Plasma melting cracking treating equipment

A pyrolysis treatment and plasma technology, which is applied in the field of ion melting and cracking treatment equipment, can solve problems such as difficult sealing, short electrodes, and equipment not working properly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

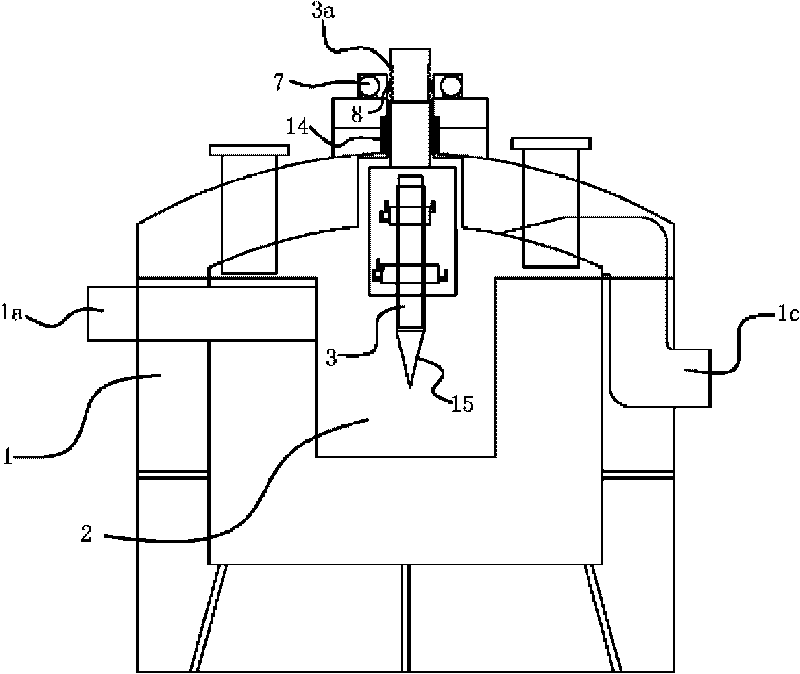

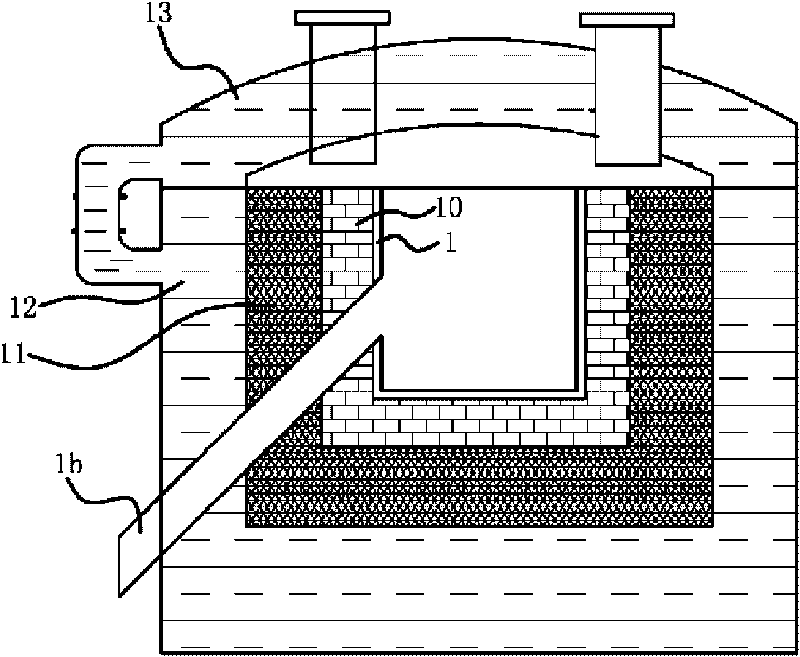

[0029] Such as figure 1 with figure 2 As shown, the plasma melting and cracking treatment equipment includes a body of furnace 1 having a feed port 1a and a discharge port 1b, and an incineration chamber 2 is provided in the body of furnace 1, and the incineration chamber 2 and the above-mentioned feed port 1a It communicates with the discharge port 1b, and a gas outlet 1c communicating with the incineration chamber 2 is also provided on the furnace body 1. A plasma torch generator capable of generating a plasma jet flame is also provided on the top of the furnace body 1, so One end of the plasma torch generator mentioned above penetrates in the combustion chamber 2, and the other end penetrates the body of furnace 1 and links to each other with a lifting mechanism that can drive it up and down.

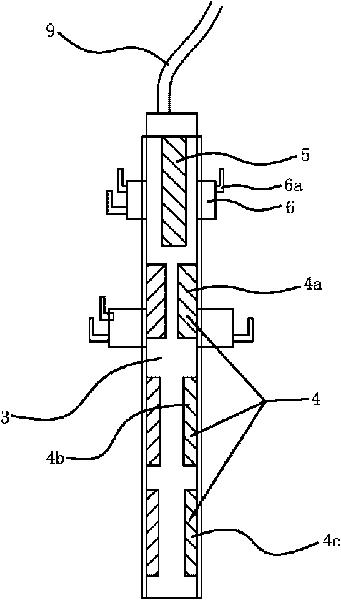

[0030] The plasma torch generator comprises a torch rod 3, an anode 4, a cathode 5 and a gas transfer sleeve 6, the inside of the torch rod 3 has a cavity, and the anode 4 and the ...

Embodiment 2

[0038] The content in the second embodiment is roughly the same as that in the first embodiment, the difference is that the lifting mechanism in the first embodiment includes a motor 7 and a worm wheel 8, and the output shaft of the motor 7 is fixedly connected with the worm wheel 8 , the worm gear of the worm wheel 8 meshes with the above-mentioned tooth groove 3a; and the lifting mechanism in the second embodiment is a lifting cylinder, and the piston rod of the lifting cylinder is fixedly connected with the above-mentioned flare rod 3 . The work of cylinder, piston rod lifts up and down, thus drives the up and down of the torch rod 3 that is connected with it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com