Preparation method of yttrium oxide-stabilized zirconium oxide powder with hollow spherical nanostructure

A technology for stabilizing zirconia and nanostructure, which is applied in the field of preparation of hollow spherical nanostructure yttrium oxide stabilized zirconia powder, achieving the effects of high fluidity, low bulk density and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

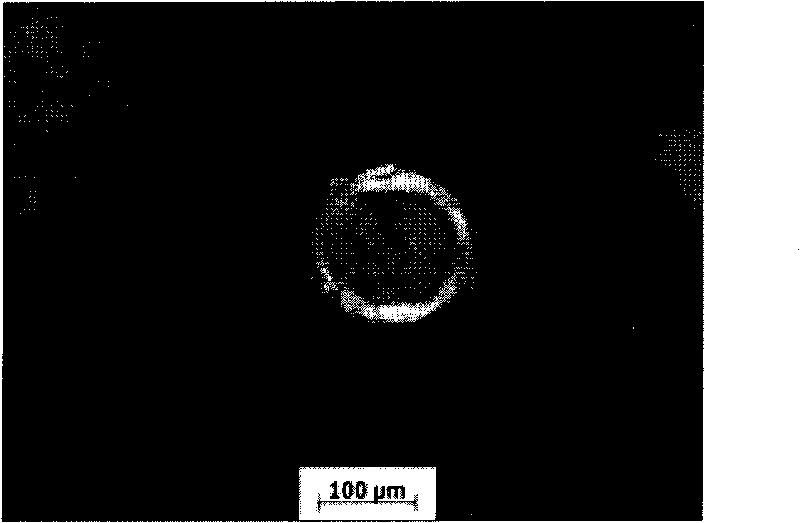

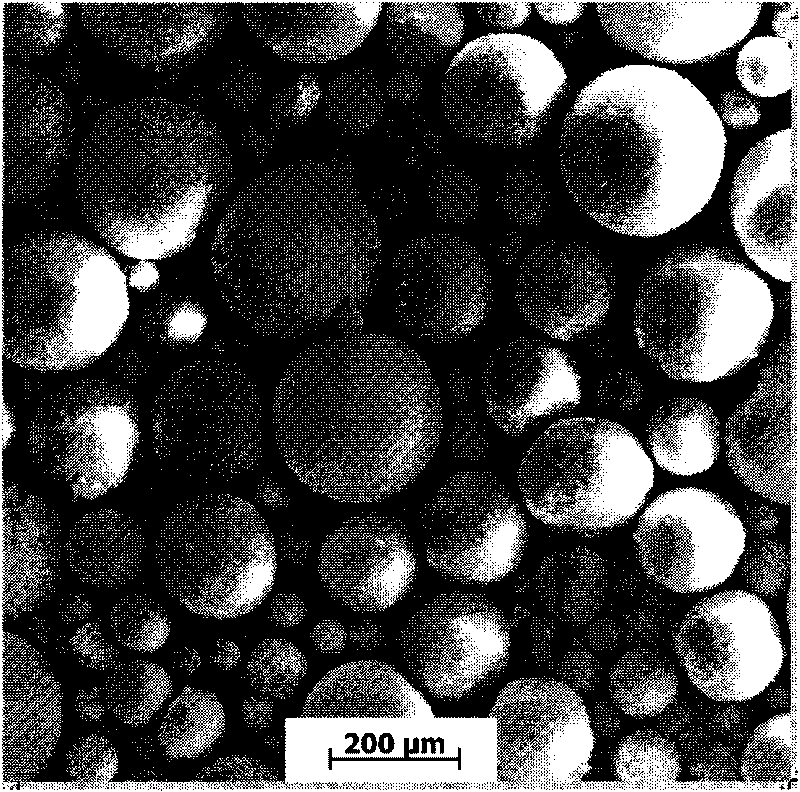

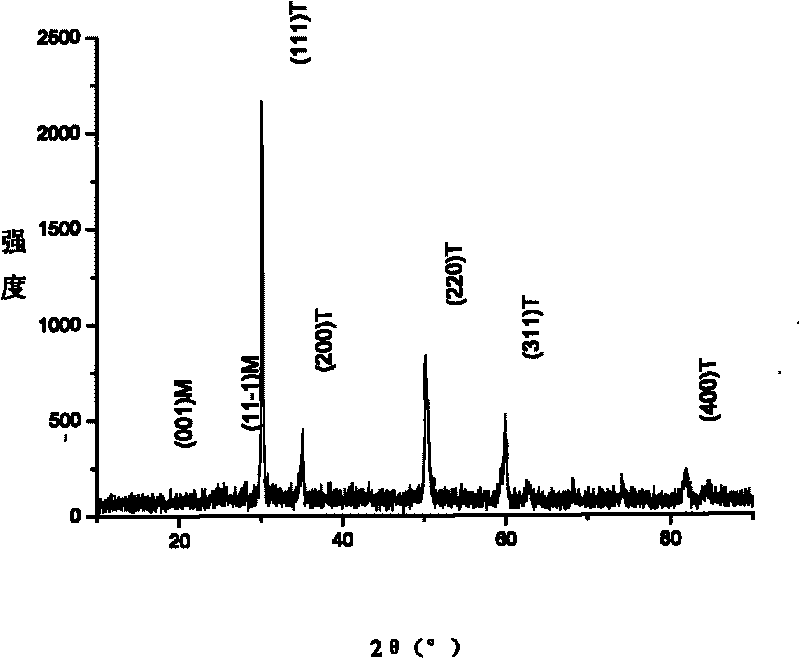

[0026] A method for preparing hollow spherical nano-structured yttrium oxide stabilized zirconia powder:

[0027] (1) Preparation of amorphous yttria stabilized zirconia powder with an amorphous phase structure,

[0028] ①According to the weight ratio of yttrium chloride: zirconium oxychloride=1:11, take yttrium chloride and zirconium oxychloride, add yttrium chloride and zirconium oxychloride to water, completely dissolve and mix thoroughly;

[0029] ② Add 40% ammonia water uniformly and quickly to co-precipitate the two salts to obtain yttria-stabilized zirconia with crystal water. After aging for 5 hours, a gel is obtained;

[0030] ③Fully mix the gel and water in a mass ratio of 1:1, add a dispersant and a binder to the mixed liquid. The dispersant is ethylene glycol, and the added amount is 3% of the weight percentage of the slurry. The binder adopts polyvinyl alcohol, and the addition amount is 3% of the weight percentage of the slurry;

[0031] ④ Ball milling for 60 minutes, aft...

Embodiment 2

[0040] A method for preparing hollow spherical nano-structured yttrium oxide stabilized zirconia powder:

[0041] (1) Preparation of amorphous yttria stabilized zirconia powder with an amorphous phase structure,

[0042] ①According to the weight ratio of yttrium chloride: zirconium oxychloride=1:11, take yttrium chloride and zirconium oxychloride, add yttrium chloride and zirconium oxychloride to water, completely dissolve and mix thoroughly;

[0043] ②Add ammonia water with a concentration of 30% uniformly and quickly to co-precipitate the two salts to obtain yttria-stabilized zirconia with crystal water. After aging for 4 hours, a gel is obtained;

[0044] ③Fully mix the gel and alcohol according to the mass ratio of 1:1, add dispersant and binder to the mixed liquid, dispersant is ethylene glycol, and the added amount is 2% of the weight percentage of the slurry. The binder adopts polyvinyl alcohol, and the addition amount is 4% of the weight percentage of the slurry;

[0045] ④ Aft...

Embodiment 3

[0053] A method for preparing hollow spherical nano-structured yttrium oxide stabilized zirconia powder:

[0054] (1) Preparation of amorphous yttria stabilized zirconia powder with an amorphous phase structure,

[0055] ①According to the weight ratio of yttrium chloride: zirconium oxychloride=1:11, take yttrium chloride and zirconium oxychloride, add yttrium chloride and zirconium oxychloride to water, completely dissolve and mix thoroughly;

[0056] ② Add 50% ammonia water uniformly and quickly to co-precipitate the two salts to obtain yttria-stabilized zirconia with crystal water. After aging for 4 hours, a gel is obtained;

[0057] ③Fully mix the gel and water according to the mass ratio of 1:1, add dispersant and binder to the mixed liquid, dispersant is ethylene glycol, and the added amount is 4% of the weight percentage of the slurry. The binder adopts polyvinyl alcohol, and the addition amount is 2% of the weight percentage of the slurry;

[0058] ④ Ball milling for 40 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com