Method for producing quartz casing tube for optical fiber prefabricated stick

A technology of optical fiber preform and quartz sleeve, which is applied in the direction of manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems of high one-time investment and high hydroxyl content, and achieve good melting quality, low hydroxyl content, and temperature resistance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Quartz sleeve size: outer diameter 35mm, wall thickness 5.1mm.

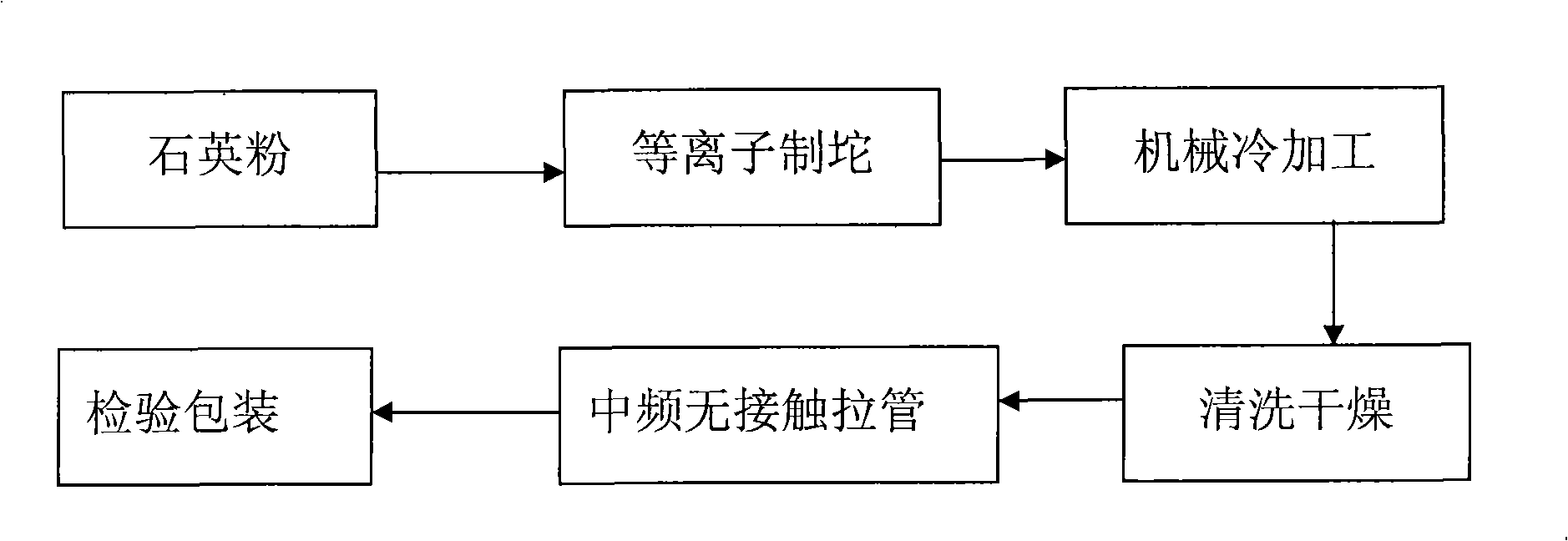

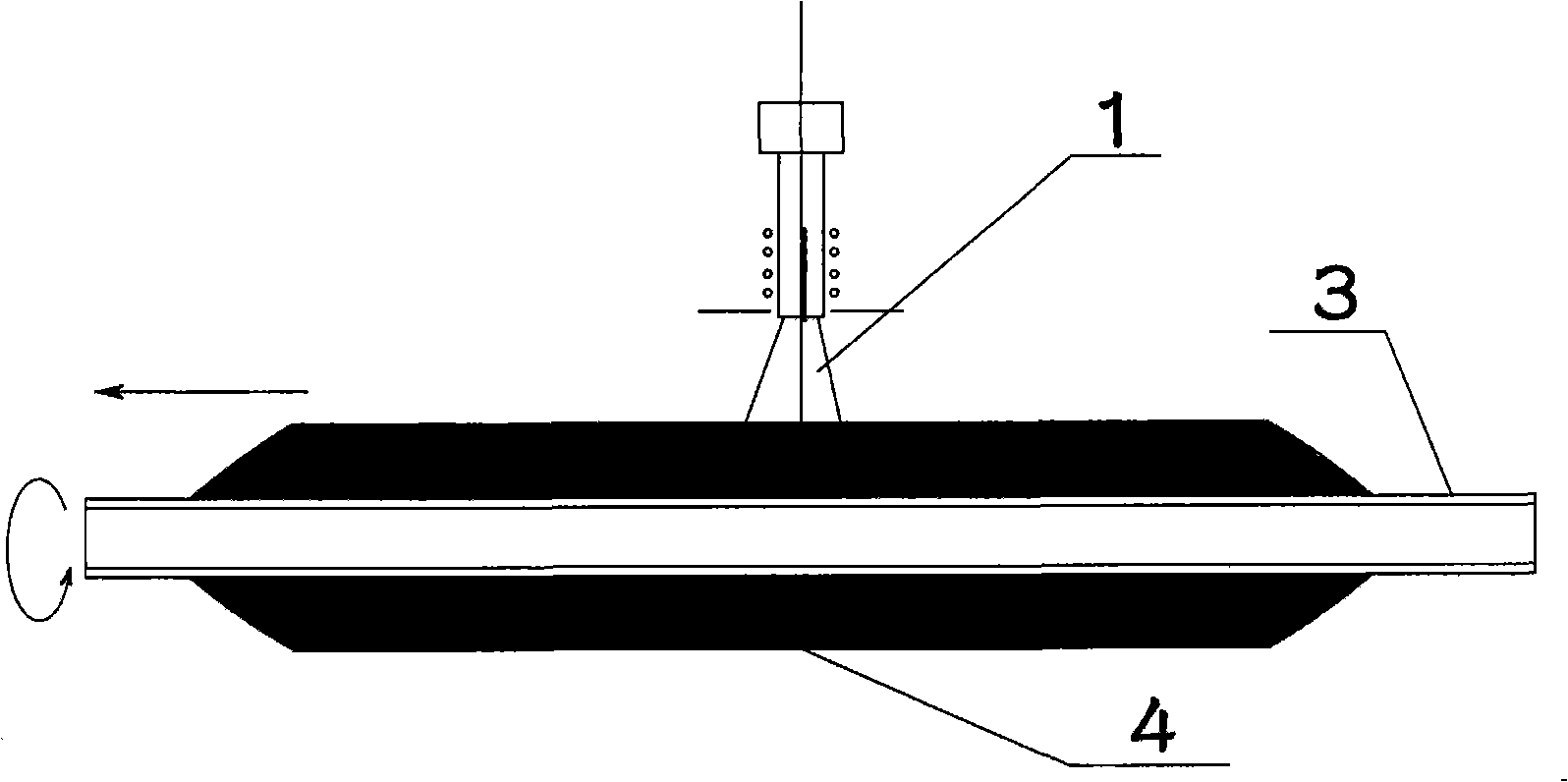

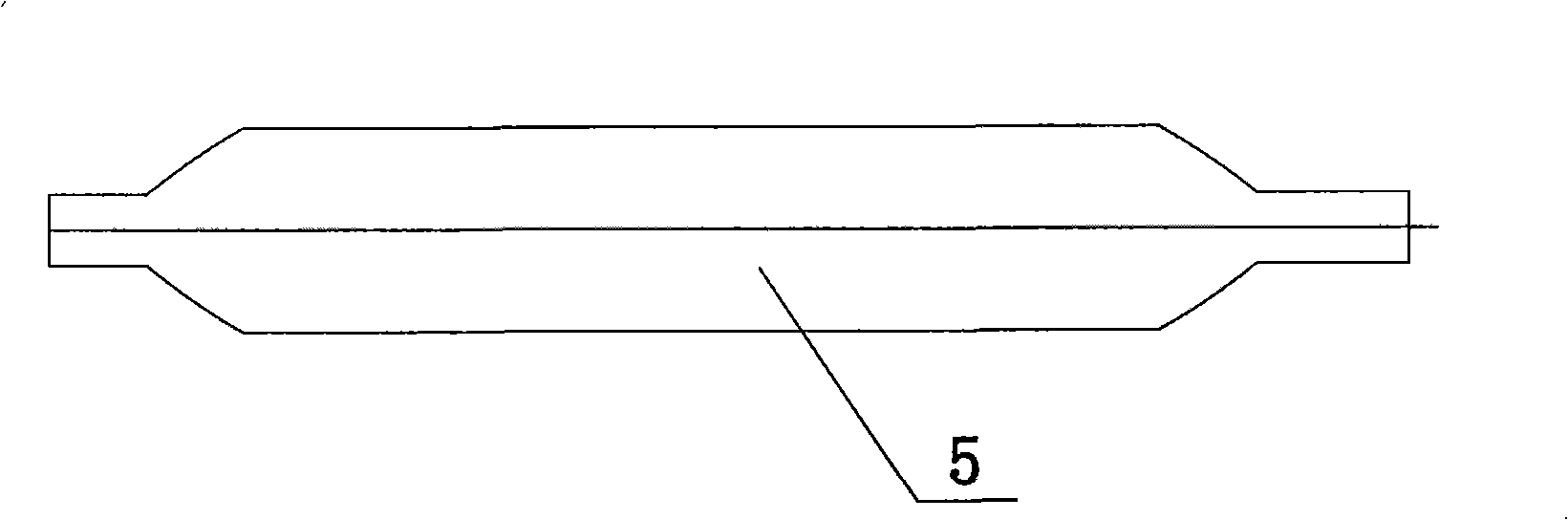

[0058] The first step: first select high-purity quartz powder (total impurity content <50ppm), use plasma flame 1 as the heat source, and deposit quartz sand layer by layer on the outer circle of the center base tube 3 in the high-frequency plasma mound machine according to a certain track. Deposit 1.4 kg per hour, directly coat the molten quartz powder 4 on the center base tube 3, and deposit it for 70 hours to form a quartz ingot 5; the second step: cold working with a metal cutting machine and diamond and other abrasive tools to the quartz ingot Grinding and honing the inner hole and outer circle. Grind the outside of the quartz wool ingot 5 into a regular cylindrical shape. Appearance size: outer diameter 139mm, inner diameter 82.12mm, length 1655mm. The third step: cleaning and drying, using trichloroethylene as a degreasing agent for degreasing for 20 minutes, using 1.5% hydrofluoric acid as a...

Embodiment 2

[0059] Embodiment 2: Quartz sleeve size: outer diameter 33mm, wall thickness 5.35mm.

[0060] The first step: first select high-purity quartz powder (total impurity content <50ppm), use plasma flame 1 as the heat source, deposit quartz sand layer by layer on the outer circle of the center base tube 3 in the high-frequency plasma mound machine, 1.5 per hour Kg, the molten quartz powder 4 is directly coated on the center base tube 3, and deposited for 67 hours to form a quartz ingot 5; the second step: cold processing uses a metal cutting machine tool to use diamond and other abrasive tools on the inner and outer holes of the quartz ingot Round for grinding and honing. Grind the exterior of the quartz wool mound 5 into a cylindrical shape with an outer diameter of 138mm, an inner diameter of 81.3mm, and a length of 1600mm. The third step: use trichloroethylene as a degreasing agent for degreasing for 18 minutes, using 1.5% hydrofluoric acid as a cleaning agent for pickling for 10 mi...

Embodiment 3

[0061] Embodiment 3: Quartz sleeve size: outer diameter 35mm, wall thickness 5.1mm.

[0062] The first step: first select high-purity quartz powder (total content of impurities <50ppm), use plasma flame 1 as the heat source, deposit quartz sand layer by layer on the outer circle of the center base tube 3 in the high-frequency plasma mound machine, 1.7 per hour Kg, the molten quartz powder 4 is directly coated on the center base tube 3, and deposited for 65 hours to form the quartz ingot 5; the second step: cold processing uses a metal cutting machine to use diamond and other abrasive tools on the inner and outer holes of the quartz ingot Round for grinding and honing. Grind the exterior of the quartz wool mound into a cylindrical shape with an outer diameter of 139mm, an inner diameter of 80.9mm, and a length of 1635mm. The third step: using trichloroethylene as a degreasing agent for degreasing for 17 minutes, using 1.5% hydrofluoric acid as a cleaning agent for pickling for 10 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com