Laser probe analyzer based on aerosolization and resonance excitation

A laser probe and aerosolization technology, applied in the direction of material excitation analysis, etc., can solve the problems of breakdown point fluctuation, difficult application, and reduce test repeatability, so as to reduce interference, precise deterministic and quantitative analysis, and improve detection limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

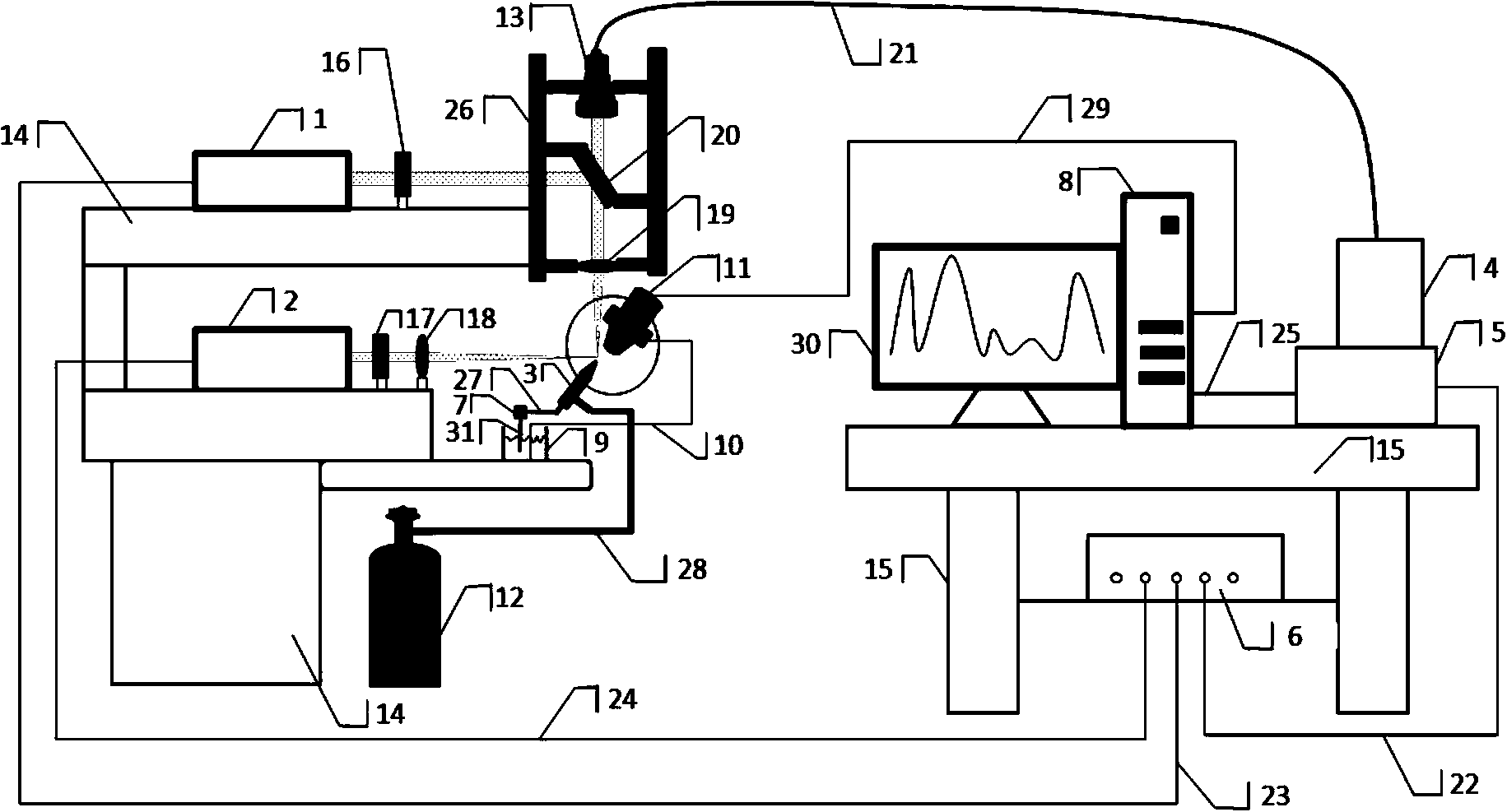

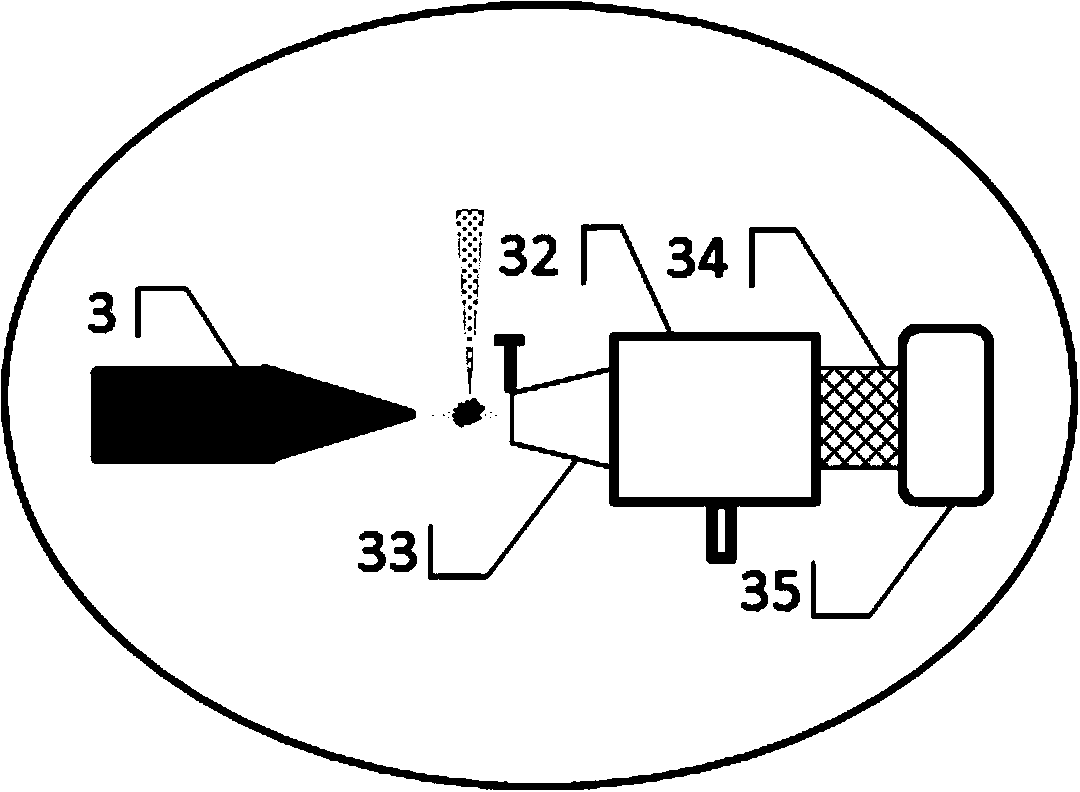

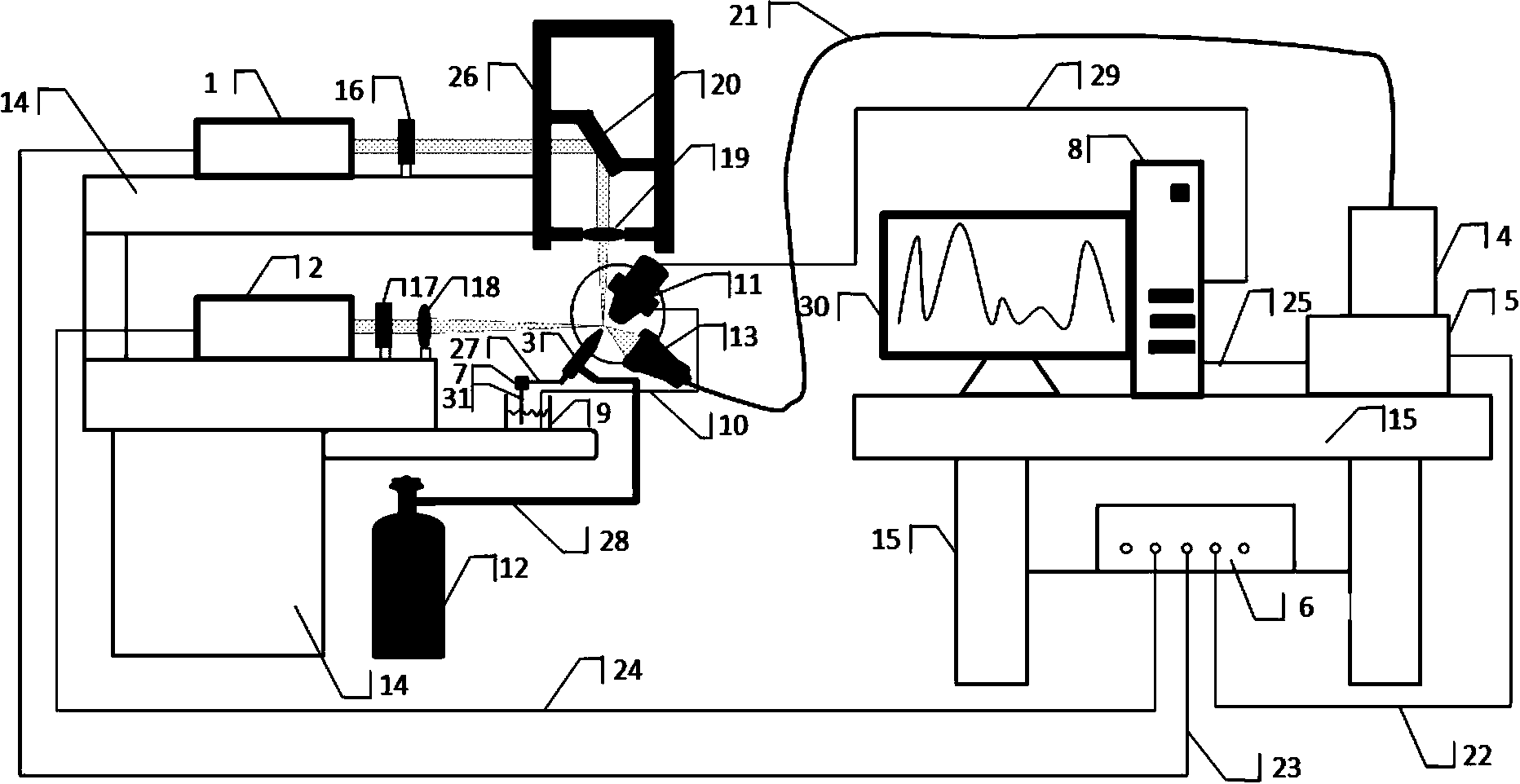

[0023] Such as figure 1 As shown, the laser probe component analyzer provided by the example of the present invention mainly includes Nd.YAG laser 1, wavelength tunable laser 2, atomizer 3, grating spectrometer 4, enhanced CCD 5, recovery system 11 and computer 8, etc.

[0024] The light outlet of the Nd.YAG laser 1, the small hole diaphragm 16 and the half-mirror 20 are on the same horizontal optical path, and the half-mirror 20 is placed at an angle of 45 degrees to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com