Preparation method of hydroxyapatite bioactive coating doped with trace elements

A technology of trace element hydroxyapatite and hydroxyapatite, applied in the direction of coating, etc., can solve the problems of unsuitability for industrial production, cumbersome preparation process, thin coating thickness, etc., to ensure chemical uniformity and improve biological activity , the effect of high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

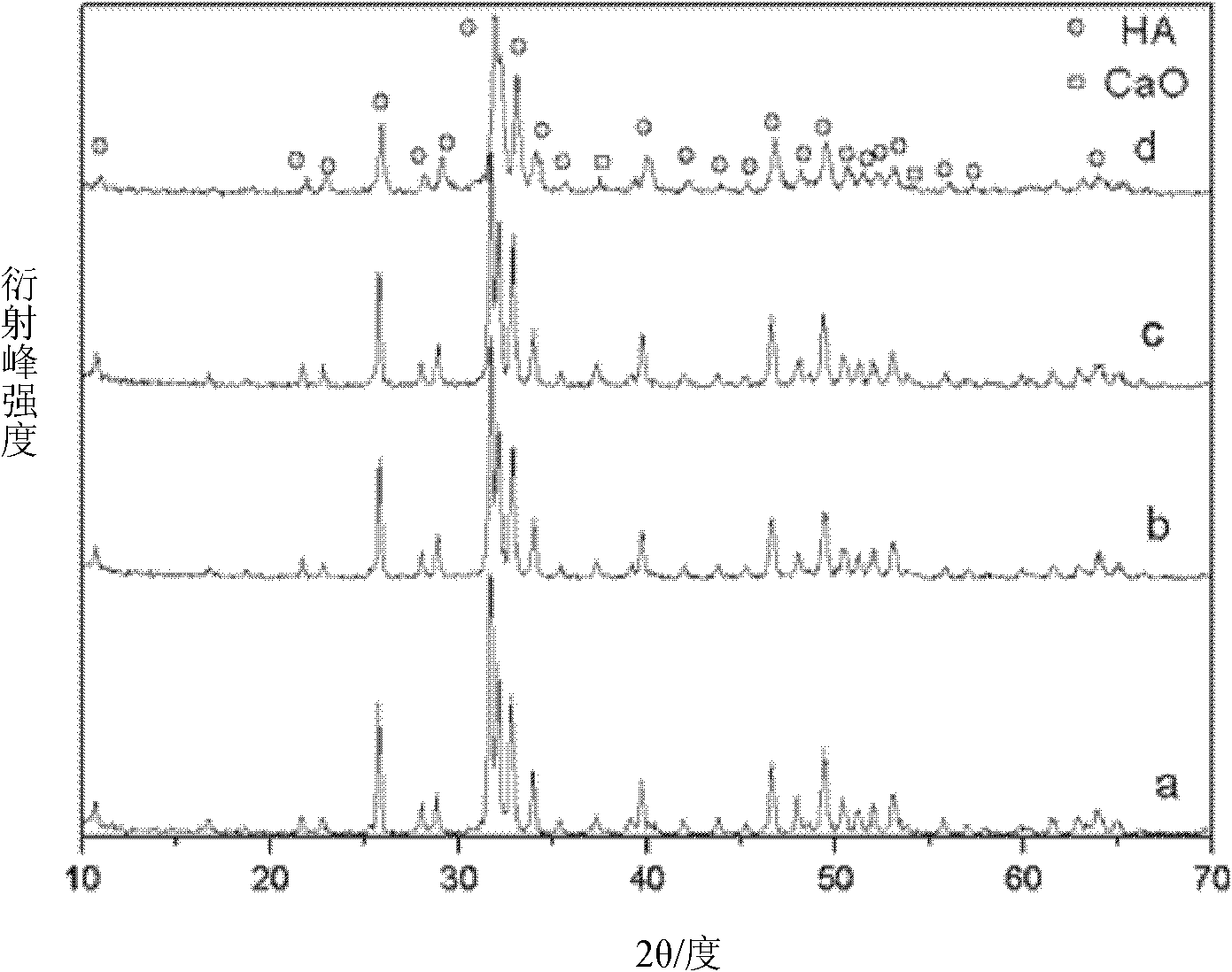

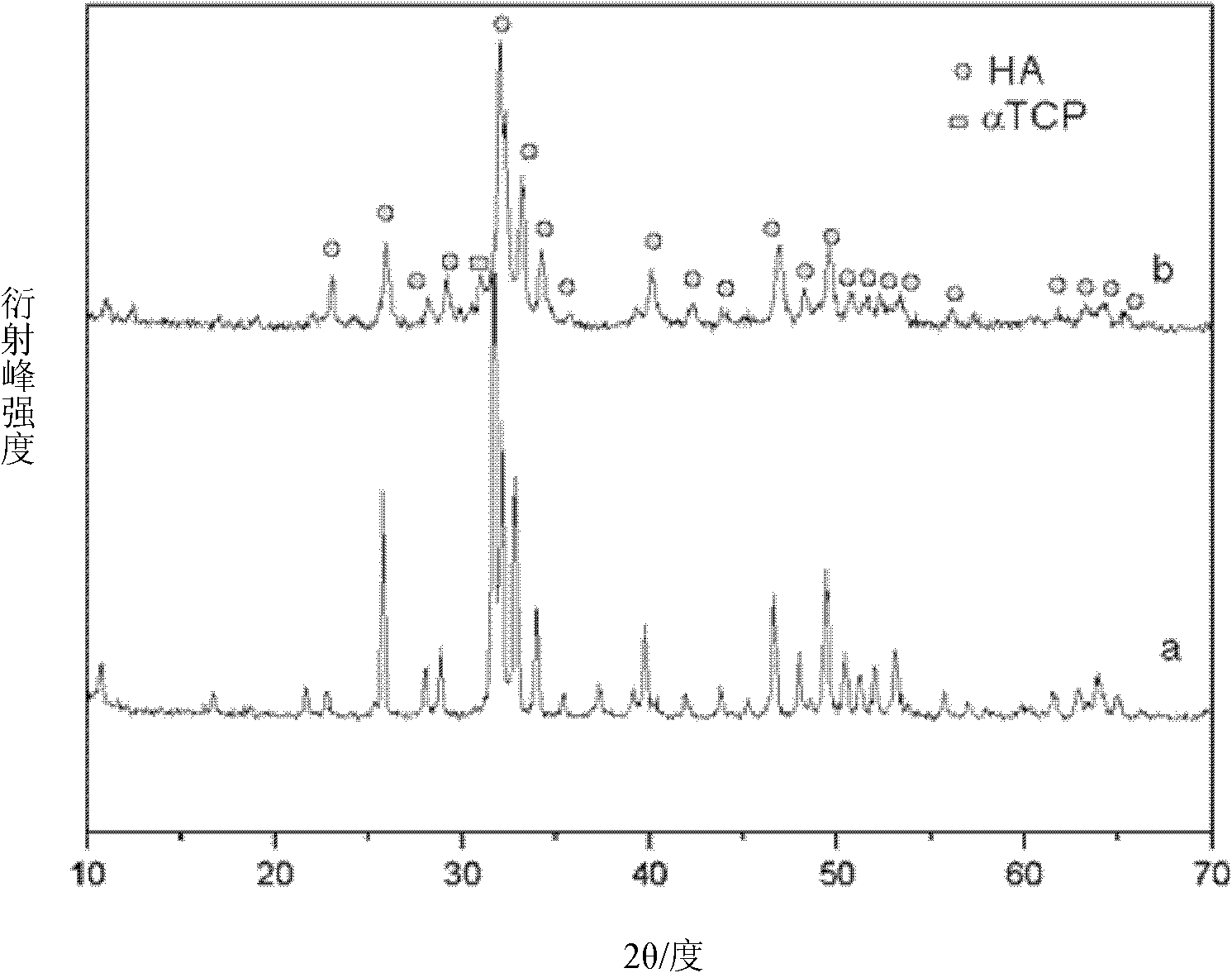

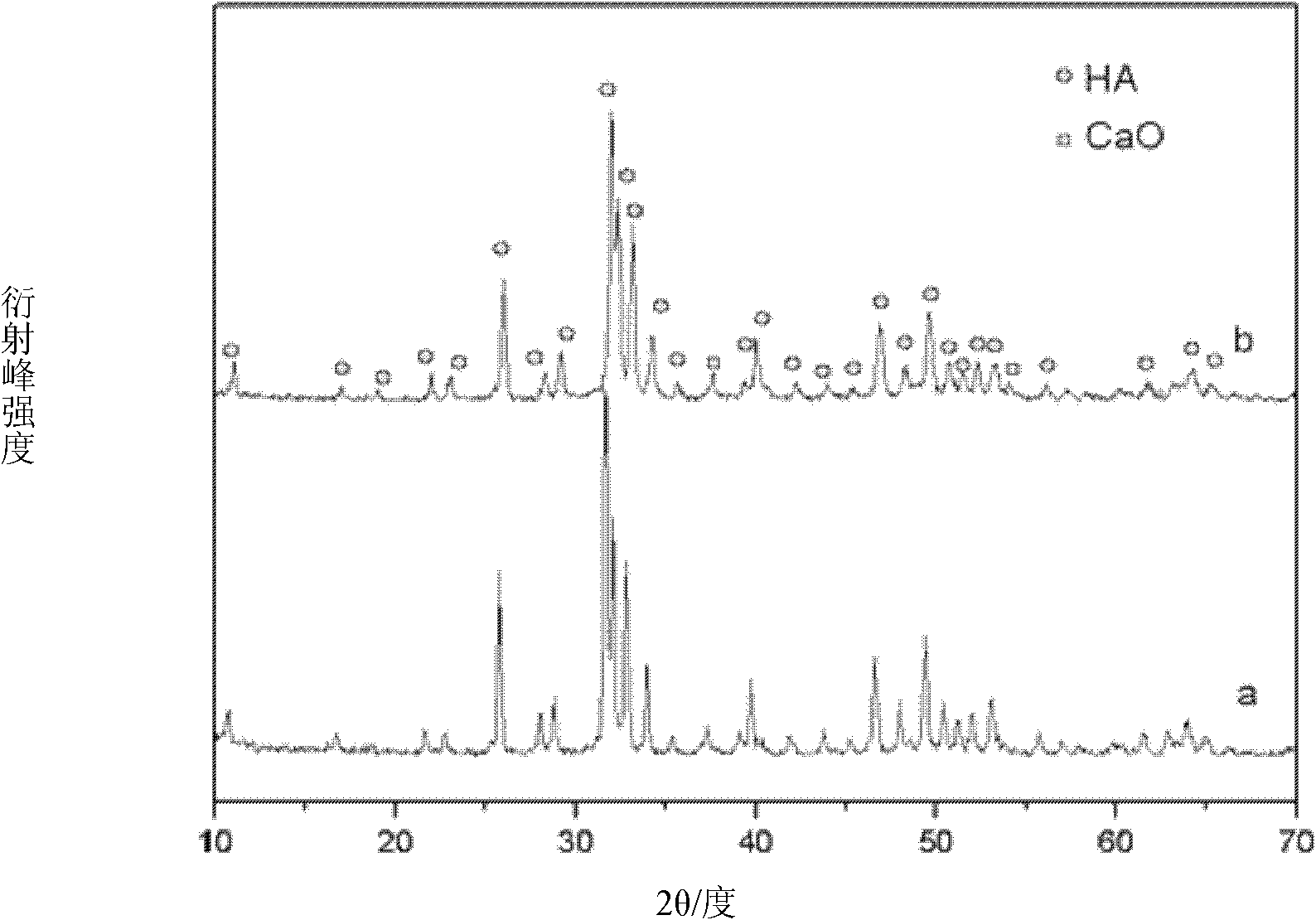

[0066] Embodiment 1 Preparation of silicon-containing hydroxyapatite coating

[0067] According to the Ca / (P+Si) molar ratio in the silicon-containing hydroxyapatite and the Ca / P molar ratio in the hydroxyapatite are equal (1.67), calculate the amount of raw materials, and take the measured 119.3g calcium nitrate under constant stirring Dissolve in 250ml of deionized water, keep the calcium nitrate aqueous solution at 60°C, add 2.8ml of tetraethyl orthosilicate to the calcium nitrate aqueous solution under constant stirring, then dissolve 38.5g of diammonium hydrogen phosphate in deionized water, and dihydrogen phosphate The ammonium aqueous solution was gradually added dropwise into the solution containing calcium nitrate and tetraethyl orthosilicate, and the pH value of the reaction solution was controlled to be 8 with ammonia water with a concentration of 30% by mass. Continue to keep stirring for 1 hour after the dropwise addition, and age for 24 hours to obtain a silicon-...

Embodiment 2

[0069] Embodiment 2 Preparation of silicon-containing hydroxyapatite coating

[0070] According to the Ca / (P+Si) molar ratio in the silicon-containing hydroxyapatite and the Ca / P molar ratio in the hydroxyapatite are equal (1.67), calculate the amount of raw materials, and take the measured 119.3g calcium nitrate under constant stirring Dissolve in 250ml of deionized water, keep the calcium nitrate aqueous solution at 70°C, add 8.4ml of tetraethyl orthosilicate to the calcium nitrate aqueous solution under constant stirring, then dissolve 35.2g of diammonium hydrogen phosphate in deionized water, and dihydrogen phosphate The ammonium aqueous solution was gradually added dropwise into the solution containing calcium nitrate and tetraethyl orthosilicate, and the pH value of the reaction solution was controlled to be 9 with ammonia water with a concentration of 25% by mass. Continue to keep stirring for 1.5 hours after the dropwise addition, and age for 24 hours to obtain a silic...

Embodiment 3

[0072] Embodiment 3 Preparation of silicon-containing hydroxyapatite coating

[0073] According to the Ca / (P+Si) molar ratio in the silicon-containing hydroxyapatite and the Ca / P molar ratio in the hydroxyapatite are equal (1.67), calculate the amount of raw materials, and take the measured 119.3g calcium nitrate under constant stirring Dissolve in 250ml of deionized water, keep the calcium nitrate aqueous solution at 80°C, add 5.6ml of ethyl orthosilicate to the calcium nitrate aqueous solution under constant stirring, then dissolve 36.9g of diammonium hydrogen phosphate in deionized water, and dihydrogen phosphate The ammonium aqueous solution was gradually added dropwise into the solution containing calcium nitrate and tetraethyl orthosilicate, and the pH value of the reaction solution was controlled to be 10 with ammonia water with a concentration of 20% by mass. Continue to keep stirring for 0.5 hours after the dropwise addition, and age for 48 hours to obtain a silicon-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com