A nano/columnar-like mixed structure thermal barrier coating and its preparation method

A Thermal Barrier Coating, Hybrid Structure Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

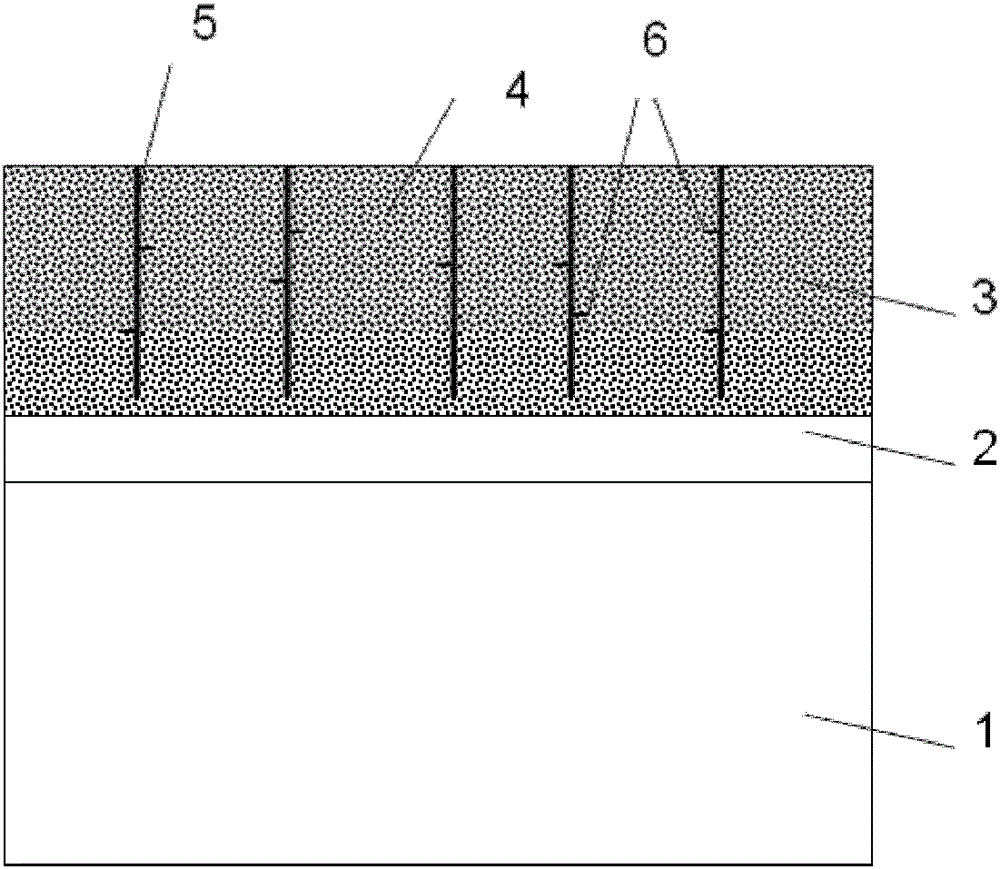

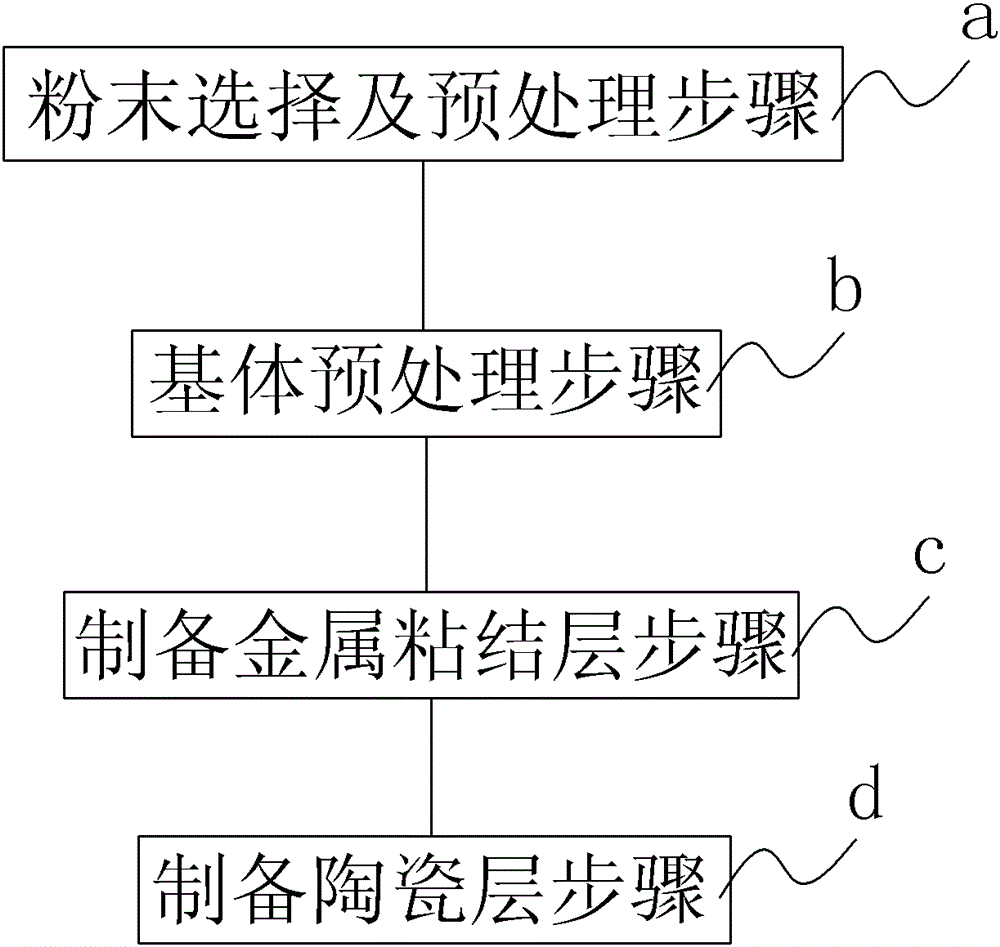

[0062] see figure 2 , figure 2 It is a flow chart of the method of the present invention. The preparation method of the hybrid structure thermal barrier coating of the present invention comprises the following steps:

[0063] Powder selection and pretreatment step a, select nano-agglomerated YSZ spray powder and perform high-temperature sintering or plasma densification treatment; preferably, the nano-agglomerated YSZ spray powder contains 6-8 wt% Y 2 o 3 Partially stabilized ZrO 2 , and the fluidity of the nano-agglomerated YSZ spray powder is less than 60s / 50g, and the bulk density is greater than 1.6g / cm 3 .

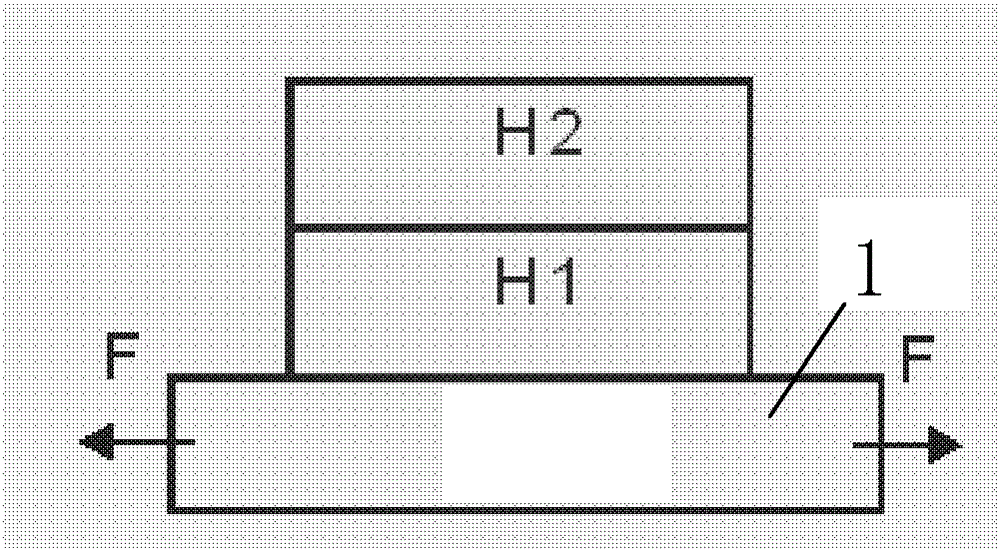

[0064] In the substrate pretreatment step b, the substrate 1 is provided and the substrate 1 is cleaned and sandblasted; the substrate 1 is preferably a high-temperature alloy or heat-resistant steel.

[0065] Prepare the metal bonding layer step c, the metal alloy powder is prepared by plasma spraying or supersonic flame spraying to prepare the metal bonding ...

Embodiment 1

[0085] Example 1: Preparation of coating on the surface of DZ40M superalloy substrate 1

[0086] Step a: Powder selection and preparation

[0087] Select nanometer YSZ agglomerated powder, after powder agglomeration, undergo plasma densification treatment, the particle size range of the sprayed powder is -90μm~+37μm, and the bulk density is 1.74g / cm 3 , the fluidity is 52s / 50g, the powder is used for plasma spraying after drying at 100°C for 2 hours.

[0088] Step b: Substrate 1 pretreatment

[0089] Choose a cobalt-based superalloy, the grade is DZ40M, soak the superalloy substrate 1 in acetone, take it out and dry it after 1 hour; Compressed air blows off residual sand particles on the surface.

[0090] Step c: Preparation of metal bonding layer 2 by supersonic flame spraying

[0091] The preparation of the bonding layer is mainly NiCrAlY metal alloy powder, the particle size range of the powder is -45μm ~ +15μm, according to the preparation process parameters of the met...

Embodiment 2

[0095] Embodiment 2: prepare coating on MGH754Ni-Cr alloy substrate surface

[0096] Step a: Powder selection and preparation

[0097] Select nanometer YSZ agglomerated powder, after powder agglomeration, undergo plasma densification treatment, the particle size range of the sprayed powder is -61μm~+38μm, and the bulk density is 1.85g / cm 3 , the fluidity is 47s / 50g, the powder is used for plasma spraying after drying at 100°C for 2 hours.

[0098] Step b: Substrate 1 pretreatment

[0099] Select the dispersion strengthened NiCr heat-resistant alloy, the grade is MGH754, soak the superalloy substrate 1 in acetone, take it out and dry it after 1 hour; 1 Use compressed air to blow off the residual sand particles on the surface.

[0100] Step c: Preparation of metal bonding layer 2 by plasma spraying

[0101] For the preparation of the bonding layer, the metal alloy powder whose main component is NiCoCrAlY is selected, and the particle size range of the powder is -75μm~+45μm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com