Patents

Literature

32results about How to "Improve thermal cycle life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and preparation method thereof

ActiveCN105862038ALow thermal conductivityImprove toughnessMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionZirconate

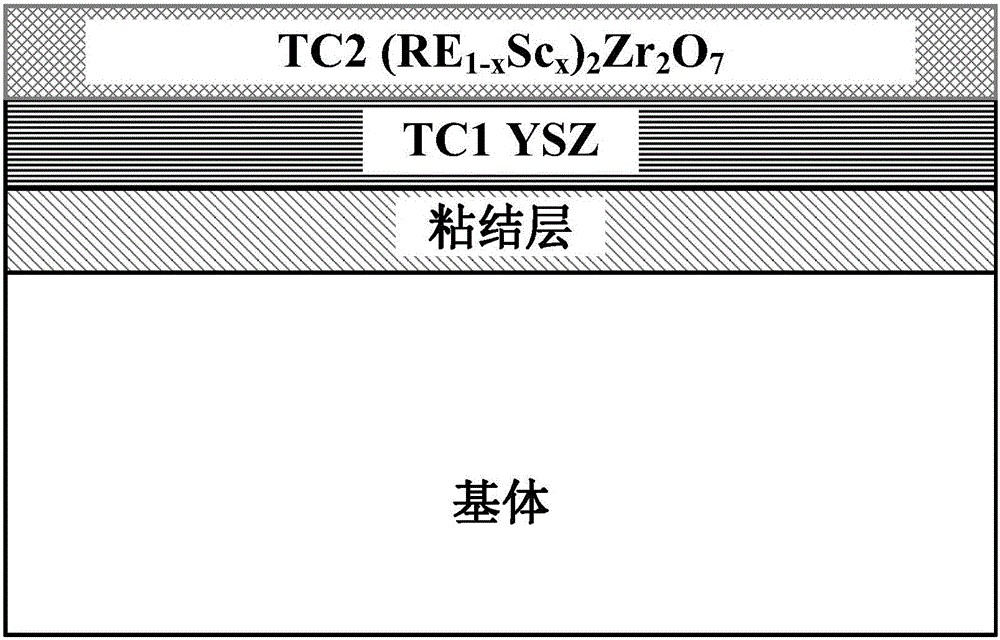

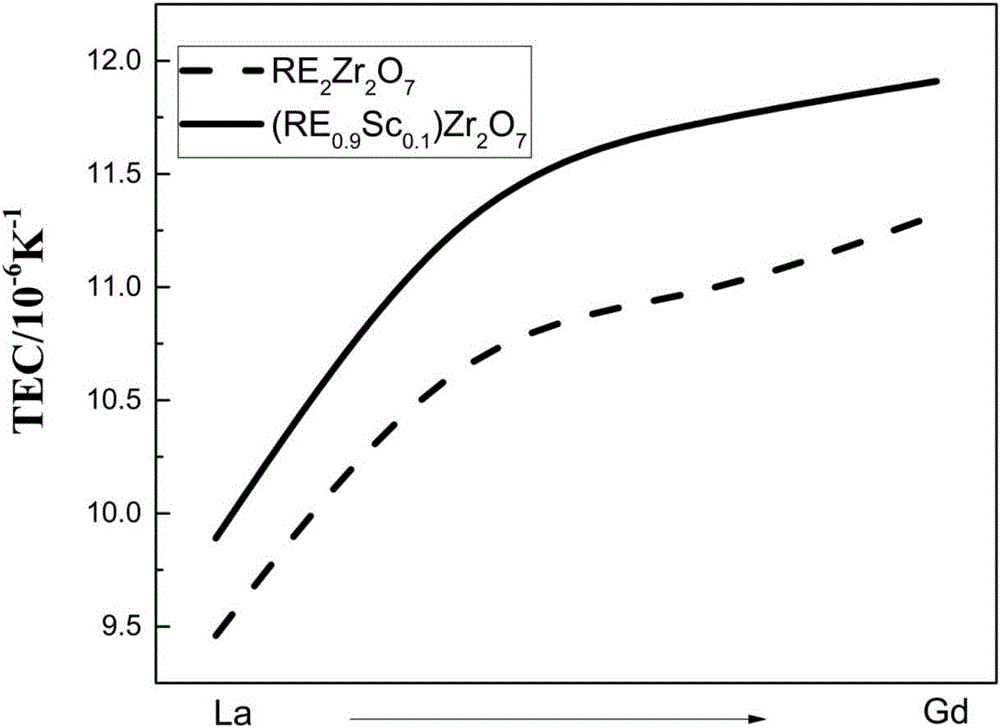

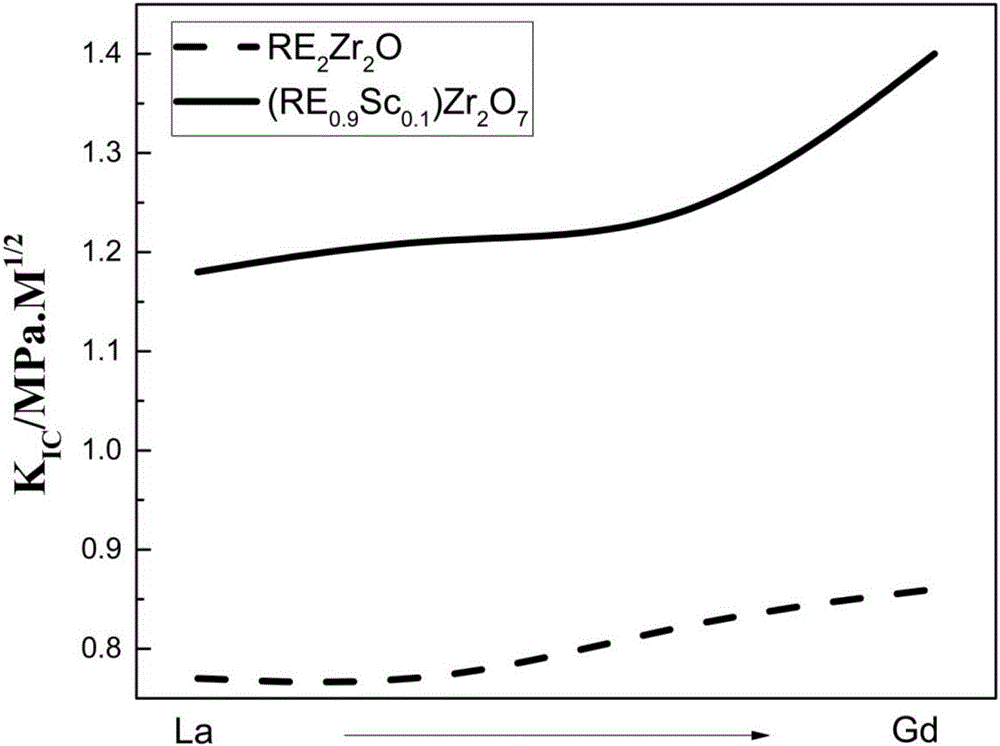

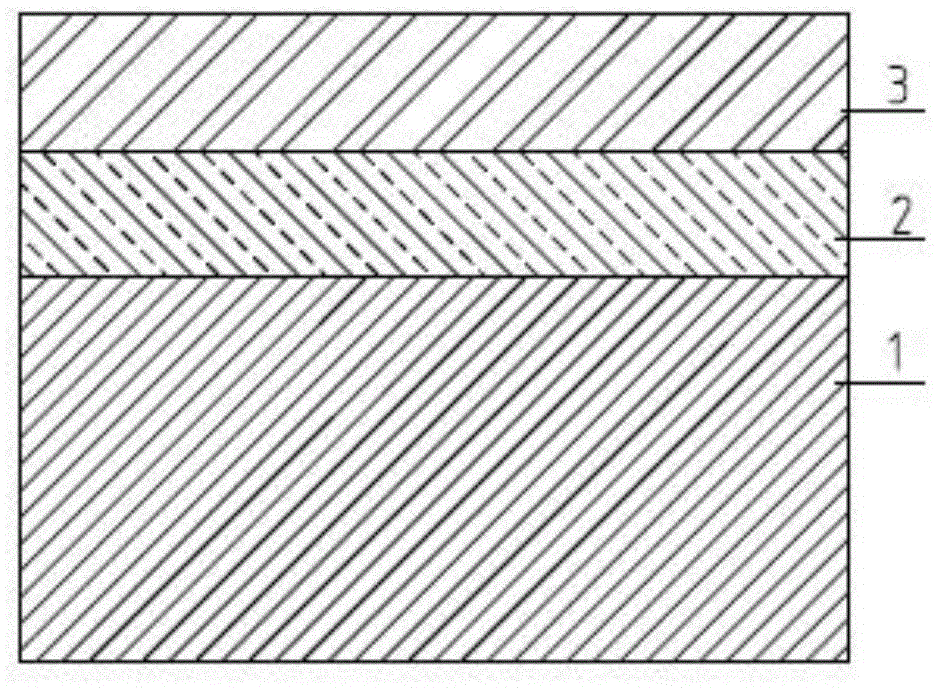

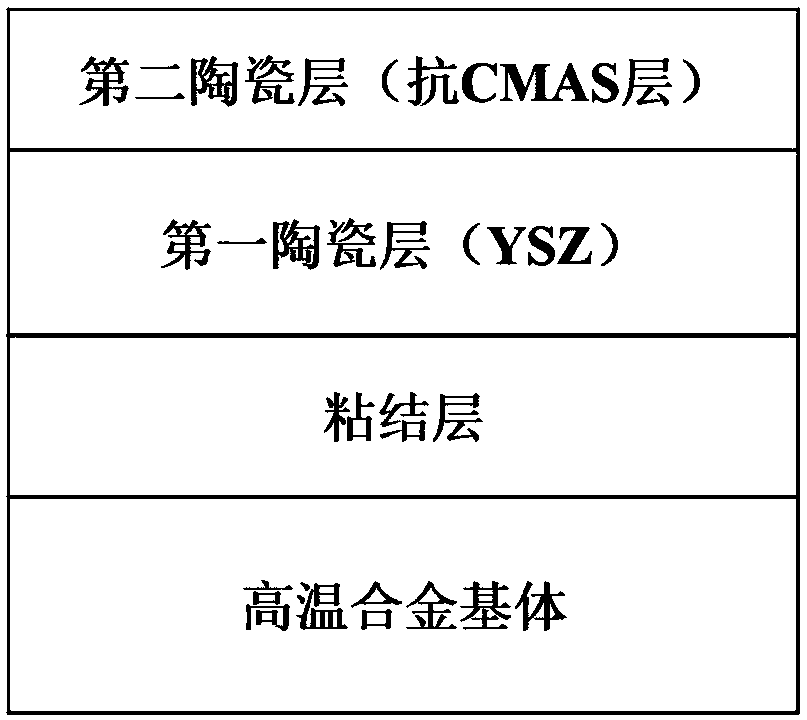

The invention relates to an anti-CMAS-corrosion ultrahigh-temperature-resistant long-service-life thermal barrier coating and a preparation method thereof. The thermal barrier coating is sequentially provided with a binding layer, a first ceramic layer and a second ceramic layer on a matrix from bottom to top, the binding layer is made of an MCrAlX alloy, M refers to Ni, or Co or a composition of Ni and Co, X refers to one of or a composition of two of Y, Hf, Si and Pt, the first ceramic layer is made of YSZ, and the second ceramic layer is rare earth zirconate with Sc2O3. The preparation method includes that an electron beam physical vapor deposition method or an atmosphere plasma spraying method are adopted. Sc2O3 is doped in a rare earth zirconate coating, so that heat conductivity of the coating can be further lowered, toughness of the coating is improved, anti-CMAS-corrosion capability of the coating is improved, thermal cycling life of the coating can be prolonged, and high-temperature stability of the coating under CMAS coupling action can be improved.

Owner:TIANJIN UNIV

Nano insulating coating

The invention discloses a nano insulating coating which is prepared from the following raw materials in parts by weight: 100 parts of an organosiloxane modified acrylic emulsion, 5-12 parts of a silicon dioxide aerogel, 1-2.6 parts of ceramic fibers, 1-2.5 parts of a carbon nano tube, 0.2-1 part of calcium silicate, 2-5 parts of nano zirconium oxide, 3-7 parts of nano zinc oxide, 5-9 parts of calcium carbonate whiskers, 15-20 parts of sepiolite, 5-20 parts of expanded perlite, 8-15 parts of nano titanium dioxide, 0.8-2.0 parts of a segmented copolymer, 1.5-3.8 parts of dodecanol ester, 0.2-5.0 parts of benzotriazole, 2-3.5 parts of a defoaming agent, 0.5-2 parts of glycerol, 0-1.5 parts of a thickener, 3-10 parts of a coupling agent and 30-60 parts of water. The nano insulating coating disclosed by the invention is good in insulation, high-temperature resistant, high in strength and pollution resistant and is strong in adhesive force and long in service life of building wall spaces and base bodies.

Owner:南京红枫环保材料有限公司

High-temperature oxidation resistant coating on niobium alloy surface and preparation method of high-temperature oxidation resistant coating

InactiveCN104561882AHigh strengthImprove toughnessMolten spray coatingHigh energyOxidation resistant

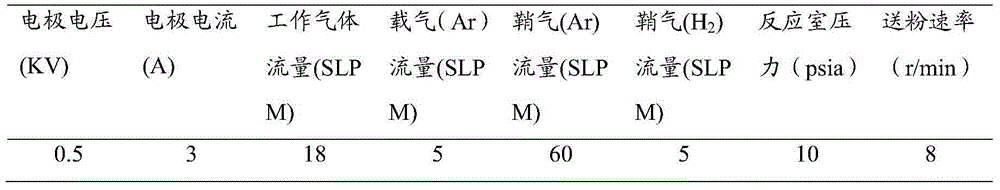

The invention belongs to the field of thermal spraying, and relates to a high-temperature oxidation resistant coating on a niobium alloy surface and a preparation method of the high-temperature oxidation resistant coating. The coating is in a dual-layer structure with a bottom coating Mo1-xWx(Si1-y-zAlyBz)2 and a surface coating Mo1-xWx(Si1-y-zAlyBz)2-(10-20)%wt HfSi2, and prepared on a niobium alloy matrix surface by a high-energy plasma spraying process, wherein a bottom coating powder material Mo1-xWx(Si1-y-zAlyBz)2 is prepared by a self-propagating process, and the spherical particles meeting the requirements of the spraying process are obtained by applying a plasma spheroidizing process; surface coating powder materials Mo1-xWx(Si1-y-zAlyBz)2 and HfSi2 are mixed evenly in a mechanical mixing manner. The coating has excellent high-temperature oxidation resistance at 1500-1800 DEG C, and can be applied to high-temperature protection of niobium alloy parts.

Owner:CHINA IRON & STEEL RES INST GRP +1

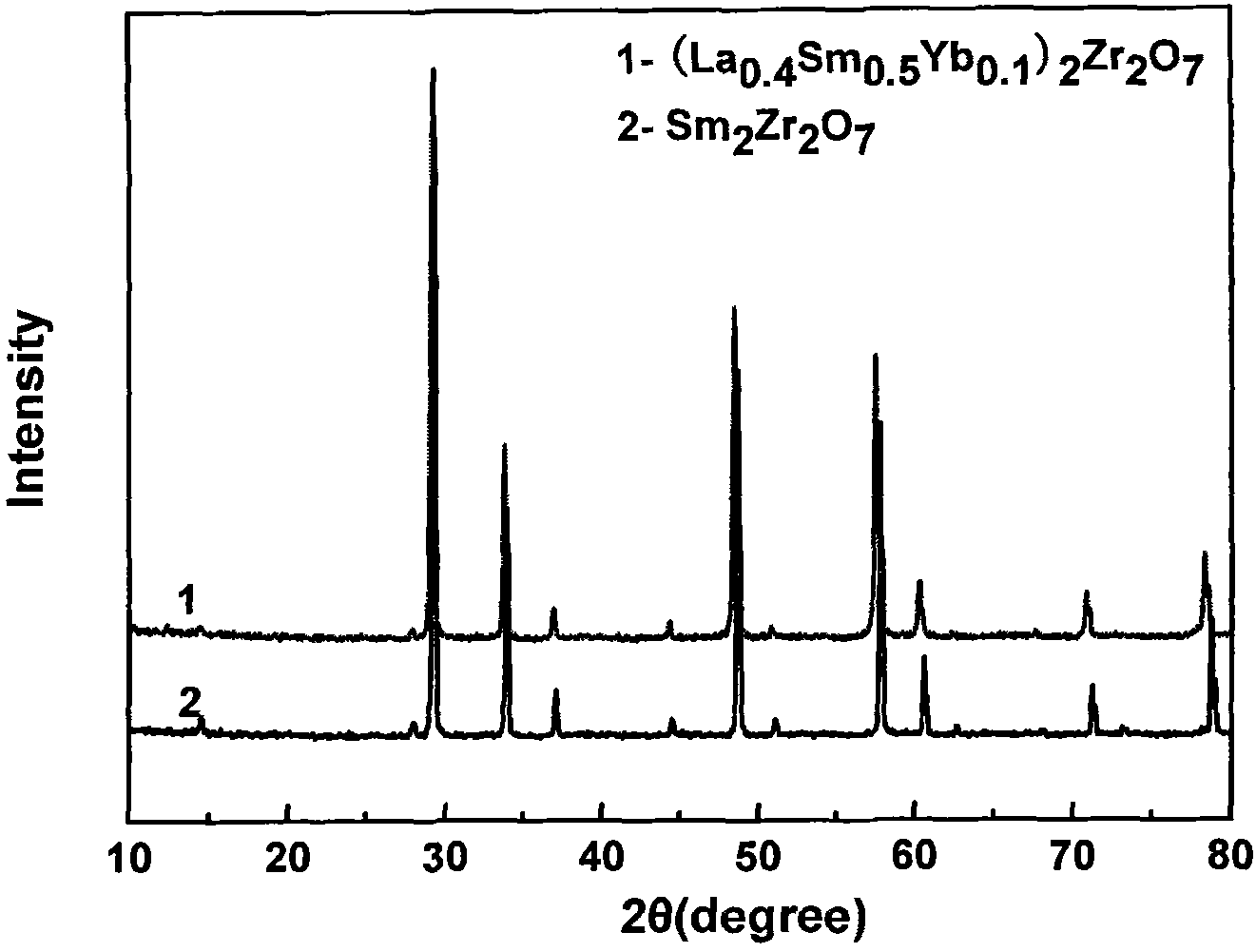

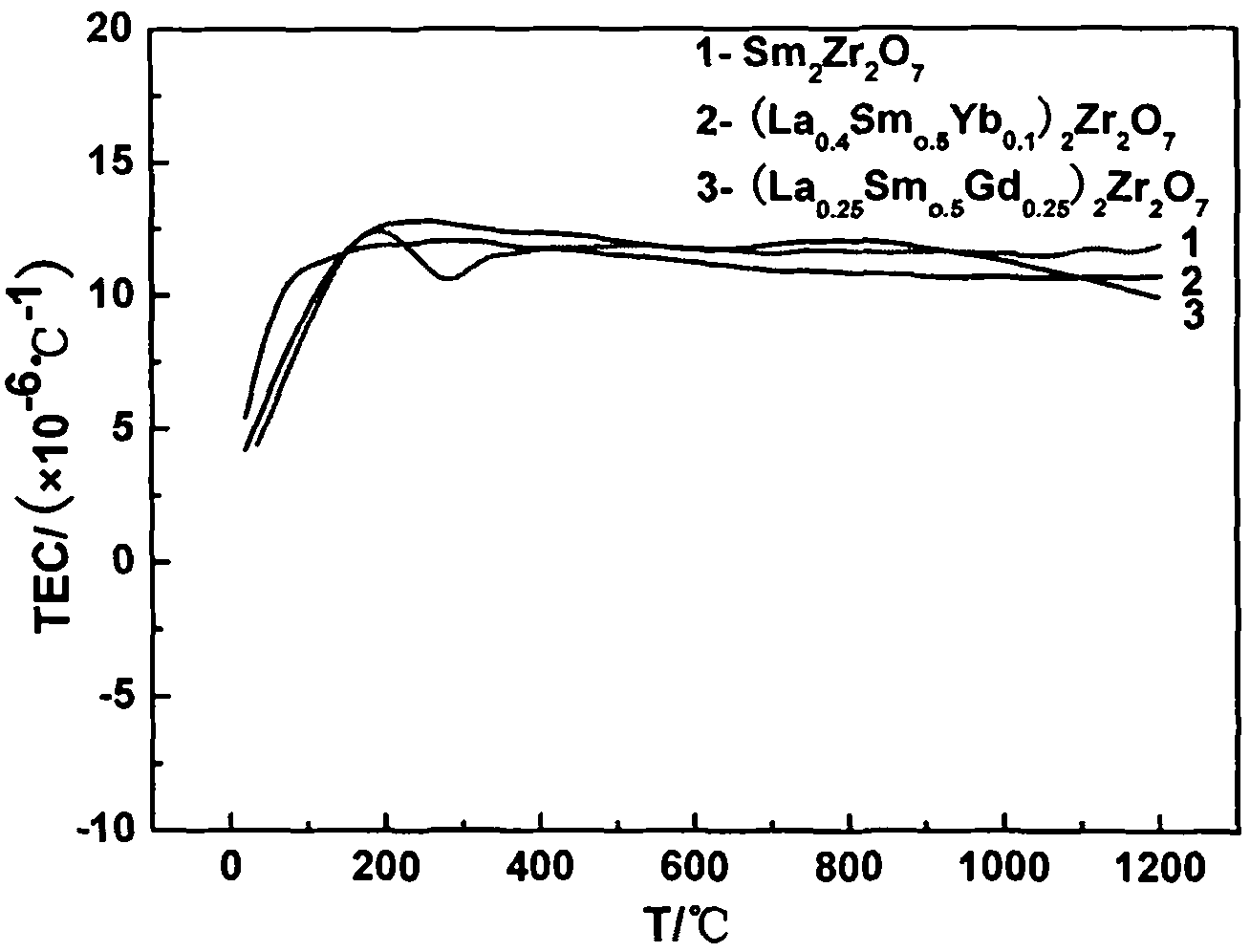

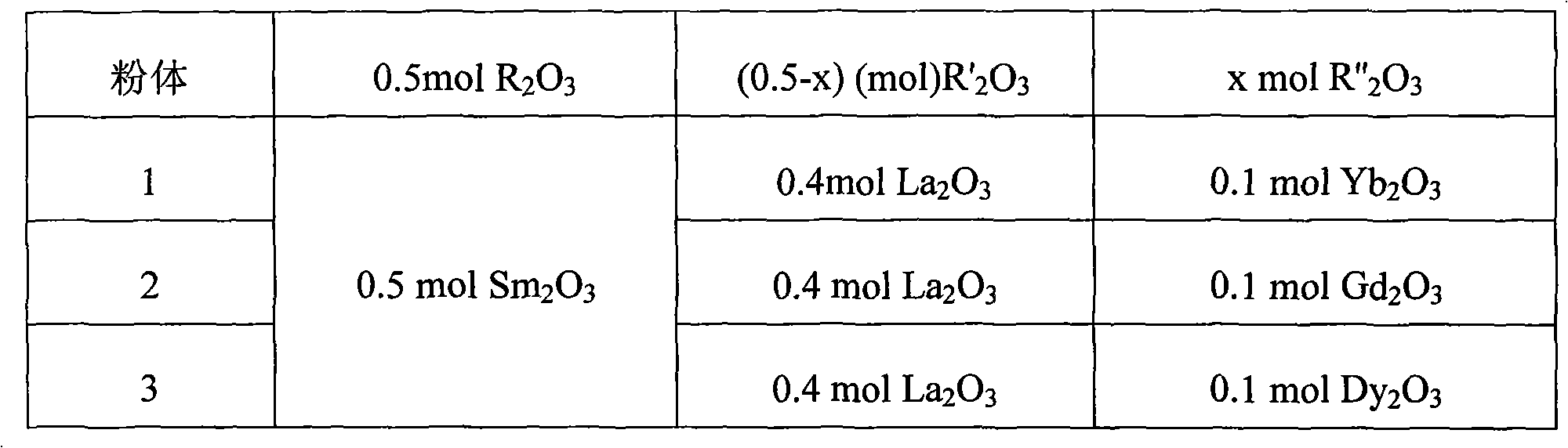

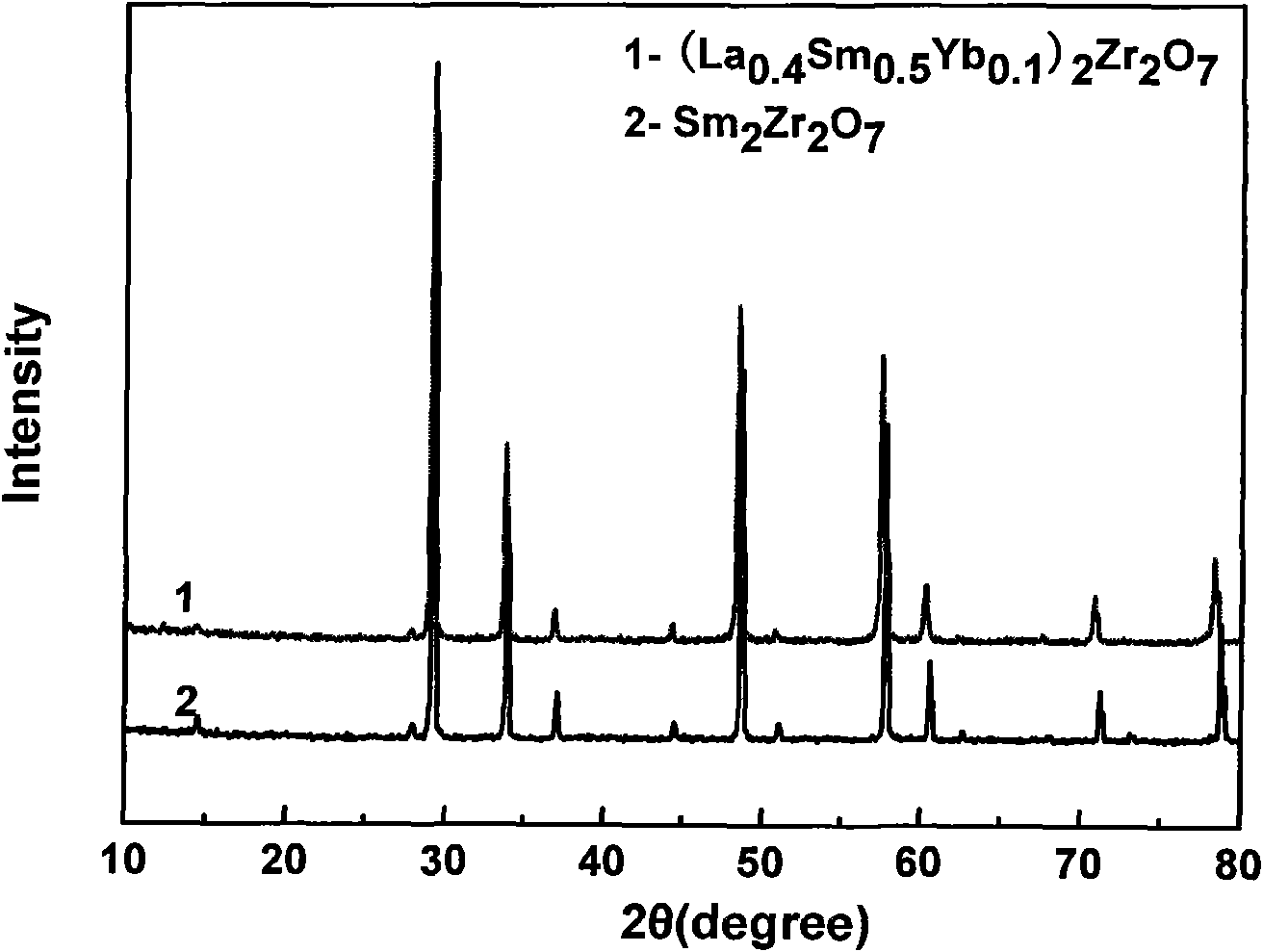

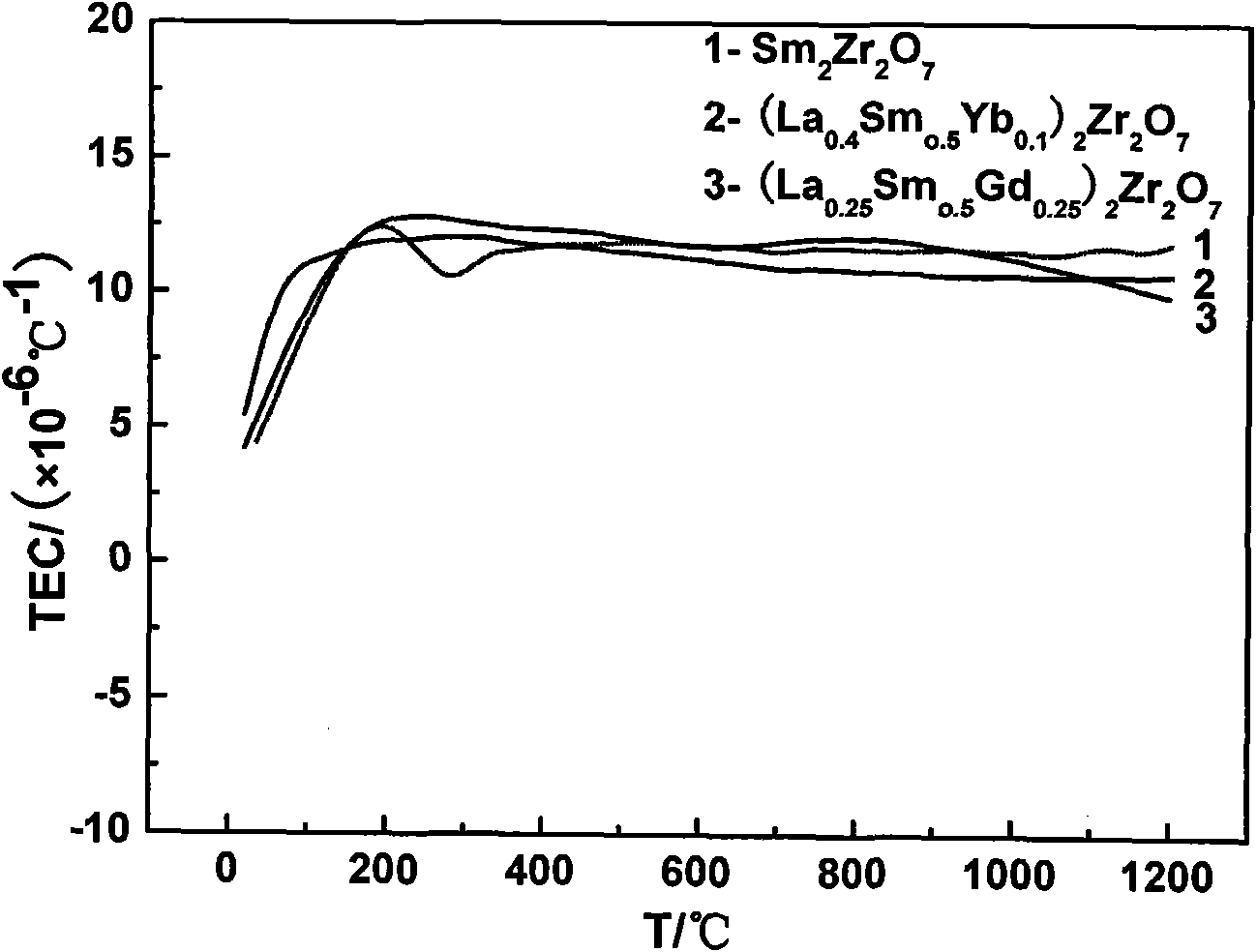

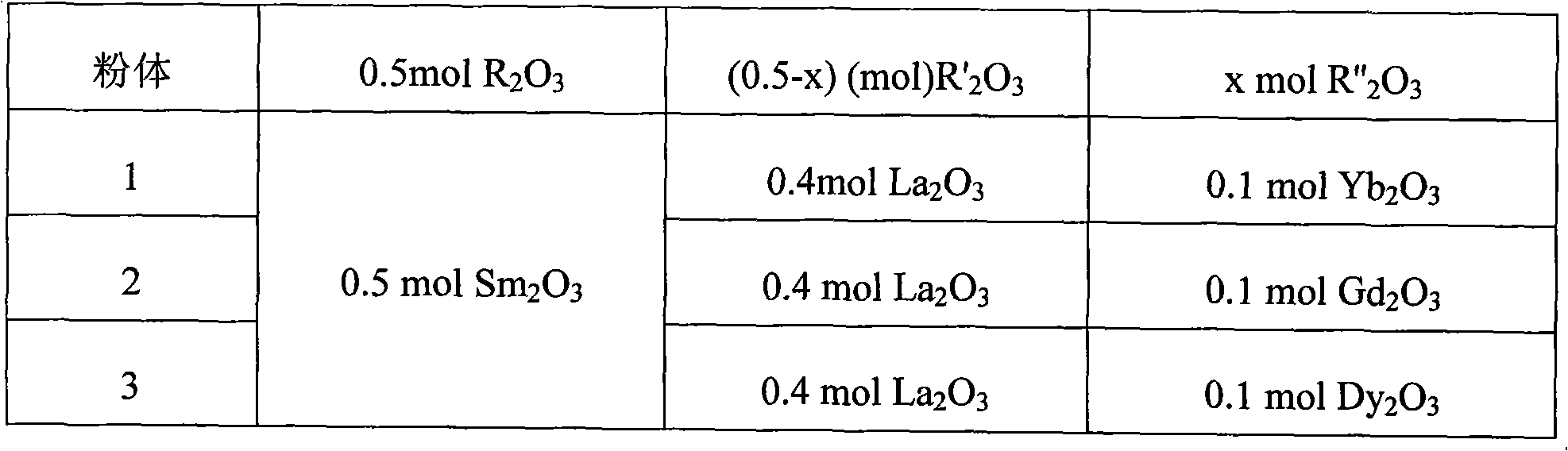

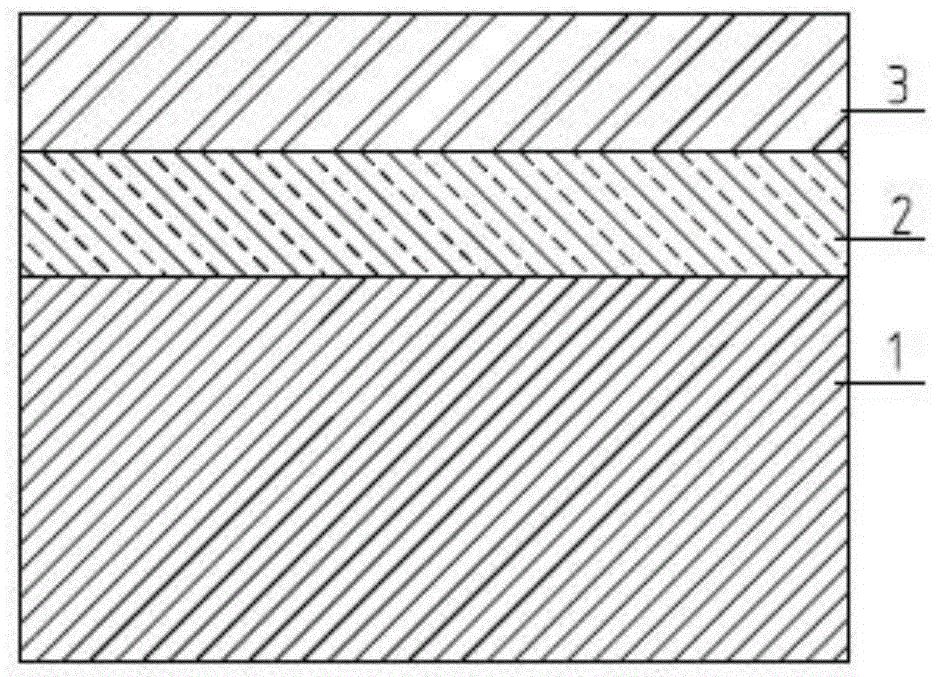

Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

ActiveCN102070335AImprove wild swingsLow thermal conductivityMolten spray coatingRare-earth elementZirconate

The invention discloses a pyrochlore structural rare-earth zirconate material system capable of being used for a heat barrier coating. The chemical composition of the material is (0.5-x)R'2O3-0.5Sm2O3-xR''2O3-2ZrO2, wherein x is more than 0 and less than or equal to 0.25; the R' is rare-earth elements or composition thereof, the ion radius of which is greater than that of Sm; and R'' is rare-earth elements or composition thereof, the ion radius of which is smaller than that of Sm. The material provided by the invention has low thermal conductivity, high thermal stability and high-temperature sintering resistance; the thermal expansion performance of the material is stable compared with a single pyrochlore structural material; and the material is favorable for reducing thermal stress generated by mismatching of thermal expansion coefficients in the thermal cycle process, and can prolong the thermal cycle life of the coating. Because of good high-temperature phase stability, the pyrochlore structural rare-earth zirconate material can be used for designing and preparing a novel high-temperature heat barrier coating material, the use temperature of which is below 1,550 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

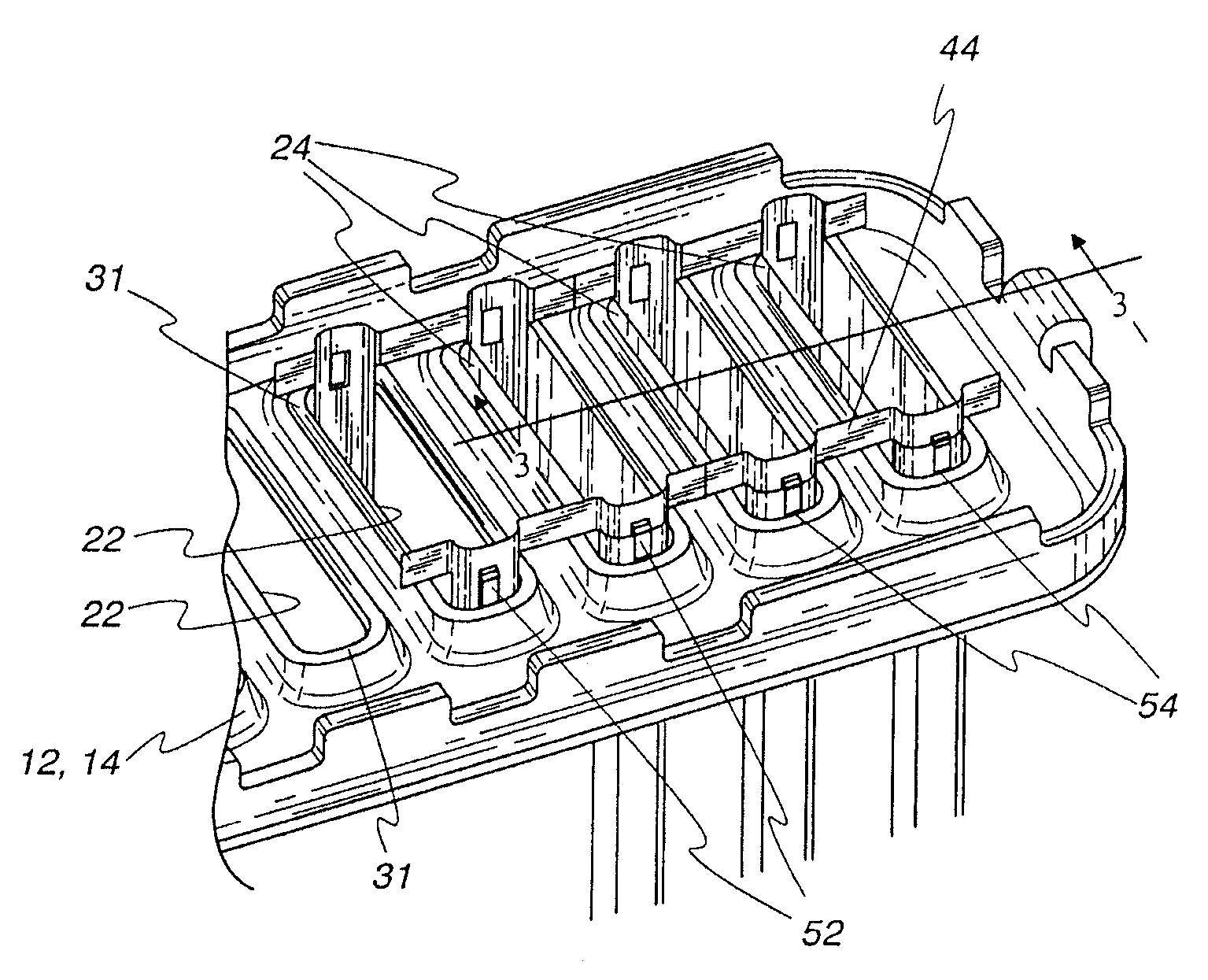

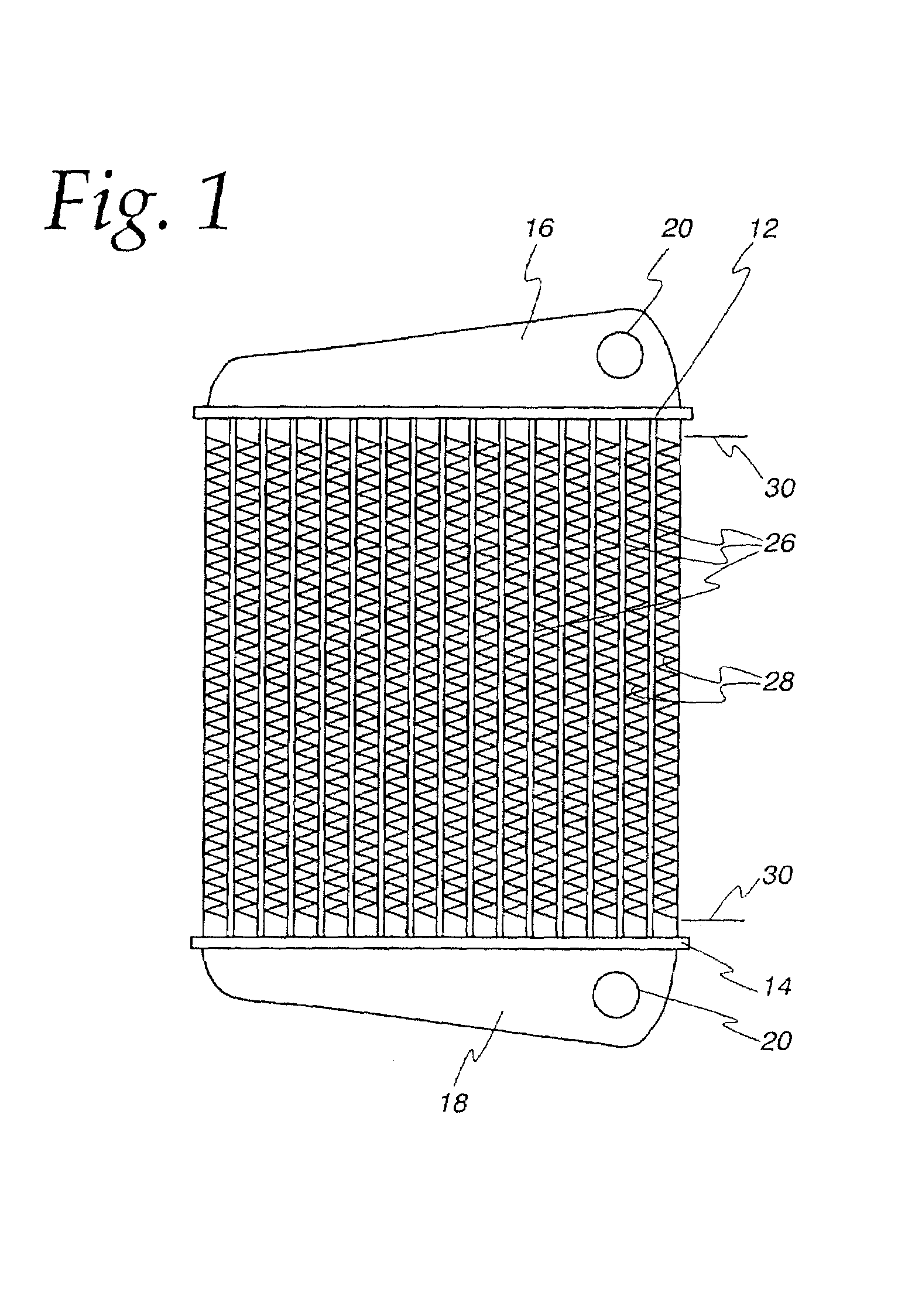

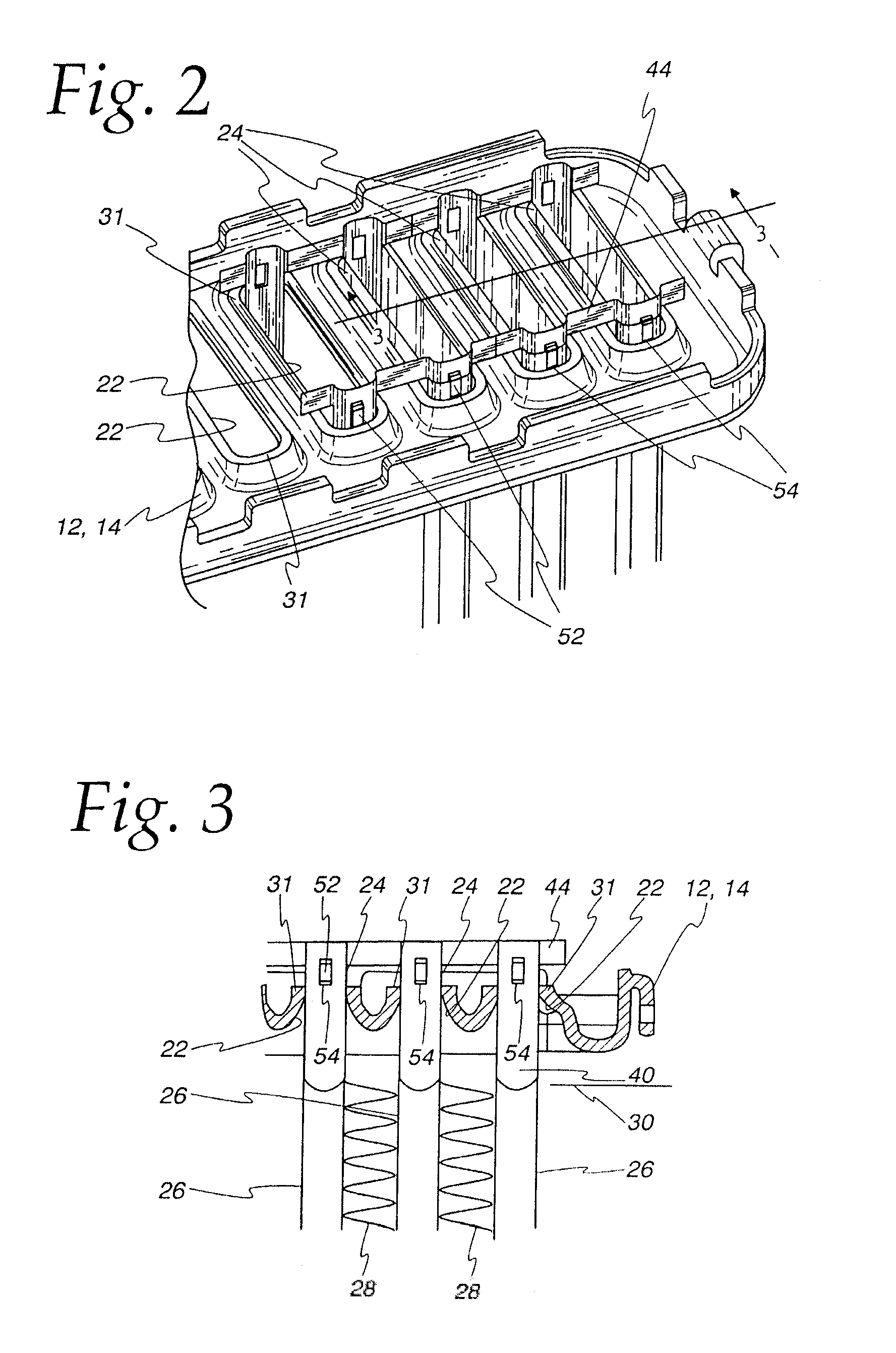

Thermal cycling resistant tube to header joint for heat exchangers

InactiveUS7461689B2Improve thermal cycle lifeMinimizes material requirementReinforcing meansMetal-working apparatusStructural engineeringMechanical engineering

A reduction in tube to header joint failures in a heat exchanger having spaced headers (12,14), elongated, side-by-side parallel spaced tube slots (22) in the headers (12,14) along the length thereof and a plurality of flattened tubes (26) having ends (24) received in the tube slots (22) and metallurgically bonded to the header (12,14) thereat was achieved through the use of a reinforcing structure (38) having at least two projections (40) having a cross sectional shape complimentary to at least a part of the surface of the tubes (26) at their ends (24) and a length sufficient to extend along the tube ends (24) to a location past the metallurgical bonds between the tube ends (24) and a header (12,14), and a spine (44) extending transverse to the projection. Also disclosed is a reinforcing structure (38) and a method of reinforcing the tube to header joints in a heat exchanger.

Owner:MODINE MFG CO

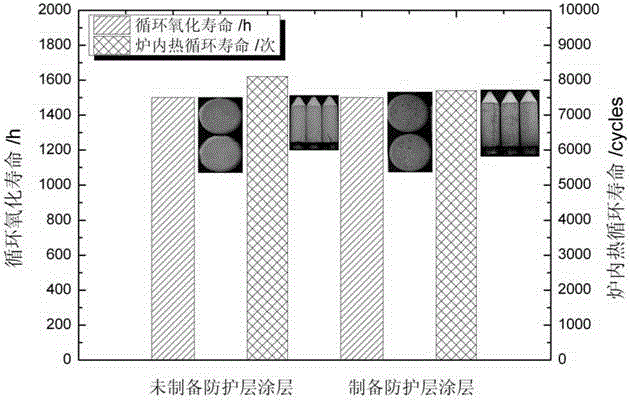

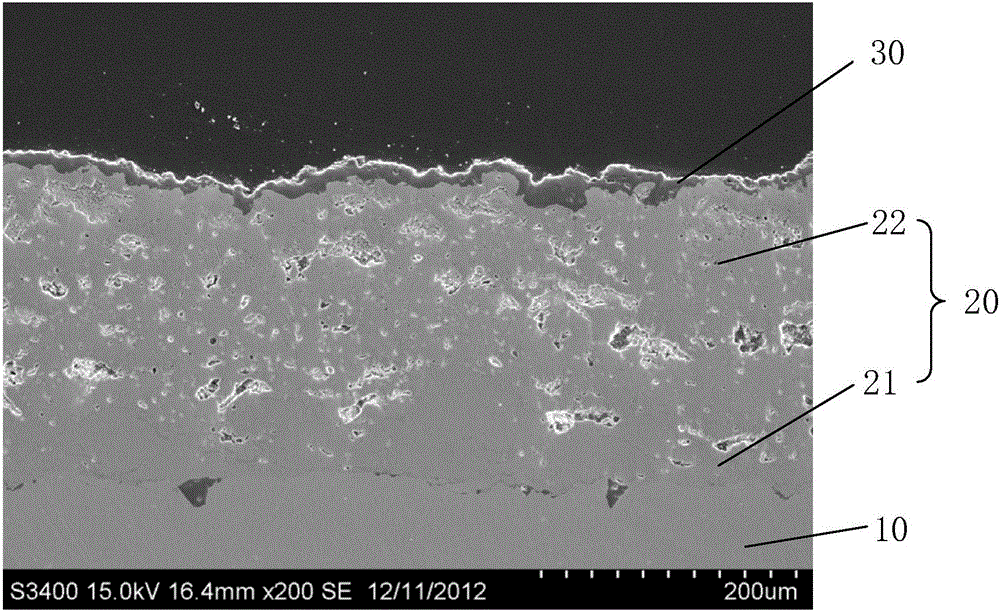

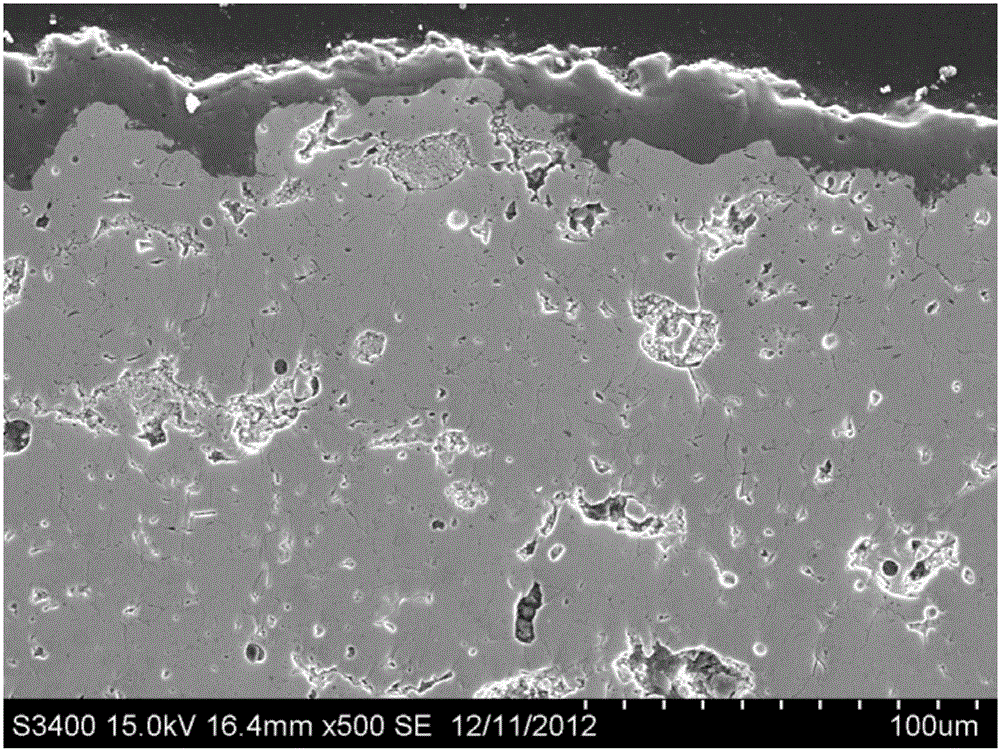

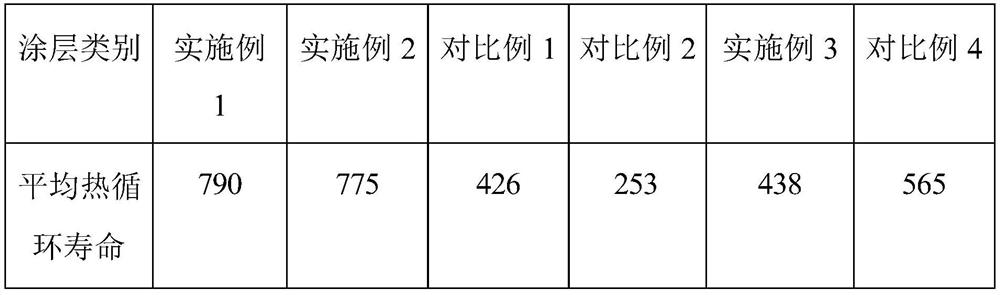

Protective coating for molten sediment on surface of thermal barrier coating and preparation method thereof

InactiveCN106191752AImprove thermal cycle lifeDelayed infiltration reactionMolten spray coatingSuperalloyThermal barrier coating

The invention discloses a protective coating for molten sediment on the surface of a thermal barrier coating and a preparation method thereof. The thermal barrier coating comprises at least one bonding layer and at least one ceramic layer, the surface of a high-temperature alloy matrix is coated with the bonding layers, and the surfaces of the bonding layers are coated with the ceramic layers. The ceramic layers making contact with the bonding layers are yttrium-oxide-based partially stabilized zirconium oxide layers. The surfaces of the ceramic layers are further coated with the protective coating. The protective coating is prepared from aluminum-oxide-based spraying powder through a supersonic-speed plasma spraying technique. The preparation method of the protective coating includes the steps of drying of the aluminum-oxide-based spraying powder, workpiece clamping, parameter adjustment, even preheating of the surface of the thermal barrier coating through plasma flames generated by a spray gun of ultrasonic-speed plasma spraying equipment, starting of powder feeding, and forming of the protective coating by spraying the aluminum-oxide-based spraying powder to the surface of the thermal barrier coating one to three times.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

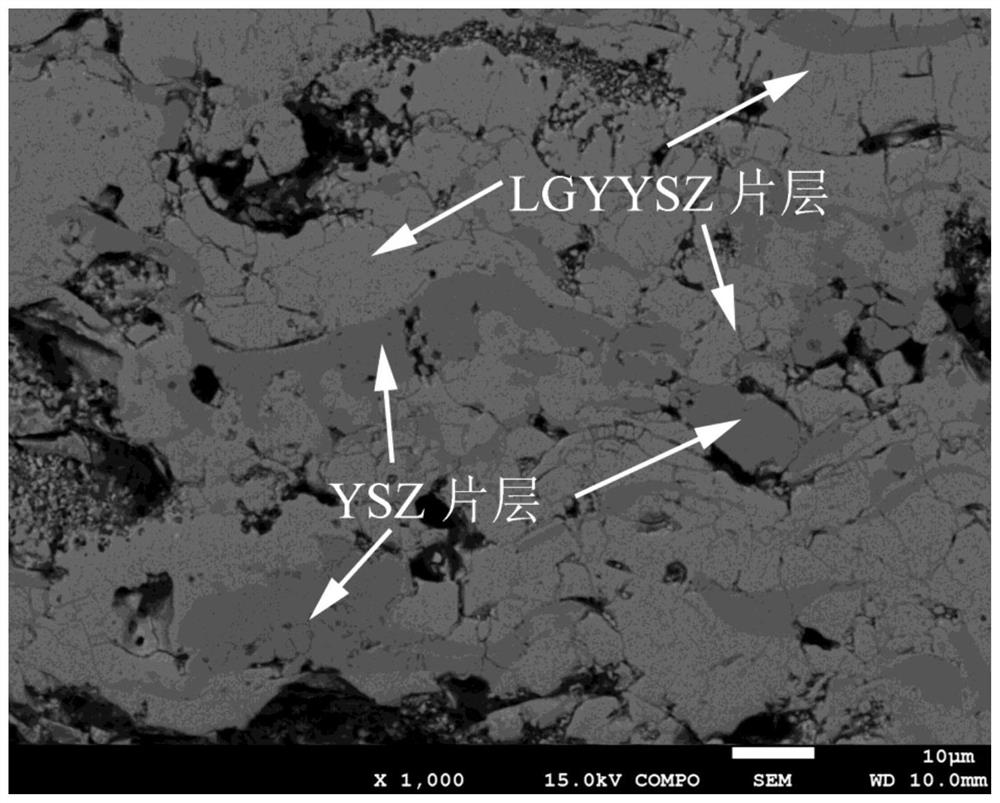

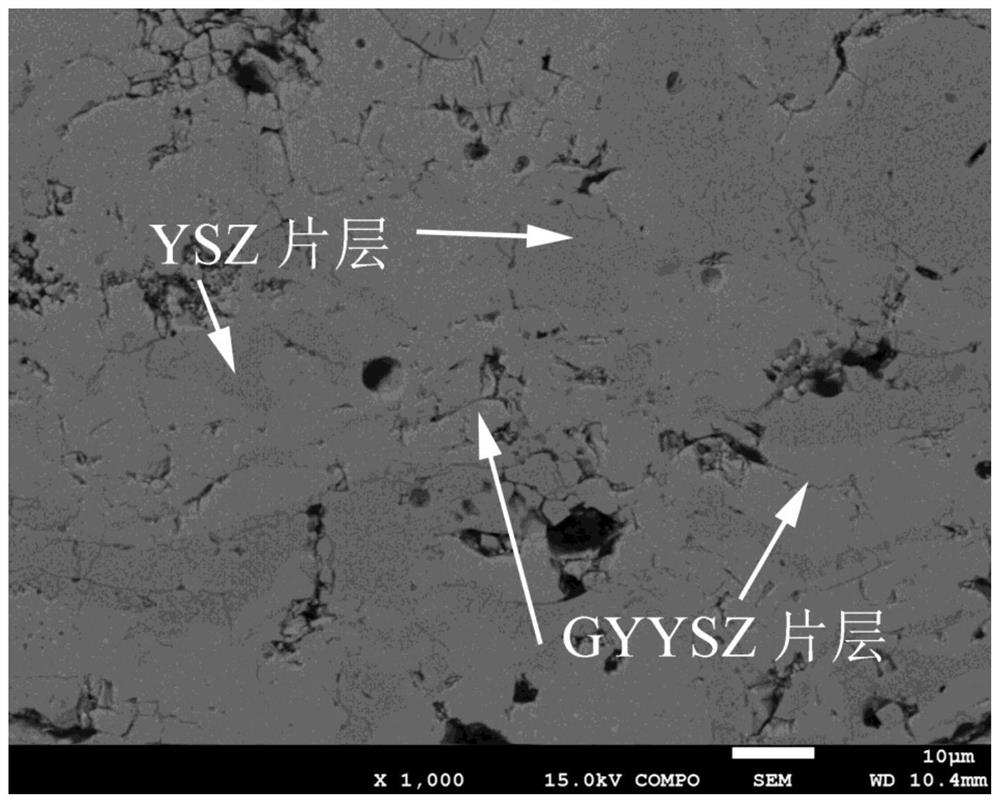

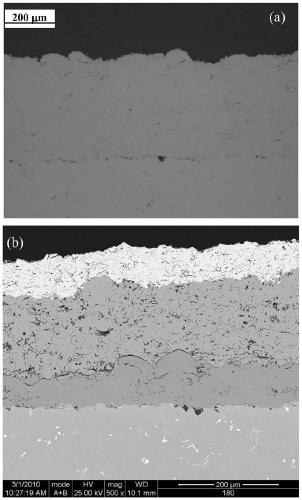

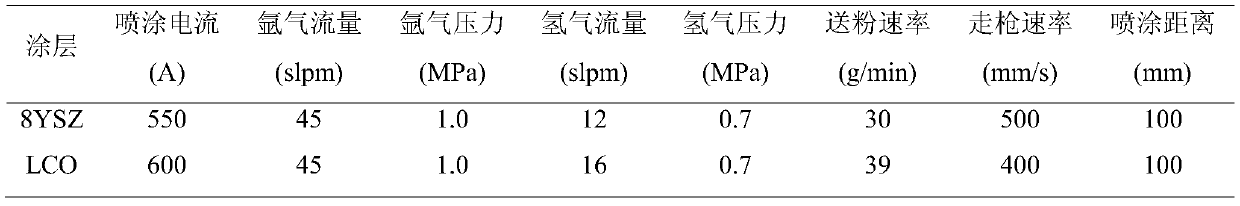

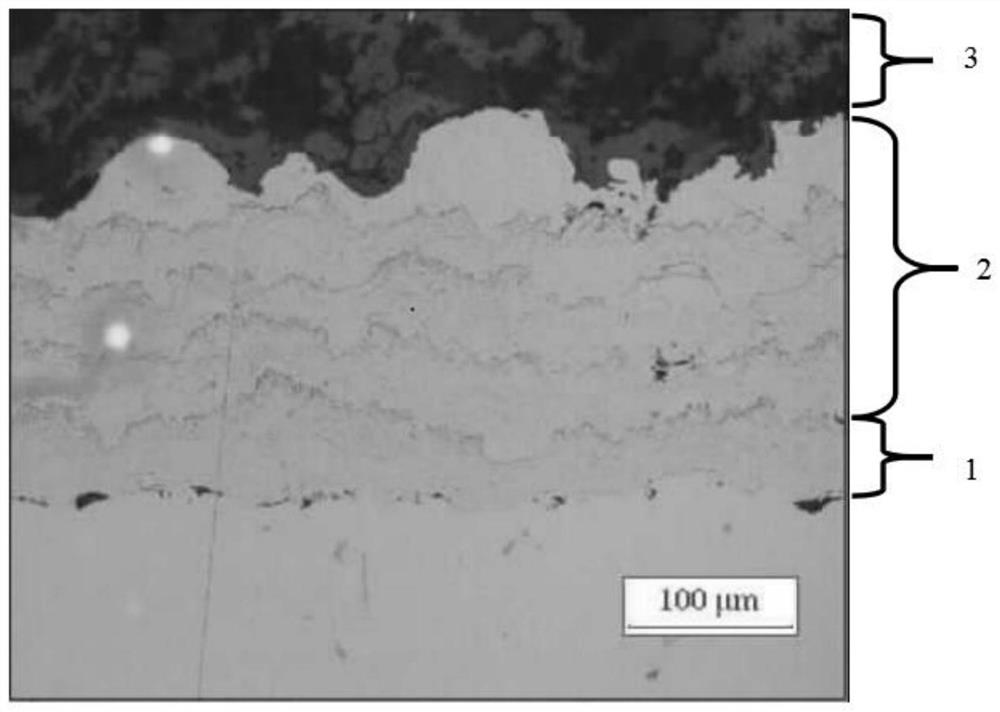

Thermal barrier coating with composite double-ceramic-layer structure and preparation method thereof

PendingCN113388801AHigh thermal conductivityImproved coefficient of thermal expansionMolten spray coatingComposite ceramicThermal barrier coating

The invention relates to a thermal barrier coating with a composite double-ceramic-layer structure and a preparation method thereof, and belongs to the technical field of thermal barrier coating preparation. The thermal barrier coating sequentially comprises a thermal barrier coating bonding layer, a YSZ ceramic layer and a composite ceramic layer from a base body to the top; the composite ceramic layer is composed of a high-toughness ceramic material and a high-rare-earth-content doped zirconium oxide material according to the volume ratio of (1 to 4): (4 to 1); the high-toughness ceramic material is a ceramic material with the fracture toughness being greater than 5MPa. M < 1 / 2 >; and in the high-rare-earth-content doped zirconium oxide material, the sum of the mole fractions of the doped rare earth elements is 16 percent to 30 percent. According to the thermal barrier coating, the thermal barrier coating bonding layer, the YSZ ceramic layer and the composite ceramic layer are sequentially prepared from the base body to the top through a spraying method. The thermal barrier coating can be prevented from cracking in the thermal cycle process, and the service life is long; and cracks are uniformly distributed, the anti-stripping capability is high, and the heat insulation performance is high.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

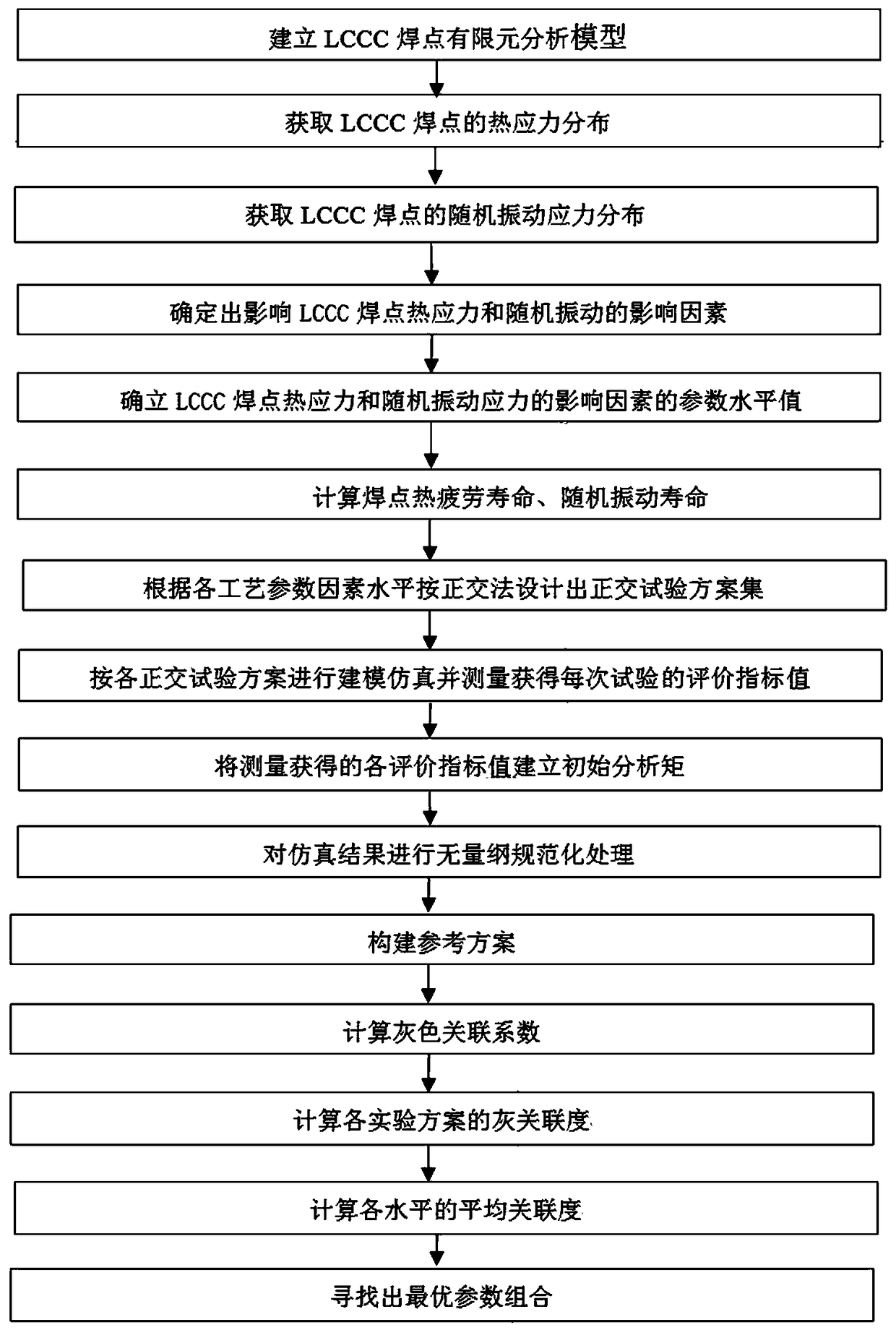

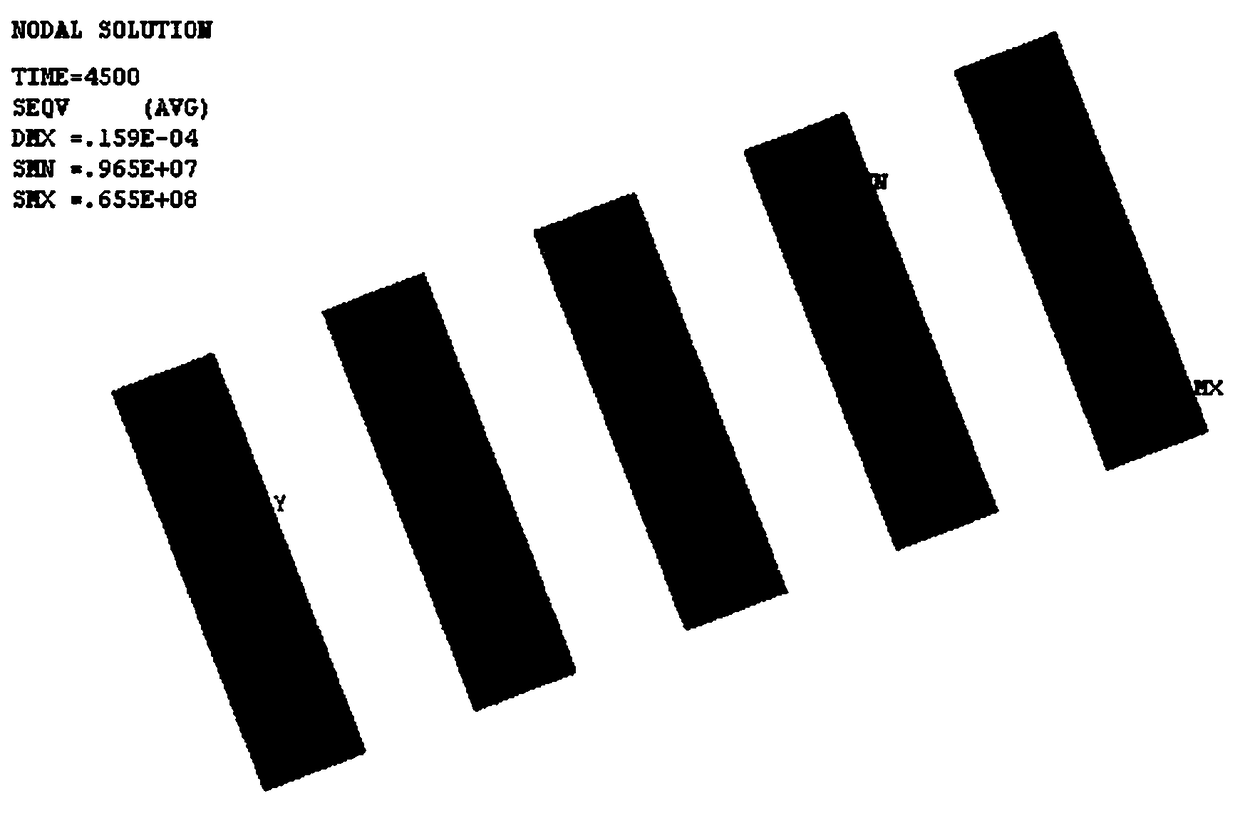

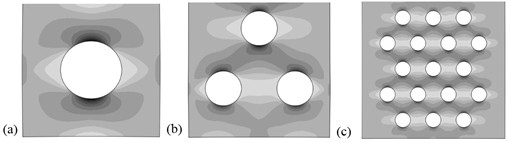

Method for optimizing thermal cycle and random vibration life of LCCC chip solder joint of car networking

ActiveCN109190223AReduce the number of experimental analyzesImprove thermal cycle lifeDesign optimisation/simulationSpecial data processing applicationsRandom vibrationElement analysis

A method for optimizing the thermal cycle and random vibration life of an LCCC chip solder joint of car networking is provided. The thermal fatigue life and random vibration life of LCCC solder jointsare calculated by establishing the finite element simulation model of LCCC solder joints and performing solder joint thermal cyclic loading and random vibration loading stress-strain finite element analysis simulation analysis. The method further comprises the steps of selecting the pad width, pad length, clearance height and steel net thickness as design variables, in order to maximize the thermal fatigue life and random vibration life of solder joints, carrying out the multi-objective reliability optimization design of LCCC solder joints by means of orthogonal test and grey relational analysis, and finally designing the parameter combinations making both the thermal cycle life and random vibration life of solder joints optimal. The method is simple and facilitates the later parameter optimization design and the optimized calculation results are ideal, and the method provides scientific guidance for the LCCC solder joint structure parameter design.

Owner:GUILIN UNIV OF ELECTRONIC TECH

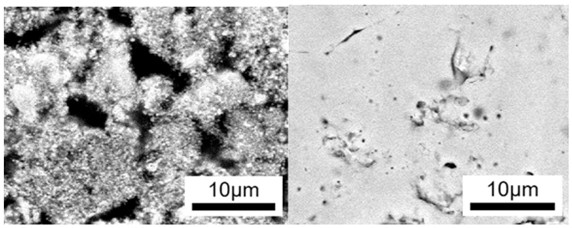

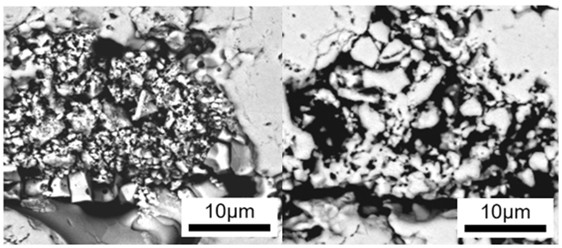

Aluminum-silicon carbide composite material with ultrahigh volume fraction and preparation method thereof

ActiveCN102173808AHigh modulus of elasticityImprove the comprehensive properties such as elastic modulusMetallic aluminumMicrometer

The invention relates to an aluminum-silicon carbide composite material with ultrahigh volume fraction and a preparation method thereof. The aluminum-silicon carbide composite material reaches ultrahigh silicon carbide volume fraction, has low preparation cost, convenient process, good combination property and high reliability and can realize the near-net-shape forming of complex shapes and largesizes. The aluminum-silicon carbide composite material comprises the following components by volume percent: 46%-55% of green silicon carbide coarse powder, 16%-23% of green silicon carbide fine powder, 8%-12% of green silicon carbide micro powder, 8%-27% of metallic aluminum, 1.9%-2.7% of metallic silicon and 0.1%-0.3% of metallic magnesium, wherein the green silicon carbide coarse powder, the green silicon carbide fine powder and the green silicon carbide micro powder respectively have the grain diameters of 120-210 micrometers, 30-63 micrometers and 6-12 micrometers.

Owner:西安明科微电子材料有限公司

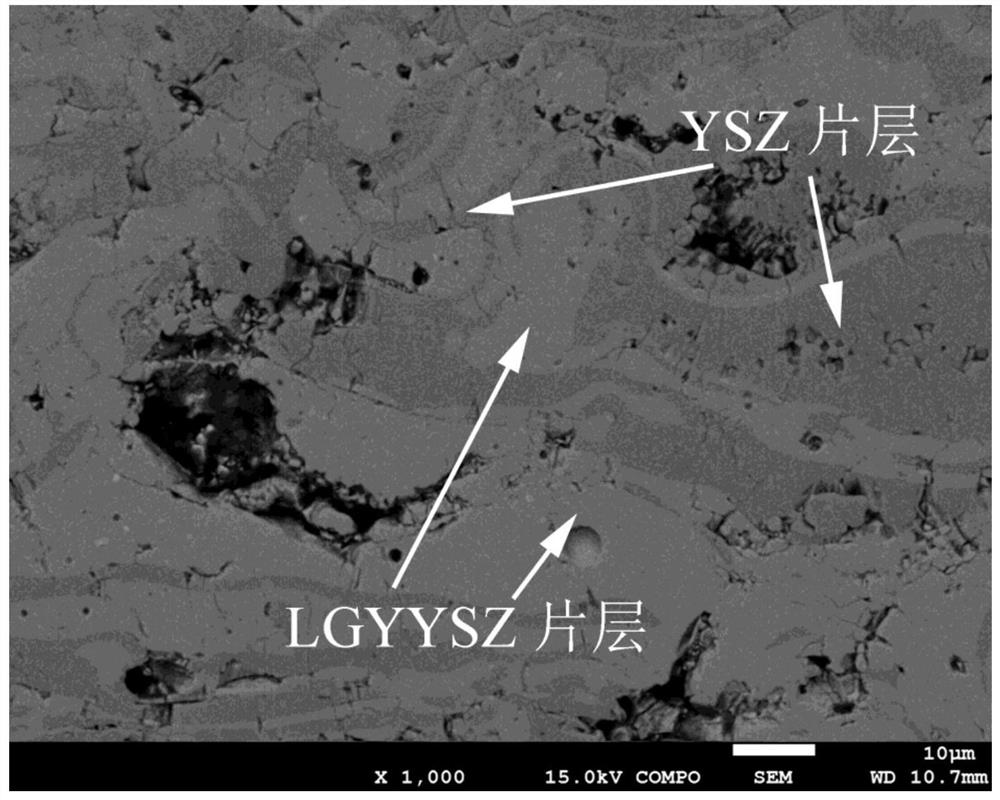

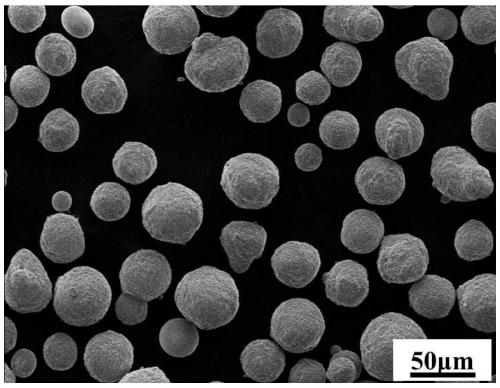

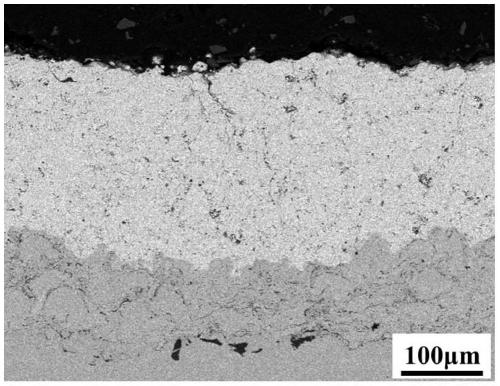

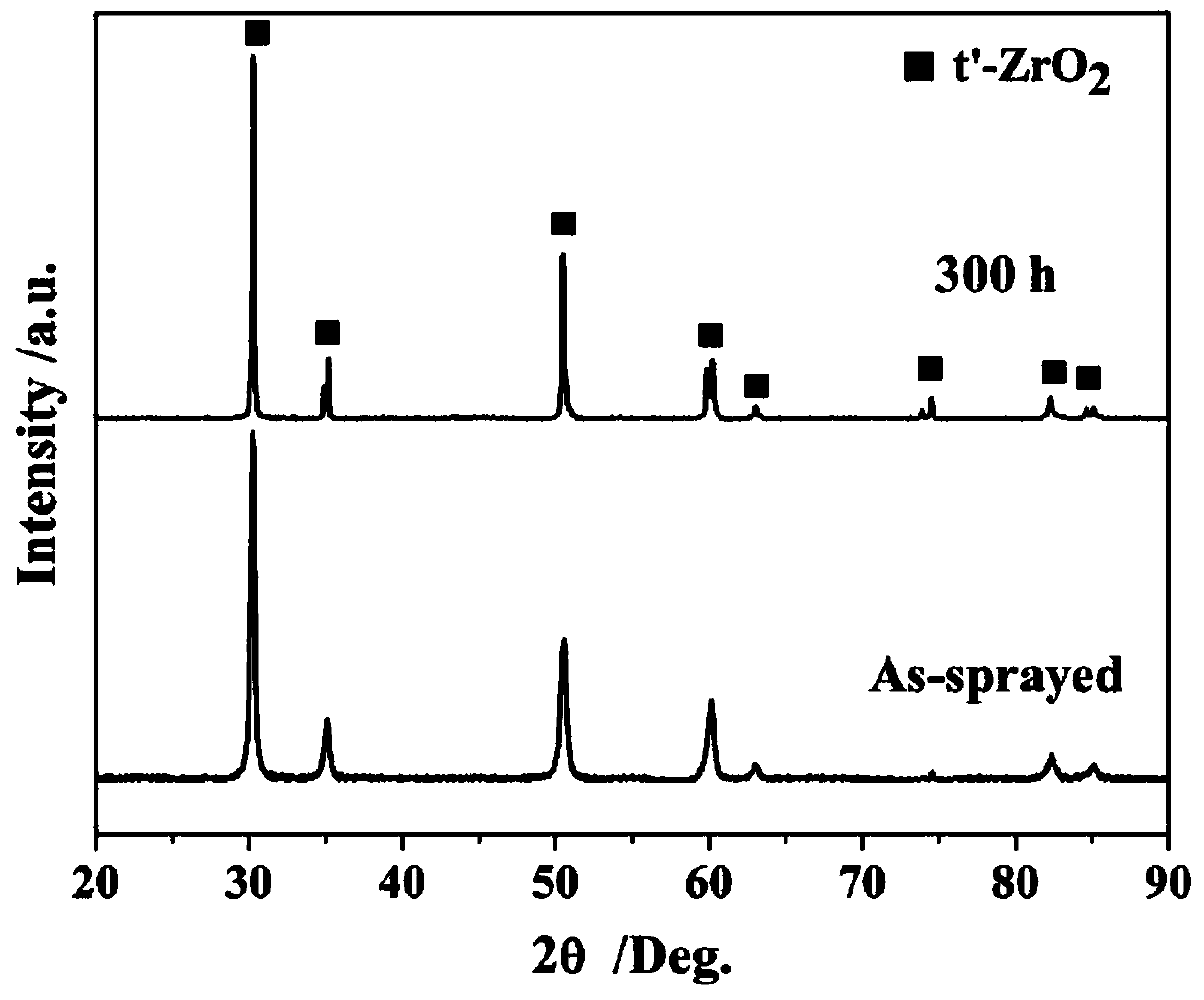

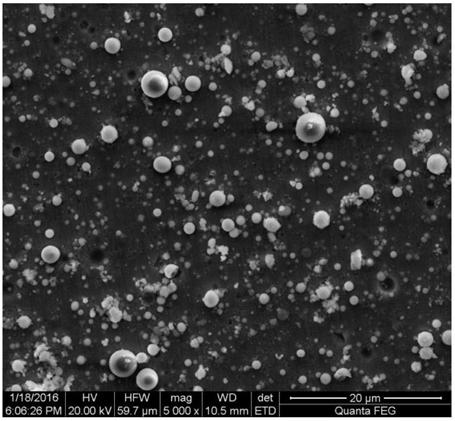

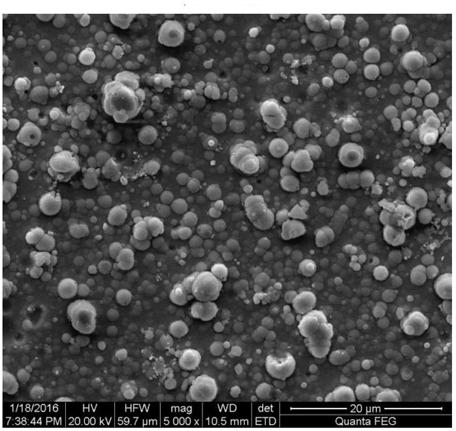

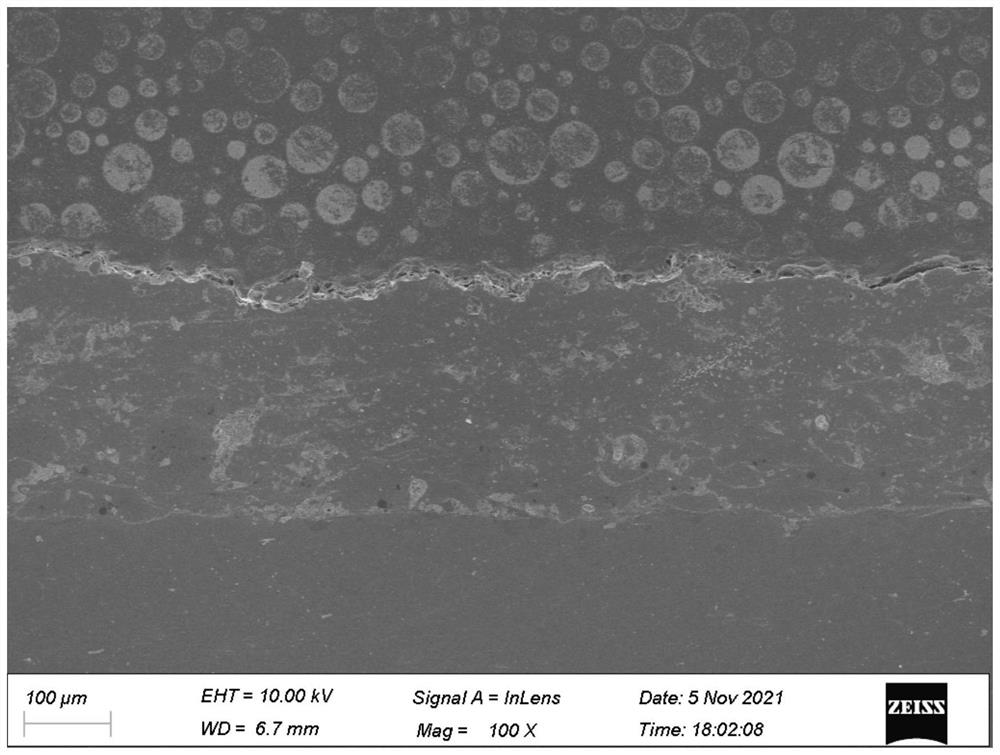

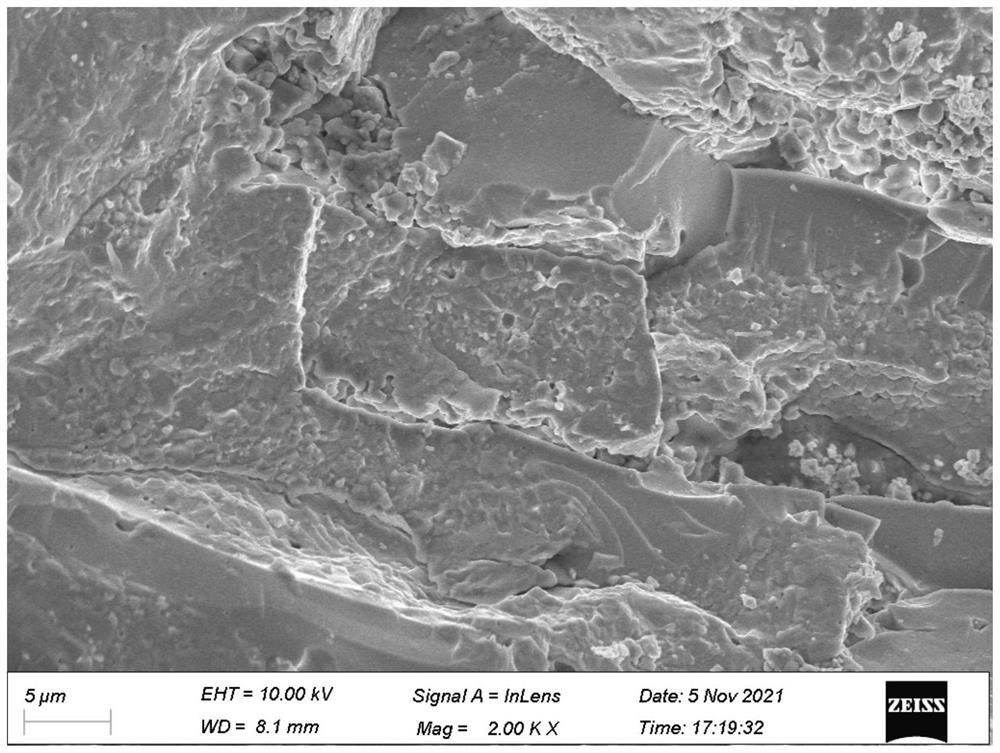

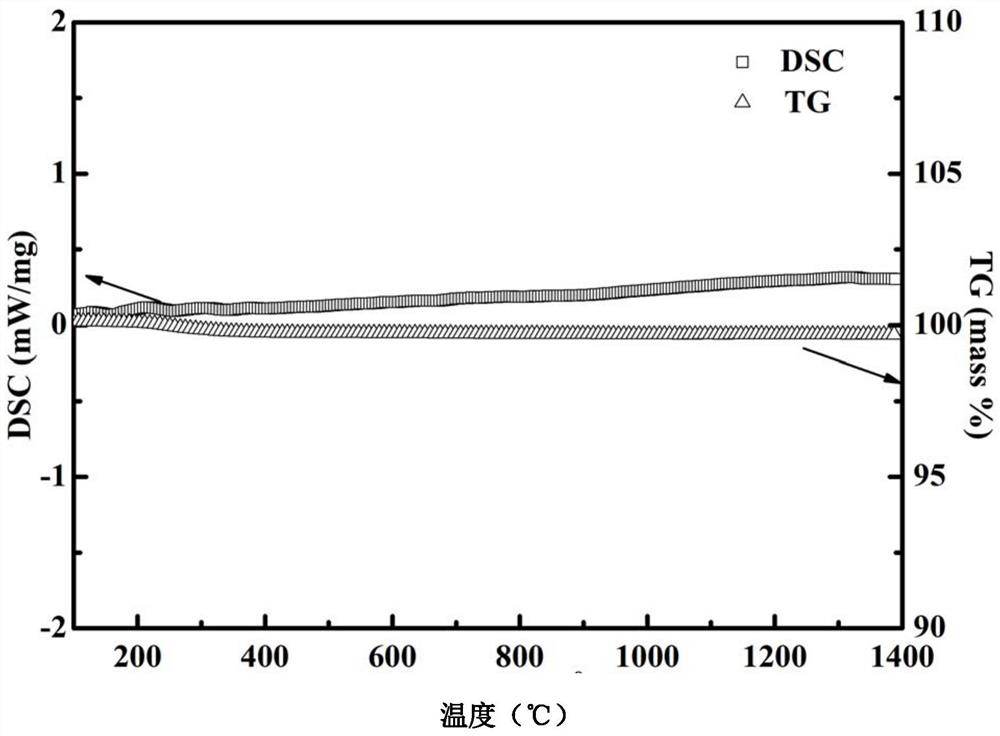

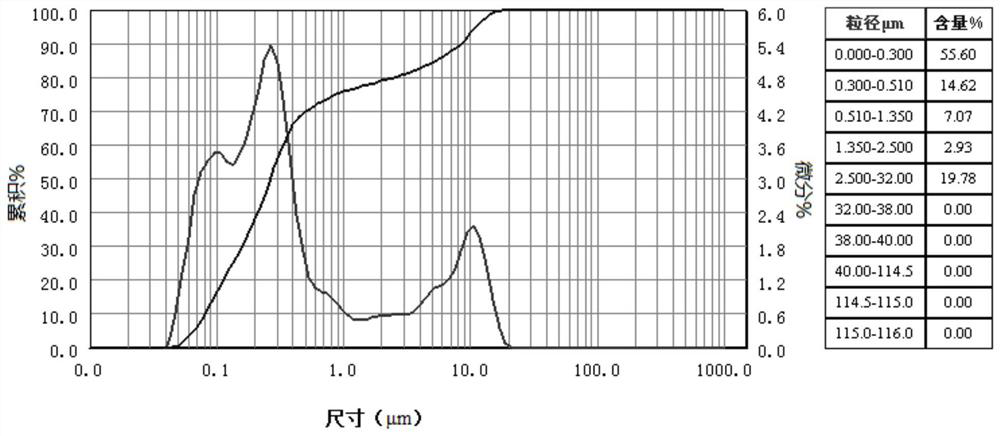

High-performance Sc-Y-co-doped zirconium oxide thermal protection coating and preparing method thereof

The invention relates to a high-performance Sc-Y-co-doped zirconium oxide thermal protection coating and a preparing method thereof. The coating is prepared on a base body by spraying Sc-Y-co-doped zirconium oxide powder through a supersonic plasma spraying technology, wherein the parameters of the supersonic plasma spraying technology are as follows: the current is 300-600A, the voltage is 100-180V, the primary gas argon flow rate is 50-200slpm, the secondary gas hydrogen flow rate is 8-30slpm, the spraying distance is 80-150mm, the powder delivery amount is 20-60g / min, and the moving speed of a spray gun is 500-800mm / s. The prepared coating has a single tetragonal structure with even components, is more stable than a yttrium oxide part which is widely applied at present, has heat conductivity which is lower than that of the zirconium oxide coating and has better high-temperature stability. The coating can greatly increase the working efficiency and service life of the metal hot-end components of high-end equipment, such as aircraft engines and heavy-duty gas turbines.

Owner:XI AN JIAOTONG UNIV

Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

ActiveCN102070335BLow thermal conductivityImprove thermal stabilityMolten spray coatingRare-earth elementZirconate

The invention discloses a pyrochlore structural rare-earth zirconate material system capable of being used for a heat barrier coating. The chemical composition of the material is (0.5-x)R'2O3-0.5Sm2O3-xR''2O3-2ZrO2, wherein x is more than 0 and less than or equal to 0.25; the R' is rare-earth elements or composition thereof, the ion radius of which is greater than that of Sm; and R'' is rare-earth elements or composition thereof, the ion radius of which is smaller than that of Sm. The material provided by the invention has low thermal conductivity, high thermal stability and high-temperature sintering resistance; the thermal expansion performance of the material is stable compared with a single pyrochlore structural material; and the material is favorable for reducing thermal stress generated by mismatching of thermal expansion coefficients in the thermal cycle process, and can prolong the thermal cycle life of the coating. Because of good high-temperature phase stability, the pyrochlore structural rare-earth zirconate material can be used for designing and preparing a novel high-temperature heat barrier coating material, the use temperature of which is below 1,550 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of high temperature oxidation resistant coating on niobium alloy surface and preparation method thereof

InactiveCN104561882BHigh strengthImprove toughnessMolten spray coatingHigh energyOxidation resistant

The invention belongs to the field of thermal spraying, and relates to a high-temperature oxidation resistant coating on a niobium alloy surface and a preparation method of the high-temperature oxidation resistant coating. The coating is in a dual-layer structure with a bottom coating Mo1-xWx(Si1-y-zAlyBz)2 and a surface coating Mo1-xWx(Si1-y-zAlyBz)2-(10-20)%wt HfSi2, and prepared on a niobium alloy matrix surface by a high-energy plasma spraying process, wherein a bottom coating powder material Mo1-xWx(Si1-y-zAlyBz)2 is prepared by a self-propagating process, and the spherical particles meeting the requirements of the spraying process are obtained by applying a plasma spheroidizing process; surface coating powder materials Mo1-xWx(Si1-y-zAlyBz)2 and HfSi2 are mixed evenly in a mechanical mixing manner. The coating has excellent high-temperature oxidation resistance at 1500-1800 DEG C, and can be applied to high-temperature protection of niobium alloy parts.

Owner:CHINA IRON & STEEL RES INST GRP +1

Novel heat barrier coating material

InactiveCN1329551CHigh coefficient of thermal expansionEasy to prepareMolten spray coatingBlade accessoriesRoom temperatureThermal expansion

The invention relates to a series of ceramic materials used as high temperature thermal barrier coating materials and their use, wherein the chemical constitution of the ceramic material being A2ZrxCe(1-x)2O7, wherein 0<=x<=0.9, an is one or combination of two of Nd, Sm, Eu, Gd and Tb. The ceramic material has high coefficient of thermal expansion, thus can be designed into thermal barrier coating material, whose application temperature interval is between room temperature to 1400 deg. C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Thermal barrier coating material and preparation method and application thereof

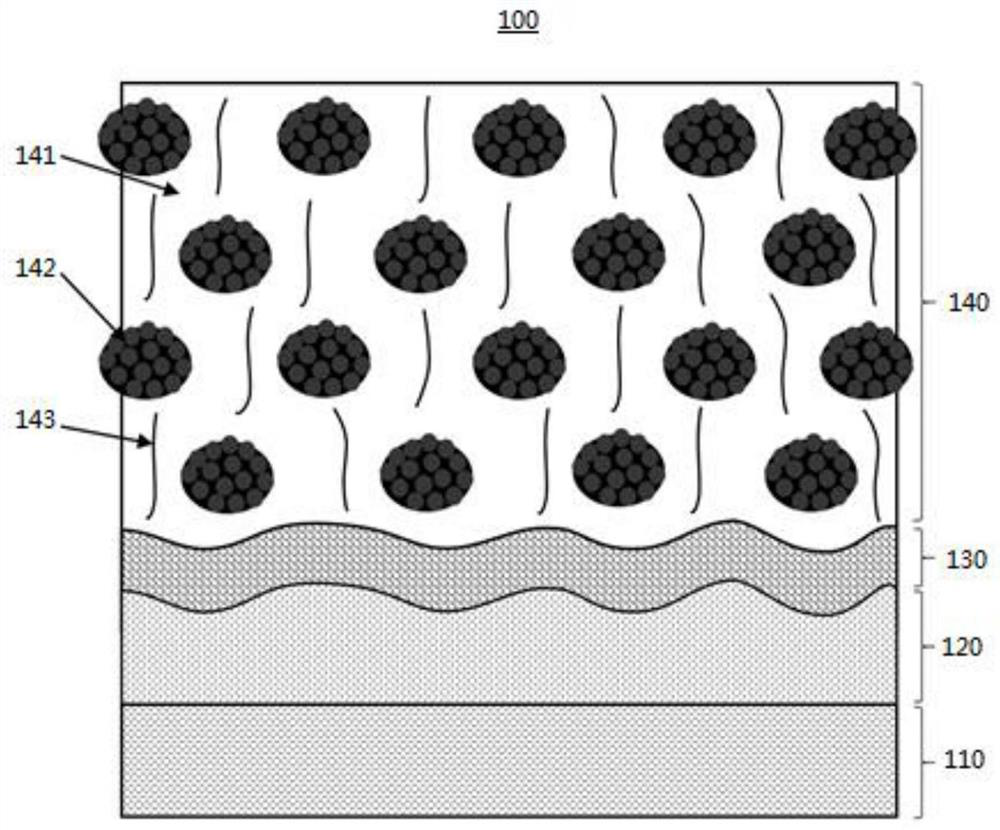

ActiveCN113930710AImproved lateral deformation complianceReduce thermal stressMolten spray coatingCrack resistanceAlloy

The invention discloses a thermal barrier coating material and a preparation method and application thereof, and relates to the technical field of thermal barrier coatings. A thermal barrier coating comprises an alloy matrix, a bonding layer, a ceramic transition layer and a ceramic surface layer which are sequentially arranged, the porosity of the ceramic transition layer is 1-8%, and the ceramic surface layer comprises a coating matrix with multiple microcracks and porous ceramic particles embedded in the coating matrix. The transverse deformation compliance of the thermal barrier coating can be improved by forming microcracks in the ceramic surface layer, and the strain tolerance of the coating is improved; and the porous ceramic particles strengthen the heat insulation capacity of the thermal barrier coating and absorb deformation energy, and the stress borne by the thermal barrier coating in the service process is reduced. Therefore, the thermal barrier coating provided by the invention can give full play to the advantages of high strain tolerance and high interface cracking resistance, and the thermal cycle life of the coating is remarkably prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of anti-CMAS corrosion micro-nano composite structure thermal barrier coating and preparation method thereof

InactiveCN106086765BGood anti-CMAS effectImprove bindingMolten spray coatingVacuum evaporation coatingMicro nanoElectron beam physical vapor deposition

Owner:BEIHANG UNIV

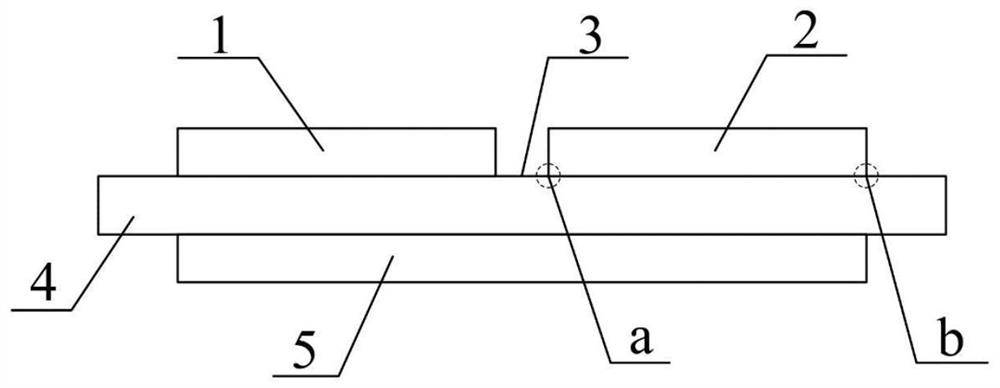

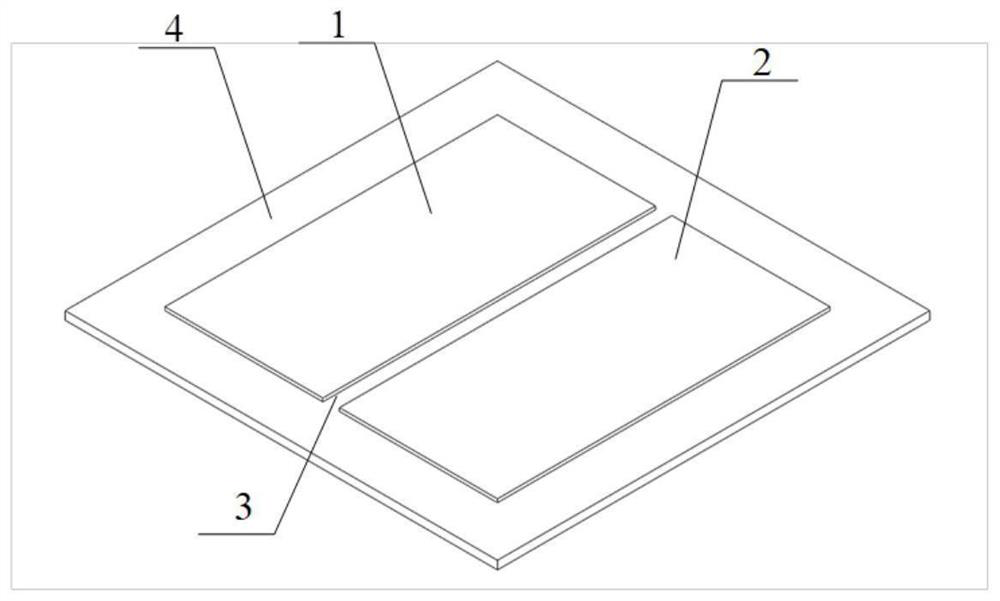

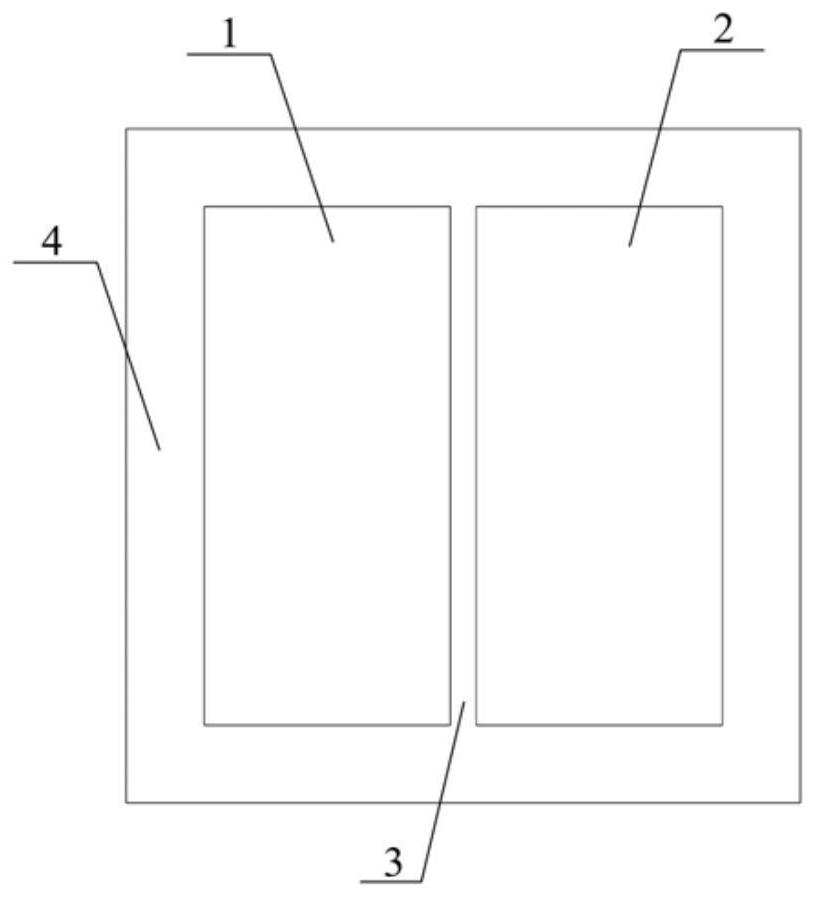

DBC substrate capable of reducing heat warping

PendingCN114759007AChange the degree of bendingImprove thermal cycle lifeSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationStructural engineering

The invention discloses a DBC substrate capable of reducing heat warping, and belongs to the technical field of power semiconductors. The structure sequentially comprises a top copper layer, an insulating ceramic layer and a bottom copper layer from top to bottom, the top copper layer is provided with a plurality of component welding areas which are arranged in parallel, and an insulation gap is arranged between every two adjacent component welding areas; the bottom copper layer is provided with a load reducing groove area, the load reducing groove area coincides with the vertical center line of the insulation gap, and the width of the load reducing groove area is not smaller than the width of the insulation gap. A plurality of load reducing grooves distributed in an array shape are formed in the load reducing groove area. The bending degree of the bottom copper layer in the area is changed by arranging the load reducing grooves distributed in the array shape, and buckling deformation caused by different thermal expansion coefficients of materials of the insulating ceramic layer and the bottom copper layer when the DBC substrate is heated can be reduced; original concentrated stress can be weakened, and the thermal cycle life of the substrate is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

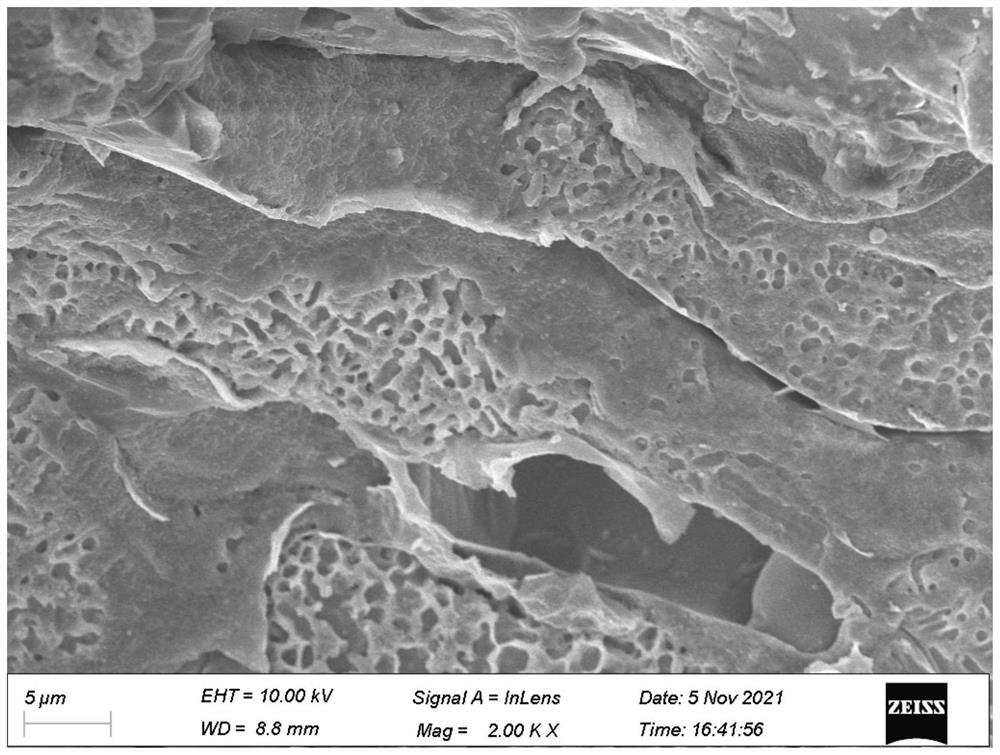

A nano/columnar-like mixed structure thermal barrier coating and its preparation method

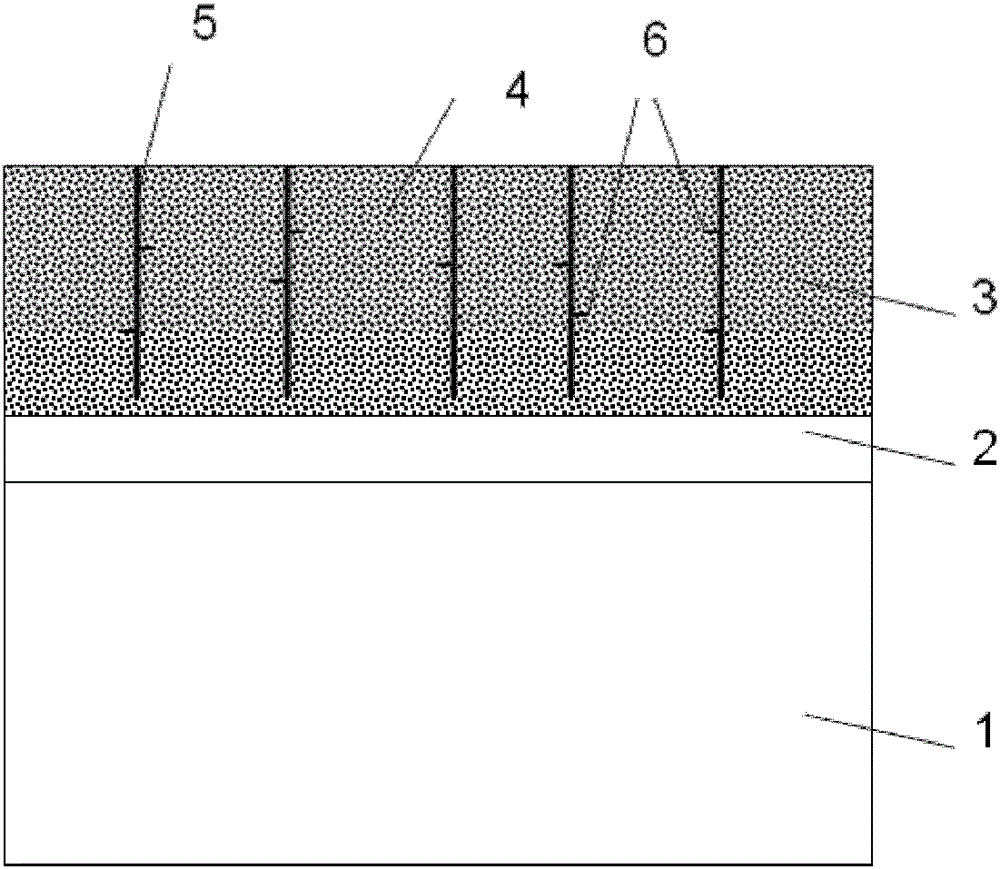

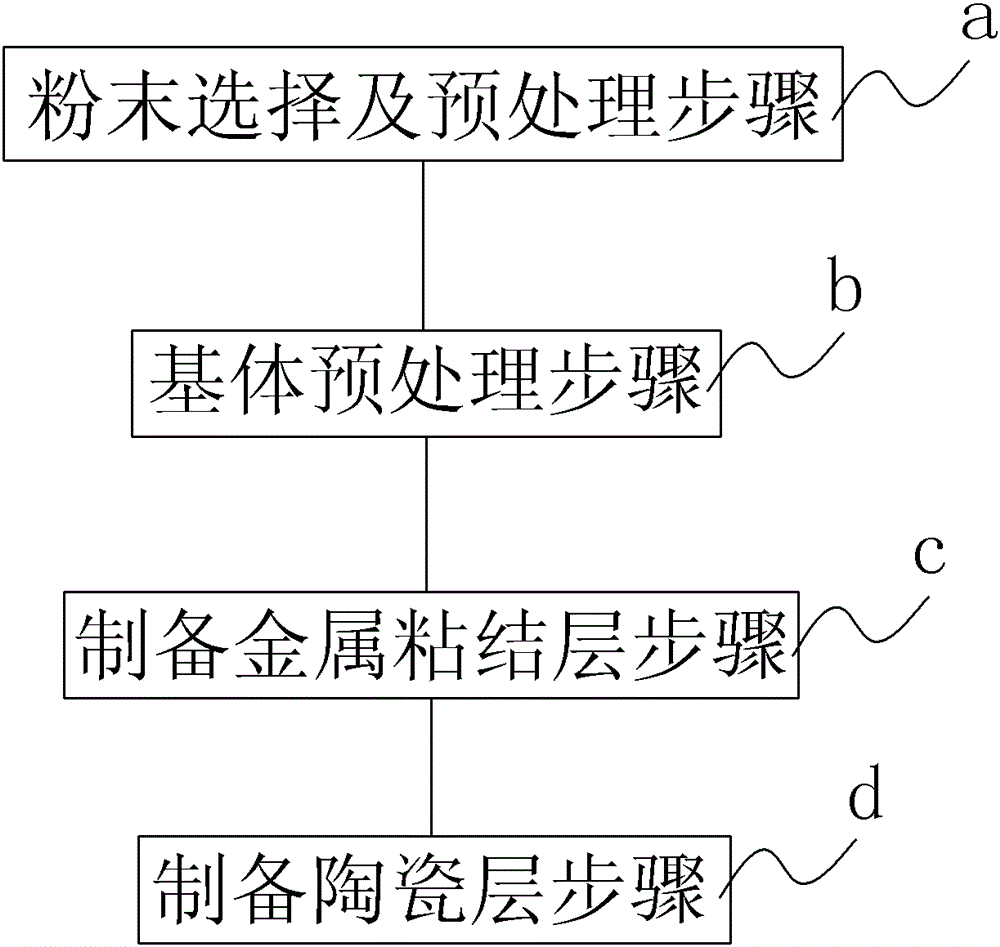

ActiveCN103009704BSmall shrinkageGood heat insulationMolten spray coatingCeramic layered productsThermal insulationNanoparticle

The invention relates to a nanometer / columnar-like crystal mixing structure thermal barrier coating and a preparation method thereof. The mixing structure thermal barrier coating is a nanometer / columnar-like crystal mixing structure coating, and comprises a substrate, a metal bonding layer and a ceramic layer, wherein the metal bonding layer and the ceramic layer are sequentially coated on the substrate, the ceramic layer comprises unmelted nanoparticles, nanometer pores, nanometer crystal and ultrafine crystal, and has cracks perpendicular to the substrate, and the cracks form the columnar-like crystal structure. The mixing structure thermal barrier coating preparation method comprises powder selection, a pretreatment step, a substrate pretreatment step, a metal bonding layer preparation step, and a 6-8% YSZ ceramic layer preparation step. The coating disclosed by the present invention has characteristics of high strain tolerance, excellent thermal insulation performance, high bonding strength, high thermal cycle life, and high thermal shock life, such that the thermal barrier coating has a good comprehensive performance.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

A 3D printing packaging method for flip chips

The present invention provides a 3D printing packaging method of a flip chip. The method is characterized by comprising the following steps of S1 utilizing a computer to design a three-dimensional digital model of an LED device, programming the LED device, after the hierarchical slicing processing, introducing a 3D printer, and utilizing the computer to control the hierarchical printing; S2 utilizing a suction nozzle to absorb the flip chip, and fixing under a reflector cup; S3 carrying out the 3D printing on a solder layer and a radiating substrate, wherein the radiating substrate is equipped with a leading-out circuit in electrode connection with the chip, and further can comprises a step S4 of filling the fluorescent powder. Relative to the general packaging, according to the present invention, the die bonding wires and the eutectic solders are not needed, the packaging yield is improved, a support and a PCB or a COB do not need to purchase, the packaging cost is reduced, the packaging research and development cycle is shortened, and the packaging appearance diversity is increased, and the LED thinning and miniaturization are promoted.

Owner:GUANGDONG DELI PHOTOELECTRIC

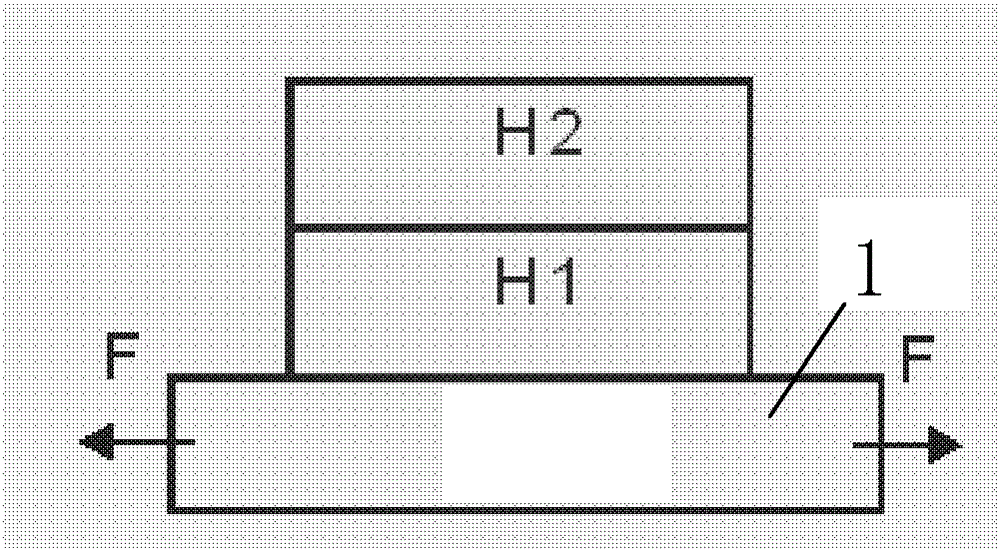

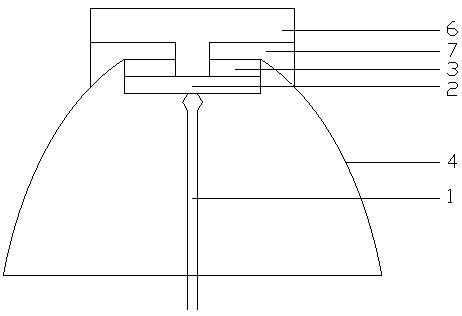

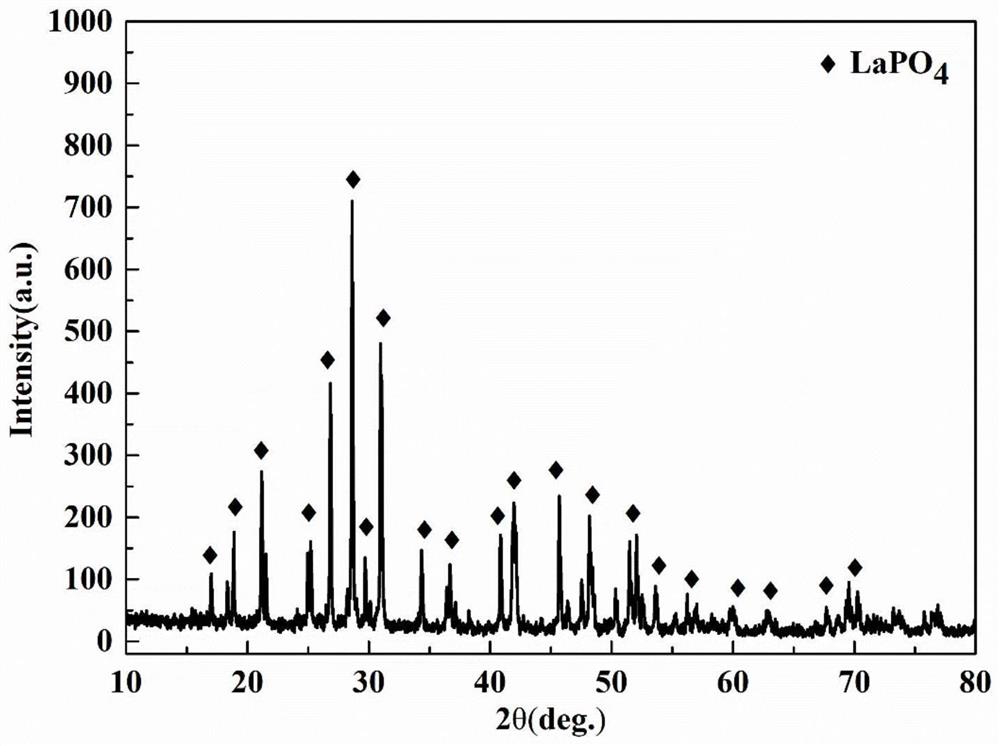

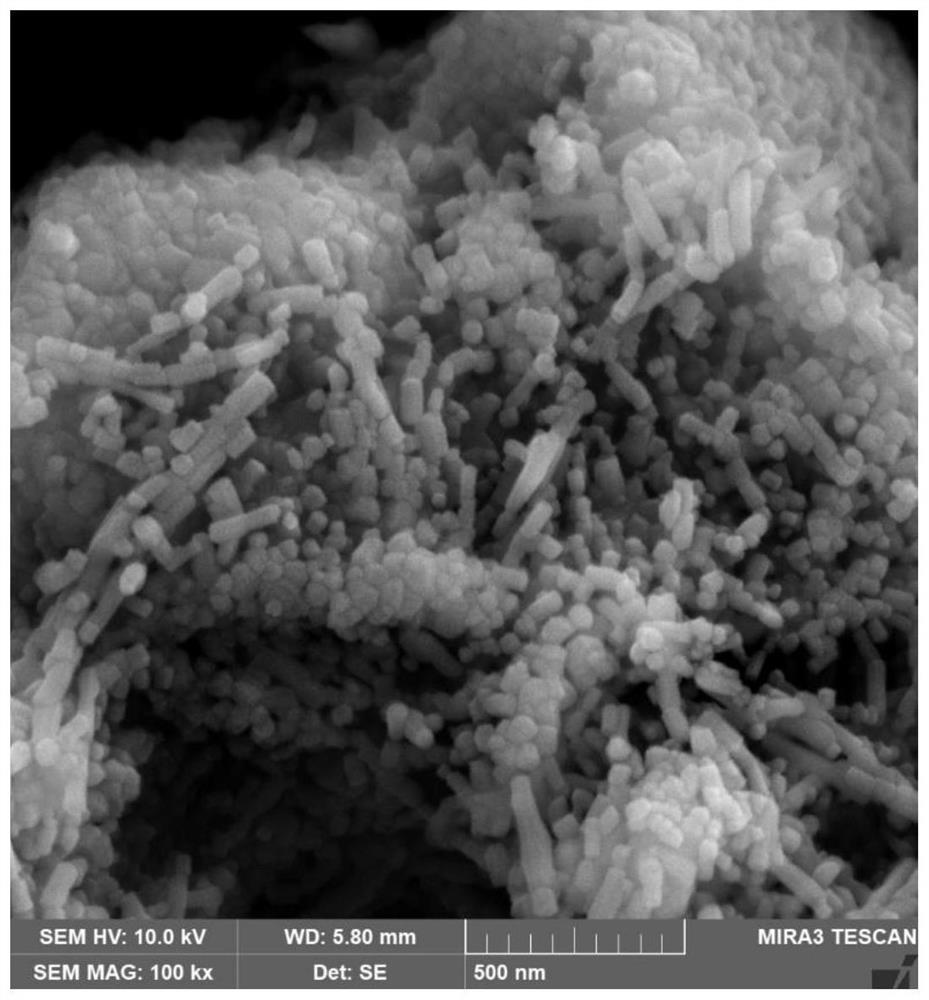

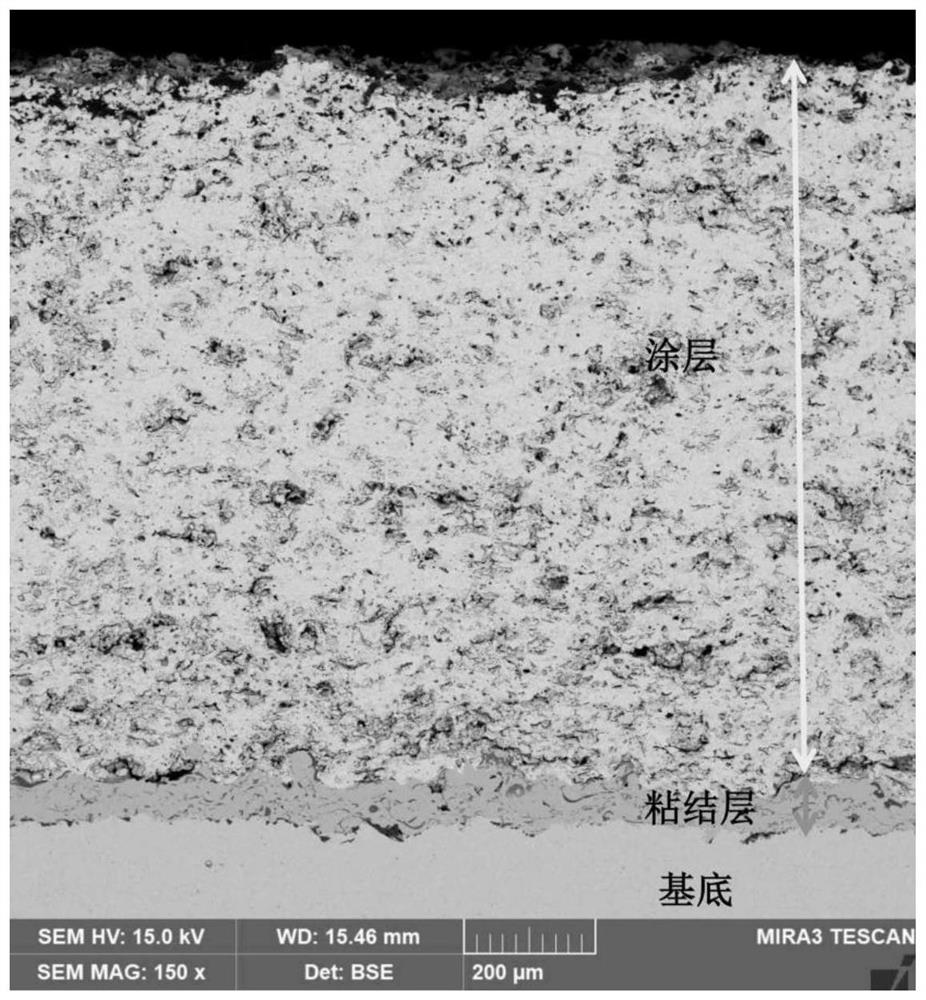

Thick thermal barrier coating with long thermal cycle life and preparation method of thick thermal barrier coating

PendingCN113913730AImprove thermal shock resistanceAchieving controllable equipmentMolten spray coatingBlade accessoriesCeramic coatingThermal barrier coating

The invention relates to the field of high-temperature functional ceramic coating materials, in particular to a thick thermal barrier coating with a long thermal cycle life. The thick thermal barrier coating sequentially comprises a metal bonding layer and a ceramic layer from bottom to top on the surface of a substrate, the ceramic layer is a nano lanthanum phosphate-8YSZ composite coating, and the mass fraction of lanthanum phosphate in the ceramic layer is 1-10%. According to the thick thermal barrier coating with the high thermal cycle life, the 8YSZ thermal barrier coating is modified by adding nano lanthanum phosphate, and the content of lanthanum phosphate is regulated and controlled, so that the fracture toughness and strain tolerance of the coating are effectively improved, the thermal shock resistance of the coating is effectively improved, the thermal cycle life of the coating is effectively prolonged, and controllable preparation of the thick thermal barrier coating is achieved.

Owner:NAT UNIV OF DEFENSE TECH

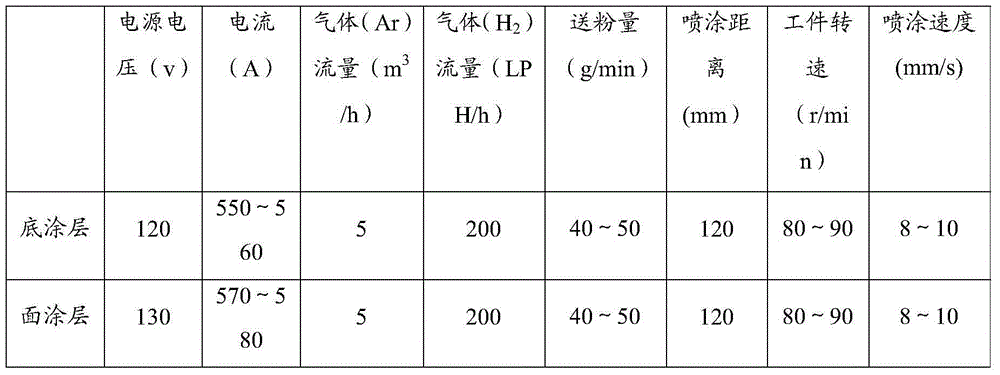

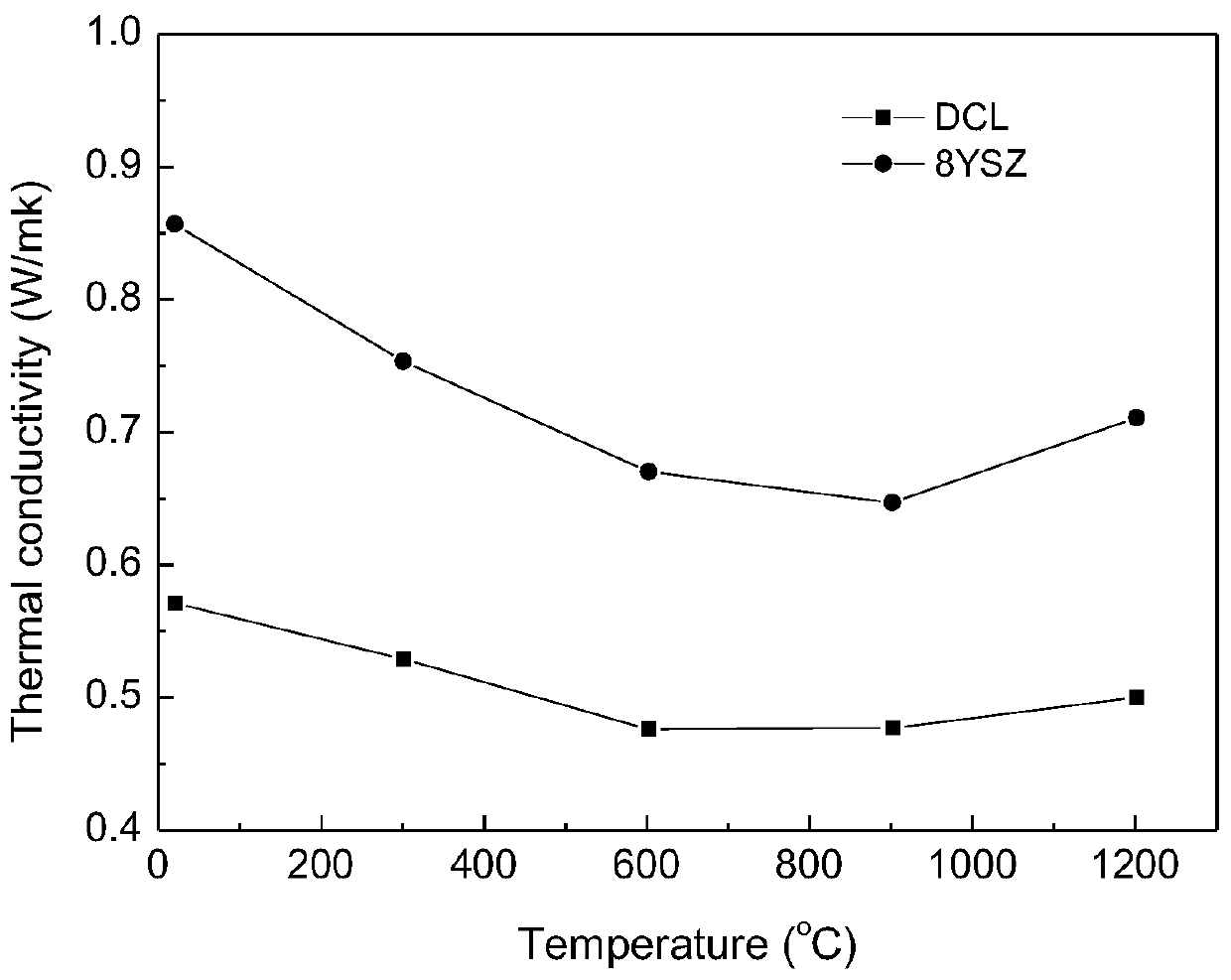

A double ceramic layer thermal barrier coating system and its composite preparation process

ActiveCN108060384BGuaranteed surface roughnessImprove antioxidant capacityMolten spray coatingSurface roughnessSuperalloy

The invention provides a double-ceramic-layer thermal barrier coating system and a composite preparation technology thereof, and belongs to the technical field of coating. The double-ceramic-layer thermal barrier coating system includes a bonding layer on a high temperature alloy basal body, a YSZ coating and a lanthanum-cerium oxide coating. The composite preparation technology includes the stepsthat after the high temperature alloy basal body is preprocessed, a dense MCrAlY bonding layer is sprayed on the high temperature alloy basal body by a supersonic speed flame spraying device or explosive spraying, so that the MCrAlY bonding layer is obtained, wherein the HV0.3 of the MCrAlY bonding layer is 300-380, and the surface roughness Ra of the bonding layer is 5.0-9.0[mu]m; and the YSZ coating is sprayed on the surface of the MCrAlY bonding layer by an atmospheric plasma spraying device, and the double-ceramic-layer thermal barrier coating system is obtained. The thermal barrier coating system prepared by the technology has both super-high temperature resistance and satisfactory coating thermal cycling performance, and the thermal cycling life of the thermal barrier coating is prolonged.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A nano thermal insulation coating

The invention discloses a nano insulating coating which is prepared from the following raw materials in parts by weight: 100 parts of an organosiloxane modified acrylic emulsion, 5-12 parts of a silicon dioxide aerogel, 1-2.6 parts of ceramic fibers, 1-2.5 parts of a carbon nano tube, 0.2-1 part of calcium silicate, 2-5 parts of nano zirconium oxide, 3-7 parts of nano zinc oxide, 5-9 parts of calcium carbonate whiskers, 15-20 parts of sepiolite, 5-20 parts of expanded perlite, 8-15 parts of nano titanium dioxide, 0.8-2.0 parts of a segmented copolymer, 1.5-3.8 parts of dodecanol ester, 0.2-5.0 parts of benzotriazole, 2-3.5 parts of a defoaming agent, 0.5-2 parts of glycerol, 0-1.5 parts of a thickener, 3-10 parts of a coupling agent and 30-60 parts of water. The nano insulating coating disclosed by the invention is good in insulation, high-temperature resistant, high in strength and pollution resistant and is strong in adhesive force and long in service life of building wall spaces and base bodies.

Owner:南京红枫环保材料有限公司

Aluminum-silicon carbide composite material with ultrahigh volume fraction and preparation method thereof

ActiveCN102173808BHigh modulus of elasticityImprove the comprehensive properties such as elastic modulusMetallic aluminumMicrometer

The invention relates to an aluminum-silicon carbide composite material with ultrahigh volume fraction and a preparation method thereof. The aluminum-silicon carbide composite material reaches ultrahigh silicon carbide volume fraction, has low preparation cost, convenient process, good combination property and high reliability and can realize the near-net-shape forming of complex shapes and large sizes. The aluminum-silicon carbide composite material comprises the following components by volume percent: 46%-55% of green silicon carbide coarse powder, 16%-23% of green silicon carbide fine powder, 8%-12% of green silicon carbide micro powder, 8%-27% of metallic aluminum, 1.9%-2.7% of metallic silicon and 0.1%-0.3% of metallic magnesium, wherein the green silicon carbide coarse powder, the green silicon carbide fine powder and the green silicon carbide micro powder respectively have the grain diameters of 120-210 micrometers, 30-63 micrometers and 6-12 micrometers.

Owner:西安明科微电子材料有限公司

Double-layer anti-oxidation bonding bottom layer high-temperature sealing coating and preparation method thereof

ActiveCN112048696ALow oxygenReduce porosityMolten spray coatingEfficient propulsion technologiesPolyesterBi layer

The invention discloses a double-layer anti-oxidation bonding bottom layer high-temperature sealing coating and a preparation method thereof, and belongs to the technical field of aero-engine coatings. The double-layer anti-oxidation bonding bottom layer high-temperature sealing coating structurally comprises a CoNiCrAlY anti-oxidation bottom layer, a CoNiCrAlY middle bonding transition layer anda ZrO2.Y2O3 ceramic sealing layer. CoNiCrAlY system materials with two particle sizes are adopted to spray the anti-oxidation bottom layer and the middle bonding coating, ZrO2.Y2O3 ceramic system materials containing hexagonal boron nitride and polyester are adopted to spray a wearable sealing surface layer, the high-temperature sealing coating is obtained, the bonding strength can be improved by10MPa or above, the high-temperature oxidation resistance can be improved by 15% or above, and the thermal cycle life can be prolonged by 25% or above; and the problems that layers of an existing high-temperature sealing coating are not matched, the bonding performance is poor, the erosion resistance and the scraping resistance are poor, and large coating blocks are peeled off are solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

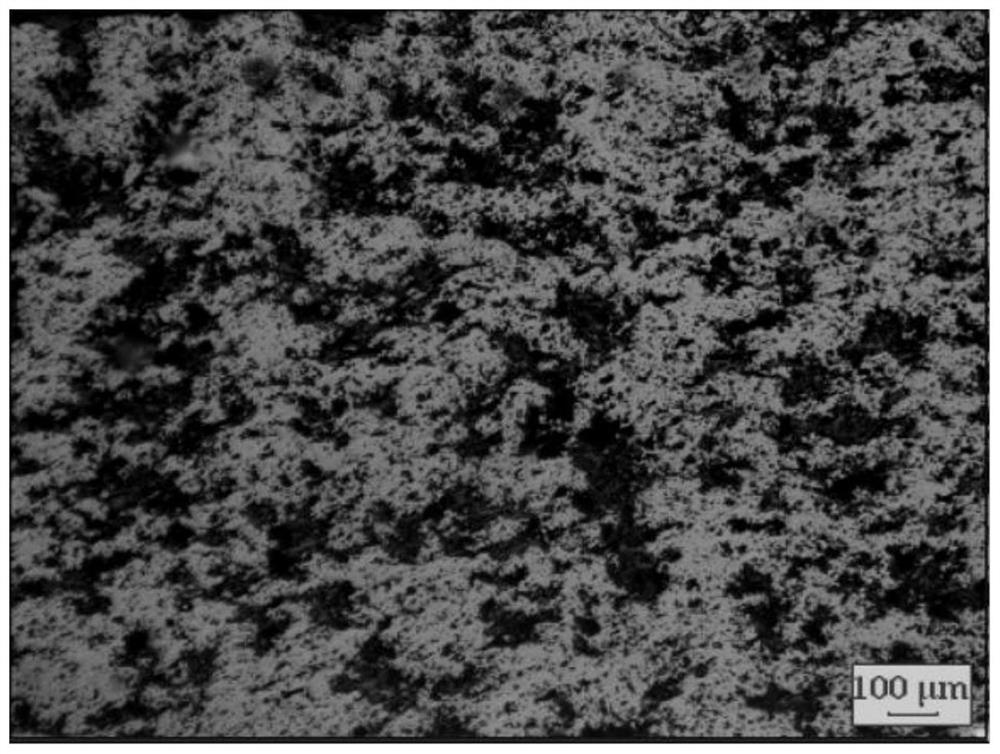

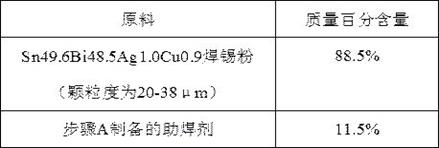

Low-temperature lead-free solder paste and preparation method thereof

ActiveCN111318832BIncreased solidus temperatureHigh tensile strengthWelding/cutting media/materialsSoldering mediaAlloyCopper

The invention discloses a low-temperature lead-free solder paste and a preparation method thereof. The low-temperature lead-free solder paste is composed of the following raw materials in mass percent: low-temperature tin-bismuth-silver-copper quaternary lead-free solder powder 86% to 91%; flux 9 %~14%; wherein, the low-temperature tin-bismuth-silver-copper quaternary lead-free solder powder is composed of four elements: tin-bismuth-silver-copper, wherein the mass percentage of bismuth is 46-52%, and the mass percentage of copper 0.3-1.2%, the mass percentage composition of silver is 0.4-1.2%, and the mass percentage composition of tin is 45.6-53.3%; Adopt the solder paste that the present invention makes, its bismuth content is relatively high but the range is reasonable, can The solidus temperature of the product is increased from 138°C to 151°C, which is suitable for low-temperature packaging technology, and the peak soldering temperature does not exceed 200°C. Compared with the Sn42Bi58 alloy, this product has better tensile strength, shear strength, drop resistance and thermal cycle Life expectancy has been greatly improved.

Owner:DONGGUAN YONGAN TECH

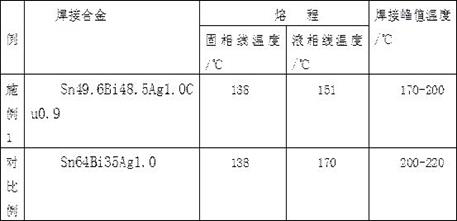

Advanced bond coat materials for tbc with improved thermal cyclic fatigue and sulfidation resistance

PendingUS20220145426A1Prevent oxidationReduce layeringTurbinesMolten spray coatingBond coatingCerium

A bond coating material providing unexpectedly high thermal cyclic fatigue resistance and sulfidation resistance, and unexpectedly prolonged thermal cycle life in high temperature environments of gas turbine engine components with and without the presence of sulfur contains: a) 10% to 30% by weight chromium, b) at least one of tantalum and molybdenum in a total amount of 3% to 15% by weight, c) 5% to 13% by weight aluminum, d) 0.1% to 1.4% by weight silicon, e) 0.1% to 0.8% by weight yttrium, f) 0% to 1.2% by weight carbon, g) 0% to 1% by weight dysprosium, h) 0% to 1% by weight cerium, i) the balance being nickel, and the percentages of a) to i) adding up to 100% by weight. The total amount of tantalum and molybdenum, and the amounts of aluminum and silicon are each critical for avoiding delamination of a top coat from a bond coat.

Owner:SULZER METCO (US) INC

Particulate matter for thermal barrier coating and preparation method thereof, thermal barrier coating and engine

ActiveCN113929474BImprove high temperature thermal cycling performanceGood stress buffering effectMolten spray coatingCeramicwareParticulatesMicroparticle

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Preparation method of high-entropy rare earth aluminate thermal protection coating

PendingCN114774834AImprove thermal cycle lifeGood thermal shock resistanceMolten spray coatingChemistryEnvironmental geology

The invention relates to a preparation method of a high-entropy rare earth aluminate thermal protection coating, and belongs to the technical field of thermal protection coatings. The preparation method comprises the following steps: firstly, preparing a NiCrCoAlY bonding layer on a substrate with the surface roughness of 4-8 microns by adopting a thermal spraying process, and then, directly preparing a high-entropy rare earth aluminate layer on the NiCrCoAlY bonding layer by adopting an atmospheric plasma spraying process, or firstly, preparing a YSZ or Al2O3 intermediate layer on the NiCrCoAlY bonding layer by adopting the thermal spraying process, and then, preparing the high-entropy rare earth aluminate layer on the NiCrCoAlY bonding layer by adopting the high-entropy rare earth aluminate layer on the NiCrCoAlY bonding layer by adopting the high-entropy rare earth aluminate layer. And preparing a high-entropy rare earth aluminate layer on the intermediate layer by adopting an atmospheric plasma spraying process, so as to form the high-entropy rare earth aluminate thermal protection coating on the substrate. According to the method disclosed by the invention, the high-entropy rare earth aluminate ceramic thermal protection coating with low porosity, high deposition rate and good thermal shock resistance can be obtained by optimizing process conditions, and the requirement of long-term use under a high-temperature service condition can be met.

Owner:ZHENGZHOU UNIV

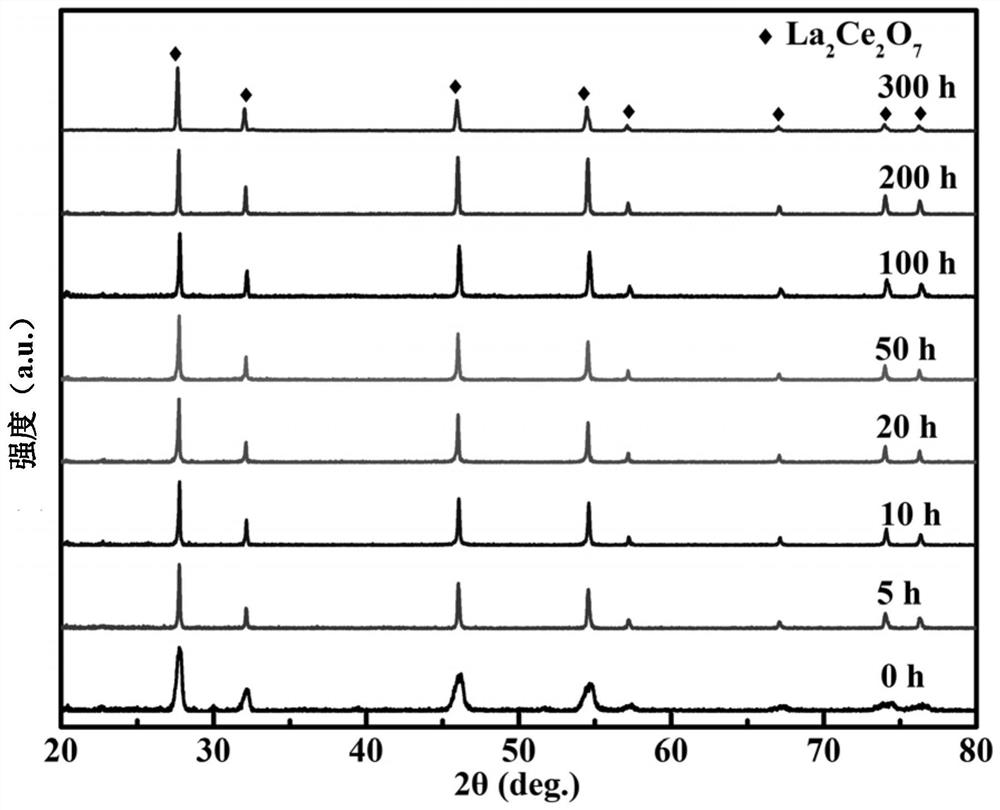

A kind of preparation method of thermal barrier coating with interlayer pore structure

ActiveCN110106463BGood phase stability at high temperatureUniform interlayer pore structureMolten spray coatingPhysical chemistrySlurry

The invention relates to a preparation method of a thermal barrier coating with an interlayer pore structure, which comprises La 2 o 3 , CeO 2 , ZrO 2 The powder is heat-treated; the heat-treated powder is mixed with a dispersant in proportion, and deionized water is added for ball milling to obtain a slurry; La 2 o 3 , CeO 2 , ZrO 2 The molar ratio between the powders is 0.5:(1-x):x, wherein 0≤x≤0.8; the slurry after ball milling is dried and heat-treated to form a phase to obtain a phase-forming powder; the phase-forming powder is mixed with deionized water and dispersed The mixture is ball-milled to obtain a suspension; the suspension is used as a raw material, and the suspension plasma spraying method is used to spray on the base material. The present invention adopts the La prepared by the suspension plasma spraying method 2 (Ce 1‑x Zr x ) 2 o 7 The coating has excellent high-temperature phase stability, and the prepared coating has a uniform interlayer pore structure, which is conducive to reducing the thermal conductivity of the coating and improving the thermal cycle life of the coating.

Owner:INNER MONGOLIA UNIV OF TECH

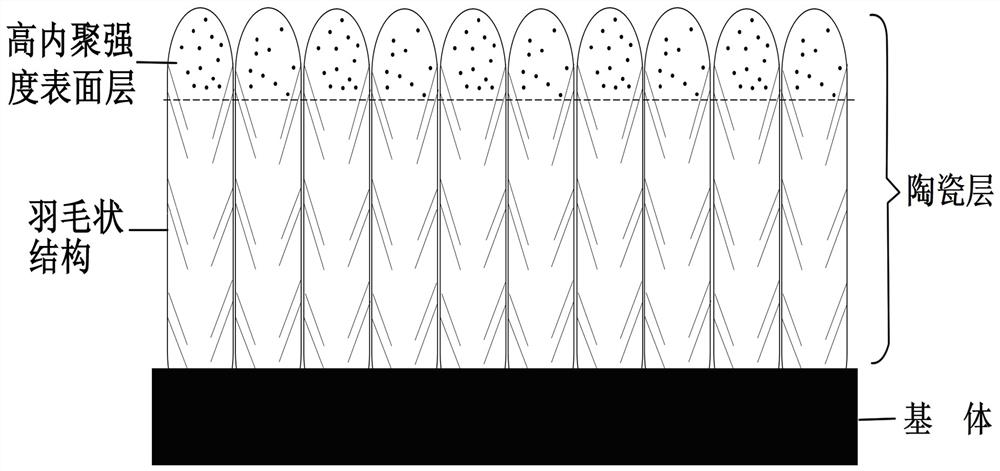

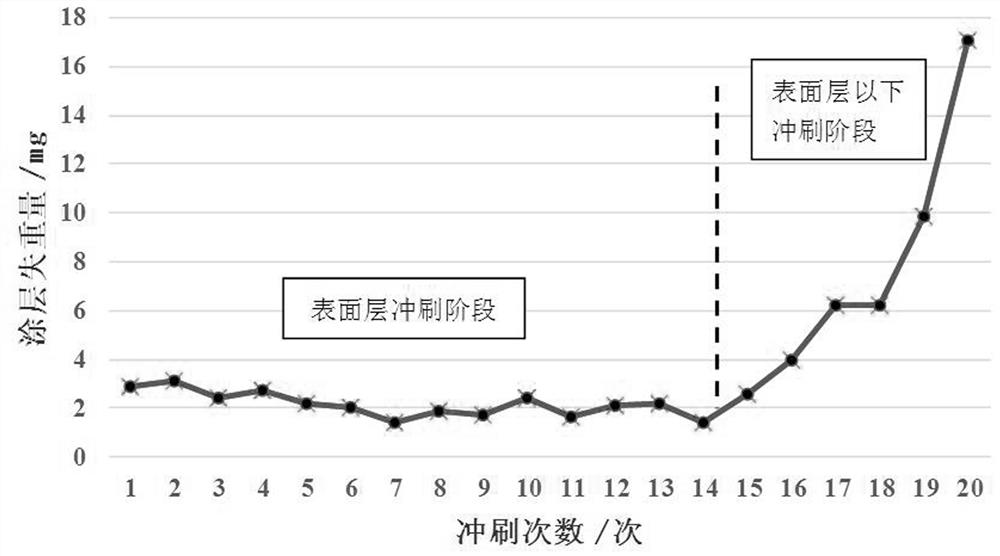

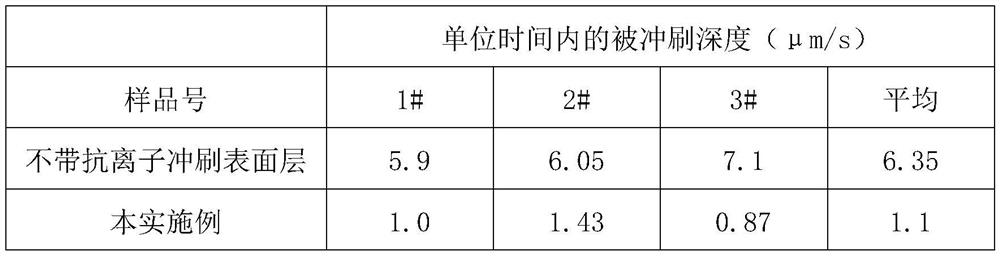

A kind of thermal barrier coating with anti-particle scour surface layer and preparation method thereof

ActiveCN108411242BImprove performanceImprove thermal cycle lifeMolten spray coatingCohesive strengthThermal barrier coating

The invention discloses a thermal barrier coating layer with a particle scouring resistant surface layer and a preparation method thereof. The thermal barrier coating layer is a ceramic layer with a feather structure and arranged on a basal body by adopting a plasma spraying-physical vapor deposition process; the upper end part of the ceramic layer is a high-cohesion-strength surface layer; the part, below the high-cohesion-strength surface layer, of the ceramic layer is in no-interface connection with the high-cohesion-strength surface layer; and the high-cohesion-strength surface layer has the same material components, object phases and macroscopic feather structures with the ceramic layer below the surface layer. The thermal barrier coating layer is simple in process, low in cost and high in coating bonding strength; and the prepared thermal barrier coating layer with the high-cohesion-strength surface layer can greatly improve the particle scouring resistance, and is long in service life.

Owner:GUANGDONG INST OF NEW MATERIALS

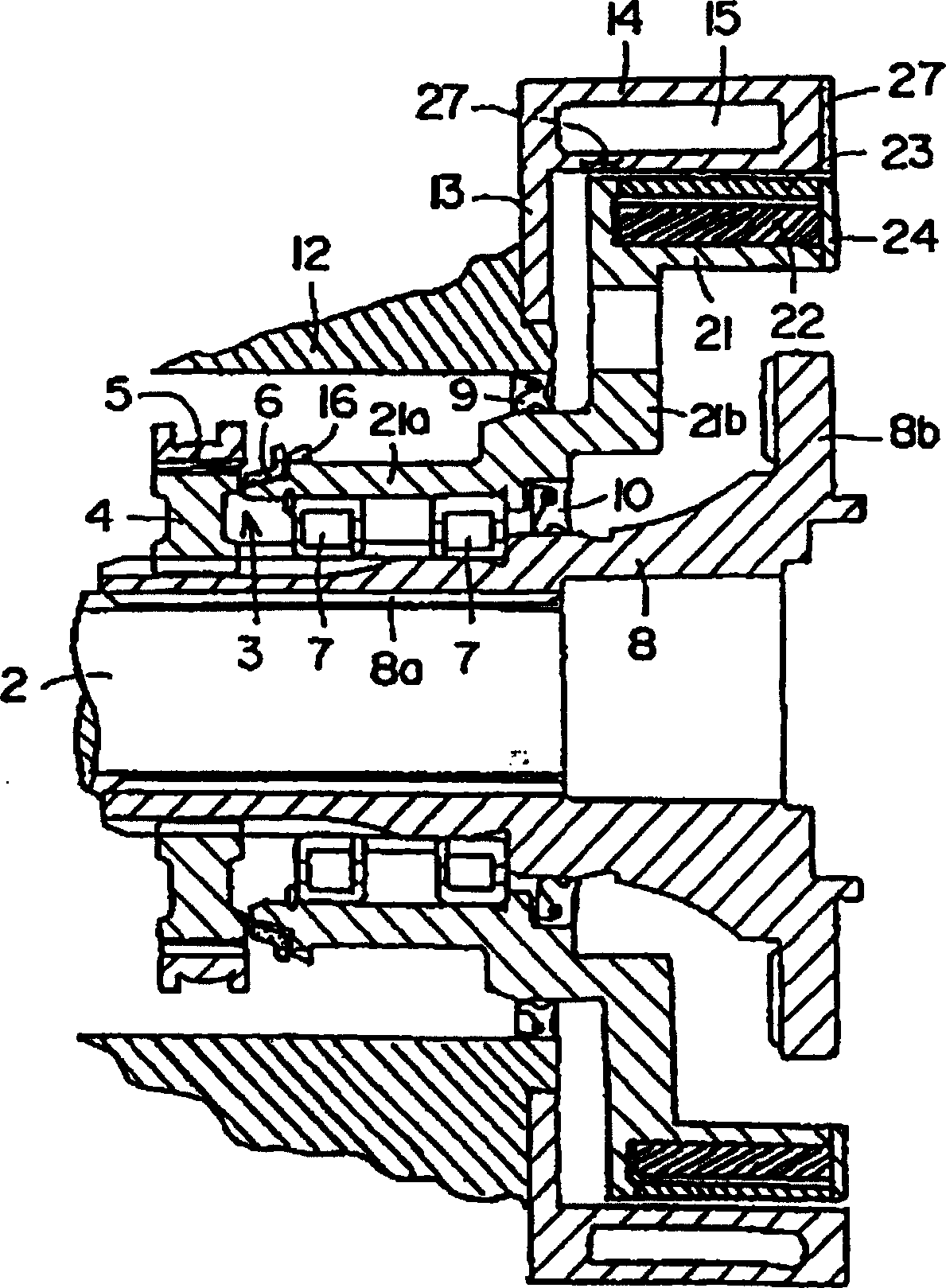

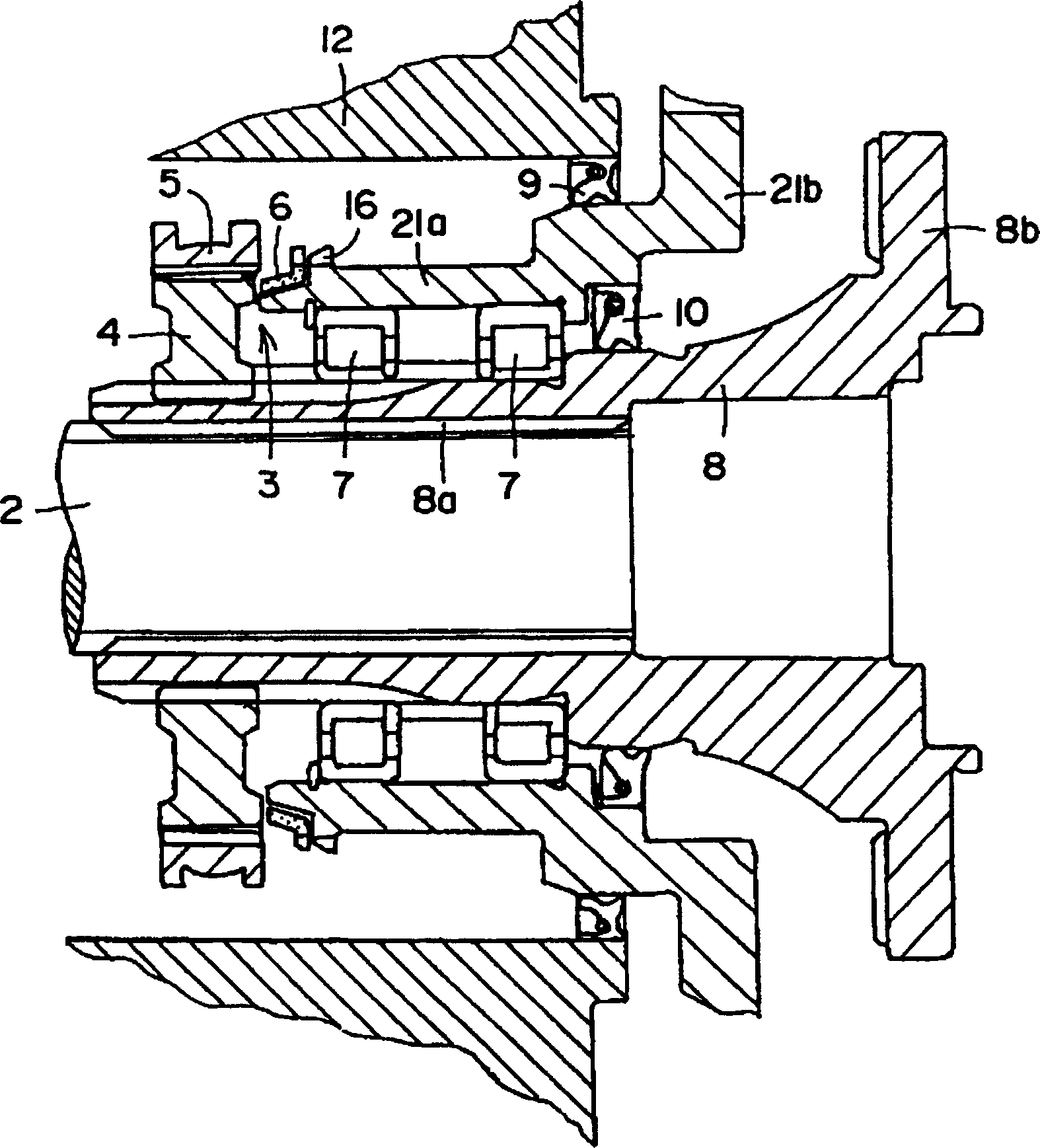

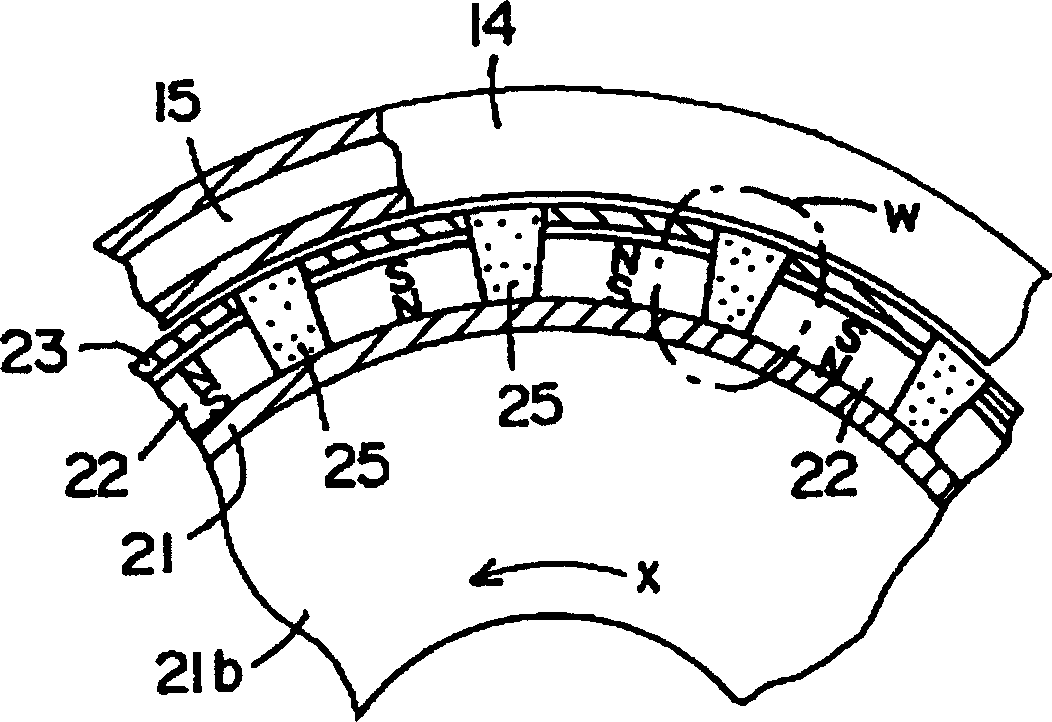

Eddy current speed reducer

InactiveCN1187881CImprove thermal cycle lifeReduce heat lossAsynchronous induction clutches/brakesEddy currentHeat losses

The invention is able to enhance a lifetime of a heat cycle of a stator by reducing a heat loss by composing of a rotor combined to a magnet and a stator having a cooling unit, and by avoiding the rotor from rotating at a non-braking time. The cylindrical stator 14 formed from a ferromagnetic body is fixed to a non-rotating portion of a case 12 and the like of a speed changer, and a cylindrical rotor 21, which positions at the inside of the stator 14 and is formed from a magnetic body having a number of magnets 22 with an equal interval in its peripheral direction, is held to a rotating shaft 2 through a bearing 7. A clutch mechanism 3 is arranged between the rotating shaft 2 and the rotor 21. Then, the braking-time clutch mechanism 3 is connected so that an eddy current, based on the magnetic field that extends to the stator 14 from the magnets 22, shall generate a braking force at the rotor 21.

Owner:ISUZU MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com