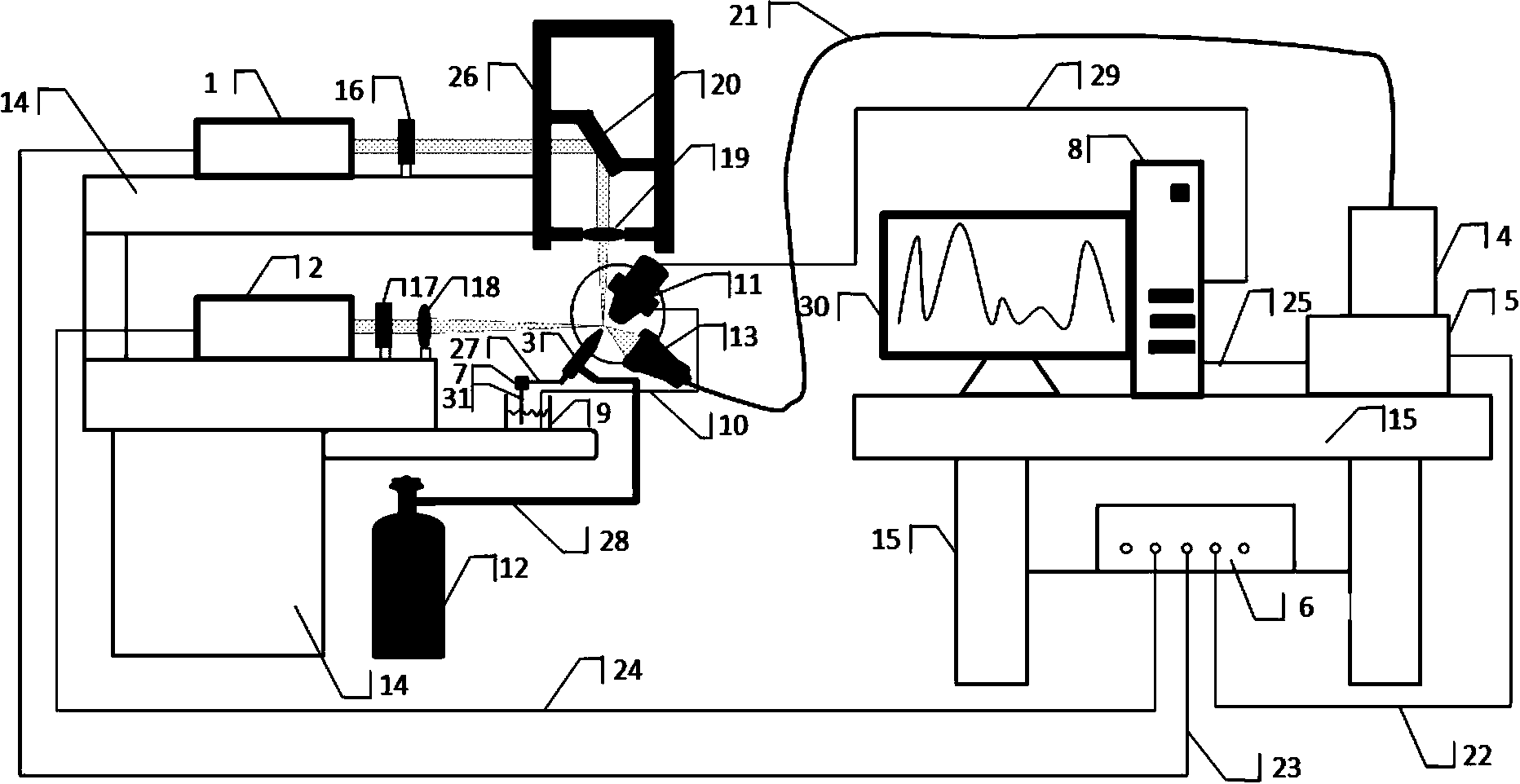

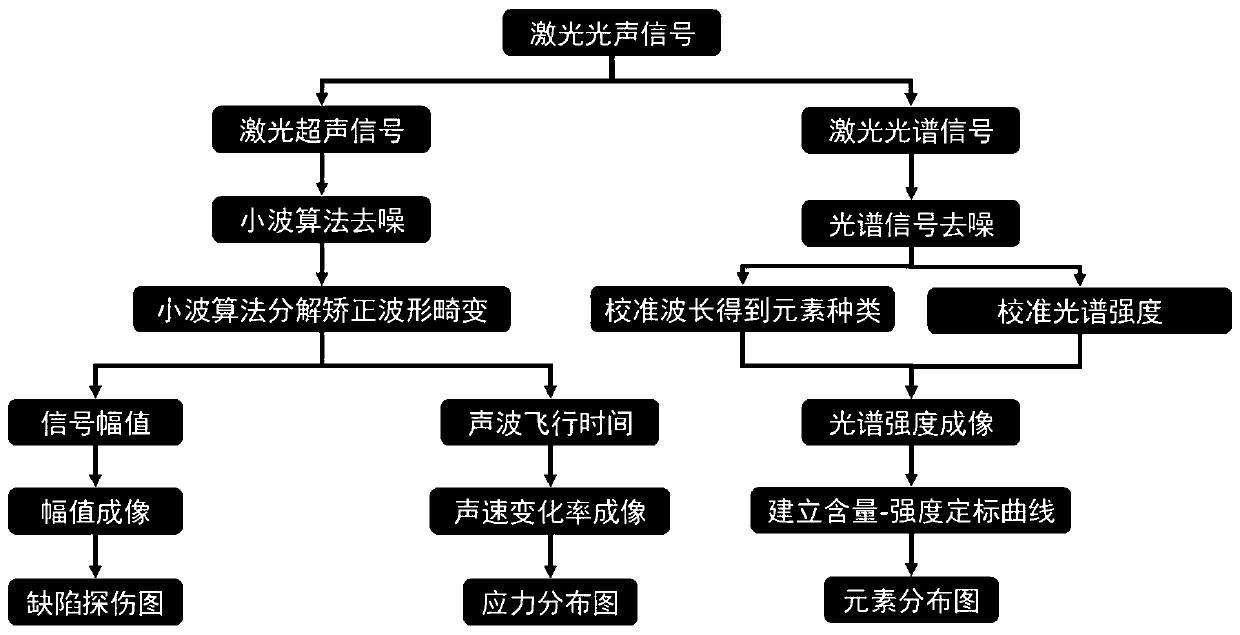

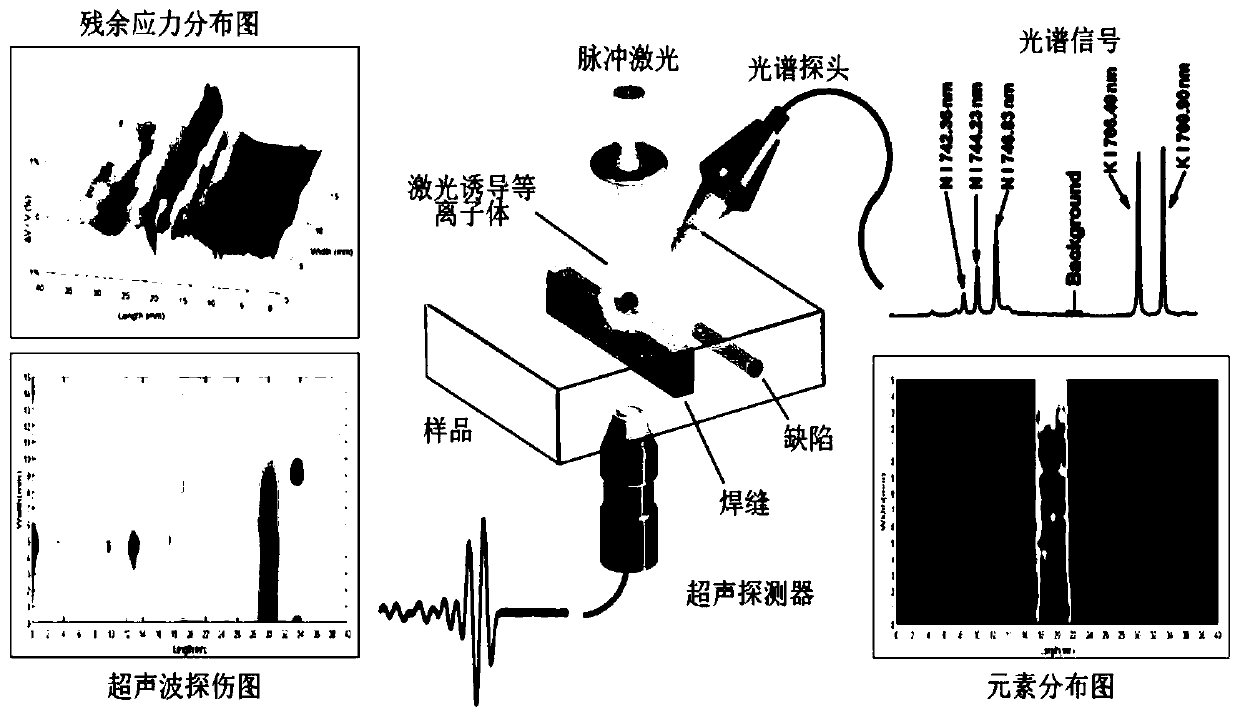

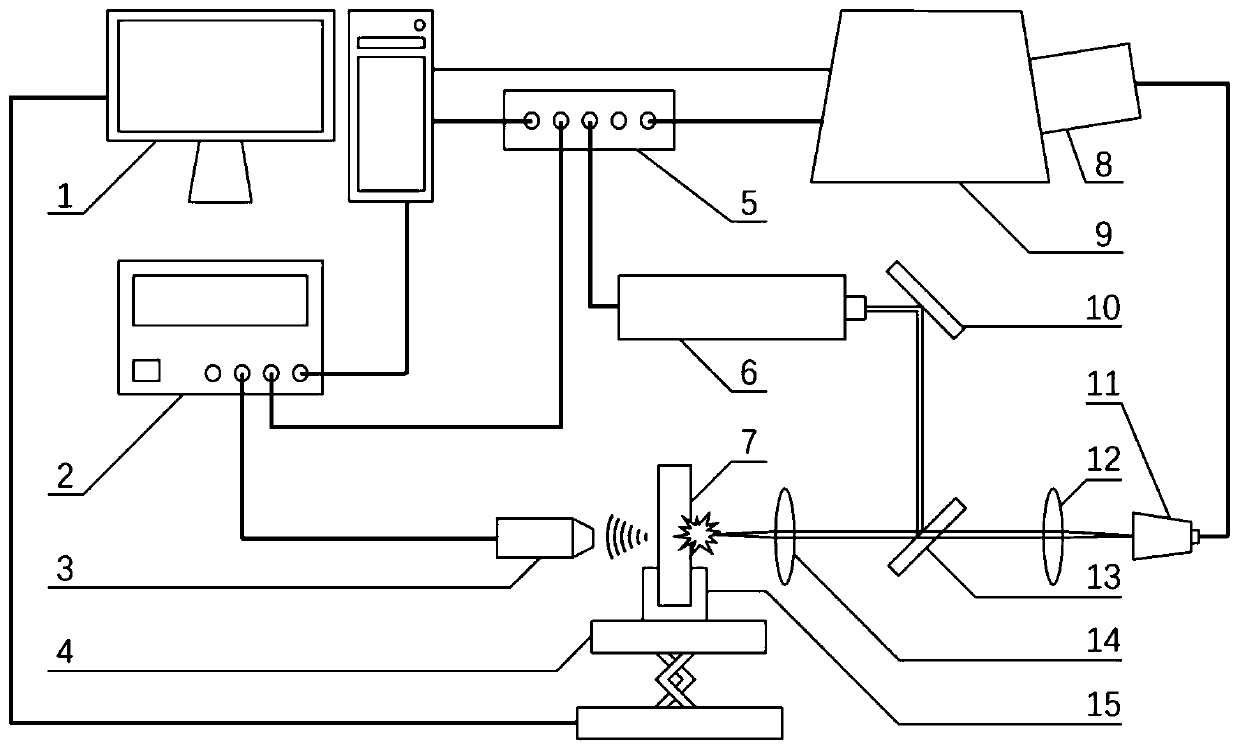

Method and device for simultaneously detecting elements, defects and residual stress

ActiveCN109990829AComprehensive parametersRealize visualizationAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansElemental compositionLighting spectrum

The invention discloses a multifunctional laser photoacoustic detection method and device for elements, defects and residual stress, and belongs to the field of laser material detection. Pulse laser is incident to the surface of a sample to be detected by utilizing a pulse laser in order to generate plasma and ultrasonic waves, and the elemental composition, the structural defects and the residualstress of the sample can be simultaneously analyzed. The detection system comprises an excitation unit, a spectrum detection unit, an ultrasonic detection unit and an analysis control unit, wherein adigital delayer is connected to a computer; a high-precision 3D displacement platform is electrically connected to the digital delayer; the pulse laser emitted by the pulse laser is modulated, focused and incident to the surface of the sample to be detected through a light path system in order to generate the plasma and ultrasonic waves at the same time; the ultrasonic detection unit is used fordetecting the ultrasonic waves; and the spectrum detection unit is used for detecting a visible light spectrum emitted by plasma flame. According to the method and the device, simultaneous detection and analysis of the elemental composition, the defects and the residual stress of the sample can be realized.

Owner:HUAZHONG UNIV OF SCI & TECH

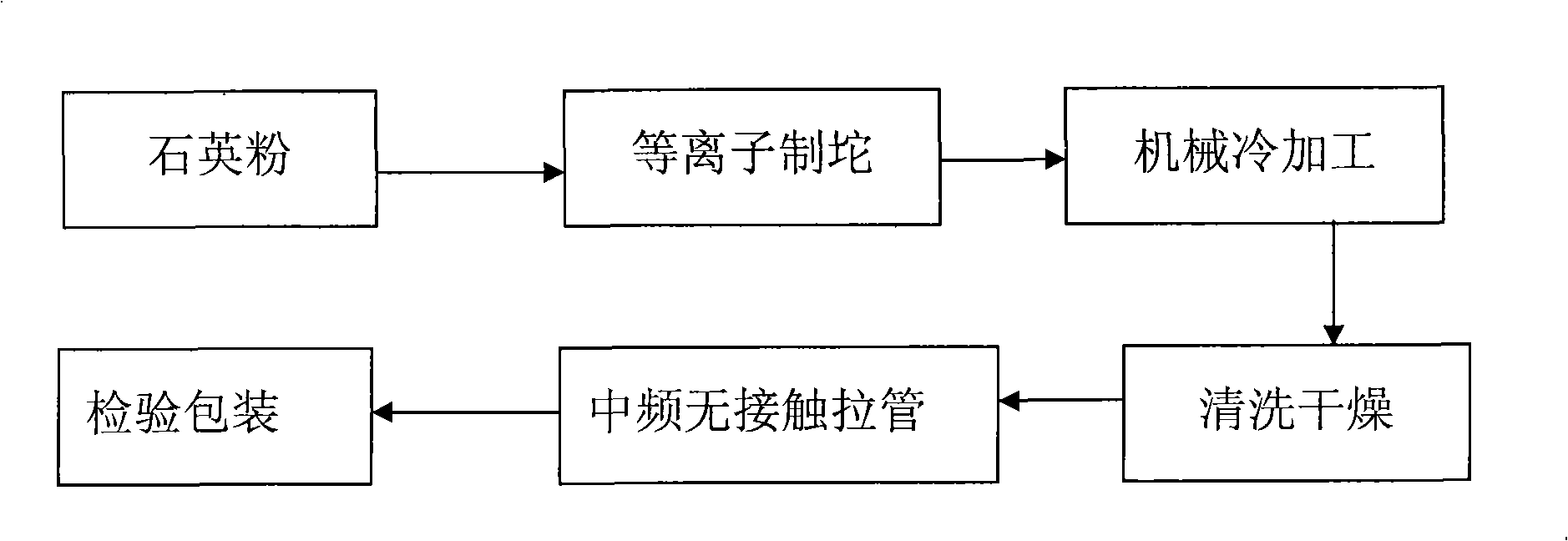

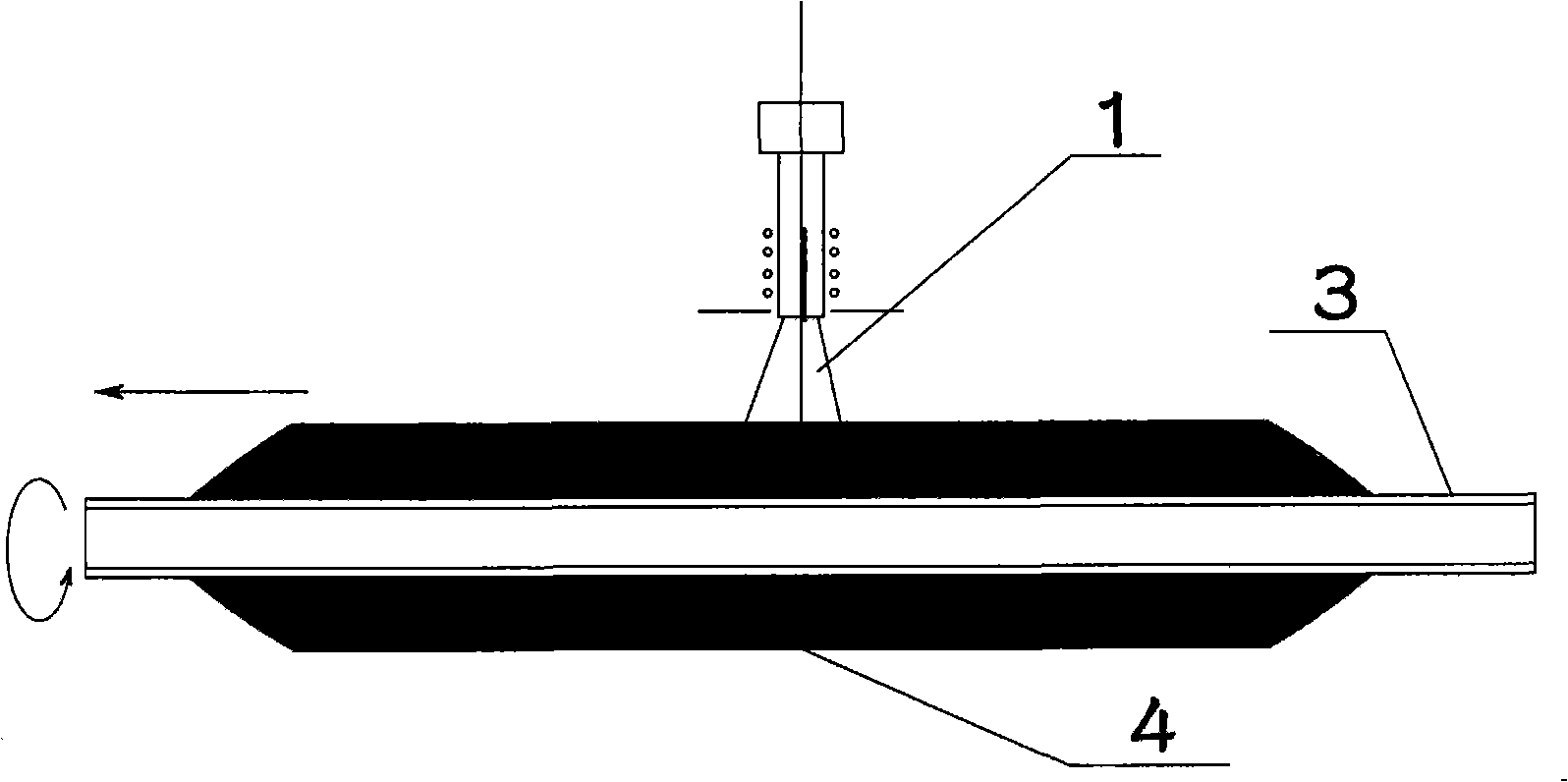

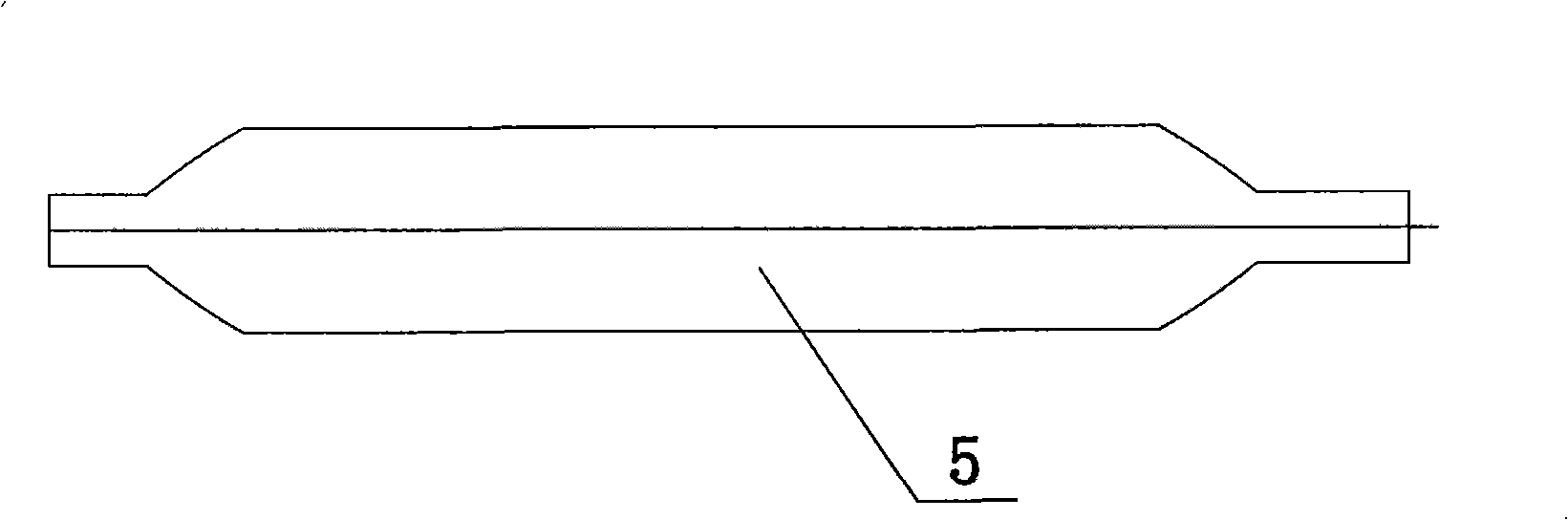

Method for producing quartz casing tube for optical fiber prefabricated stick

The invention discloses a method for producing a quartz sleeve for a fiber precast rod. The method comprises the following steps of: 1 weight manufacturing; 2 mechanical cold machining; 3 cleaning and drying; 4 tube drawing in a medium-frequency contactless mode; and 5 checkup and packaging, wherein, in step one, a weight is manufactured by adopting an external sedimentation mode of plasma horizontal type solid phase; in step two, an inner hole and an outer circle of the quartz weight are subject to the machining of grinding and honing by adopting a metal cutting machine tool matched with diamond and other grinding tools; in step three, the quartz weight is subject to degreasing, acidification, washing by pure water, drying and packaging for standby; in step four, the net quartz weight is hung in a medium-frequency furnace, heated up to a certain temperature, softened and deformed and drawn into the needed quartz sleeve by a tube drawing machine; and in step five, the quartz sleeve is checked and packaged. The method adopts plasma flame for heating and fully melts down raw materials in order that no bubble is in the gross quartz weight and can not introduce external impurities in order that melted quartz powder has high purity; the melted quartz powder has a characteristic of low hydroxyl group; secondary molding adopts medium frequency for heating and has no hydrogen and oxygen sources; and the final quartz sleeve has low hydroxyl content and good temperature resistance.

Owner:久智光电子材料科技有限公司

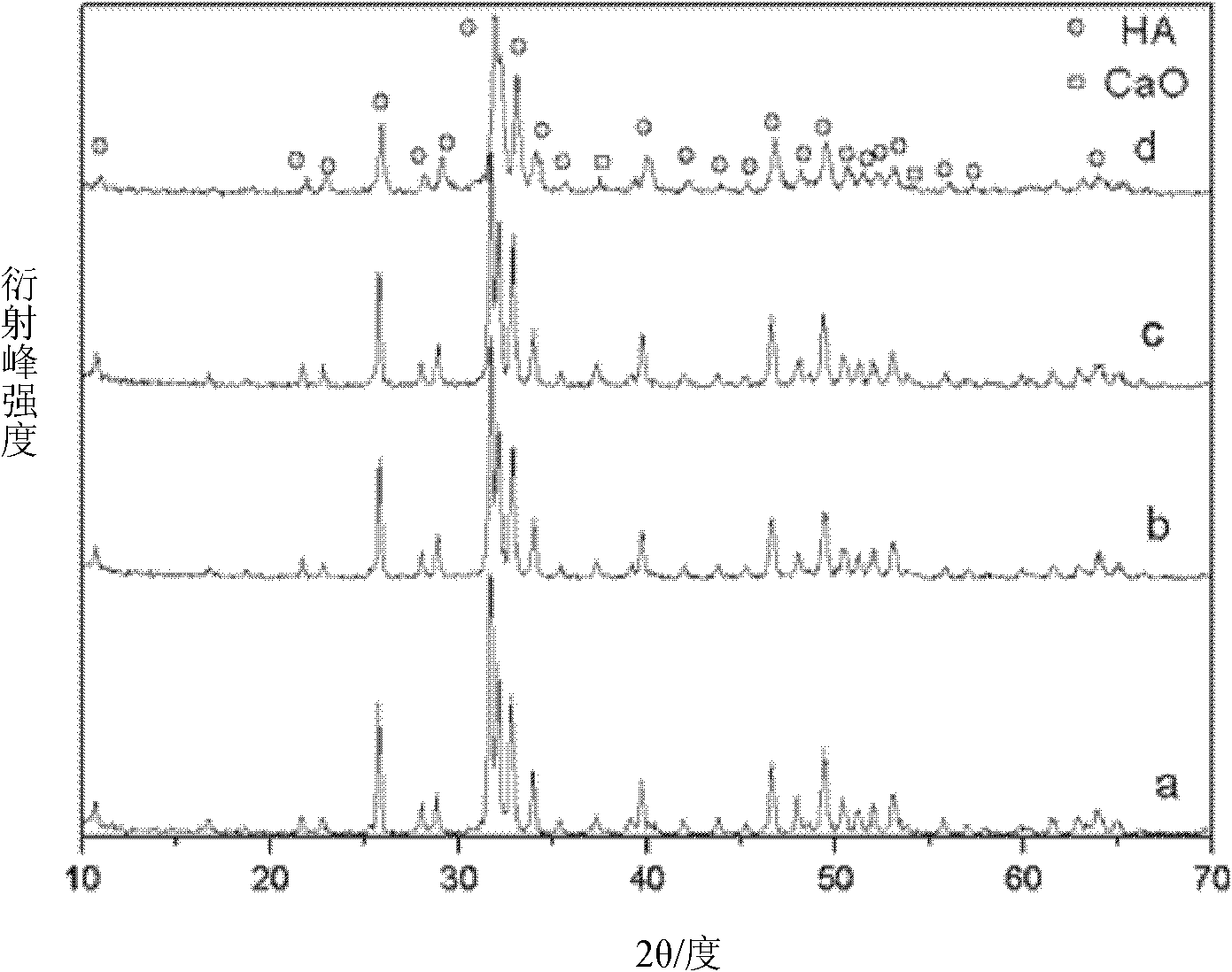

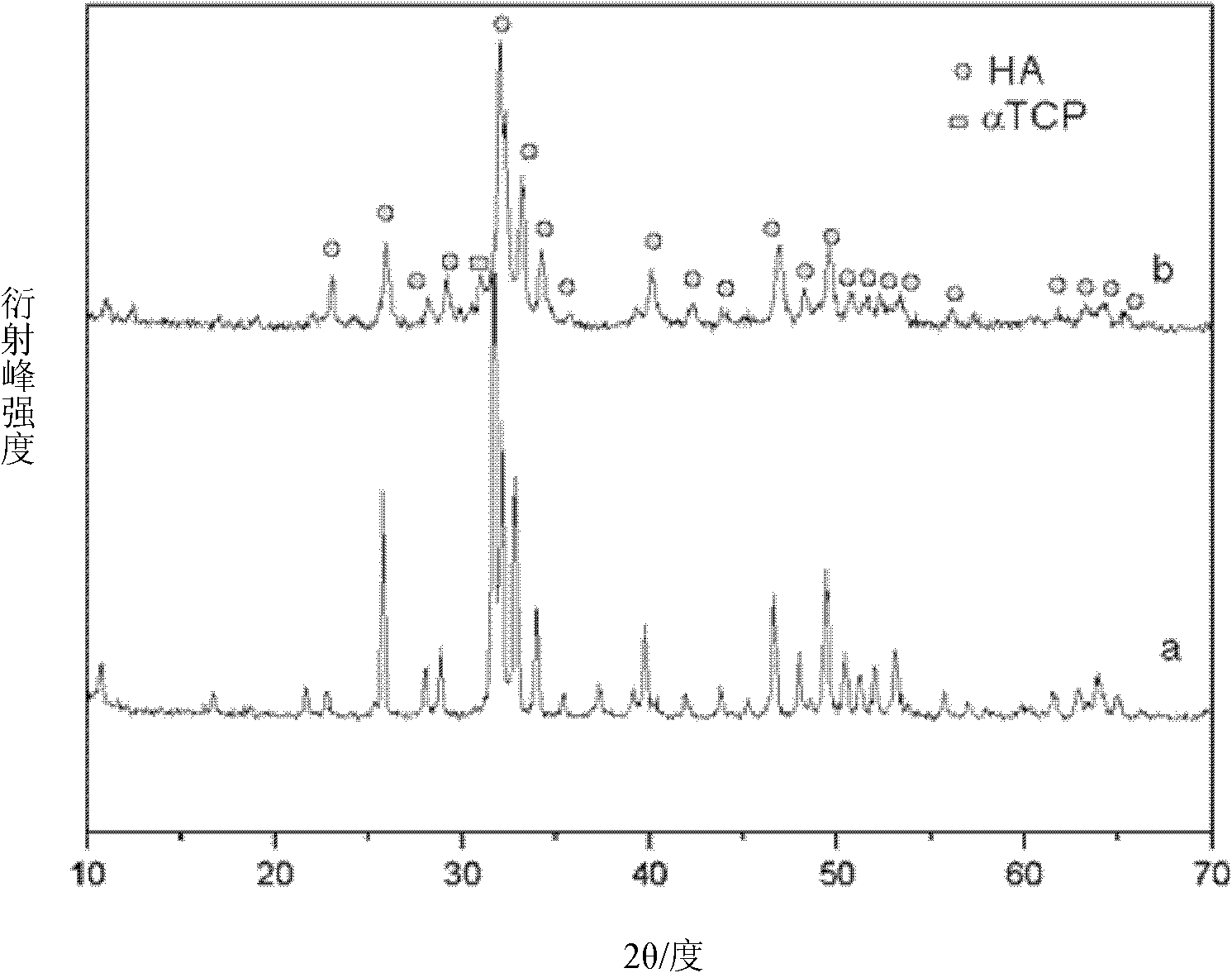

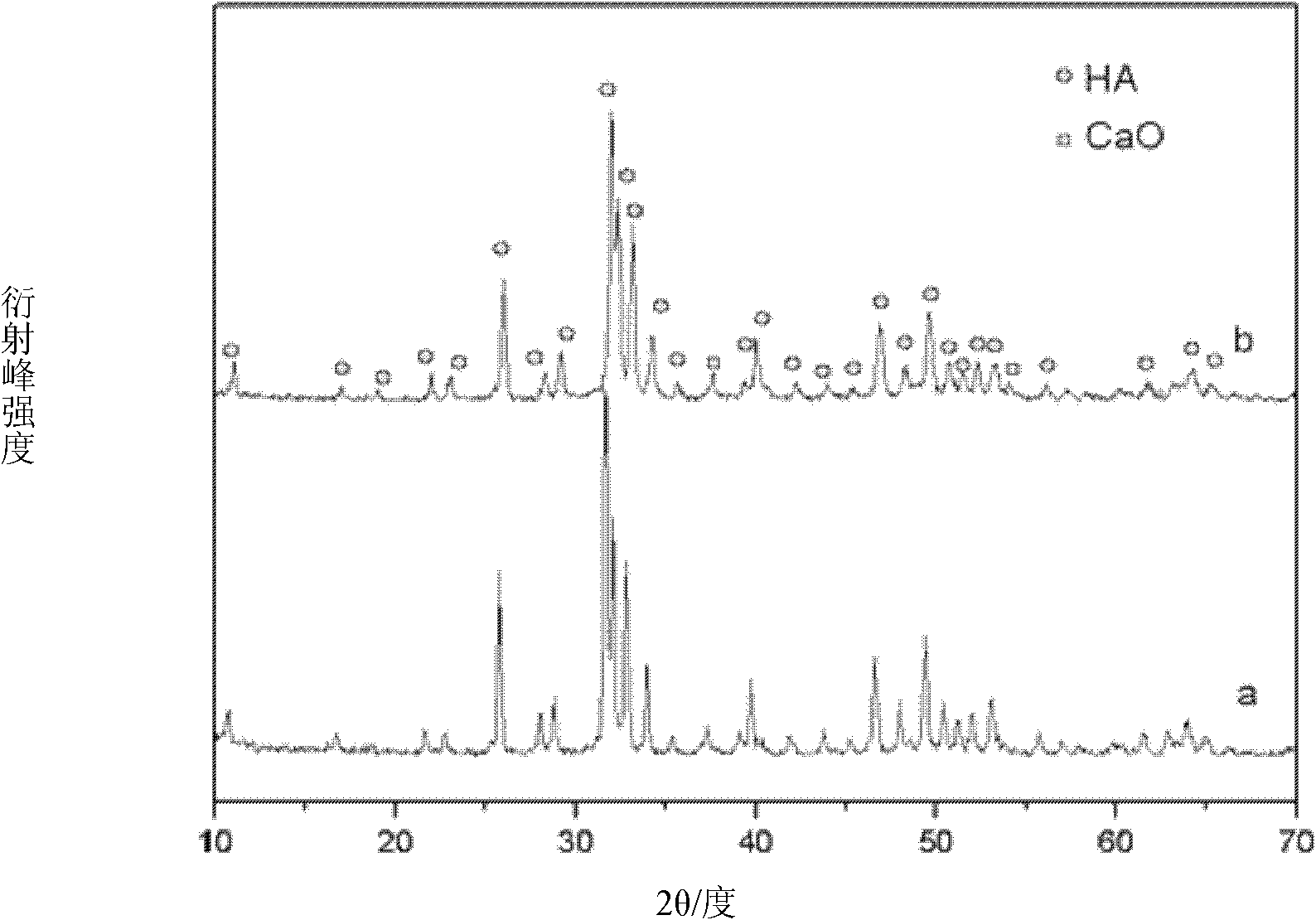

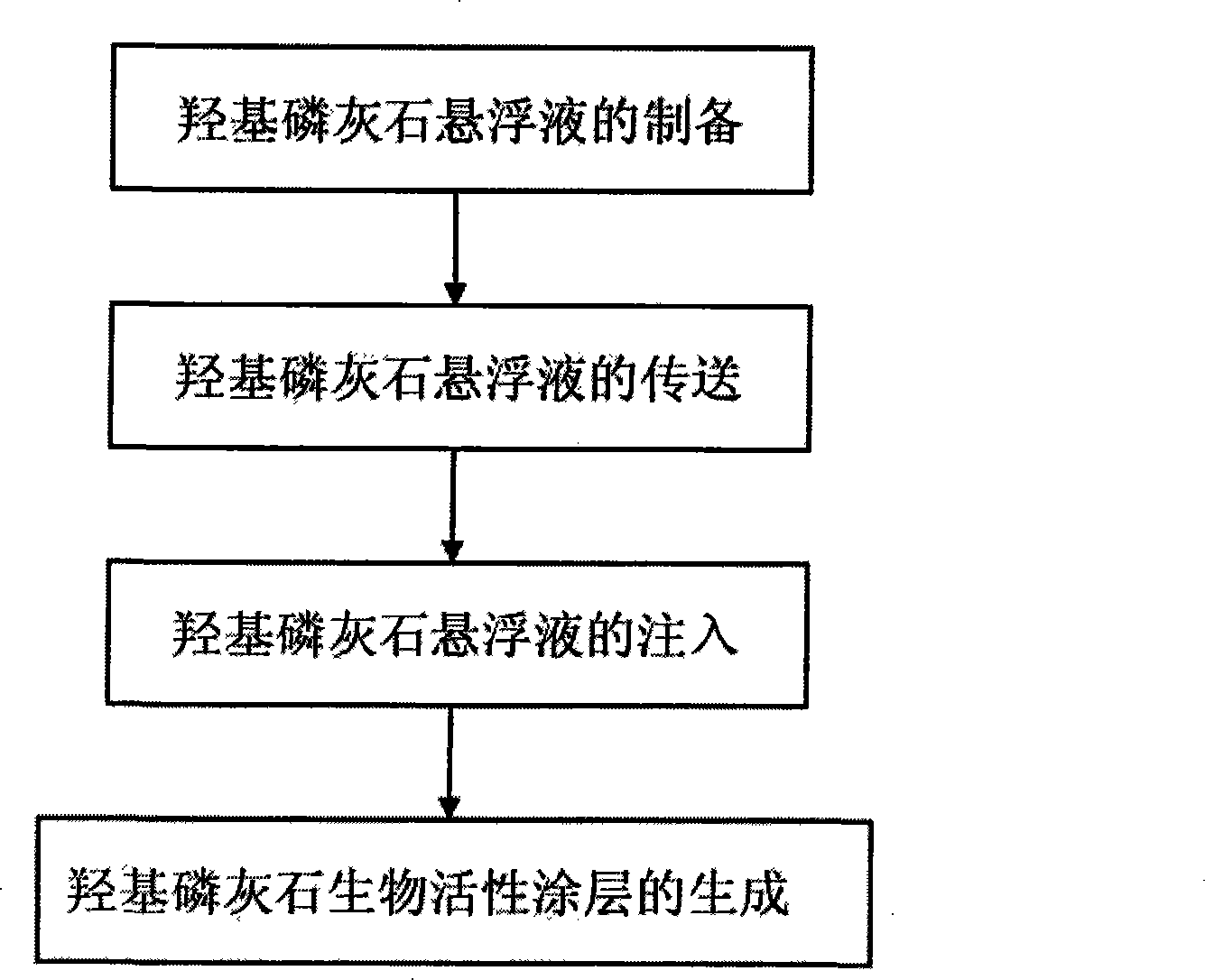

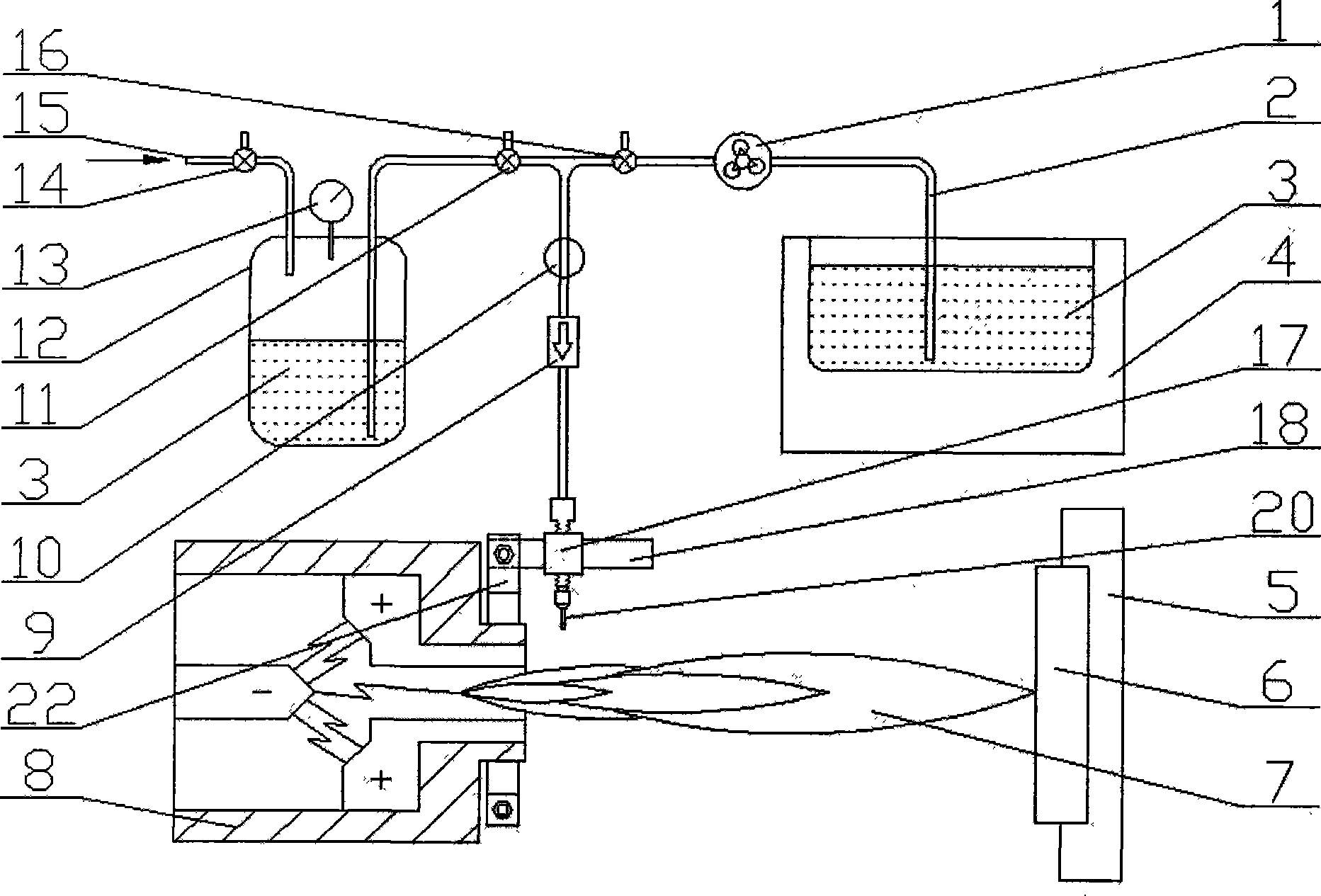

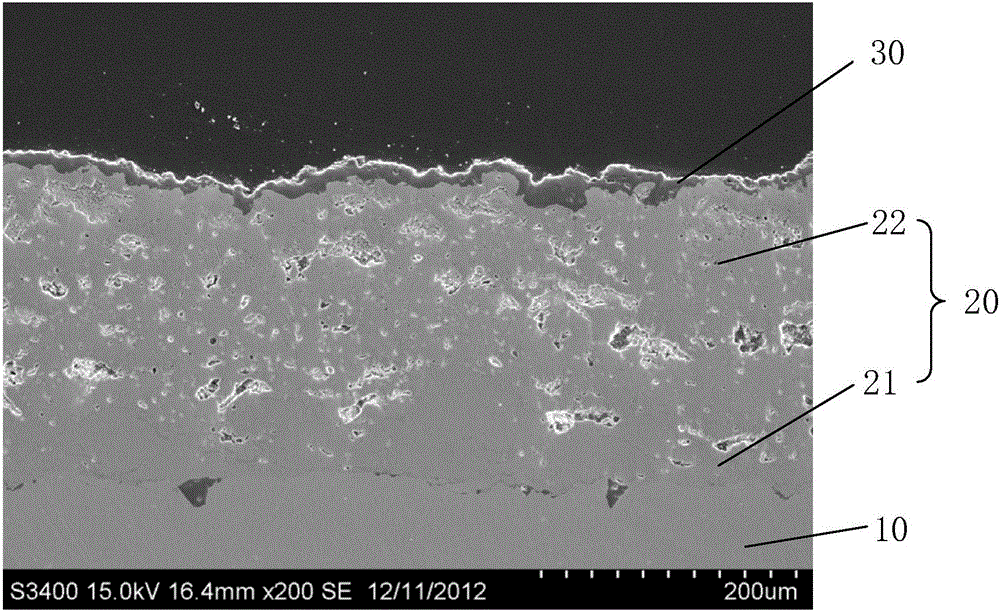

Preparation method of hydroxyapatite bioactive coating doped with trace elements

The invention belongs to the technical field of biomedical composite materials, in particular to a preparation method of a hydroxyapatite bioactive bionic coating containing trace elements. The method comprises the following steps of: firstly, reacting raw materials for preparing hydroxyapatite containing the trace elements according to the proportion at a certain temperature to obtain a suspension; and then transmitting the suspension as a precursor liquid to a high-temperature area of plasma flame and directly spraying the suspension on a biomedical metal substrate to form the hydroxyapatite coating containing the trace elements. The invention has simple process and low production cost; and the obtained hydroxyapatite coating contains the trace elements such as silicon, magnesium and the like closer to human bony bionic components and has better osteogenesis capability and important application value.

Owner:SICHUAN UNIV

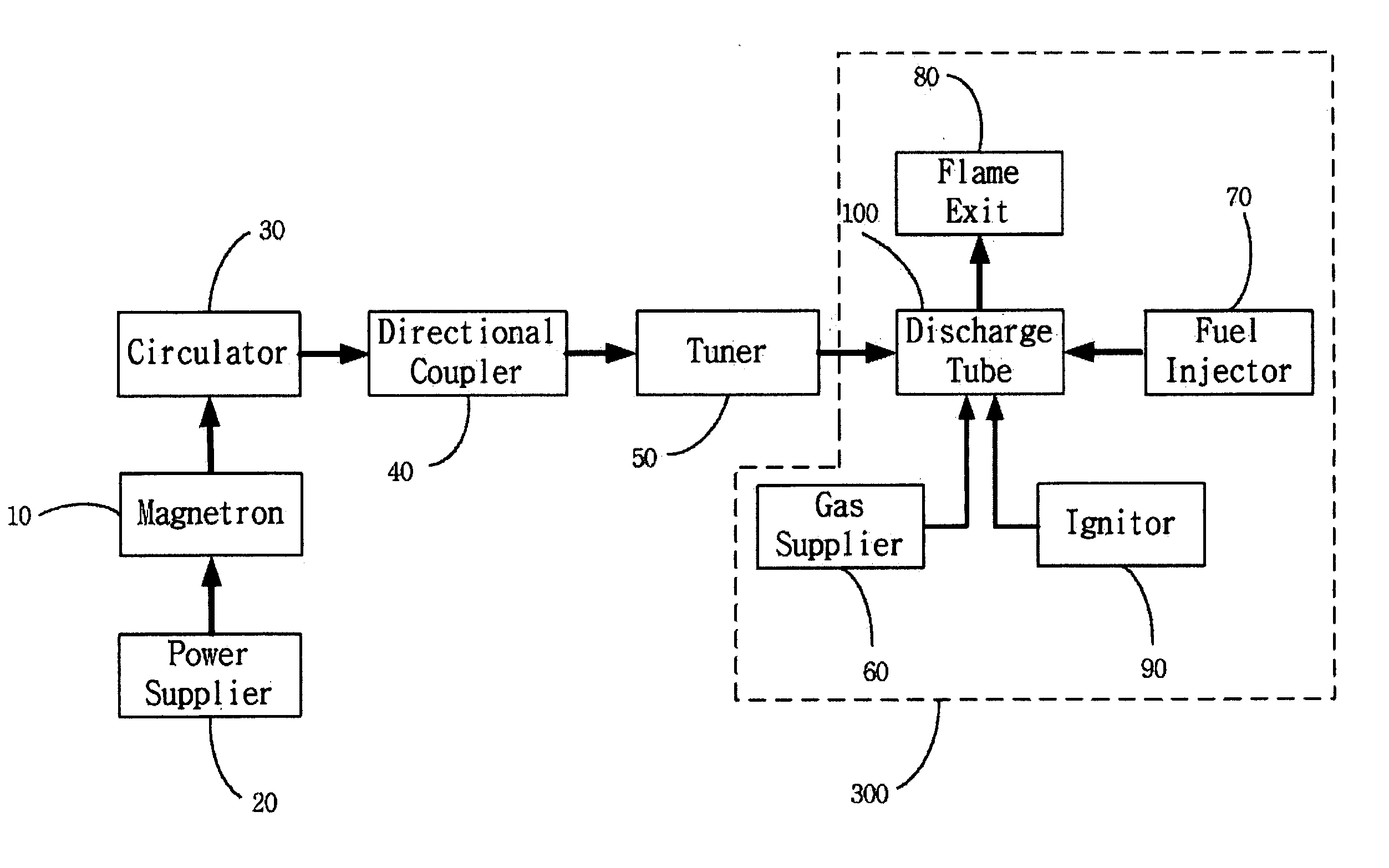

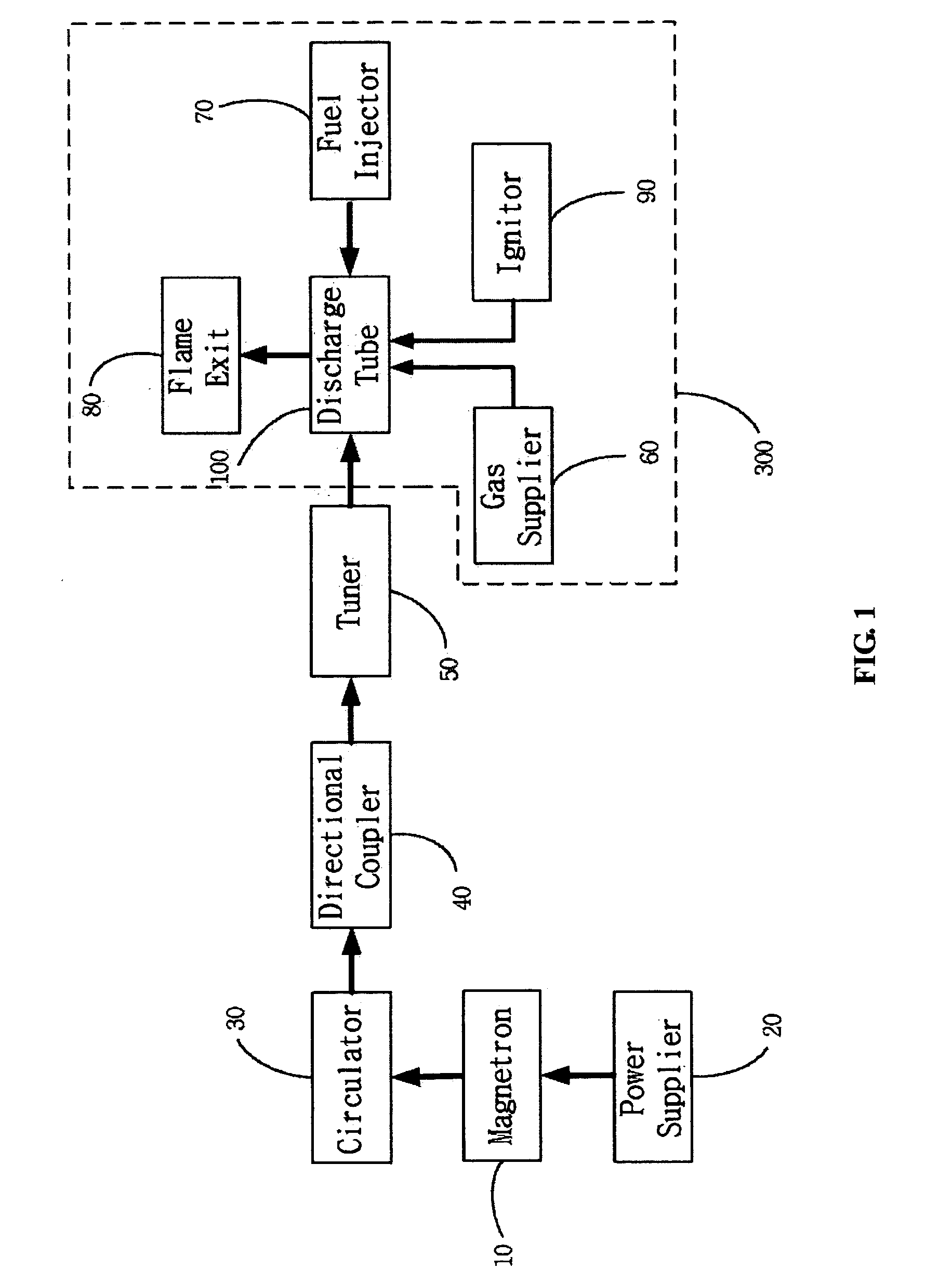

Microwave plasma burner

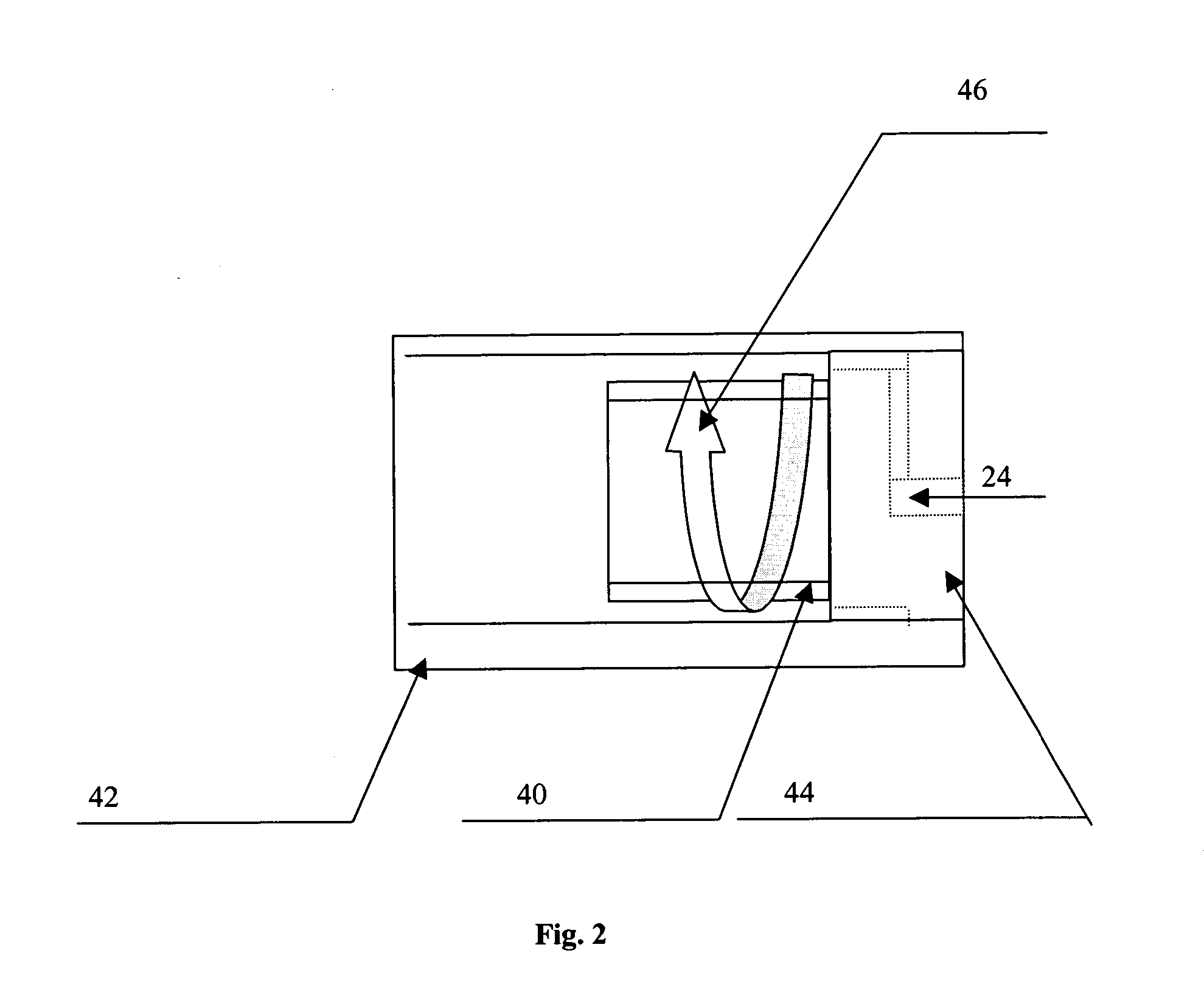

InactiveUS20070007257A1Protecting publicIncrease temperatureArc welding apparatusPlasma techniqueEngineeringWaveguide

The present invention relates to an apparatus for generating flames and more particularly to the microwave plasma burner for generation of high-temperature plasma flame by injecting gaseous, liquid or solid-powder hydrocarbon-fuels into plasma generated by microwaves. The invention provides a compact and portable apparatus for generating plasma flame. The apparatus includes a magnetron, an electrical power supplier, a waveguide system, a microwave power monitering system, stub tuners, a discharge tube, a gas supply system, a plasma ignitor and a fuel supply system. The method and apparatus is described for generation of a large volume of high-temperature plasma by injecting gaseous, liquid or solid-powder hydrocarbon-fuels into the microwave plasma torch to decompose the hydrogen and carbon containing fuels, and to mix the resultant gaseous hydrogen and carbon compounds with air or oxygen gas, instantaneously generating a large volume of high-temperature flames.

Owner:UHM HAN S

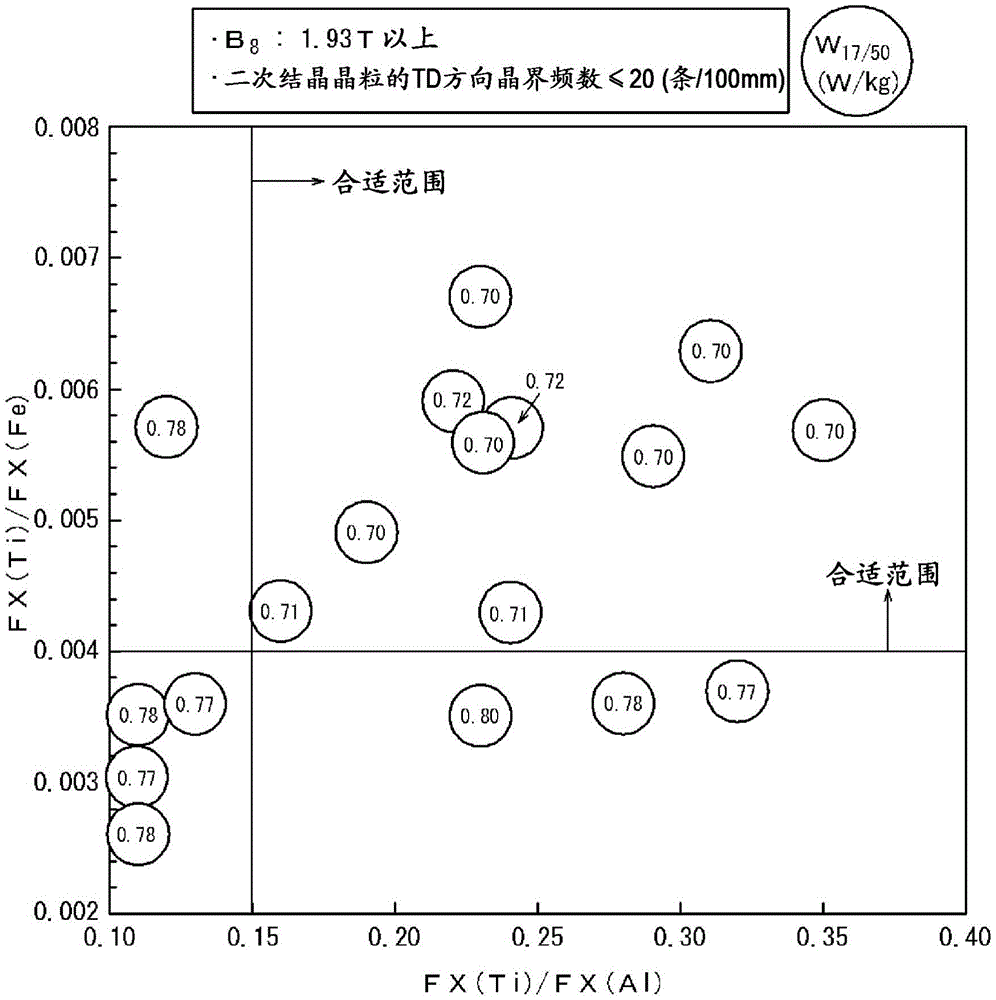

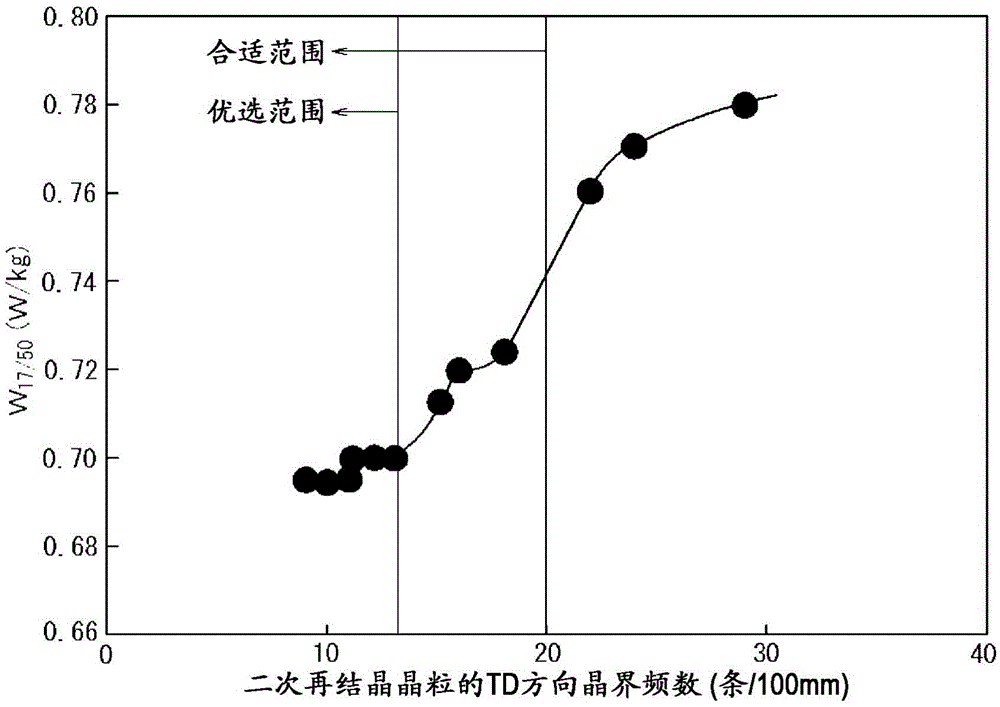

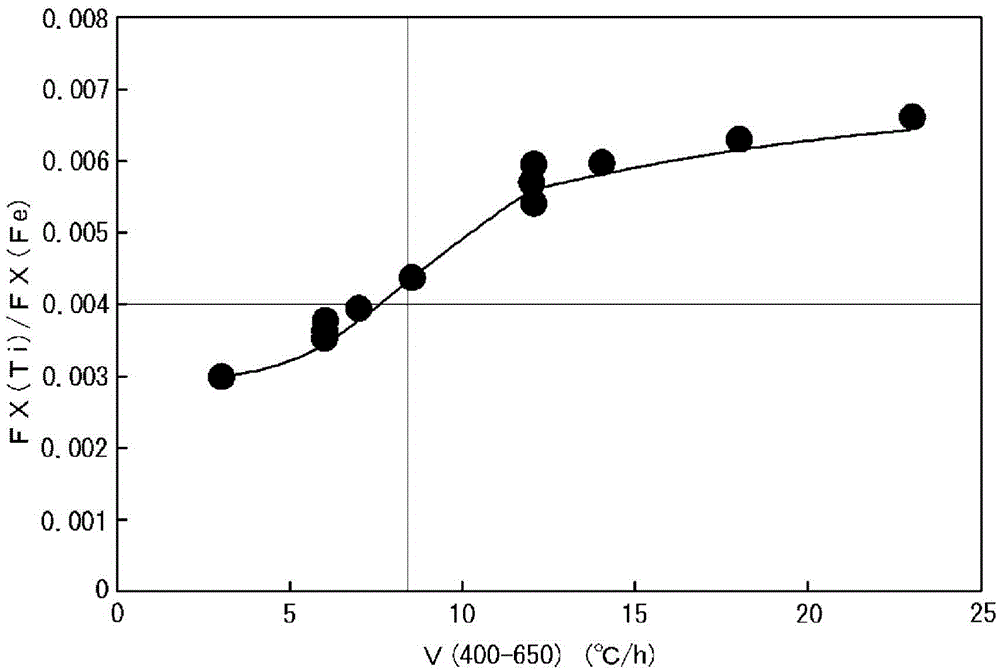

Grain-oriented electromagnetic steel sheet, and manufacturing method therefor

ActiveCN105555984AExcellent adhesionReduce iron lossInorganic material magnetismFurnace typesSheet steelX-ray

A grain-oriented electromagnetic steel sheet having a forsterite base film and an insulating tension coating on the surface thereof, wherein if magnetic domain refinement processing is performed by using a laser beam, a plasma flame, or electron beam irradiation, a sufficient iron loss reduction effect is achieved within a range in which film peeling does not occur, said effect being achieved by: the relationships FX(Ti) / FX(Al) >= 0.15 and FX(Ti) / FX(Fe) >= 0.004 being satisfied if FX(Ti) is Ti strength, FX(Al) is Al strength, and FX(Fe) is Fe strength when the surface has been quantitatively analysed by X-ray fluorescence analysis; furthermore, the grain boundary frequency of secondary recrystallised grains in the direction perpendicular to rolling being 20 boundaries / 100 mm or less; and moreover, the relationship t(Fo) / t(C) >= 0.3 being satisfied if t(Fo) is the average thickness of the forsterite base film and t(C) is the thickness of the insulating tension coating.

Owner:JFE STEEL CORP

Laser photoacoustic compound detection method for elements and defects and system thereof

InactiveCN107607520AImprove detection efficiencyLow costAnalysis by thermal excitationOptically investigating flaws/contaminationLighting spectrumPlasma flame

Belonging to the laser material detection field, the invention discloses a laser photoacoustic compound detection method for elements and defects and a system thereof. A pulsed laser is incident to ananalysis sample to generate plasma and ultrasonic wave for simultaneous analysis of sample elementary composition and structural defects. The detection system comprises the pulsed laser, a spectrum detection unit, an ultrasonic detection unit, a sample stage unit and an analysis control unit. The analysis control unit comprises a digital time delayer and a computer, the digital time delayer is connected to the computer, the sample stage unit includes a 3D displacement platform, the 3D displacement platform s electrically connected to the digital time delayer, pulse laser emitted by the pulsedlaser is incident to a to-be-analyzed sample to produce plasma and ultrasonic wave simultaneously, the ultrasonic detection unit is used for detection of ultrasonic wave, and the spectrum detection unit is used for detection of a visible light spectrum emitted by plasma flame. The method and device provided by the invention can realize detection and analysis of sample elements and defects simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

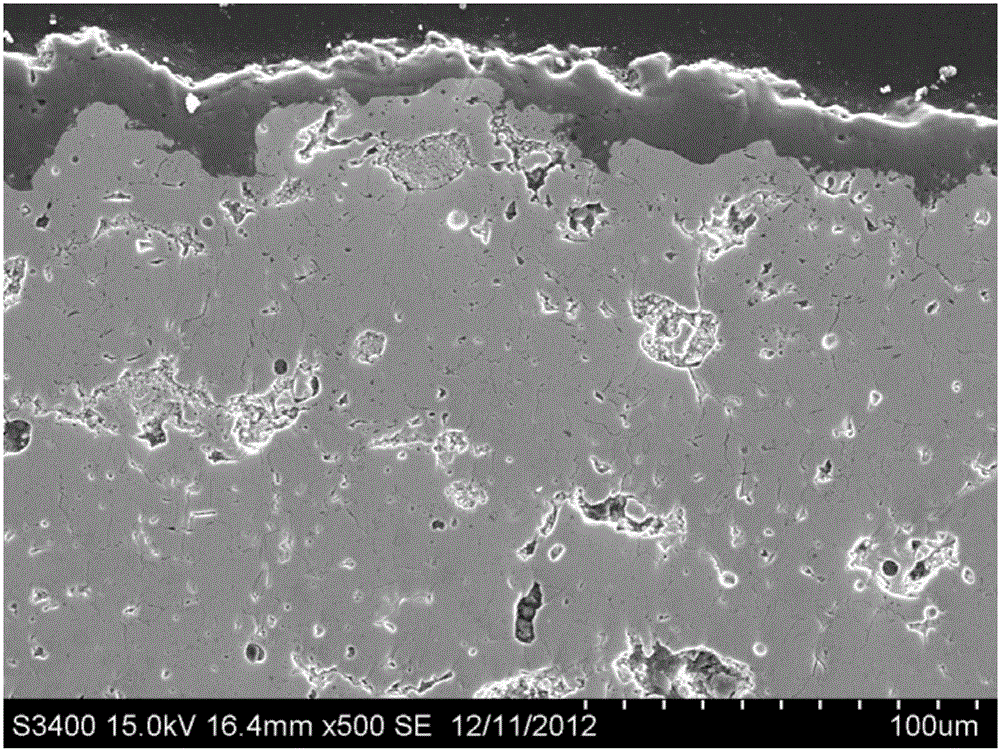

Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

InactiveCN101250681AIncrease productivityReduce manufacturing costMolten spray coatingProsthesisPeristaltic pumpApatite

The invention relates to a method for spraying suspending liquid plasma to prepare hydroxyapatite bioactive coating, which comprises following steps: adopting hydroxyapatite suspending liquid as plasma spraying raw materials, adopting a pressure tank or an electronic peristaltic pump as a power transmitting device to transmit the hydroxyapatite suspending liquid, adopting an atomizing nozzle with a small angle to inject the hydroxyapatite suspending liquid into a central region of plasma flame directly and radially or adopting a duct with small diameter to inject the hydroxyapatite suspending liquid into the central region of the plasma flame directly and radially in a linear type jet-flow mode, exchanging heat between the suspending liquid and high temperature plasma flame through transmitting and injecting the suspending liquid, and directly generating the hydroxyapatite bioactive coating on the surface of a biological medical metal base through vaporizing liquid in the suspending liquid, crushing particles, smelting and depositing. The method simplifies a tedious technological link for preparing the spraying raw materials in a method for spraying powder plasma, the spraying raw materials and energy are saved, and the structural homogeneity of the hydroxyapatite bioactive coating which is prepared is good.

Owner:SICHUAN UNIV

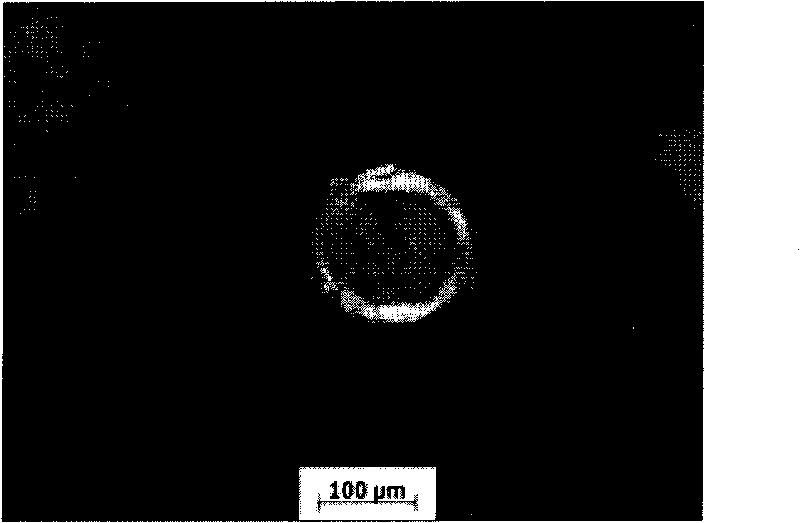

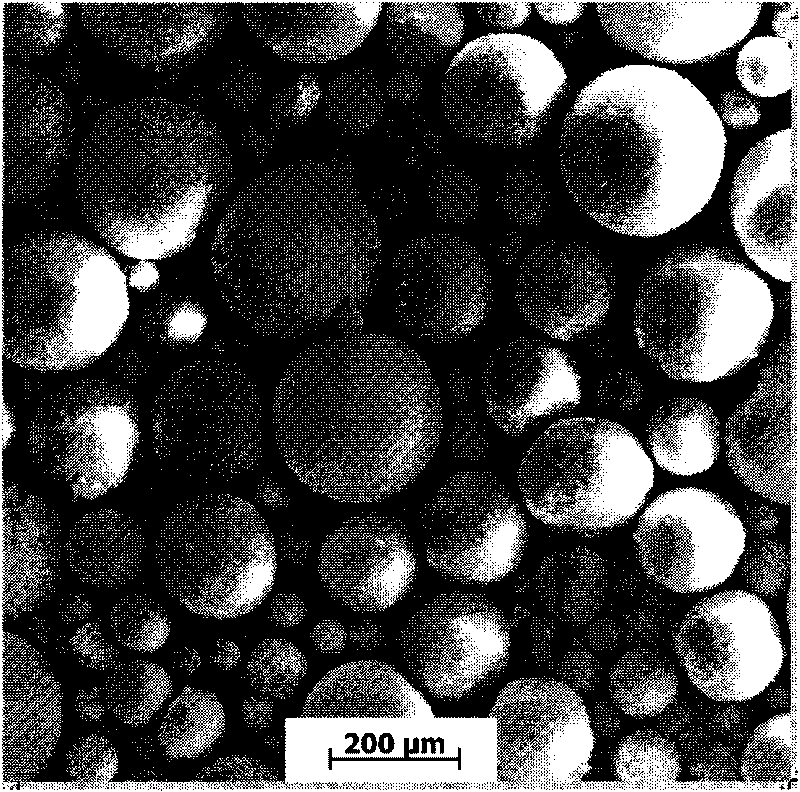

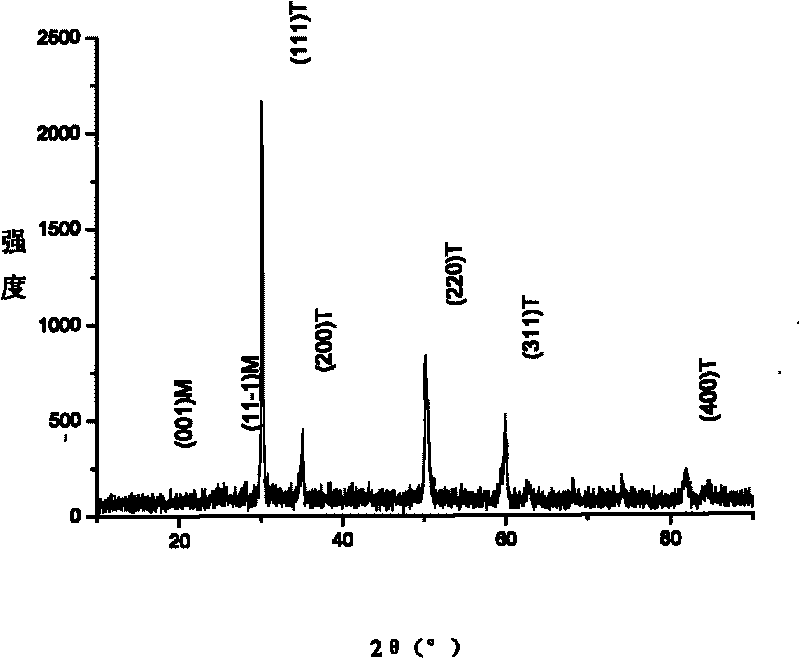

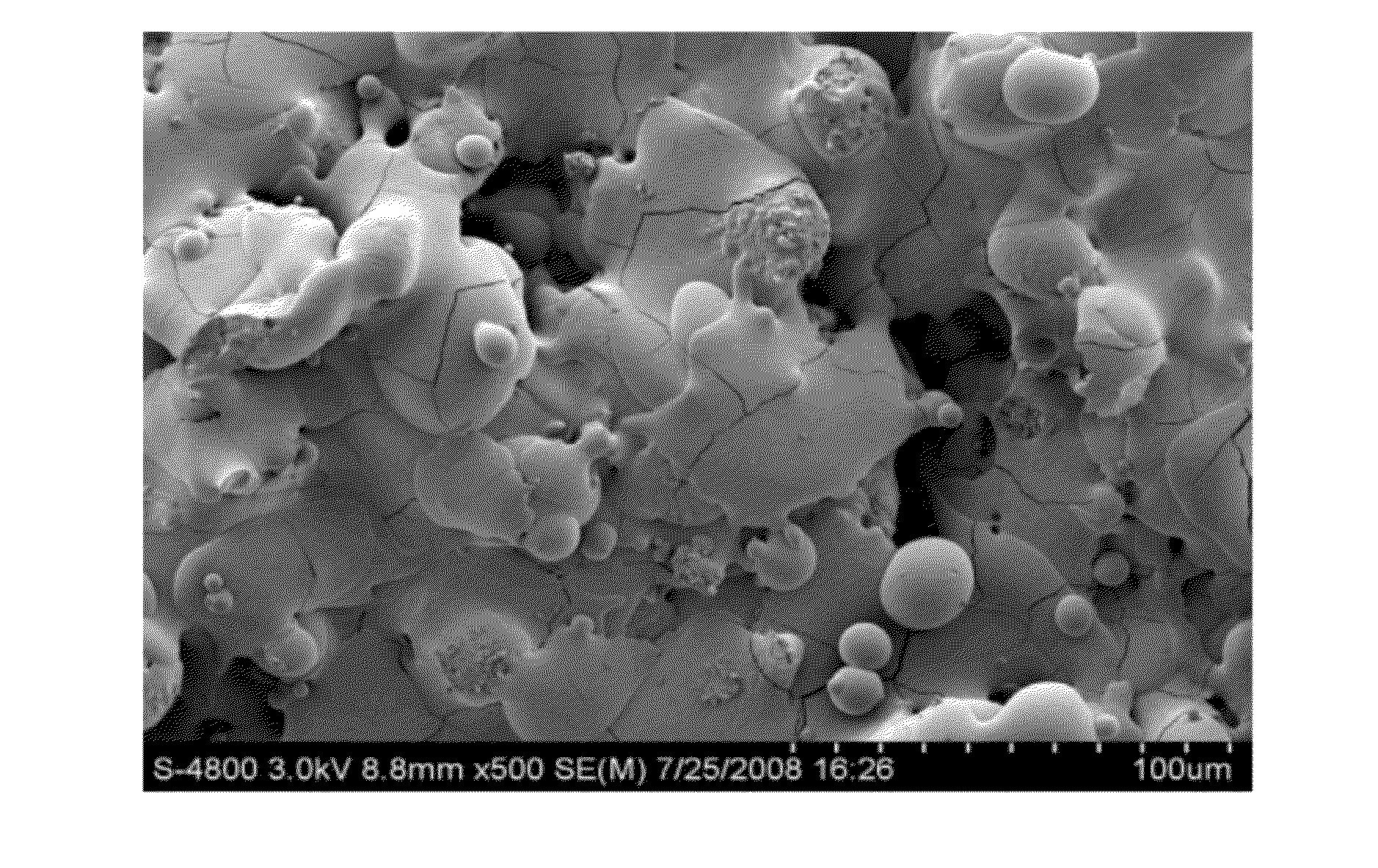

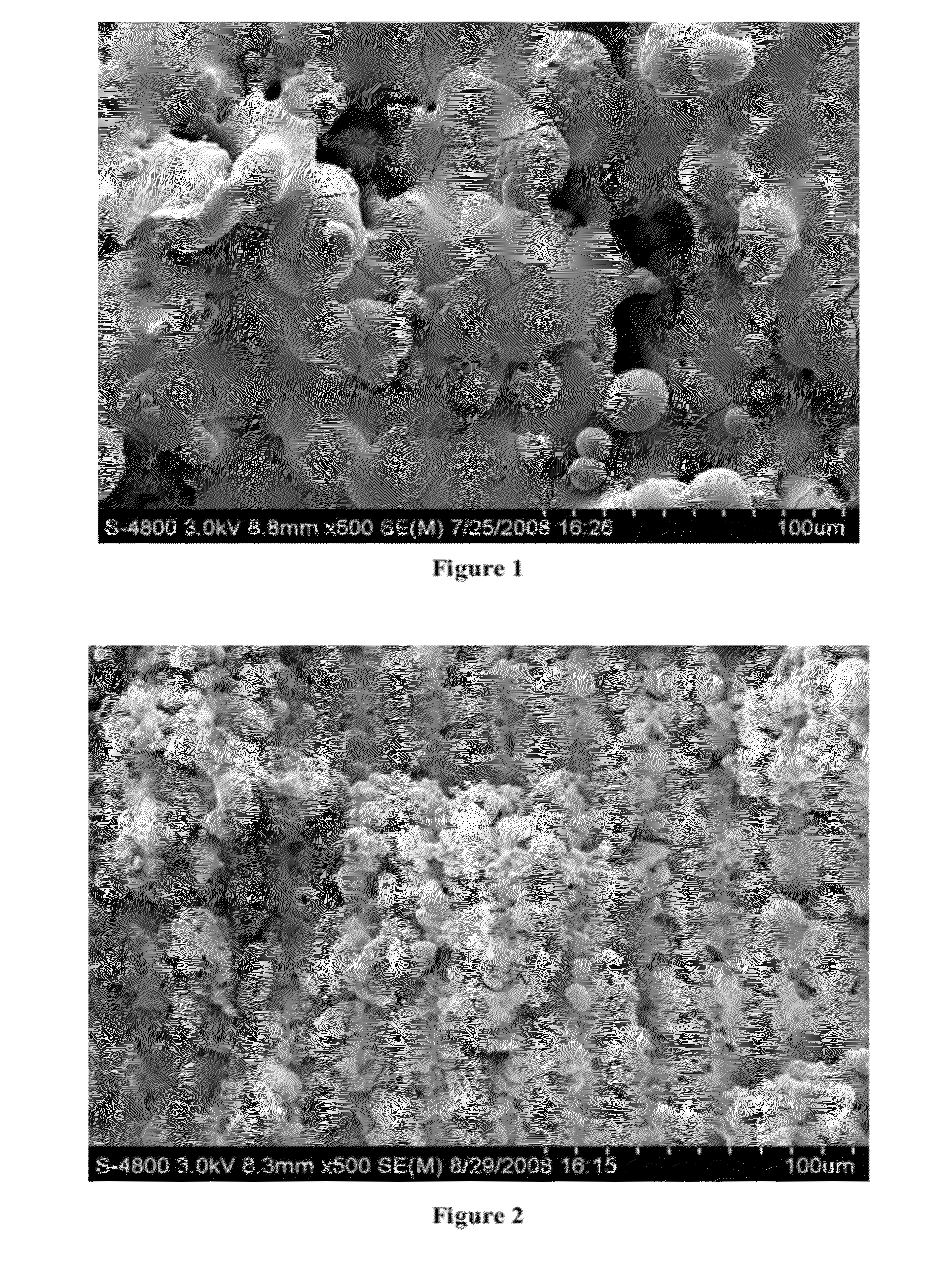

Preparation method of yttrium oxide-stabilized zirconium oxide powder with hollow spherical nanostructure

The invention provides a preparation method of yttrium oxide-stabilized zirconium oxide powder with hollow a spherical nanostructure, belonging to the technical field of material preparation. The method comprises the steps of: taking noncrystal yttrium oxide-stabilized zirconium oxide powder with an amorphous phase structure as raw materials; heating with over-distance plasma flame; collecting by means of water cooling; and drying with low temperature to prepare the yttrium oxide-stabilized zirconium oxide powder with the hollow spherical nanostructure. The prepared powder has the characteristics of low fill density and high fluidity, and the like, and the microstructure is the nanocrystalline hollow spherical nanostructure, therefore, the powder is particularly suitable for a plasma spraying technology to prepare a high-temperature abrasion-resistant good-sealing coating, has simple technological process and high technology content, and can be produced in batch. Meanwhile, the powder material also can be used for the other spraying technologies (such as a hypersonic flame spraying technology and a detonation spraying technology) to prepare an oxygen sensor coating, an oxygen separation membrane, a fuel battery coating, and the like, and can be used for the fields of aerospace, precise instrument, petroleum and electron, etc.

Owner:GRIPM ADVANCED MATERIALS CO LTD

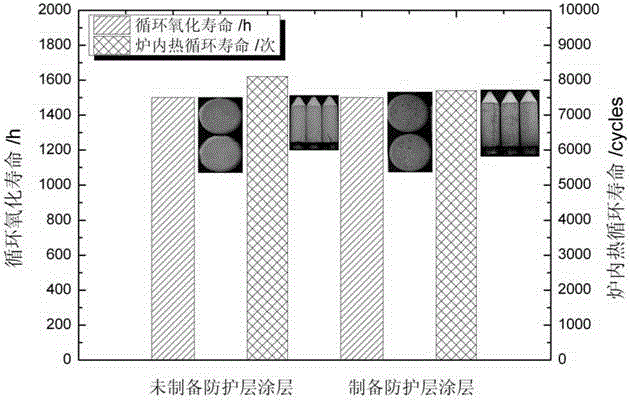

Protective coating for molten sediment on surface of thermal barrier coating and preparation method thereof

InactiveCN106191752AImprove thermal cycle lifeDelayed infiltration reactionMolten spray coatingSuperalloyThermal barrier coating

The invention discloses a protective coating for molten sediment on the surface of a thermal barrier coating and a preparation method thereof. The thermal barrier coating comprises at least one bonding layer and at least one ceramic layer, the surface of a high-temperature alloy matrix is coated with the bonding layers, and the surfaces of the bonding layers are coated with the ceramic layers. The ceramic layers making contact with the bonding layers are yttrium-oxide-based partially stabilized zirconium oxide layers. The surfaces of the ceramic layers are further coated with the protective coating. The protective coating is prepared from aluminum-oxide-based spraying powder through a supersonic-speed plasma spraying technique. The preparation method of the protective coating includes the steps of drying of the aluminum-oxide-based spraying powder, workpiece clamping, parameter adjustment, even preheating of the surface of the thermal barrier coating through plasma flames generated by a spray gun of ultrasonic-speed plasma spraying equipment, starting of powder feeding, and forming of the protective coating by spraying the aluminum-oxide-based spraying powder to the surface of the thermal barrier coating one to three times.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Method for preparing porous hydroxyapatite coatings by suspension plasma spraying

InactiveUS20120052183A1Good biological propertiesSimple methodMolten spray coatingPharmaceutical containersDecompositionApatite

The present invention relates to a preparation method for porous hydroxyapatite coatings. In particular, it is a method of using suspension plasma spraying to prepare porous hydroxyapatite coatings, which belongs to the technical field of biomedical material preparations. The present invention added a pore-forming agent into the hydroxyapatite suspension with a solid content of 16%-45%. After full stirring, the feedstock materials for plasma spraying were transferred into the injection system, and injected into the high temperature area of the central plasma flame. Then, the feedstock materials made the heat exchange with the high plasma flame of plasma spraying gun. Then the sprayed raw materials were subjected to breakup and refinement of the droplets, solvent evaporation, the decomposition and gasification of the pore-forming agent and melting of feedstock materials. Finally, the porous hydroxyapatite coatings are directly deposited onto the substrate surfaces of the biomedical materials.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com