Cantilever type numerical control plasma flame structural steel three-dimensional cutting machine

A plasma and cutting machine technology, used in gas flame welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of cumbersome use process, inaccurate positioning during cutting process, low cutting efficiency, etc., and achieves simple and convenient operation. The effect of good running stability and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

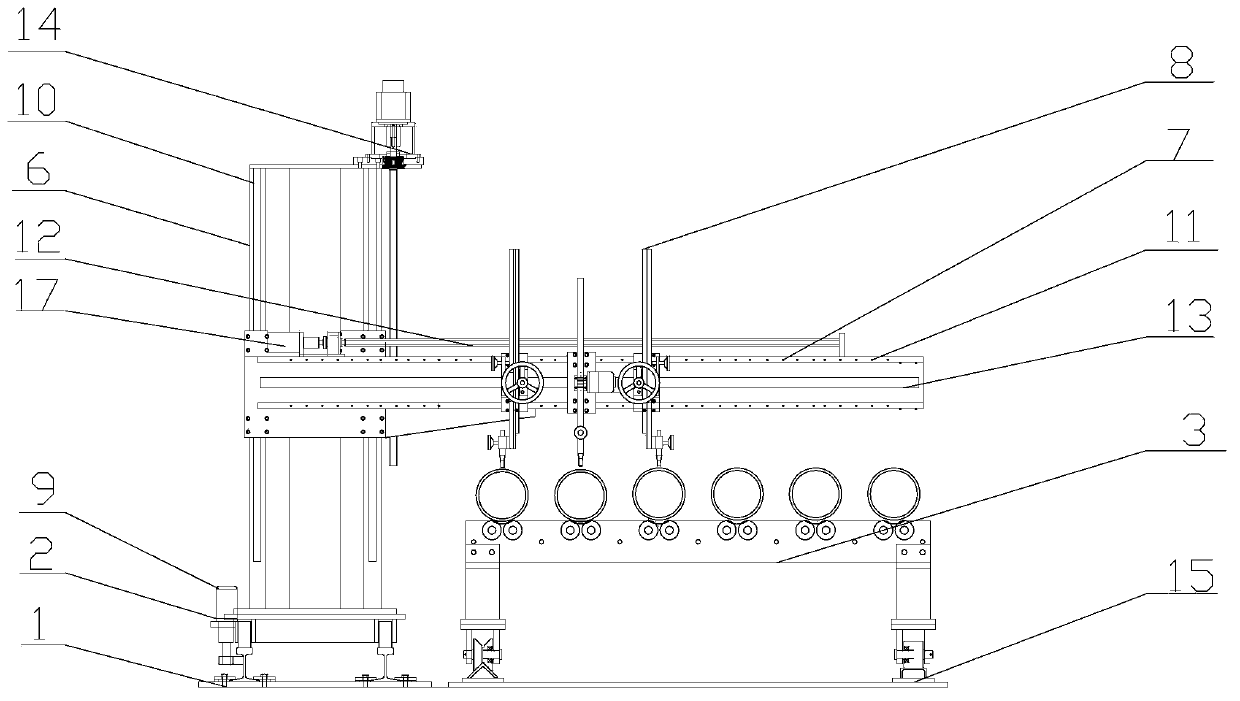

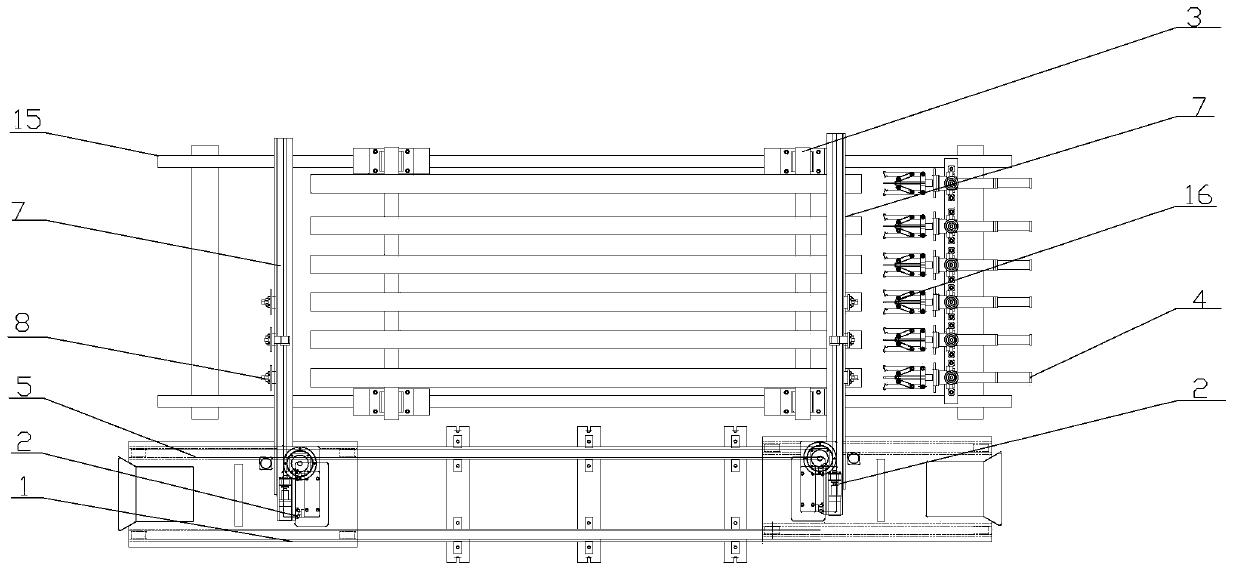

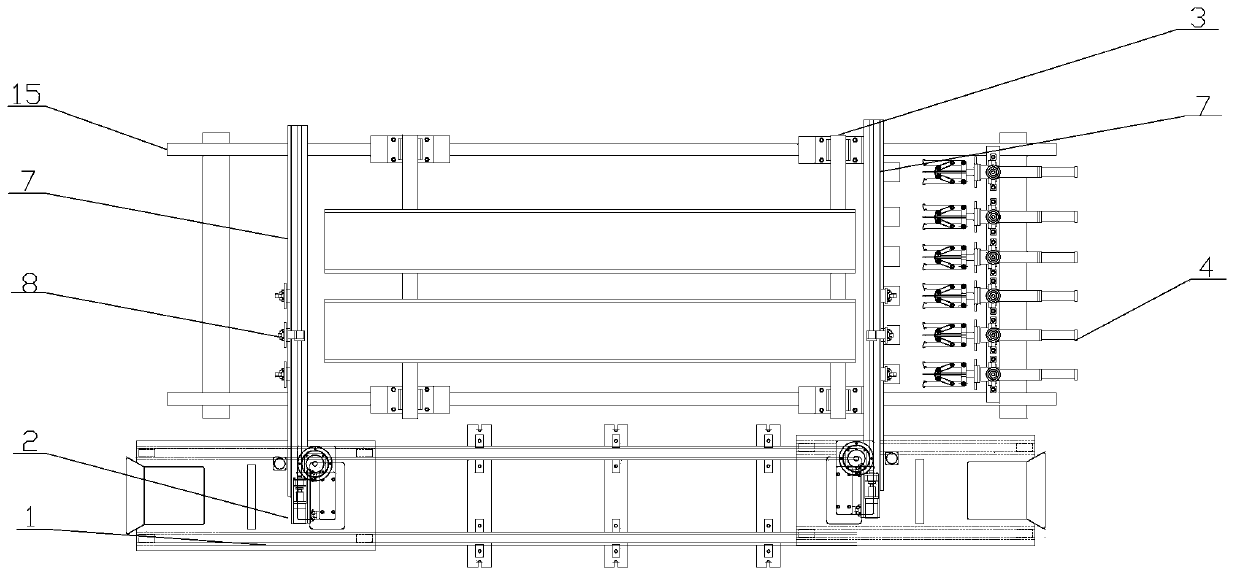

[0021] see figure 1 and figure 2 , a cantilever type CNC plasma flame-shaped steel three-dimensional cutting machine, including two parallel Y-axis guide rails 1, two movable CNC cutting hosts 2 placed on the Y-axis guide rails 1, a roller turning material rack for placing steel pipes 3, and a design Pneumatic clamping and indexing device 4 at one end of the roller turning rack 3; the CNC cutting host 2 includes a traveling trolley 5, a column 6, a cantilever 7 and a cutting torch 8, and the traveling trolley 5 is driven by a Y-axis servo motor 9 along the Y axis. Axis movement, the column 6 is fixed on the trolley 5 and is perpendicular to the Y axis. A parallel X-axis guide rail 11, the torch 8 is driven by an X-axis servo motor 17 to move along the X-axis.

[0022] A ball screw 12 and a transmission steel belt 13 are arranged between the two guide rails of the Z-axis guide rail 10 , and the ball screw 12 is controlled by a Z-axis servo motor 14 installed on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com