Eddy current speed reducer

A deceleration device and eddy current technology, applied in the direction of asynchronous induction clutch/brake, etc., can solve problems such as poor efficiency of installation and operation, corrosion, troublesome manufacturing of support mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

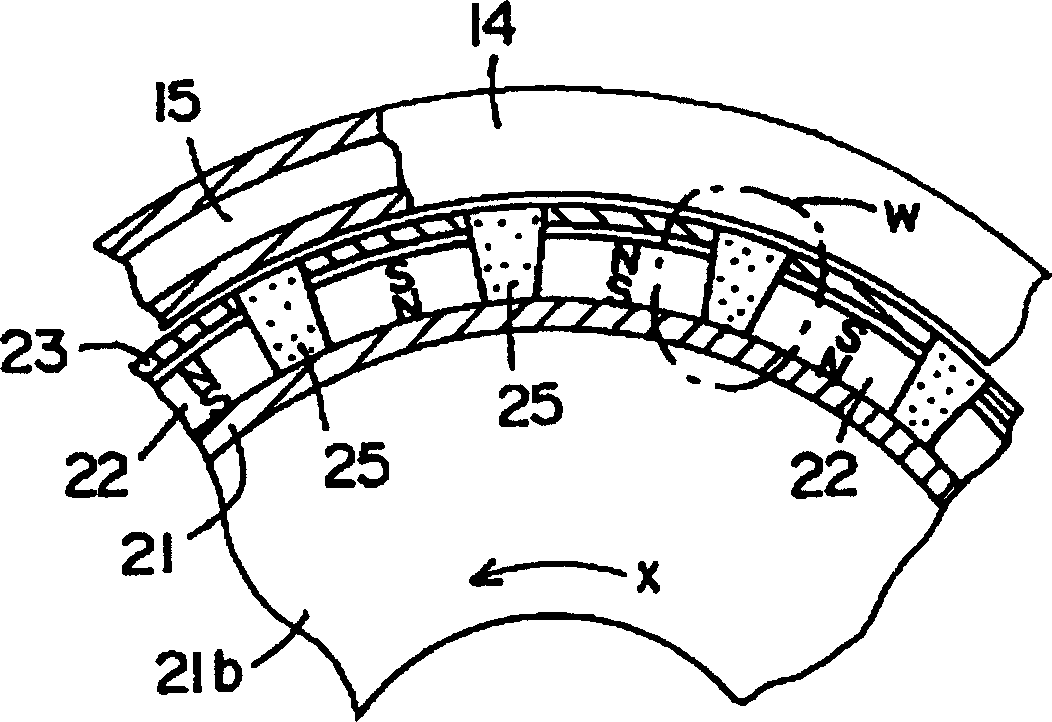

[0015] The eddy current speed reducer consists of a rotor with multiple magnets and a stator with a cooling device. During non-braking, since the clutch mechanism is disengaged and the rotor does not rotate, no leakage magnetic field occurs and heat loss can be reduced. Also, the thermal cycle life of the stator is improved.

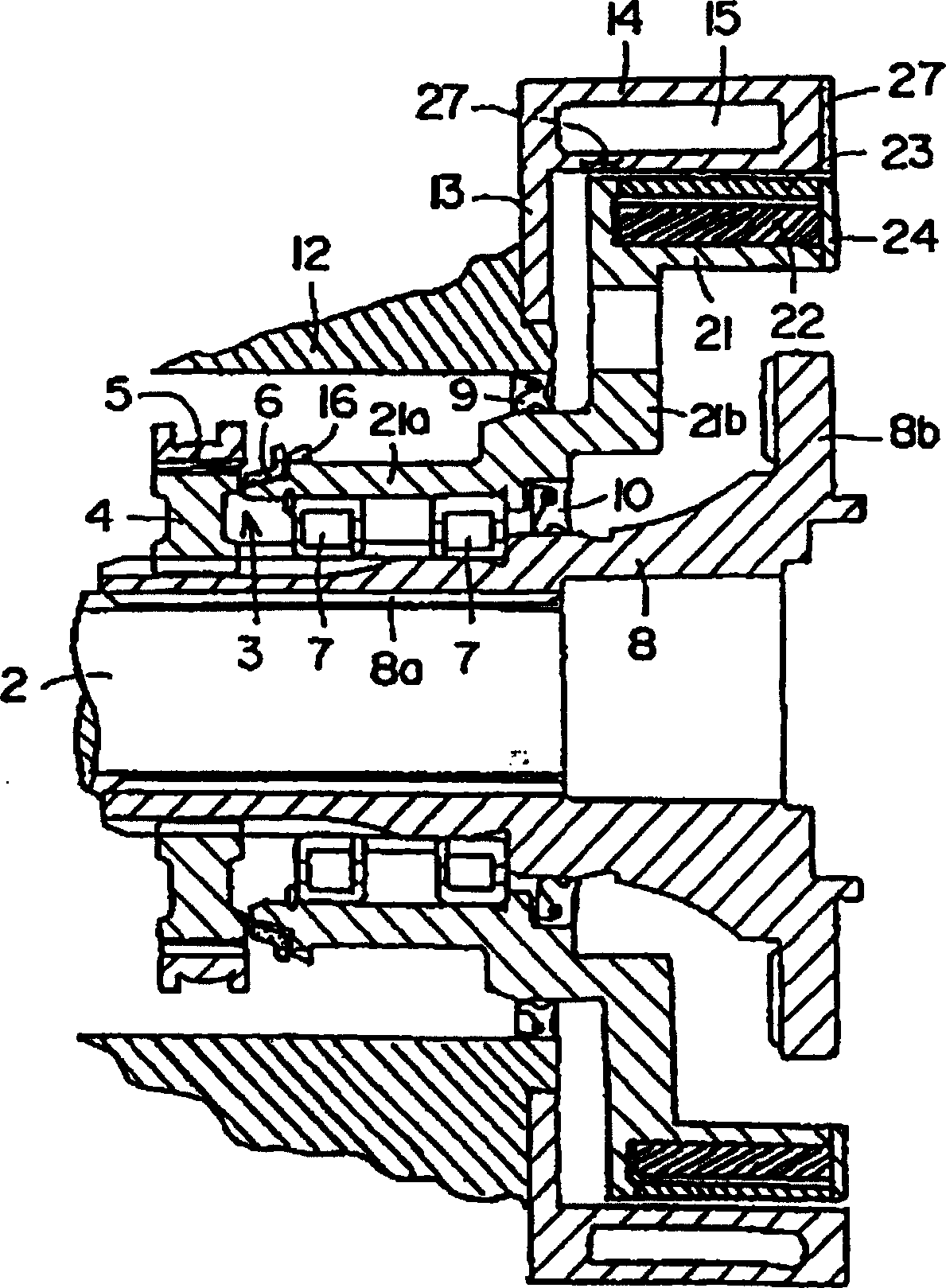

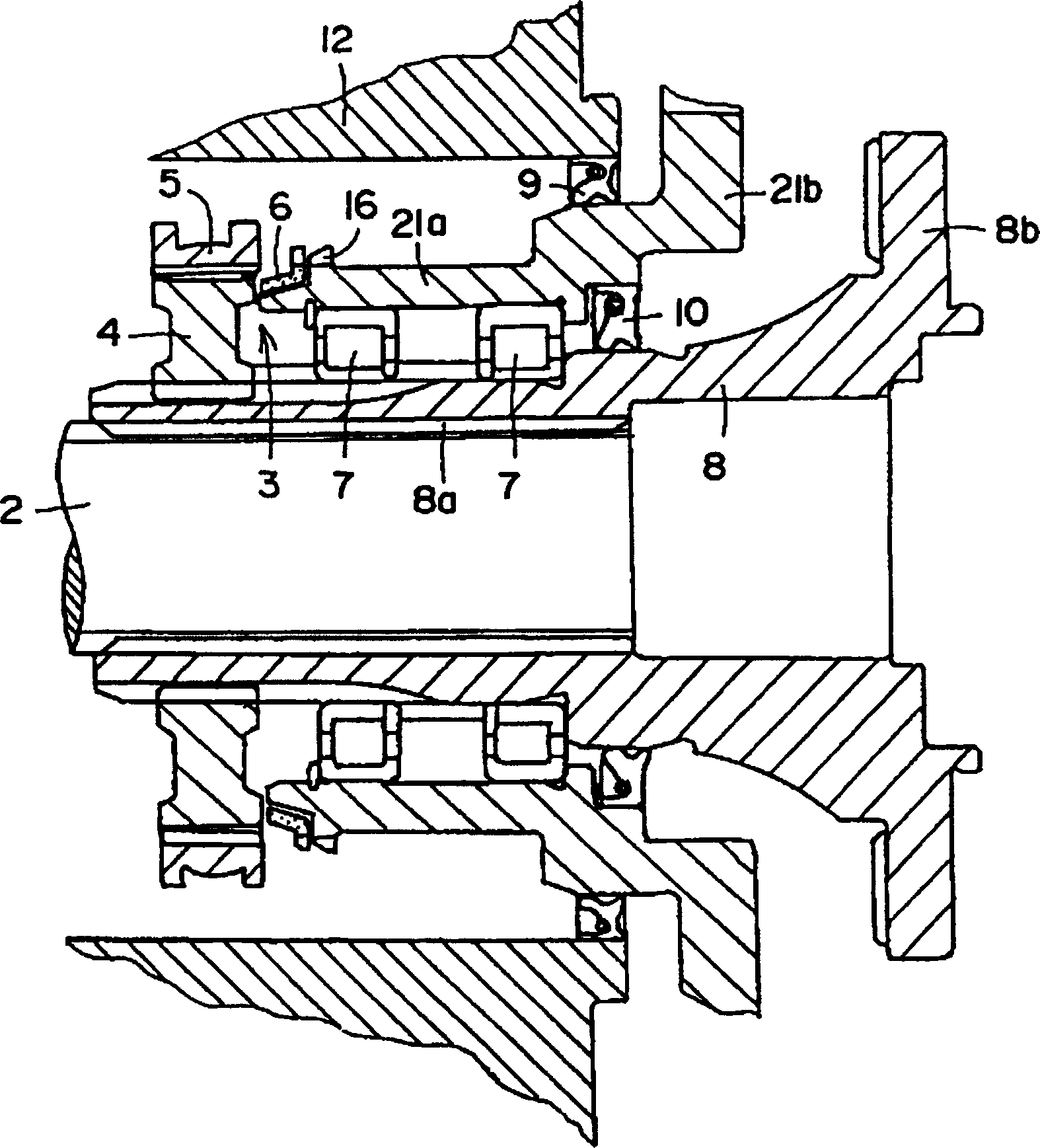

[0016] Such as figure 1 As shown, the embodiment in which the eddy current deceleration device of the present invention is installed on the output rotating shaft 2 of the transmission will be described. A rotor 21 in the shape of a rotor 21, magnets 22 coupled to the outer peripheral surface of the rotor 21 at equal intervals in the circumferential direction, and a cylindrical stator 14 formed of a magnetic material covering the rotor 21 are constituted. The stator 14 is configured by accommodating a cooling medium in an annular cooling chamber 15 and circulating the cooling medium from the outside. The end flange 13 of the stator 14 is joined to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com