Patents

Literature

56results about How to "Increased strain tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

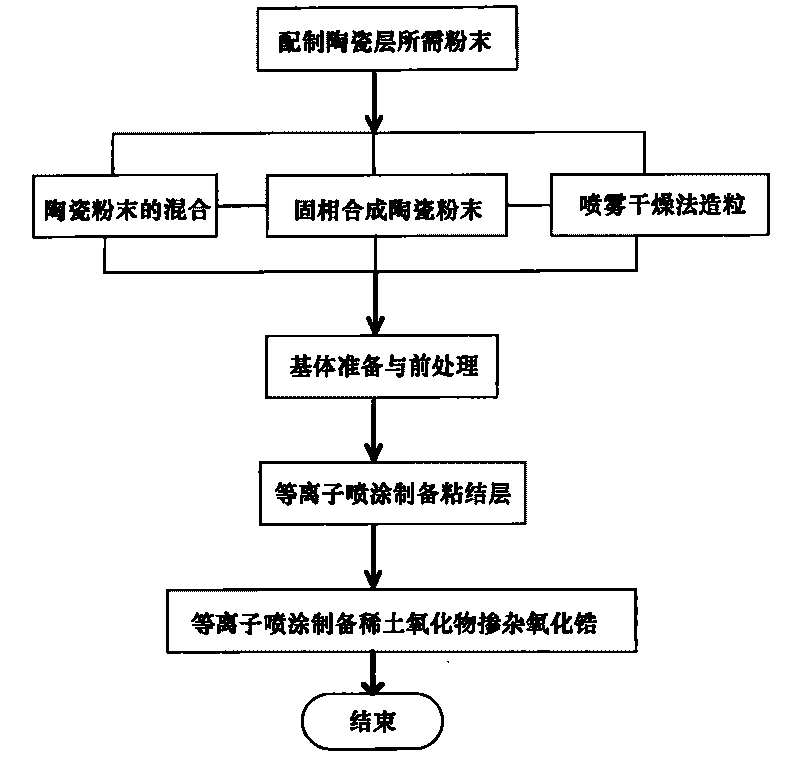

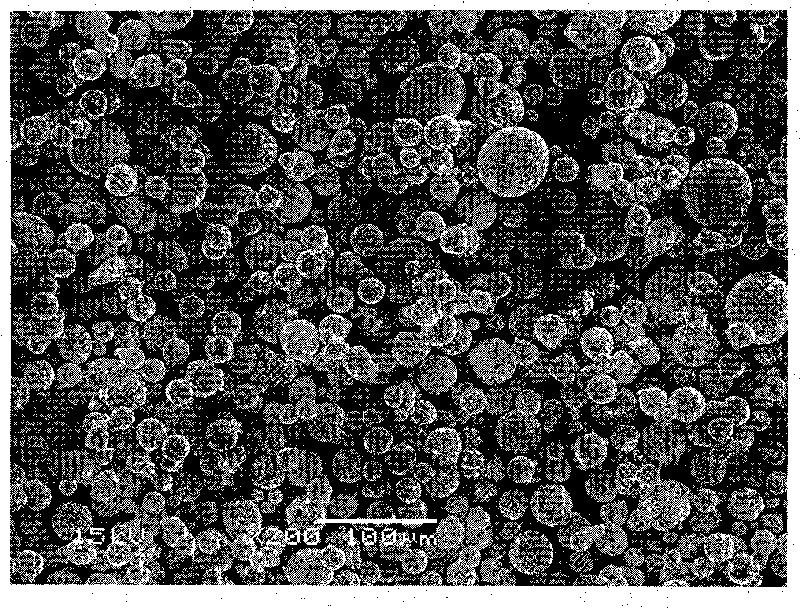

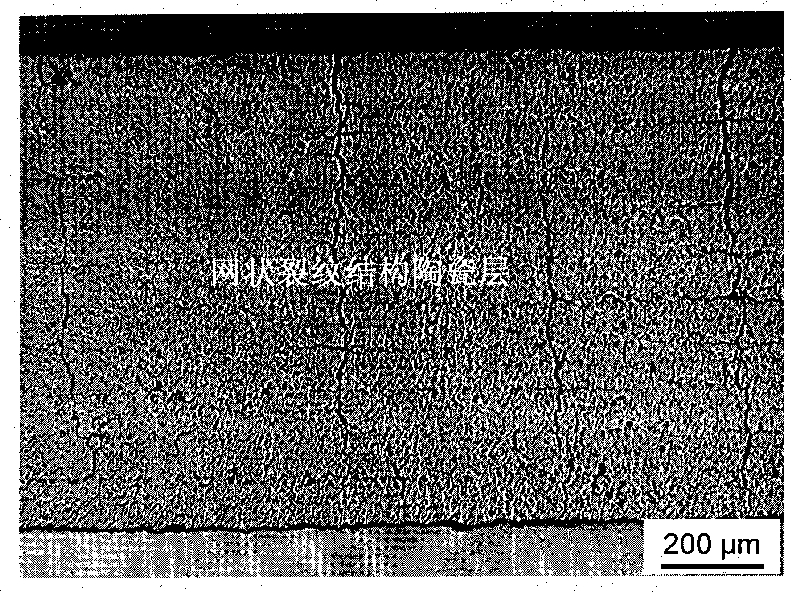

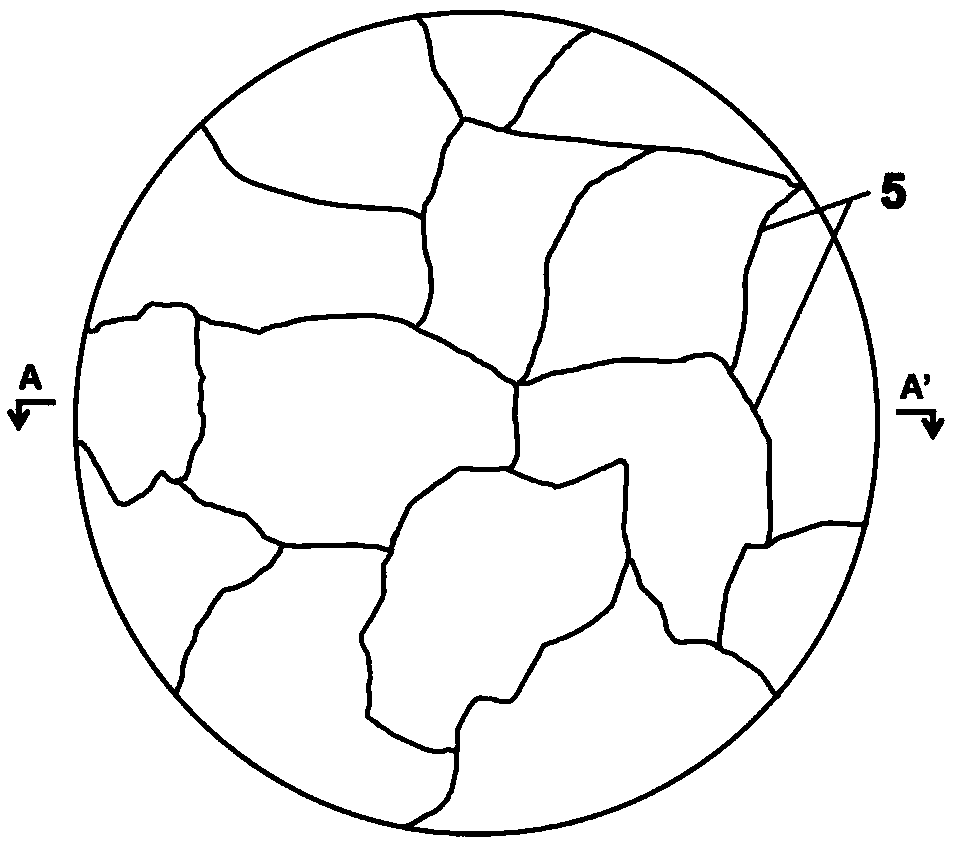

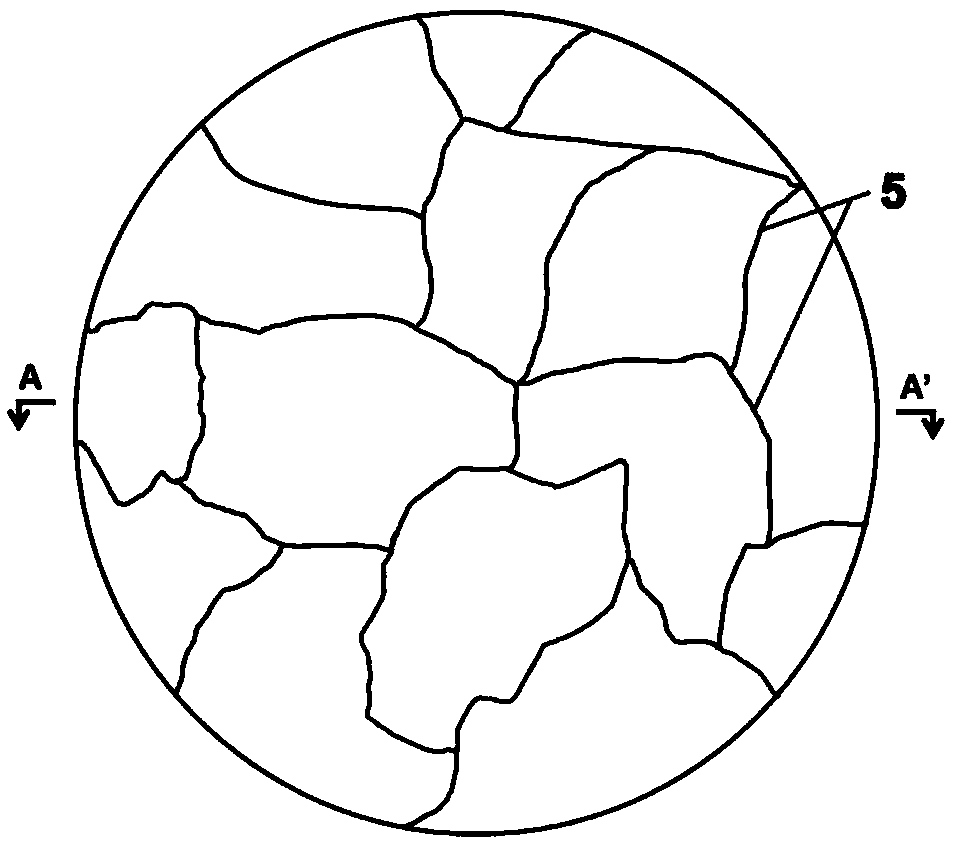

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

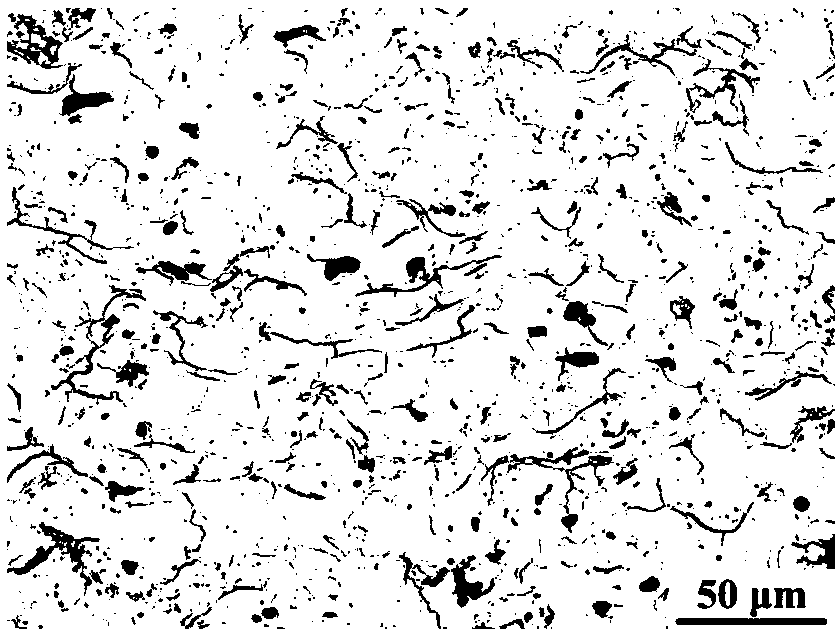

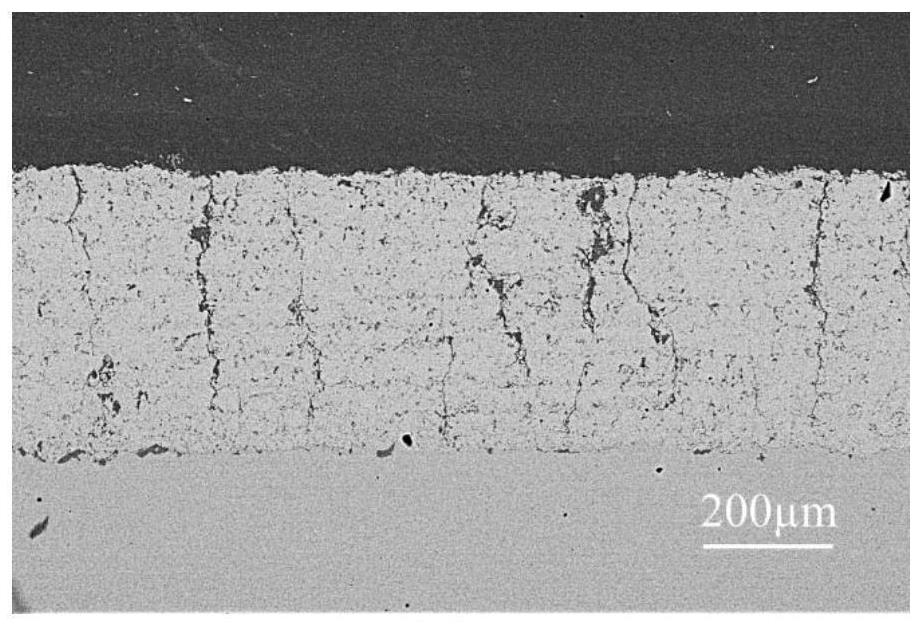

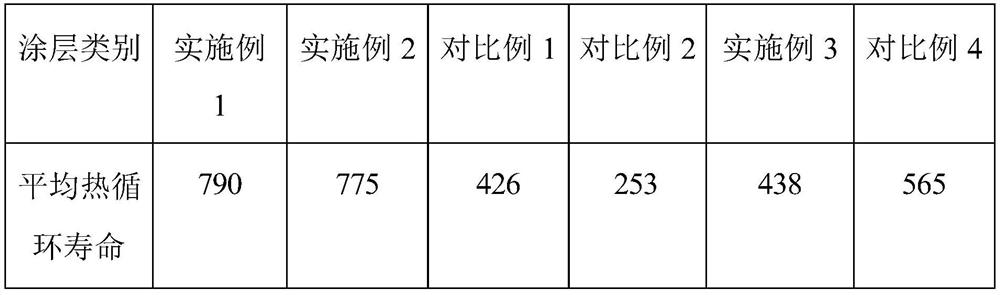

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

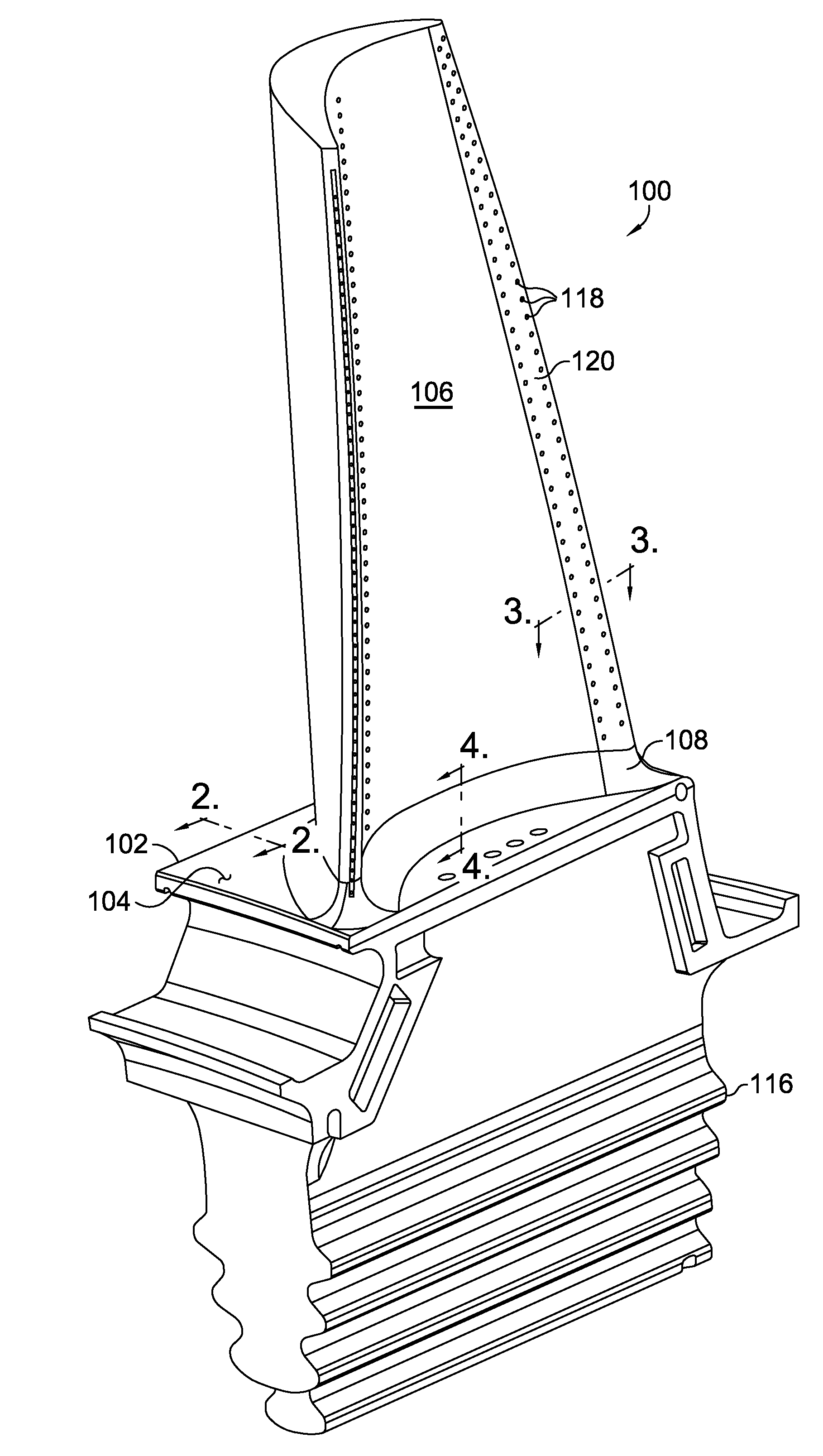

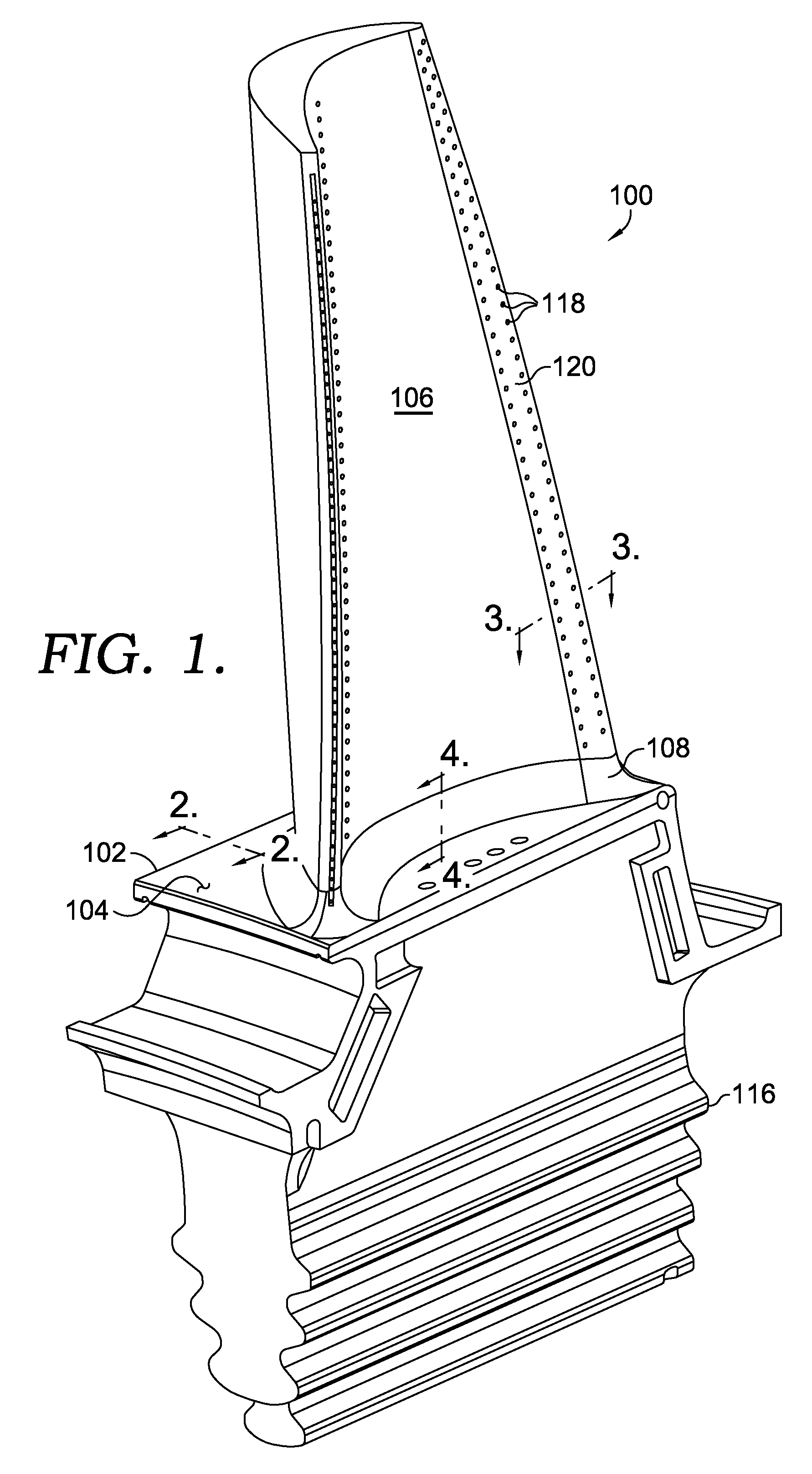

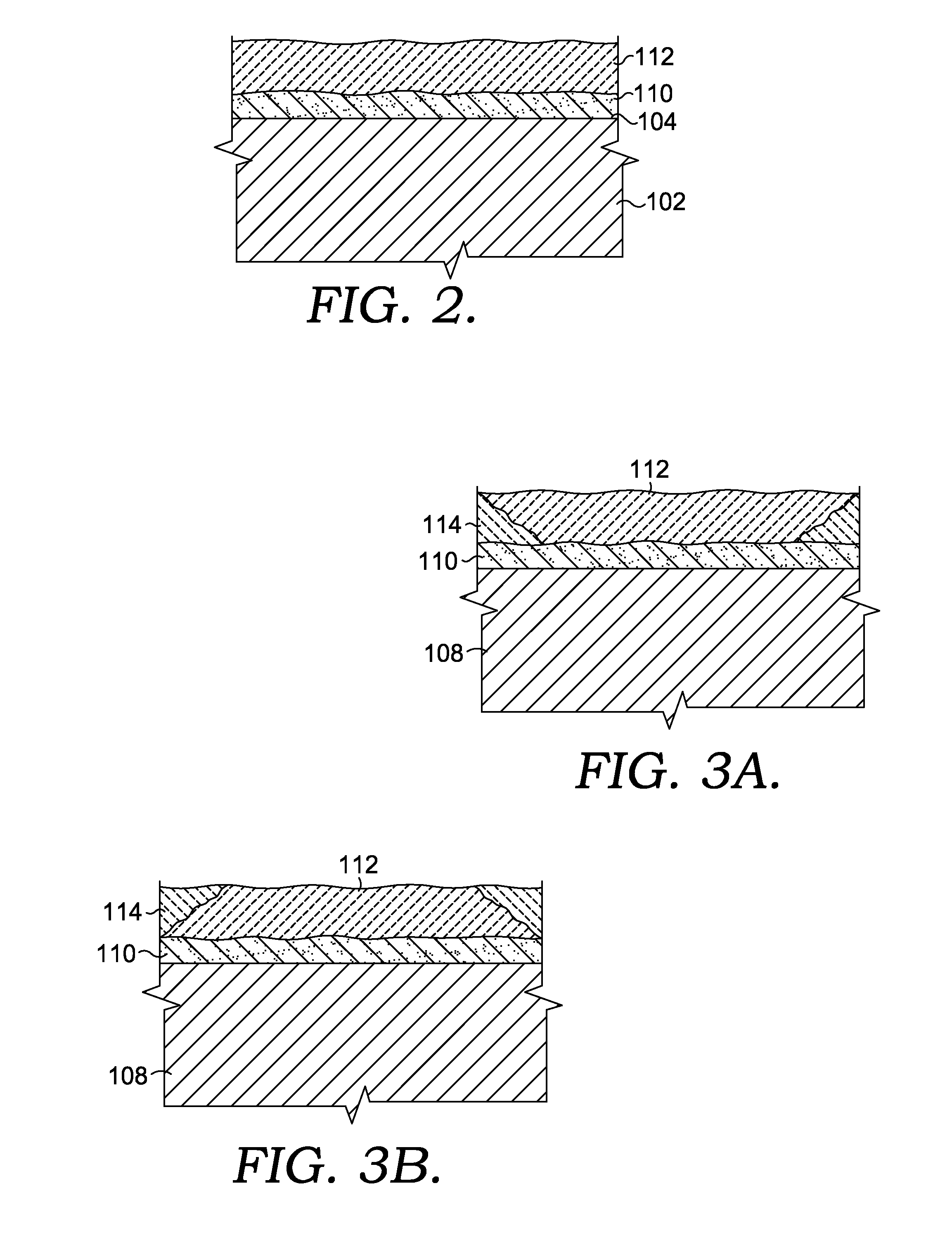

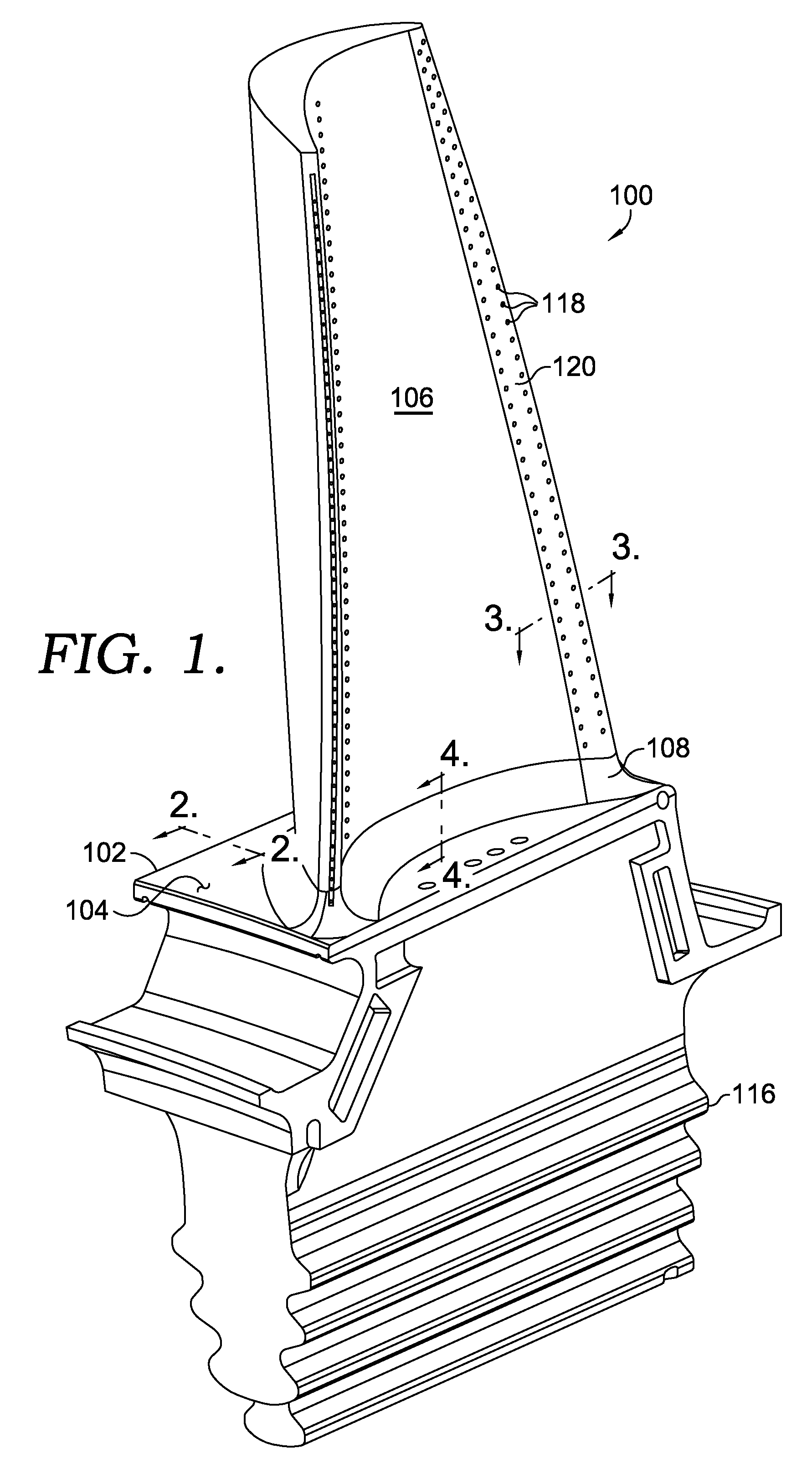

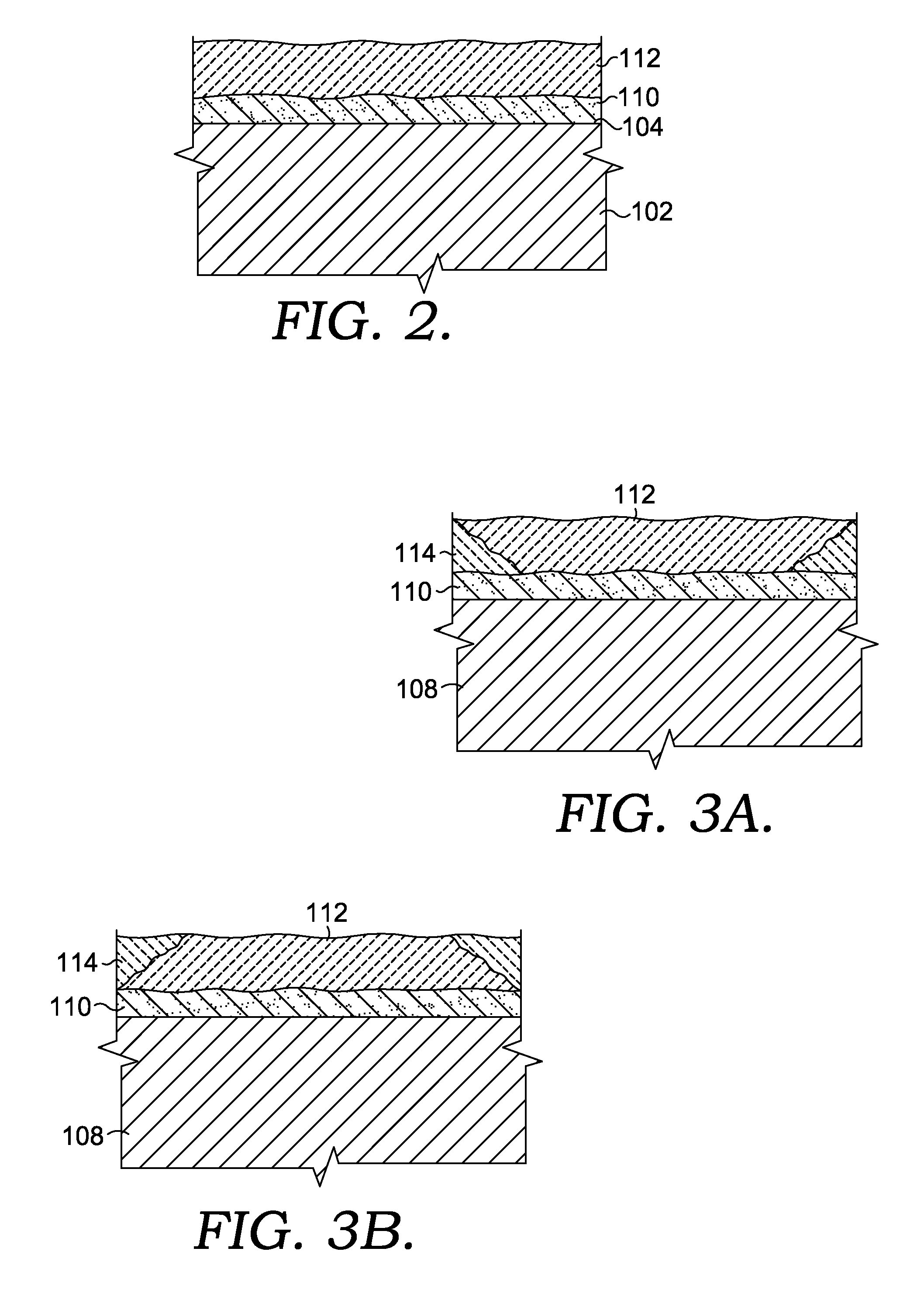

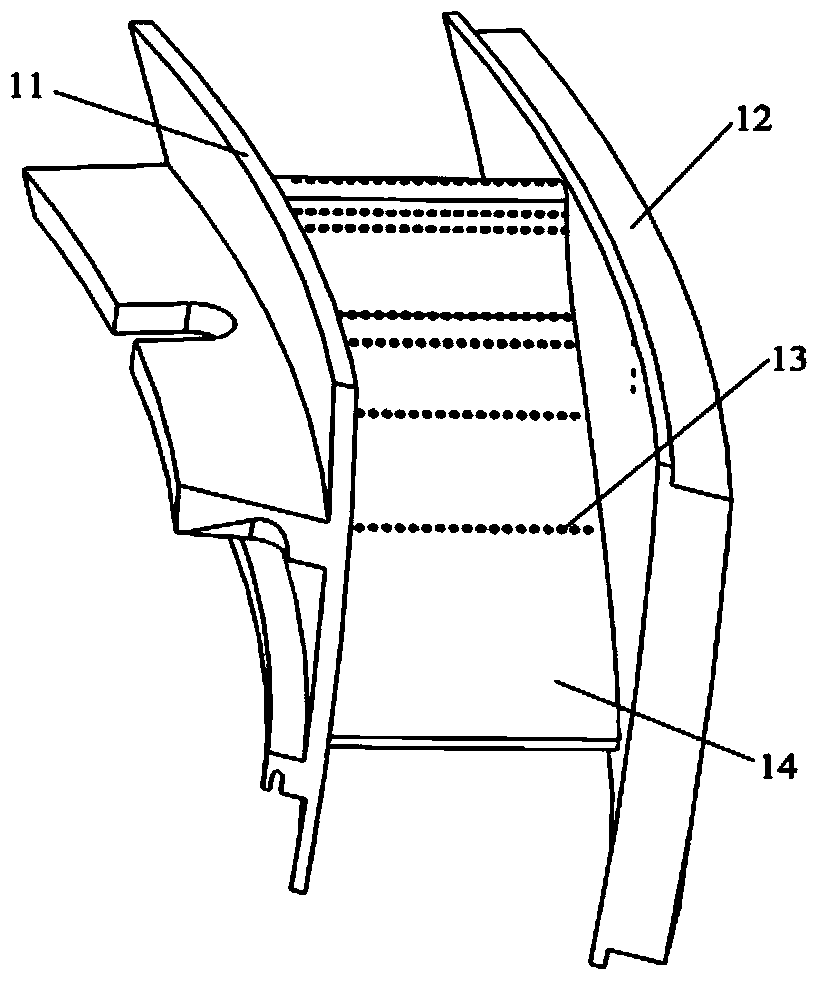

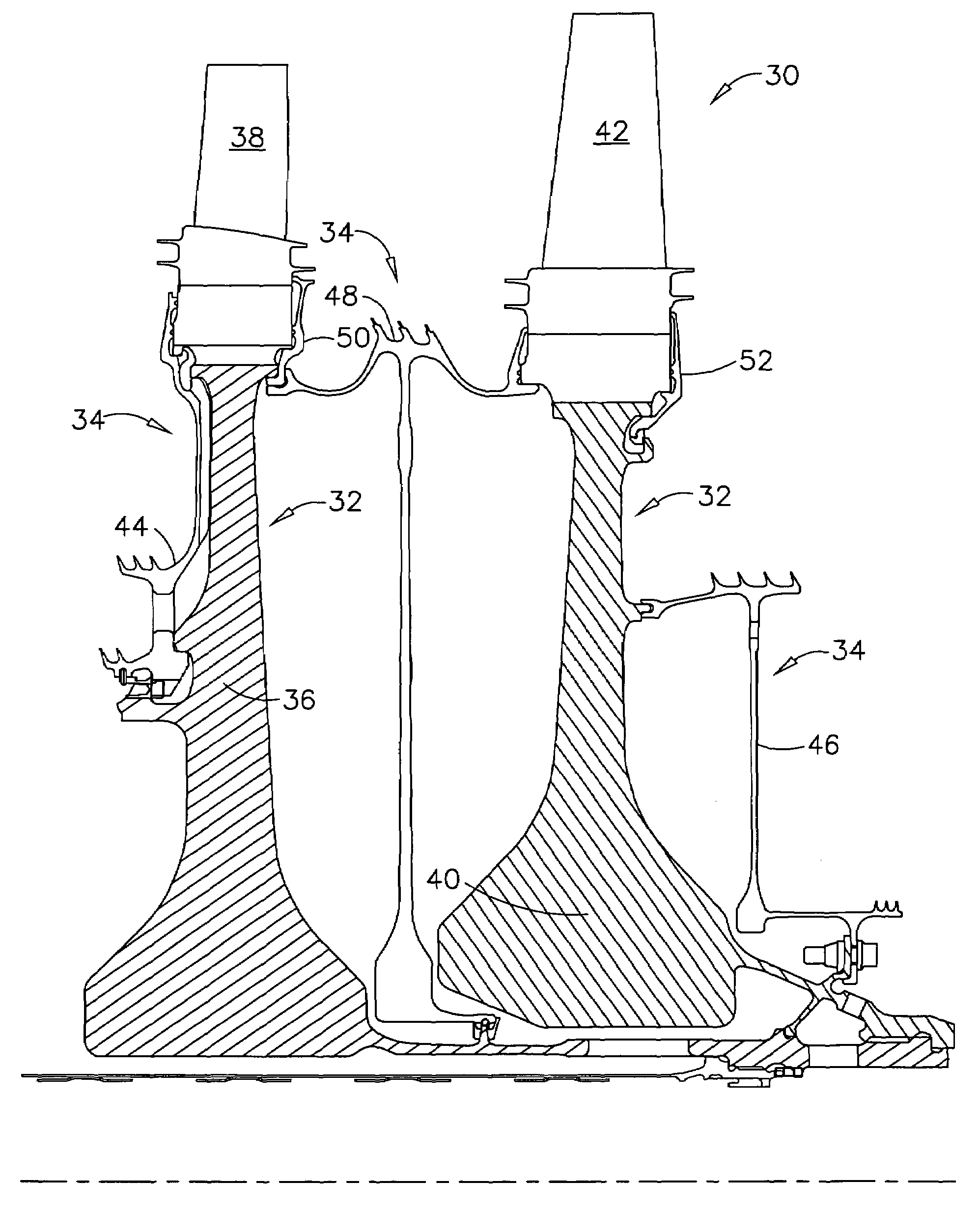

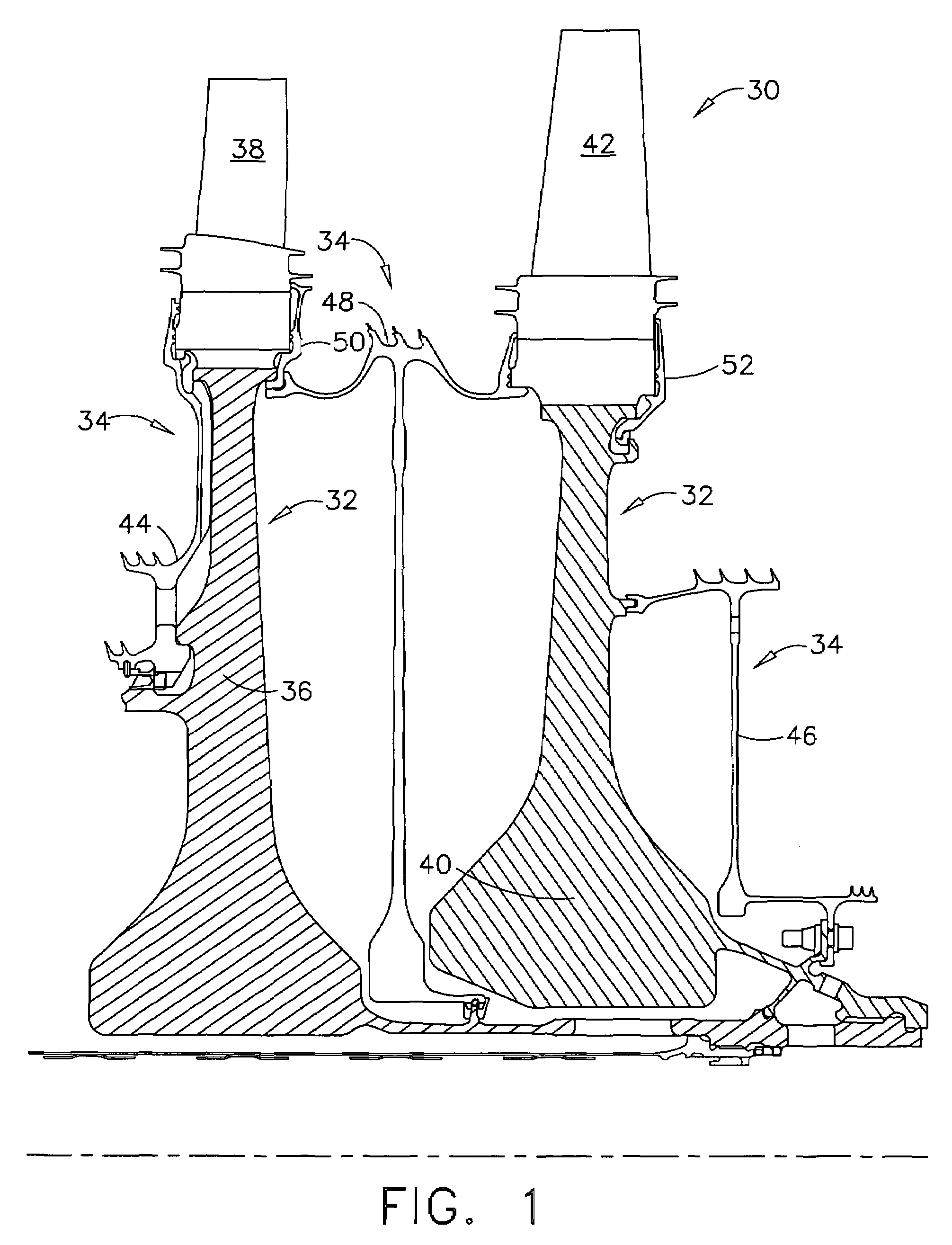

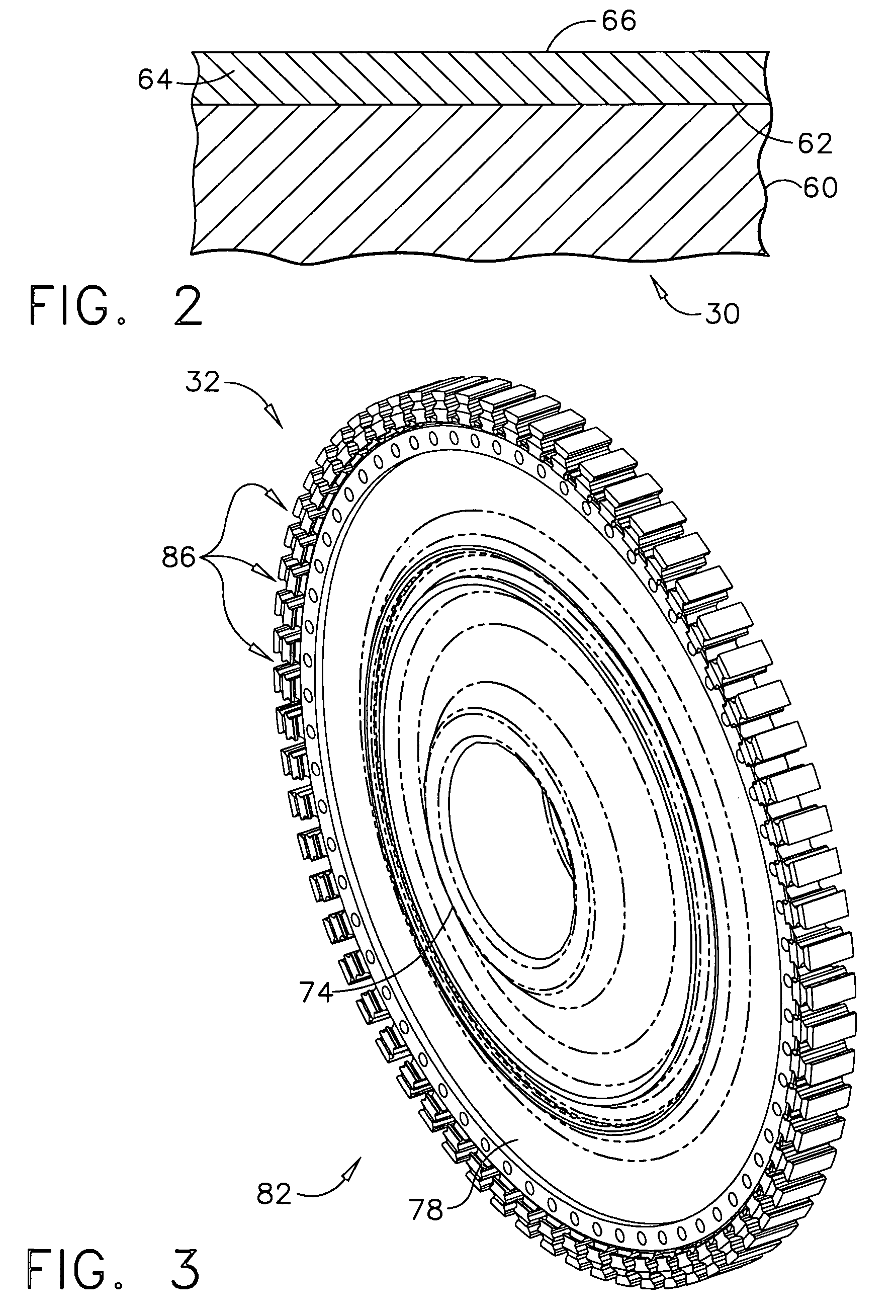

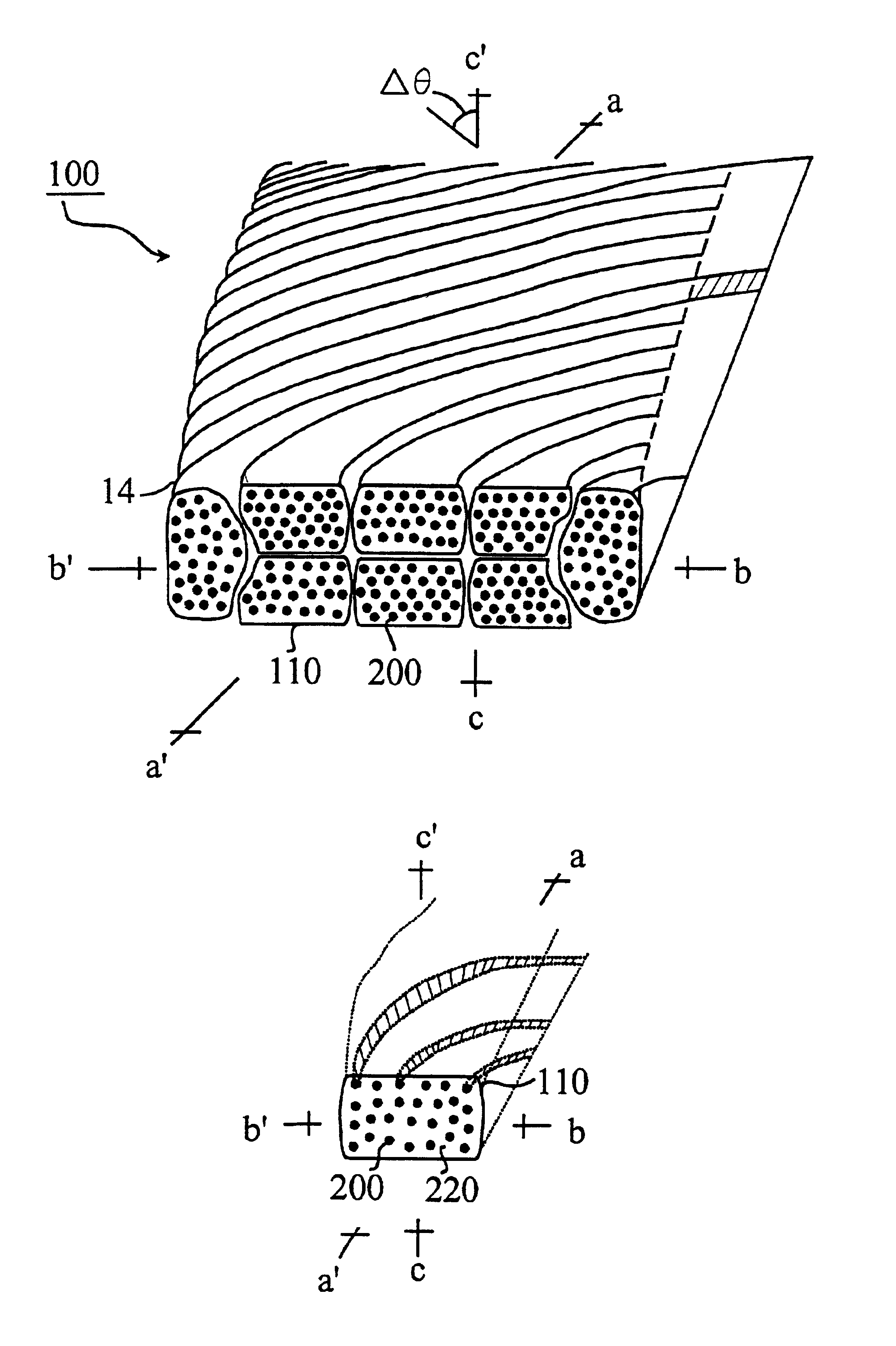

Application of Dense Vertically Cracked and Porous Thermal Barrier Coating to a Gas Turbine Component

InactiveUS20110038710A1Increase temperatureIncreased strain toleranceMolten spray coatingPropellersBond coatingEngineering

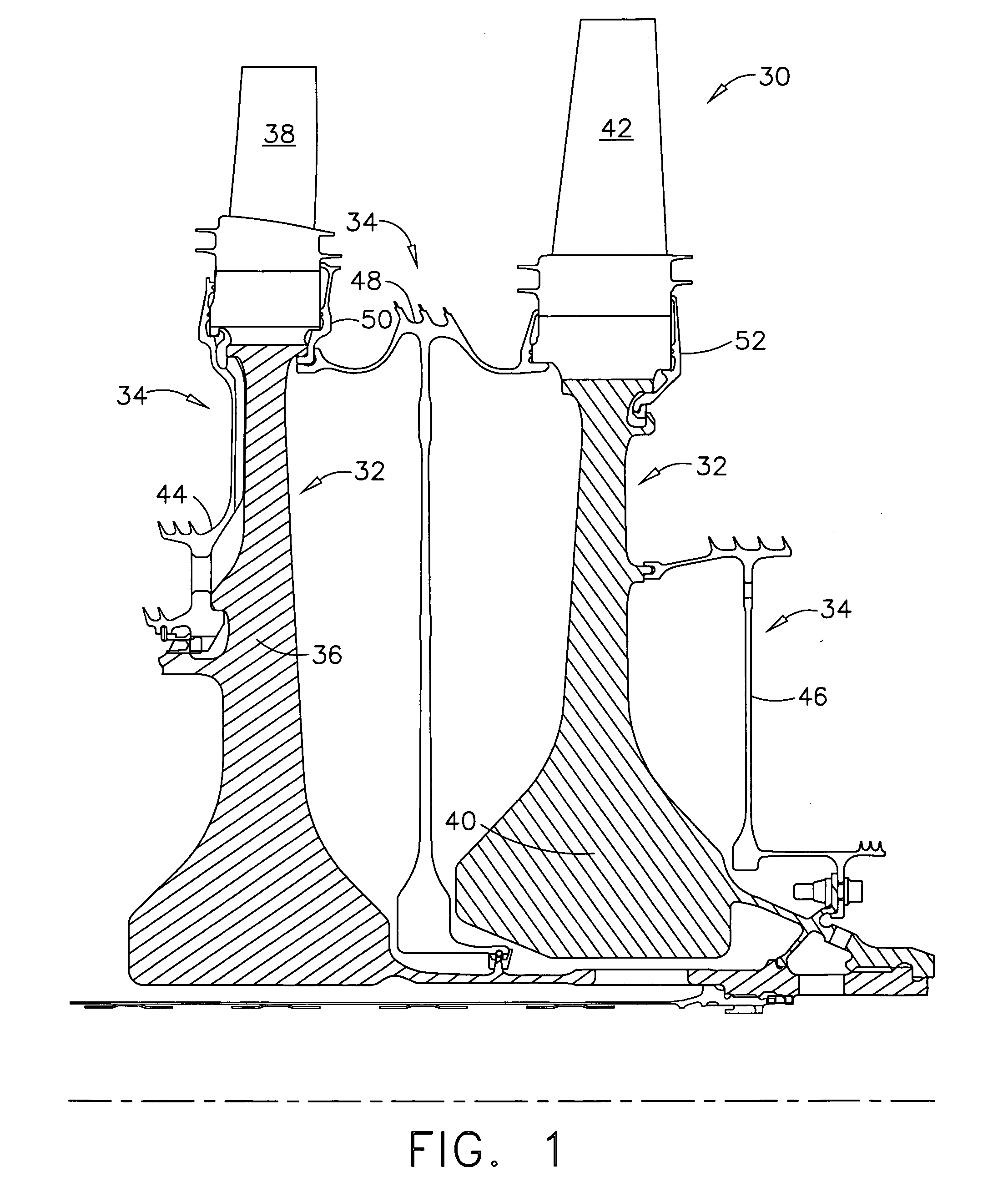

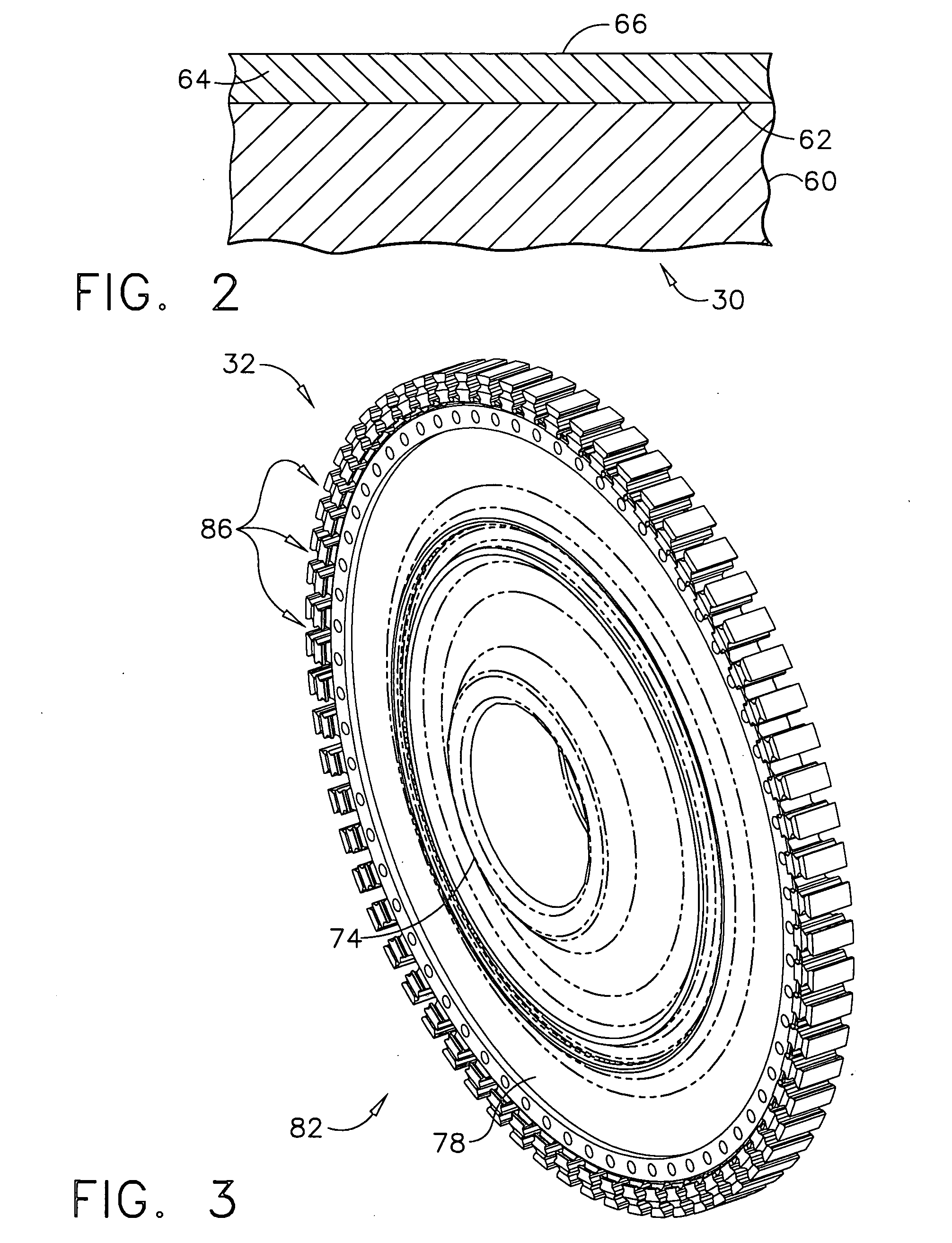

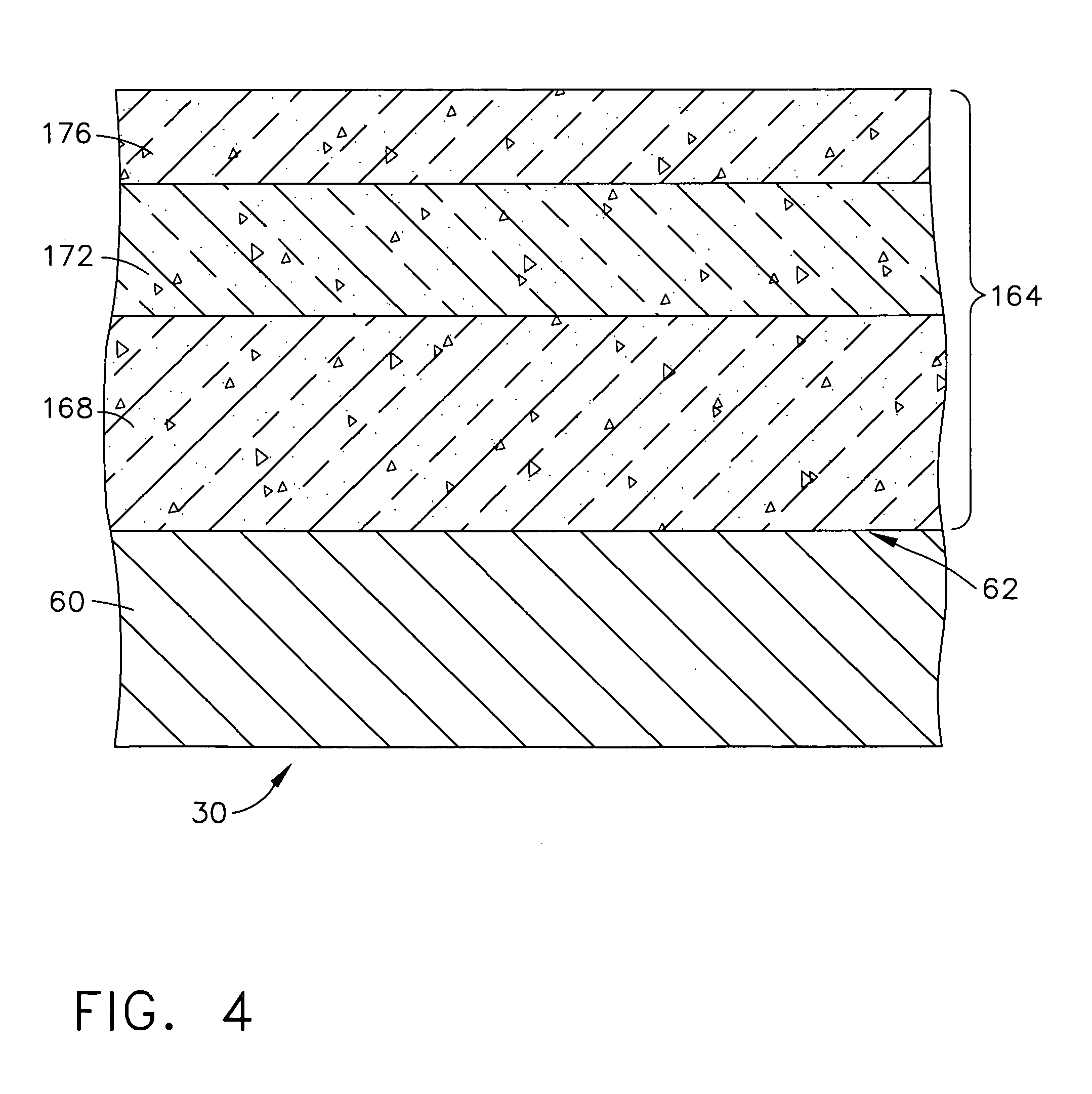

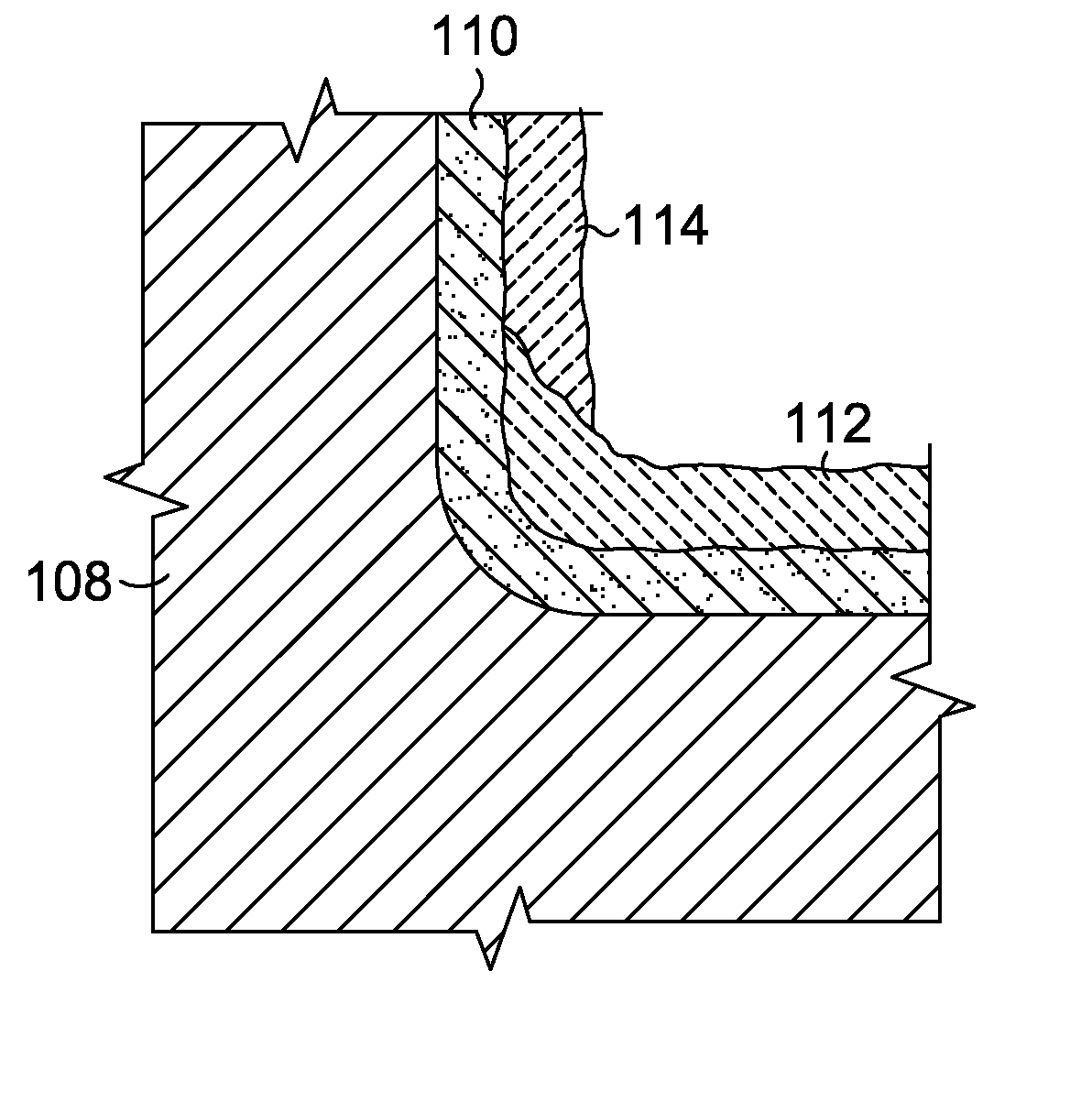

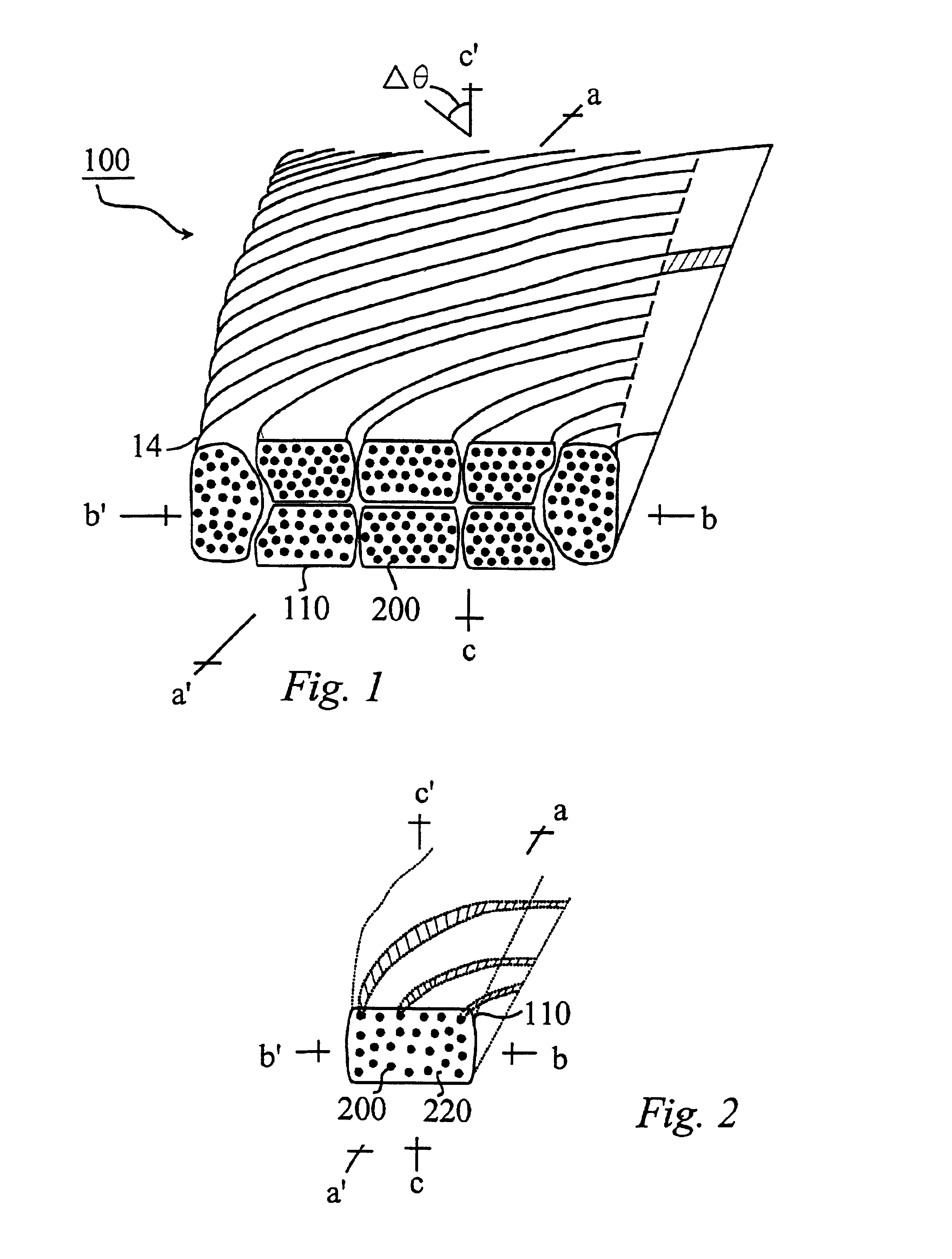

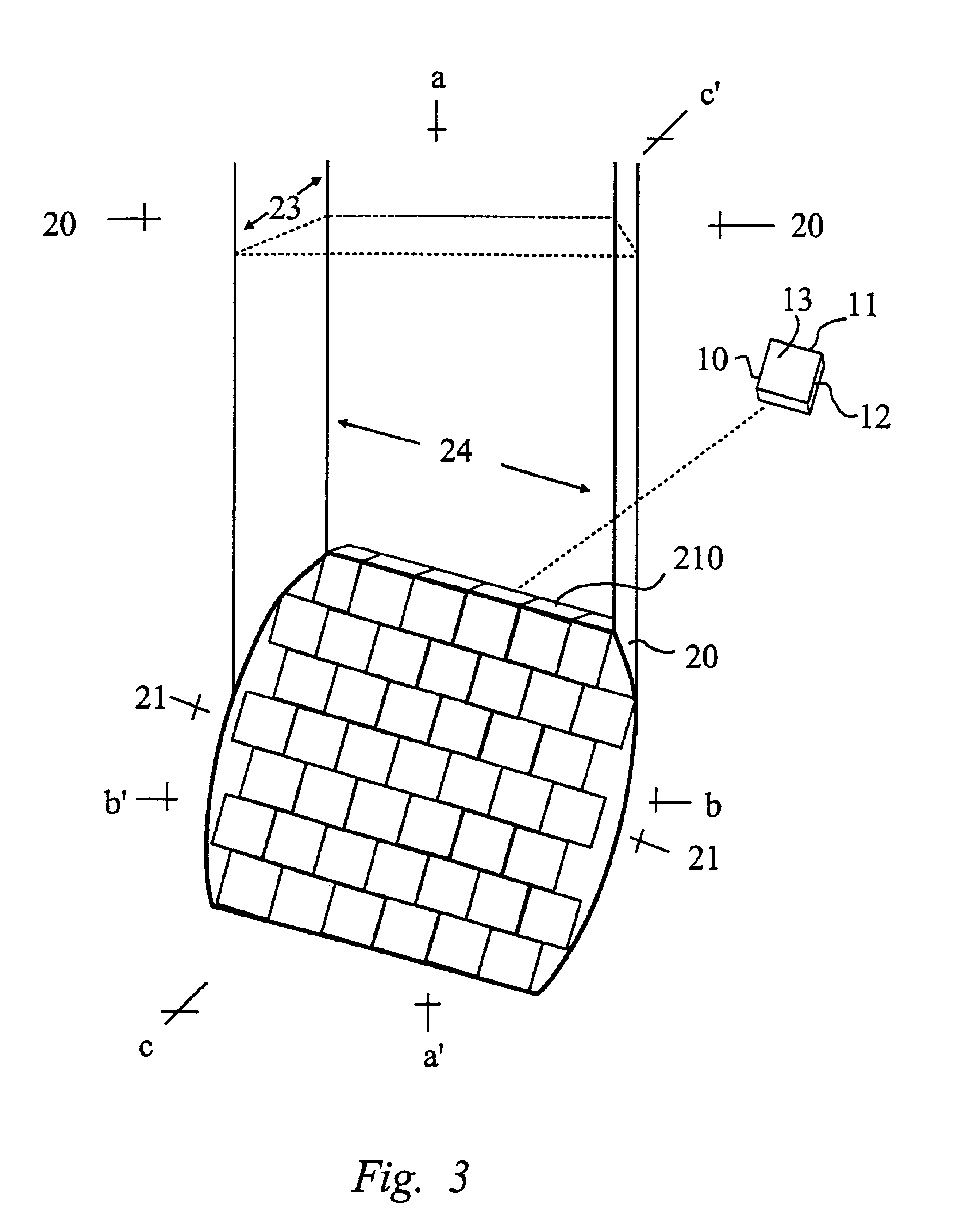

A configuration for coating a turbine component such as a blade or vane with various forms of thermal barrier coating to provide enhanced temperature capability and increased strain tolerance is disclosed. A gas path surface of the platform, airfoil and airfoil fillet region are first coated with a bond coating. A dense vertically cracked (DVC) thermal barrier coating is then applied to at least the gas path surface of the platform and can be applied to the fillet region. A porous thermal barrier coating is then applied to at least the airfoil. The porous thermal barrier coating can also be applied over the DVC thermal barrier coating if desired.

Owner:ANSALDO ENERGIA IP UK LTD

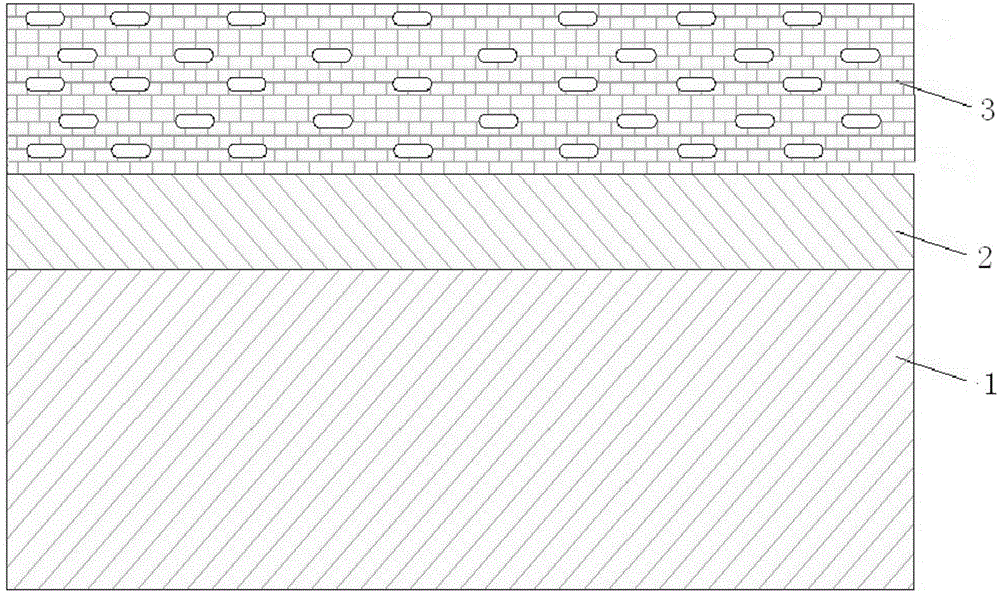

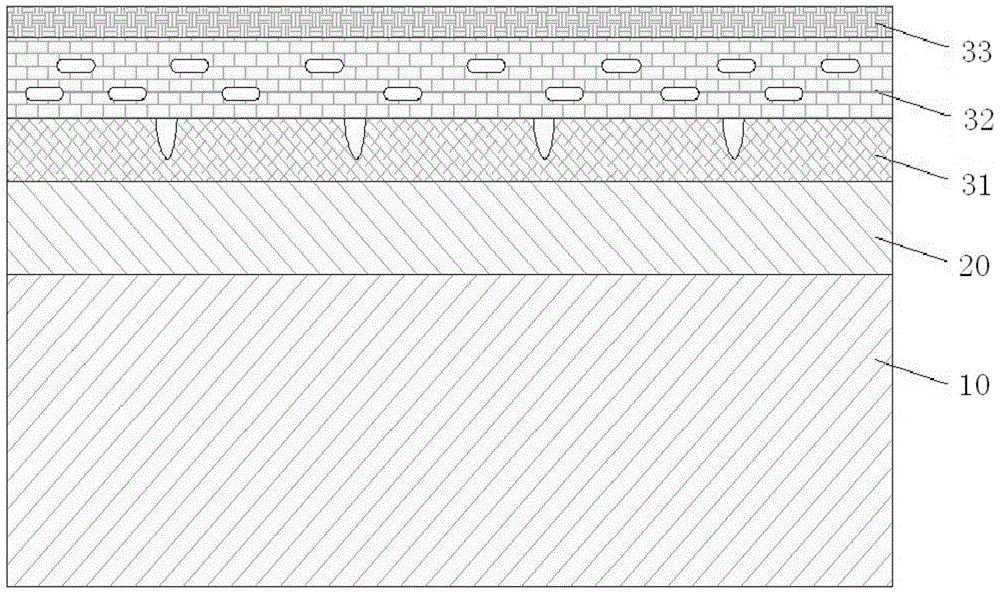

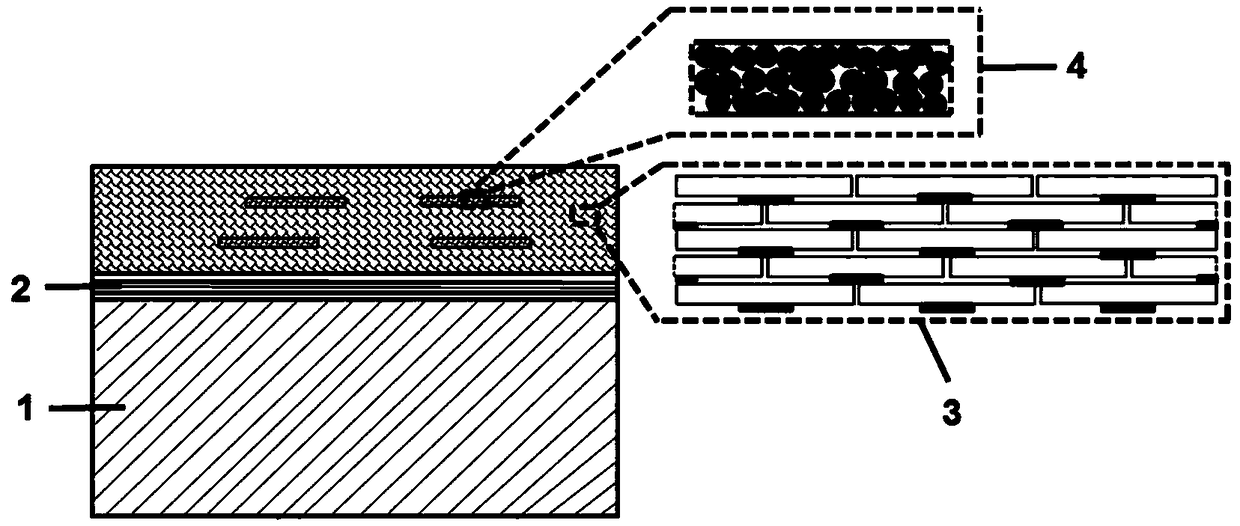

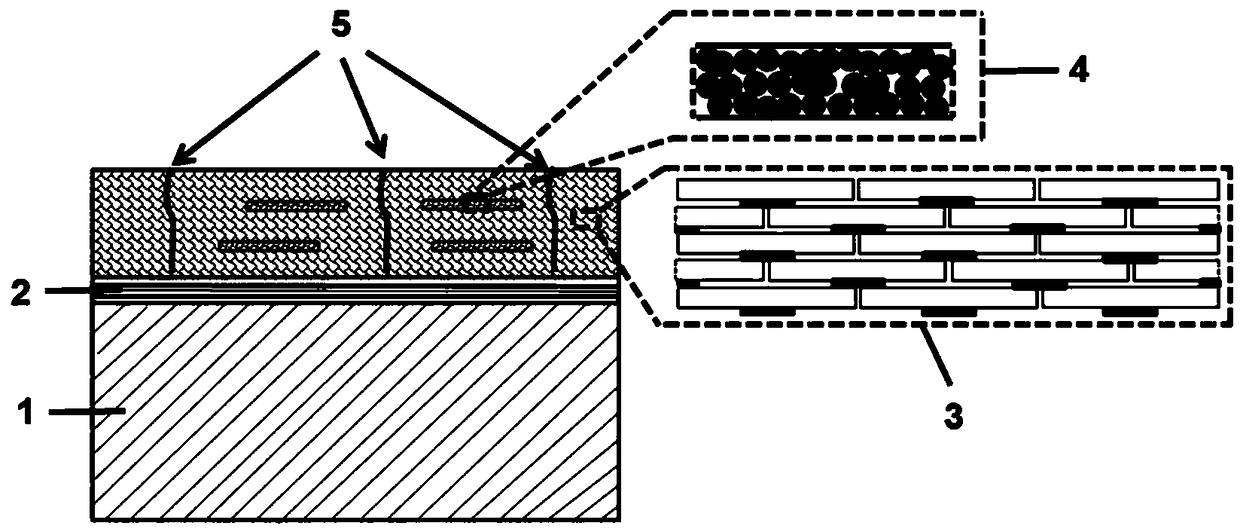

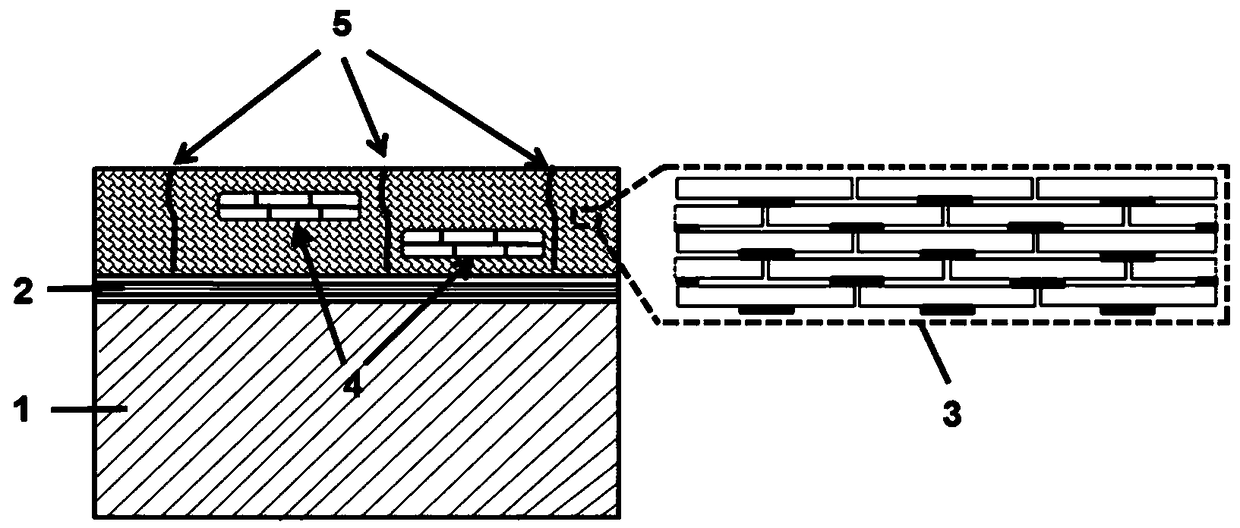

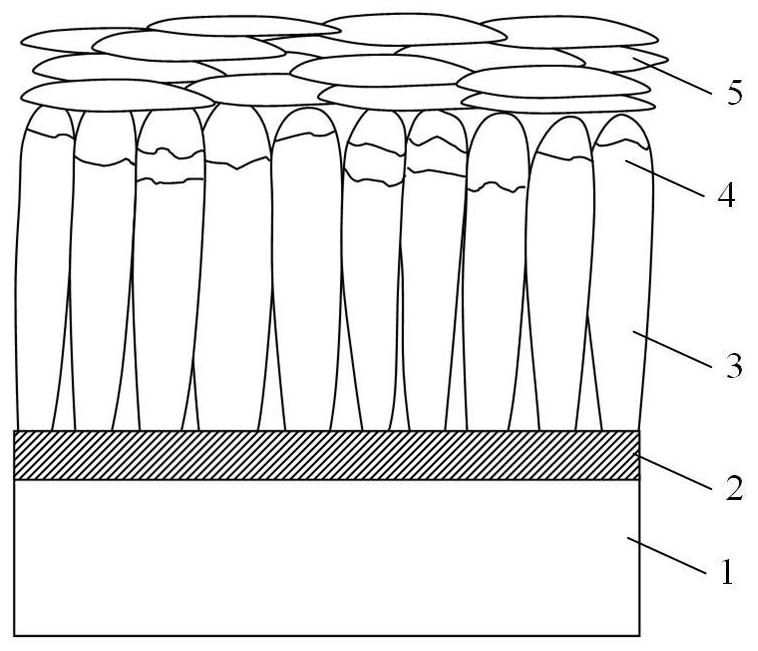

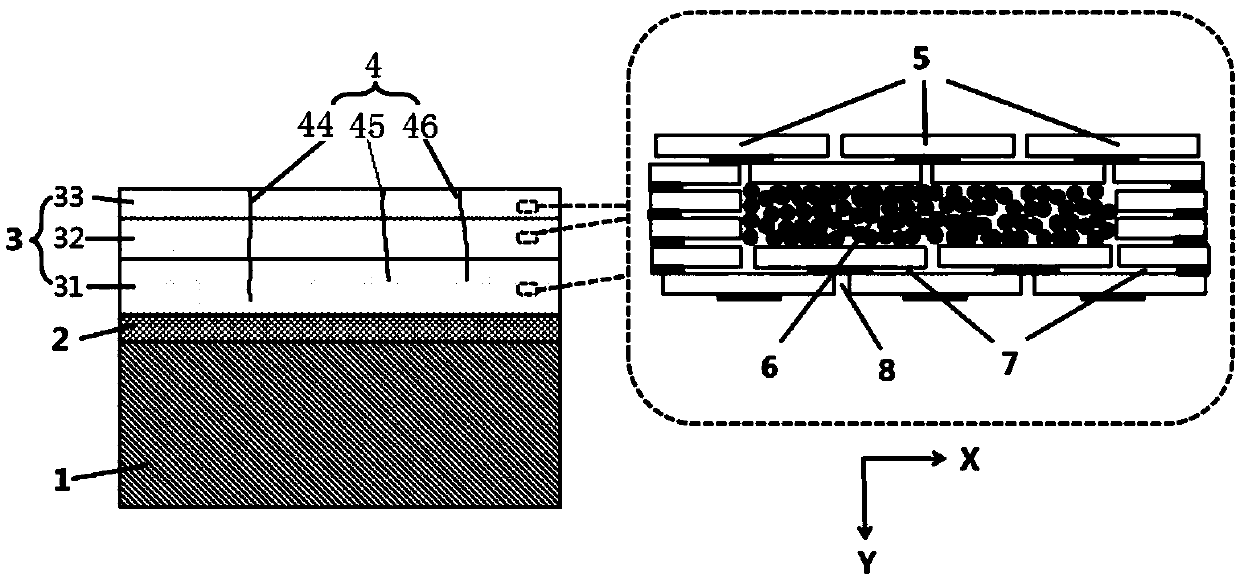

Multi-layer thermal barrier coating and forming method thereof

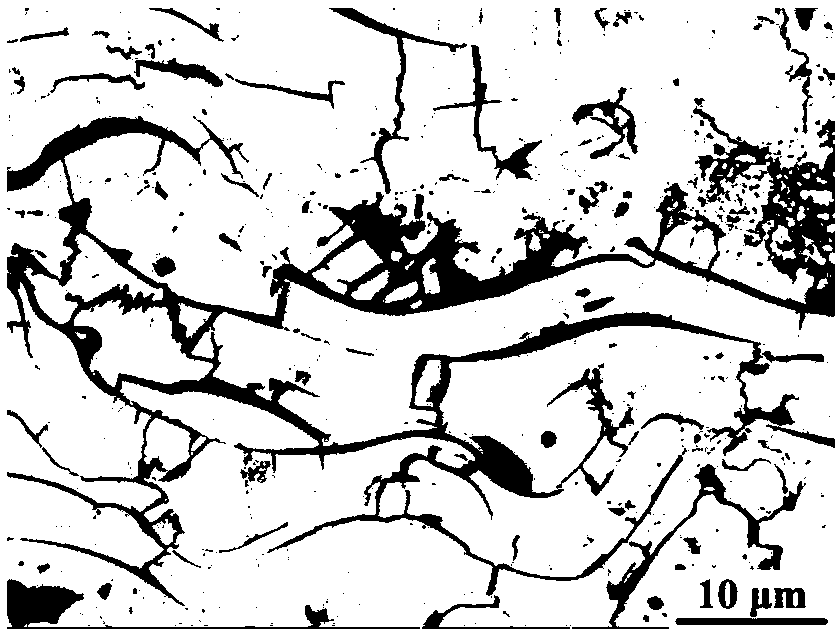

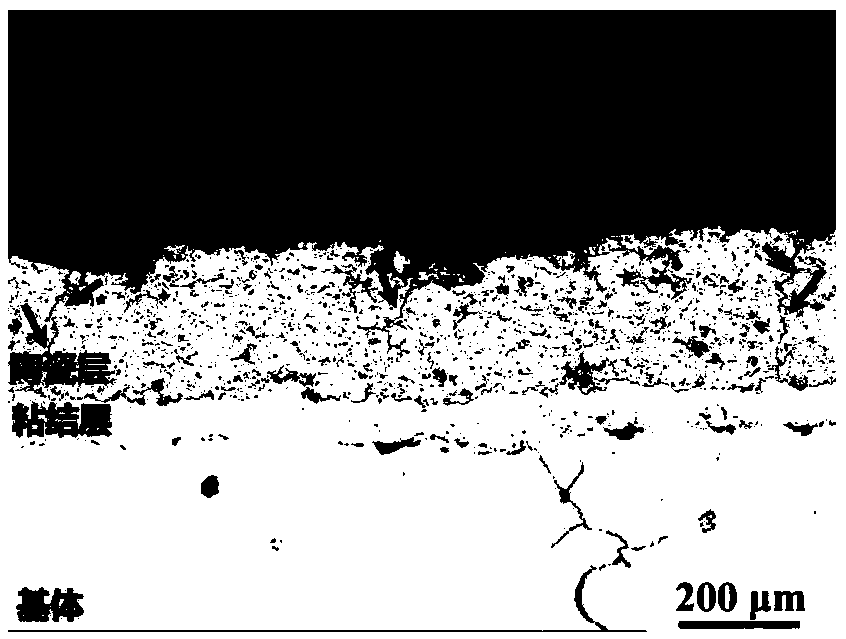

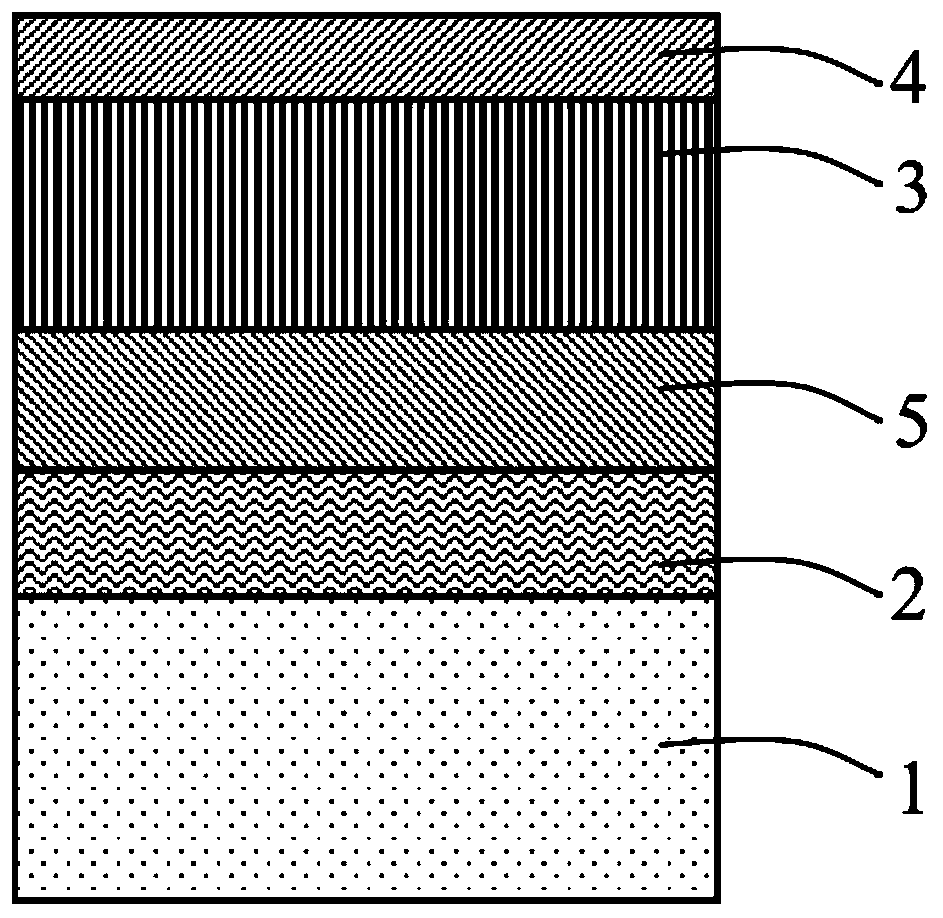

ActiveCN104451519AIncreased strain toleranceHigh crack resistanceMolten spray coatingEfficient propulsion technologiesThermal barrier coatingPlasma sprayed

The invention relates to a multi-layer thermal barrier coating. The coating comprises a base body, a binding layer and a ceramic top layer which are sequentially arranged from bottom to top, wherein the ceramic top layer consists of a vertical-crack-containing ceramic bottom layer with different microstructures, a porous intermediate ceramic layer and a compact ceramic top layer, which are sequentially arranged from bottom to top; the invention further provides a forming method of the multi-layer thermal barrier coating; the forming method comprises the following steps: providing the base body and the binding layer; forming the vertical-crack-containing ceramic bottom layer on the upper surface of the binding layer by plasma spraying; forming the porous intermediate ceramic layer on the upper surface of the vertical-crack-containing ceramic bottom layer by virtue of plasma spraying; forming the compact ceramic top layer on the upper surface of the porous intermediate ceramic layer by virtue of plasma spraying. The multi-layer thermal barrier coating containing different microstructures is formed by the vertical-crack-containing ceramic bottom layer, the porous intermediate ceramic layer and the compact ceramic top layer which are sequentially arranged from bottom to top, so that the multi-layer thermal barrier coating has a thermal cycle service life which multiple times that of the existing thermal barrier coating.

Owner:EAST CHINA UNIV OF SCI & TECH

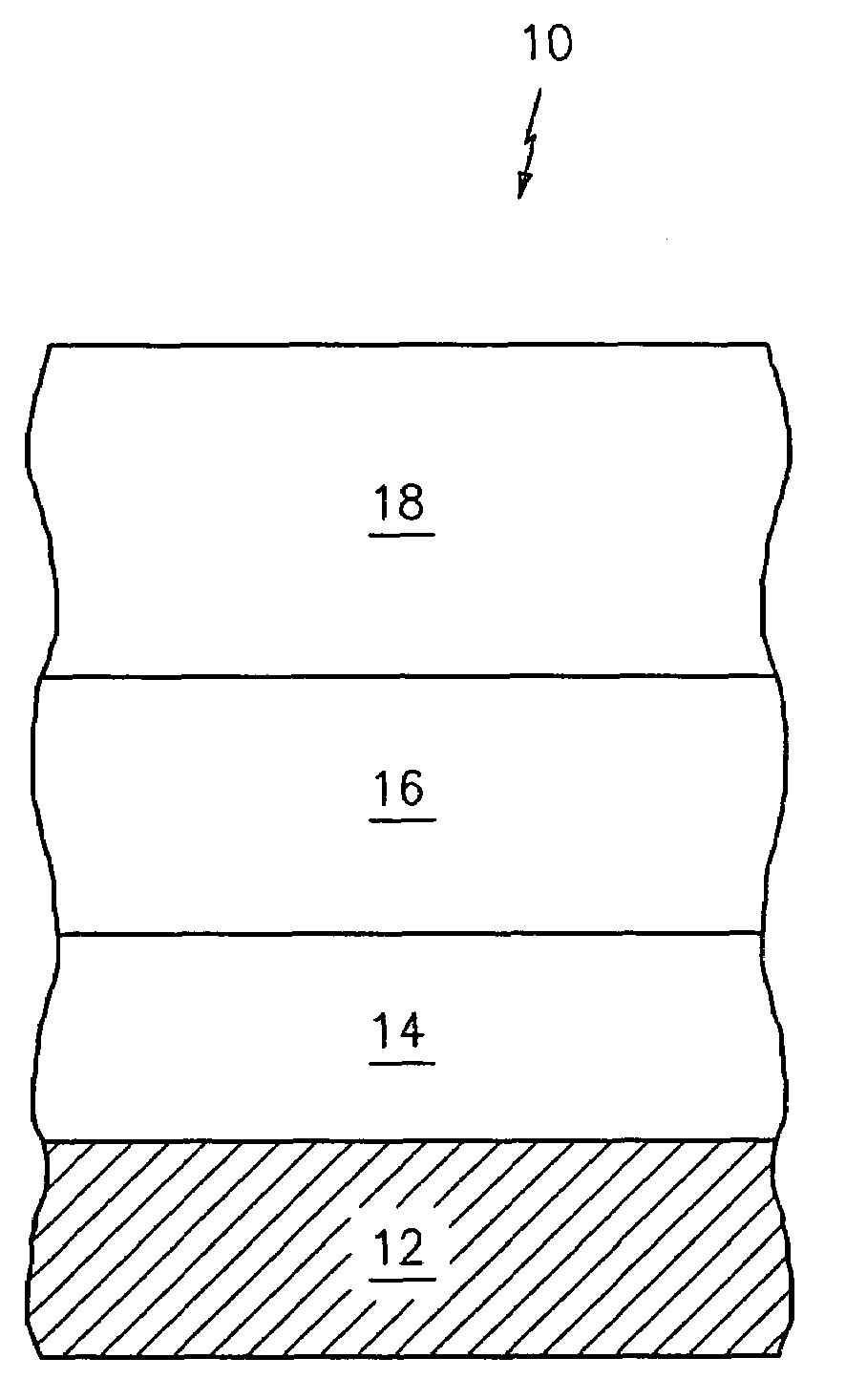

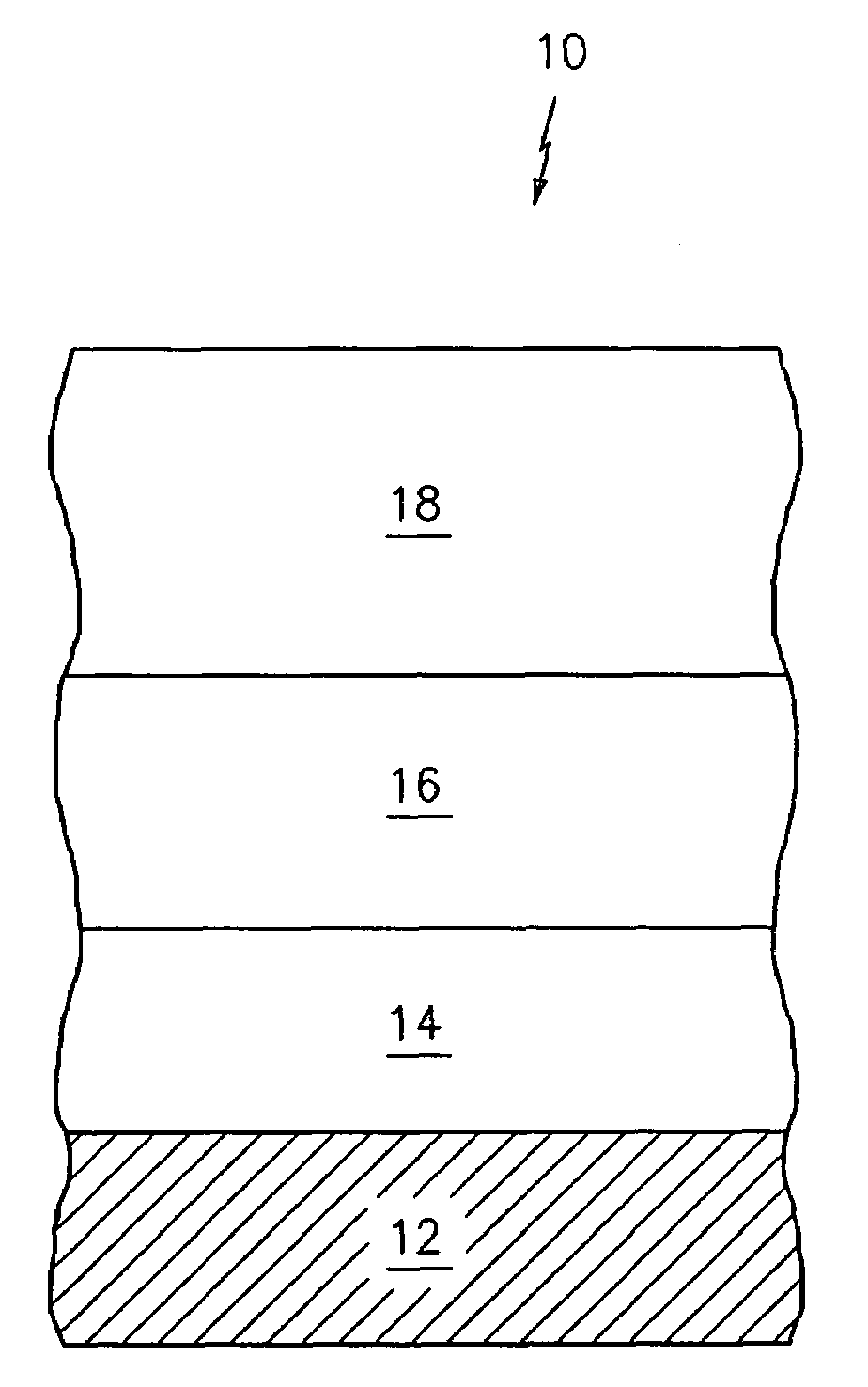

Method for manufacturing articles for high temperature use, and articles made therewith

InactiveUS20040062954A1Improve complianceImprove suppression propertiesMolten spray coatingPropellersMetallurgyHot Temperature

A method for manufacturing an article for use in a high-temperature environment, and an article for use in such an environment, are presented. The method comprises providing a substrate; selecting a desired vertical crack density for a protective coating to be deposited on the substrate; providing a powder, wherein the powder has a size range selected to provide a coating having the desired vertical crack density; and applying a thermal-sprayed coating to the substrate, the coating having the desired vertical crack density, wherein the powder is used as a raw material for the coating.

Owner:GENERAL ELECTRIC CO

Particulate corrosion resistant coating composition, coated turbine component and method for coating same

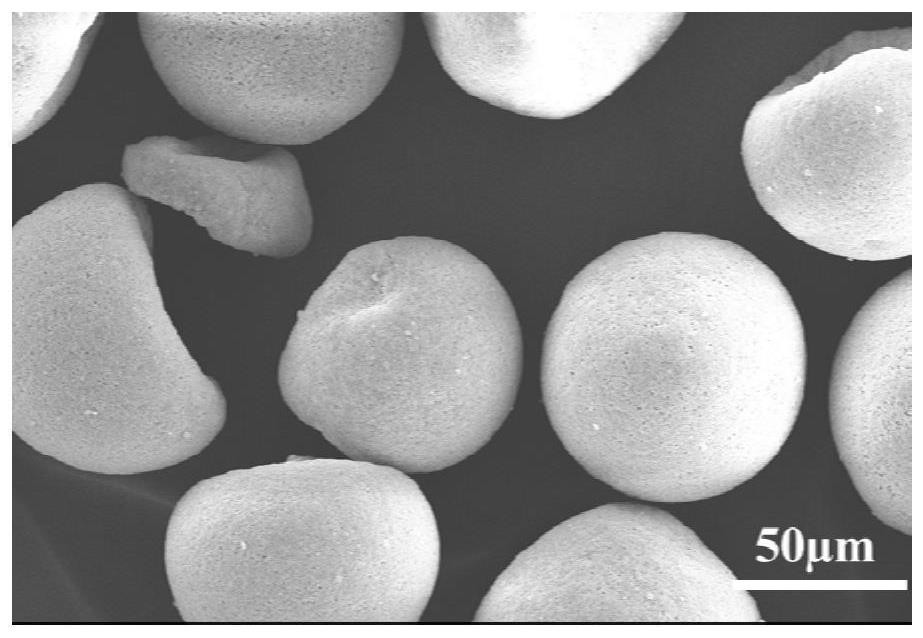

ActiveUS20070141371A1Increased strain toleranceNot easy to peel offRecord information storageCeramic layered productsParticulatesEquivalent spherical diameter

A composition comprising a glass-forming binder component and a particulate corrosion resistant component. The particulate corrosion resistant component comprises corrosion resistant particulates having: a CTEp of at least about 4 and being solid at a temperature of about 1300° F. (704° C.) or greater; and a maximum median particle size defined by one of the following formulas: (a) for a CTEp of 8 or less, an Mp equal to or less than (4.375×CTEp)−10; and (b) for a CTEp of greater than 8, an Mp equal to or less than (−4.375×CTEp)+60, wherein CTEp is the average CTE of the corrosion resistant particulates and wherein Mp is the median equivalent spherical diameter (ESD), in microns, of the corrosion resistant particulates. Also disclosed is an article comprising a turbine component comprising a metal substrate and a corrosion resistant coating overlaying the metal substrate, as well as a method for forming at least one layer of the corrosion resistant coating adjacent to the metal substrate. The corrosion resistant coating has a maximum thickness defined by one of the following formulas: (3) for a CTEp of 8 or less, an Tc equal to or less than (1.5×CTEp)−3.5; and (4) for a CTEp of greater than 8, an Tc equal to or less than (−1.5×CTEp)+20.5, wherein Tc is the thickness, in mils, of the corrosion resistant coating.

Owner:GENERAL ELECTRIC CO

Application of dense vertically cracked and porous thermal barrier coating to a gas turbine component

InactiveUS8511993B2Increase temperatureIncreased strain toleranceMolten spray coatingPropellersBond coatingEngineering

A configuration for coating a turbine component such as a blade or vane with various forms of thermal barrier coating to provide enhanced temperature capability and increased strain tolerance is disclosed. A gas path surface of the platform, airfoil and airfoil fillet region are first coated with a bond coating. A dense vertically cracked (DVC) thermal barrier coating is then applied to at least the gas path surface of the platform and can be applied to the fillet region. A porous thermal barrier coating is then applied to at least the airfoil. The porous thermal barrier coating can also be applied over the DVC thermal barrier coating if desired.

Owner:ANSALDO ENERGIA IP UK LTD

Dual layer ceramic coating

InactiveUS20080044663A1Increased strain toleranceIncreased durabilityMolten spray coatingGlass/slag layered productsMetallurgyCeramic coating

Owner:UNITED TECH CORP

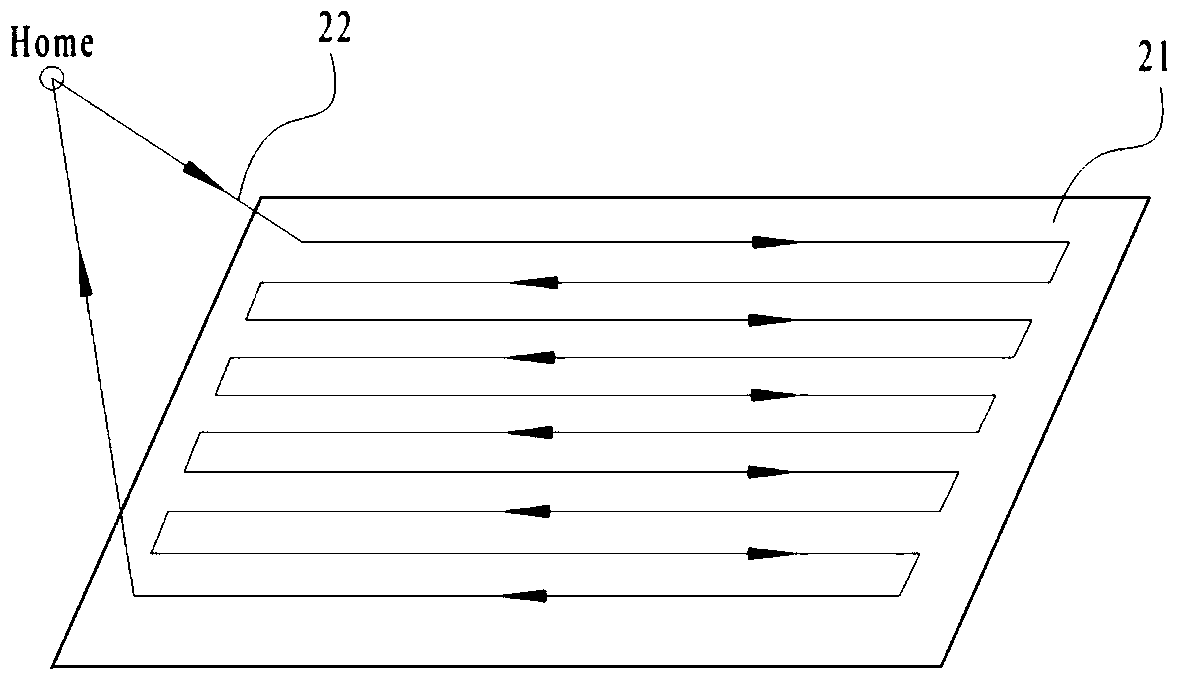

Automatic preparation method of long-service-life cylinder-like crystal structural thermal barrier coating on surface of guide blade of hot end part of fuel machine

ActiveCN104233178AIncreased strain toleranceExtend your lifeMolten spray coatingEfficient propulsion technologiesManipulatorMoving speed

The invention relates to an automatic preparation method of a long-service-life cylinder-like crystal structural thermal barrier coating on the surface of a guide blade of a hot end part of a fuel machine. According to the invention, a supersonic flame spray gun and a plasma spray gun are respectively clamped by manipulators; an automatic spraying program is compiled; for a supersonic flame spraying bonding layer, by a main program, a distance from a TCP (Transmission Control Protocol) point to a spray gun orifice is set into 330 to 350mm, a moving speed of the spray gun is set into 500 to 600m / s and a spacing of spraying profiles is set into 20 to 30mm; for a plasma spraying ceramic layer, by the main program, a distance from the TCP point to a spray gun orifice is set into 60 to 70mm, a moving speed of the spray gun is set into 200 to 250m / s, a spacing of spraying profiles is set into 3 to 7mm; in the plasma spraying program compiling process, the trend of each spraying profile is of a shape of a Chinese character 'gong'. The automatic preparation method sequentially comprises the steps of preparation and pretreatment of a matrix, preparation of a bonding layer, preheating of the hot end part and preparation of a ceramic layer; a scanning electron microscope is adopted to observe; the prepared ceramic layer is of a cylinder-like crystal structure; strain tolerance and the thermal shock resistance service life of the coating are obviously improved; compared with the service life of the conventional structural thermal barrier coating, the service life of the coating is obviously prolonged.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE

Anti-sintering dual-die composite structure thermal barrier coating and preparation technology thereof

ActiveCN109023364AHigh feasibilityRealize engineering applicationMolten spray coatingSuperimposed coating processHeat flowPre treatment

The invention discloses a preparation technology of an anti-sintering dual-die composite structure thermal barrier coating. The preparation technology includes the steps that first, metal is depositedon a substrate to form a metal bonding layer; second, first thermal barrier coating material powder and second thermal barrier coating material powder are deposited on the metal bonding layer in an alternative layered mode through a thermal spraying method to form a composite layered structure thermal barrier coating; and third, a plurality of longitudinal holes are formed in the composite layered structure thermal barrier coating through a strong flow impingement cooling pretreatment technology, and accordingly the dual-die composite structure thermal barrier coating can be obtained. According to the dual-die composite structure provided by the invention, the multiple holes perpendicular to the heat flow direction are spontaneously formed on service, high-strain tolerance is maintained and thus the characteristics of being resistant to sintering and long in service life are achieved.

Owner:咸阳瞪羚谷新材料科技有限公司

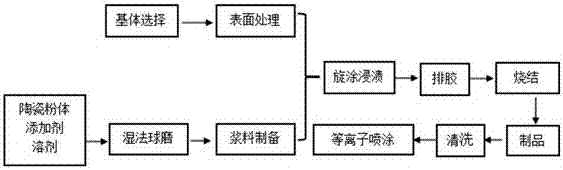

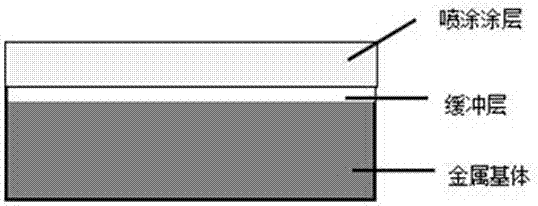

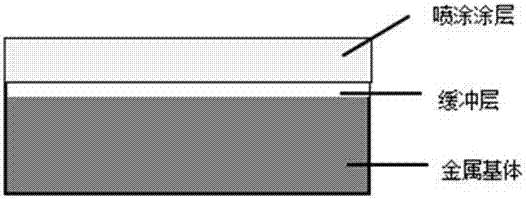

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

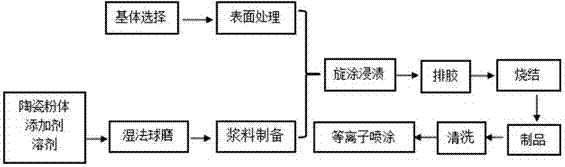

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

Particulate corrosion resistant coating composition, coated turbine component and method for coating same

ActiveUS7604867B2Increased strain toleranceNot easy to peel offRecord information storageCeramic layered productsParticulatesEquivalent spherical diameter

A composition comprising a glass-forming binder component and a particulate corrosion resistant component. The particulate corrosion resistant component comprises corrosion resistant particulates having: a CTEp of at least about 4 and being solid at a temperature of about 1300° F. (704° C.) or greater; and a maximum median particle size defined by one of the following formulas: (a) for a CTEp of 8 or less, an Mp equal to or less than (4.375×CTEp)−10; and (b) for a CTEp of greater than 8, an Mp equal to or less than (−4.375×CTEp)+60, wherein CTEp is the average CTE of the corrosion resistant particulates and wherein Mp is the median equivalent spherical diameter (ESD), in microns, of the corrosion resistant particulates. Also disclosed is an article comprising a turbine component comprising a metal substrate and a corrosion resistant coating overlaying the metal substrate, as well as a method for forming at least one layer of the corrosion resistant coating adjacent to the metal substrate. The corrosion resistant coating has a maximum thickness defined by one of the following formulas: (3) for a CTEp of 8 or less, an Tc equal to or less than (1.5×CTEp)−3.5; and (4) for a CTEp of greater than 8, an Tc equal to or less than (−1.5×CTEp)+20.5, wherein Tc is the thickness, in mils, of the corrosion resistant coating.

Owner:GENERAL ELECTRIC CO

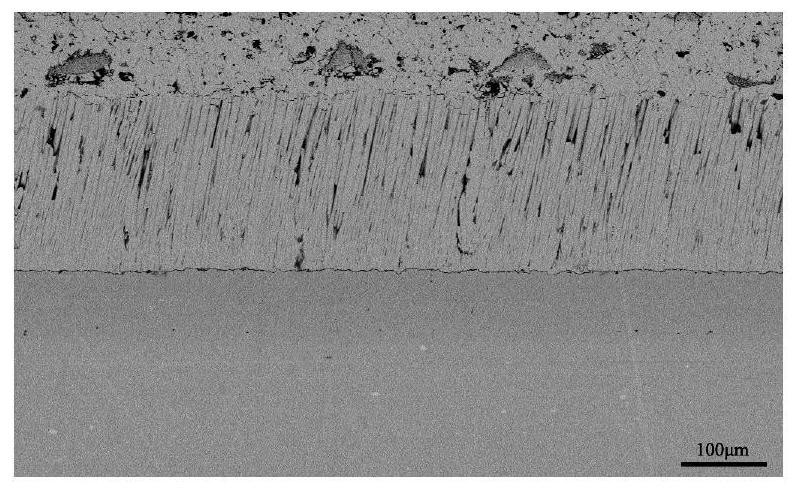

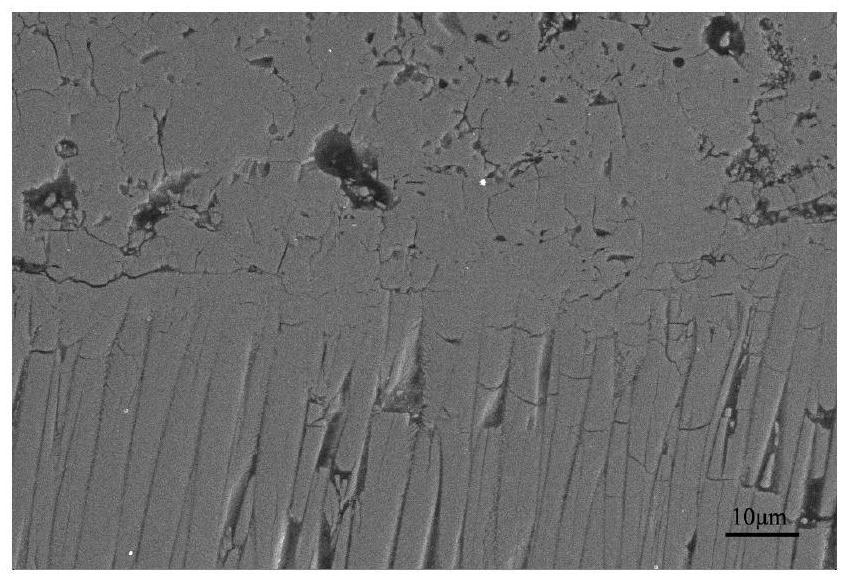

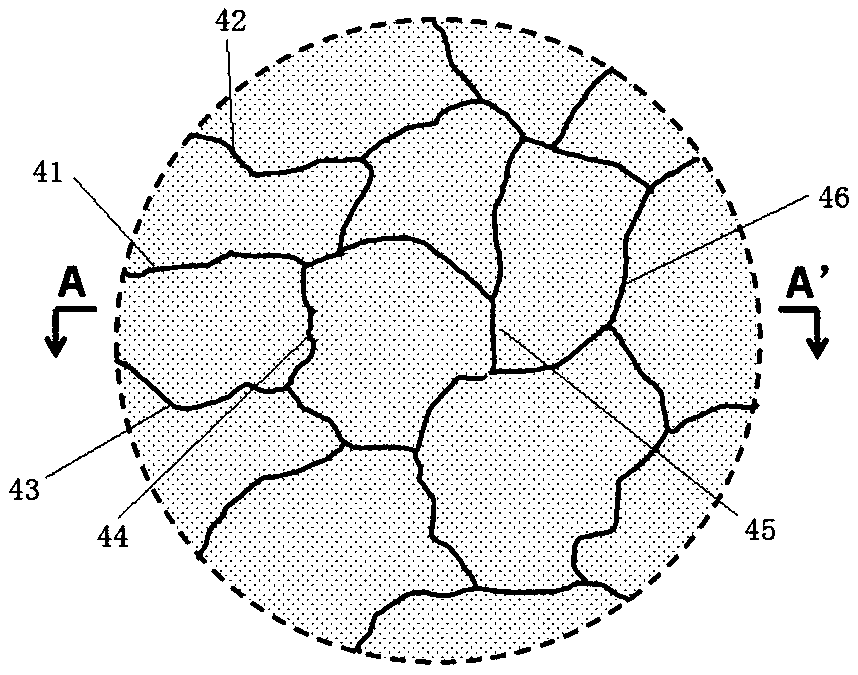

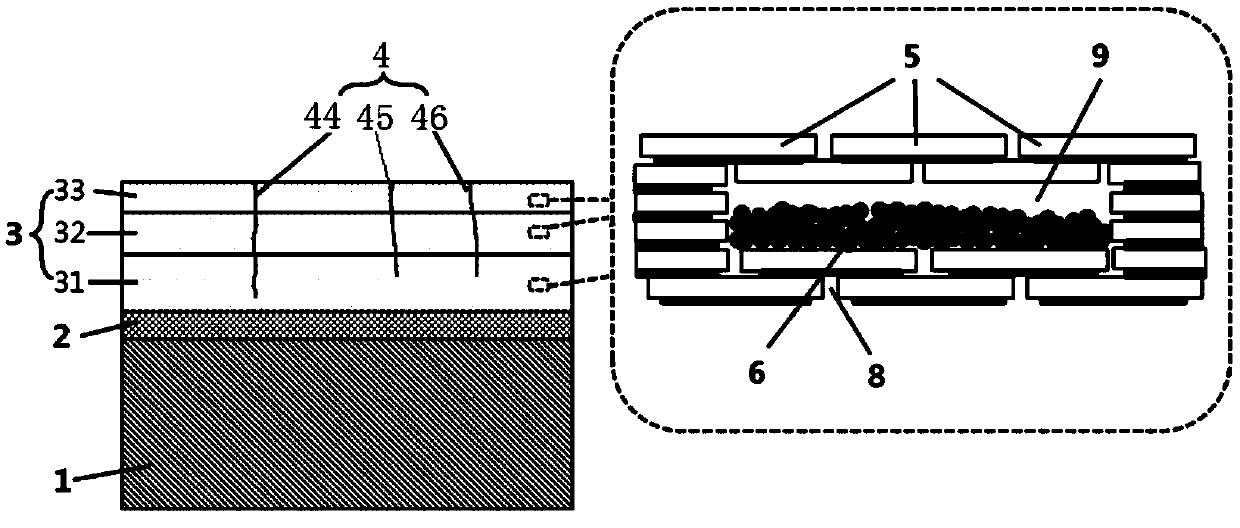

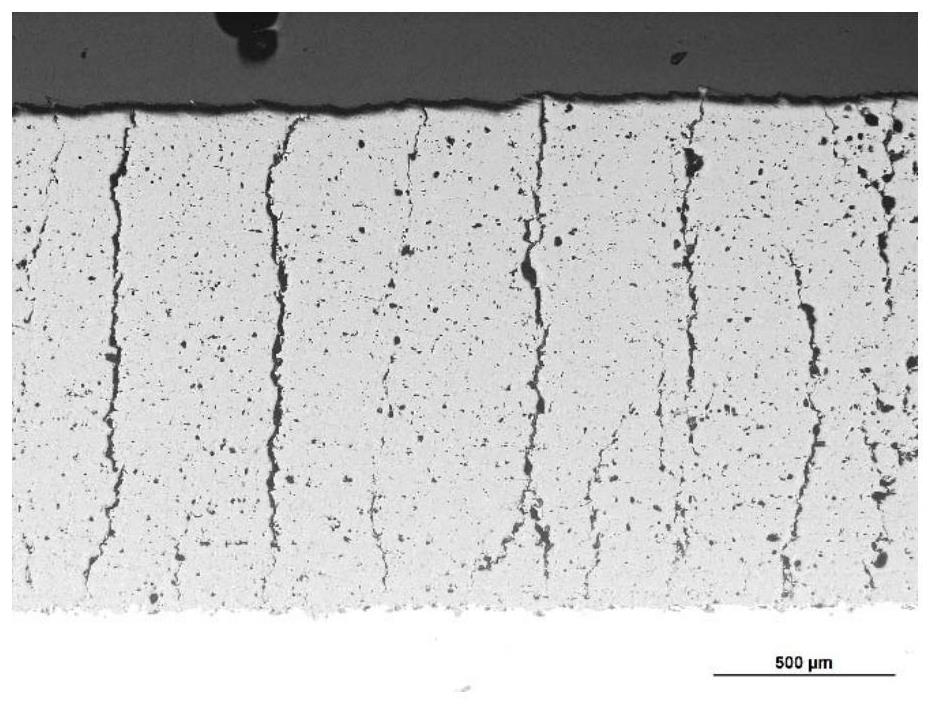

Columnar layer double-mode structure thermal barrier coating and preparation method thereof

ActiveCN109266996AIncreased strain toleranceExtended service lifeMolten spray coatingThermal insulationThermal barrier coating

The invention provides a columnar layer double-mode structure thermal barrier coating and a preparation method thereof, wherein the thermal barrier coating is formed by stacking flat particle layers formed by material powder to form a layered structure, has vertical pores, and is divided into a plurality of blocks by the vertical pores to form a columnar structure. During the preparation, thermalbarrier coating powder is subjected to spray deposition through a thermal spray coating method to prepare a layered thermal barrier coating formed by stacking flat particles, and a plurality of vertical pores are formed in the layered thermal barrier coating through a stress excitation and pore induction pretreatment process to obtain the columnar layer double-mode structure thermal barrier coating. According to the present invention, with the columnar layer double-mode structure thermal barrier coating, the service life of the coating is significantly prolonged while the vertical thermal insulation performance of the coating is maintained so as to integrate the high thermal insulation and long service life of the coating.

Owner:XI AN JIAOTONG UNIV

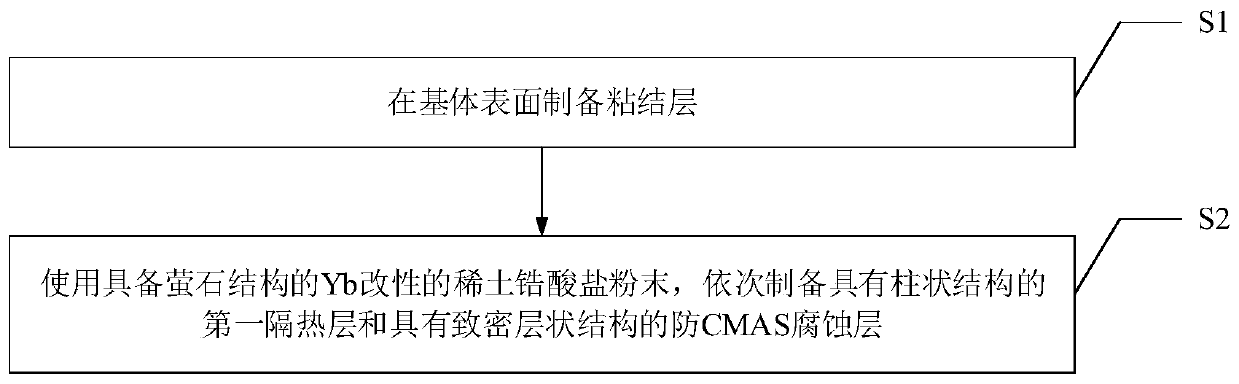

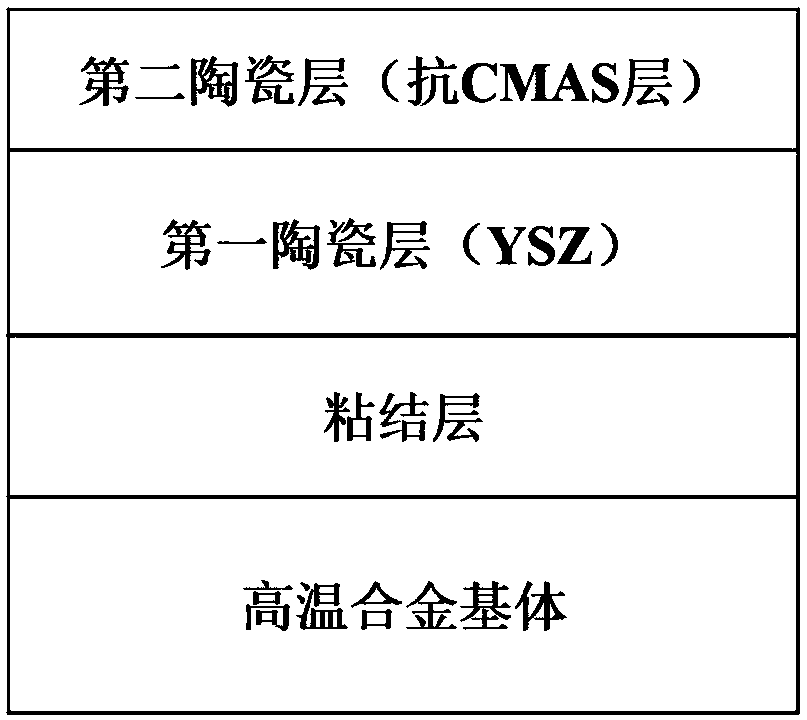

Yb modified CMAS prevention composite structure thermal barrier coating and preparing method thereof

ActiveCN111471998APrevent penetrationImprove thermal shock performanceMolten spray coatingSuperimposed coating processInsulation layerThermal break

The invention discloses an Yb modified CMAS prevention composite structure thermal barrier coating and a preparing method thereof. A CMAS corrosion prevention layer adopts Yb modified rare earth zirconate to form a compact layered structure, at the high temperature, the layered structure can have a reaction with CMAS to form a compact blocking layer, permeation of molten CMAS to the interior of the thermal barrier coating can be prevented, a first heat insulation layer adopts Yb modified rare earth zirconate to form a columnar structure, enough heat insulation performance and high strain tolerance can be provided for the thermal barrier coating, the thermal shock property of the thermal barrier coating is improved, the service life of the thermal barrier coating can be prolonged, the CMAScorrosion prevention layer and the first heat insulation layer are made of materials of the same elements, heat mis-match stress between the two layers can be relieved, combining strength of the two layers can be improved, the thermal barrier coating has the advantages of being low in heat conduction rate, stable in phase, high in combining strength, and high in sintering resisting capacity, the service life under the high-temperature service condition is long, combination strength between dual layers of ceramic can be high, and combination strength between a ceramic layer and a metal bondinglayer is high.

Owner:BEIHANG UNIV

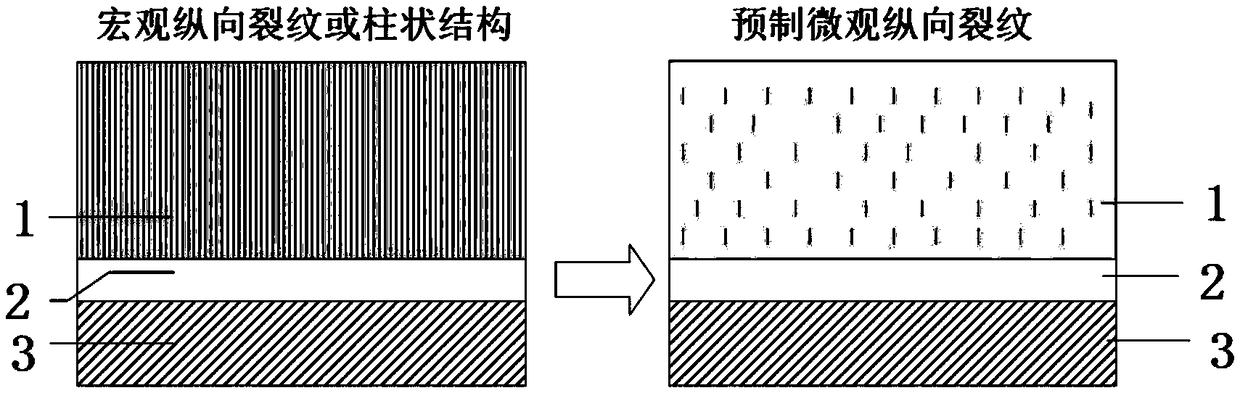

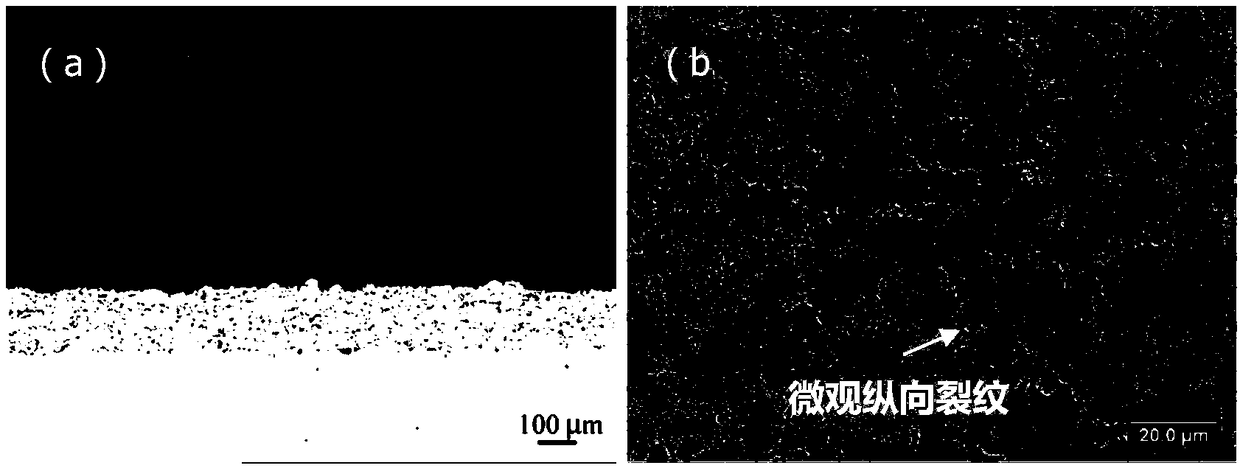

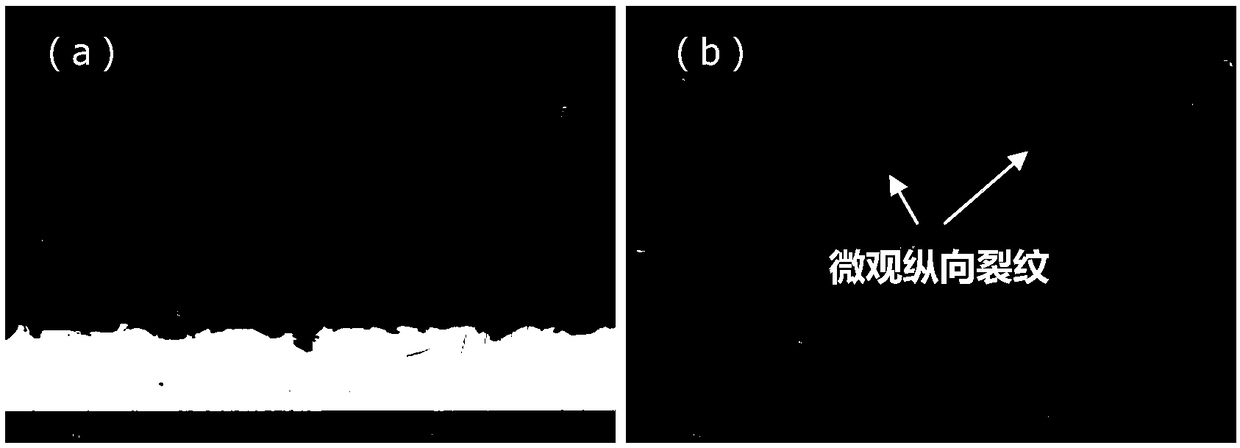

Thermal barrier coating provided with prefabricated microcosmic longitudinal crack structure and preparing method of thermal barrier coating

ActiveCN108660407AEasy to operateNo secondary pollutionMolten spray coatingElectron beam physical vapor depositionHigh density

The invention discloses a thermal barrier coating provided with a prefabricated microcosmic longitudinal crack structure and a preparing method of the thermal barrier coating. A ceramic heat isolationlayer of the thermal barrier coating comprises an implanted high-density microcosmic longitudinal crack. According to the preparing method, the atmosphere plasma spraying technology is utilized for being coupled with the dry ice particle spraying technology to prepare the ceramic heat isolation layer, and the microcosmic longitudinal crack is implanted in the ceramic heat isolation layer throughonline quenching on ceramic fusion particles via the dry ice particle spraying technology. Compared with thermal barrier coatings prepared through traditional atmosphere plasma spraying and EB-PVD (Electron beam-physical vapor deposition) methods, the thermal barrier coating provided with the prefabricated microcosmic longitudinal crack structure and prepared through the design has the low heat conductivity of the thermal barrier coating prepared through traditional plasma spraying and also has high strain tolerance of the thermal barrier coating prepared through the EB-PVD technology, stressgenerated due to unmatched heat stress can be effectively released under the premise that the coating heat impacts, heat isolation and CMAS (CaO-MgO-Al2O3-SiO2) corrosion resistance are not lowered, and accordingly the heat cycle service life of the thermal barrier coating under the severe working condition is prolonged.

Owner:WUHAN UNIV OF TECH

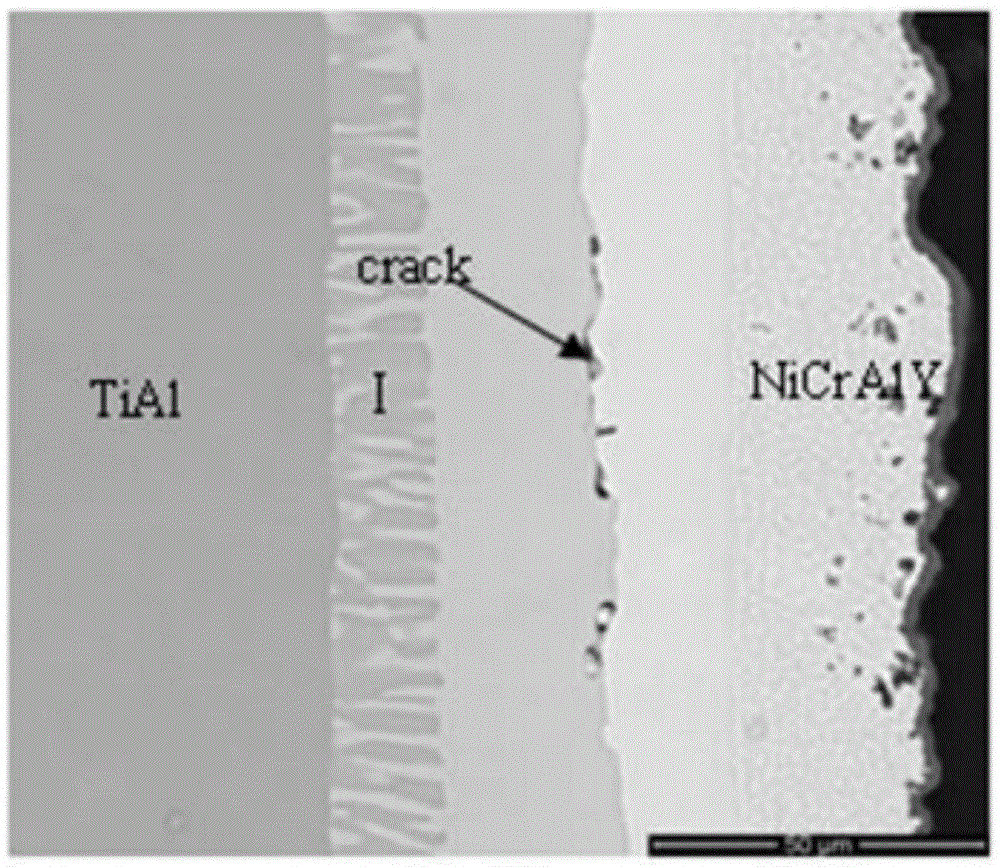

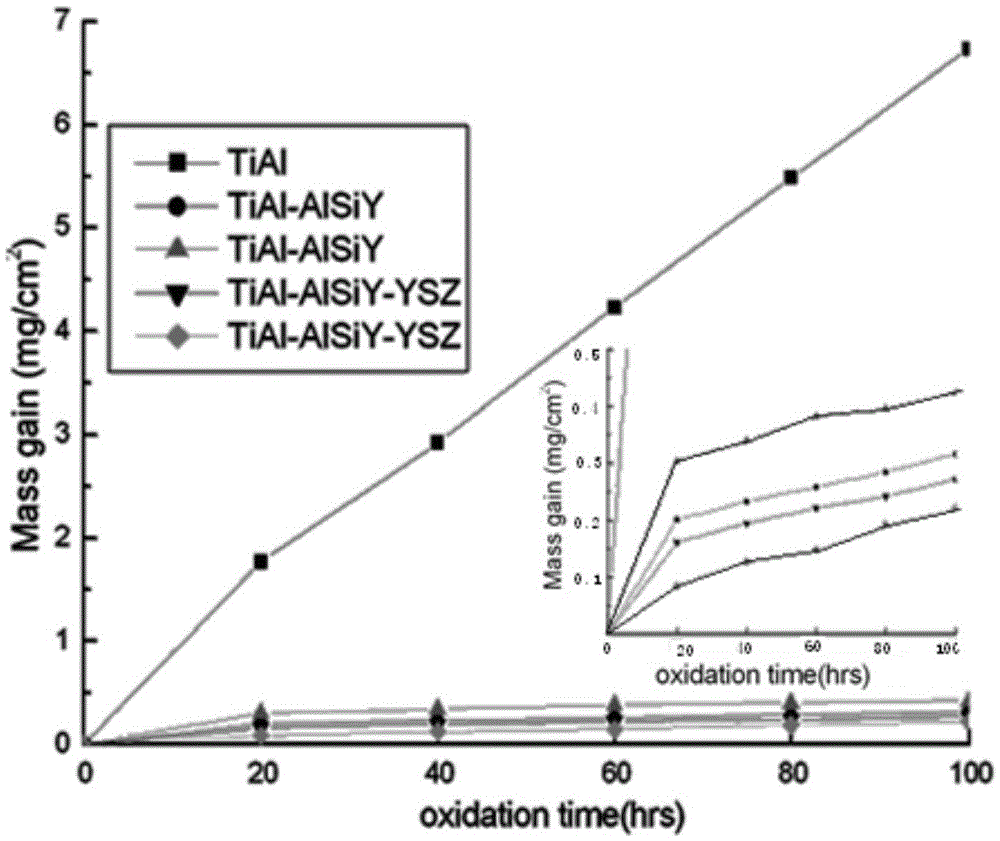

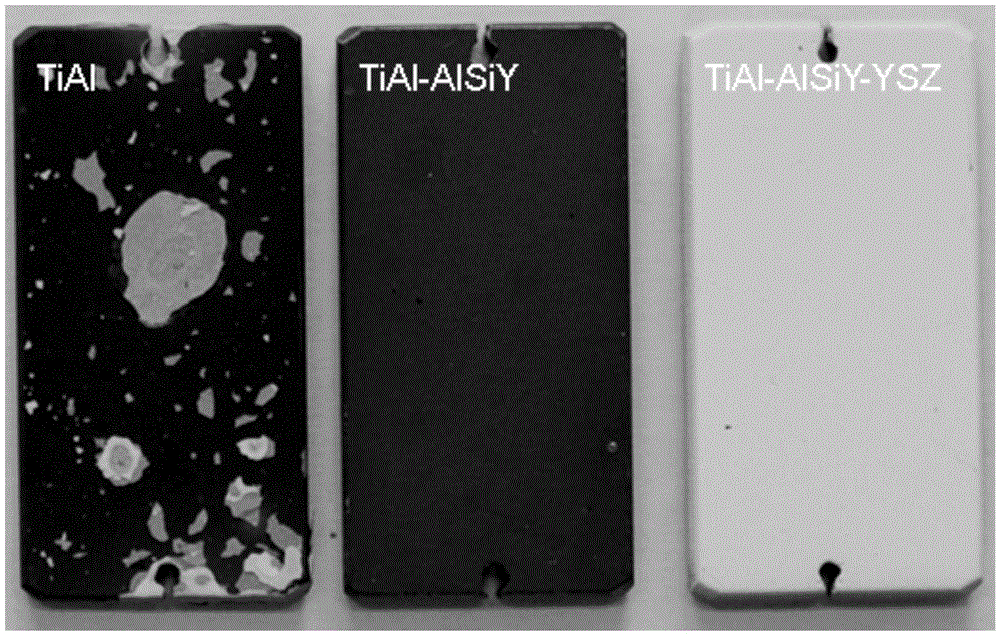

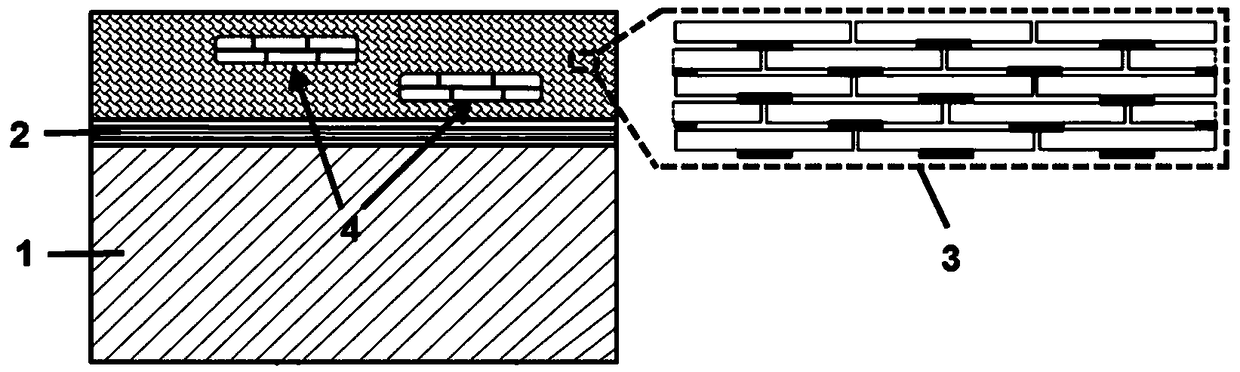

Coating improving oxidation resistance of TiAl alloy and preparing method of coating

ActiveCN105463382AGood compatibilityImprove antioxidant capacityVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionGas phase

The invention relates to a coating and a preparing method thereof, in particular to a coating improving oxidation resistance of TiAl alloy and a preparing method of the coating. The coating improving oxidation resistance of TiAl alloy comprises an AlSiY bottom layer and a YSZ ceramic face layer, the AlSiY bottom layer is prepared through vacuum arc plating, and high-temperature diffusion and wet grit blasting treatment is carried out. The YSZ ceramic face layer of a columnar crystal structure is prepared through an electron beam physical vapor deposition method, and a typical columnar crystal structure is presented. The interfacial compatibility of the coating improving oxidation resistance of TiAl alloy and TiAl alloy is good, the oxidation resistance is superior, and the strain tolerance is high.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Anti-sintering dual-mode complex structure thermal barrier coating layer and preparation process thereof

ActiveCN109161889AHigh feasibilityRealize engineering applicationMolten spray coatingSuperimposed coating processDual modeAdhesive

The invention discloses an anti-sintering dual-mode complex structure thermal barrier coating layer and a preparation process thereof. The preparation process comprises the following steps: Step I, depositing a metal on a matrix to form a metal adhesive layer; Step II, alternating layering and depositing thermal barrier coating layer powder and phase-change shrinkable ceramic material powder on the metal adhesive layer to form a composite lamellar structure thermal barrier coating layer; Step III, forming a plurality of longitudinal pores in the composite lamellar structure thermal barrier coating layer through strong flow impact cooling pretreatment process to obtain a dual-mode complex structure thermal barrier coating layer; Step IV, generating phase-change shrinkage through a second lamella unit in a thermal treatment or actual application process of the dual-mode complex structure thermal barrier coating layer and the matrix, so as to obtain the anti-sintering dual-mode complex structure thermal barrier coating layer. The structure of the anti-sintering dual-mode complex structure thermal barrier coating layer spontaneously forms a plurality of pores perpendicular to a heat flow direction when serving in a high temperature environment, maintains a high strain tolerance and has the characteristics of sintering resistance and long service life.

Owner:咸阳瞪羚谷新材料科技有限公司

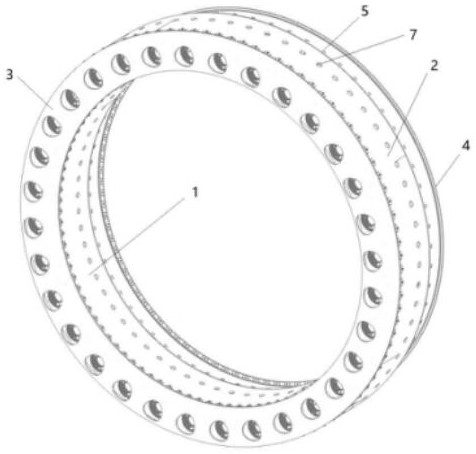

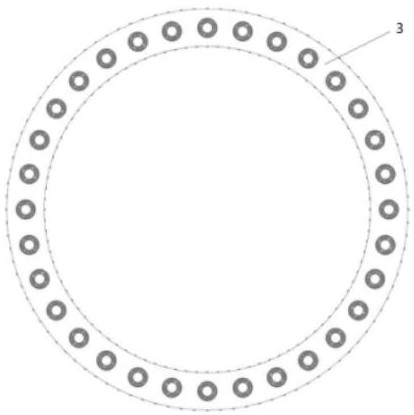

Ceramic-based annular flame tube

InactiveCN112503574AIncrease thrust-to-weight ratioIncreased strain toleranceContinuous combustion chamberCooling effectSuperalloy

The invention relates to a ceramic-based annular flame tube. The ceramic-based annular flame tube comprises a tube main body, a rear support and a front end cover, wherein the tube main body and the rear support are made of integrally-woven SiCf / SiCm materials, and the front end cover is made of high-temperature alloy. According to the ceramic-based annular flame tube, ellipse-like inclined holesare designed to be formed in the tube wall of the flame tube, and the circumferential inclination angle is set to achieve the optimal cooling effect; in order to solve the problem of thermal mismatchof connection between parts made of different materials, thermal mismatch compensation slits are formed in a head joint and the rear support; and the flame tube made of a ceramic matrix composite is mainly applied to aero-engines and has the characteristics of being light in weight, high in using temperature, good in cooling effect, convenient to machine and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Thickness-adjustable heat insulation/infrared stealth composite coating, titanium alloy material with surface coated with coating and preparation method of titanium alloy material

ActiveCN111118439AWith thermal insulationWith high temperature infrared stealth performanceMolten spray coatingAluminateCeramic coating

The invention relates to the field of high-temperature functional ceramic coating materials, and particularly discloses a thickness-adjustable thermal insulation / infrared stealth composite coating. The composite coating is of a multi-layer stacked structure and sequentially comprises a metal bonding layer, a ceramic layer and an infrared low-emissivity layer from inside to outside, the ceramic layer is a lanthanum phosphate-hexaaluminate composite ceramic layer, and the infrared low-emissivity layer is a low-emissivity coating which is formed by taking Bi2O3-Al2O3-TiO2-Li2O-SiO2 series low-melting-point glass as a binding phase and taking silver as a conductive phase. A titanium alloy material with the surface coated with the coating and a preparation method of the titanium alloy materialare further provided. The heat insulation / infrared stealth composite coating has the characteristics of excellent thermal shock resistance and high-temperature infrared low emissivity; and the thickness of the coating can be regulated and controlled according to different actual application requirements, and the density and the heat insulation performance of the coating surface can be regulated.

Owner:NAT UNIV OF DEFENSE TECH

EB-PVD/APS composite structure double-ceramic-layer thermal barrier coating and preparation method thereof

PendingCN111962028AHigh bonding strengthIncreased strain toleranceMolten spray coatingVacuum evaporation coatingElectron beam physical vapor depositionThermal insulation

The invention discloses an EB-PVD / APS composite structure double-ceramic-layer thermal barrier coating. The thermal barrier coating comprises a MCrAlY metal bonding layer, a columnar crystal structureceramic layer, a layer-like-structured columnar crystal transition layer and a layered structure ceramic layer, wherein the layer-like-structured columnar crystal transition layer is obtained by performing surface treatment on the columnar crystal structure ceramic layer, and a thickness of the layer-like-structured columnar crystal transition layer is 20-50 micrometers. A preparation method of the thermal barrier coating combines the thermal barrier coating characteristics of a columnar crystal structure prepared by electron beam physical vapor deposition and an atmospheric plasma spraying layered structure, the layer-like-structured columnar crystal transition layer improves bonding capacity between the layered structure and the columnar crystal structure ceramic layer, bending resistance and thermal shock resistance of the thermal barrier coating are remarkably improved, the long service life and the high thermal insulation performance of the composite structure double-ceramic-layer thermal barrier coating are achieved, and the long service life and high thermal insulation coordination design of the novel structural thermal barrier coating are realized at a low cost.

Owner:BEIJING GOLDEN WHEEL SPECIAL MACHINE

Anti-sintering long-service-life gradient column layer composite structure thermal barrier coating and preparation method thereof

The invention discloses an anti-sintering long-service-life gradient column layer composite structure thermal barrier coating and a preparation method thereof. The coating is divided by longitudinal gaps and formed by superposing N sub-layers and is of a gradient column layer composite structure. The ratios of the thicknesses of all sub-layers to the thermal conductivity are the same. The thermalconductivity of the sub-layers is decreased progressively by the equal difference from the first sub-layer close to a bonding layer to the N sub-layer. Each sub-layer is formed by depositing firstthermal barrier coating material powder and second thermal barrier coating material powder in an alternately-layering manner. The formation compactness of the first thermal barrier coating material powder is greater than that of 90% of slice layer units. The formation compactness of the second thermal barrier coating material powder is less than that of 60% of the slice layer units. The volume ofa second thermal barrier coating material accounts for 10-50% of the total volume of the thermal barrier coating. By means of the anti-sintering long-service-life gradient column layer composite structure thermal barrier coating and the preparation method thereof, the purpose that the ceramic coating resists to sintering in a high-temperature environment is achieved; by means of the gradient columnar structure design, the reverse restriction relation of a singular structure coating for the thermal insulation capability and the service life is broken through; and collaborative design of sintering resistance and the long service life is guaranteed.

Owner:XI AN JIAOTONG UNIV

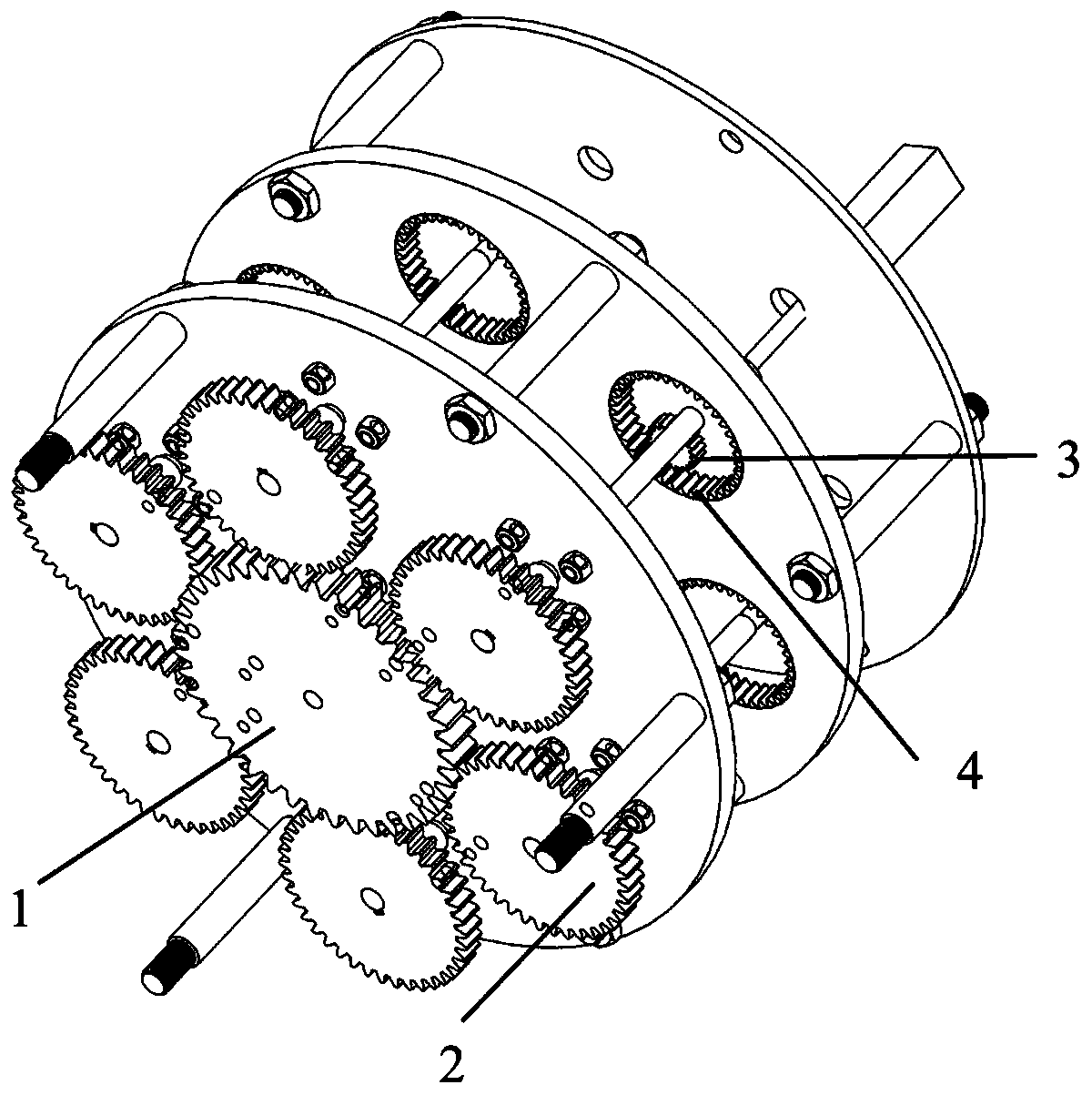

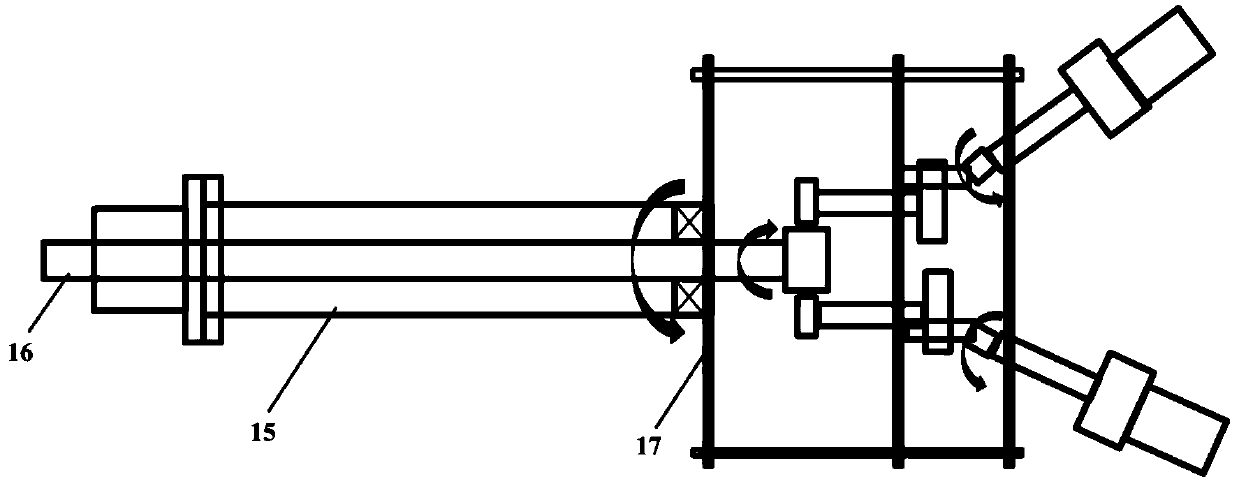

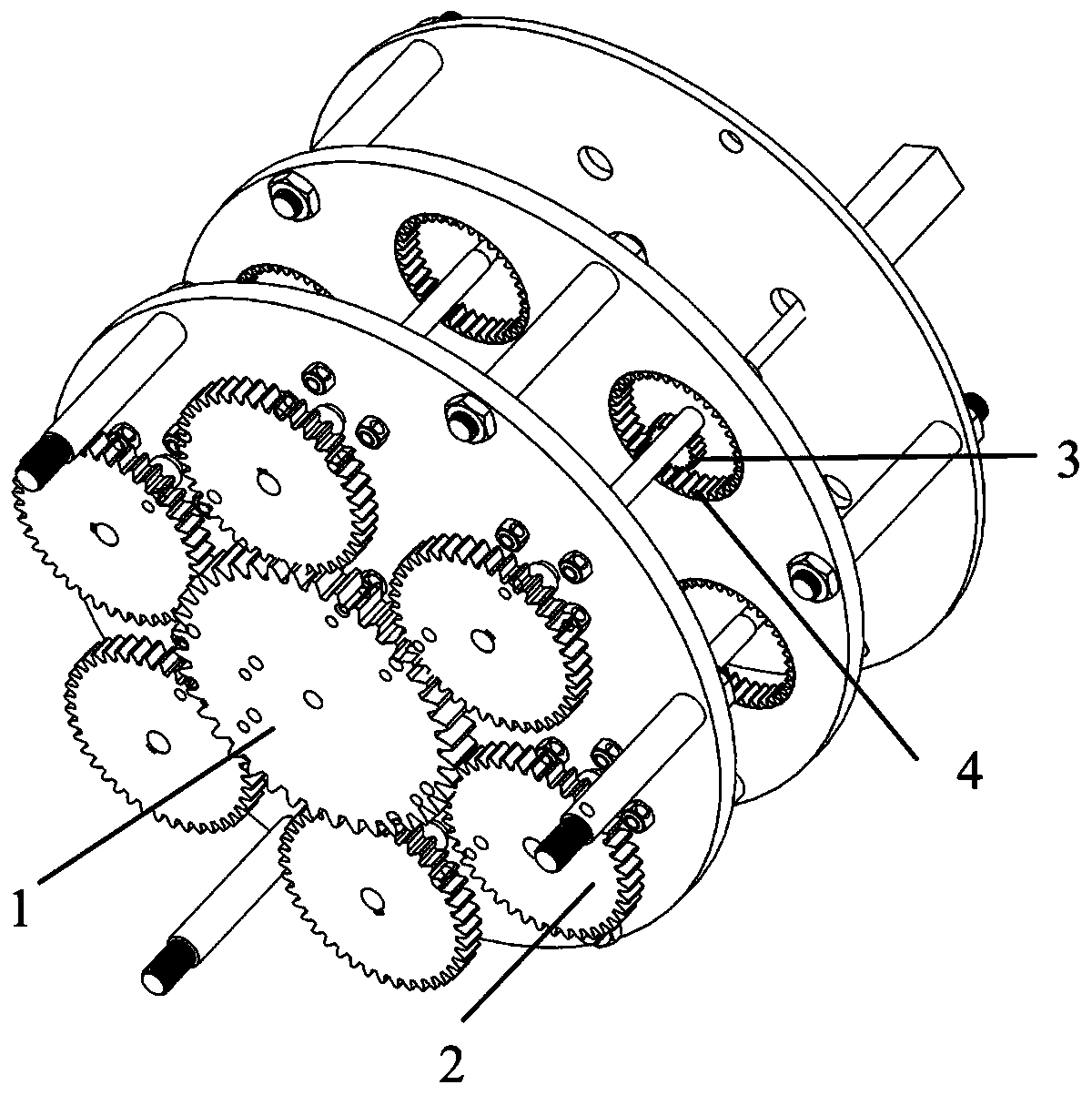

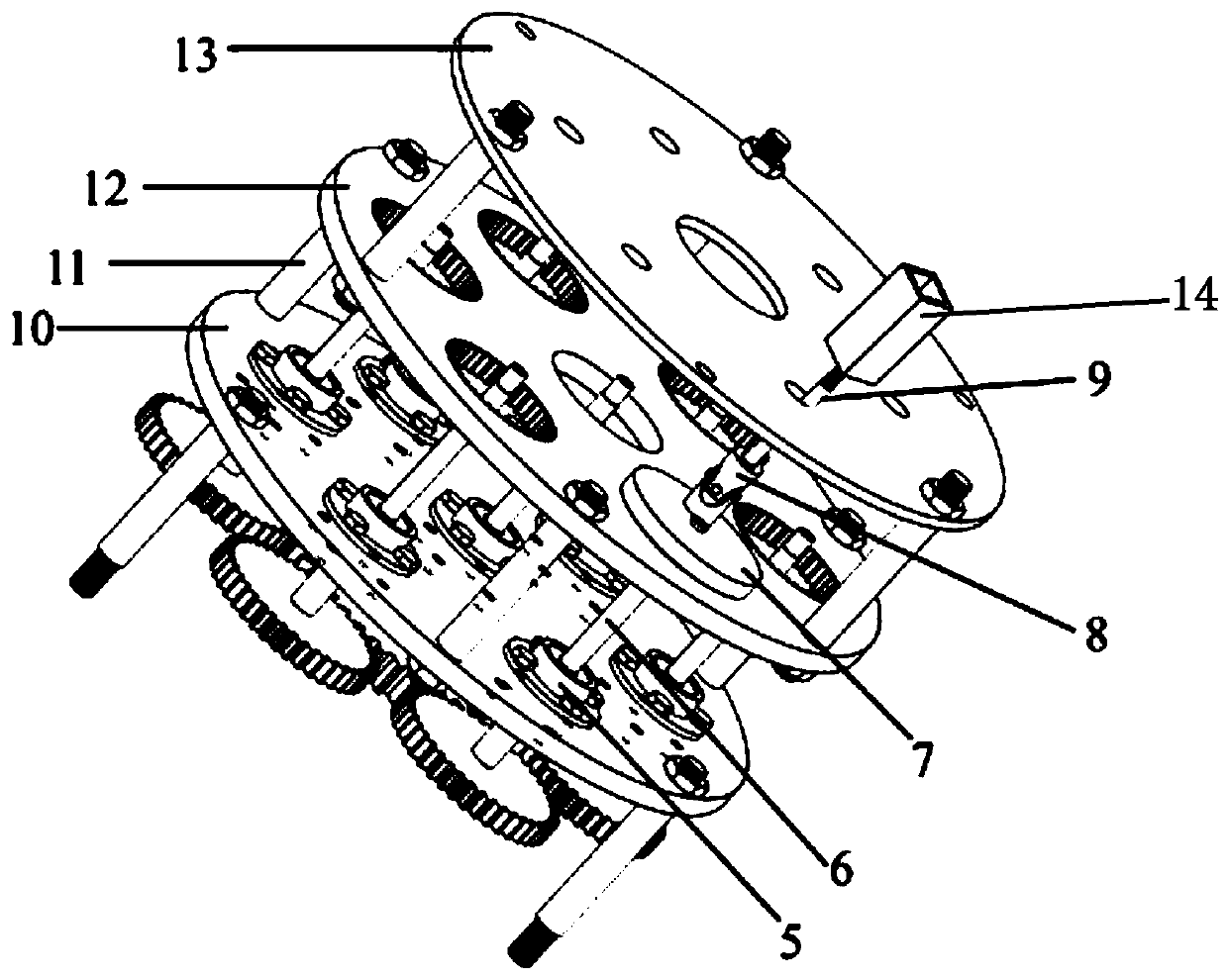

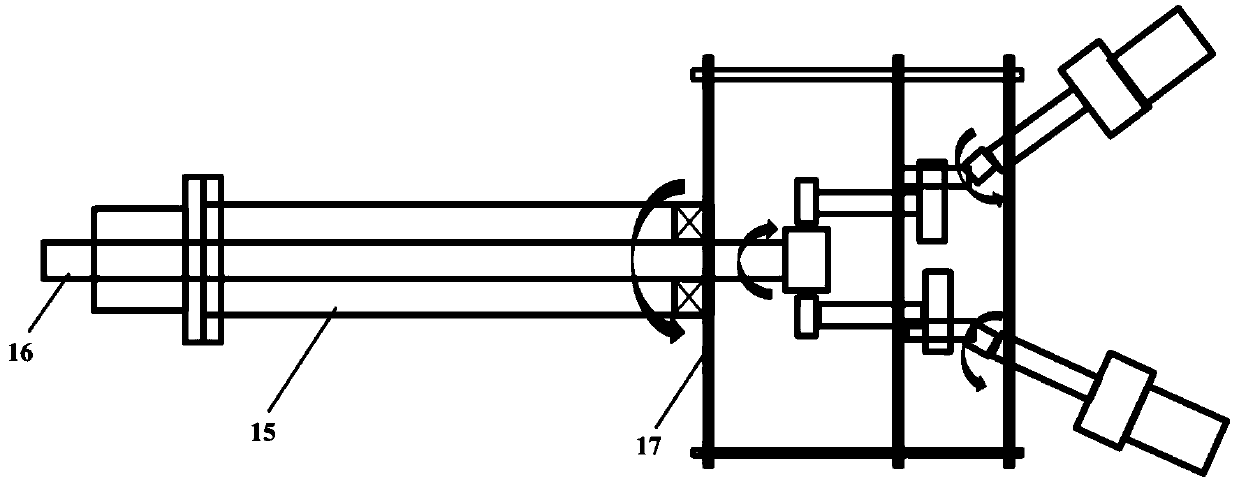

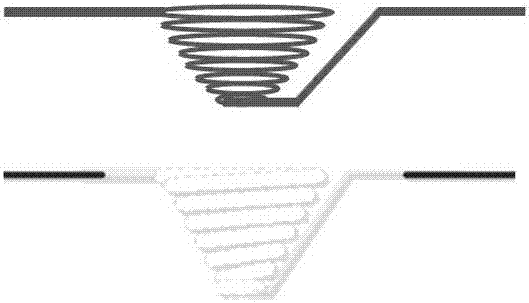

Clamping device for preparing thermal barrier coating through electron beam physical vapor deposition

ActiveCN110760809AImprove thickness uniformityImprove uniformityVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionThermal barrier coating

The invention discloses a clamping device for preparing a thermal barrier coating through electron beam physical vapor deposition. The clamping device comprises a revolution assembly, a rotation assembly, a supporting assembly and a swinging assembly. Through the technical scheme of the invention, it can be achieved that a blade workpiece conducts revolution and rotation stably and controllably and meanwhile can achieve swinging at a certain angle while revolution and rotation are conducted, accordingly, the preheating temperature of a complex-structure blade and the thickness uniformity of the coating are improved, deposited vapor multi-angle entering can be achieved advantageously, developed columnar crystal growing is facilitated, the uniformity and strain tolerance of the microstructure of the coating are improved, and the service life of the coating is prolonged.

Owner:BEIHANG UNIV +1

CrAlN thermal insulation coating for aluminum alloy piston combustor surface and preparation method thereof

ActiveCN108728804AIncrease ionization rateHigh ion energyVacuum evaporation coatingSputtering coatingCombustion chamberThermal insulation

The invention discloses a CrAlN thermal insulation coating for an aluminum alloy piston combustor surface and a preparation method thereof. The CrAlN thermal insulation coating comprises a transitionlayer and a thermal insulation layer from the inside out in order, the transition layer is a CrAl coating, and the thermal insulation layer is a CrAlN coating. The method adopts filtered cathodic vacuum arc technique, takes a CrAl alloy target material (Cr, Al metal target) as the cathode, performs deposition of the CrAl coating on the aluminum alloy surface to form a transition layer, then uses nitrogen as the working gas, and coats the transition layer surface with the CrAlN coating evenly to form the thermal insulation layer. The CrAlN thermal insulation coating provided by the invention not only solves the problem of poor binding force and bearing ability caused by large difference of basic physical properties between the CrAlN coating and the aluminum alloy substrate material, also the coating is uniform and compact, has good film-substrate combination state and hardness up to 40GPa, and shows good high temperature thermal insulation properties and thermal shock resistance in piston thermal load test. The CrAlN thermal insulation coating provided by the invention significantly improves the performance reliability and service life of the aluminum alloy piston, and can meet thehigh power and low emission development requirements of modern engines.

Owner:XIANGTAN UNIV

DVC thermal barrier coating and preparation method and application thereof

PendingCN114592164AReduce high temperature fatigue oxidationInterface is well integratedMolten spray coatingEfficient propulsion technologiesChemical compositionWorking temperature

The invention relates to a preparation method of a DVC thermal barrier coating, which comprises the following steps: providing powder, the chemical components of which are YSZ or YSZ + xGd2O3 + yYb2O3 or Gd2Zr2O7 + zYb2O3 or LaMgAl11O19 or La2 (Zr0. 7Ce0. 3) 2O7, x + y is less than or equal to 12wt%, z is less than or equal to 20wt%; the powder forms the DVC thermal barrier coating through high-heat-enthalpy atmosphere plasma spraying. The invention further provides the DVC thermal barrier coating obtained through the preparation method. The invention further provides application of the DVC thermal barrier coating. The DVC thermal barrier coating is used for a high-temperature hot end component of an aero-engine or a gas turbine. The chemical components of the DVC thermal barrier coating are YSZ or YSZ + xGd2O3 + yYb2O3 or Gd2Zr2O7 + zYb2O3 or LaMgAl11O19 or La2 (Zr0. 7Ce0. 3) 2O7, the applicable material range is wide, the strain tolerance can be increased, the working temperature can be increased, the erosion and erosion resistance can be improved, and the thermal shock resistance cycle life can be prolonged.

Owner:EAST CHINA UNIV OF SCI & TECH +3

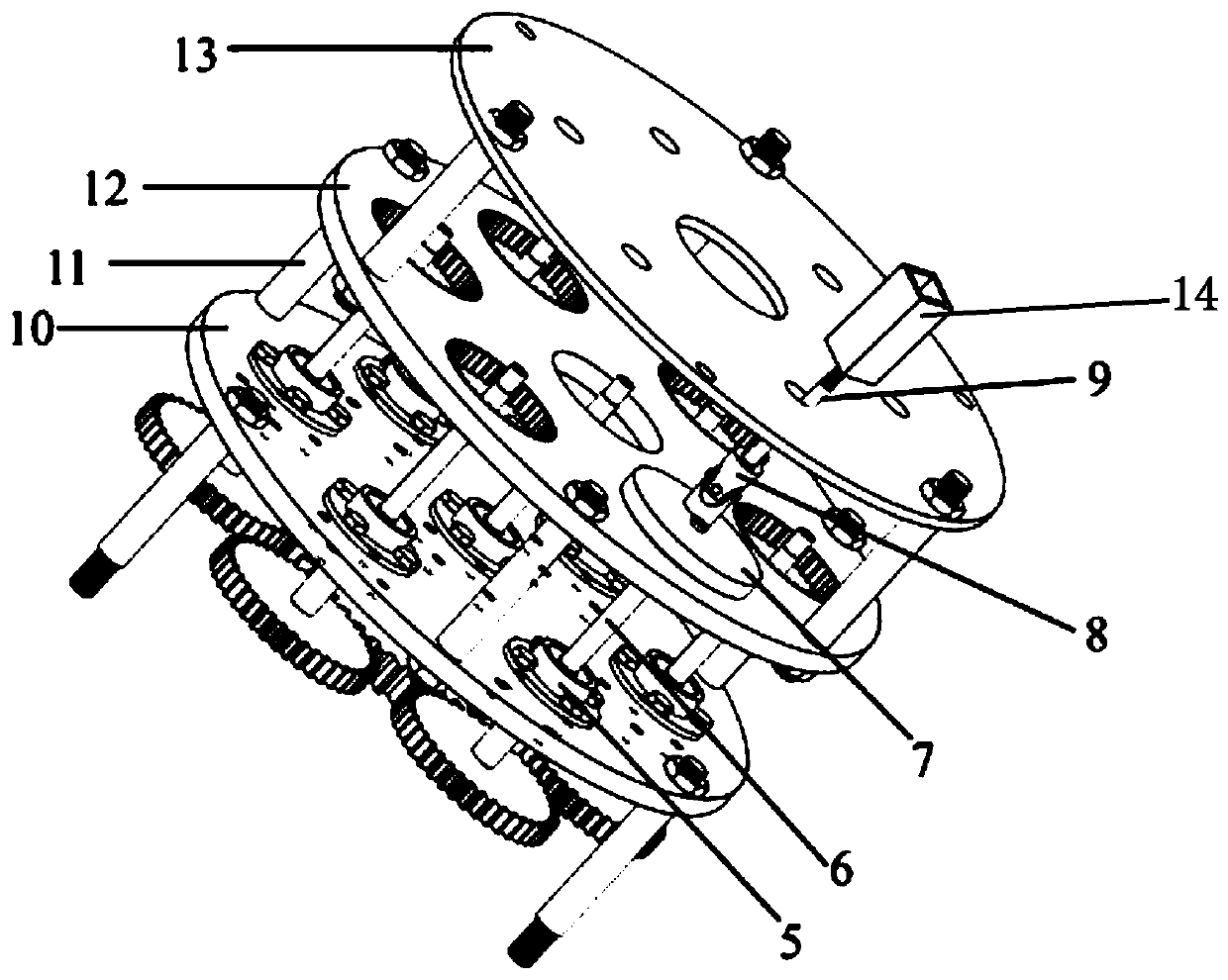

A clamping device for preparing thermal barrier coatings by electron beam physical vapor deposition

ActiveCN110760809BImprove thickness uniformityImprove uniformityVacuum evaporation coatingSputtering coatingElectron beam physical vapor depositionThermal barrier coating

The invention discloses a clamping device for preparing a thermal barrier coating through electron beam physical vapor deposition. The clamping device comprises a revolution assembly, a rotation assembly, a supporting assembly and a swinging assembly. Through the technical scheme of the invention, it can be achieved that a blade workpiece conducts revolution and rotation stably and controllably and meanwhile can achieve swinging at a certain angle while revolution and rotation are conducted, accordingly, the preheating temperature of a complex-structure blade and the thickness uniformity of the coating are improved, deposited vapor multi-angle entering can be achieved advantageously, developed columnar crystal growing is facilitated, the uniformity and strain tolerance of the microstructure of the coating are improved, and the service life of the coating is prolonged.

Owner:BEIHANG UNIV +1

Anti-thermal-shock thermal barrier coating with low thermal conductivity and preparation method thereof

InactiveCN105088126AImprove insulation performanceHigh surface hardnessMolten spray coatingPorosityOxygen vacancy

The invention discloses an anti-thermal-shock thermal barrier coating with low thermal conductivity. Compared with a traditional thermal barrier coating, carbon powder is added, after high temperature calcination modification is conducted, the porosity rate of a ceramic phase can be increased, and the thermal insulating performance of the coating can be significantly improved. In addition, by means of a modification method, Zr<4+> is replaced with Y<3+> and Ce<4+> in zirconium dioxide crystal lattices, oxygen vacancies and local stress fields are produced, the phonon scattering in the crystal lattices is increased, and the thermal conductivity is significantly decreased; the atomic mass of solid solution atoms Ce is far larger than that of Y, the scattering intensity of phonons in the anti-thermal-shock thermal barrier coating can be significantly improved, and therefore the thermal conductivity is decreased. According to the anti-thermal-shock thermal barrier coating with the low thermal conductivity and a preparation method thereof, the preparation technology is simple, the prepared coating is high in surface hardness, low in water absorption, good in toughness, not prone to cracking and layering, high in strain tolerance and long in anti-thermal-shock life, and the service life of the anti-thermal-shock thermal barrier coating with the low thermal conductivity is significantly prolonged compared with a thermal barrier coating of a conventional structure.

Owner:MAANSHAN LANKE REMFG TECH

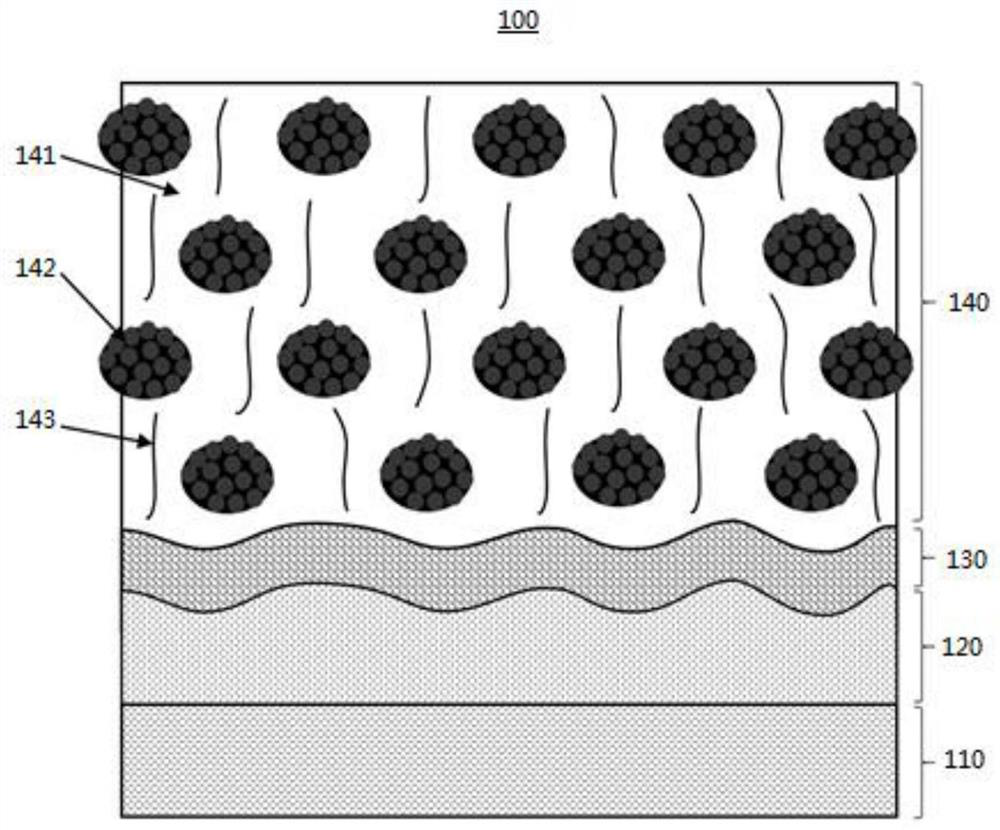

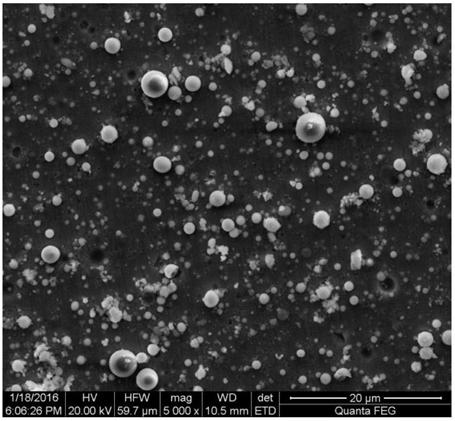

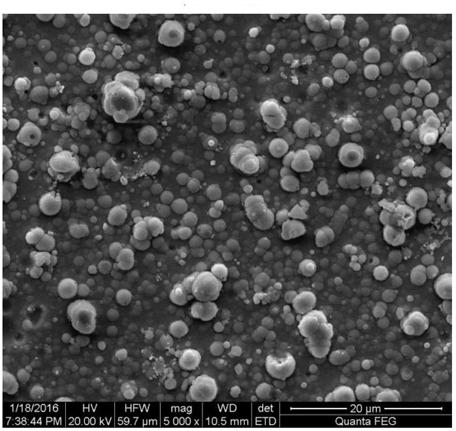

Thermal barrier coating material and preparation method and application thereof

ActiveCN113930710AImproved lateral deformation complianceReduce thermal stressMolten spray coatingCrack resistanceAlloy

The invention discloses a thermal barrier coating material and a preparation method and application thereof, and relates to the technical field of thermal barrier coatings. A thermal barrier coating comprises an alloy matrix, a bonding layer, a ceramic transition layer and a ceramic surface layer which are sequentially arranged, the porosity of the ceramic transition layer is 1-8%, and the ceramic surface layer comprises a coating matrix with multiple microcracks and porous ceramic particles embedded in the coating matrix. The transverse deformation compliance of the thermal barrier coating can be improved by forming microcracks in the ceramic surface layer, and the strain tolerance of the coating is improved; and the porous ceramic particles strengthen the heat insulation capacity of the thermal barrier coating and absorb deformation energy, and the stress borne by the thermal barrier coating in the service process is reduced. Therefore, the thermal barrier coating provided by the invention can give full play to the advantages of high strain tolerance and high interface cracking resistance, and the thermal cycle life of the coating is remarkably prolonged.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of anti-CMAS corrosion micro-nano composite structure thermal barrier coating and preparation method thereof

InactiveCN106086765BGood anti-CMAS effectImprove bindingMolten spray coatingVacuum evaporation coatingMicro nanoElectron beam physical vapor deposition

Owner:BEIHANG UNIV

Cabled conductors containing anisotropic superconducting compounds

InactiveUS6906265B2Increased strain toleranceImprove performanceSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentCompound aElectrical conductor

A cabled conductor comprises a plurality of transposed strands each comprising one or more preferably twisted filaments preferably surrounded or supported by a matrix material and comprising textured anisotropic superconducting compounds which have crystallographic grain alignment that is substantially unidirectional and independent of the rotational orientation of the strands and filaments in the cabled conductors. The cabled conductor is made by forming a plurality of suitable composite strands, forming a cabled intermediate from the strands by transposing them about the longitudinal axis of the conductor at a preselected strand lay pitch, and, texturing the strands in one or more steps including at least one step involving application of a texturing process with a primary component directed orthogonal to the widest longitudinal cross-section of the cabled intermediate, at least one such orthogonal texturing step occurring subsequent to said strand transposition step. In a preferred embodiment, the filament cross-section, filament twist pitch, and strand lay pitch are cooperatively selected to provide a filament transposition area which is always at least ten times the preferred direction area of a typical grain of the desired anisotropic superconducting compound. For materials requiring biaxial texture, the texturing step preferably includes application of a texturing process with a second primary component in a predetermined direction in the plane of the widest longitudinal cross-section of the conductor.

Owner:AMERICAN SUPERCONDUCTOR

Internal heating type integrated evaporation basket with aluminum oxide vesicular structure buffer layer

InactiveCN107245698AGuaranteed bonding strengthHigh bonding strengthMolten spray coatingVacuum evaporation coatingPorosityVacuum evaporation

The invention discloses an internal heating type integrated evaporation basket with an aluminum oxide vesicular structure buffer layer. Two layers of coatings are totally arranged on the surface of the evaporation basket, the inner layer is a Al2O3 buffer layer of a loose vesicular structure, the outer layer is a compact and low-porosity corrosion resistance Al2O3 coating, and a spinning impregnation technology is adopted for preparing a Al2O3 buffer layer with the thickness ranging from 0.15 mm to 0.5 mm on the surface of a base; and then a plasma spraying technology is adopted for preparing a Al2O3 corrosion resistance layer with the thickness ranging from 0.5 mm to 1 mm on the evaporation basket on the buffer layer in a spraying manner. According to the internal heating type integrated evaporation basket, a composite process is adopted for preparing the Al2O3 coating evaporation basket of different microstructures, the buffer layer of the vesicular structure can achieve the stress releasing effect on service, and the problem of base oxidation caused by follow-up spraying can be prevented; and the compact and low-porosity Al2O3 coating layer has the excellent corrosion resistance, and the internal heating type integrated evaporation basket can be permanently and widely applied to the technical field of metal thin film vacuum evaporation.

Owner:FUZHOU UNIV

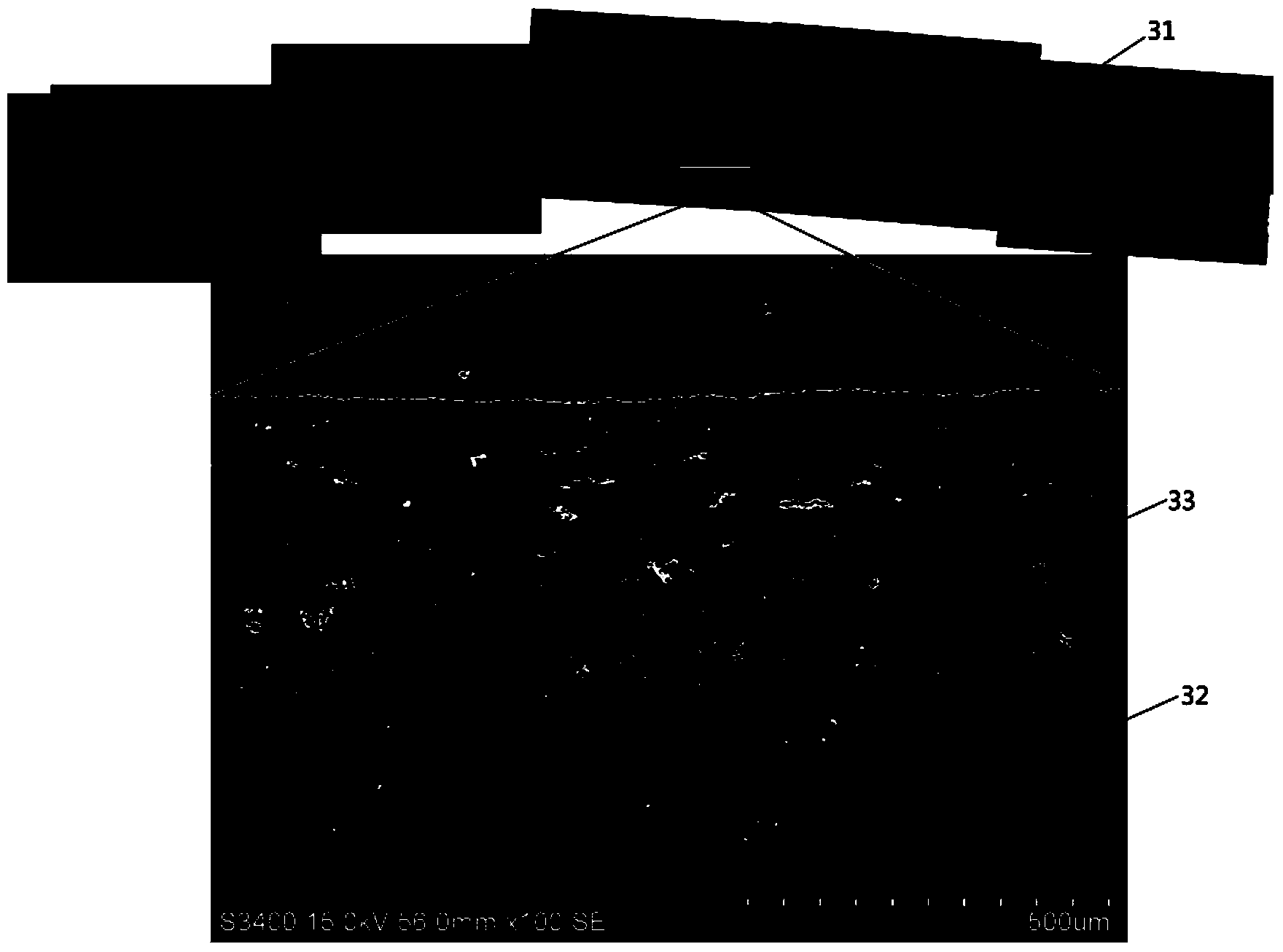

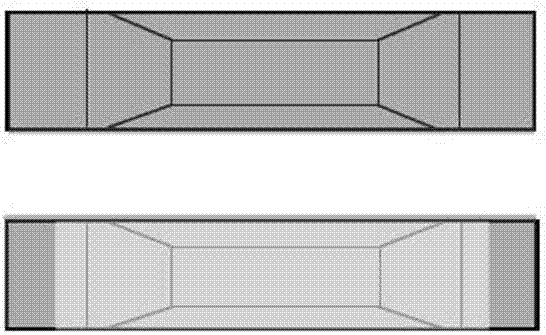

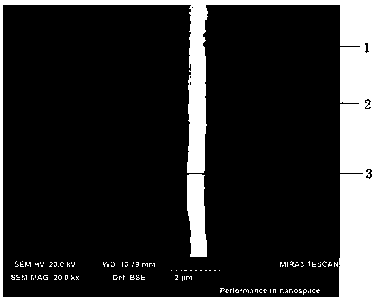

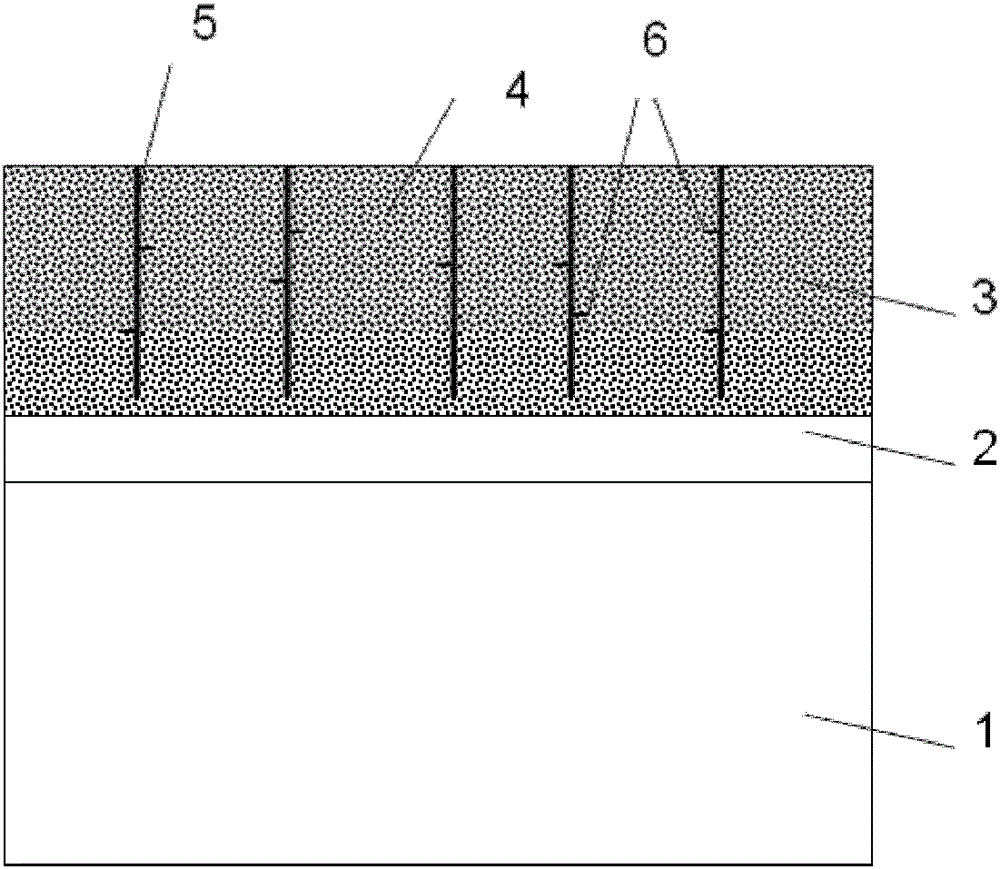

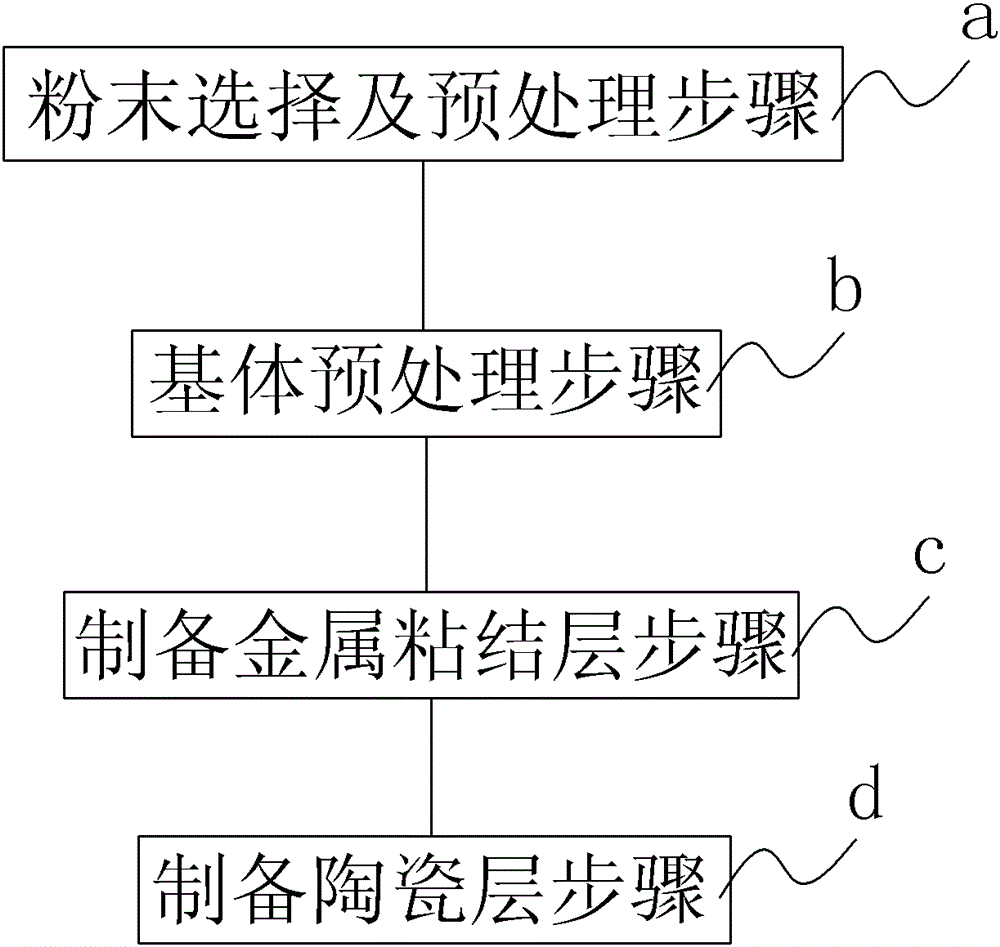

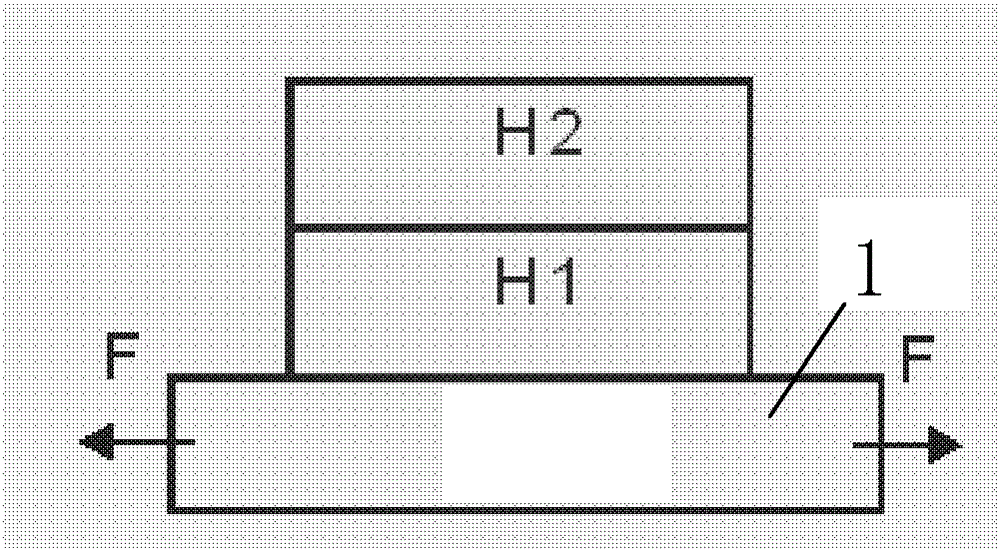

A nano/columnar-like mixed structure thermal barrier coating and its preparation method

ActiveCN103009704BSmall shrinkageGood heat insulationMolten spray coatingCeramic layered productsThermal insulationNanoparticle

The invention relates to a nanometer / columnar-like crystal mixing structure thermal barrier coating and a preparation method thereof. The mixing structure thermal barrier coating is a nanometer / columnar-like crystal mixing structure coating, and comprises a substrate, a metal bonding layer and a ceramic layer, wherein the metal bonding layer and the ceramic layer are sequentially coated on the substrate, the ceramic layer comprises unmelted nanoparticles, nanometer pores, nanometer crystal and ultrafine crystal, and has cracks perpendicular to the substrate, and the cracks form the columnar-like crystal structure. The mixing structure thermal barrier coating preparation method comprises powder selection, a pretreatment step, a substrate pretreatment step, a metal bonding layer preparation step, and a 6-8% YSZ ceramic layer preparation step. The coating disclosed by the present invention has characteristics of high strain tolerance, excellent thermal insulation performance, high bonding strength, high thermal cycle life, and high thermal shock life, such that the thermal barrier coating has a good comprehensive performance.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com